A kind of preparation method of the polymer of lipoic acid compound

A technology for lipoic acids and compounds, which is applied in the field of polymer preparation, can solve the problems of complex reaction conditions, difficult control of configuration and molecular weight, etc., and achieves the effects of simple preparation method, rapid and efficient ring-opening polymerization, and wide sources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Solvent-free direct hot melt catalytic polymerization:

[0035]It is weighed in a clean small flask in a clean small flask. The acetone solution of the amine hexafluorophosphate continues to be heated in the flask for 5 minutes. The molar ratio of the hydraulic acid compound and the catalyst is 4000: 4, stop heating, cooling the liquid to room temperature, i.e., the hot melt catalytic polymerization process is completed to obtain a dry gel of a sulfuric polymer.

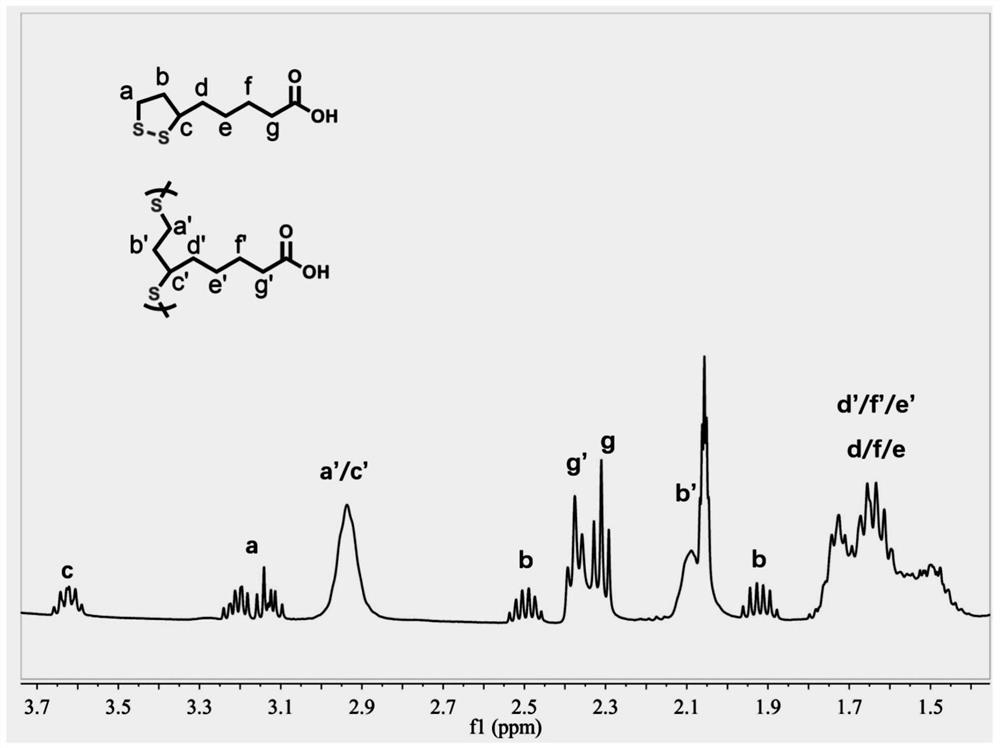

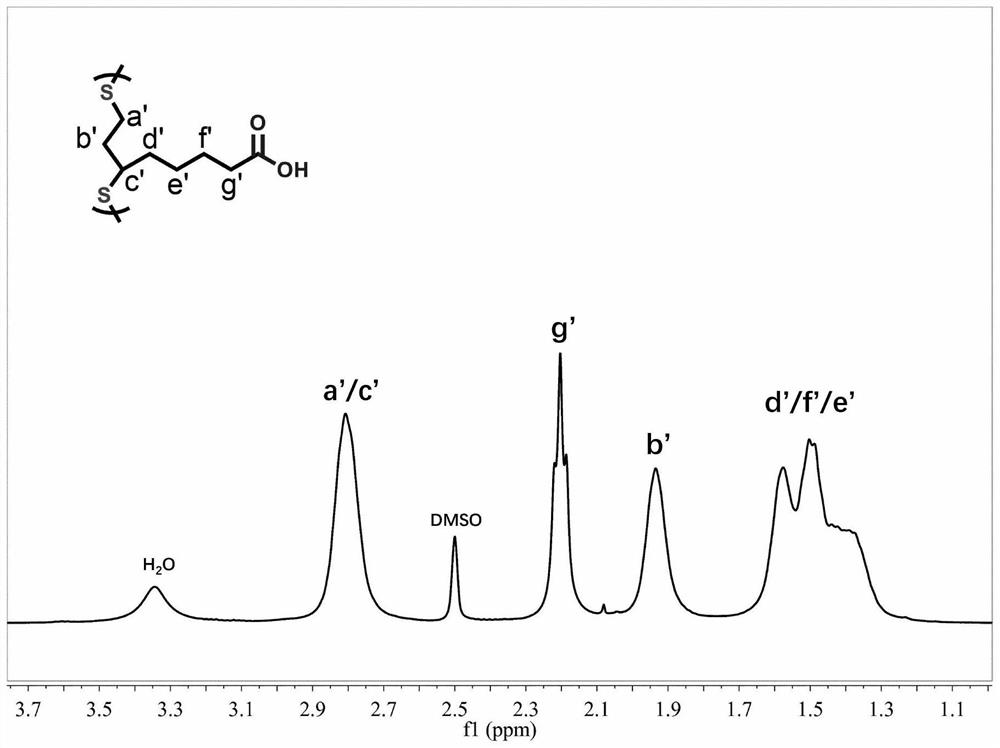

[0036] figure 1 A sulfuric polymer image is shown in Example 1 Direct hot melt catalyst polymerization, which can be seen from the figure, a yellow transparent elastic dry gel shape; figure 2 For example, the nuclear magnetic resonance spectrum of the sulfic acid polymer dry gel obtained by the solvent-free direct hot melt catalyst, can be seen from the figure, and most of the sulfic acid monomers have been transformed into polysulculin; image 3 The sulfuric polymer dry gel obtained by the solvent-free direct hot...

Embodiment 2~4

[0038] In addition to alter the molar ratio of the sulfic acid, the catalyst, the remaining steps and conditions are the same as in Example 1, as shown in Table 1:

[0039] Table 1

[0040]

Embodiment 5

[0042] EtOAc EtOAc EtOAc m., The acetone solution was then added 20 ul of 0.725 mol / ln-n-butylbenzylamine hexafluorophosphate to the flask, and the mixture was continued for 1 minute, the viscosity of the solution was gradually increased, and then placed in an open polytetrafluoroide mold. At room temperature, the solvent was evaporated in 1 hour to give a dry gel of a sulfic acid polymer.

[0043] Figure 4 A gel image schematic diagram of a hydrochloric polymer obtained by catalyzing a polymerization of a room temperature solution; it can be seen from the figure, a yellow transparent elastic dry gel shape.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com