Environmentally-friendly flame-retardant polymer cement waterproof coating and production process therefor

A waterproof coating and production process technology, applied in the field of architectural waterproof coatings and waterproof coatings, can solve the problems of harmful organic compounds, low tensile strength, poor low temperature flexibility, etc., to reduce safety hazards, high tensile strength, low temperature flexibility Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] Embodiment 1 A kind of environment-friendly flame-retardant polymer cement waterproof coating

[0062] The waterproof coating includes two components of liquid material and powder material, and the weight ratio of liquid material and powder material is liquid material: powder material = 1:1.

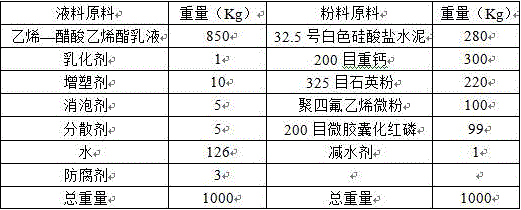

[0063] The formula of the waterproof coating is

[0064]

[0065] The glass transition temperature of the ethylene-vinyl acetate emulsion is -12°C;

[0066] Described defoamer is organosilicon type defoamer;

[0067] The preservatives used are isothiazolinones;

[0068] The polytetrafluoroethylene micropowder mesh number is 1250 mesh;

[0069] The dispersant is sodium polyacrylate.

Embodiment 2

[0070] Embodiment 2 A kind of environment-friendly flame-retardant polymer cement waterproof coating

[0071] The waterproof coating includes two components of liquid material and powder material, and the weight ratio of liquid material and powder material is liquid material: powder material = 1:1.2.

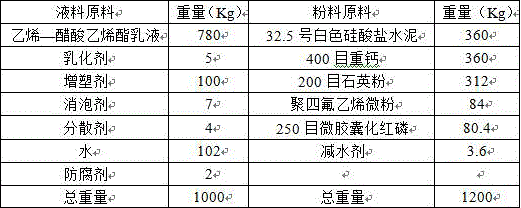

[0072] The formula of the waterproof coating is

[0073]

[0074] The glass transition temperature of the ethylene-vinyl acetate emulsion is 9°C;

[0075] Described defoamer is organosilicon type defoamer;

[0076] The preservatives used are isothiazolinones;

[0077] The polytetrafluoroethylene micropowder mesh number is 1250 mesh;

[0078] The water reducer is a melamine-based high-efficiency water reducer;

[0079] The emulsifier model is AS-801;

[0080] Described plasticizer is chlorinated paraffin-52;

[0081] The dispersant is sodium polyacrylate.

Embodiment 3

[0082] Embodiment 3 A kind of environment-friendly flame-retardant polymer cement waterproof coating

[0083]The waterproof coating includes two components of liquid material and powder material, and the weight ratio of liquid material and powder material is liquid material: powder material = 1:1.5.

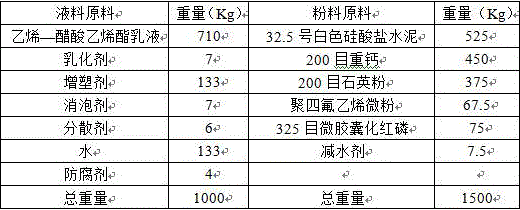

[0084] The formula of described waterproof paint is:

[0085]

[0086] The glass transition temperature of the ethylene-vinyl acetate emulsion is 0.8°C;

[0087] The defoamer is a mineral oil defoamer;

[0088] The preservatives used are isothiazolinones;

[0089] The polytetrafluoroethylene micropowder mesh number is 1250 mesh;

[0090] The water reducer is a melamine polycarboxylate water reducer;

[0091] The emulsifier model is AS-801;

[0092] Described plasticizer is chlorinated paraffin-52;

[0093] The dispersant is sodium polyacrylate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com