Heat-sealing stone paper

A technology of stone paper and heat-sealing layer, applied in layered products, synthetic resin layered products, chemical instruments and methods, etc., can solve problems such as large waste of resources and unfavorable environmental protection, and achieve energy saving, good uniformity and shortening. The effect of the production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

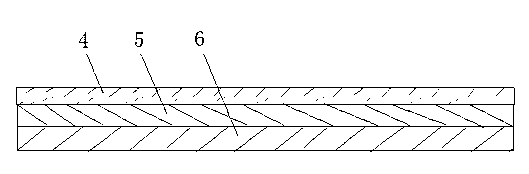

[0023] The heat-sealable stone paper comprises an upper layer, an intermediate base layer and a lower layer, the upper layer and the lower layer are heat-sealing layers, the intermediate base layer is a foam layer, and the mass ratio of the upper layer, the lower layer, and the intermediate base layer is 15:85, that is, the upper layer: the intermediate base layer : lower layer = mass ratio of 7.5:80:7.5, where:

[0024] The heat-sealing layer is composed of the following components by mass ratio: 8% LLDPE, 90% PP and 2% oleic acid amide;

[0025] The foam layer is composed of the following components by mass ratio: 65% calcium carbonate powder with a fineness of 1250 mesh, 30% polypropylene PP, 1% aluminate, 1% polyethylene wax, 1% paraffin wax, 1% stearic acid %, DCP initiator 0.2%, antioxidant 0.3% (ie 0.2% 1076+0.1% DSTP), AC blowing agent 0.5%;

[0026] It is prepared by the following conventional method: the material of the above middle base layer (i.e. foam layer) is f...

Embodiment 2

[0029] The heat-sealable stone paper comprises an upper layer, an intermediate base layer and a lower layer, the upper layer is a heat-sealable layer, the lower layer is a non-heat-sealable layer, the intermediate base layer is a foam layer, and the mass ratio of the upper layer and the lower layer to the intermediate base layer is 20:80, that is Upper layer: middle base layer: the mass ratio of lower layer=10:80:10; Wherein:

[0030] The heat-sealing layer is composed of the following mass ratio components: 46% EVA, 50% LLDPE and 4% anti-adhesive agent (that is, talcum powder filled masterbatch);

[0031] The foam layer is composed of the following components by mass ratio: 40% calcium carbonate powder with a fineness of 800 mesh and talcum powder, 15% high-density polyethylene HDPE, 0.5% aluminate, 1% polyethylene wax, paraffin wax 1%, stearic acid 1%, DCP initiator 0.2%, antioxidant 0.3% (ie 0.1% 168+0.2% 1010), AC foaming agent 1%;

[0032] The non-heat-sealing layer is c...

Embodiment 3

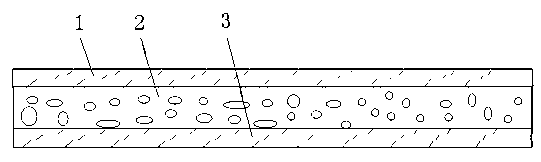

[0036] The heat-sealable stone paper comprises an upper layer, an intermediate base layer and a lower layer, the upper layer and the lower layer are heat-sealing layers, the intermediate base layer is a non-foaming layer, and the mass ratio of the upper layer 1 and the lower layer 3 to the intermediate base layer 2 is 1:99, that is Upper layer: middle base layer: the mass ratio of lower layer=0.5:90:0.5; Wherein:

[0037] The heat-sealing layer is composed of the following mass ratio components: 50% mPE and 50% LDPE;

[0038] The non-foaming layer is composed of the following components by mass ratio: 30% of diatomite and kaolin with a fineness of 950 meshes, 18% of LDPE and LLDPE, 0.9% of aluminate, 1% of polyethylene wax, and 1% of paraffin wax. %, stearic acid 0.8%, antioxidant (1010) 0.3%;

[0039] It is prepared by the following conventional method: the material of the above middle base layer (i.e. foaming layer) is fed into a main extruder, the material of the upper lay...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com