High-performance building structure refractory steel plates and manufacturing method thereof

A technology of building structure and manufacturing method, applied in temperature control and other directions, can solve the problems of high production cost, large variation range of yield strength, poor fire resistance and difficult to meet the design requirements of building fire resistance, and achieve the effect of low cost and simple chemical composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

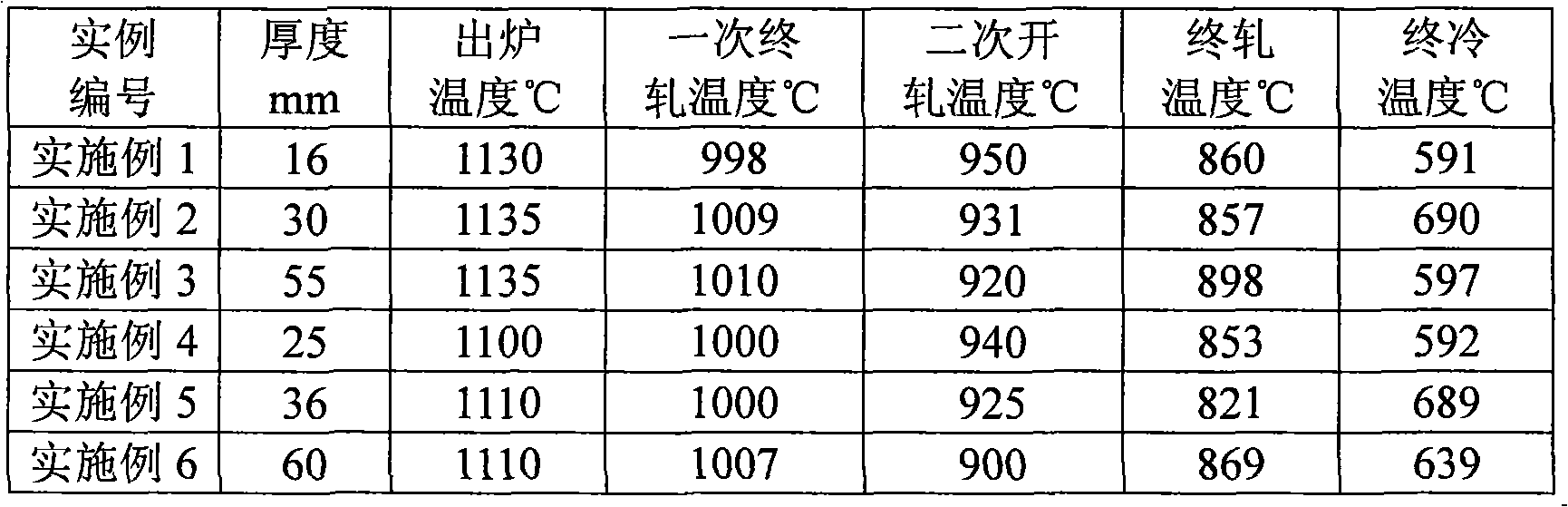

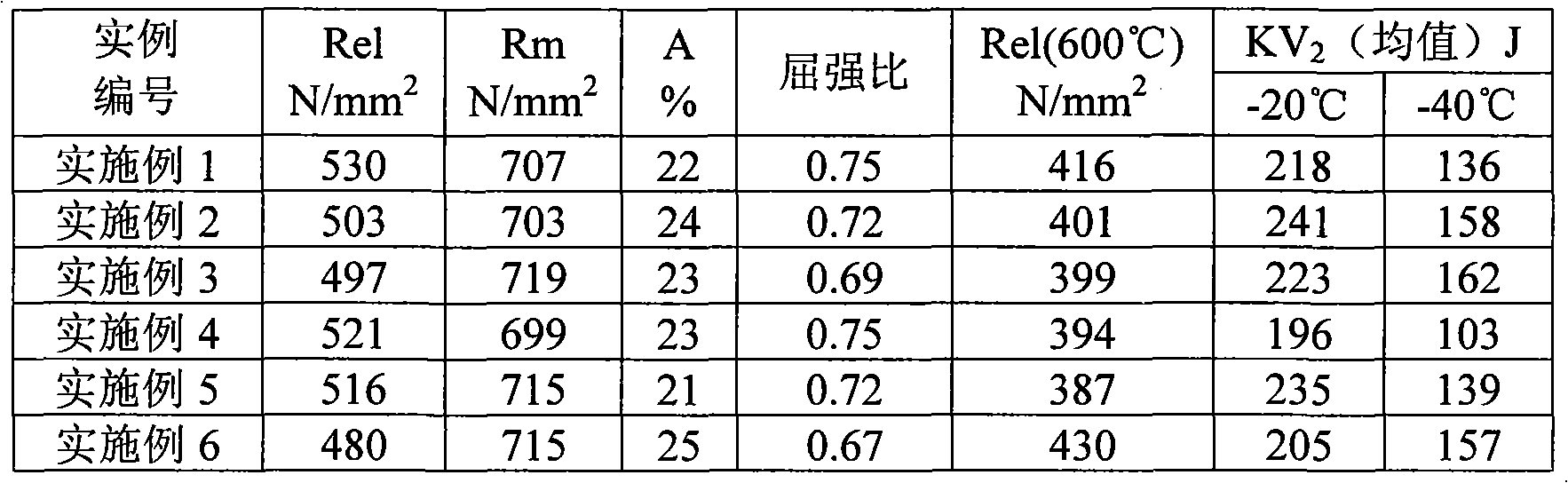

Examples

Embodiment Construction

[0038] The chemical composition of the steel of the present invention is mainly low C, low Mo or low Cr, and its specific chemical composition is, in weight percentage: C0.02%~0.12%, Si0.05%~0.50%, Mn0.80%~1.50%, Nb0.010%~0.050%, Ti0.010%~0.040%, Als0.010%~0.050%, Cr0.20%~0.60%, Mo0.20%~0.40%, its P≤0.015%, S≤0.005% , [N]≤0.0040%, [O]≤0.0020%, the balance is Fe and unavoidable impurities.

[0039] The concrete production technological process of steel of the present invention is:

[0040] Steelmaking - refining - continuous casting - billet heating - two-stage controlled rolling - controlled cooling - heat preservation self-tempering - finished product.

[0041] Smelting process: pretreatment of molten iron, smelting by converter, top blowing or top-bottom compound blowing, refining treatment, and microalloying, to control the impurity content in the steel, and to control the Als content at 0.010% according to the oxygen content in the molten steel ~0.050%, adding Ti microal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com