Patents

Literature

47results about How to "Fast reciprocating motion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

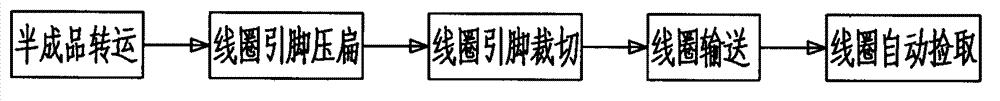

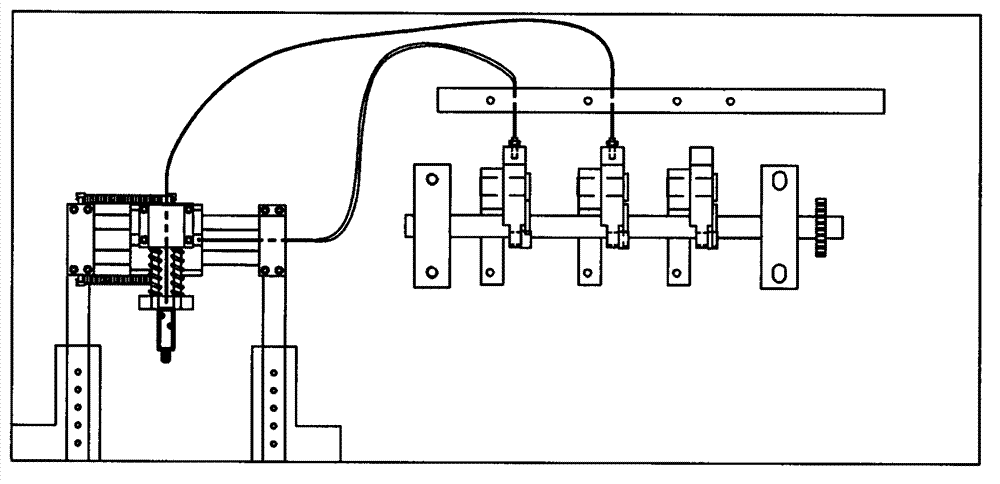

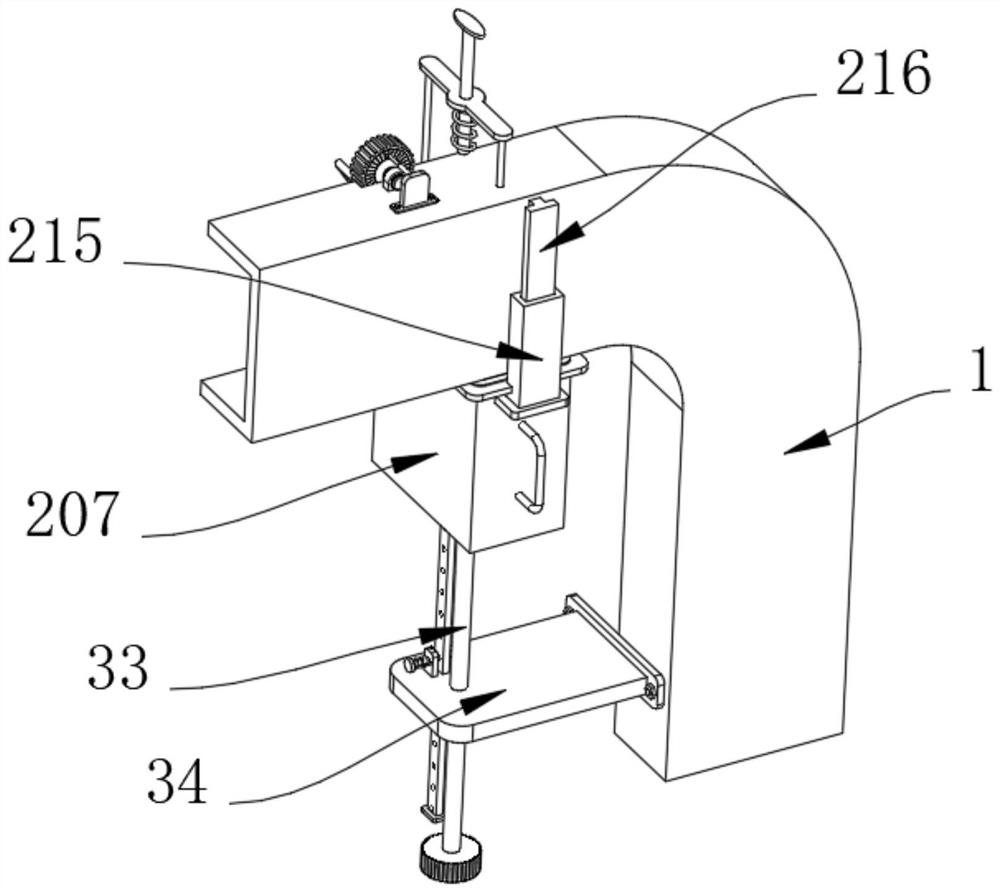

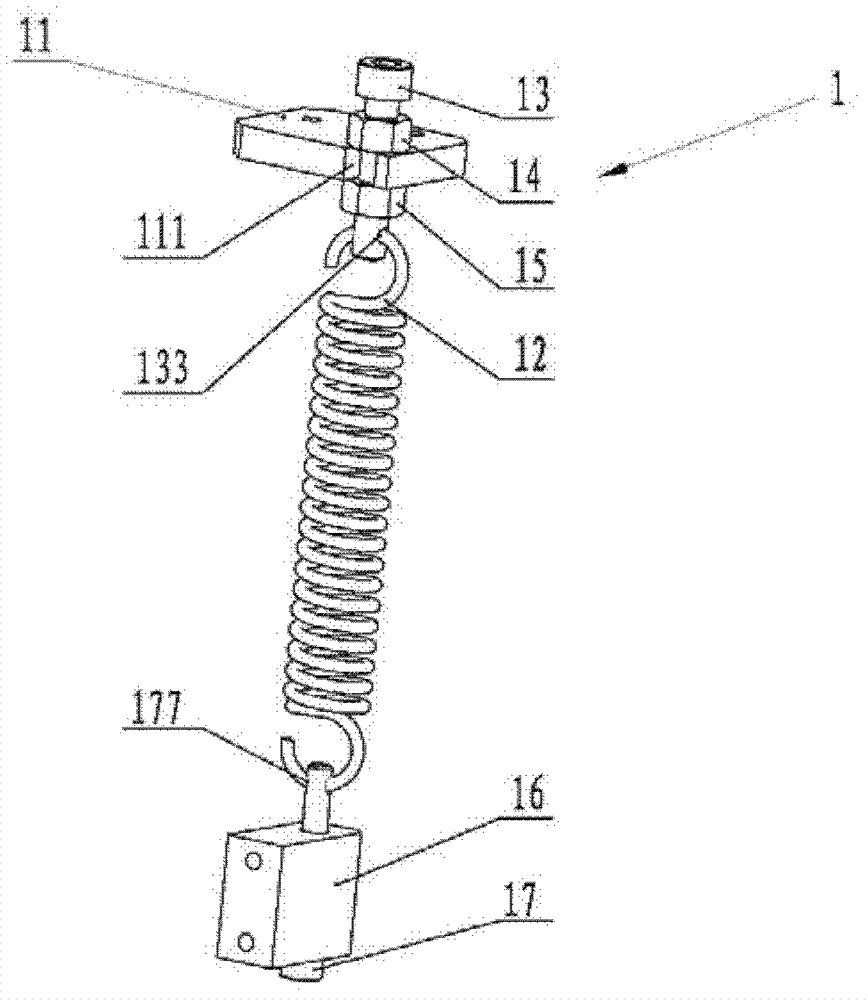

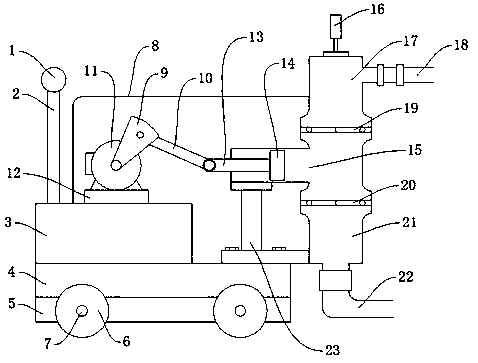

Coil forming machine

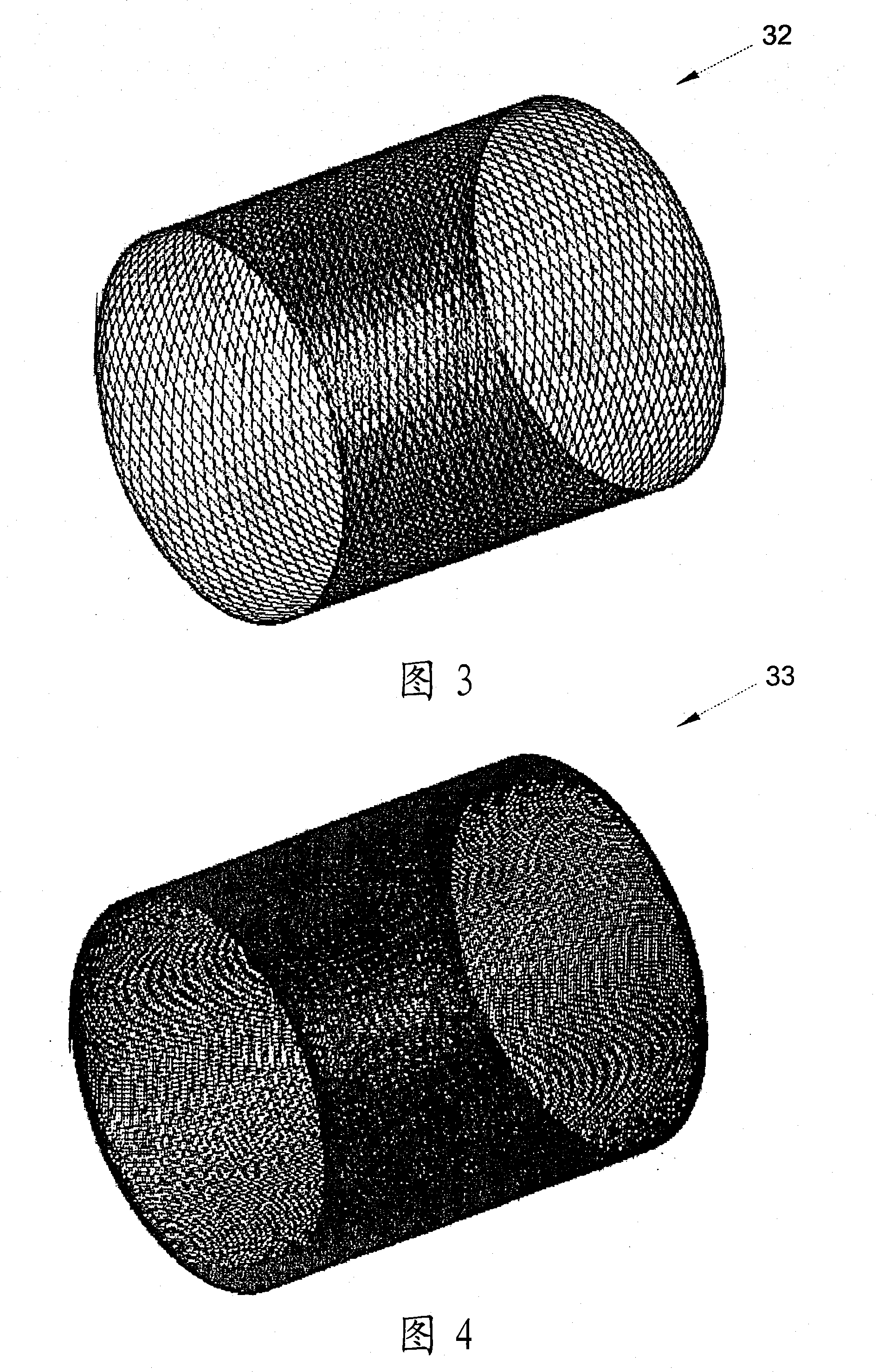

ActiveCN102760569AShort lateral movement distanceFast reciprocating motionManufacturing stator/rotor bodiesCoils manufactureManipulatorWork in process

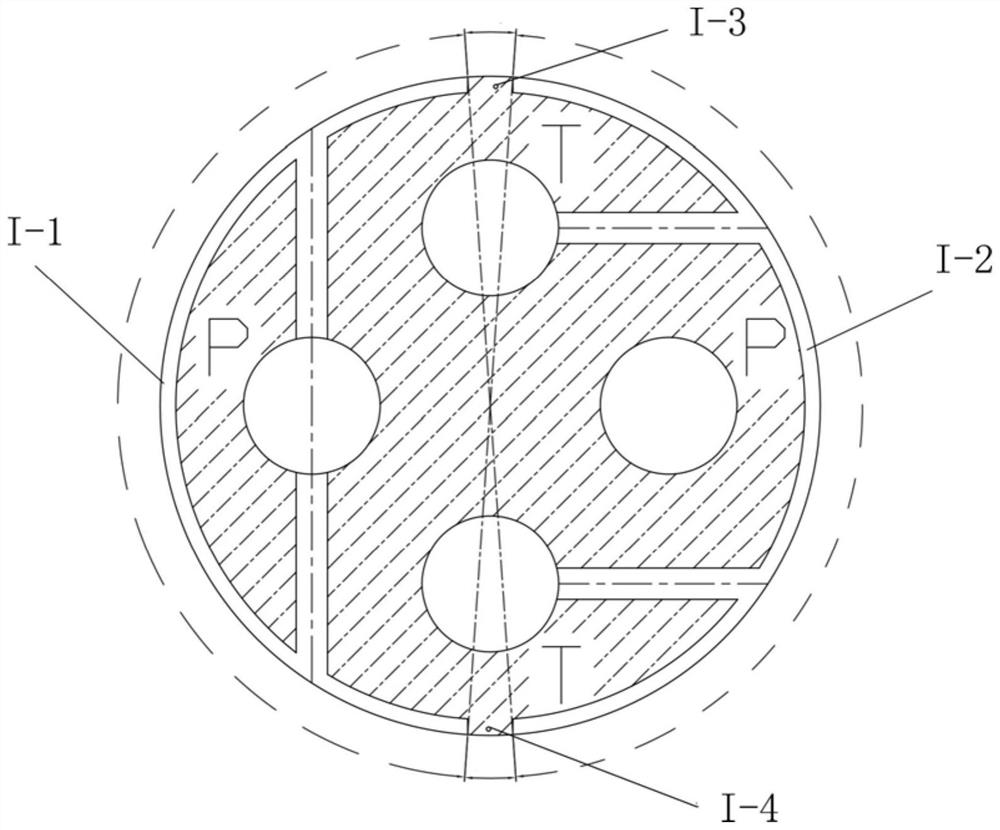

The invention discloses a coil forming machine, comprising a semi-finished product transfer arm, a coil pin flattening device, a coil pin trimming device, a coil conveying device and a coil automatic picking device, wherein the semi-finished product transfer arm comprises left and right guide rails fixedly arranged on the body of a processing machine, left and right slide blocks arranged along the left and right guide rails, upper and lower guide rails fixedly connected with the left and right slide blocks, upper and lower slide blocks sliding along the upper and lower side rails, and pneumatic chucks fixedly connected with the upper and lower side blocks; and the coil automatic picking device comprises a picking mechanism, a bearing mechanism and an accounting mechanism. The transfer arm of the coil forming machine has short transverse displacement distance and quickly performs reciprocating motion, so that the transferring time of the semi-finished products is reduced greatly, and the production efficiency is improved. The picking mechanism of the coil forming machine is an automatic picking mechanism, and automatically sleeves the coils on a core bar after picking the coils, so that the whole process from picking and placing the coils is finished automatically, the picking speed is high, labor force is saved, and production efficiency is improved.

Owner:昆山广辉精密五金有限公司

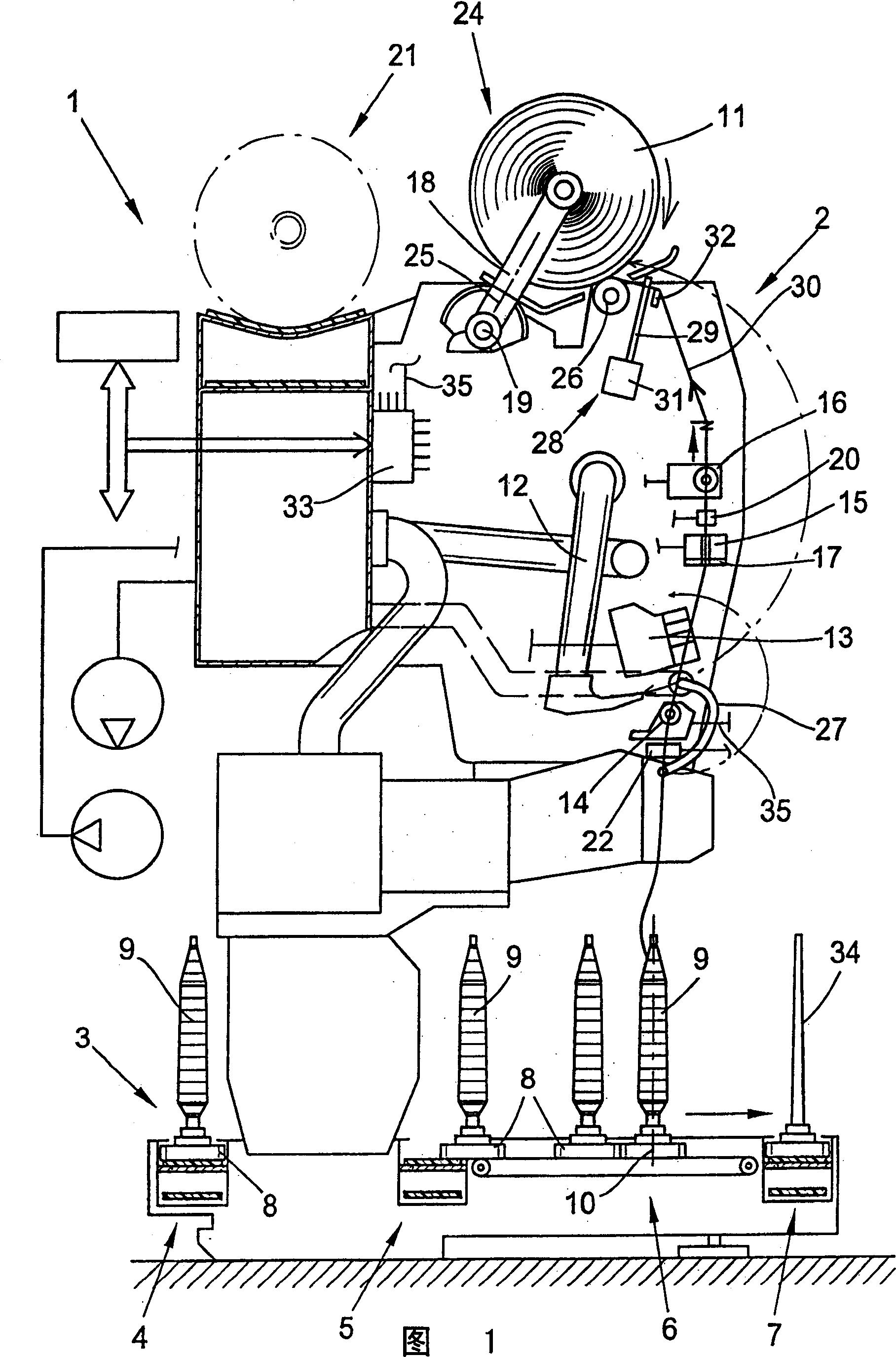

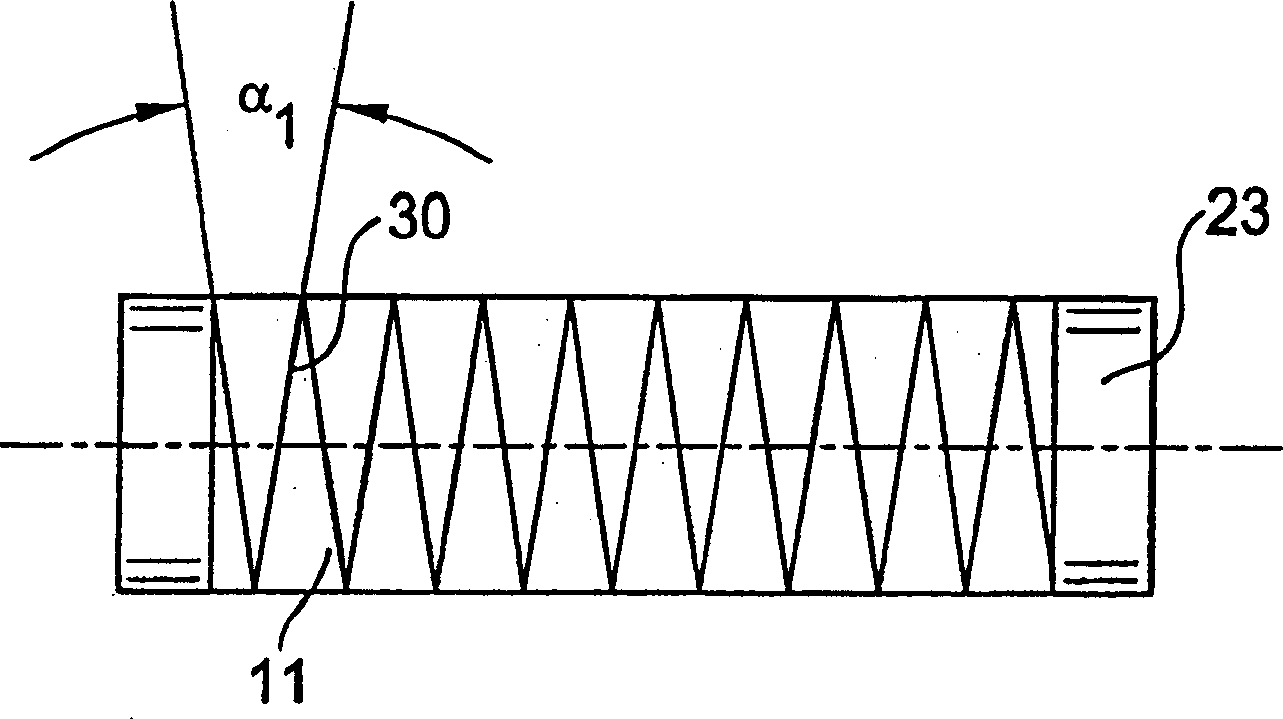

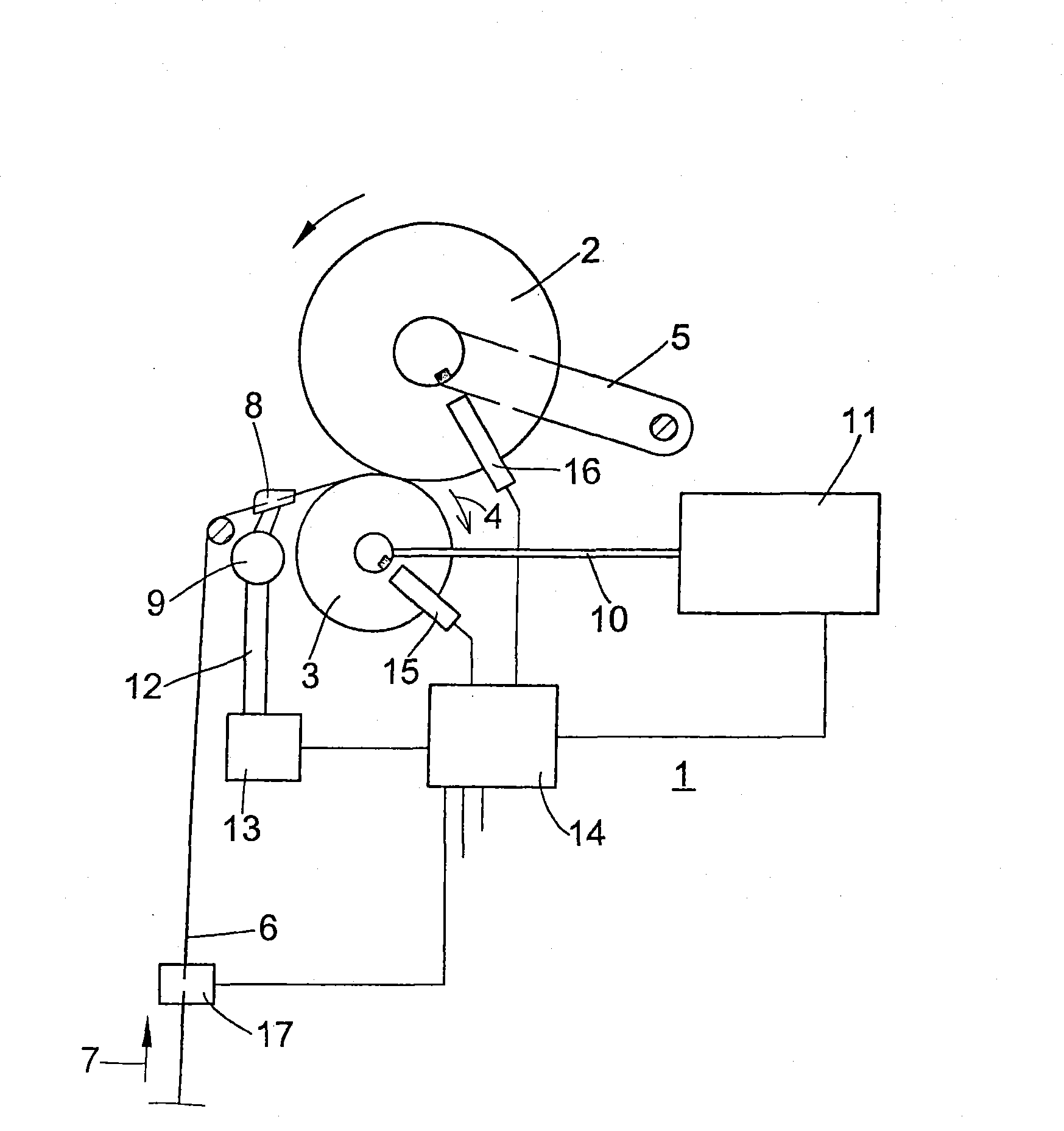

Method for manufacturing cross winding bobbin

To produce a cross wound bobbin (11), at the workstation (2) of a bobbin winder (1), the yarn (30) is wound at the start of a winding cycle at a crossing angle to increase the density of the bobbin core. The crossing angle is increased significantly during the winding cycle, so that the density of the wound bobbin is reduced progressively outwards. The increased crossing angle acts against the yarn laying width, and the stroke movement of the reciprocating yarn guide (29) has a defined increase.

