Sheet material feeding and discharging device, mobile phone glass machining center and machining method

A technology for processing centers and plates, applied in the direction of processing models, glass manufacturing equipment, glass cutting devices, etc., can solve the problems of long loading and unloading time, multiple racks and space, etc., and achieve improved loading and unloading efficiency and large operating space , The effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

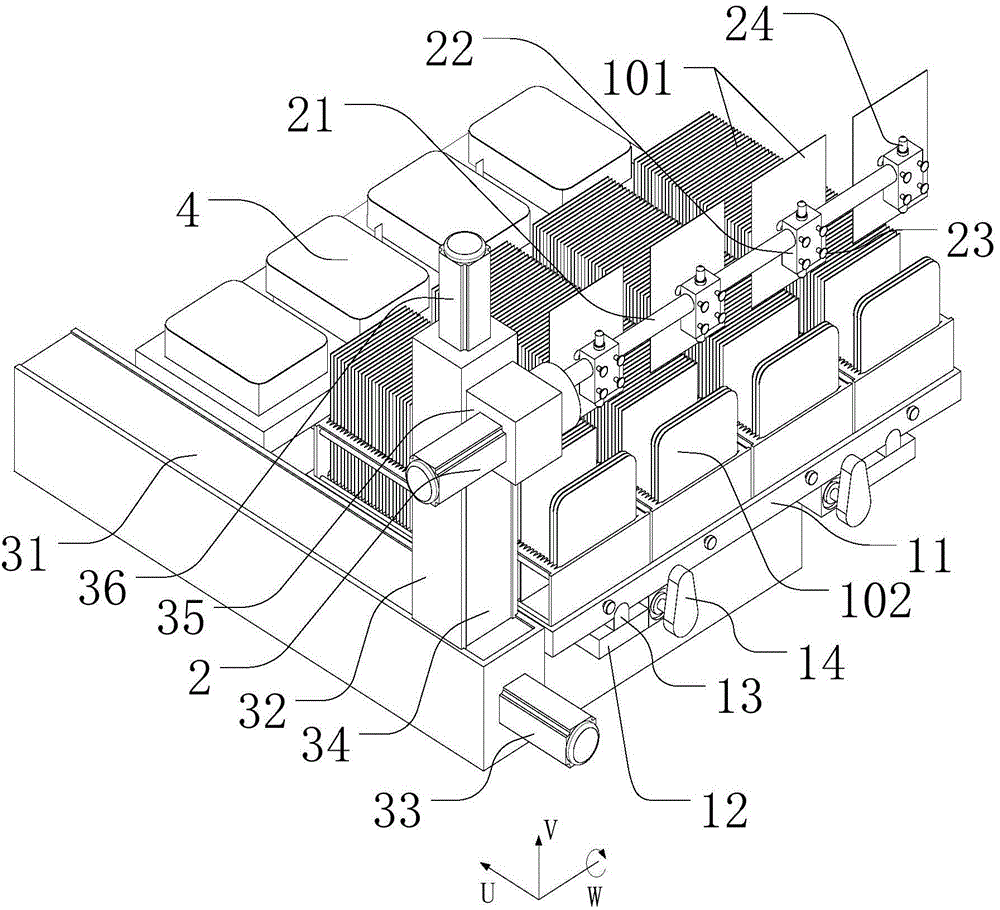

[0030] An embodiment of the present invention provides a board loading and unloading device, such as figure 1 As shown, it includes: a trough 1 for vertically arranging the plates and sharing the plate 101 to be processed with the processed plate 102; The first driving mechanism of the movement, and the rotating block 22 installed on the rotating rod 21, the front and rear sides of the rotating block 22 are equipped with pick-and-place parts 23 for picking and placing plates, and the rotating mechanism 2 is installed on the first driving mechanism Above and the rotating block 22 is located above the trough 1, and a processing table 3 for further processing of the plates is provided in the direction in which the plates are arranged.

