Assembled FRP high-water-material mining combined pillar and construction method

A technology of high-water materials and construction methods, applied in pillars/supports, mining equipment, earthwork drilling, etc., can solve the problems of high early strength, large deformation capacity, buckling deformation structure and other problems, achieve simple operation and reduce stacking area. , Improve the effect of longitudinal bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

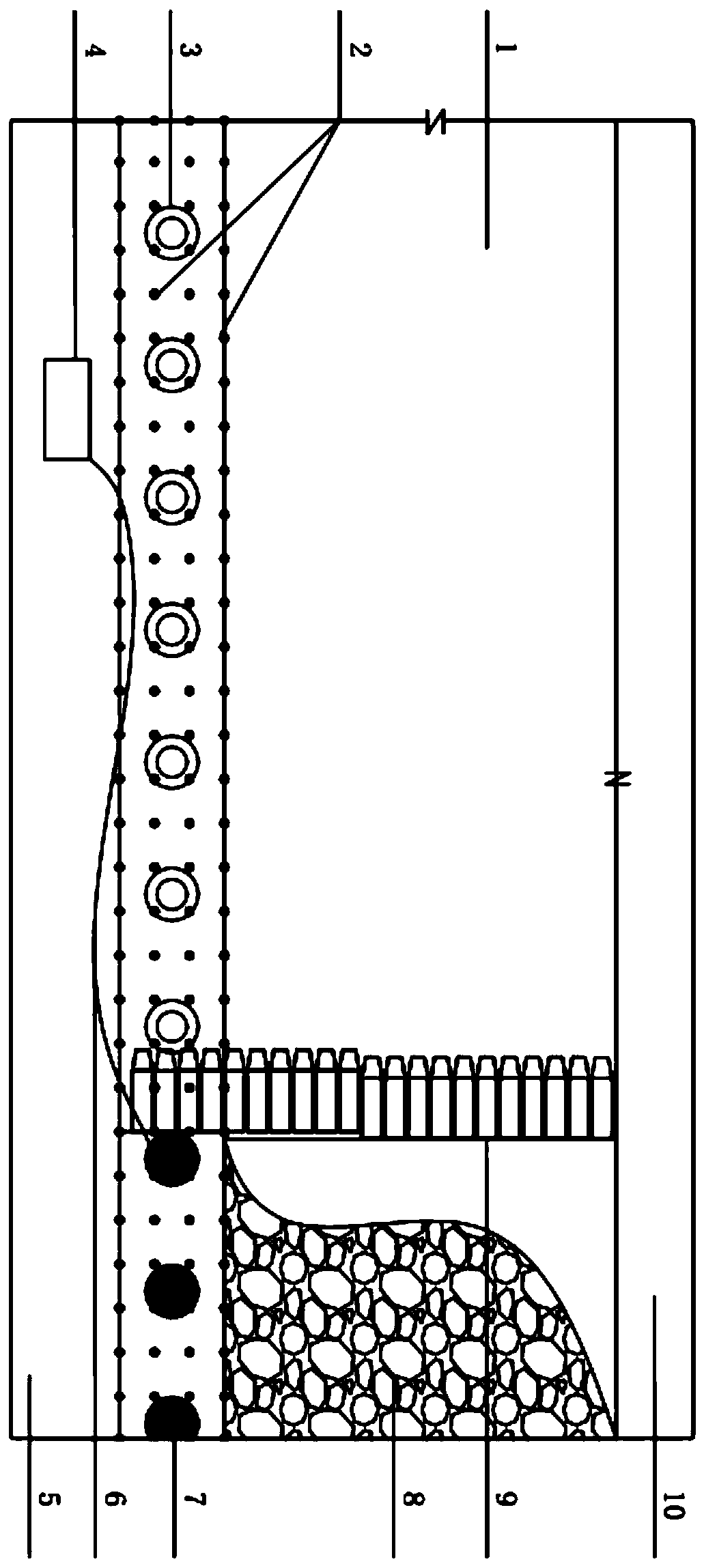

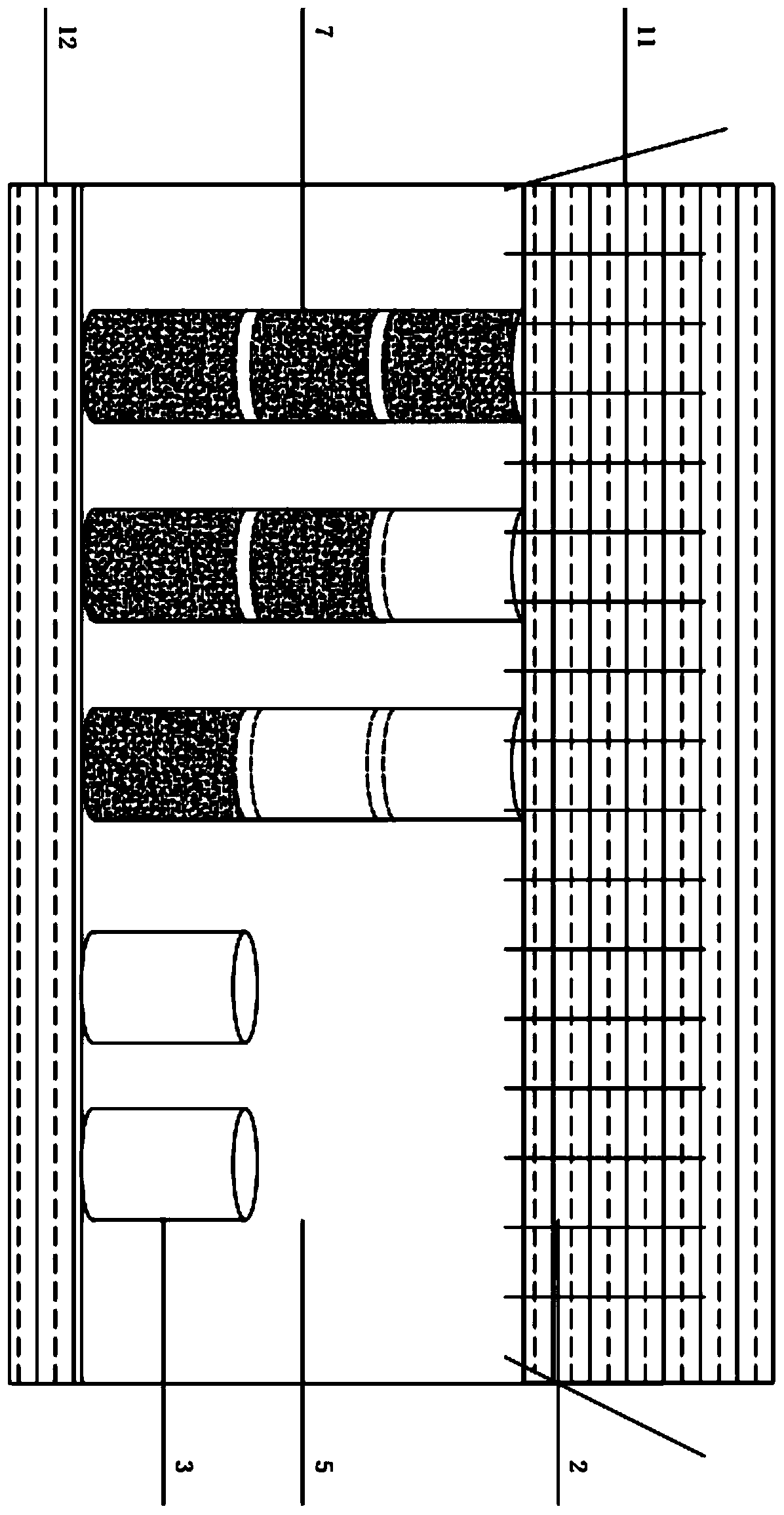