Owner:SAURER GERMANY GMBH & CO KG

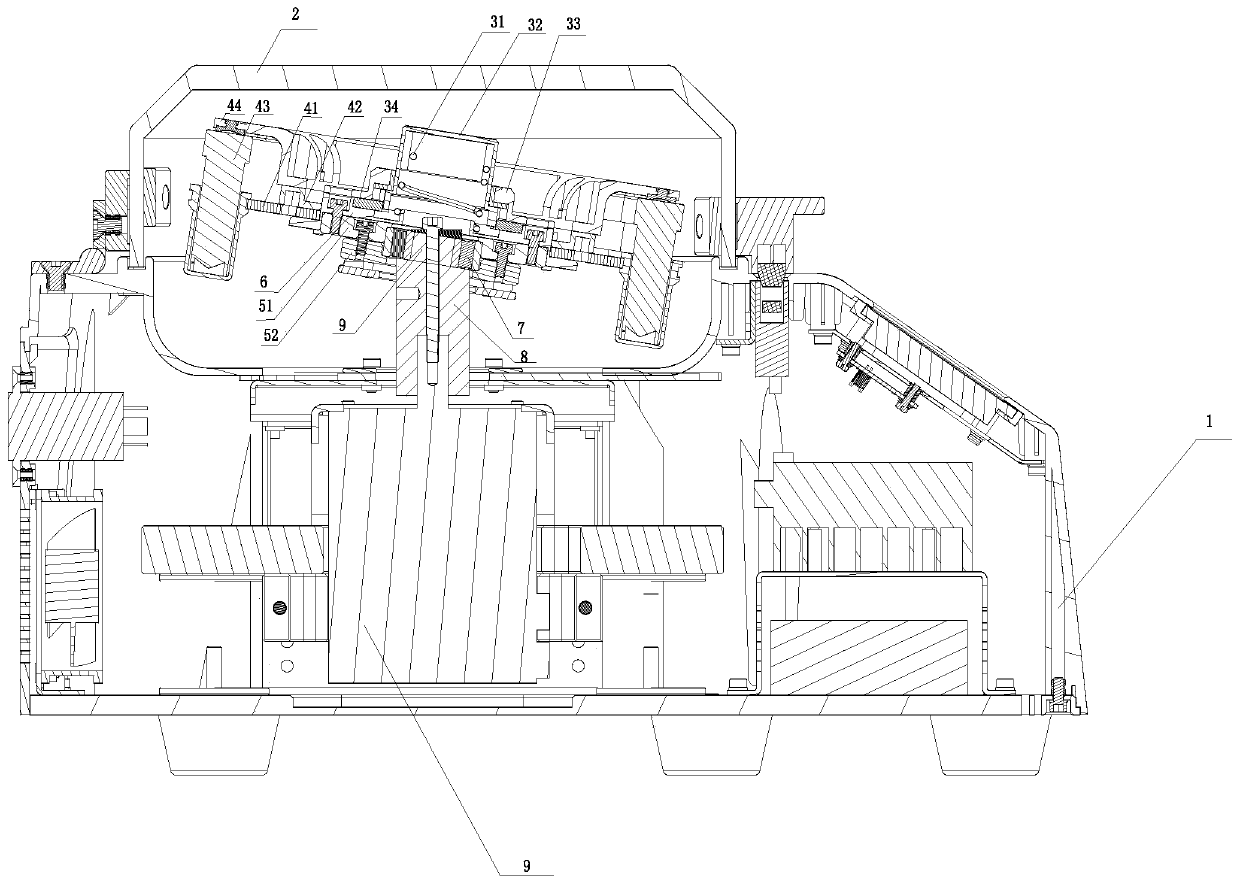

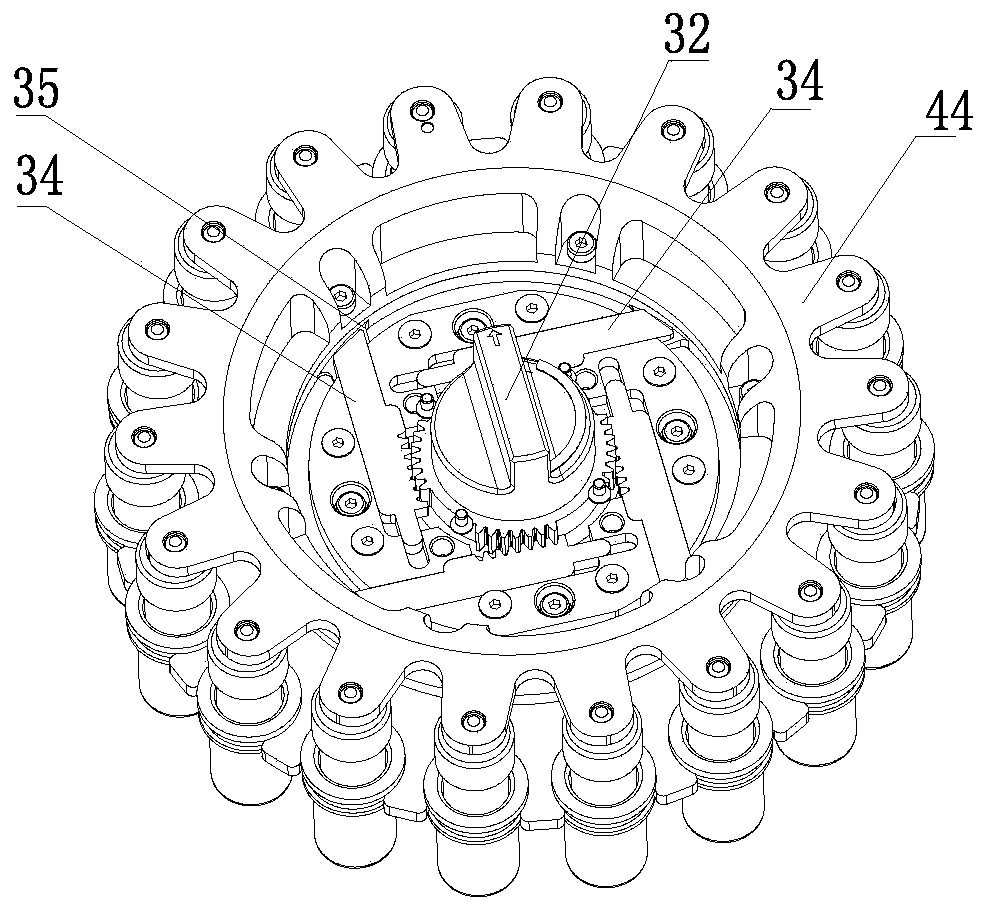

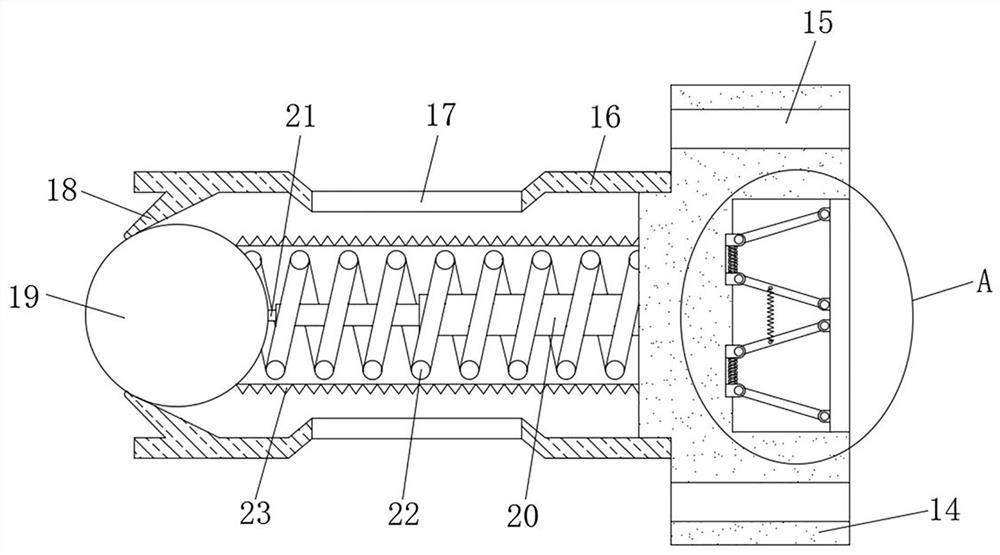

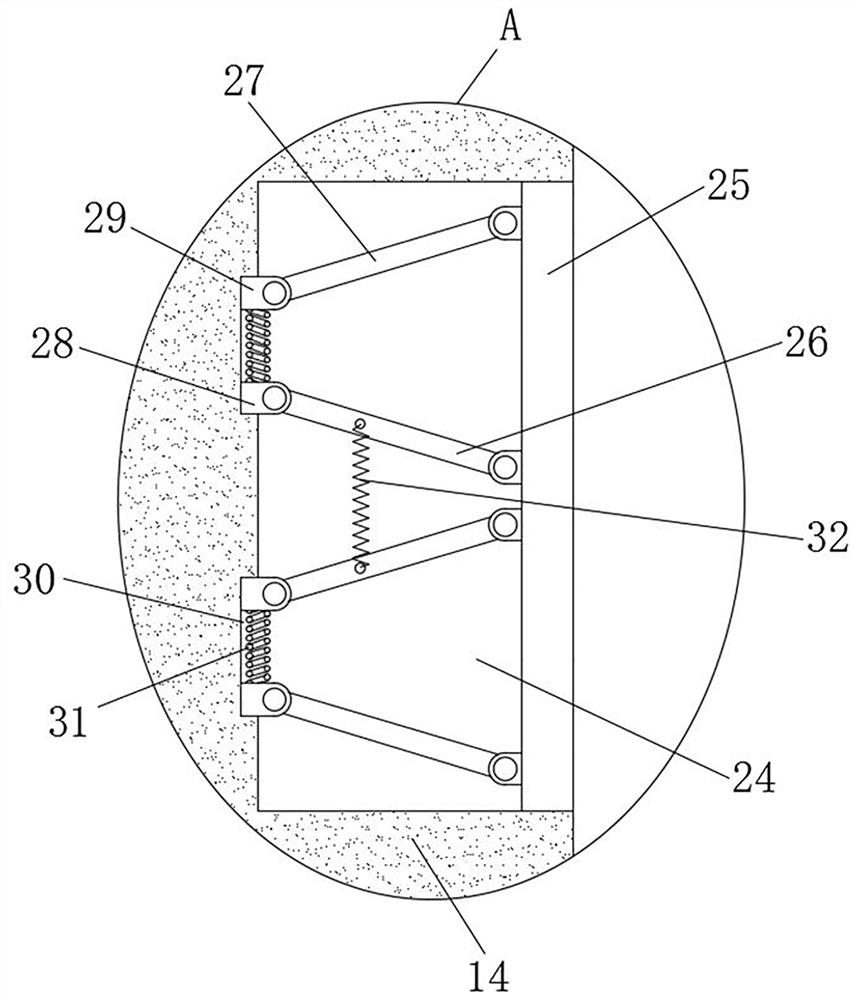

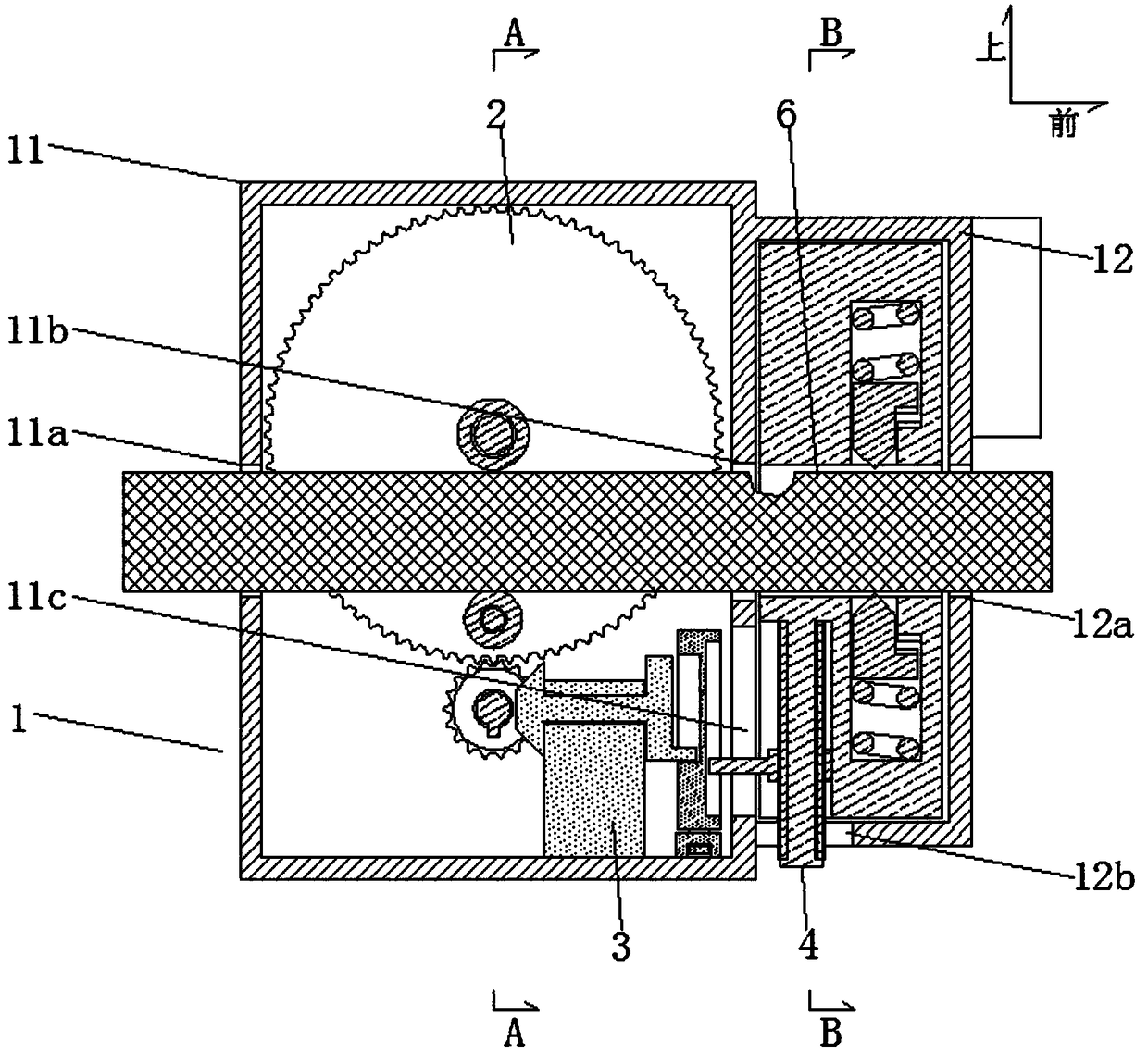

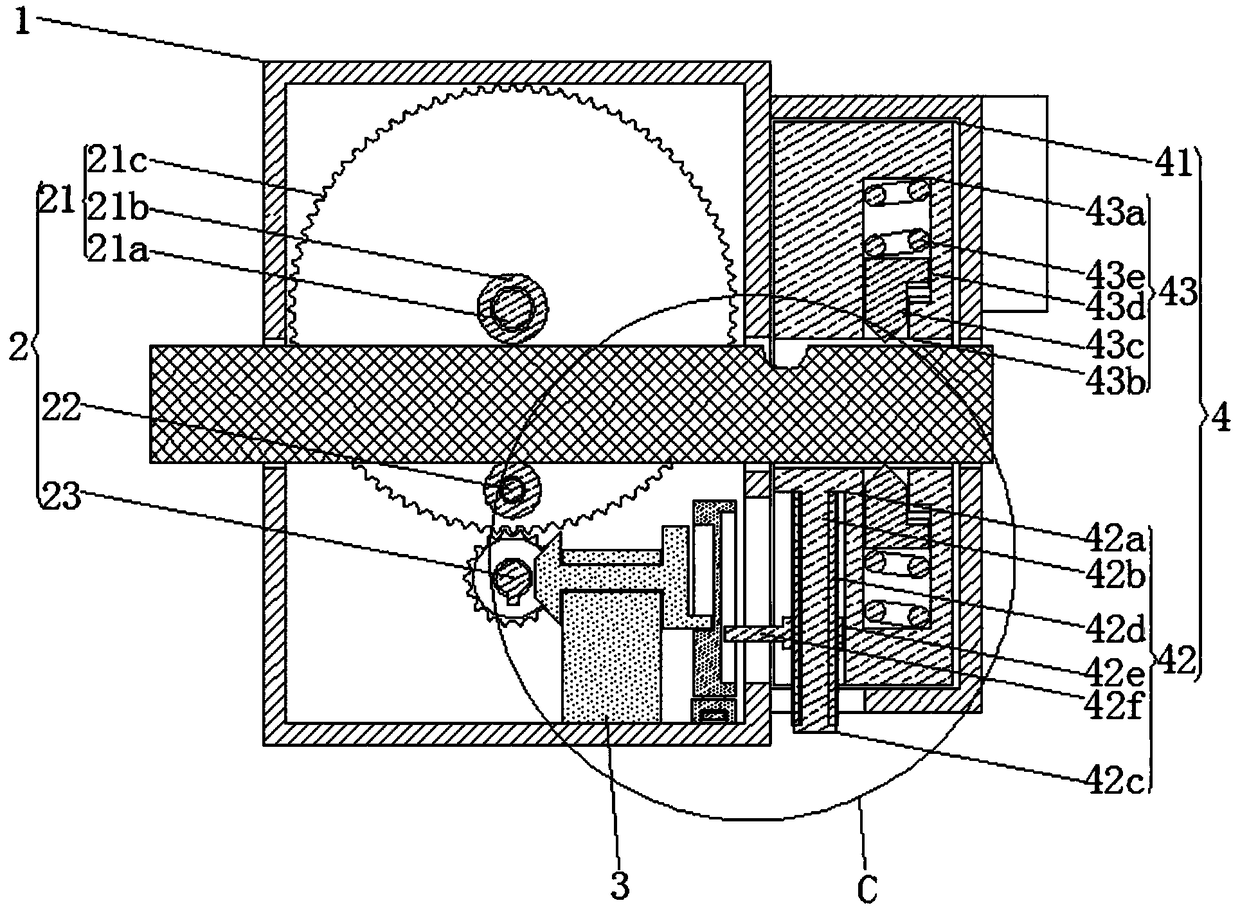

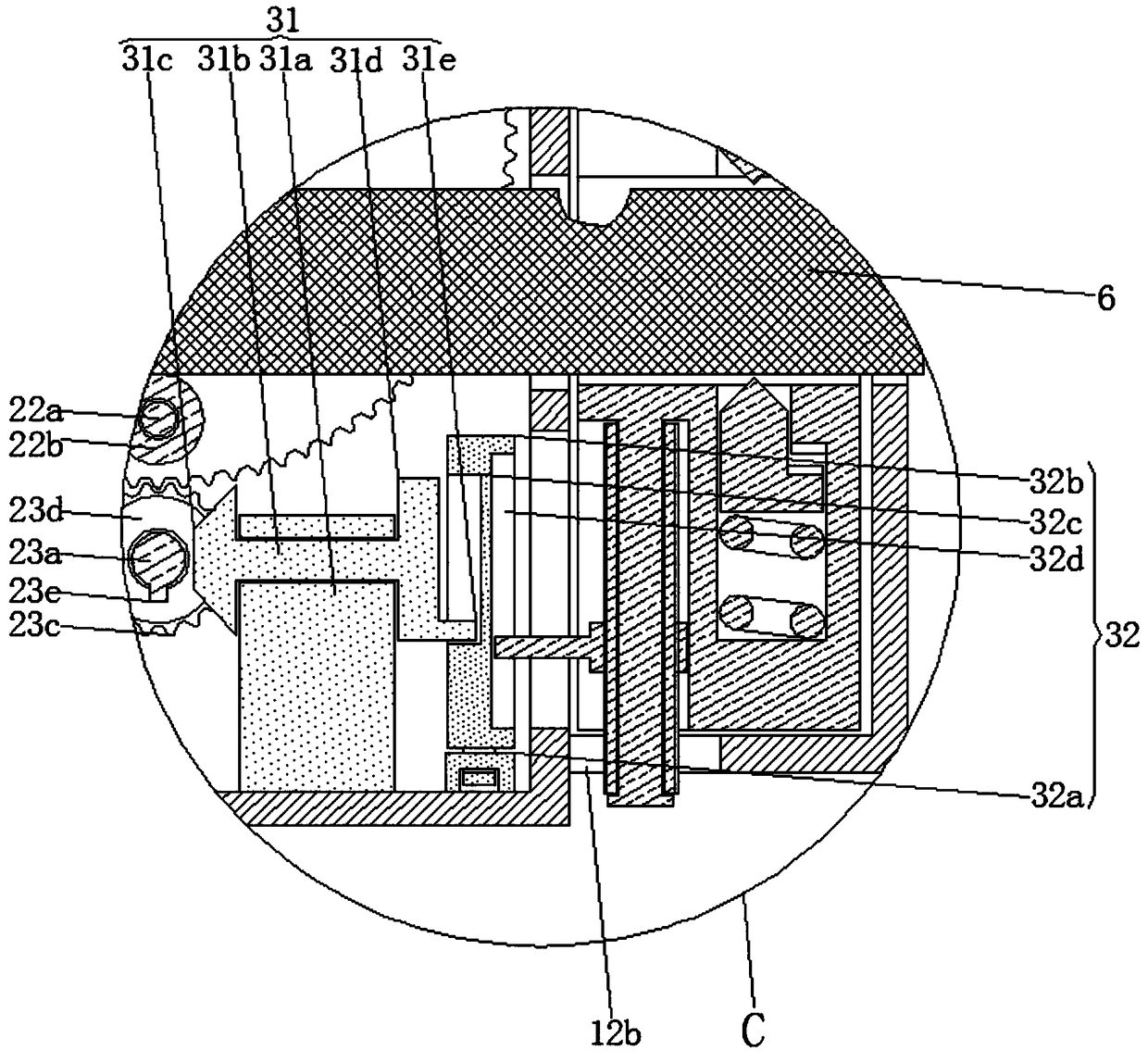

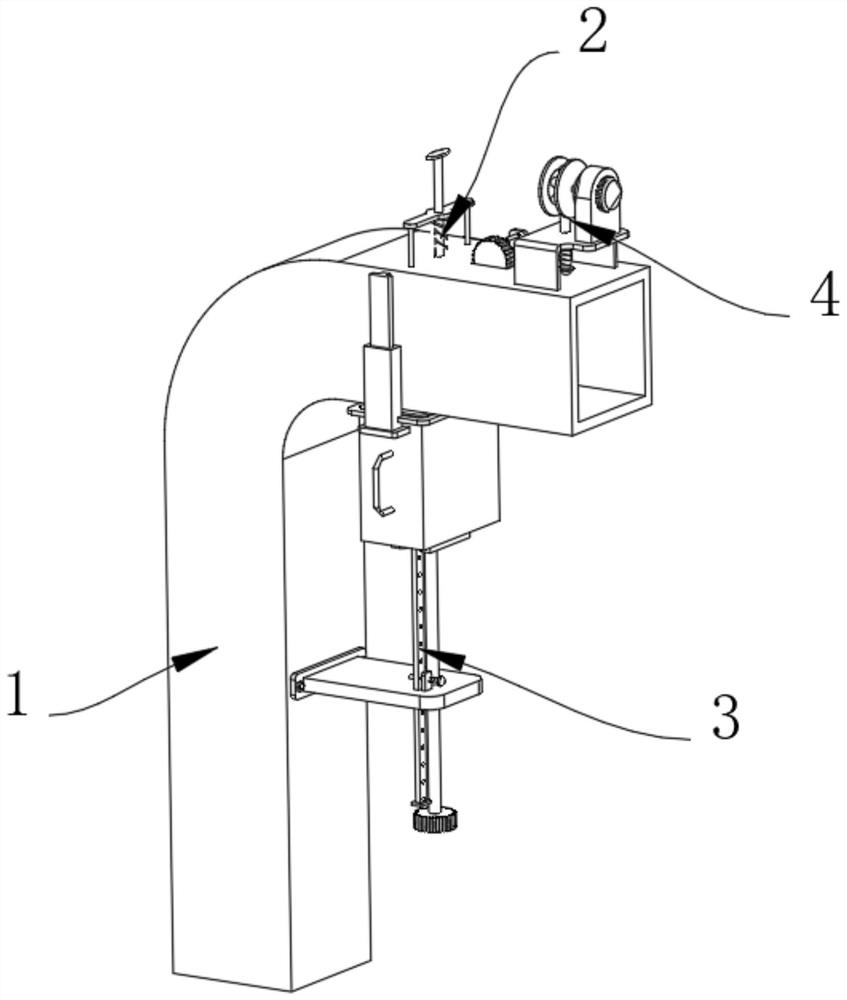

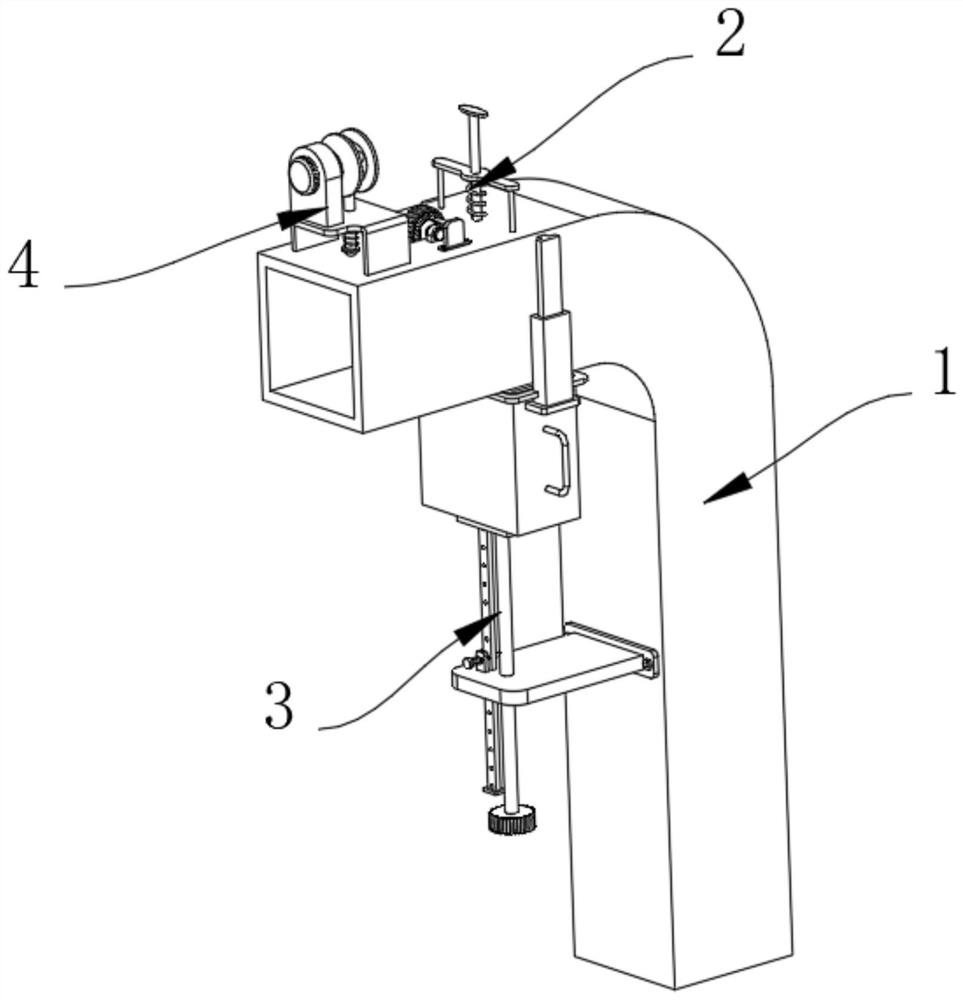

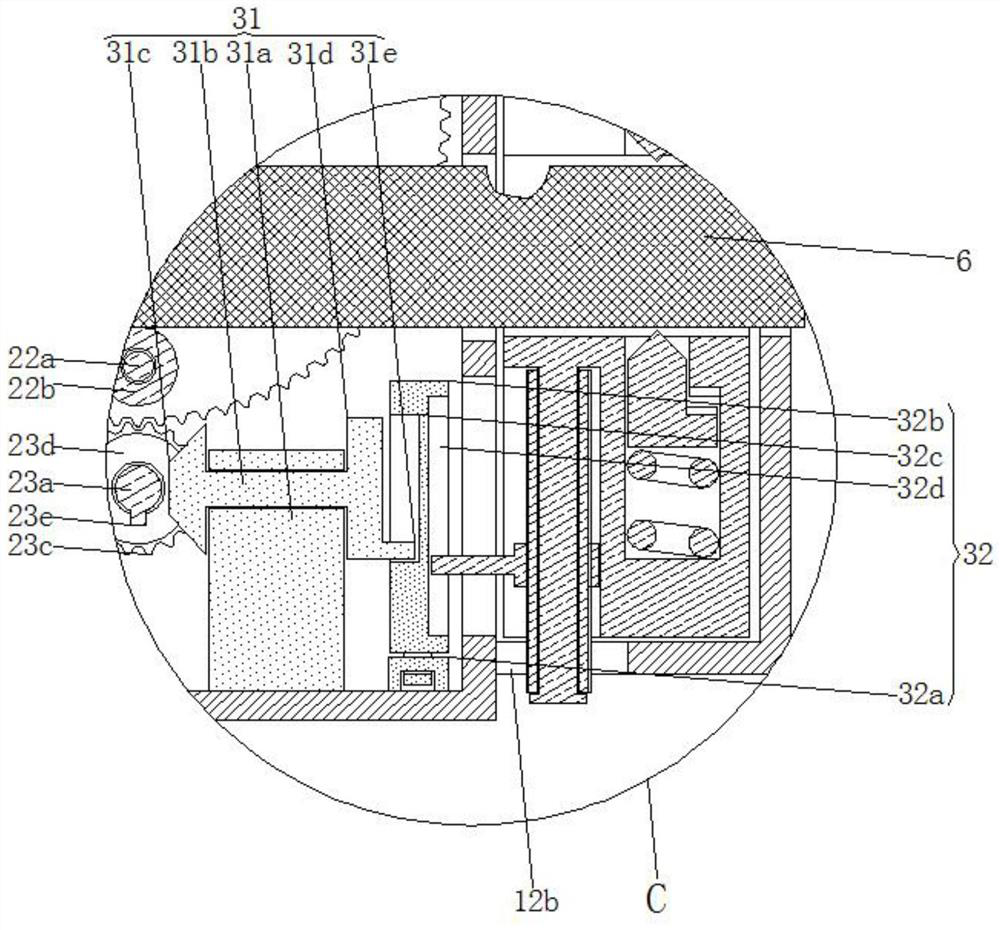

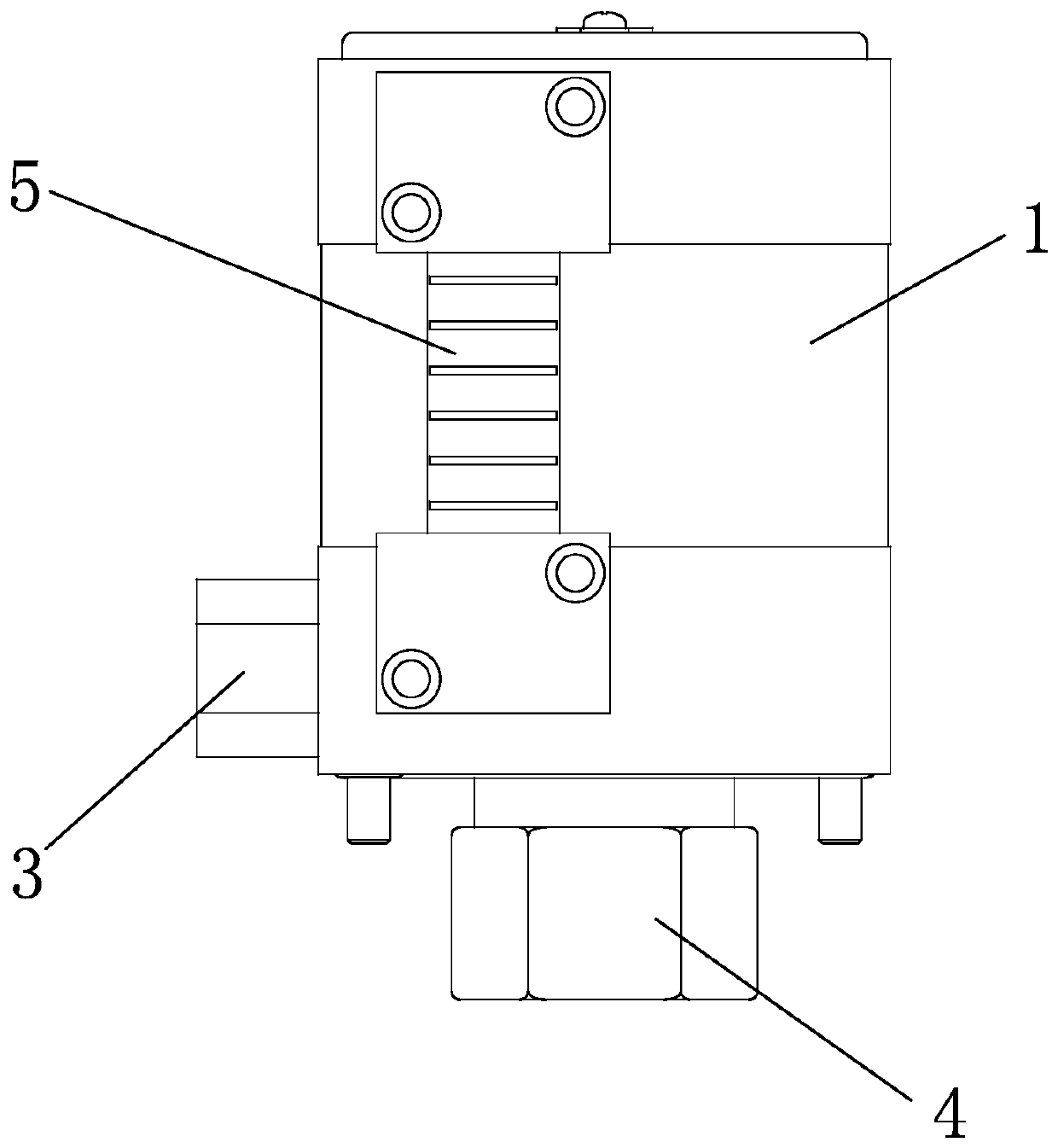

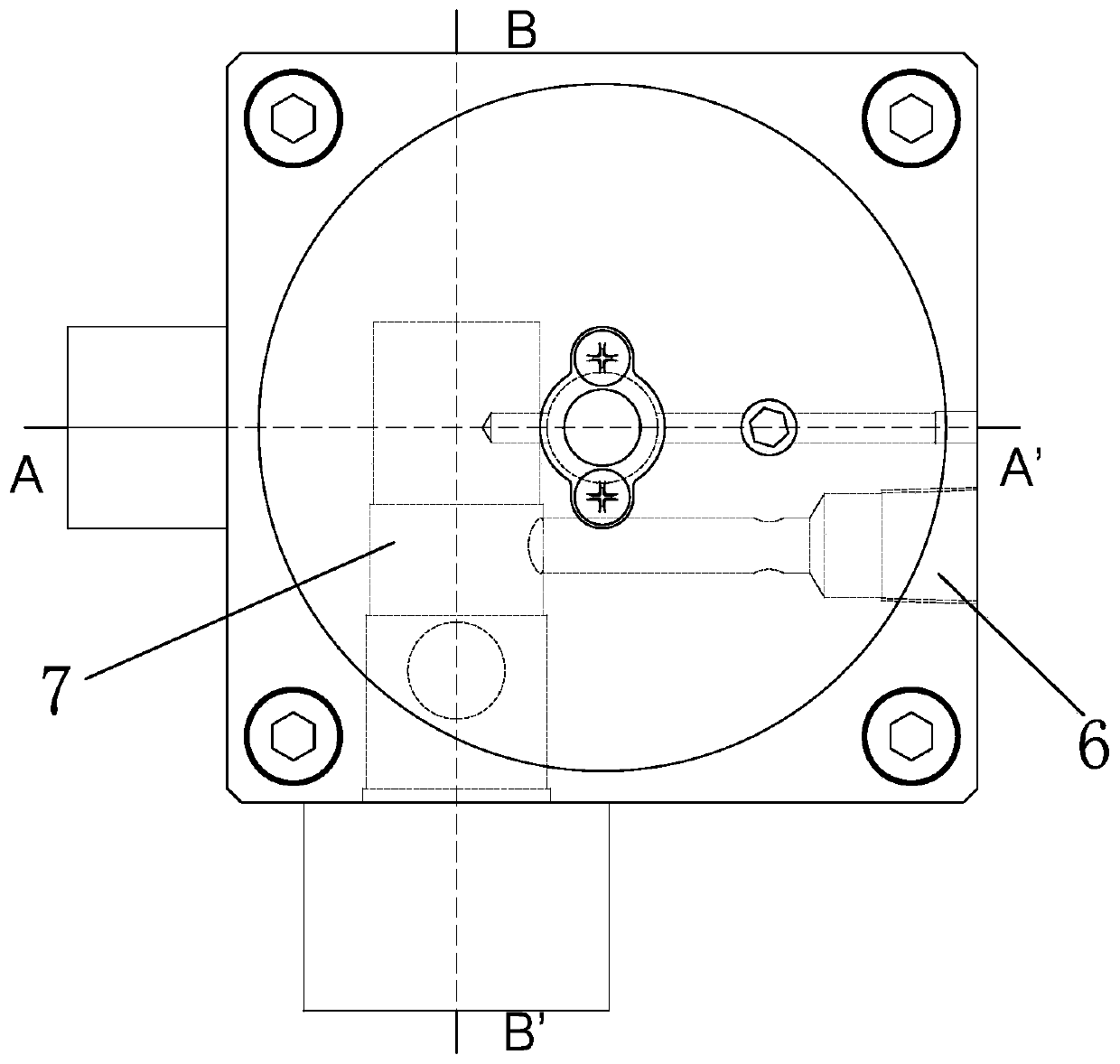

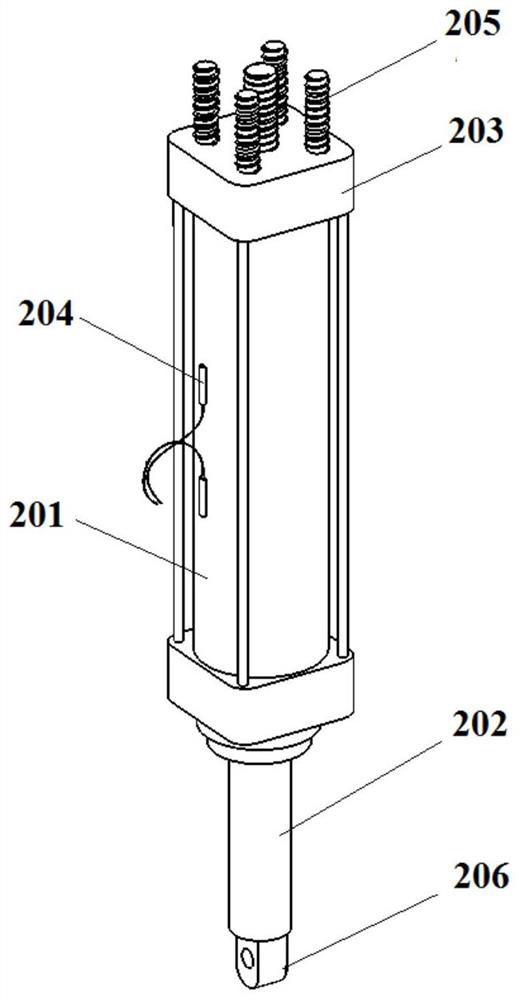

On-site detection instrument for drugs in hair

InactiveCN109794327AQuick installation and lockingFast reciprocating motionPreparing sample for investigationGrain treatmentsReciprocating motionDrive shaft

The invention discloses an on-site detection instrument for drugs in hair. The on-site detection instrument for the drugs in the hair comprises a machine box and a motor located in the machine box, and a swing mechanism and a tube plate assembly are further arranged in the machine box; the swing mechanism comprises a transmission shaft assembly, wherein a transmission shaft is driven to rotate along a shaft core by the motor, an eccentric shaft is fixedly arranged on the end part of the transmission shaft, and a shaft core of the eccentric shaft and the shaft core of the transmission shaft areat an included angle of 10-15 degrees; and a bearing sleeves the eccentric shaft, a swing assembly and the eccentric shaft are coaxially arranged and the swing assembly swings with the rotation of the eccentric shaft, a fixing device is arranged above the swing assembly, the fixing device comprises a fixing disk and a knob assembly, a convex platform is arranged on the fixing disk, and a base disk is installed on the convex platform. According to the on-site detection instrument for the drugs in the hair, the high-frequency swing of a rotating disk can be realized through the rotation of theeccentric shaft, so that a rotating cylinder on the rotating disk is driven to swing in a high-frequency mode to further drive high-frequency reciprocating motion of grinding beads to grind keratin materials, liquid in a grinding tube is detected on a corresponding colloidal gold plate, and screening results can be displayed.

Owner:中科万孚(苏州)科技有限公司

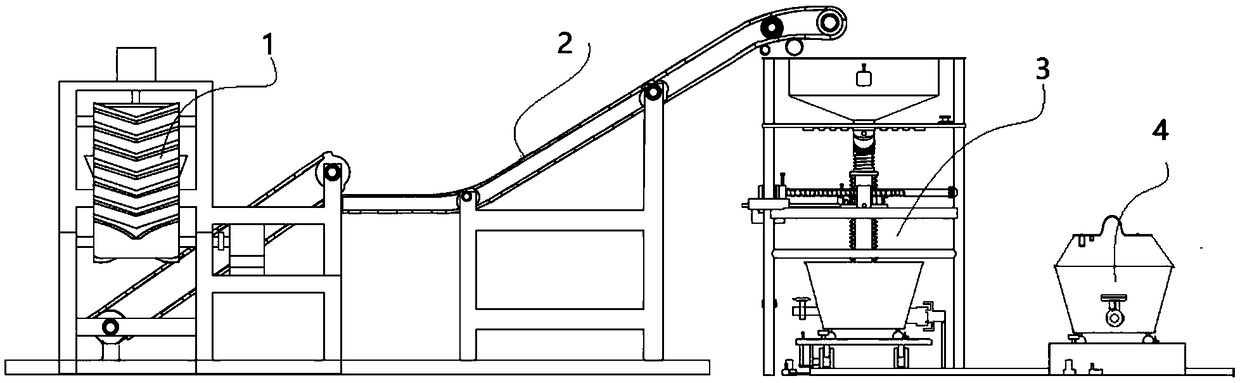

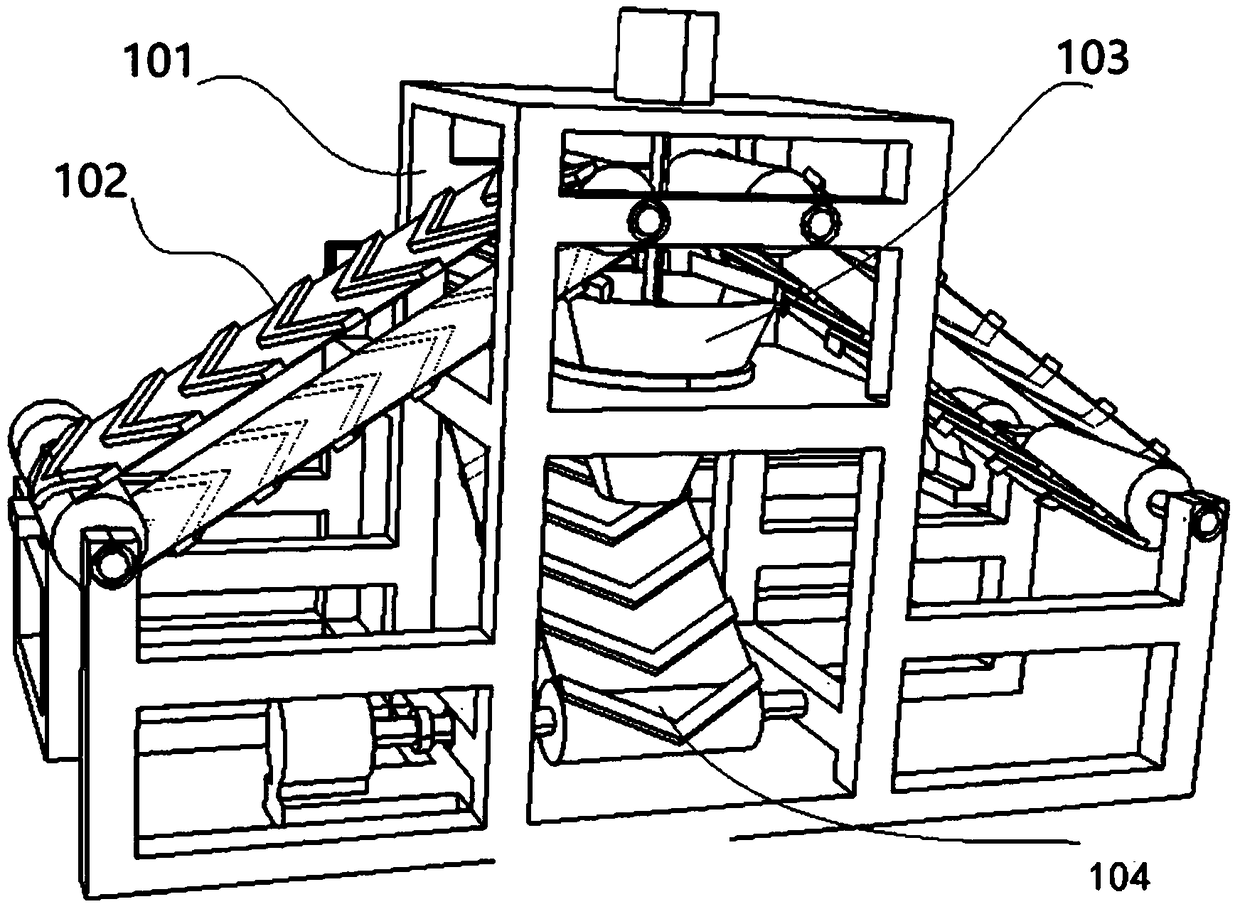

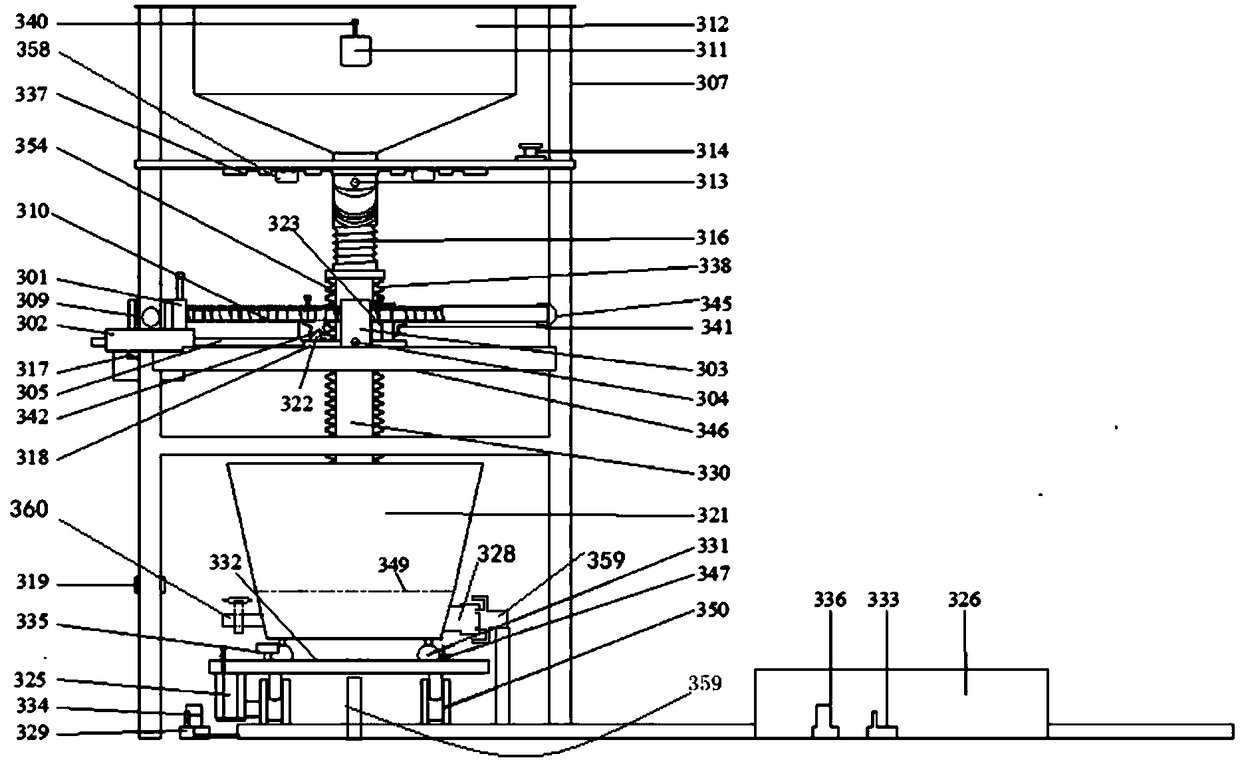

Full-automatic liquor steaming equipment based on feeding upon steam

PendingCN109439502AAdd evenlyFast reciprocating motionAlcoholic beverage preparationElectricitySteaming

