Mineral fiber insulation having thermoplastic polymer binder and method of making the same

a technology of thermoplastic polymer and mineral fiber insulation, which is applied in the field of mineral fiber insulation products and methods of making the same, can solve the problems of increasing the cost of manufacturing process, increasing the cost of production, and the binder material on the mineral fibers is sticky, so as to reduce the amount of binder that is needed, avoid or substantially reduce contamination and other problems, and improve the effect of quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

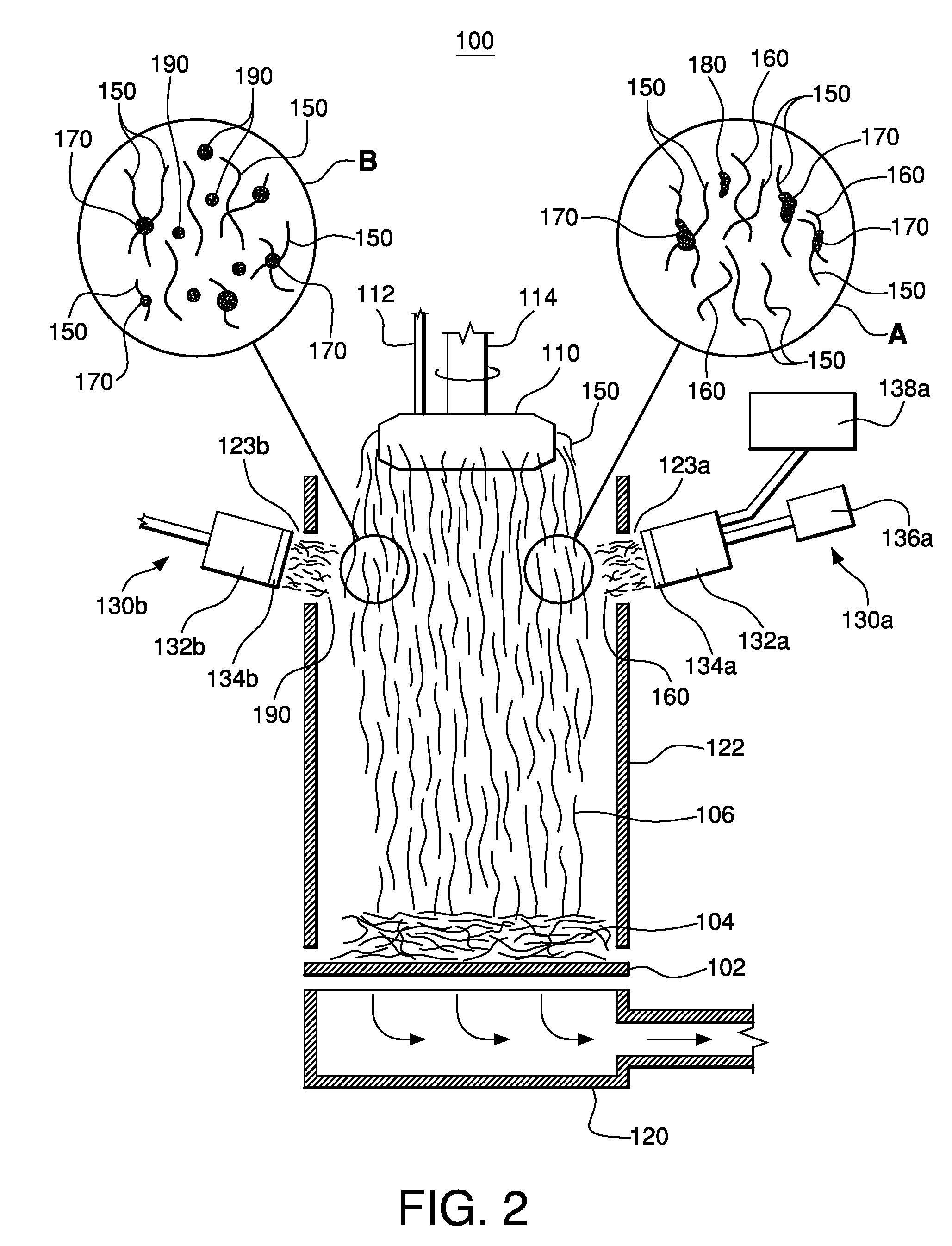

[0027]FIG. 2 is a schematic front elevational view of the insulation manufacturing system 100. The system 100 includes thermoplastic binder applicator devices 130a and / or 130b disposed to introduce thermoplastic binder directly into the veil 106. More specifically, the applicator devices 130a, 130b introduce a non-aqueous, formaldehyde-free thermoplastic binder to the veil 106. In one embodiment, the applicator 130a is a hot melt applicator which blows thermoplastic binder fibers 160 into veil 106 to commingle with rotary fibers 150 from fiberizing apparatus 110. Applicator 130a includes a hot melt gun 132a with a die head or nozzle labeled 134a connected thereto. A source of hydraulic and / or pneumatic pressure 136a is coupled to the gun 132a for use in extruding the thermoplastic and / or blowing the extruded thermoplastic. A thermoplastic polymer melter or extruder 138a is also coupled to the gun 132a. Melted thermoplastic binder is provided to the gun 132a from polymer melter 138a ...

second embodiment

[0038]FIG. 3 is a schematic front elevational view of an insulation manufacturing system 100A according to the system. The system is identical to that shown in FIG. 2 and described above except for replacement of some or all of melt blown applicators 130a and / or 130b with polymer powder provider apparatus 210. Polymer powder provider apparatus 210 provides the thermoplastic binder in solid, powdered form, shown as particles 200, which are blown into veil 106. Some of the particles may melt upon contact with veil 106, forming melt bonds 170 with the rotary fibers 106.

[0039]In one embodiment, the apparatus 210 includes a chamber 212 for storage of the thermoplastic binder in powdered form. The binder particles 200 can be blown from the chamber 212 using air source (e.g., a blower) 216 through pipe or other conduit 214 into the forming hood 122 to veil 106. In one embodiment, the powdered binder particles are ground from a source material using grinding techniques familiar to those in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameters | aaaaa | aaaaa |

| diameters | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com