Material taking and placing device and material replacing device with same

A technology of picking and unloading and cranking, which is applied in the direction of packaging, etc., can solve the problems of limited space for replacement material equipment, low efficiency of picking and unloading, and no picking and unloading device, etc., to achieve compact structure, high efficiency of picking and unloading, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

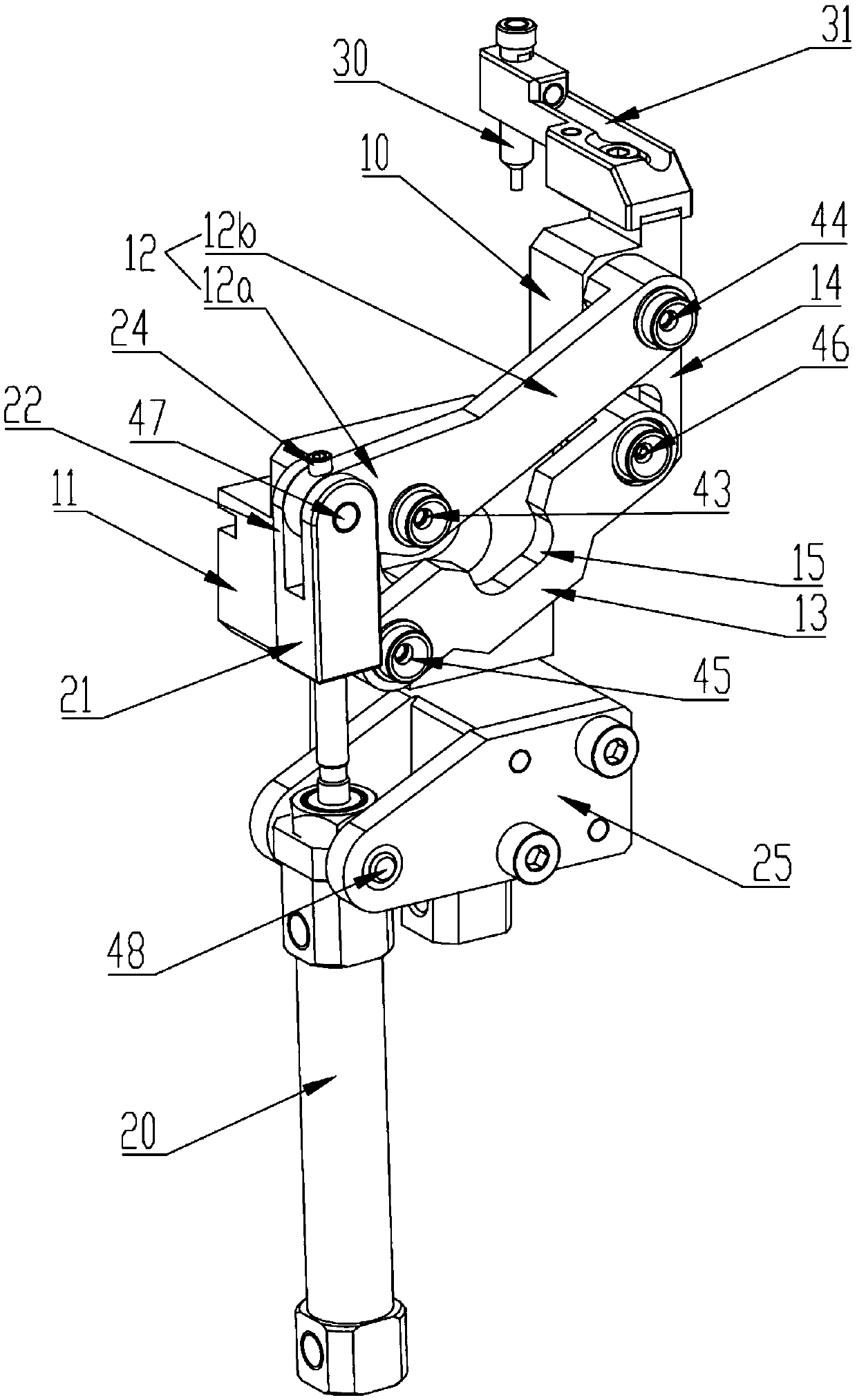

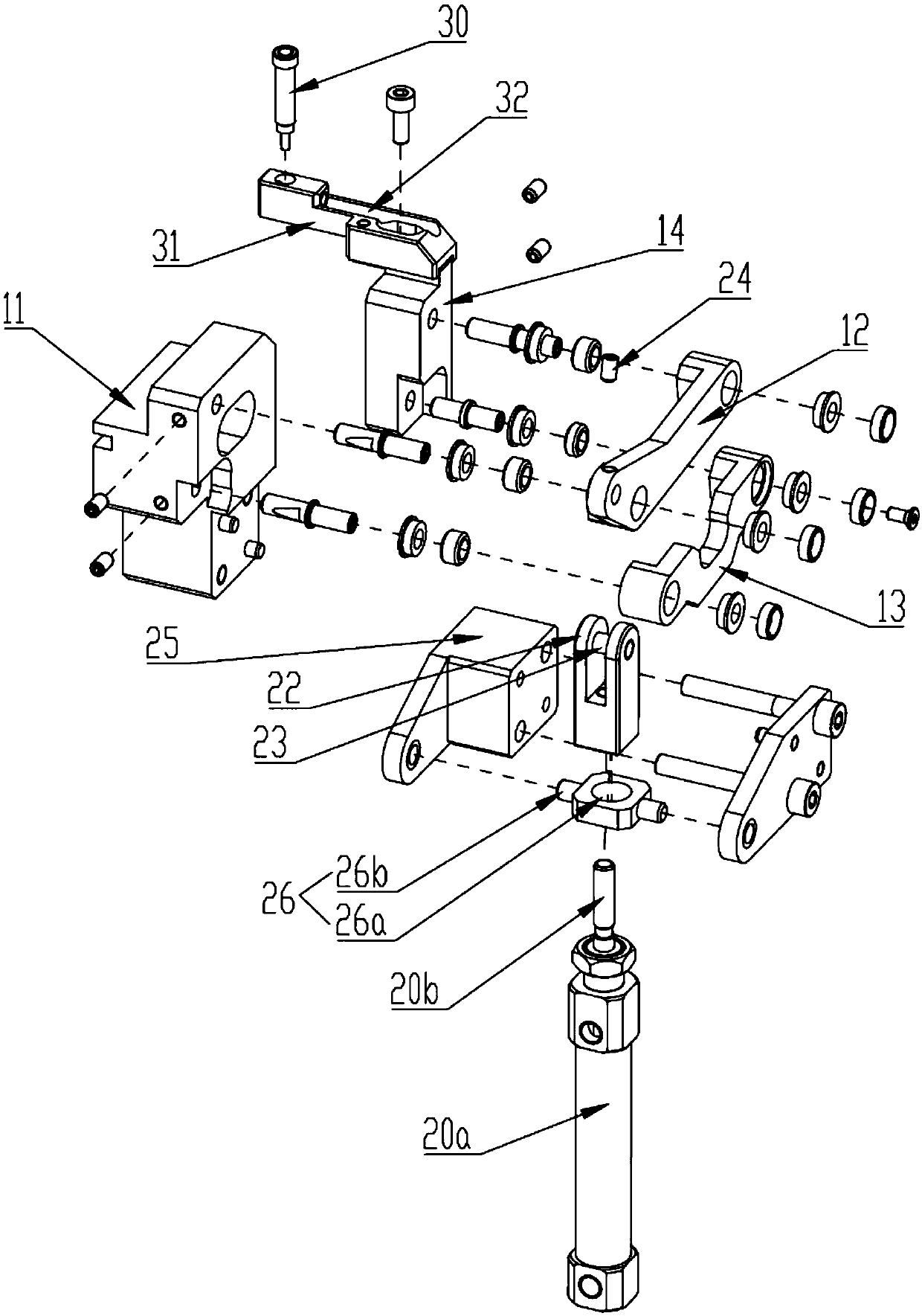

[0028] see Figure 1 to Figure 2 , the present invention provides a pick-and-place material device 40, which includes a parallelogram mechanism 10, a cylinder 20, and a suction cup 30; the parallelogram mechanism 10 includes a base 11, a first crank 12, a second crank 13 and a connecting rod 14 The first end of the first crank 12 is hinged to the first hinge point 43 of the base 11, and the second end of the first crank 12 is hinged to the second hinge point 44 of the connecting rod 14; The first end of the second crank 13 is hinged to the third hinge point 45 of the base 11, and the second end of the second crank 13 is hinged to the fourth hinge point 46 of the connecting rod 14; specifically, The projection connection line of the first hinge point 43, the second hinge point 44, the third hinge point 45 and the fourth hinge point 46 on the same plane perpendicular to the axial direction of the hinge rotation axis can always be form a parallelogram. The cylinder 20 is connec...