The invention provides full-automatic liquor steaming equipment based on feeding upon steam, and belongs to the field of full-automatic liquor steaming equipment. The full-automatic liquor steaming equipment comprises a V-shaped automatic stirring device, a liquor steaming raw material conveyor belt, a feeding-upon-steam liquor steaming device and a track steamer device. The full-automatic liquorsteaming equipment has the advantages that a micro-pressure film electric contact pressure sensor and an infrared thermal imager are integrated to accurately judge the steaming state of steamed liquorin an unclosed area, misjudgment caused by many different factors is eliminated, and feeding-upon-steam is realized for the first time in the field of liquor steaming; the circulating track steamer is adopted, so that continuous liquor steaming is realized, the utilization rate of the sensor and the equipment is increased, the liquor steaming speed is increased, and equipment support is providedfor efficiency improvement of automatic liquor steaming and baijiu brewing.

Owner:ANHUI AGRICULTURAL UNIVERSITY

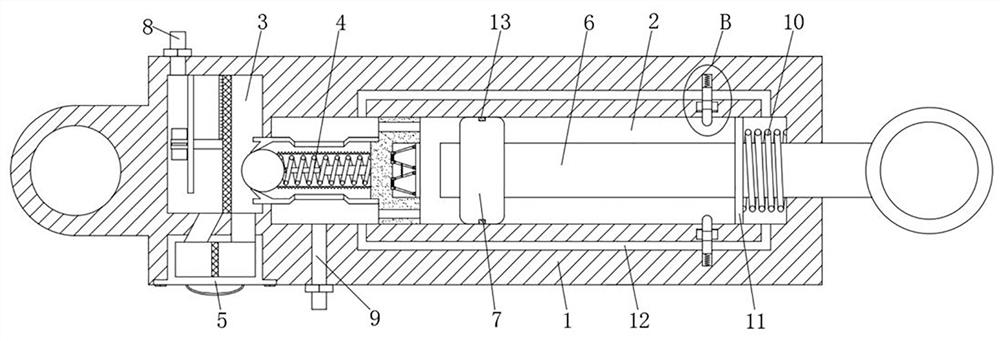

Hydraulic oil cylinder with high buffering performance

ActiveCN113323942APrevent extractionFast reciprocating motionServomotor componentsHydraulic ramEngineering

The invention discloses a hydraulic oil cylinder with high buffering performance, and relates to the technical field of hydraulic oil cylinders. The hydraulic oil cylinder comprises a cylinder body, a piston cavity, an oil cavity, an oil guide mechanism and a dust storage box, the oil cavity is formed in the left side of the cylinder body, the piston cavity is formed in the right side of the cylinder body, the oil guide mechanism is installed in the left side of the piston cavity, the end of the oil guide mechanism communicates with the oil cavity, meanwhile, a piston rod is arranged in the piston cavity, the right side end of the piston rod extends out of the side wall of the cylinder body, a sliding plate is arranged on the right side of a fixing block of the oil guide mechanism, and when the piston rod retracts, the end of the piston rod impacts the sliding plate, the sliding plate extrudes a first connecting rod and a second connecting rod inwards, therefore, a first extension spring and a second extension spring generate elastic restoring force to buffer the impact force, a first buffer spring is arranged on the right side of the piston cavity, when the piston rod stretches out, a piston extrudes the first buffer spring rightwards through a sliding ring, the piston rod is buffered, and the buffer performance of the hydraulic oil cylinder is better.

Owner:烟台山河液压部件有限公司

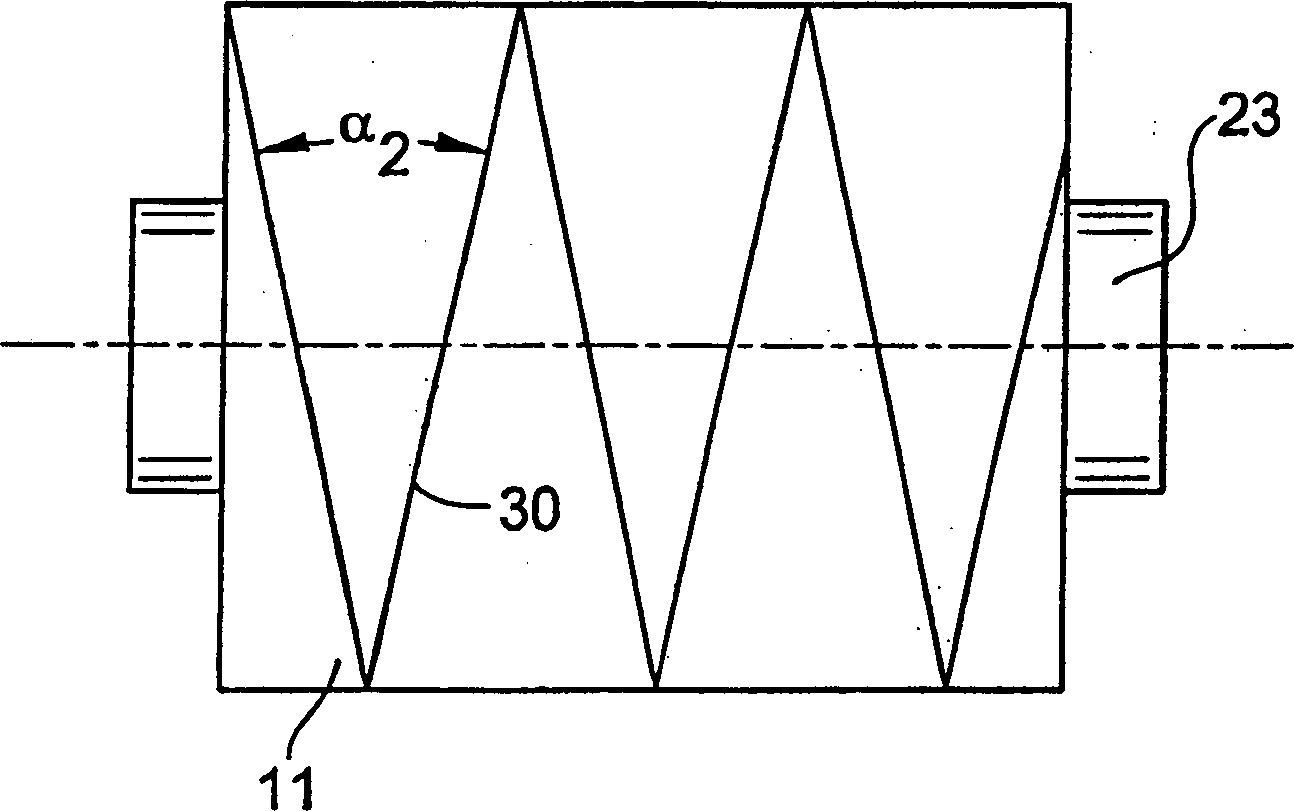

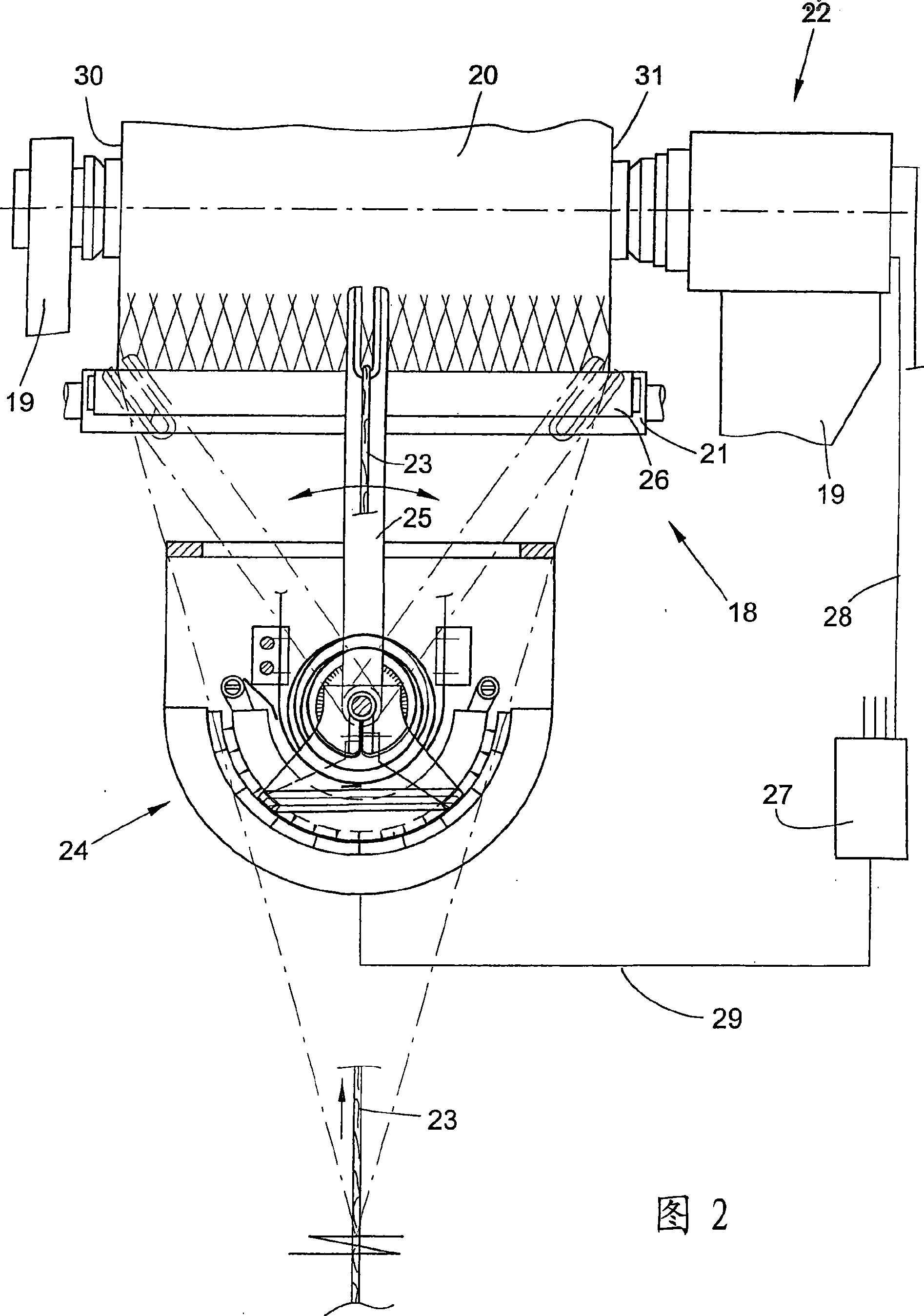

Crosswound bobbin and method for producing such a bobbin

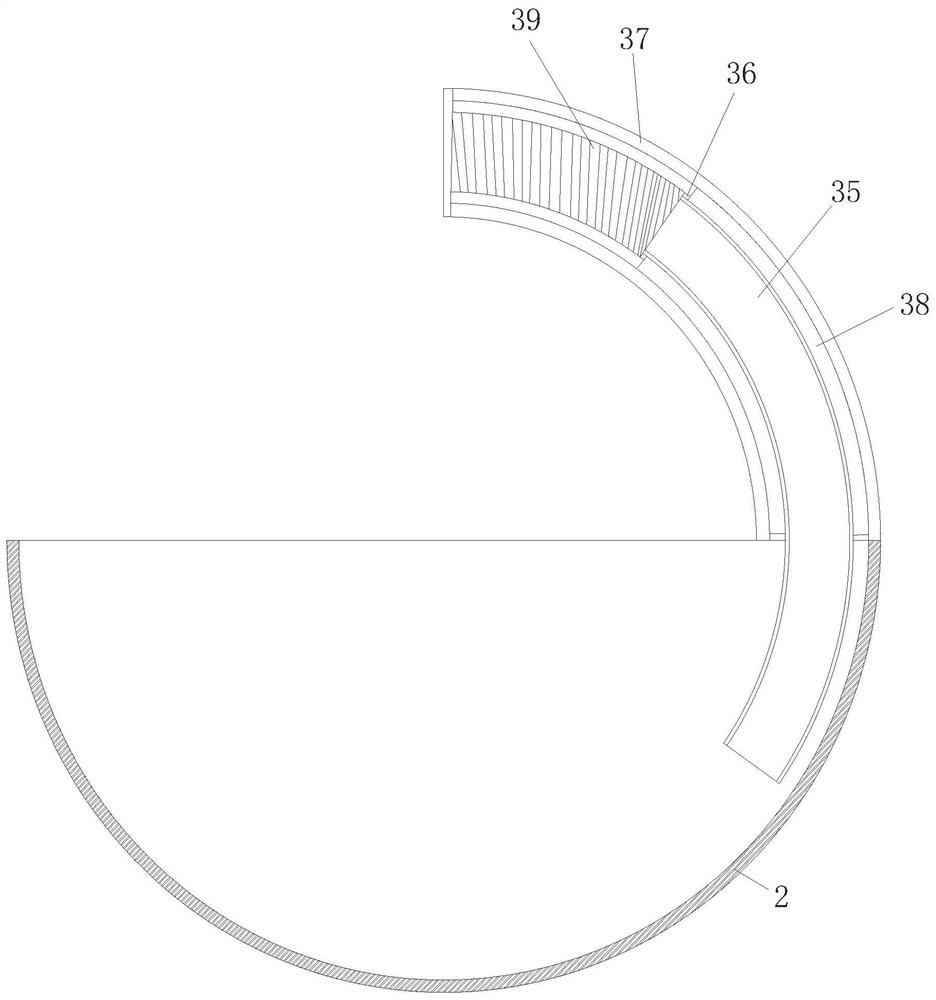

During the production of cross-wound bobbins, the yarn wound onto the cross-wound bobbins is reciprocated by means of a yarn guide, which can be controlled independently of the drive of the cross-wound bobbins and determines the laying width. Here, the laying width is variable. A portion of the cheese layer has a different width than the rest. The rhombus of the cheese layer is all closed. The invention can be installed in the winding position of spinning machines producing cross-wound bobbins and improves package density, uniformity and unwinding performance of cross-wound bobbins.

