Transfer platform

A platform and workbench technology, applied in the field of automatic assembly lines, can solve problems such as uneven spacing, difficulty in taking materials at the same time, non-adjustable spacing between transfer components, etc., to achieve improved efficiency, simple structure, and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

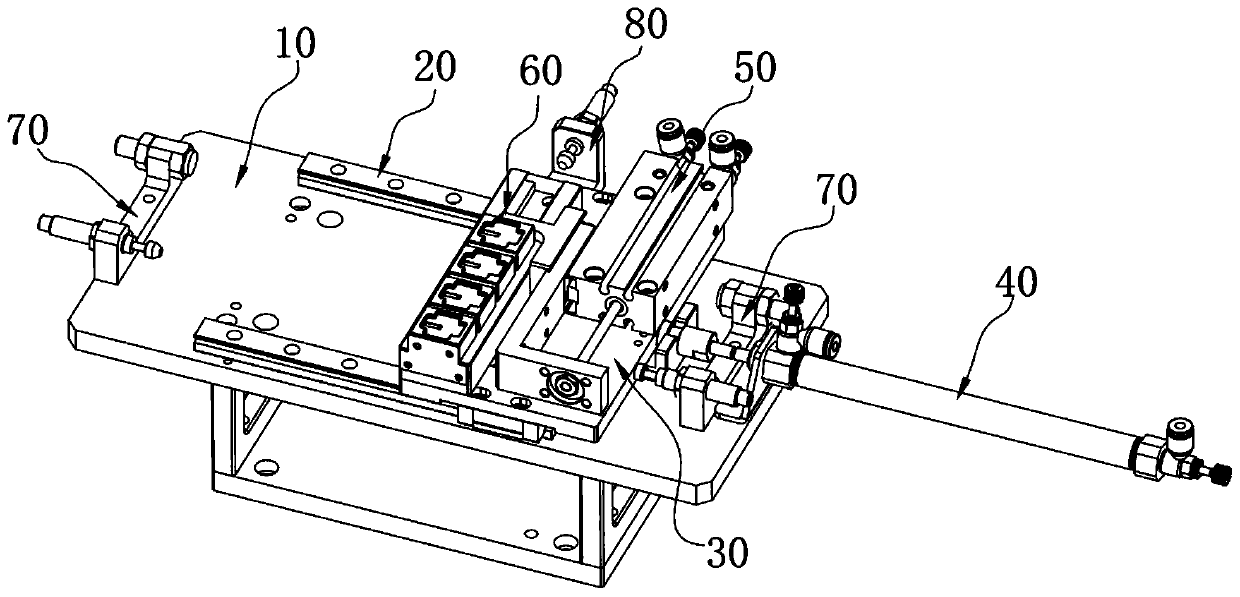

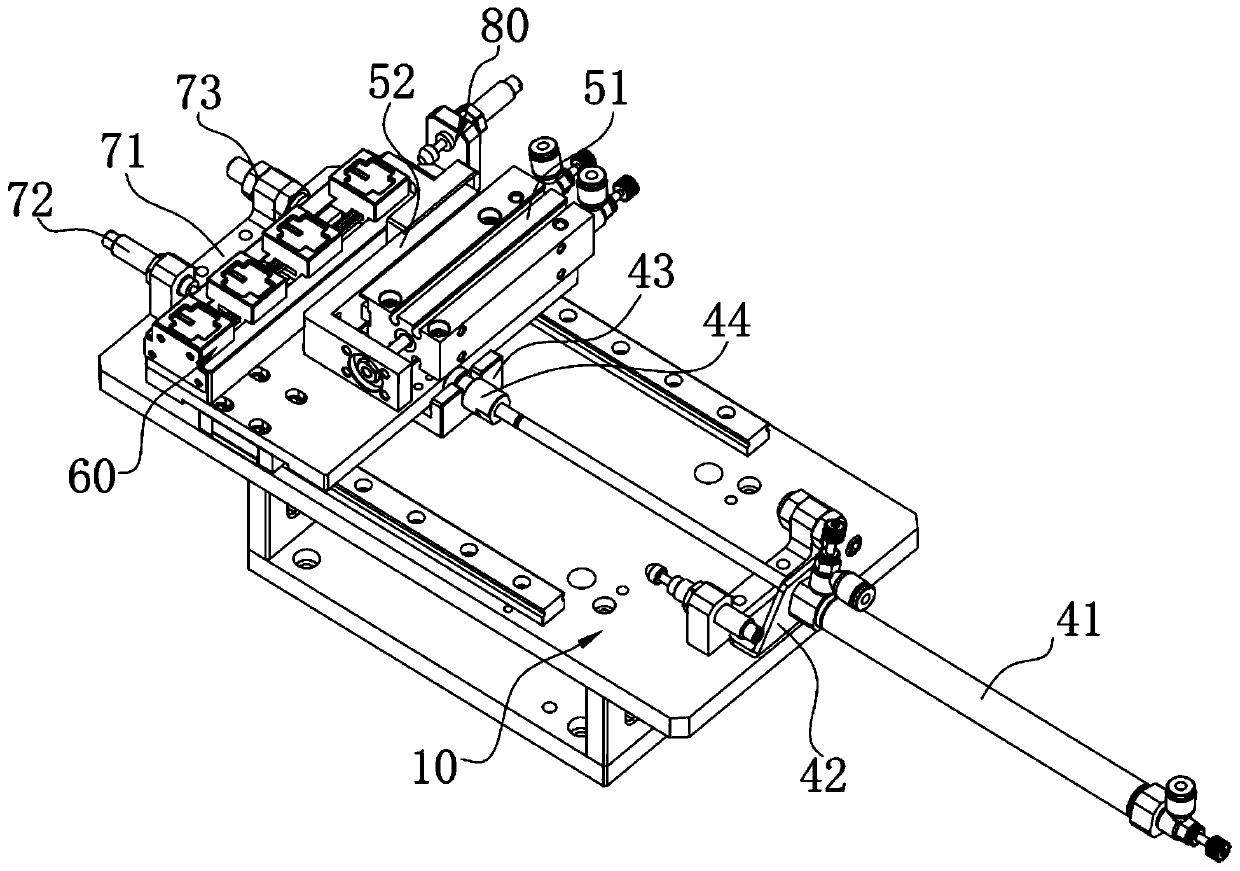

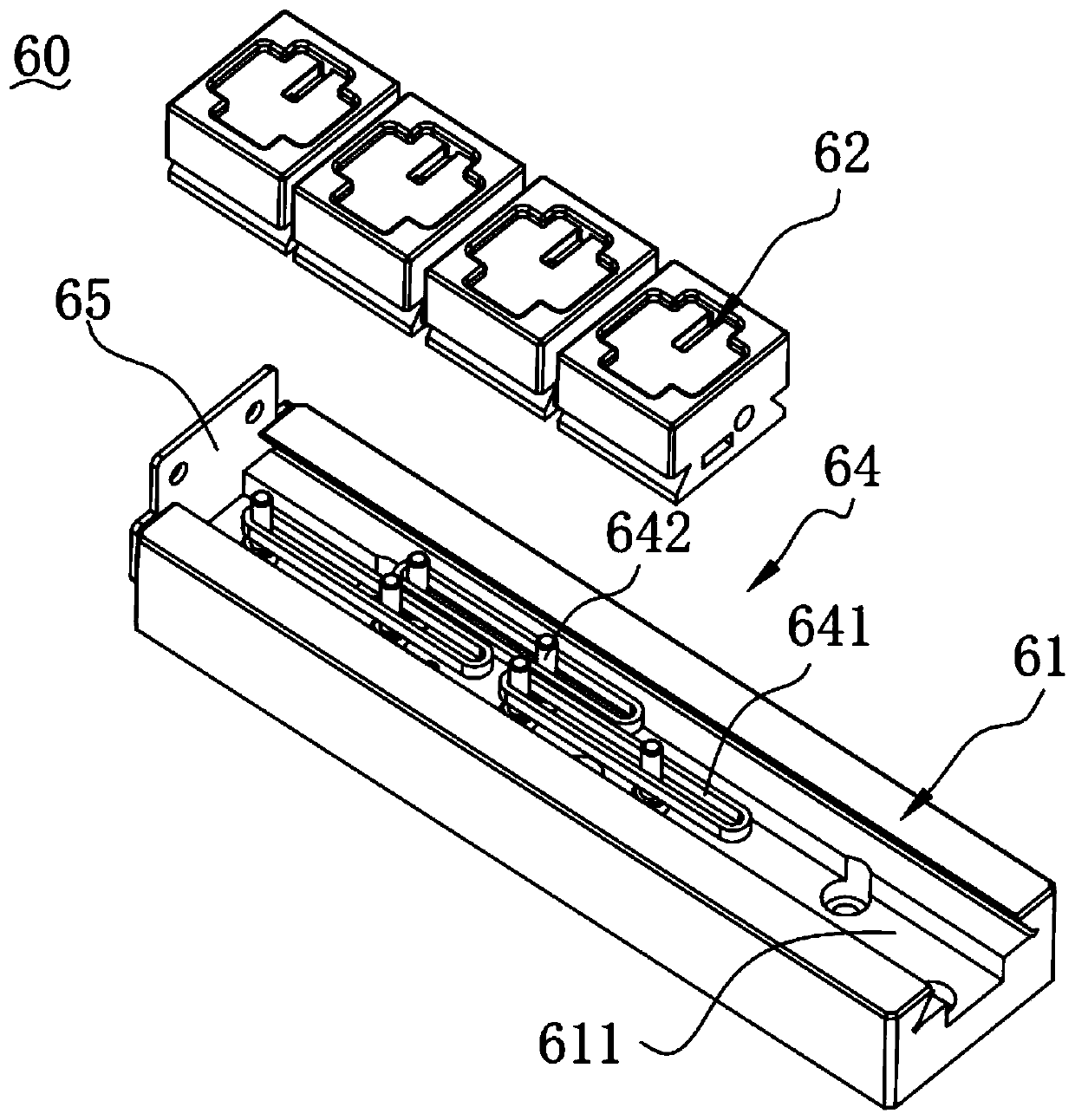

[0024] Such as Figure 1 to Figure 7 As shown, the present invention provides a transfer platform, including: a medium-load assembly 60 having a first station and a second station, which includes a slide seat 61 formed with a chute 611 , slidably arranged on the chute 611 A plurality of seats 62 on the top, a first limiting unit 63 arranged on the side wall of the seats 62 so that the distance between the seats 62 meets the distance required by the first station, and a spacer 63 arranged on the On the carrier 62, the distance between the carriers 62 meets the second spacing unit 64 required by the second station; the middle load assembly 60 is driven to move so that the middle load assembly 60 obtains the required distance. the first drive unit 40 of the first station and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com