Method and module for building basic furniture component

A basic home and component technology, applied in the direction of furniture connection, connecting components, mechanical equipment, etc., can solve the problems of scrapping, inability to modify, inability to modify furniture shape and size, etc., to improve the use efficiency and life, size and size. The effect of less shape change and easy to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

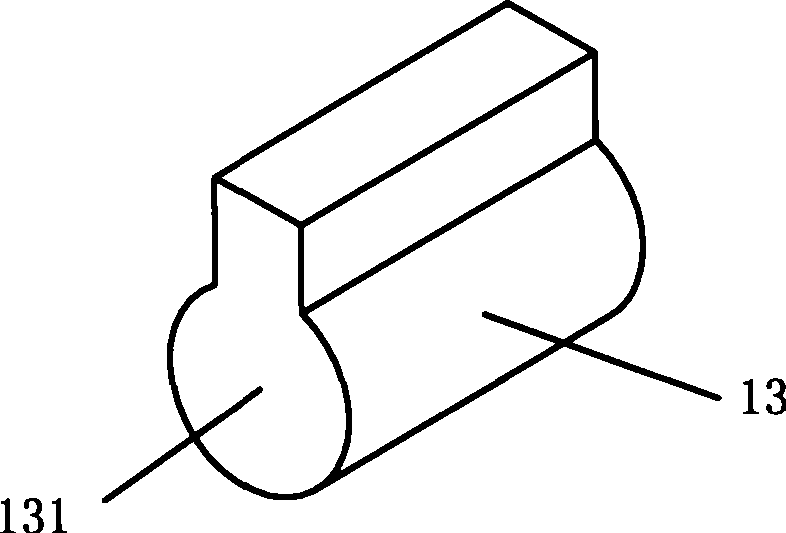

[0035] The present invention constructs the module of basic furniture component, should select certain size in advance in the scale range between 1cm-10cm as standard size, produces each kind of module by this standard size. Modules of different materials (such as wood, glass, stone, resin) and different colors can be produced, and patterns can be painted on the exposed surface of the modules, just like floor tiles, which can spell out patterns or patterns when used to enhance the final product. beautiful. Each type of module has at least one side with a mortise, and various modules can be firmly connected into one body through the mortise strips inserted in the corresponding mortise.