Owner:RIETER AUTOMATIC WINDER GMBH

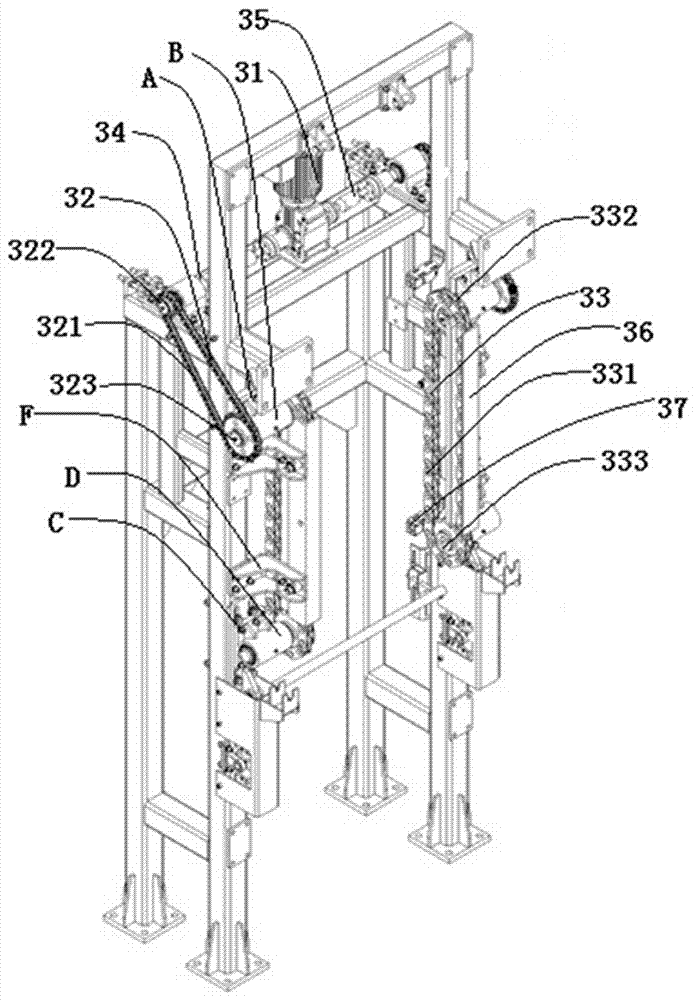

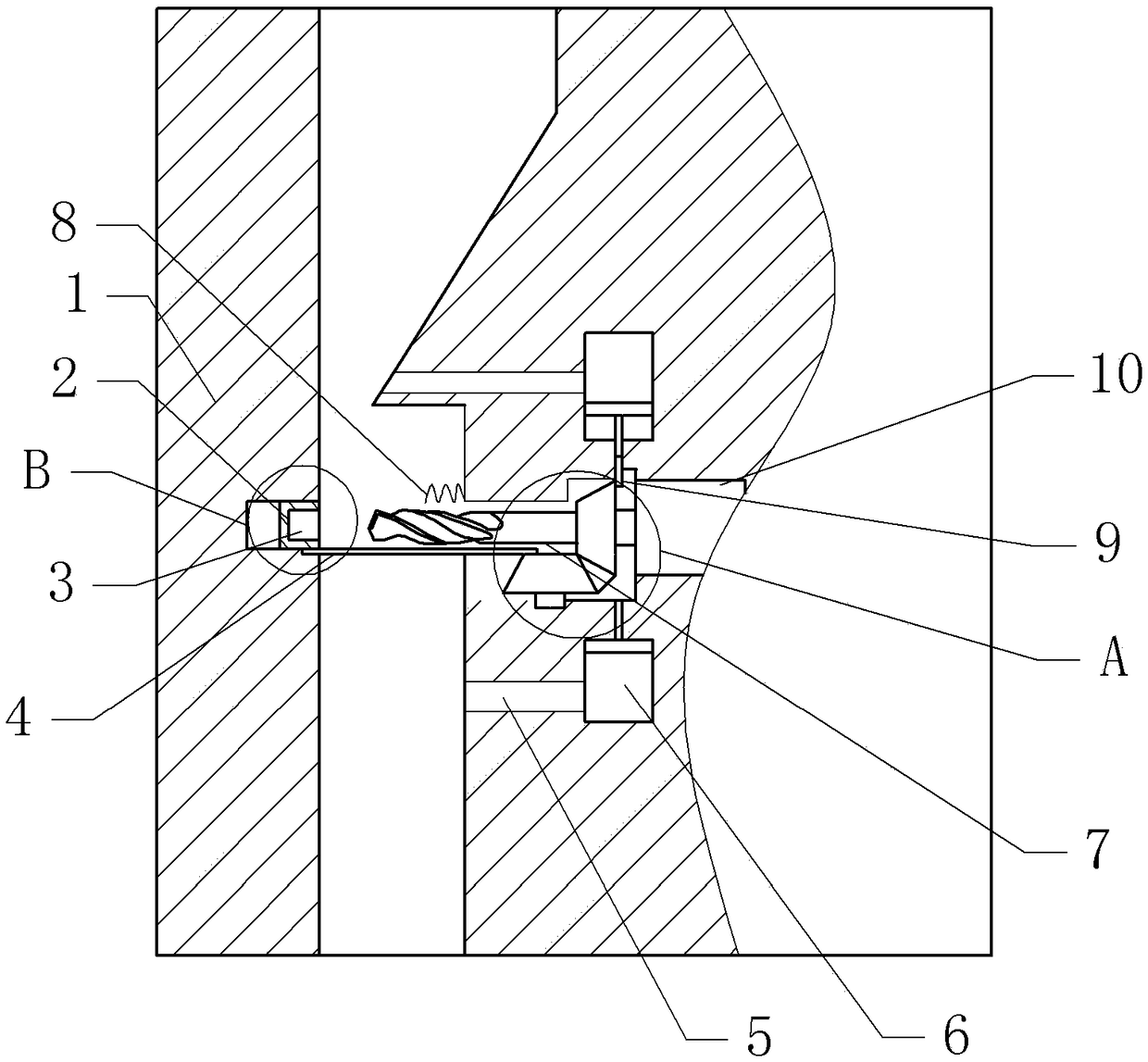

Electro-deposition metal stripping device and method

ActiveCN107190284AFast reciprocating motionEliminate closed cylinderElectrolysis componentsProcess efficiency improvementMetal stripsDrive wheel

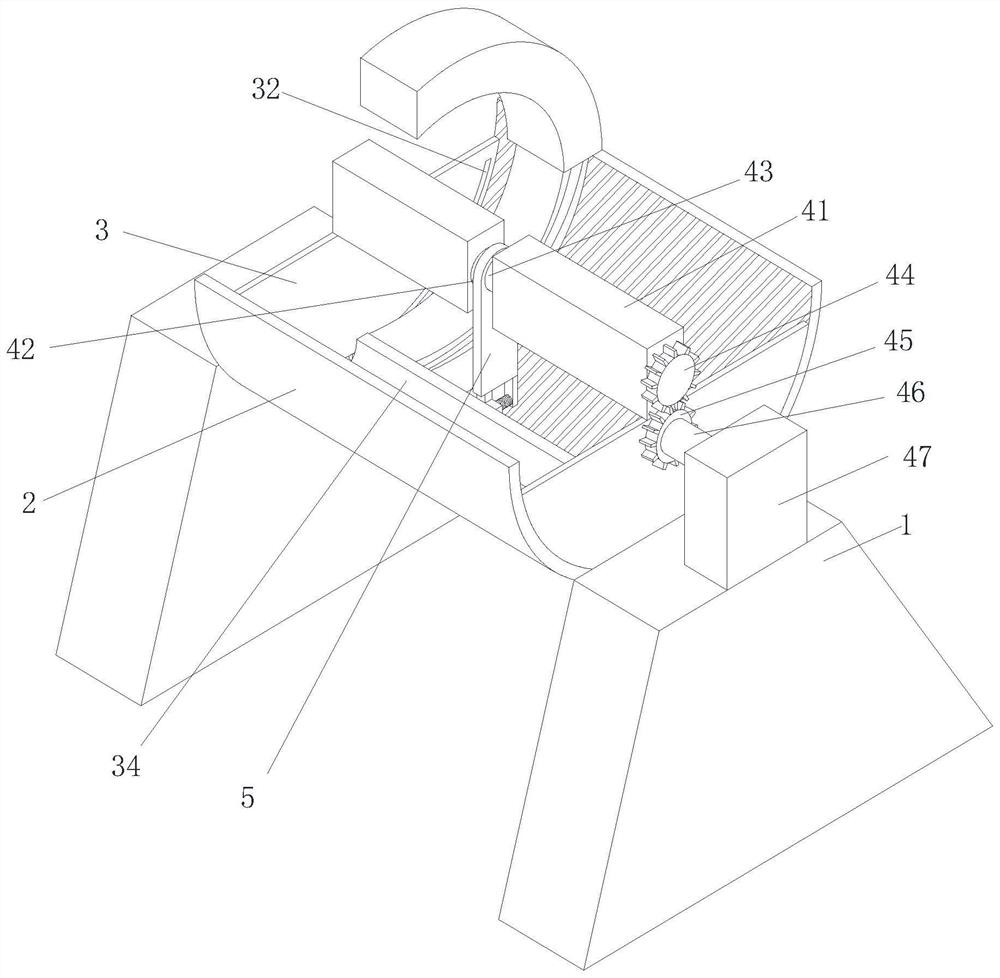

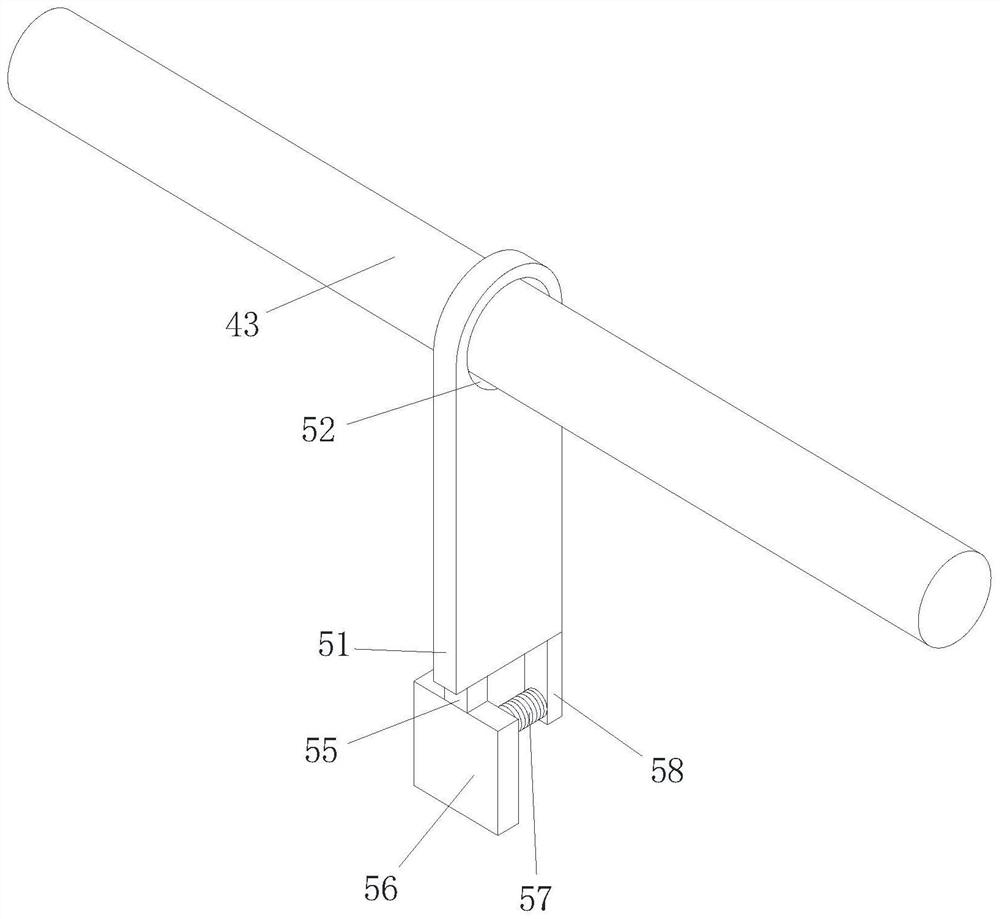

The invention discloses an electro-deposition metal stripping device and method. The electro-deposition metal stripping device comprises a rack, a stripping knife part and a driving part, wherein the driving part comprises a power source, a transmission mechanism and a guide mechanism; the transmission mechanism and the guide mechanism are arranged on two sides of the rack and have the same structure; the transmission mechanism comprises a minor sprocket and a big sprocket connected through a transmission chain; the guide mechanism comprises a driving wheel and a driven wheel connected through a guide chain; the minor sprocket is connected with the power source through a power shaft; the big sprocket is connected with the driving wheel through a transmission shaft I arranged on a mounting base I; the driven wheel is connected with a transmission shaft II; the transmission shaft II is arranged on a mounting base II; the mounting base I and the mounting base II are arranged on the rack; and the mounting base I is arranged at the upper part of the mounting base II. The stripping knife is arranged on the guide chain to realize lifting motion of the stripping knife; and in addition, closing of the stripping knife is automatically implemented completely without additional power driving, so that a stripping knife closing air cylinder is not needed, and stopless rapid reciprocating motion of the stripping knife is realized.

Owner:株洲优瑞科有色装备有限公司

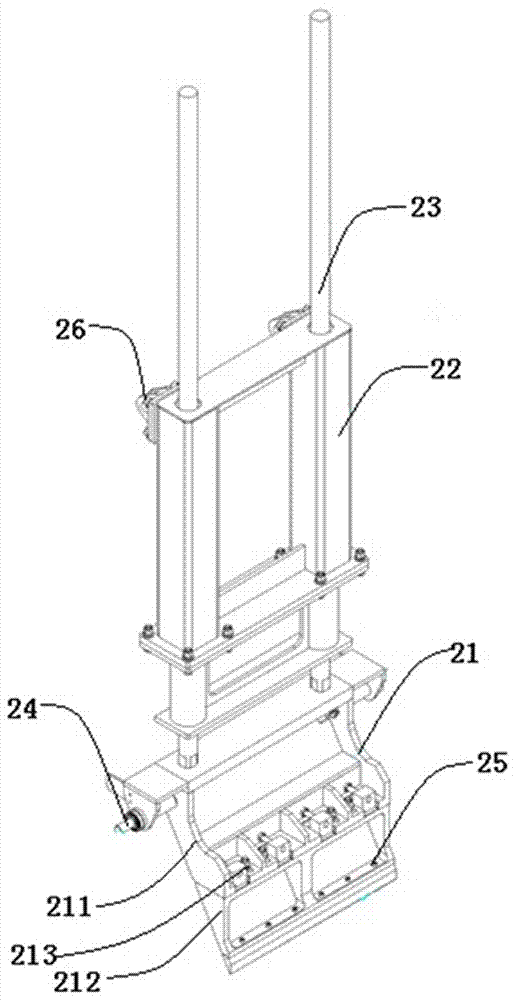

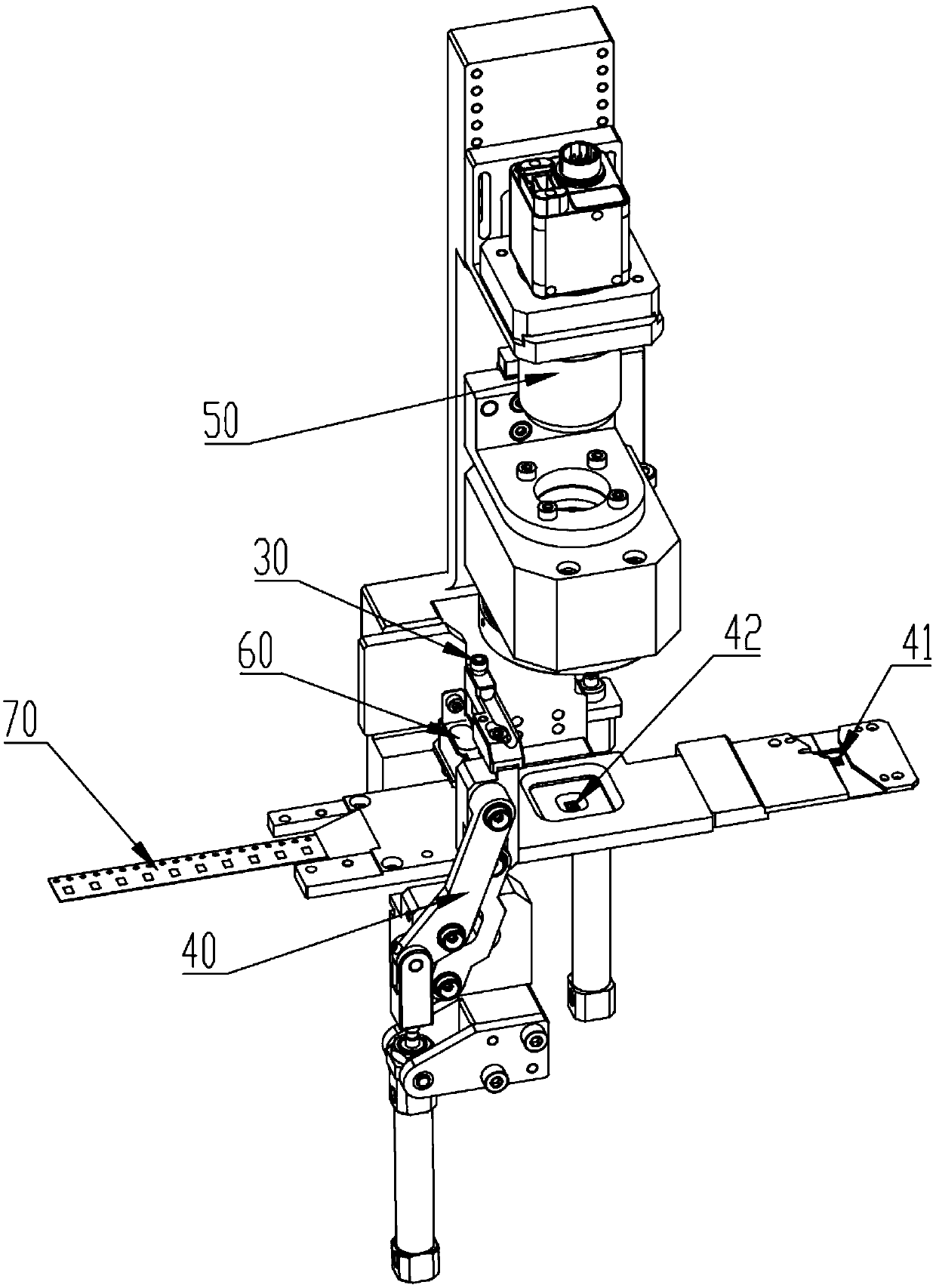

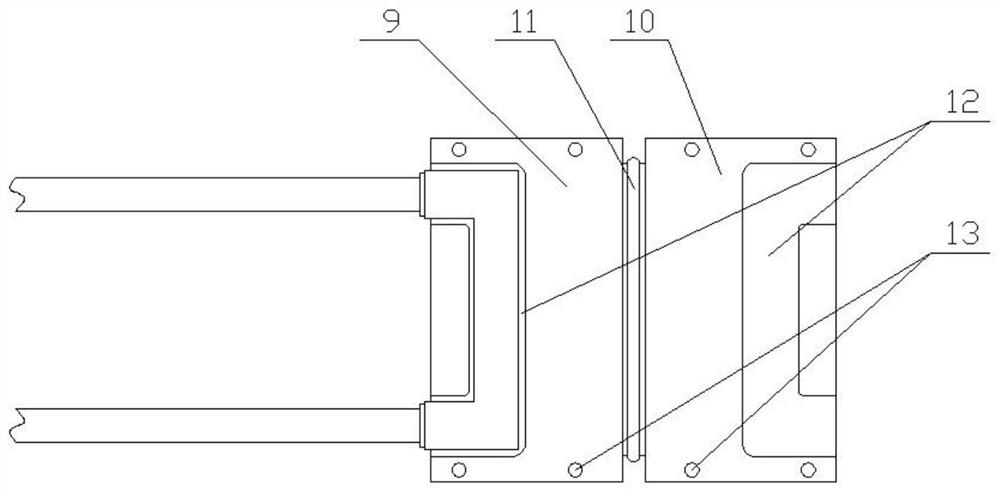

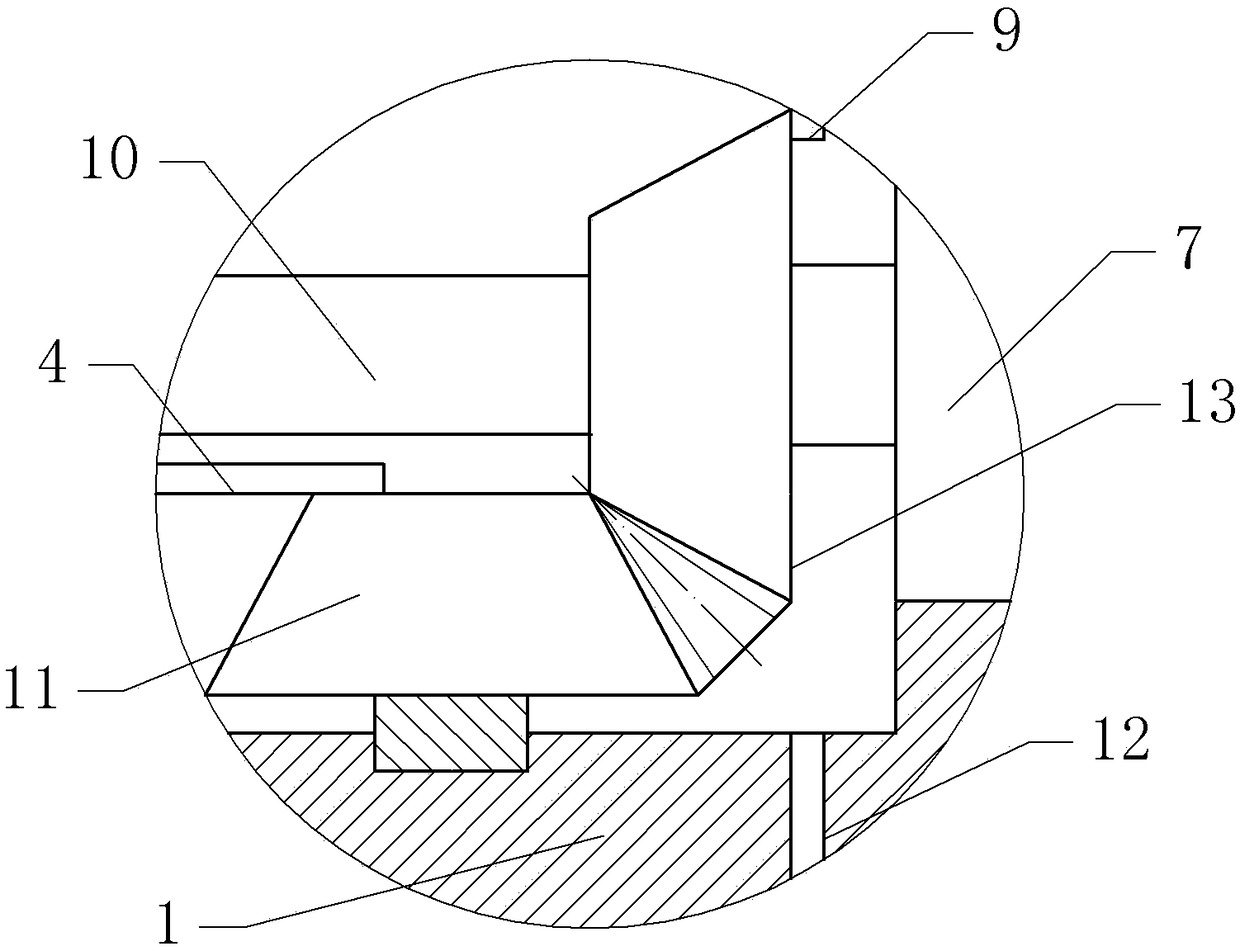

Material taking and placing device and material replacing device with same

ActiveCN110481841AImprove the efficiency of picking and unloadingCompact structurePackagingEngineeringMechanical engineering

The invention discloses a material taking and placing device and a material replacing device with the same. The material taking and placing device comprises a parallelogram mechanism, a cylinder and asucker, wherein the parallelogram mechanism comprises a base, a first crank, a second crank and a connecting rod; the first end of the first crank is hinged to a first hinging point of the base, andthe second end of the first crank is hinged to a second hinging point of the connecting rod; the first end of the second crank is hinged to the third hinging point of the base, and the second end of the second crank is hinged to the fourth hinging point of the connecting rod; the cylinder is connected with the first crank; the cylinder is capable of driving the first crank to rotate around the first hinging point; and sucker is connected with the connecting rod and used for taking and placing materials. The material taking and placing device has the advantages of being high in material takingand placing efficiency, compact in structure, low in cost and long in service life.

Owner:深圳市复德科技有限公司

Cable testing device for line standardization design and using method thereof

InactiveCN109142982ADamage detectionWith stroke amplificationMaterial analysis by electric/magnetic meansTesting manufactured objectsWave shapeEngineering

The invention relates to a cable testing device for line standardization design. The cable testing device includes a device shell, an input device, a transmission device, a trigger device and an alarmdevice. A testing method of the cable testing device for the line standardization design includes the following steps: step 1, installation; step 2, driving; and step 3, detection. According to the invention, the testing device travels on a cable, trigger switches synchronously oscillate while travelling along the cable, and so the trigger switches form wave-shaped forward trajectories on the cable. When the trigger switches pass through a damaged part on the cable, a compression spring drives a corresponding sliding inserting rod and limit side block to go down, a metal moving contact and ametal static contact are in contact, and so a buzzer is powered and sounds, thereby detecting that the surface of the cable is damaged.

Owner:山东弘图电力科技有限公司 +1

Smoke dust treatment device for large casting equipment and use method of smoke dust treatment device

PendingCN114699854AImprove sealingHave a restrictive effectDispersed particle filtrationTransportation and packagingExhaust fumesEngineering

The invention provides a smoke dust treatment device for large casting equipment and a using method thereof, and relates to the technical field of smoke dust treatment devices.The smoke dust treatment device comprises a smoke exhaust pipe, a supporting structure and a filtering structure, the filtering structure is arranged on the upper surface of the short arm end of the smoke exhaust pipe and comprises a motor, and the motor is fixedly connected to the surface of the smoke exhaust pipe; the output end of the motor is fixedly connected with a gear A. A reserved hole is formed in the position, corresponding to the gear A, of the smoke exhaust pipe. The tooth surface of the gear A is meshed with a gear B. The two sides of the gear B are fixedly connected with filter plates used for filtering dust in waste gas, and the two sides of each filter plate are rotationally connected with the smoke exhaust pipe. The side, close to the motor, of the smoke exhaust pipe is fixedly connected with a fixing plate. According to the smoke dust treatment device, the problems that filtered dust is inconvenient to clean in time on the premise that a traditional smoke dust treatment device can filter smoke dust, and normal exhaust of the waste gas pipe is easily affected due to accumulation of the dust in the waste gas pipe are solved.

Owner:芜湖久弘重工股份有限公司

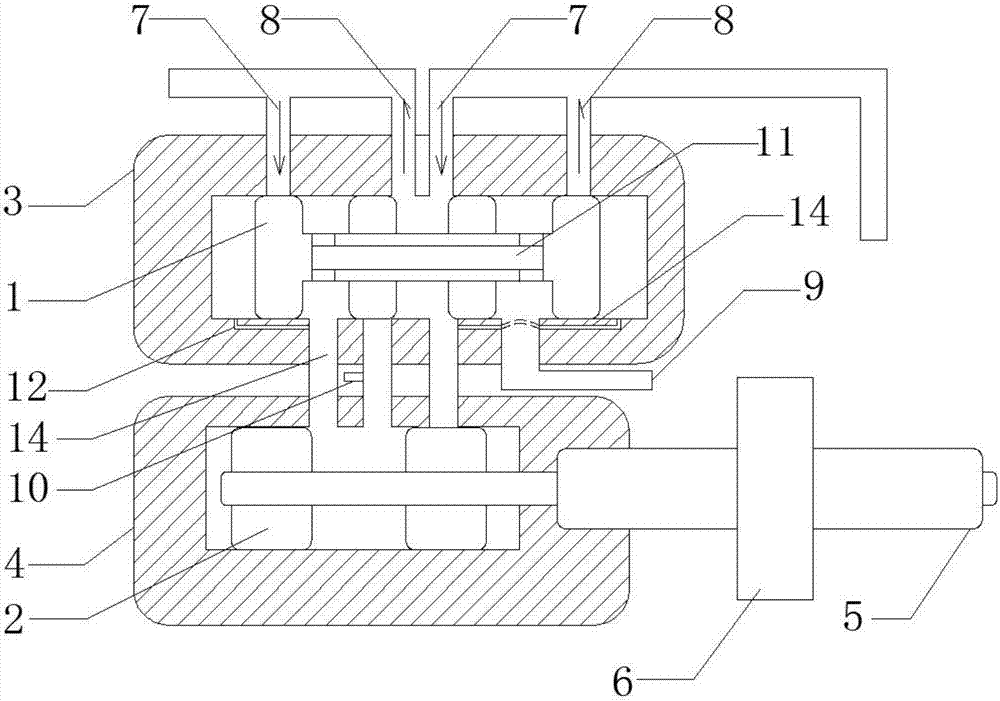

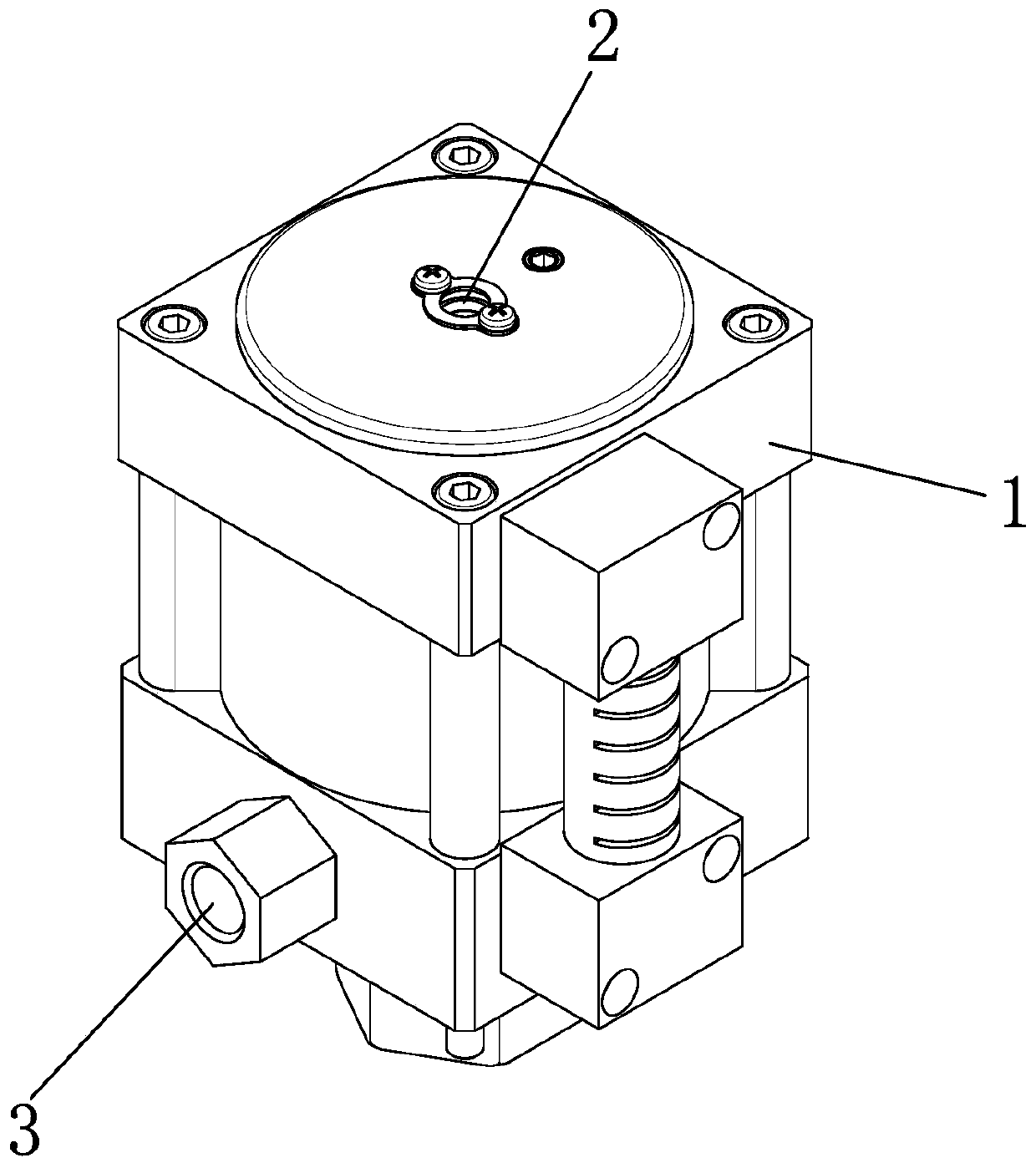

Automatic reciprocating fluid valve

InactiveCN107191623AFast reciprocating motionImprove work efficiencyOperating means/releasing devices for valvesMultiple way valvesSpool valveFailure rate

The invention provides an automatic reciprocating fluid valve, and relates to the field of valves. The automatic reciprocating fluid valve comprises a reciprocating valve element, a reversing valve element, a reciprocating valve body, a reversing valve body, a mechanical connecting rod and a piston; the reciprocating valve body and the reversing valve body are hollow cavities; the piston is located outside the reversing valve body and is arranged at one end of the mechanical connecting rod in a sleeving mode; the reversing valve element is located in the cavity of the reversing valve body and is arranged at the other end of the mechanical connecting rod in a sleeving mode; the reciprocating valve element is located in the cavity of the reciprocating valve body; and two fluid inlets and two fluid outlets are formed in the upper end of the reciprocating valve body. The automatic reciprocating fluid valve has the advantages that the self-power of fluid is used for achieving automatic reversing of the fluid in the reciprocating motion process of a fluid executing mechanism, an electromagnetic or manual valve does not need to be arranged at the power end, the reciprocating motion speed of the executing mechanism can be accelerated by installing the device on the executing mechanism, and therefore the working efficiency can be improved, and the fault rate can be reduced due to the fact that the electromagnetic valve is not adopted.

