Surface light source

By designing the prism part and reflective side structure in the surface light source, the light mixing distance and light mixing effect of the beam are increased, the light spot problem in the narrow frame design is solved, and the uniformity of light output and cost reduction are achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

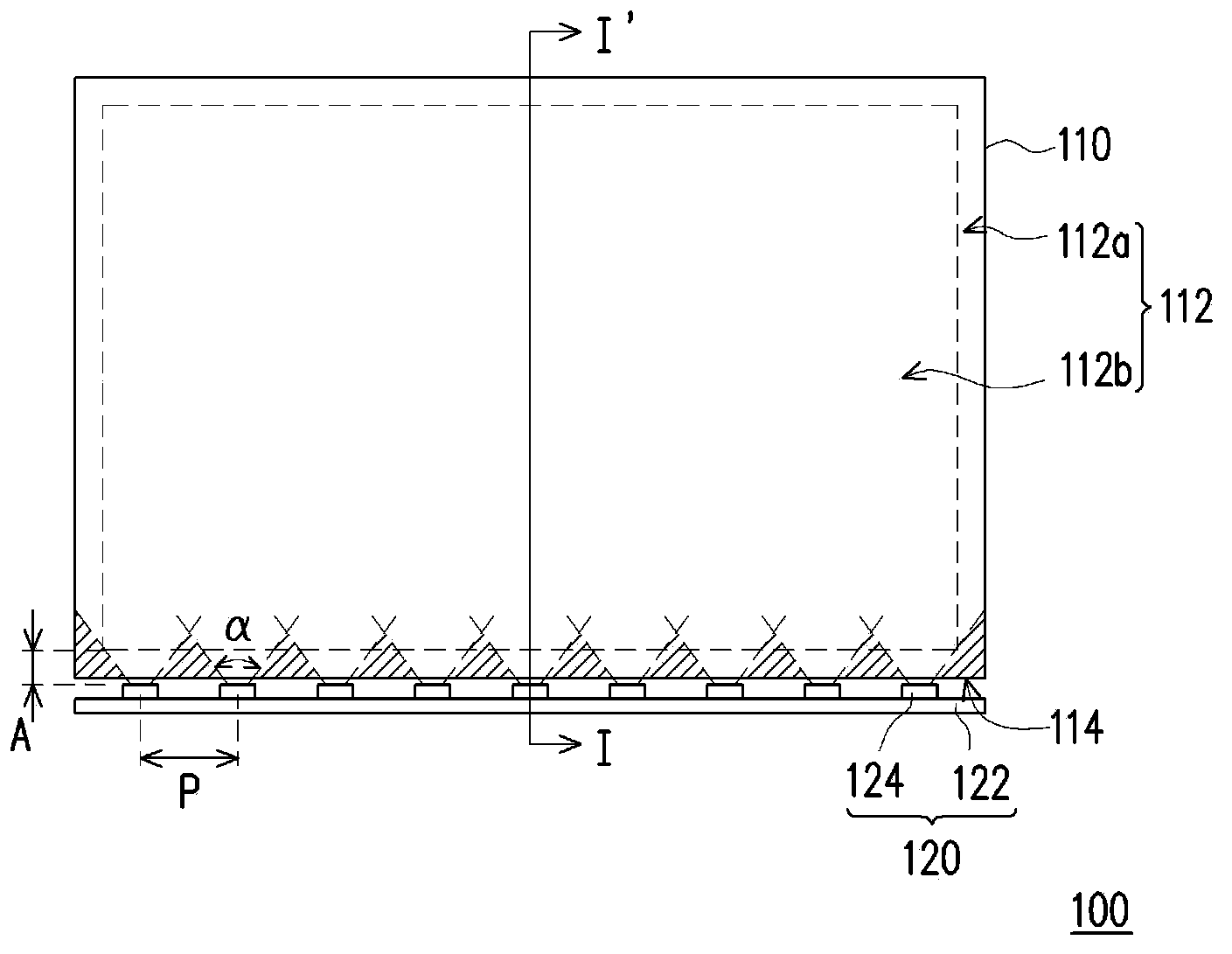

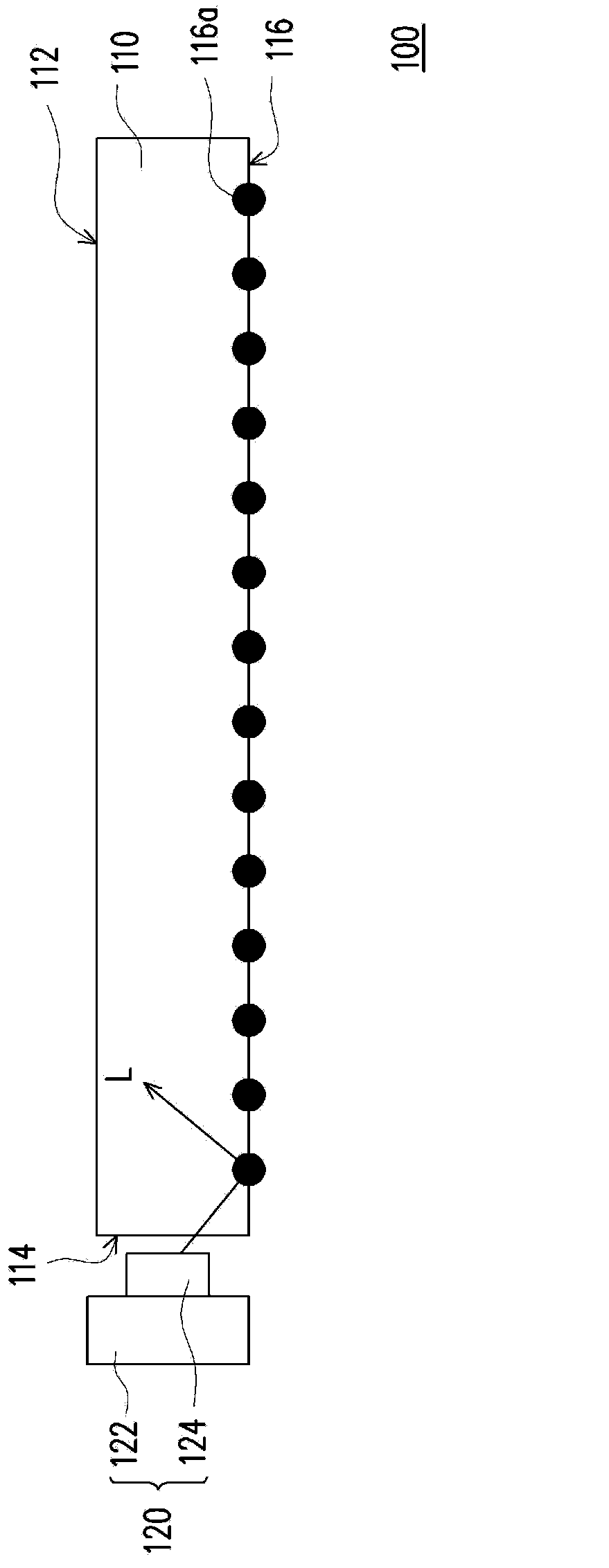

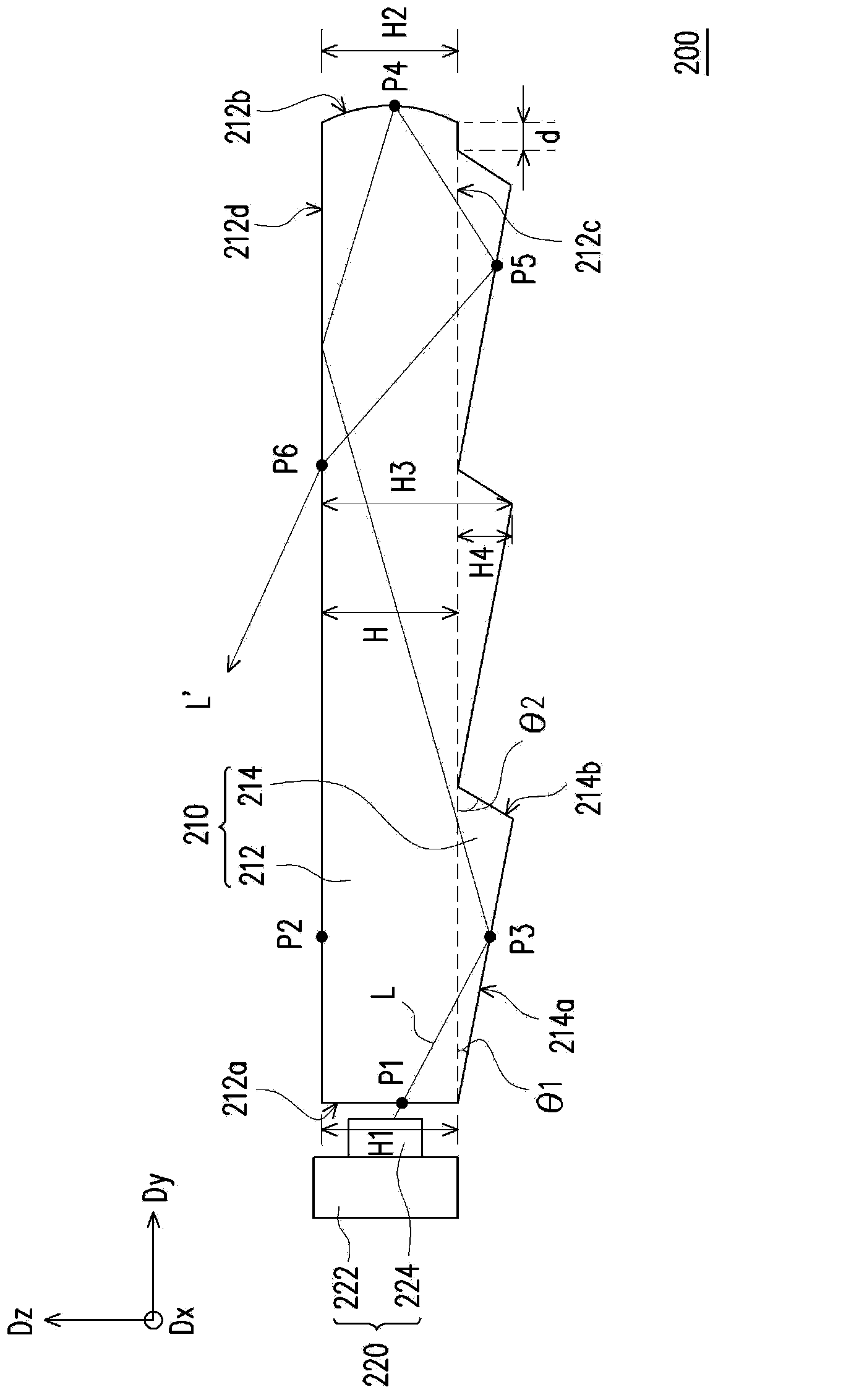

[0036] image 3 It is a schematic cross-sectional view of the surface light source according to the first embodiment of the present invention. Please refer to image 3 , the surface light source 200 of this embodiment includes a light guide plate 210 and a light source device 220 . The light guide plate 210 has a plate body 212 and a plurality of prism portions 214, wherein the plate body 212 has a light incident side 212a, a reflective side 212b opposite to the light incident side 212a, a bottom