[0031] In this embodiment, in order to facilitate the understanding of the technical solution, with reference to the accompanying drawings, it is defined that the arrangement direction of the plates is the vertical direction, the extension directi...

Embodiment 2

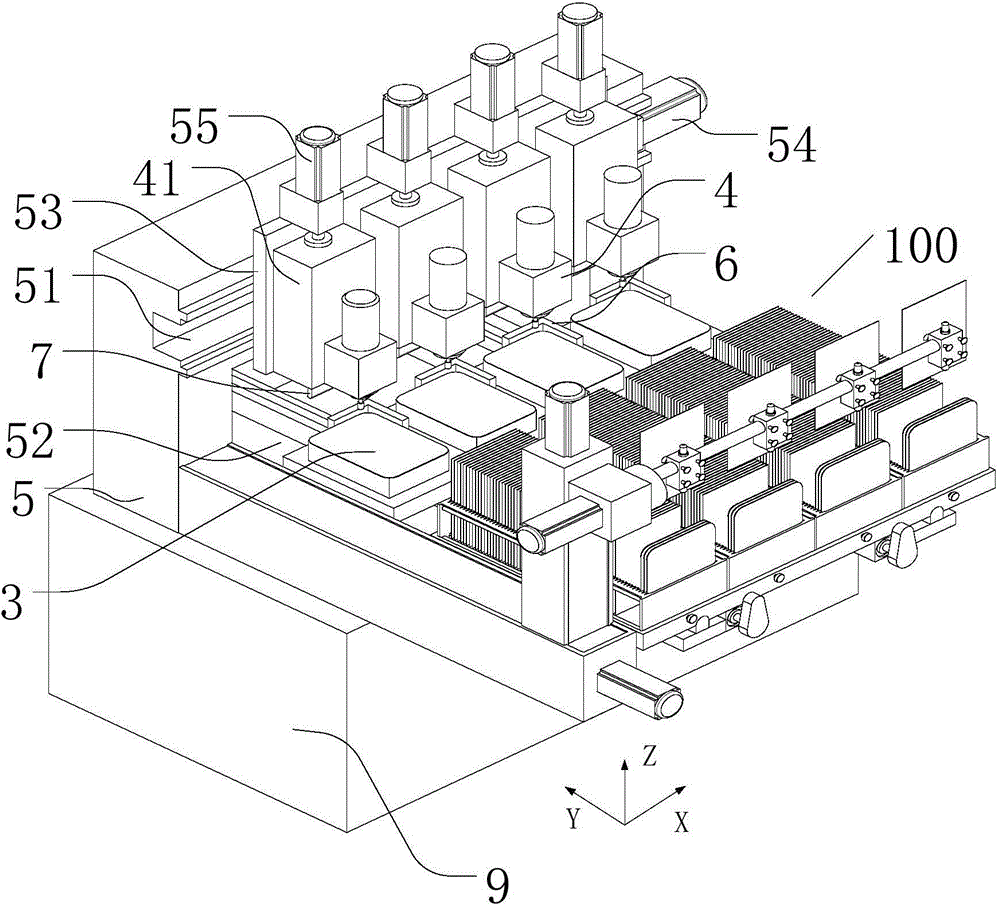

[0038] Provide a kind of mobile phone glass processing center in the present embodiment, as figure 2 As shown, it includes the plate loading and unloading device 100 in the above-mentioned embodiment 1, and also includes a processing head 4 located above the processing table 3, and is used to carry the processing head 4 relative to the processing table 3 in the X, Y, and Z axis directions. The second drive mechanism for the upper movement. In this embodiment, the processing machine head and the second driving mechanism actually form a processing machine tool. In this way, the robot arm for picking and placing plates is combined with the processing machine tool to obtain a more efficient processing device. Of course, this is not simple. Combination, but the corresponding combination of the processing machine tool and the components of the plate loading and unloading device.

[0039] The defined X, Y, and Z axes are Cartesian coordinate systems, refer to figure 2 , the X axi...