Owner:无锡市锡蒙机电科技有限公司

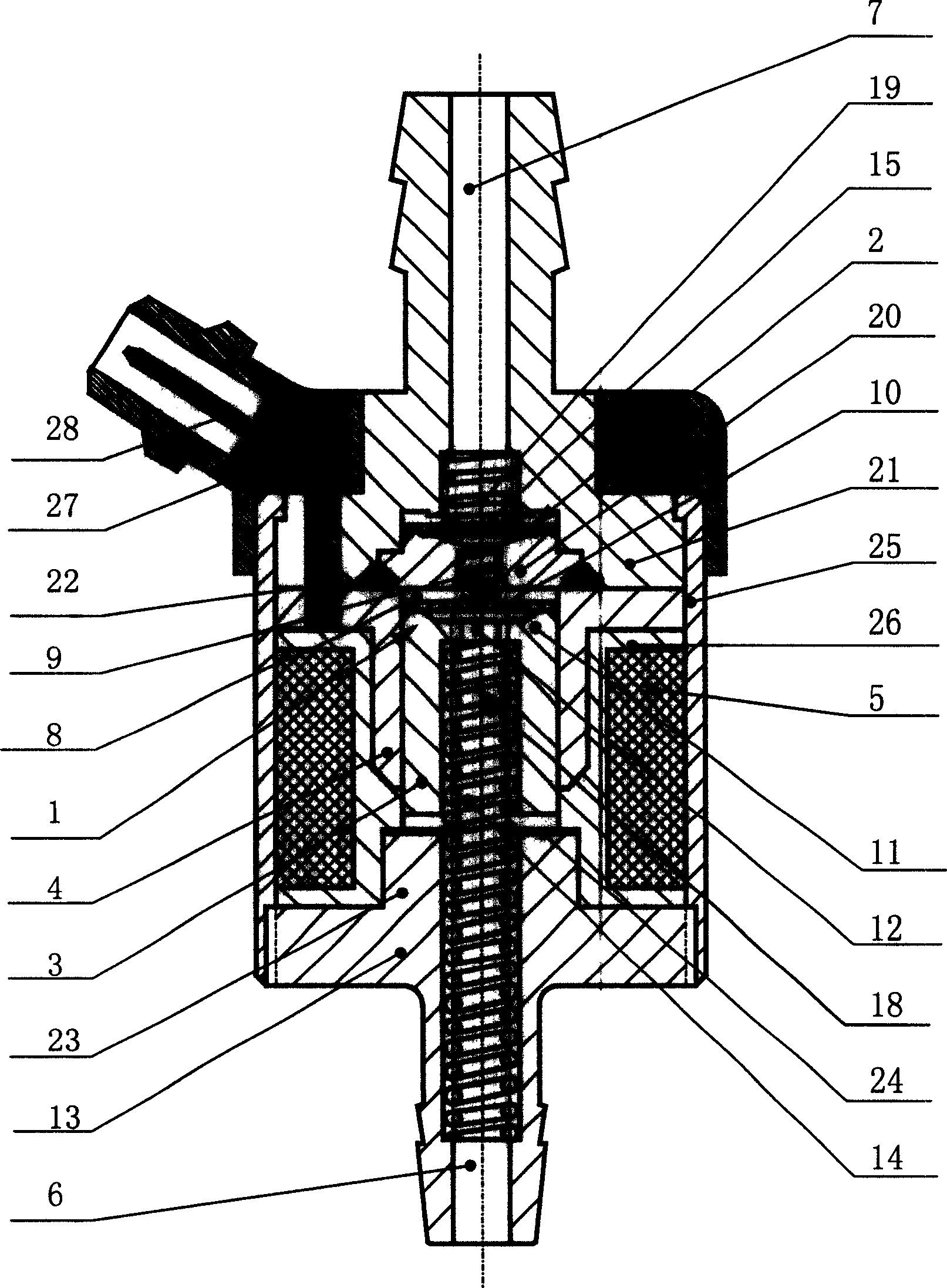

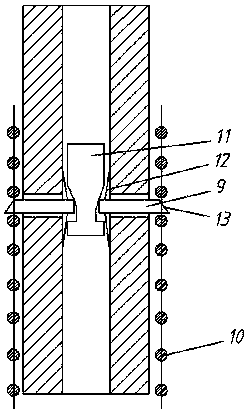

Electromagnetic plunge pump

InactiveCN1587699AImprove self-priming performanceReduce volumeFuel injection apparatusPumpsEngineeringElectric control

The invention relates to a electromagnetic tube-plug pump, using for pressure oil supplying in the oil-spraying system of compressor. It mainly includes oil-entering salves, oil-out salve, shaft-plug, coil and so on. The oil-entering salve includes an oil-entering salve spring, the oil-entering salve pith, and an oil-entering salve stand. The oil-entering salves stand is connected with plug, and communicated with oil-entering salve stand. The oil-entering salve stand is connected with plug, and communicated with oil-entering entrance by oil-entering holes inside the shaft-plug. There is a reduced spring between the shaft-plug and the lid bellow, along with the axis of shaft-plug, the shape of the entrance and exit of oil salve pith is disc, outside are oil-entering groove and oil-out groove. The benefit result of this invention is: because there is no reduce spring in the compressor cavity, it can reduce the dangerous capacity in the cavity, enhance the self-absorbing capacity and reduce air-hindernig phenomenon. That makes sure a higher oil-supporting pressure and especially apply for the electric-controlling spraying system of the motor engine. Certainly it also can apply for the other areas.

Owner:汪峰

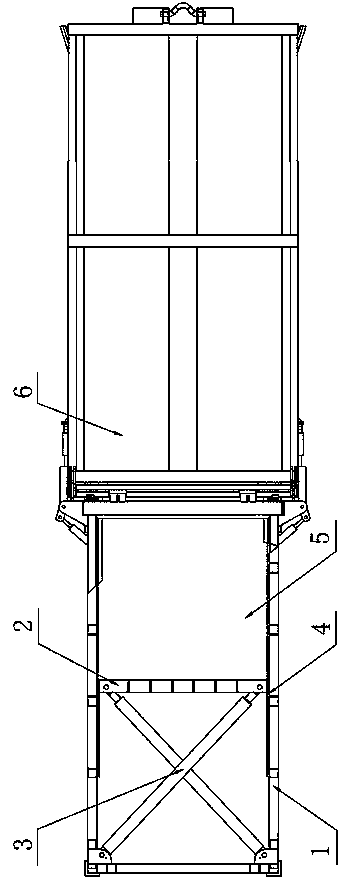

Compact trash compactor

InactiveCN103465501AImprove work efficiencyIncrease in sizePressesReciprocating motionSmall footprint

The invention discloses a compact trash compactor. The compact trash compactor comprises a compactor body, a pressure head, pressure head guide rails and a compacting chamber. Power of the pressure head is provided by cross cylinders directly, so that the pressure head moves along the forward and backward directions of the pressure head guide rails; the cross cylinders are arranged on the left and the right of the pressure head. According to the compact trash compactor, after the cross cylinders are used, on the premise that the compacting strength of compacting equipment is not changed, the pressure head mounting distance is reduced by half, but the pressure head stroke distance is increased by 30%, and the reciprocating speed is improved; after the mounting distance of the pressure head of the trash compacting equipment is reduced, space saved effectively is applied to a trash bin, so that the trash bin is enlarged, and the working efficiency of the compacting equipment is greatly improved; due to the reasonable thrust direction, the pressure head operates stably in the compacting chamber, and the trash blocks are compactly formed and not easy to scatter; the volume of the compacting equipment is reduced, the shape is compact, equipment is small in occupied area during transportation and mounting, and lots of land civil engineering costs are saved.

Owner:SHANDONG JINGHUA ENVIRONMENTAL SCI & TECH

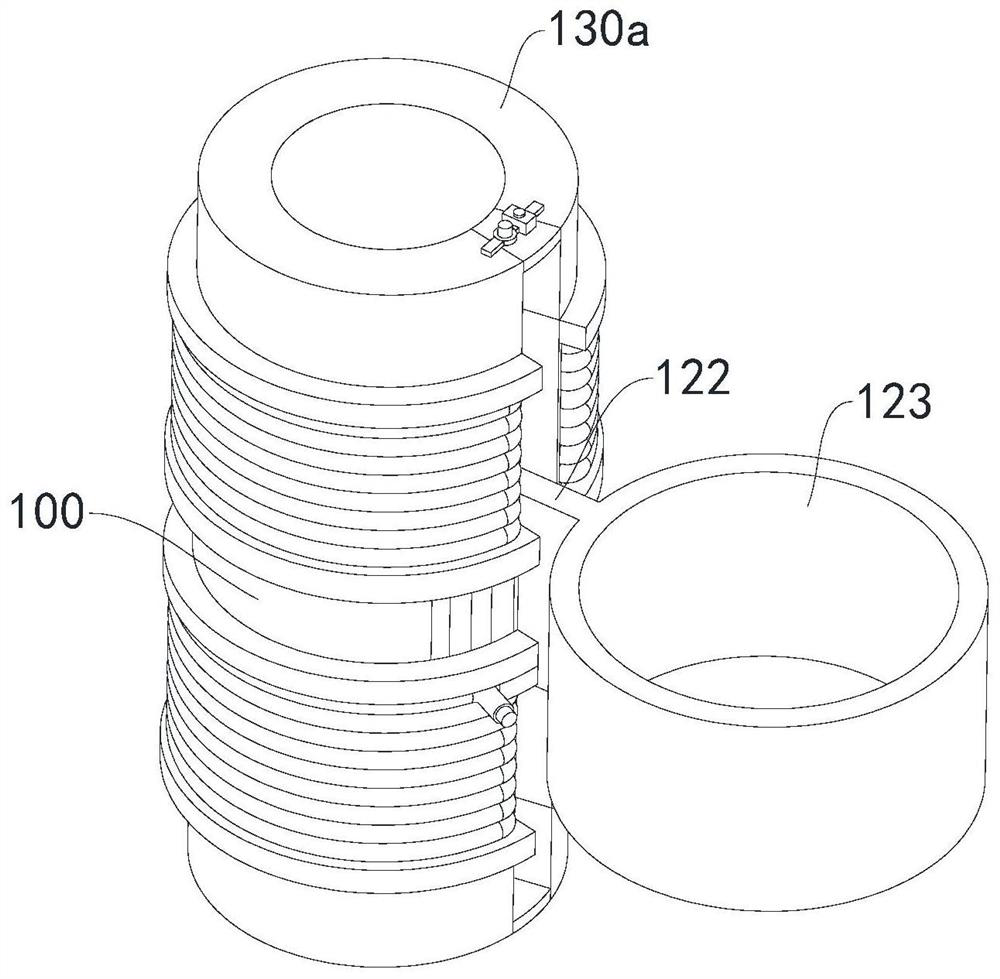

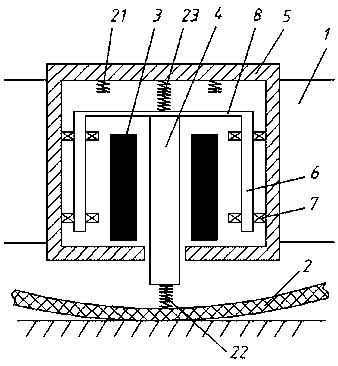

Reciprocating mechanism

PendingCN112932933AReduce vibrationSmall volumnVibration massageSuction-kneading massageReciprocating motionEngineering

The invention provides a reciprocating mechanism. The reciprocating mechanism comprises: a base body, wherein an accommodating space is formed in the base body, and a first opening extending in the axial direction of the base body is formed in the peripheral wall of the base body; an electromagnetic coil which comprises a C-shaped first coil group and a C-shaped second coil group, the first coil group and the second coil group are respectively provided with a second opening corresponding to the first opening and are respectively wound on the periphery of the base body at an interval, the first coil group and the second coil group are communicated with each other, and when being electrified, the current direction in the first coil assembly is configured to be opposite to the current direction in the second coil assembly; a permanent magnet which is movably arranged in the accommodating space; and a connecting part, wherein one end of the connecting part is connected with the permanent magnet, and the other end of the connecting part extends to the outside of the base body through the first opening and the second opening. The reciprocating mechanism is small in length, low in noise and capable of rapidly reciprocating.

Owner:SHENZHEN VINCENT TECH CO LTD

Device for stacking and storing micropore plates and micropore plate transferring device and method

Owner:北京爱博生生物技术有限公司 +1

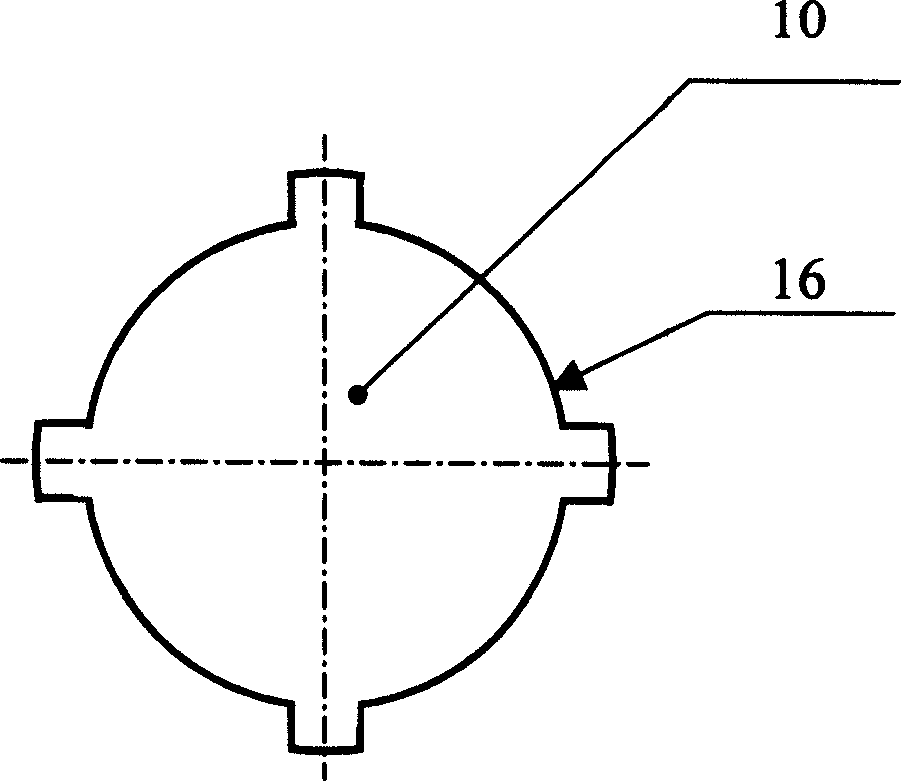

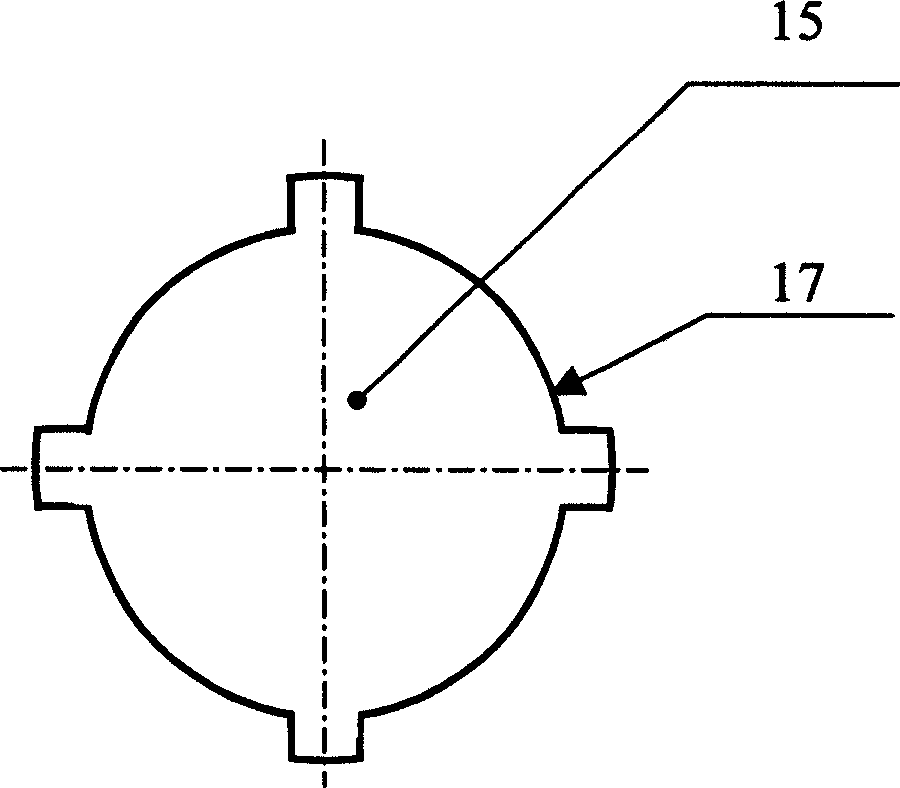

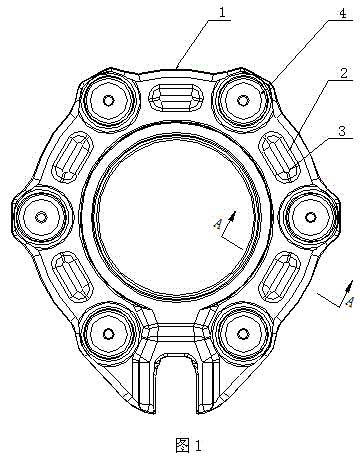

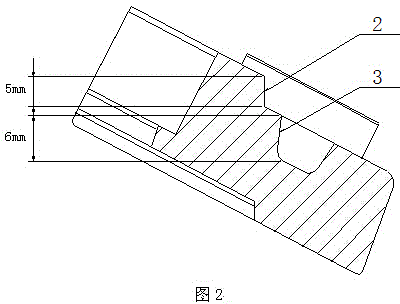

Planet plate structure of motor rotor

InactiveCN104595470AReduce power consumptionSmall transmission torqueMechanical energy handlingGearing detailsReciprocating motionEngineering

The invention relates to a motor rotor, in particular to a planet plate structure of a motor rotor. The planet plate structure comprises a planet plate body as well as piston holes which are unfirmly formed in the surface of the planet plate body and is characterized by further comprising step grooves which are unfirmly formed in the outer circle of the surface of the planet plate body and adopt a kidney-shape design, each step groove comprises a large kidney-shaped groove with the depth of 5 mm and a small kidney-shaped groove located in the large kidney-shaped groove and with the depth of the 6 mm. Compared with the prior art, five groups of step grooves are added on the basis of an original planet plate, the cost and the motor power consumption can be effectively reduced while the weight is reduced, transmission torque of internal components can be reduced, and rapider rotation motion of a main shaft is changed into reciprocation motion of a spherical connection rod.

Owner:HEFEI YUANKUAN SOFTWARE INFORMATION TECH

A kind of equipment for polishing the surface of the pull rod used in the manufacture of bags

ActiveCN111266986BOmit the reverse stepImprove processing efficiencyGrinding carriagesPolishing machinesPolishingElectric machinery

The invention discloses a surface polishing device for pulling rods used in the manufacture of bags and suitcases. Placed on the ground, a force-bearing plate is welded to one end of the mounting plate, and the force-bearing plate and the mounting plate are welded at a 90-degree angle. A feeding push rod is installed on the inner side of the force-bearing plate through the fixing plate, and the surface of the feeding push rod is embedded. There are fixing hoops, and two fixing hoops are used, so that the feeding push rod and the installation plate are parallel to each other, and the fixing hoops are installed on the surface of the installation plate through bolts. The present invention improves the disadvantage that the existing luggage pull rod can only be polished in a small area by arranging a polishing cylinder, a feeding push rod, a fixed box, a reciprocating motor, a grinding cylinder, a polishing pad and other structures, and realizes one-time all-round polishing; The polishing work is carried out at the same time in the direction to achieve high-efficiency polishing, reduce time consumption and improve processing efficiency.

Owner:湖南双春箱包有限公司

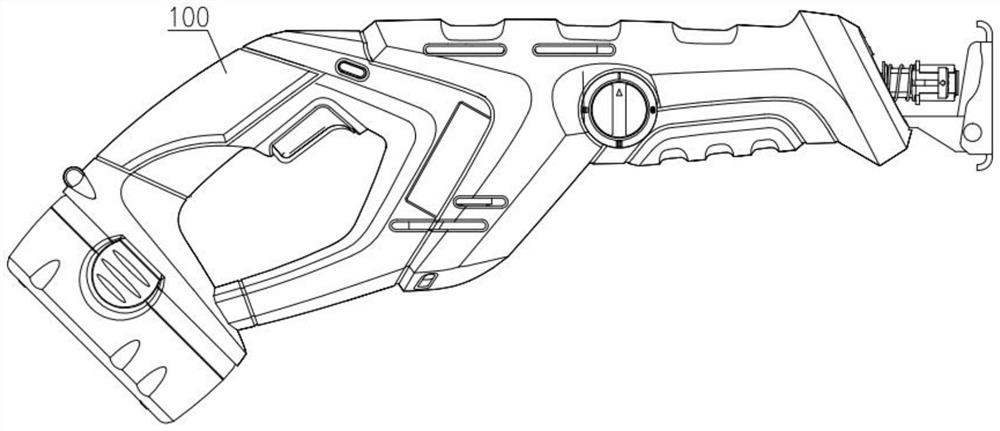

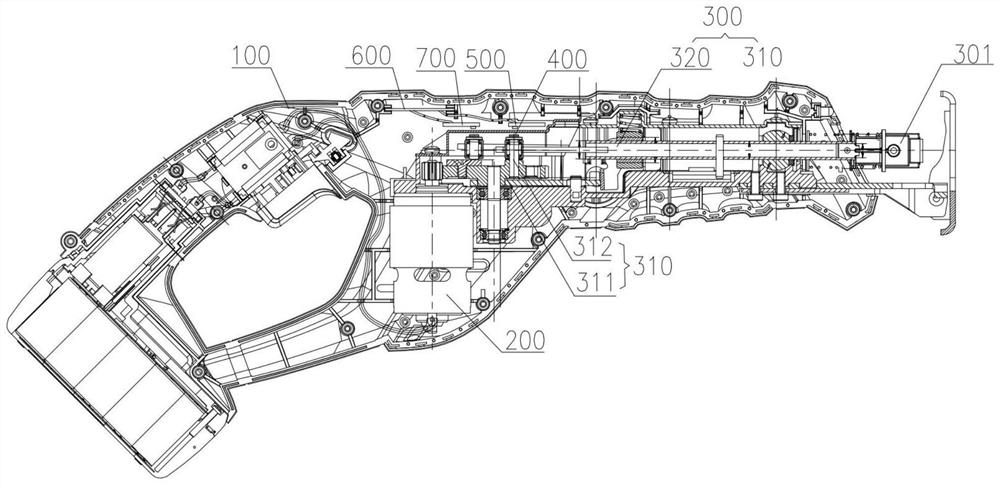

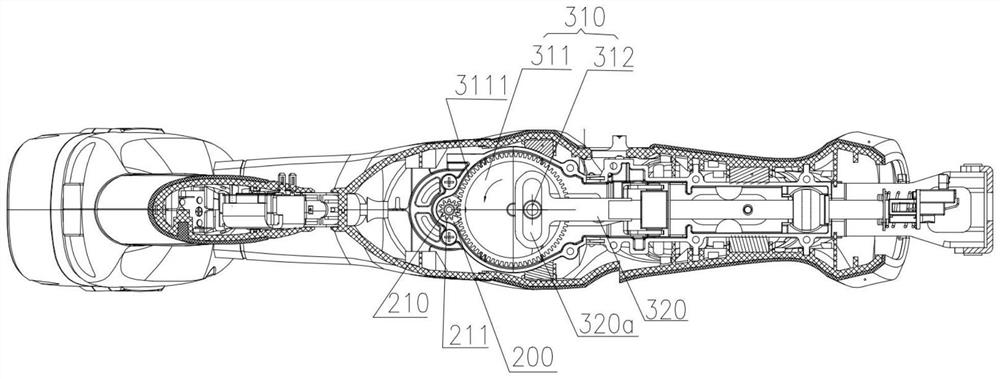

Reciprocating saw

ActiveCN112809087BReduce vibrationFast reciprocating motionMetal sawing devicesMetal sawing accessoriesReciprocating motionElectric machine

The present application relates to a reciprocating saw, which has a working stroke state and an idle stroke state, including: a casing; a motor, located in the casing; a transmission mechanism, which is driven by the motor to drive the saw blade to reciprocate; a detected object is arranged on the transmission mechanism , moves with the movement of the transmission mechanism, and can move to the first position, and when the detected object moves to the first position, the reciprocating saw is in a working stroke state or an idle stroke state; the first detector is used to detect the detected object. The object is arranged opposite to the first position; the control circuit board is electrically connected to the first detector and the motor, and when the first detector detects the object to be detected, the rotation speed of the motor is adjusted. The present application can effectively control the rotational speed of the motor according to the travel requirements, thereby solving various application problems.

Owner:POSITEC POWER TOOLS (SUZHOU) CO LTD

Wind-powered windshield wiper device

PendingCN109552254AQuick clean upNot easy to damageVehicle cleaningWindscreen wiperElectric machinery

The invention relates to a wind-powered windshield wiper device and belongs to the field of automobile energy-saving equipment. The wind-powered windshield wiper device comprises a housing, an upper cover, windshield wipers, a fan, a baffle, a motor, a first rack, brackets, a moving rod, a driving gear, a belt, windshield wiper gears, second racks, rotating plates and a driven gear; the upper cover is fixed on the upper end surface of the housing; the fan is placed in the middle of the housing; the motor is fixed on the front end surface of the housing; the baffle is placed on the front end surface of the housing and can slide relative to the housing; one end of the first rack is connected with the baffle and is in contact with the motor; the brackets are fixed on the lower end surface inthe housing; the middle parts of the windshield wipers are connected with the upper ends of the brackets and can rotate relative to the brackets; the two ends of the moving rod are placed at the lowerends of the brackets and can slide relative to the brackets; and the second racks are symmetrically fixed at the upper end of the moving rod. Wind power in the automobile running process is used as power to rapidly clean glass.

Owner:吕萌萌

Testing method of cable testing device with standardized circuit design

ActiveCN112067748ADamage detectionWith stroke amplificationTesting manufactured objectsStructural engineeringMechanical engineering

Owner:SHAANXI XIECHENG TESTING TECH CO LTD

Drilling device for automotive mounting plate

InactiveCN108500324AAchieve continuous drillingFast reciprocating motionFeeding apparatusMetal working apparatusDrill bitSlide plate

The invention relates to the technical field of processing of automotive mounting plates and discloses a drilling device for an automotive mounting plate. The drilling device comprises a drilling box,wherein feeding channels penetrating through the drilling box are formed in two sides of the drilling box, and a double-end motor is fixed to the drilling box; main bevel gears and drills are fixed to the driving shafts at two ends of the double-end motor, a spring is arranged in the periphery of each drill, and a lug is fixed to the large diameter end of each main bevel gear; air cavities are formed above and below the main bevel gear, a slide plate is slidably connected in each air cavity, a push rod is fixed to the slide plate, a reset pressure spring is arranged in the bottom of the slideplate of the air cavity below, and the air cavities communicate to the feeding channels; two auxiliary bevel gears are rotatably connected to the drilling box, the two auxiliary bevel gears are engaged to corresponding main bevel gears, the two slide blocks are slidably connected to the drilling box, the two slide blocks and the two drills are in one-to-one correspondence, and the auxiliary bevelgears drive the slide block to reciprocate. The drilling device provided by the invention is simple in structure, and can perforate and feed the mounting plate.