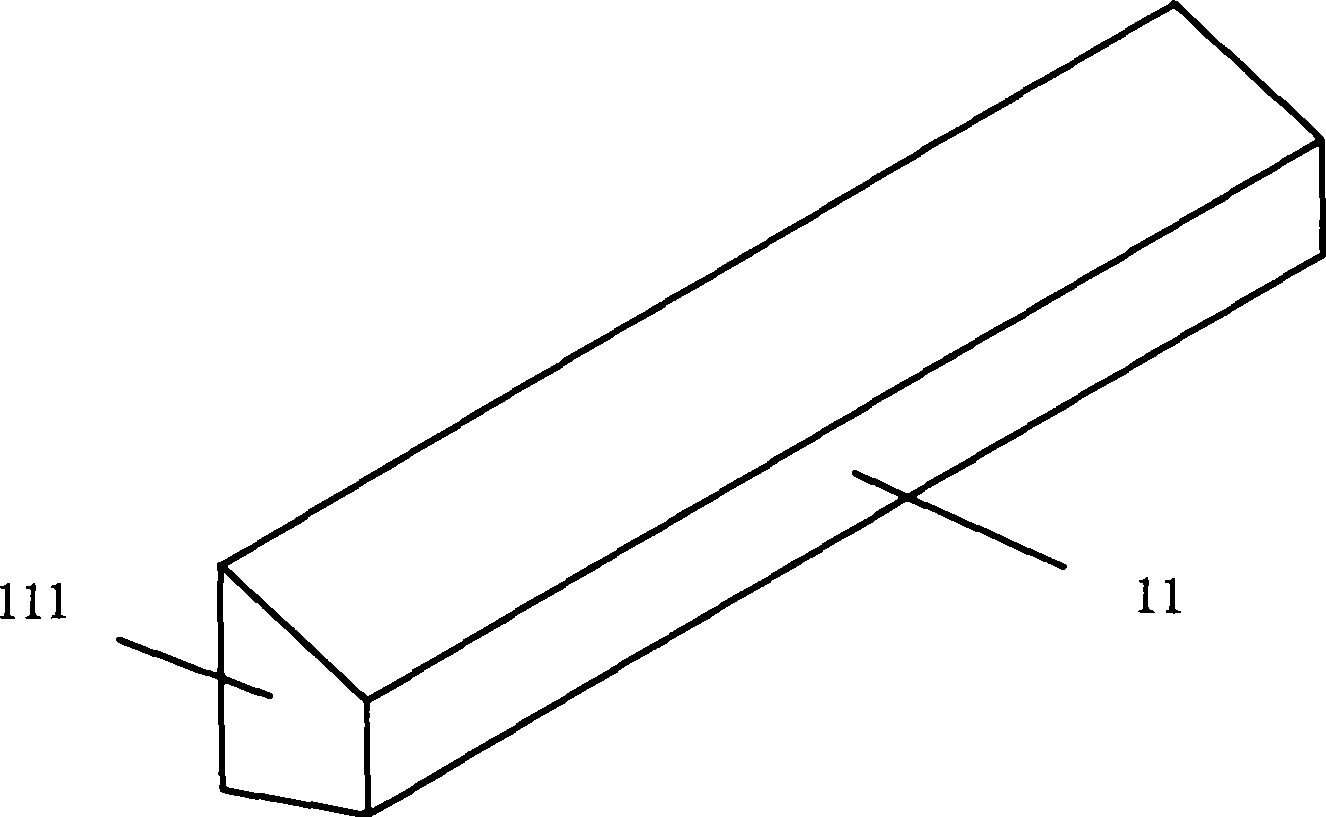

[0036] The three-dimensional structure of a tenon embodiment for connecting modules of the present invention is shown in Figure 1-1. The cross-section 111 of this tenon 11 shows that it has a dovetail-shaped single rib.

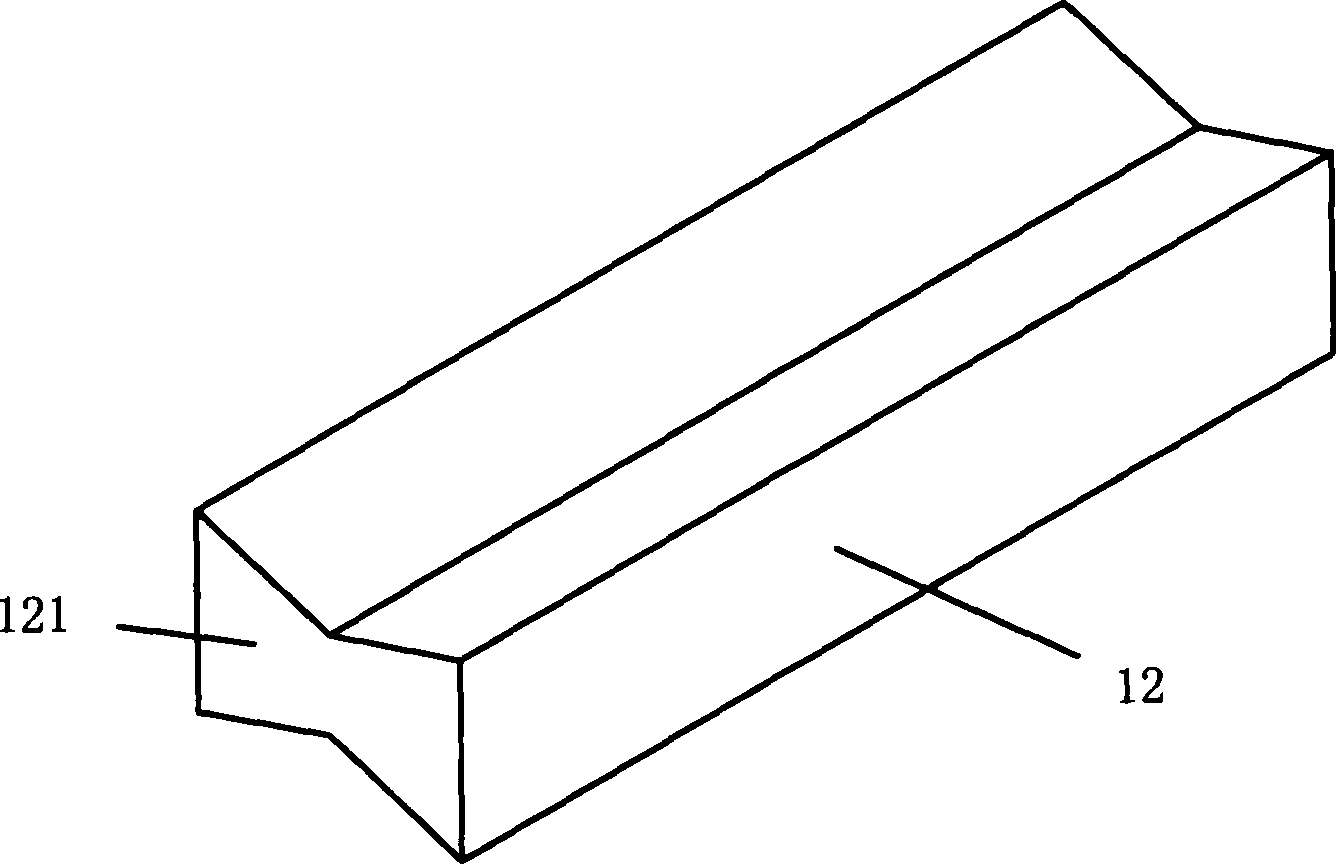

[0037] The three-dimensional structure of another embodiment of the ten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com