EVA/LLDPE composite polymer waterproof board and manufacturing process thereof

A composite polymer and waterproof board technology, which is applied in the field of EVA/LLDPE composite polymer waterproof board and its manufacturing process, can solve the problems of waterproof boards not being tear-resistant and difficult to construct, and achieve excellent low-temperature flexibility and puncture resistance, High tensile strength and wide temperature range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

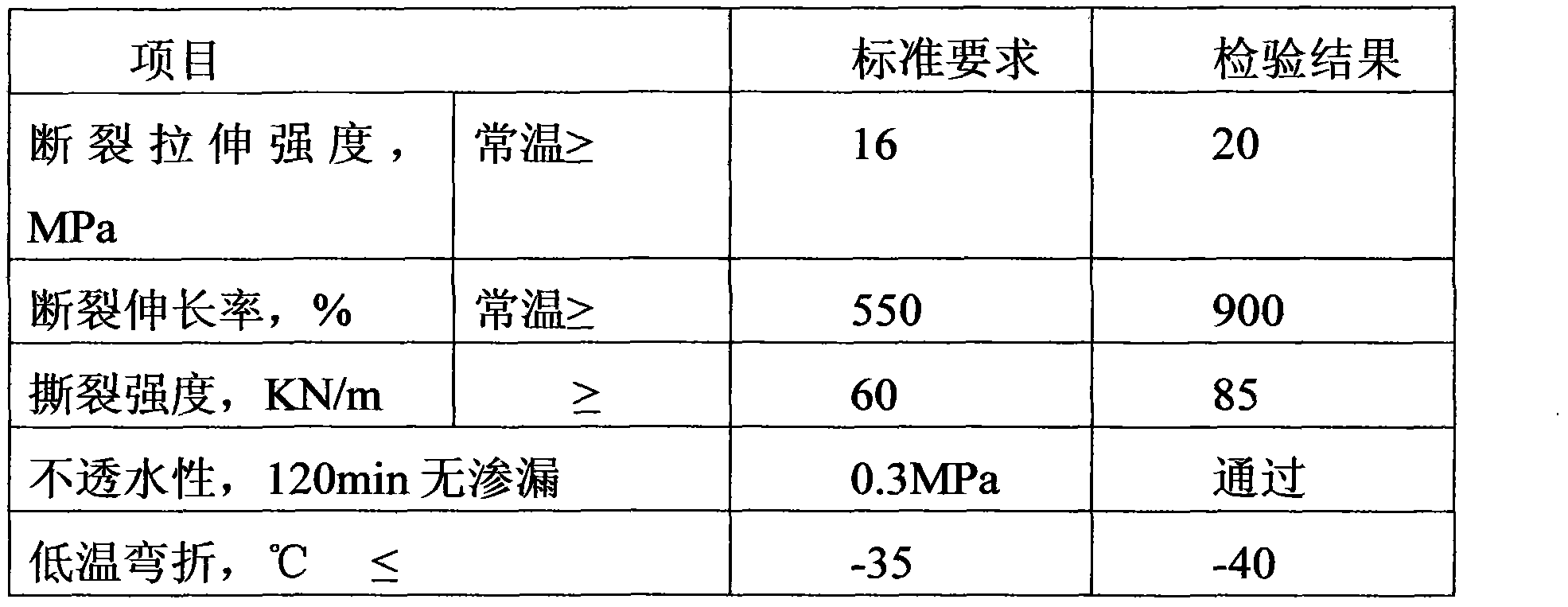

[0021] Example 1: Transparent EVA / LLDPE composite polymer waterproof board

[0022] An EVA / LLDPE composite polymer waterproof board is made of the following raw materials in parts by weight:

[0023] Ethylene-vinyl acetate copolymer 50 parts

[0024] Linear Low Density Polyethylene 50 parts

[0025] Antioxidant 1010 / 168 / 1076 0.75 parts

[0026] Antioxidant DLTP 0.25 parts

[0027] The manufacturing process of the EVA / LLDPE composite polymer waterproof board comprises the following steps:

[0028] (1) Ingredients: take the raw material components respectively according to the formula;

[0029] (2) Mixing: put the raw materials into a high-speed mixer, the temperature is 80°C, and the mixing time is 10-15 minutes;

[0030] (3) Blending extrusion: blending extrusion adopts a single-screw extruder, and the temperatures of the twin-screw feeding section, melting section, and metering section are (150±10)°C, (160±10)°C, (170±10)°C, and (170±10)°C, respectively. 10) °C;

[003...