Owner:宁波高新区新柯保汽车科技有限公司

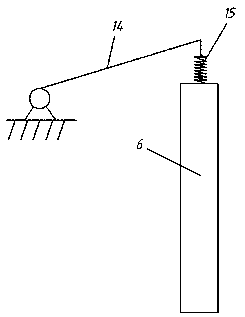

Gravity balancing device on Z-direction working platform and cutting machine

InactiveCN102284973BFast reciprocating motionSolve the problem of not being able to lock itselfMetal working apparatusLow noiseReciprocating motion

The invention provides a gravity balancing device on a Z-direction working platform, and an elastic device fixed on a base and can provide an upward force for a slide carriage. The embodiment of the invention also provides a cutting machine which comprises a Z-direction working platform, wherein the Z-direction working platform comprises a base, a screw which can be rotatably arranged on the base, and a slide carriage which is arranged on the screw and can be driven by the screw to move relative to the base; and the Z-direction working platform is provided with a gravity balancing device. When a moving part of the Z-direction working platform provided with the gravity balancing device reciprocates, the elastic device fixed on the base supplies an upward force to balance the downward gravity of the moving load, thus the problem that the screw cannot be locked automatically is solved, and the adverse effect of the load gravity is eliminated simultaneously. As for the cutting machine provided by the invention, the Z-direction working platform thereof is provided with the gravity balancing device, thus the problem that the screw cannot be locked automatically is solved, and the adverse effect of load gravity is eliminated simultaneously. The cutting machine runs with lower noise, is particularly suitable for high-speed and high-precision cutting, and greatly reduces the manufacturing cost.

Owner:CETC BEIJING ELECTRONICS EQUIP

A high-efficiency power generation wheel using tire running deformation

ActiveCN106427385BReduce forceAvoid the problem of high and low forceAuxillary drivesDynamo-electric machinesReciprocating motionEngineering

The invention discloses an efficient power-generating wheel utilizing tire driving deformation. A plurality of linear generators are arranged on a tire along the circumferential direction; stators of the linear generators are located in a shell; the axes of the stators are located on the diameter direction of the tire; two ends of rotors penetrates out of the stators; guiding shafts are symmetrically arranged on the two sides of the rotors; the guiding shafts are arranged on the shell through bearings; two guiding shafts and rotors are integrally connected toward the central end of the tire through connecting plates; one end of each rotor penetrates out of the shell so as to be in contact with the inner bottom surface of the rubber tire all the time in the rotating process of the tire and form an axial reciprocating motion between the stators under the guiding effect of the guiding shafts following the deformation of the rubber tire at the contact point; a centrifugal force balancing mechanism is arranged in the shell and is used for adjusting the acting forces between the rotors and the rubber tire under the centrifugal forces brought by different rotating speeds. The efficient power-generating wheel utilizing tire driving deformation can obviously increase the tire power-generating efficiency and can establish an excellent basis for more quick and effective popularization of the technique.