Embodiment 3

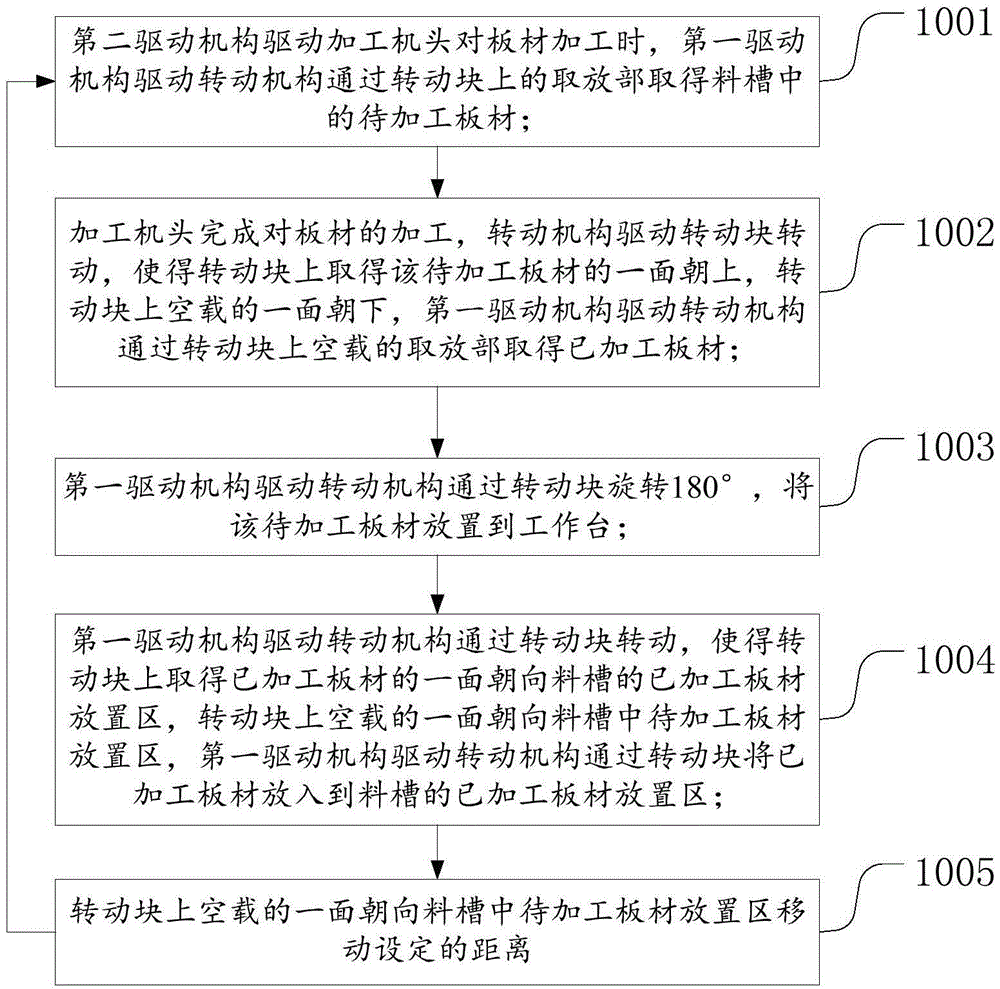

[0047] An embodiment of the present invention provides a mobile phone glass processing method, which is based on the mobile phone glass processing center in the above-mentioned embodiment 2 as hardware, and proposes a processing method that can greatly increase the processing efficiency of a machine tool.

[0048] like image 3 As shown, the processing method includes the following steps:

[0049] 1001: When the second driving mechanism drives the processing machine head to process the plate, the first driving mechanism drives the rotating mechanism to obtain the plate to be processed in the trough through the pick-and-place part on the rotating block;

[0050] 1002: The processing machine head completes the processing of the plate, the rotating mechanism drives the rotating block to rotate, so that the side of the rotating block that obtains the plate to be processed faces upward, and the unloaded side of the rotating block faces downward, and the first driving mechanism driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com