Cylindrical lithium-ion battery forming and capacity-grading equipment

A lithium-ion battery, cylindrical technology, applied in the direction of non-aqueous electrolyte battery, electrolyte battery manufacturing, sustainable manufacturing/processing, etc., can solve the problem of unreliable traceability of composition and capacity data, low efficiency of transportation and circulation, and high defect rate of battery quality, etc. problems, to achieve the effect of saving production and storage area, eliminating defective products, and high profile

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

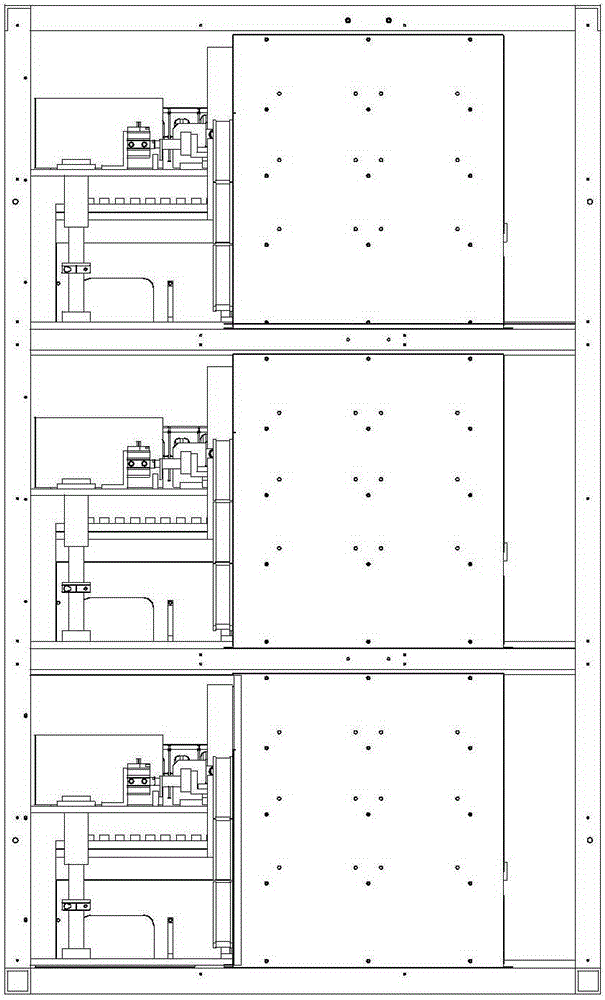

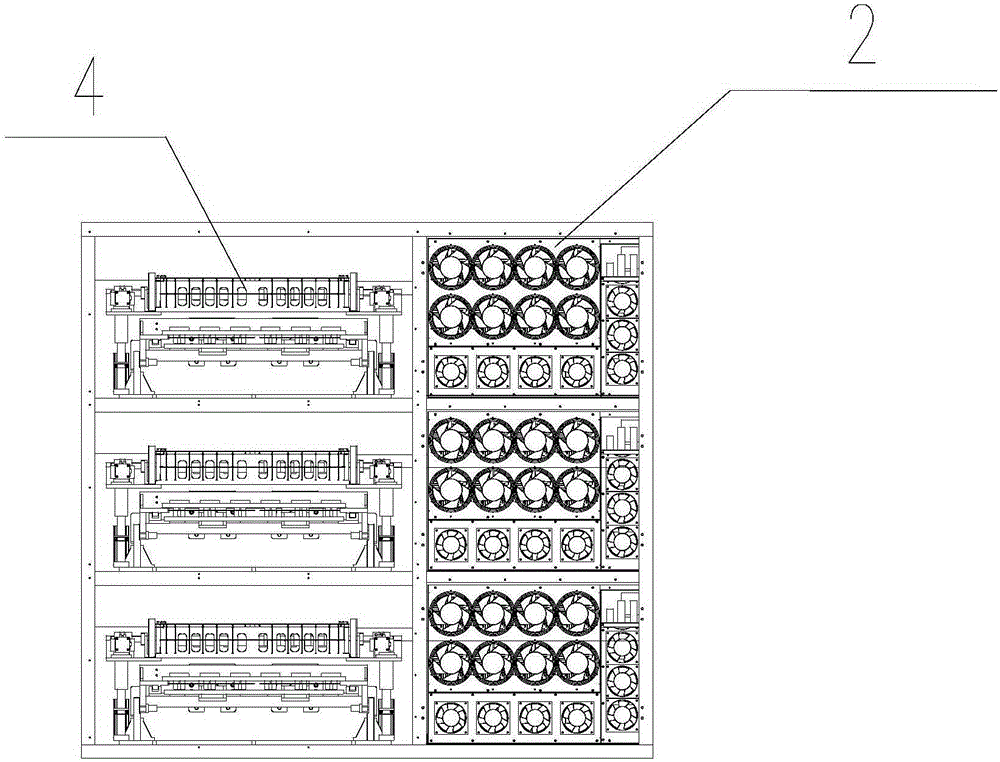

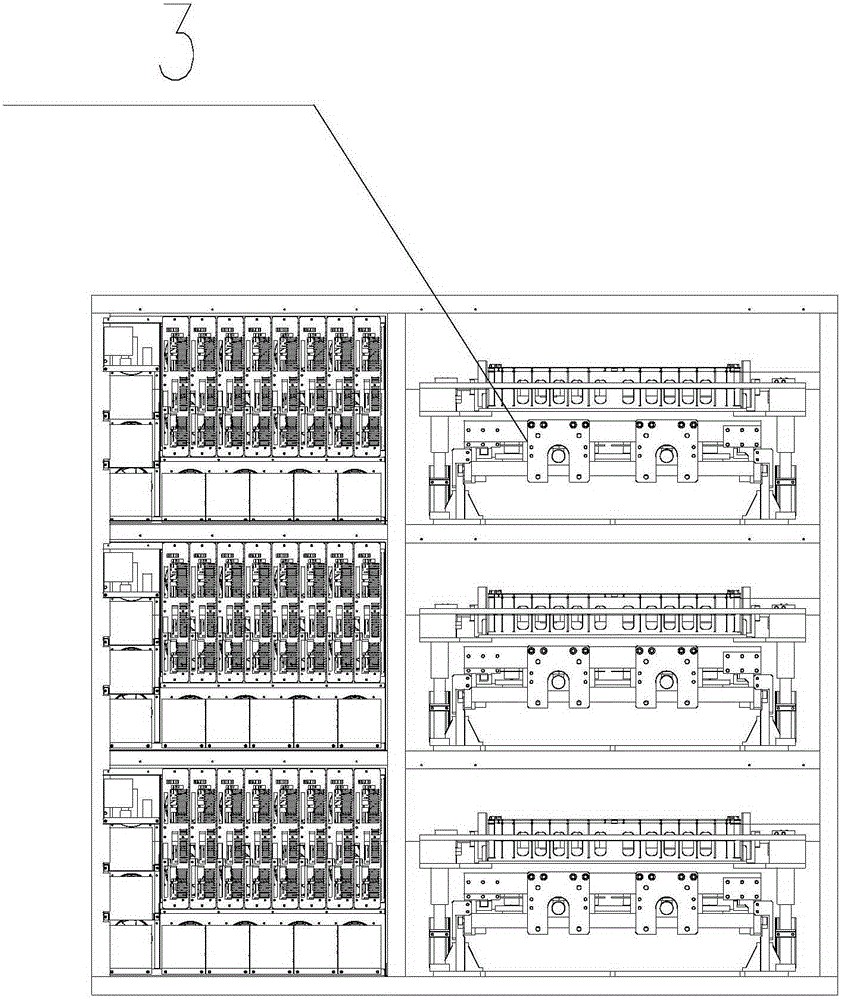

[0032] refer to Figure 1 to Figure 10 , cylindrical lithium-ion battery formation and capacity equipment, including a frame 1, also includes a charge and discharge power box 2 with variable conditions set on the frame 1, positive and negative electrode tabs for clamping cylindrical lithium-ion batteries The battery clamping movement mechanism 3, the battery tray 4 placed in the battery clamping movement mechanism and the control mechanism placed in the PC outside the frame, the charging and discharging power supply box 2 with variable conditions and the battery The clamping motion mechanism 3 is electrically connected and connected with the control mechanism respectively.

[0033] The charge-discharge power box of described variable condition comprises power box 21, is arranged on the single-chip microcomputer board 22 in the power box 21, driving power board 23, auxiliary working power supply 24, AC / DC power supply 25 and cooling fan 26 for charging, so The driving power bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com