Owner:汤明德

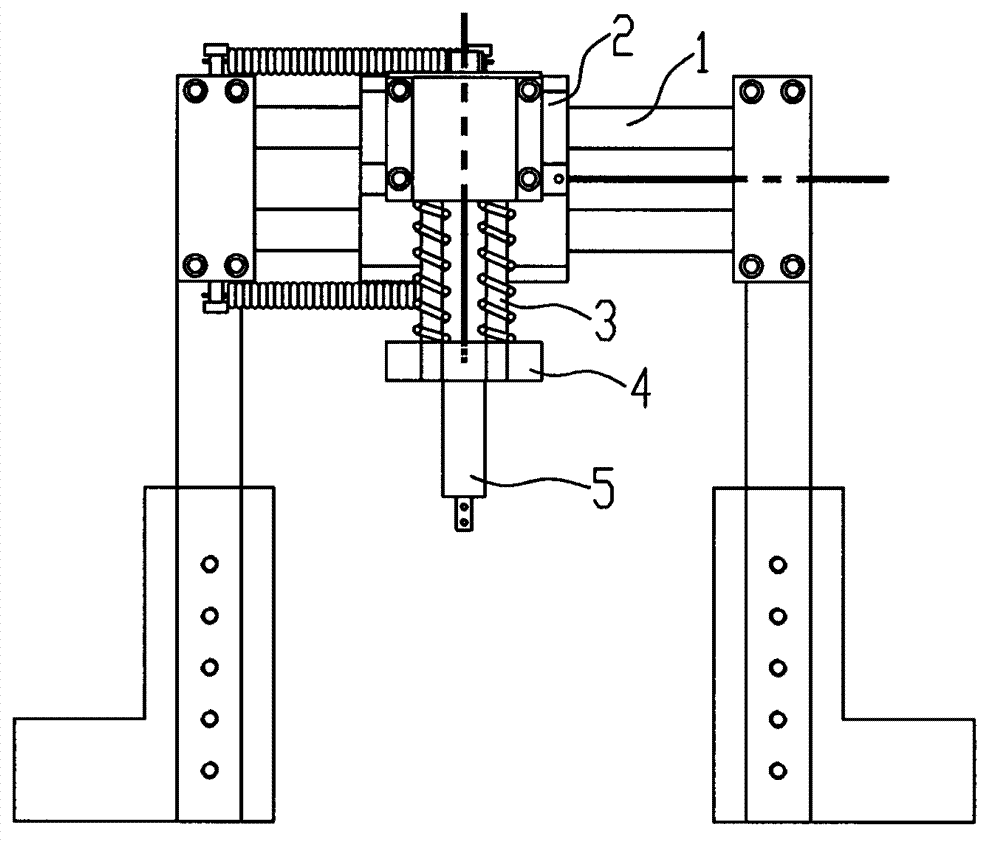

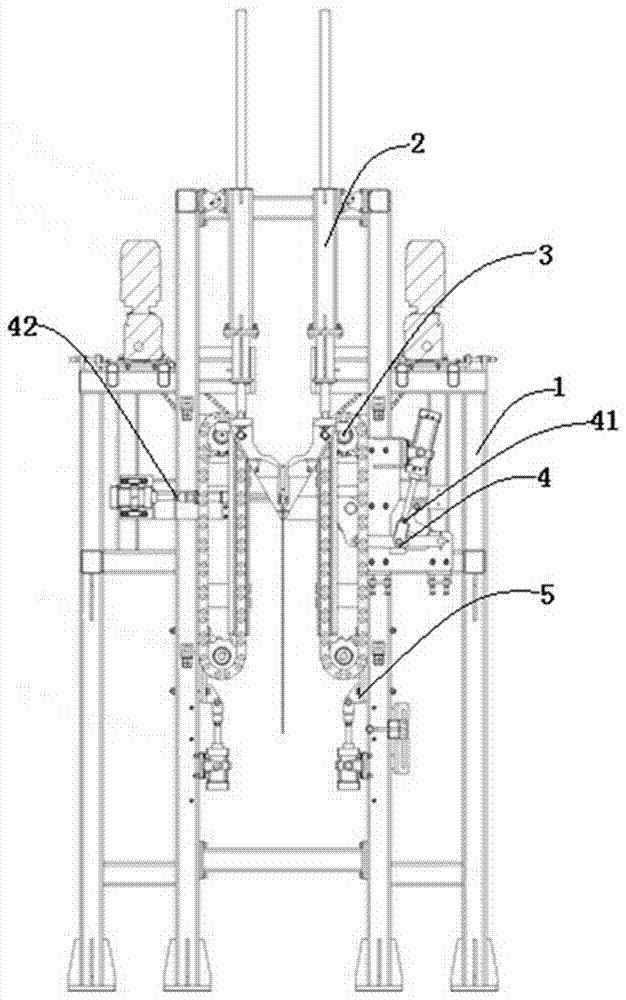

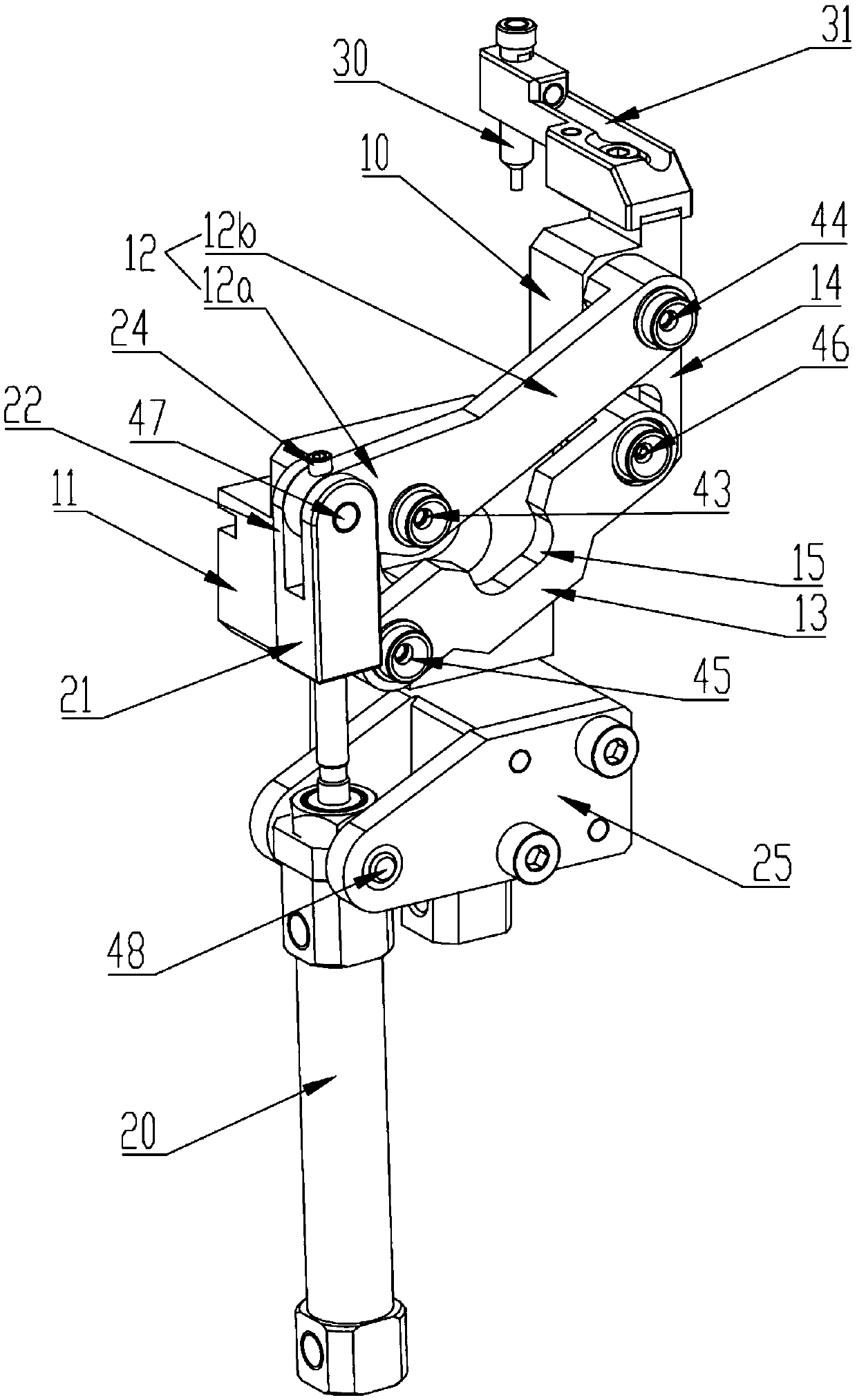

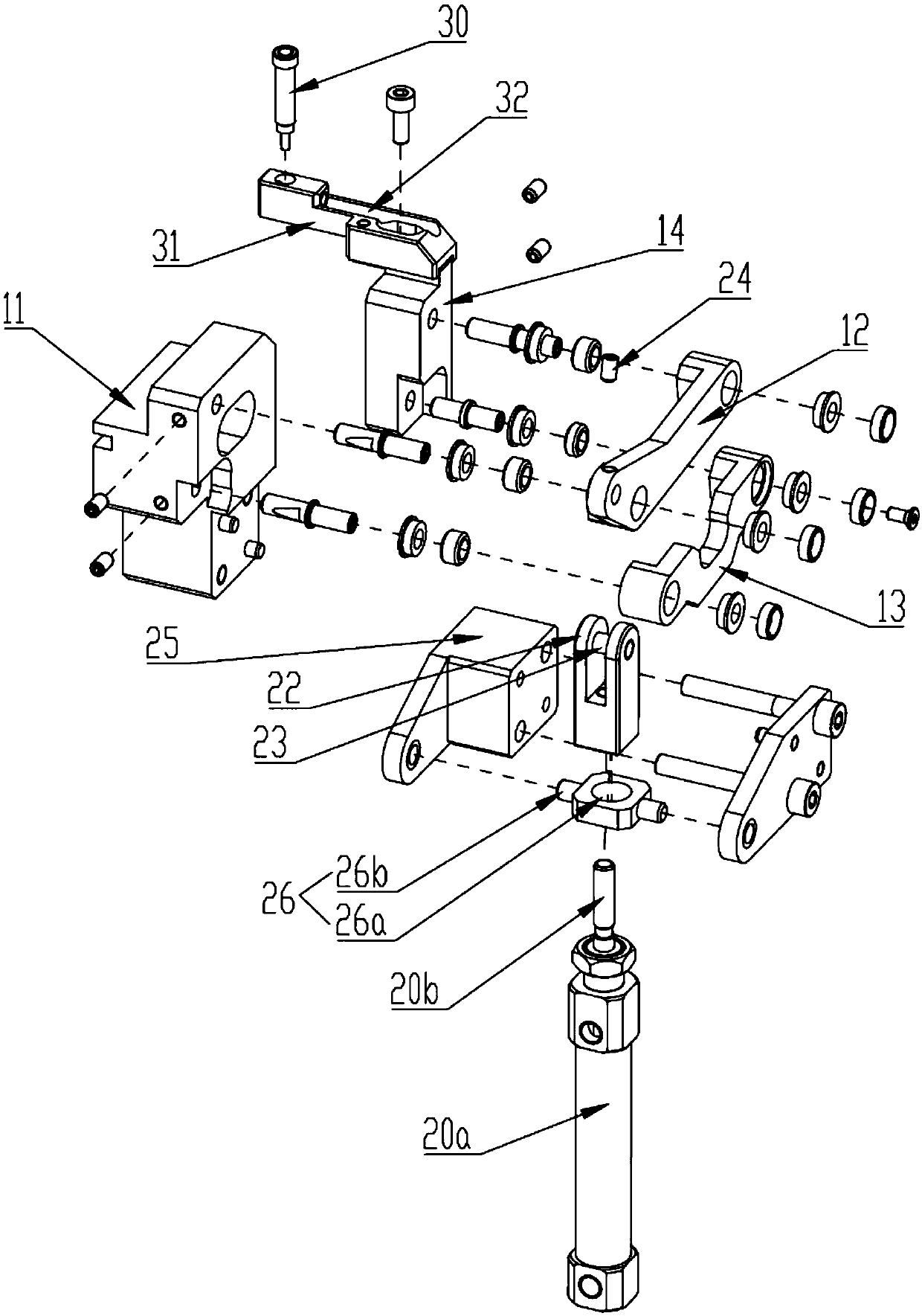

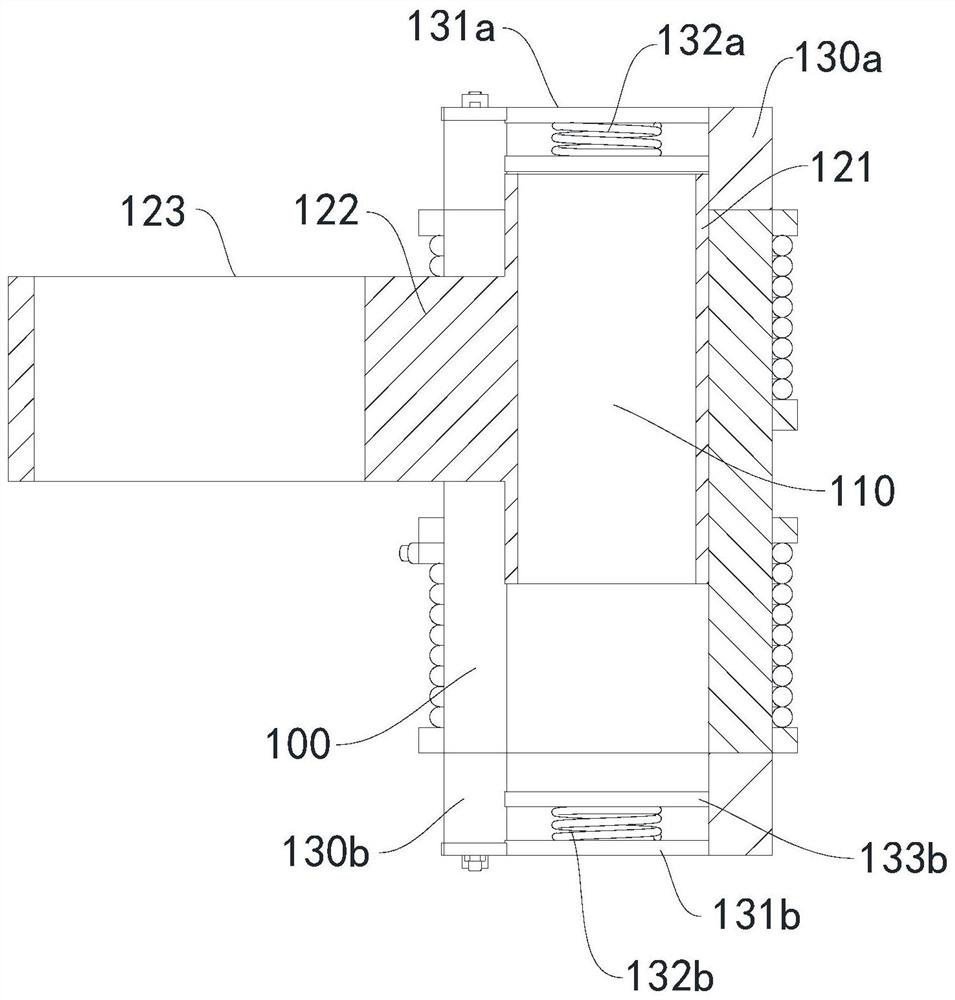

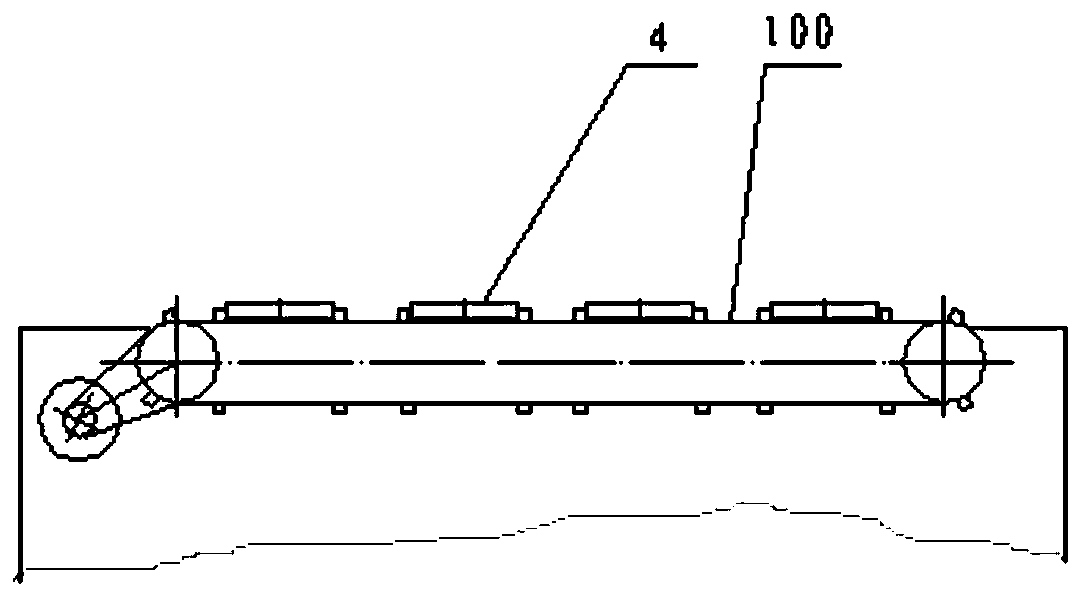

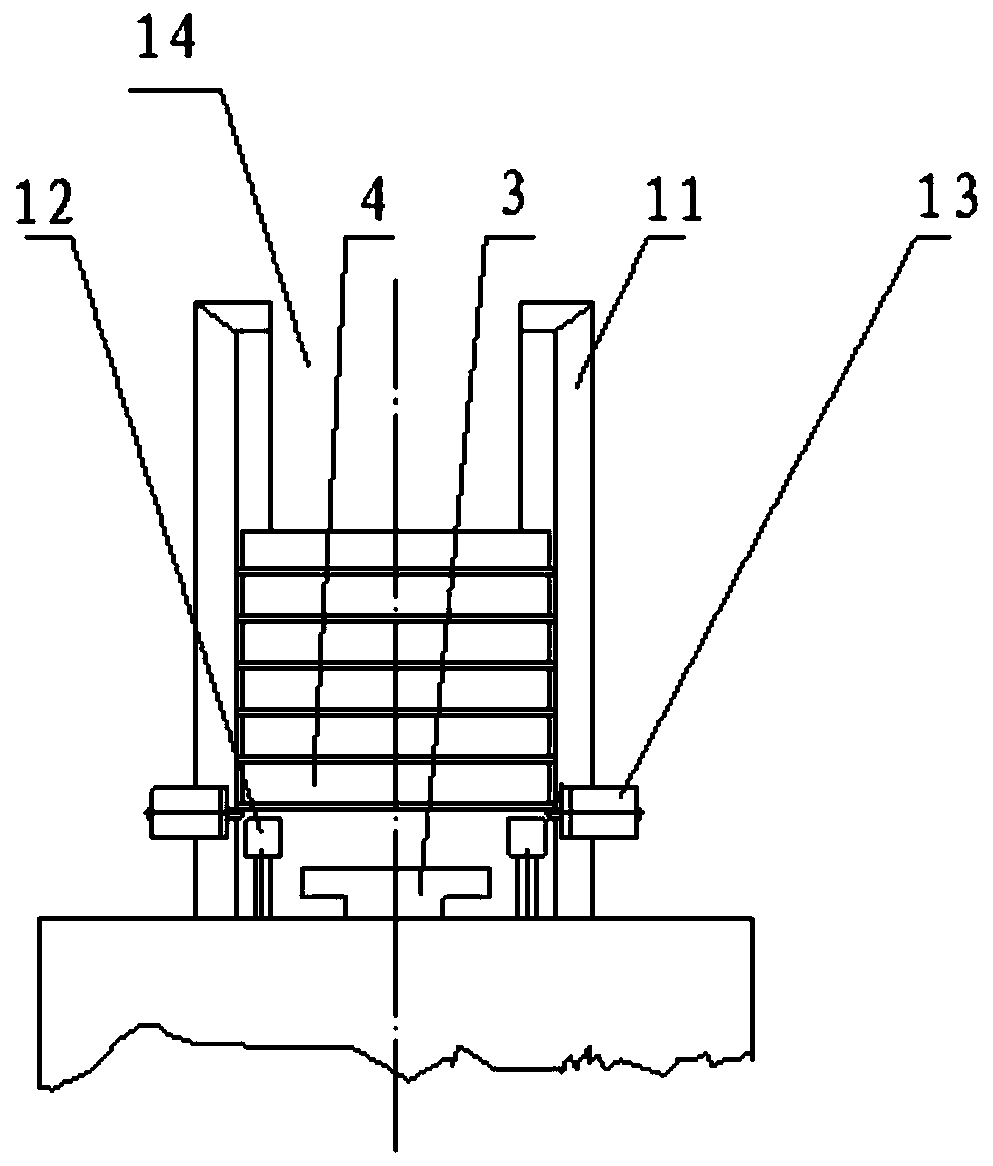

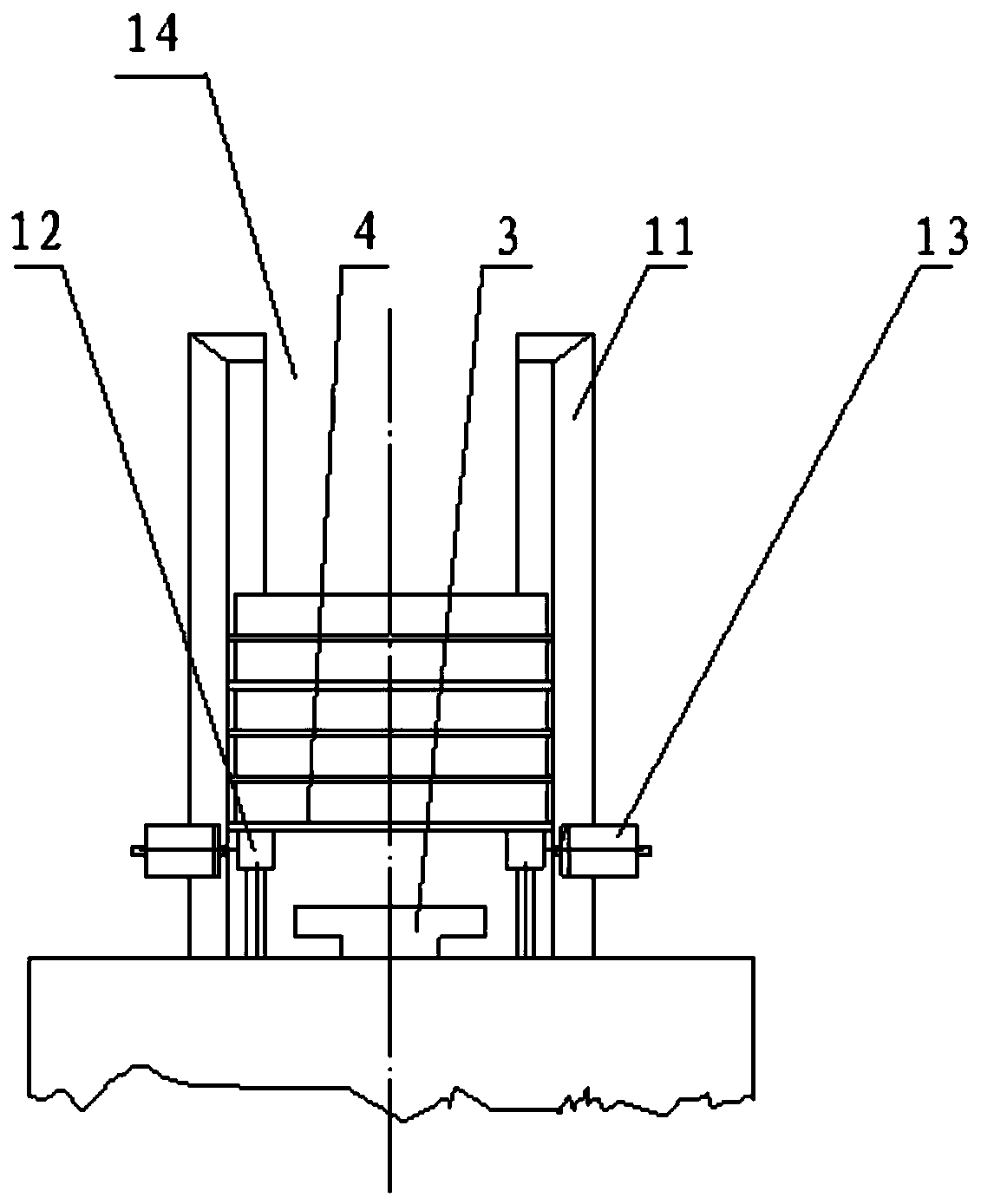

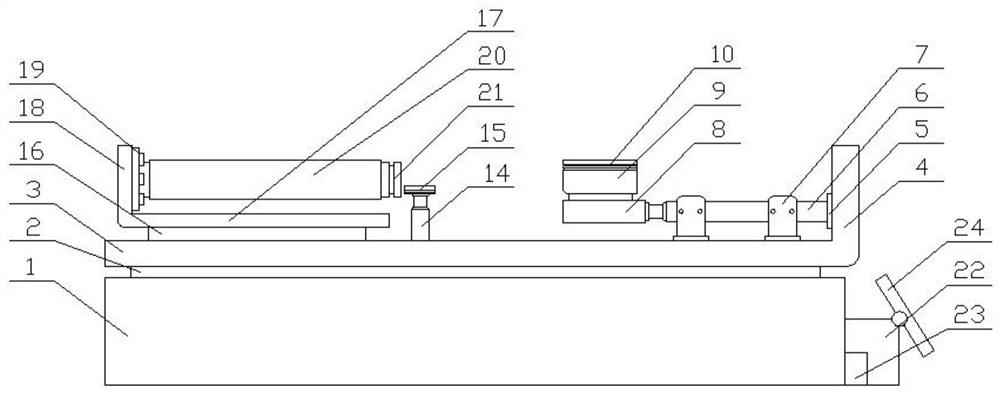

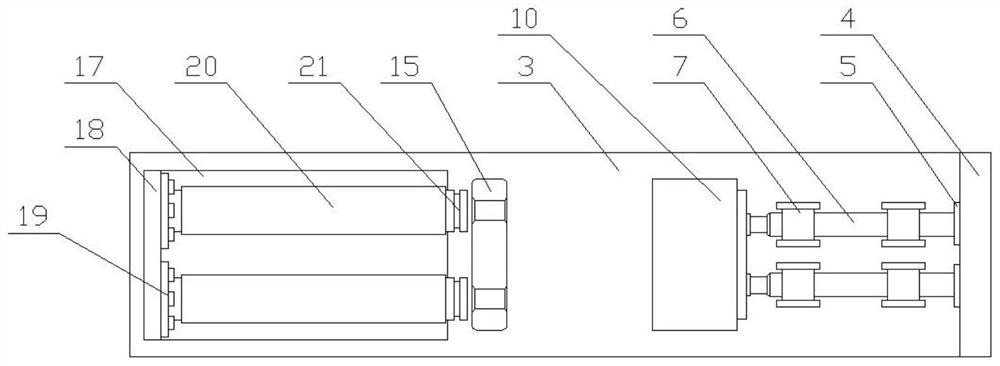

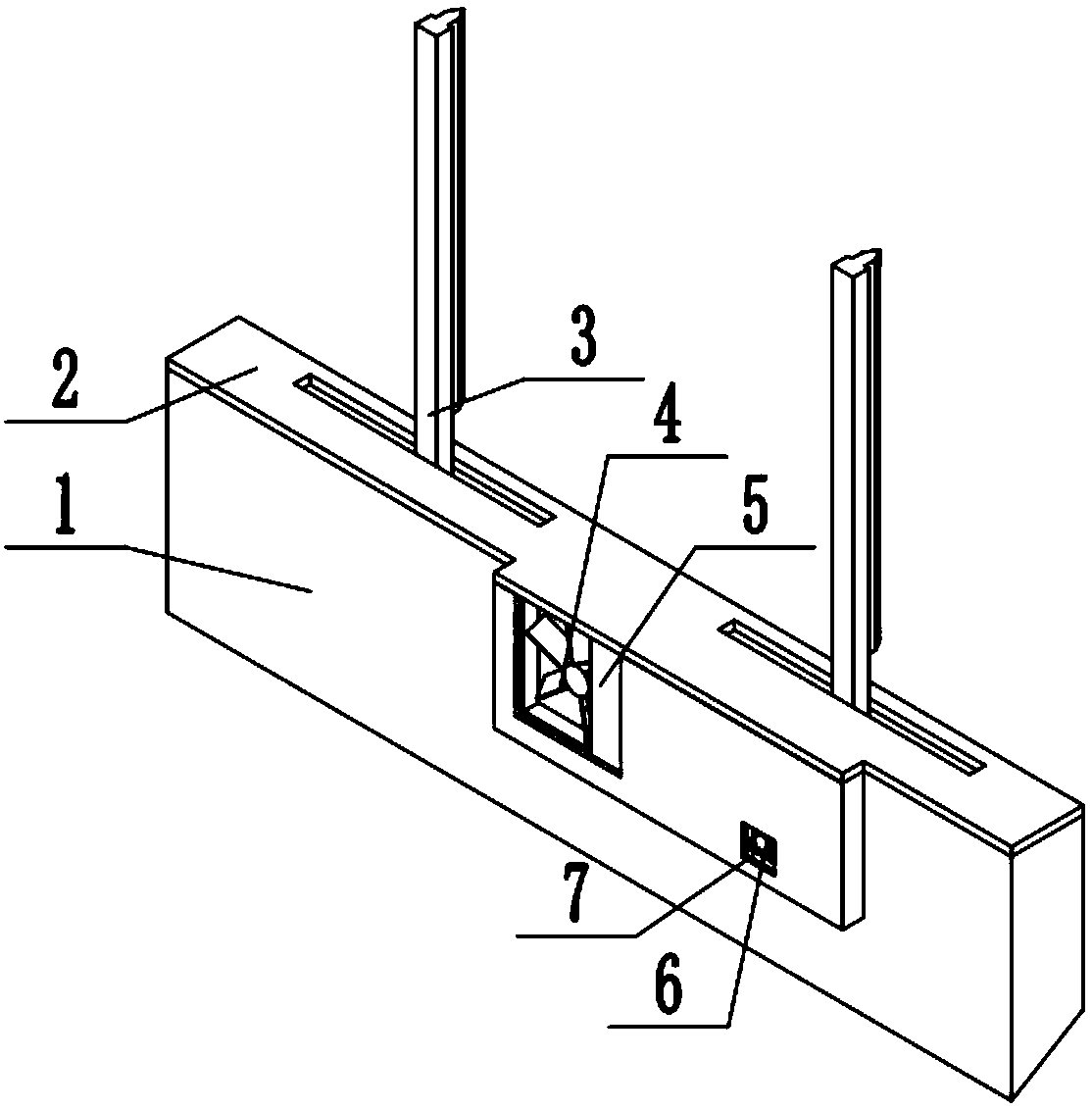

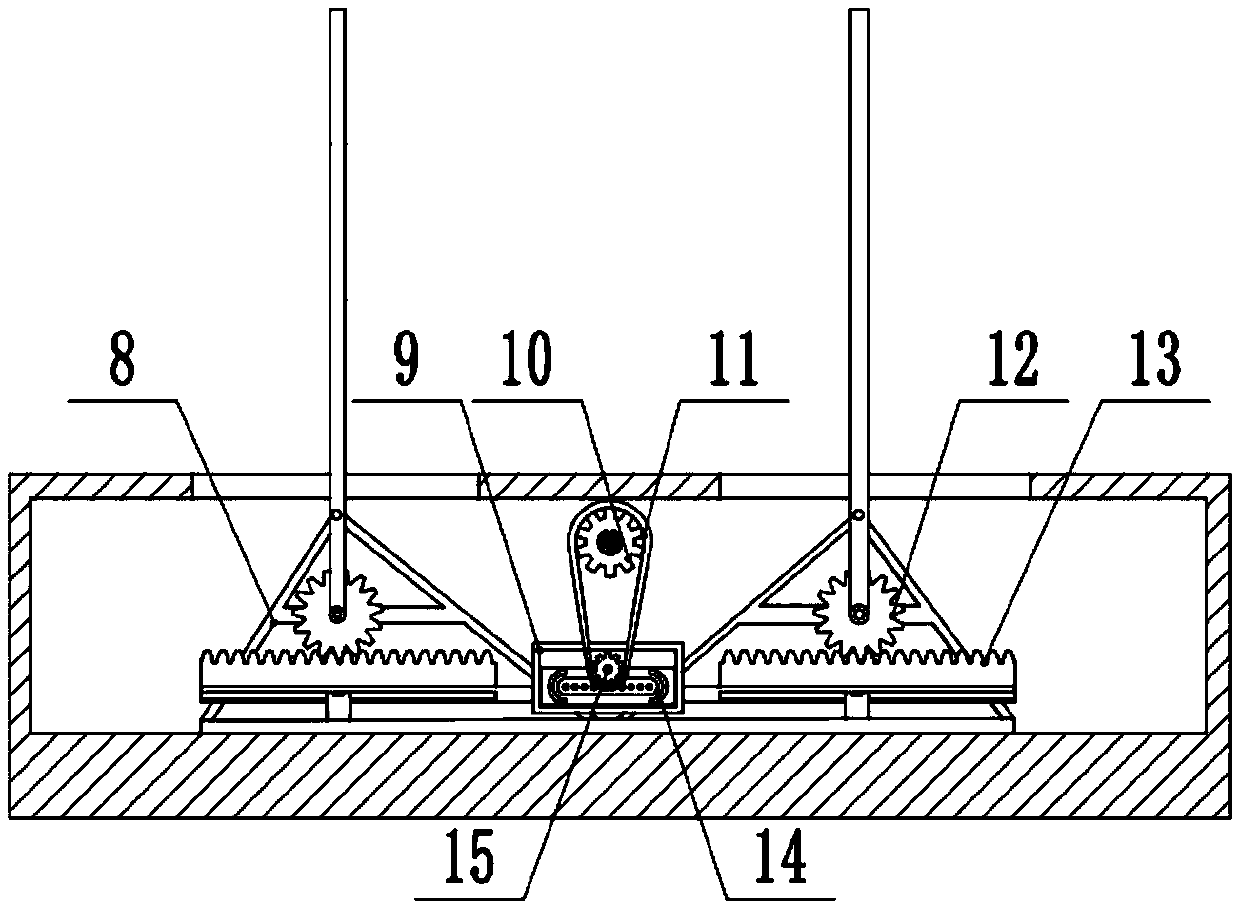

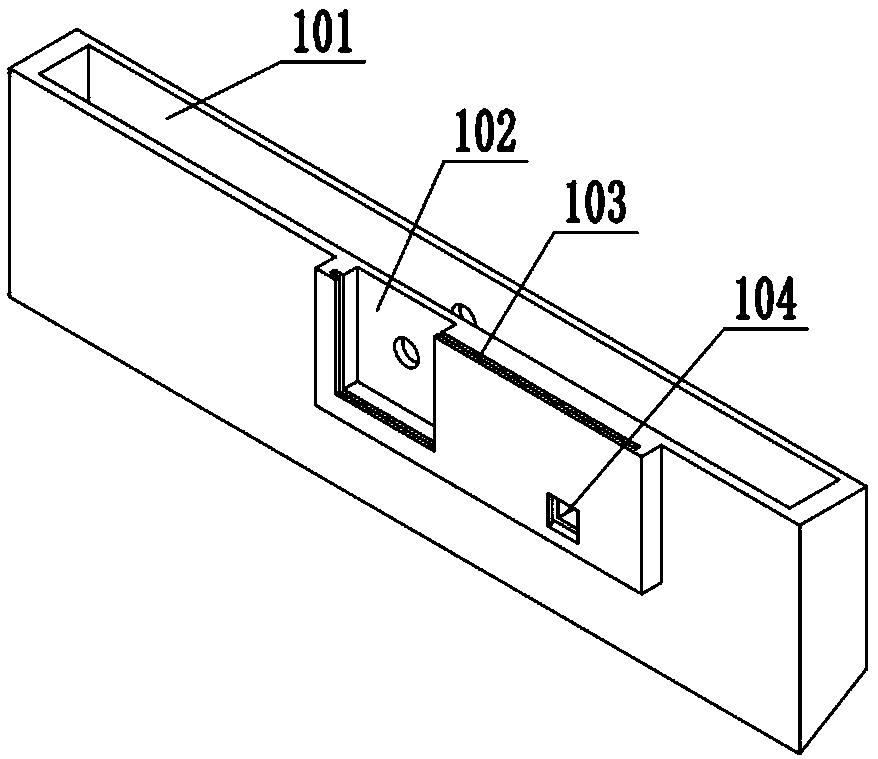

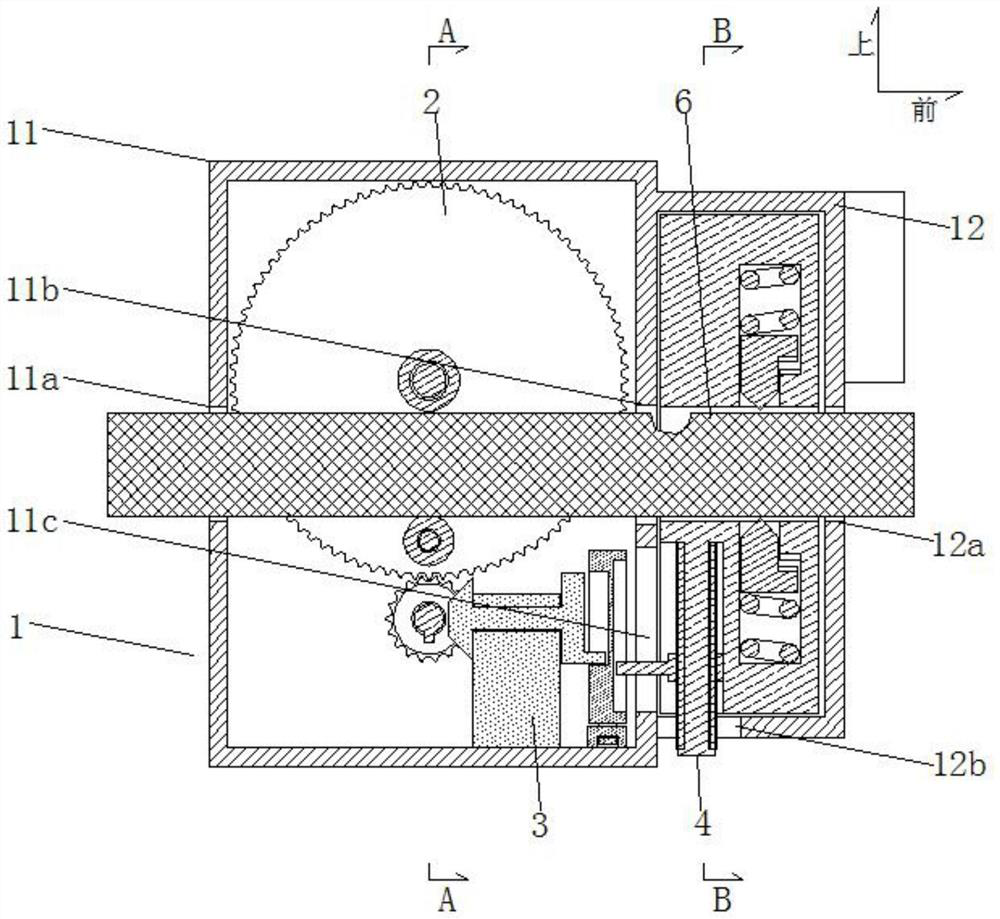

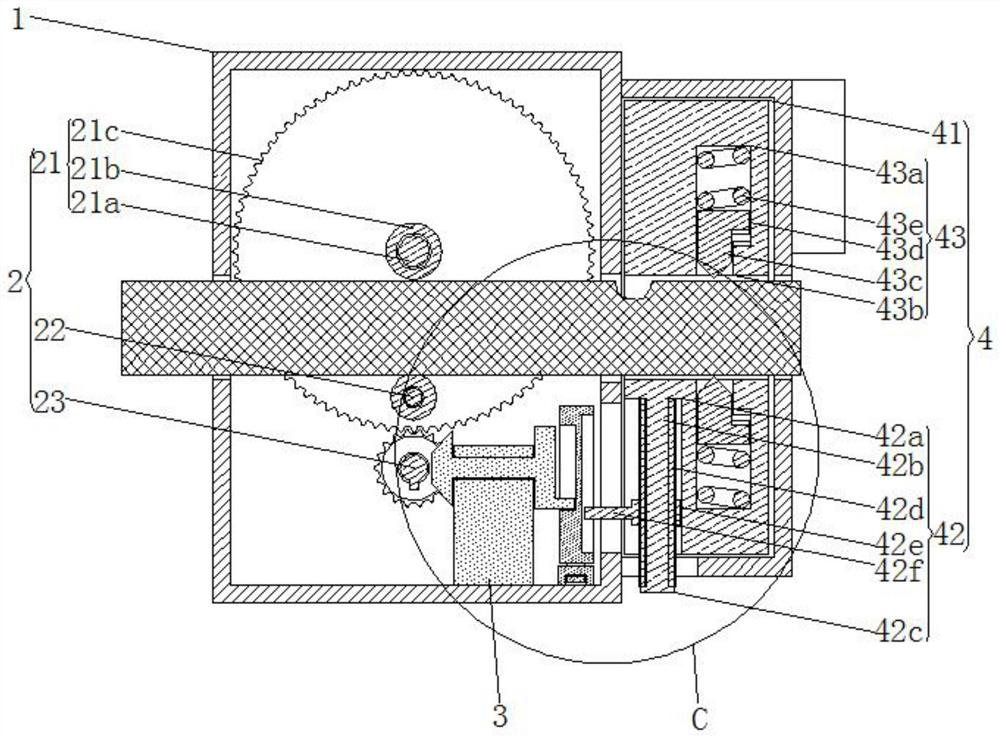

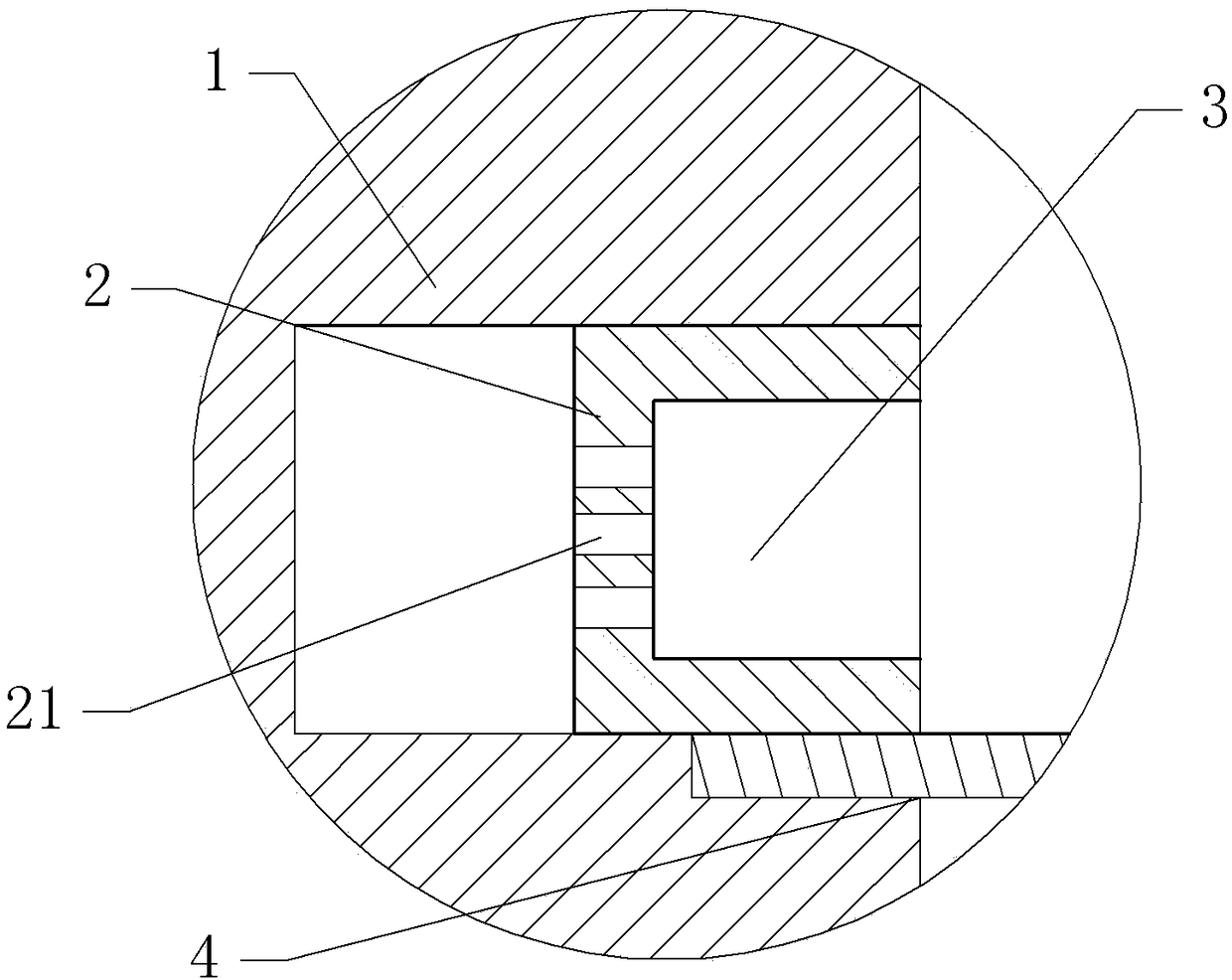

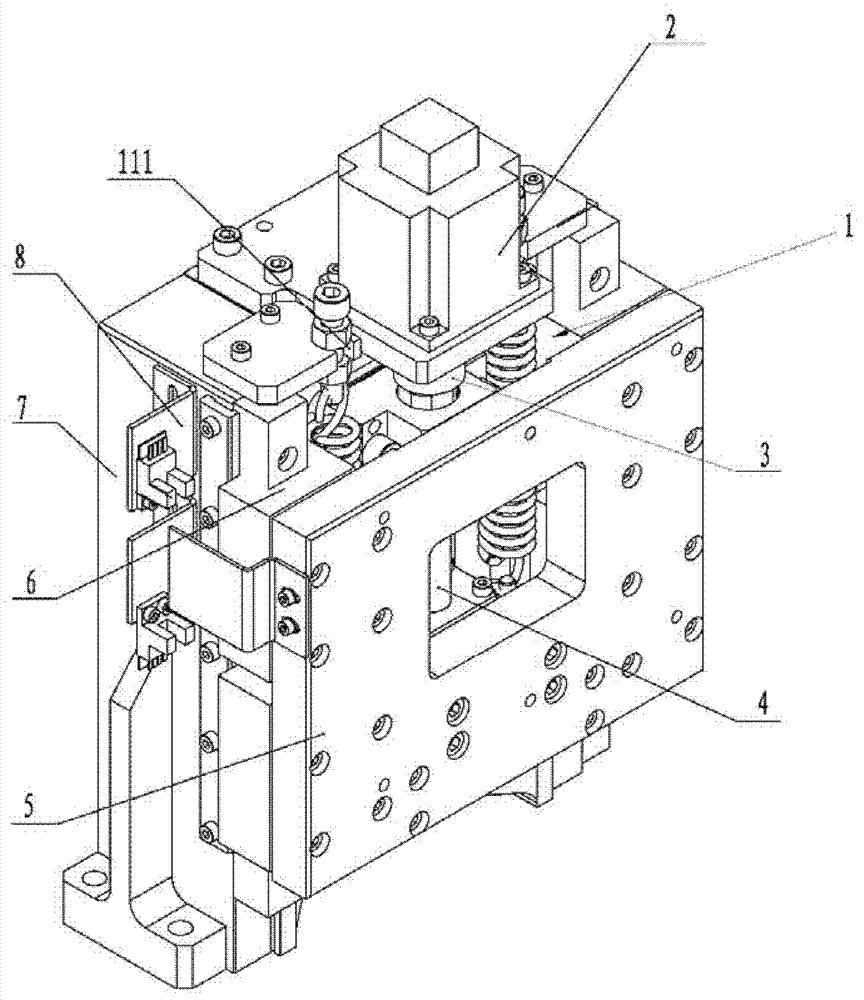

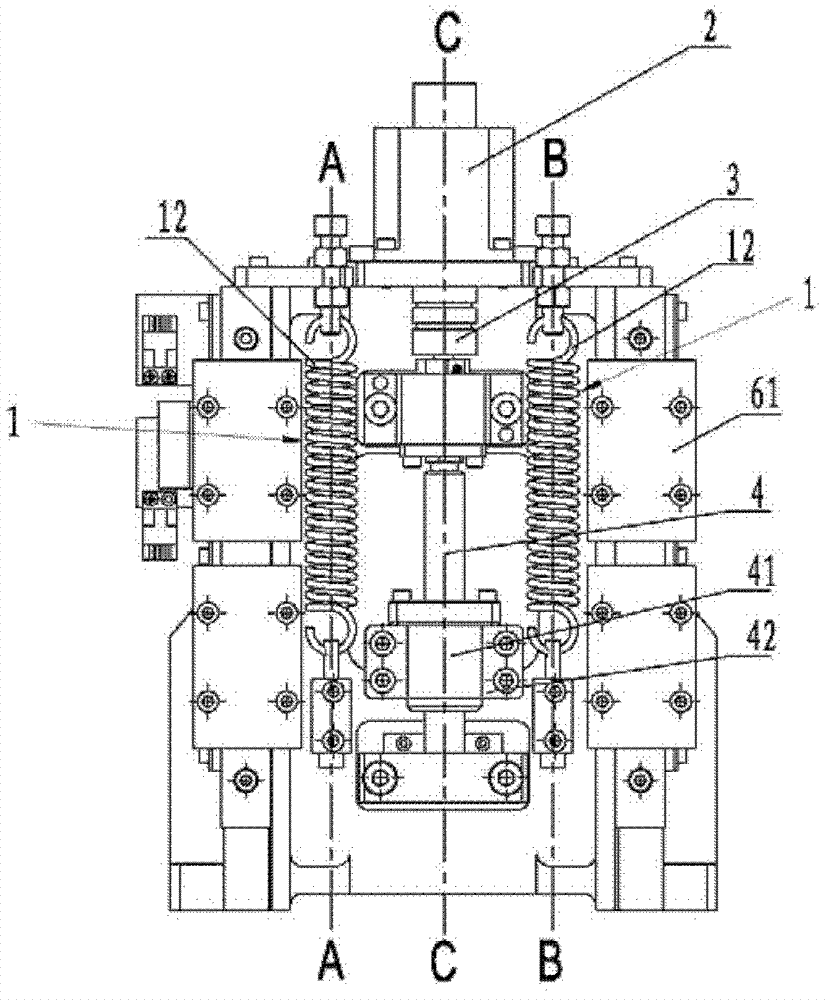

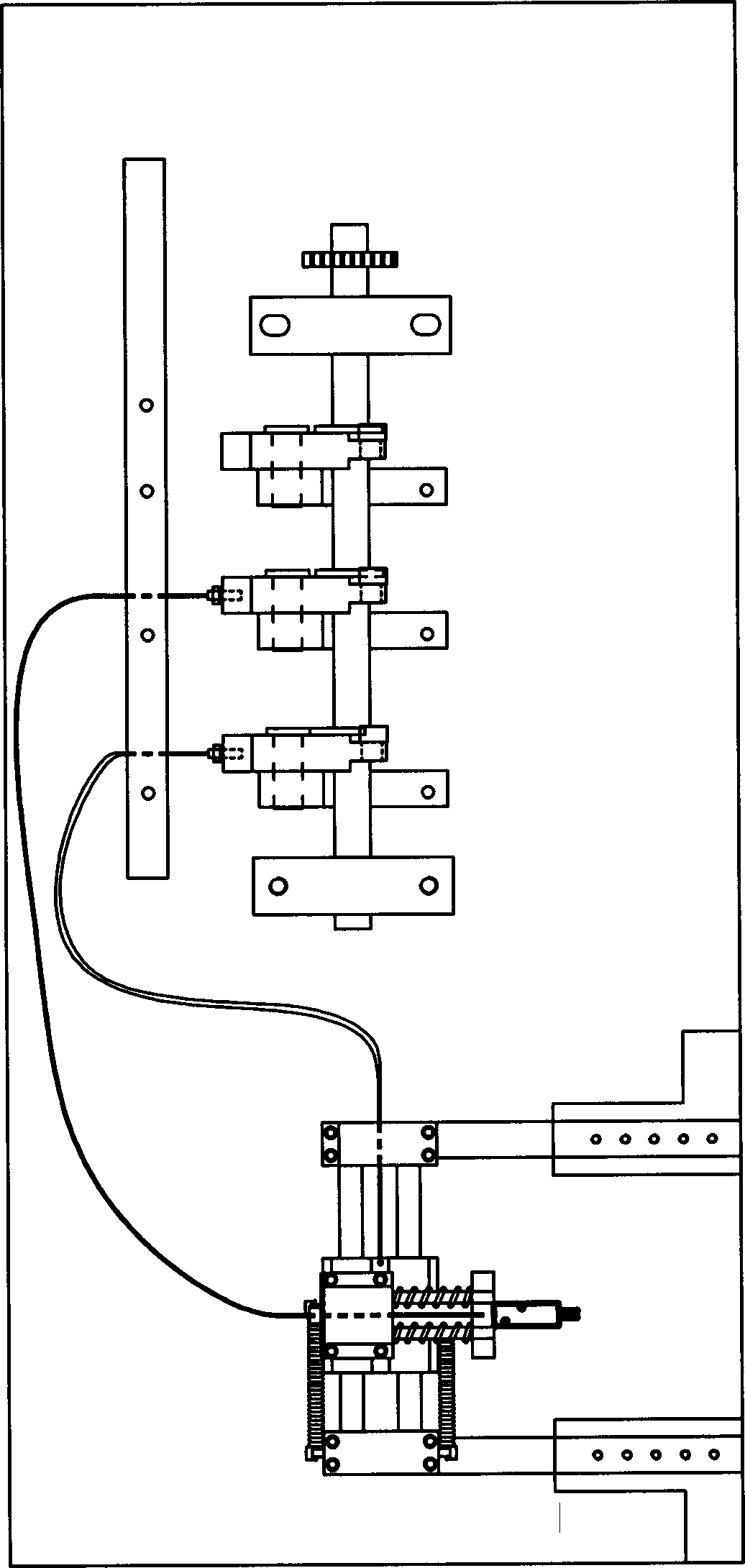

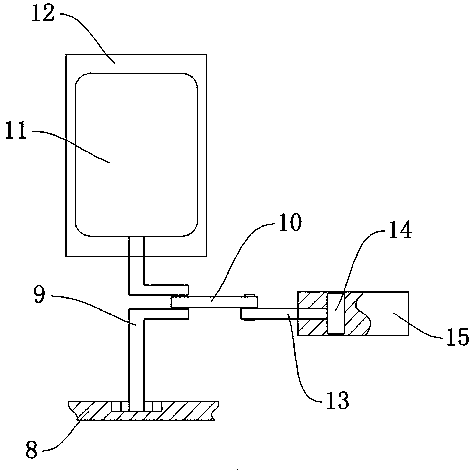

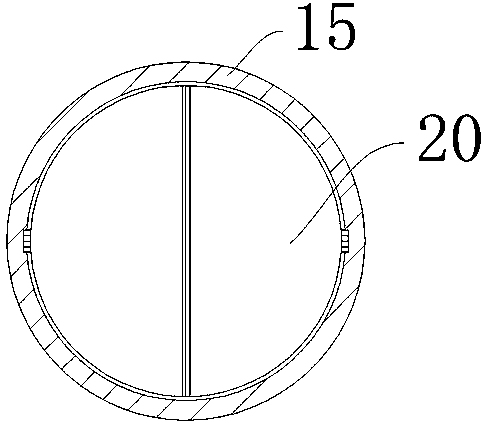

Coil processing machine and feeding method thereof

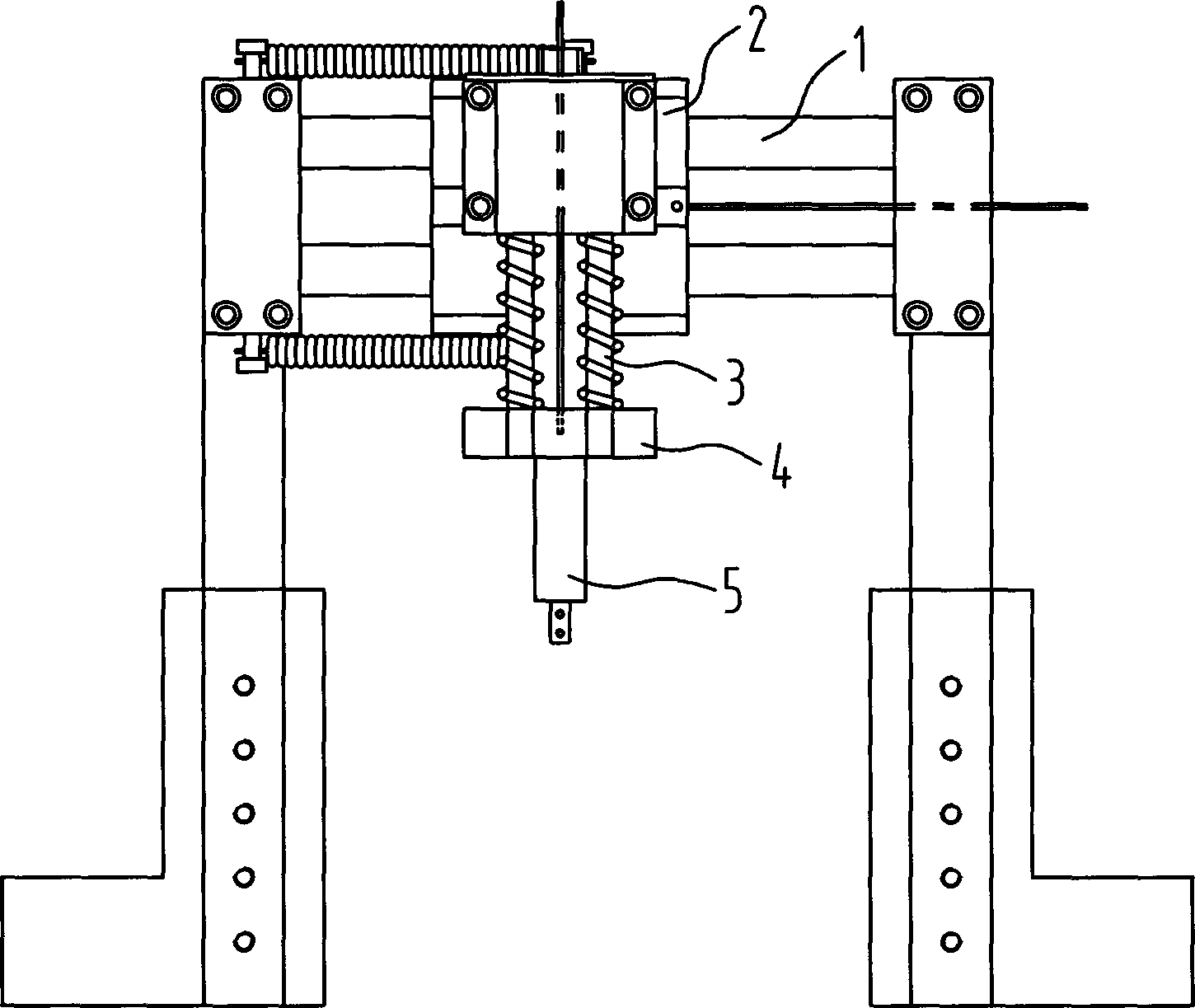

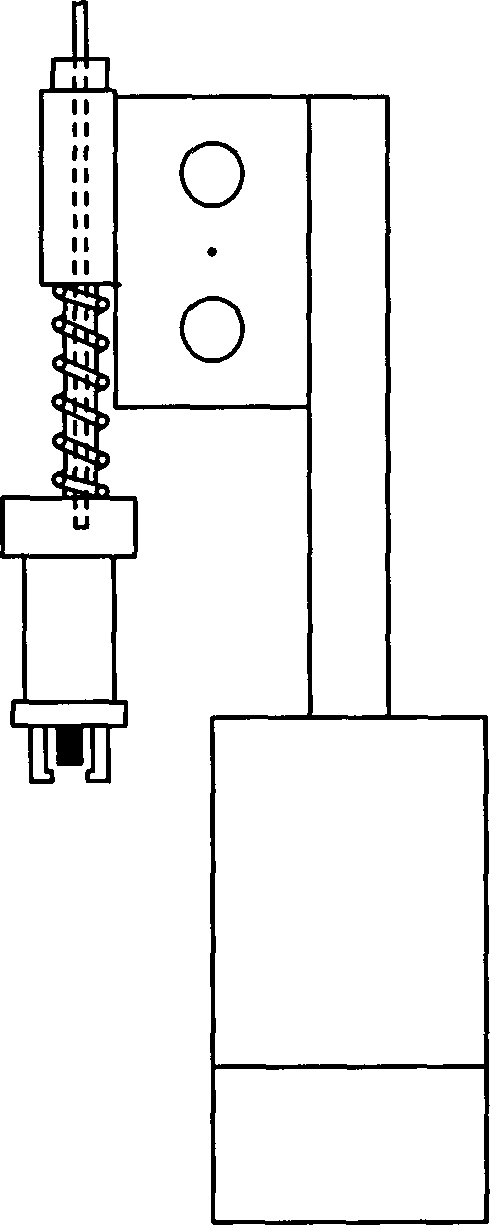

ActiveCN102738979BShort lateral movement distanceFast reciprocating motionManufacturing dynamo-electric machinesDrive wheelReciprocating motion

The invention discloses a coil processing machine and a feeding method thereof. The coil processing machine comprises a transfer manipulator; the transfer manipulator comprises left and right guide rails fixedly arranged on a processing machine body, left and right sliding blocks sliding along the left and right guide rails, upper and lower guide rails fixedly connected on the left and right sliding blocks, upper and lower sliding blocks sliding along the upper and lower guide rails and an air clamp fixedly connected with the upper and lower sliding blocks; the left and right sliding blocks are in drive connection with a left-and-right driving device; the upper and lower sliding blocks are in drive connection with an up-and-down driving device; and both the left-and-right driving device and the up-and-down driving device are formed by driving cams, driven wheels and steel wire ropes. The transfer manipulator of the coil processing machine has short transverse moving distance and high reciprocating speed, so that the transfer time of a semifinished product coil is greatly shortened and the production efficiency is improved. According to the coil processing machine, the driving cam I of the left-and-right driving device and the driving cam II of the up-and-down driving device are fixedly arranged on the same camshaft and share one power output device, so that the coil processing machine is simple in structure and low in cost.

Owner:昆山广辉精密五金有限公司

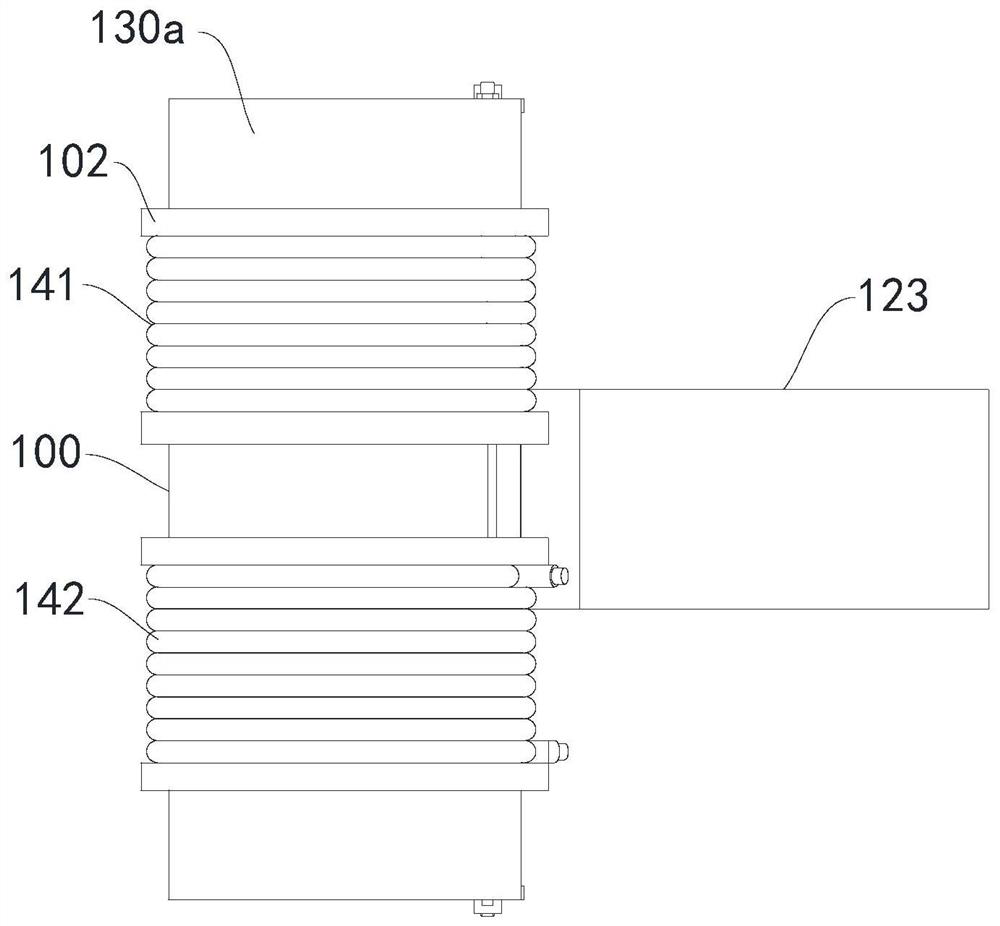

A Two-way Quick Action Large Flow Hydraulic Power Mechanism

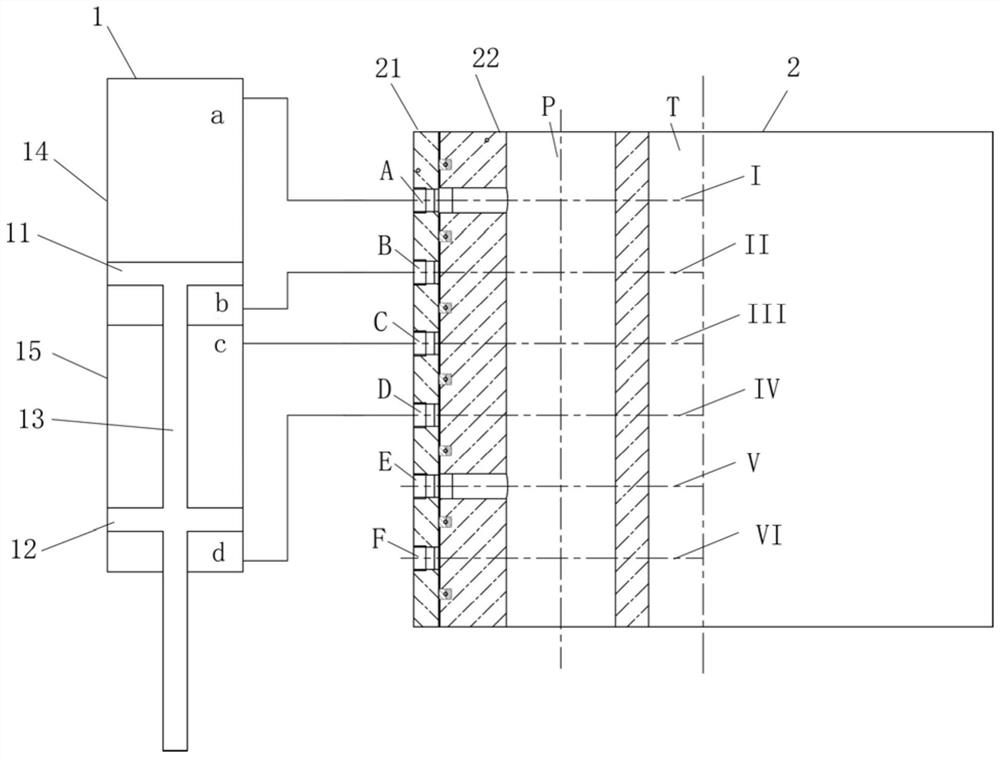

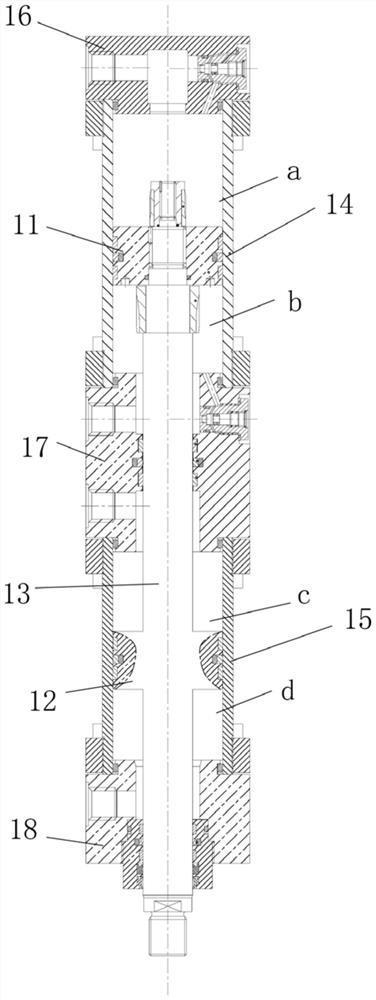

ActiveCN112983918BSimplify hydraulic control logicSimple structureServomotor componentsMultiple way valvesHydraulic cylinderReciprocating motion

The invention relates to a two-way quick-acting large-flow hydraulic power mechanism, which comprises an interconnected hydraulic actuator and a shaft distribution valve; the hydraulic actuator is a hydraulic cylinder with a double-piston structure, including a cylinder block, a front piston and a rear piston , the front piston and the rear piston are arranged on a piston rod, the cylinder body includes a front cylinder tube and a rear cylinder tube, the front piston is located in the front cylinder tube, and the front cylinder tube is divided into a first working chamber and a second working chamber, and the rear piston Located in the rear cylinder, the rear cylinder is divided into the third working chamber and the fourth working chamber; the shaft distribution valve includes the shaft distribution valve body stator and the shaft distribution valve core rotor, and the shaft distribution valve core rotor is provided with an oil supply channel and a return valve. The oil channel, the oil supply channel and the oil return channel are connected to the external pipeline, and the stator of the shaft distribution valve body and the rotor of the shaft distribution valve core are separated into four sealing areas by the sealing ring from top to bottom. Compared with the prior art, the present invention has the advantages of simplified hydraulic control logic, simple structure, convenient adjustment, convenient rapid reciprocating motion of the piston, and the like.

Owner:TONGJI UNIV

Gravel screening device for building

PendingCN113634494AFast reciprocating motionImprove practicalitySievingScreeningArchitectural engineeringStructural engineering

The invention relates to the technical field of building production, and discloses a gravel screening device for building. The gravel screening device for building comprises supporting seats, wherein two groups of the supporting seats are arranged, and filter screens are fixedly installed at the sides, close to each other, of the two sets of supporting seats. According to the invention, when a sliding block moves to the left end of a sliding groove, the sliding block is limited by the sliding groove to stop movement, at the moment, a swing block continues to rotate clockwise, a shifting block drives a rotating block to move on a fixed column, the bottom end of the shifting block is lifted, the shifting block crosses the upper end of a shovel along with clockwise movement of the swing block, and at the moment, a spring is pulled to contract to drive the moving block to move in a fixed block; when the moving block drives the shovel to move, the right side of the shovel drives gravels at the bottom sides in the supporting seats to move, the right side of the shovel enables the large-particle gravels to move away from the bottoms of the supporting seats along with the right side of the shovel, and the small-particle gravels fall to the upper ends of the supporting seats and are screened out from the supporting seats; and in this way, through continuous circulation, the small-particle gravels are screened from the supporting seats.

Owner:陈远玲

Grouting equipment used for manufacturing of cement prefabricated components

InactiveCN109702860ASimple movement structureReasonable designCeramic shaping apparatusReciprocating motionDrive shaft

