High-performance high-solid general modified epoxy antirust paint and preparation method thereof

An anti-rust coating, high solid technology, applied in the field of coatings, can solve the problems of undisclosed topcoat matching, recoatability, and prolonging the construction period, so as to improve the poorness of pure epoxy, which is not weather-resistant and easy to lose gloss, and increase the Excellent effect of crosslink density and compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

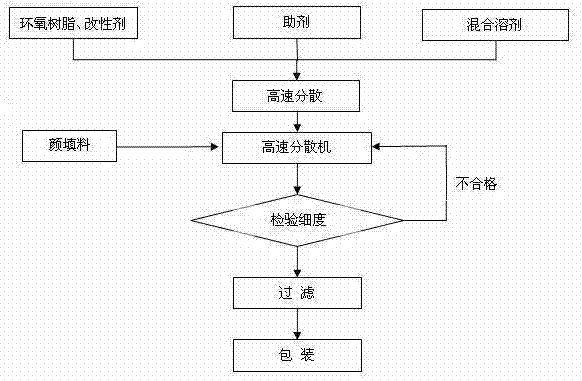

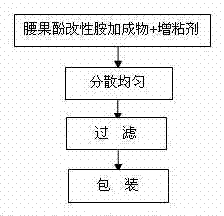

Method used

Image

Examples

Embodiment Construction

[0053] Examples of the present invention are shown in Table 3.

[0054] Table 3 Example of a high-performance high-solid general-purpose modified epoxy antirust coating

[0055] Component A raw material name Example 1 Example 2 Example 3 E44 5 7.5 10 NPPN-631 5 7.5 10 Terpene resin 11 8.5 6 Indene resin 11 8.5 6 BYK defoamer 0.5 0.3 0.1 HX leveling agent 0.5 0.3 0.1 Rheology Additives 1.0 0.7 0.5 mixed solvent 10 8 6 Active silica 10.5 8 6 talcum powder 10 8 7 Mica powder 11 9 7 Iron Oxide Red 16 20.7 23.8 B component raw material name Example 1 Example 2 Example 3 Cardanol modified amine 8 12 16 Modified silane coupling agent 0.5 1.0 1.5

[0056] Wherein embodiment 2 is done performance test, obtains following table 4 data.

[0057] Table 4

[0058]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com