High-hydroxy phenolic resin prepared by using phenols residues as raw material, and application of high-hydroxy phenolic resin to production of high-temperature-resistant paint

A high-hydroxyl phenolic resin and residue technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problems of complex treatment process, pollutant discharge, environmental pollution, etc., and achieve simple production process, low equipment investment, and comprehensive cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

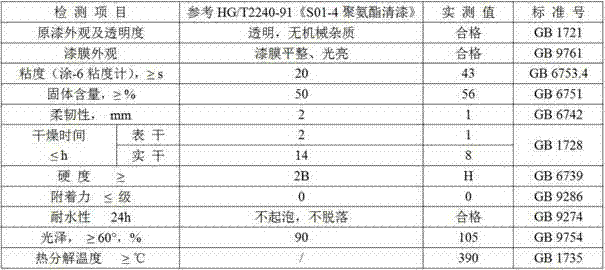

Embodiment 1

[0046] 1. Preparation of high hydroxyl phenolic resin

[0047]Add 100 parts of phenol residue, 50 parts of dicyclopentadiene, 80 parts of terpene resin, 100 parts of water, 0.5 parts of calcium oxide, and 1 part of hexamethylenetetramine into the reaction kettle, raise the temperature to 100°C, and add 50 parts of formaldehyde After 4 hours of reaction, start to add 10 parts of toluene, 50 parts of tung oil, 100 parts of pentaerythritol, 70 parts of fumaric acid, 13 parts of lead oxide, heat up to 120 ° C, and dehydrate for 2 hours; then continue to slowly heat up to 220 ° C, and react for 10 parts Hours; measure viscosity and acid value, when the system viscosity is 10-12s / Grignard tube 25 ℃, solid acid value ≤ 20mgKOH / g, lower the temperature to 150 ℃, use toluene: butyl acetate = 1: 1 mixed solvent Dilute to a viscosity of 10-15s / Grignard tube at 25°C, solid acid value ≤ 20mgKOH / g, solid hydroxyl value 150mgKOH / g, solid content 60±2%, filter and pack to obtain the modified ...

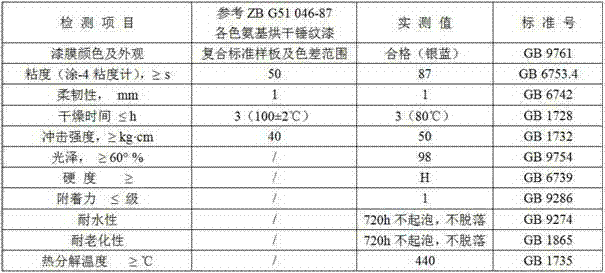

Embodiment 2

[0062] 1. Preparation of high hydroxyl phenolic resin

[0063] Add 100 parts of cresol residue, 60 parts of dimethylcyclopentadiene, 70 parts of furan resin, 100 parts of water, 1 part of zinc oxide, and 2 parts of triethylamine into the reaction kettle, raise the temperature to 90°C, and add formaldehyde 40 parts, after reacting for 5 hours, start to add 10 parts of xylene, 40 parts of linseed oil, 100 parts of pentaerythritol, 50 parts of maleic anhydride, 30 parts of phthalic anhydride, 2 parts of lithium hydroxide, heat up to 140°C, and dehydrate for 2 hours; Then continue to slowly raise the temperature to 240°C, and react for 10 hours; measure the viscosity and acid value, when the system viscosity is 10-12s / Grignard tube 25°C, and the solid acid value is ≤20mgKOH / g, cool down to 150°C, and use a mixed solvent ( Toluene:xylene=1:1) Dilute to viscosity 20-25s / Grignard tube 25℃, solid acid value ≤20mgKOH / g, solid hydroxyl value 140mgKOH / g, solid content 50±2%, filter, pack...

Embodiment 3

[0076] 1. Preparation of high hydroxyl phenolic resin

[0077] Put 100 parts of hydroquinone residue, 70 parts of dicyclopentadiene, 100 parts of rosin, 150 parts of water, 1 part of manganese dioxide, and 5 parts of ammonia water into the reaction kettle, raise the temperature to 100°C, add 70 parts of formaldehyde, and react 5 Hours later, start to add 15 parts of xylene, 70 parts of oleic acid, 30 parts of linoleic acid, 80 parts of pentaerythritol, 30 parts of glycerin, 50 parts of fumaric acid, and 80 parts of terephthalic acid, heat up to 150°C, and dehydrate for 2 hours; Then continue to slowly raise the temperature to 210°C, and react for 7 hours; measure the viscosity and acid value, when the system viscosity is 10-12s / Grignard tube 25°C, and the solid acid value is ≤20mgKOH / g, cool down to 150°C, and use a mixed solvent ( Xylene: butyl acetate = 1:1) dilute to viscosity 15-20s / Grignard tube 25°C, solid acid value ≤ 20mgKOH / g, solid hydroxyl value 120mgKOH / g, solid co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

| water resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com