Embodiment 2

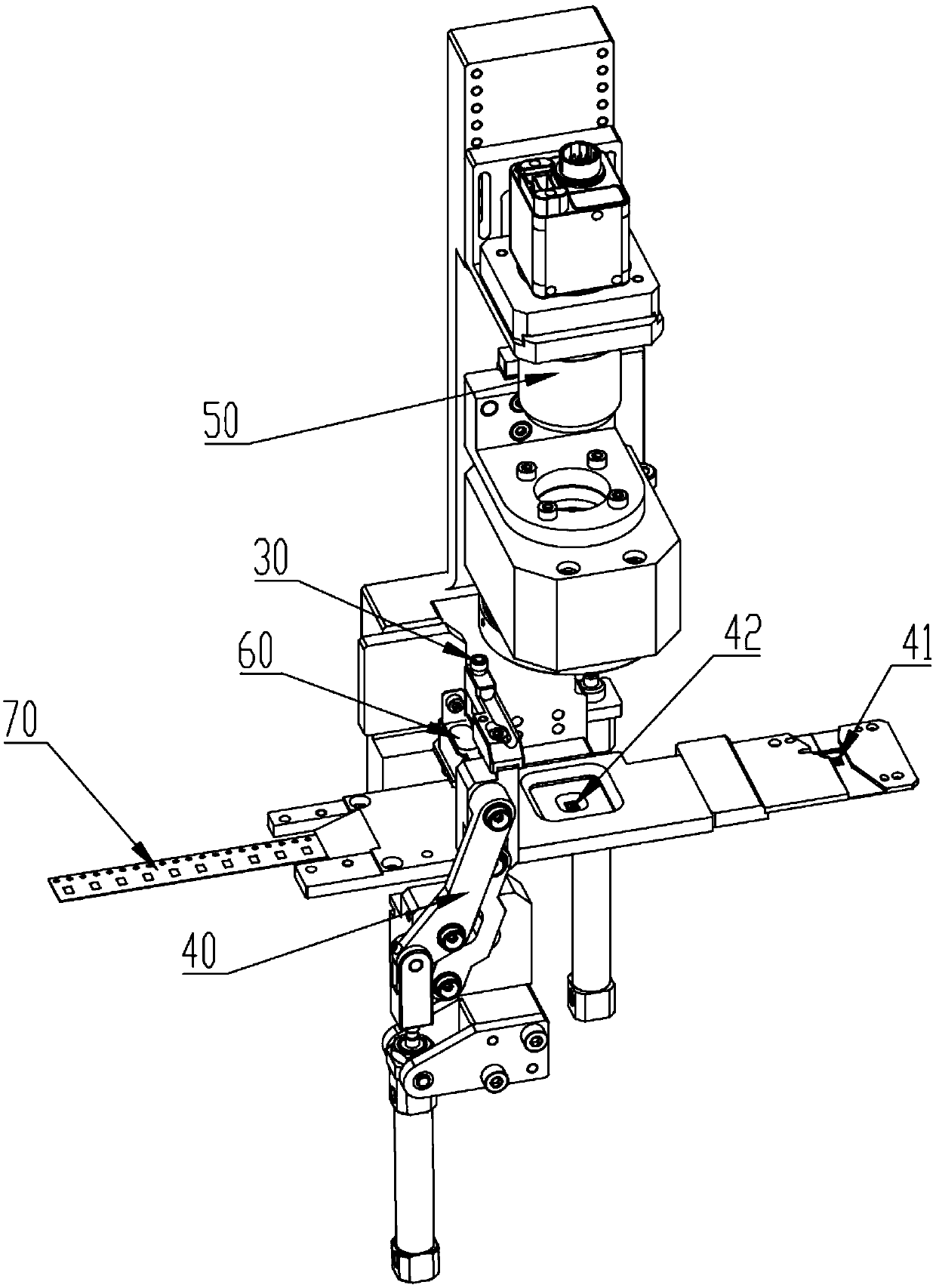

[0042] see image 3 , the present invention also provides a replacement material device, including a feeding mechanism (not shown in the figure), a carrier tape drive device (not shown in the figure) and a detection device 50, and the replacement material device also includes a Take-and-discharge device 40 with 70 take-and-discharge;

[0043] The feeding mechanism is arranged on one side of the first station 41 of the replacement material equipment, and is used to put the component to be tested on the carrier tape 70 at the first station 41;

[0044] The carrier tape driving device is connected with the carrier tape 70, and is used to drive the carrier tape 70 to move, thereby driving the component to be tested to move from the first station to the replacement device along the first direction. In the second station, the first direction is parallel to the length direction of the carrier tape;

[0045] The detection device 50 is arranged above the second station 42, and is use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com