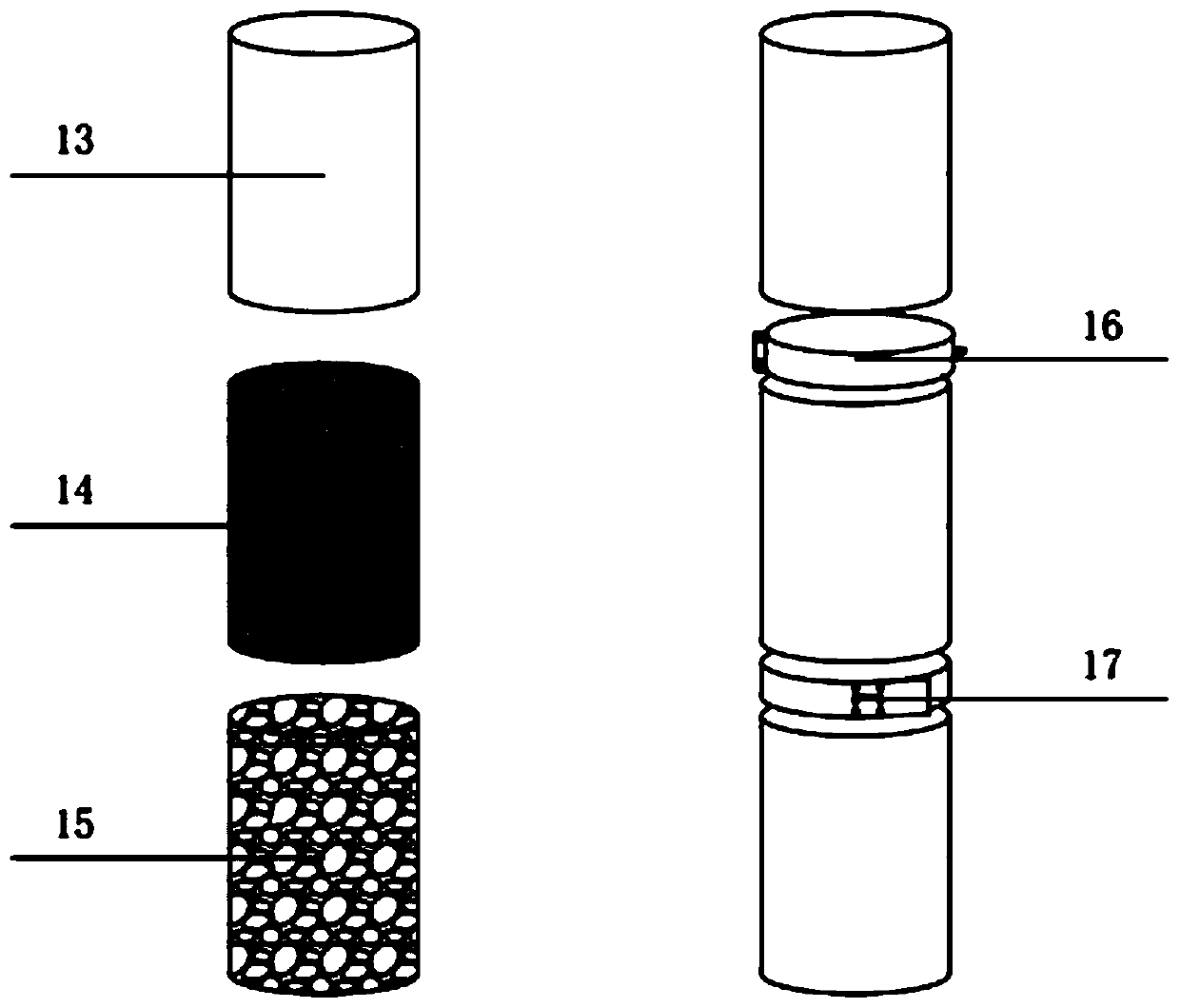

[0041] Such as Figure 1-7 As shown, an assembled FRP high-water material mining composite pillar and its construction method include a mining face 1, a mining roadway 5 and a continuous working face 10 are respectively arranged on both sides of the mining working face 1, and two sides of the mining roadway 5 are provided. The liquid injection pump 4 and the double liquid injection pump 4 are provided with a high-pressure rubber hose 6, and one side of the double liquid injection pump 4 is a pre-installation area 3, and the pre-installation area 3 is provided with a combined column 7, and the pre-installation area 3 is far away from A bolt 2 is provided on one side of the double-fluid injection pump 4, a hydraulic support 9 is provided at the front end of the recovery working face 1, and the front end of the hydraulic support 9 is the goaf 8, and the top and bottom of the recovery roadway 5 are respectively provided with a roadway roof 11 and a The roadway bottom plate 12, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com