Embodiment 2

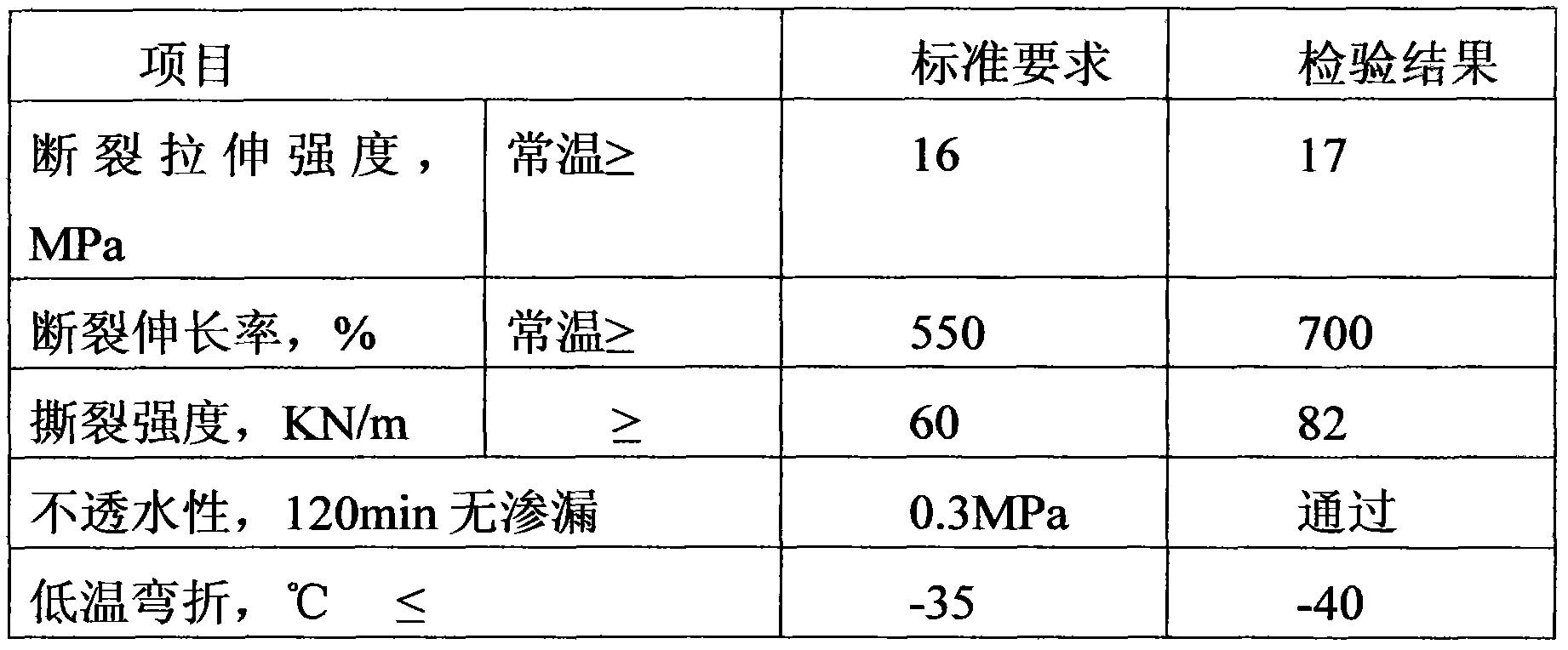

[0036] Example 2: Non-transparent EVA / LLDPE composite polymer waterproof board

[0037] An EVA / LLDPE composite polymer waterproof board is made of the following raw materials in parts by weight:

[0038] Ethylene-vinyl acetate copolymer 80 parts

[0039] Linear Low Density Polyethylene 40 parts

[0040] Antioxidant 1010 / 168 / 1076 0.9 parts

[0041] Antioxidant DLTP 0.3 parts

[0042] The manufacturing process of the EVA / LLDPE composite polymer waterproof board comprises the following steps:

[0043] (1) Ingredients: take the raw material components respectively according to the formula;

[0044] (2) Mixing: Add the raw materials into a high-speed mixer, the temperature is 80°C, and the mixing time is 10-15 minutes;

[0045] (3) Blending extrusion: blending extrusion adopts a single-screw extruder, and the temperatures of the twin-screw feeding section, melting section, and metering section are (150±10)°C, (160±10)°C, (170±10)°C, and (170±10)°C, respectively. 10) °C;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com