surface 212c, and a light exit surface 212d opposite to the bottom surface 212c, and The light-incident side 212a and the reflective side 212b are respectively connected to the bottom surface 212c and the light-out surface 212d. The prism portions 214 are substantially adjacent to the bottom surface 212c of the plate-shaped body 212, and each prism portion 214 has a first plane 214a and a second plane 214b adjacent to each other, and the included angle θ between the first plane 214a...

no. 2 example

[0080] Figure 6 It is a schematic cross-sectional view of the surface light source according to the second embodiment of the present invention. Please refer to Figure 6 , the surface light source 300 of this embodiment is similar to the surface light source 200 of the first embodiment, but the main difference between the two is: the reflective side 312b of this embodiment adopts the same Figure 5 In a similar design, the light guide plate 210' of this embodiment has a single prism portion 314, the prism portion 314 has a first plane 314a and a second plane 314b, and the distance d between the second plane 314b and the reflective side 312b is 0.

no. 3 example

[0082] Figure 7 It is a schematic cross-sectional view of the surface light source according to the third embodiment of the present invention. Please refer to Figure 7 , the surface light source 400 of this embodiment is similar to the surface light source 300 of the second embodiment, but the main difference between the two is that: the light guide plate 210 ″ of this embodiment has a single prism part 414, and the prism part 414 has a first The plane 414a and the second plane 414b, and the distance d between the second plane 414b and the reflective side 412b is not zero. For example, the length of the aforementioned distance d is smaller than the length of the bottom surface 212 c of the prism portion 414 in the direction Dy.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com