The invention discloses grouting equipment used for manufacturing of cement prefabricated components. The grouting equipment comprises wheels, an engine case, a motor and a chassis; driving shafts arearranged between the wheels; the rear sides of the wheels are provided with a wheel rack; the chassis is arranged on the wheel rack; the engine case is arranged on the chassis; the base is arranged on the engine case; the motor is arranged on the base; a support is arranged on one side of the motor; a handle is arranged on the support; a crank is arranged on the front side of the motor; a rockingrod is arranged on one side of the crank; a piston rod is arranged on one side of the rocking rod; a piston is arranged on one side of the piston rod; a piston material cylinder is arranged on the outer side of the piston; and a protection cover is arranged on the piston material cylinder. The grouting equipment has the beneficial effects that a connection rod mechanism is adopted, and the pistonmoving structure is simple, so that design is reasonable; piston movement is continuous, and reciprocating movement is rapid, so that the intermittent time for grouting is extremely short; and the working efficiency is high.

Owner:广州全系新材料股份有限公司

Pneumatic oil hydraulic pump

PendingCN110345037ASmooth switchingFast reciprocating motionPositive displacement pump componentsPiston pumpsReciprocating motionHydraulic pump

The invention discloses a pneumatic oil hydraulic pump which comprises a pump body, an actuating assembly, an oil circuit system and a gas path system. The actuating assembly comprises an actuating rod, a main piston and a reset spring; the main piston is fixedly arranged on the actuating rod in a sleeving way; the reset spring is connected with the main piston and is arranged outside the actuating rod in a sleeving way; the oil circuit system comprises an oil chamber; an oil inlet and an oil outlet are connected onto the oil chamber; a first one-way valve is arranged on the oil inlet; a second one-way valve is arranged on the oil outlet; the lower end of the actuating rod stretches into the oil chamber; and the gas path system comprises a piston chamber, a switching shaft cylinder, a gasinlet hole, a switching gas hole and an auxiliary gas outlet hole. The pneumatic oil hydraulic pump provided by the invention is simple and reasonable in structure; and the switching shaft cylinder can smoothly switch a gas path, so that the actuating rod quickly moves in a reciprocating way, the reaction speed is fast, oil supply can be continuously and stably realized, the oil pressure is stable, meanwhile, a good pressurizing effect can be achieved, and ultrahigh hydraulic pressure is provided.

Owner:山田顺精密机械(苏州)有限公司

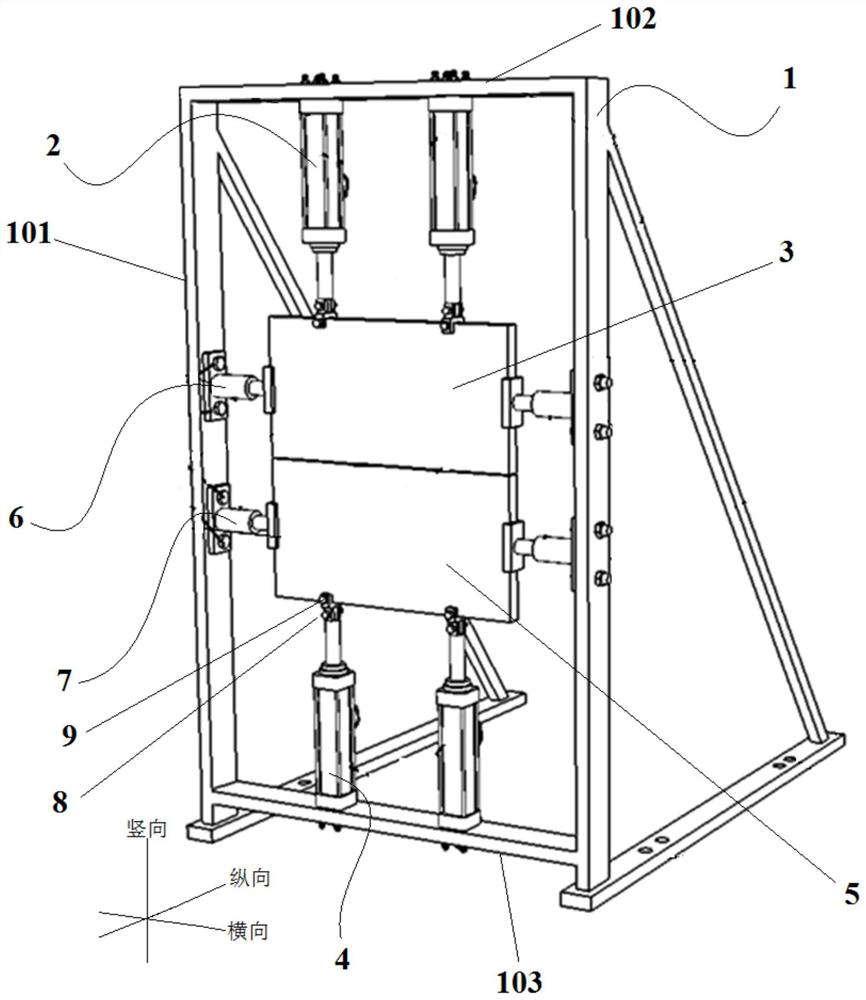

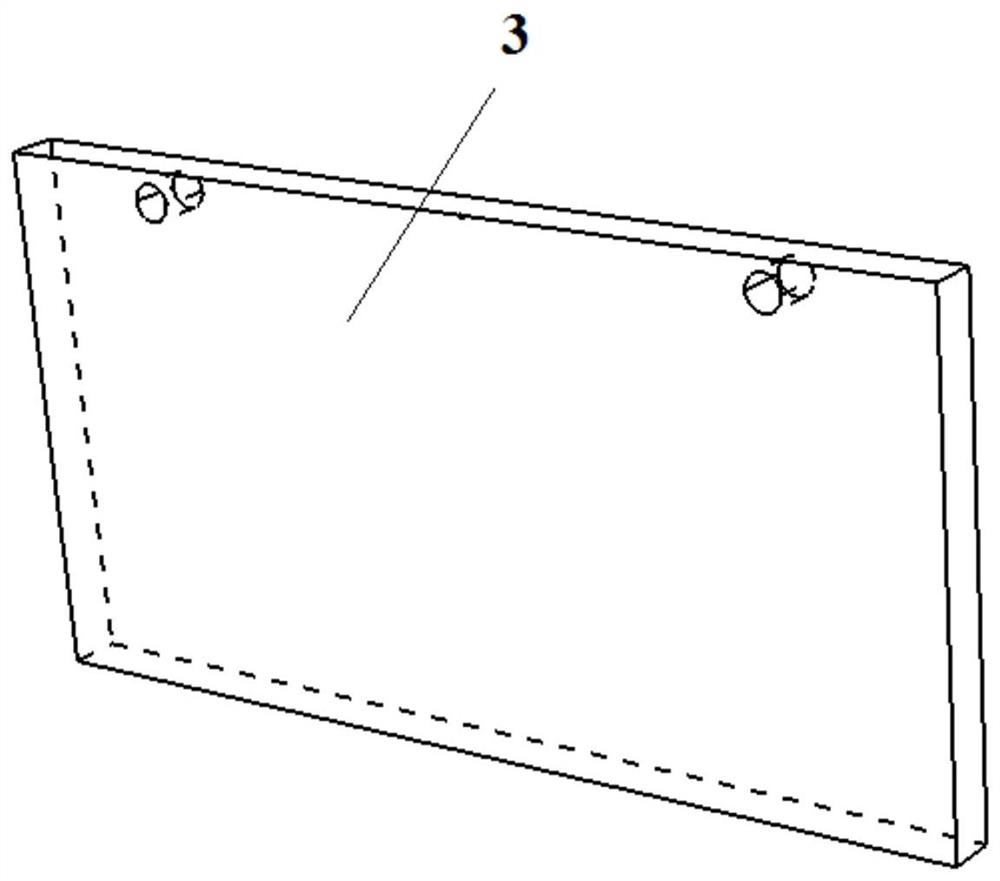

Rapid shielding protection device

PendingCN112730036AGuaranteed collectionRealize the direct shooting viewStrength propertiesEngineeringMechanical engineering

The invention provides a rapid shielding protection device which comprises a supporting frame, an upper transmission telescopic rod is arranged on an upper cross beam inwards in the vertical direction, the upper end of the upper transmission telescopic rod is fixed to the upper cross beam, and the lower end of the upper transmission telescopic rod is installed on the upper side of an upper shielding plate. A lower transmission telescopic rod is inwards arranged below the lower cross beam in the vertical direction, the lower end of the lower transmission telescopic rod is fixed to the lower cross beam, and the lower end of the lower transmission telescopic rod is installed on the lower side of the lower shielding plate; the lower side of the upper shielding plate and the upper side of the lower shielding plate are arranged in an aligned mode, and the upper shielding plate and the lower shielding plate form a shielding protection plate capable of being opened and closed in the vertical direction. According to the invention, the protection of the back-to-hand shooting camera in the fragment / projectile impact target plate test can be completed within milliseconds, the dynamic image information acquisition in the petal crevasse forming process is ensured, and the direct shooting observation of the back-to-back damage process in the fragment / projectile penetration target plate process is well realized.

Owner:XIAN MODERN CHEM RES INST

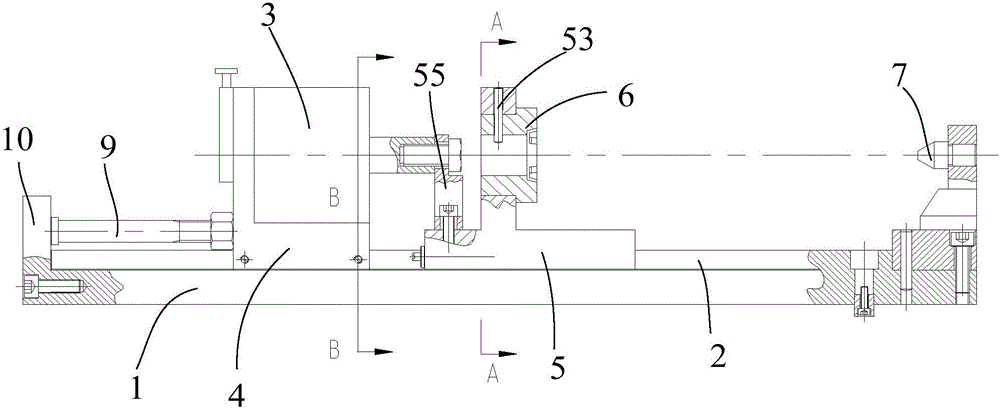

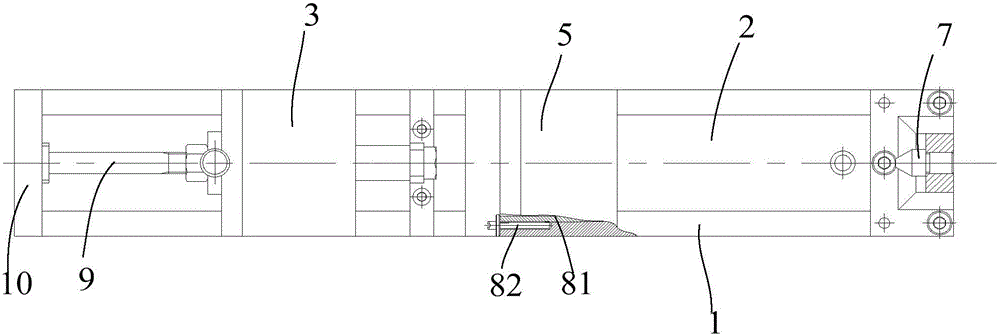

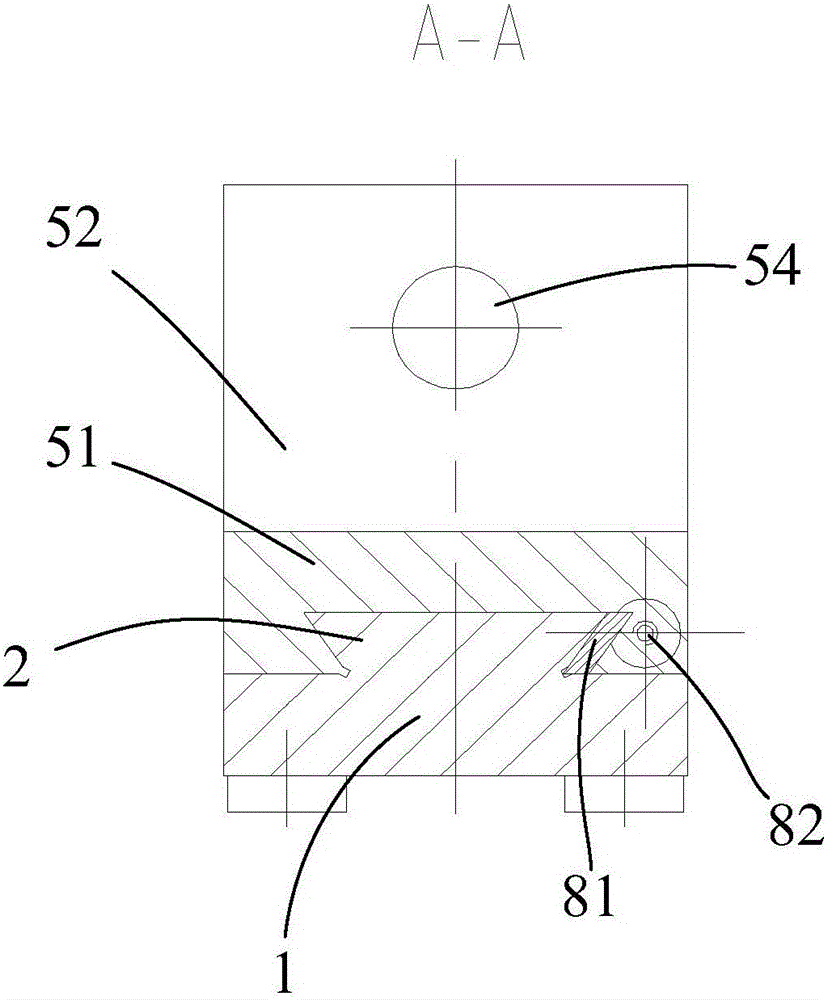

Shock absorber bottom cylinder processing tooling

InactiveCN104440319BAvoid offsetPrevent slidingWork clamping meansPositioning apparatusEngineeringMachining process

The invention provides a shock absorber bottom cylinder processing tooling. The shock absorber bottom cylinder processing tooling comprises a base, wherein a propelling mechanism is mounted at the first end of the base; an ejector pin is mounted at the second end of the base; a guide rail is arranged on the base between the propelling mechanism and the ejector pin; a sliding base is mounted on the guide rail and is connected with the propelling mechanism; the propelling mechanism can be used for pushing the sliding base and the ejector pin to be close to each other or far from each other; a positioning tooth disk is mounted on the sliding base; the center of the positioning tooth disk directly faces the center of the ejector pin. According to the shock absorber bottom cylinder processing tooling, an cylinder acts quickly; the condition that the clamping force is not enough is avoided; the positioning tooth disk can be used for avoiding the deflection of a cylinder body caused by uneven stress in the processing process; an inlay bar adjusting structure is additionally arranged, so that the abrasion of a guide rail and a dovetail groove can be modified; the clamping stagnation of the sliding base in the moving process is avoided; the great shaking is avoided; the quality of products is ensured; the labor intensity is alleviated; the production efficiency is improved; the cost is reduced.

Owner:安徽库里南实业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com