Electro-deposition metal stripping device and method

A stripping device and electrodeposition technology, applied in the electrolysis process, electrolysis components, etc., can solve the problems that the stripping knife cannot be closed automatically, and the fast reciprocating movement of the stripping knife cannot be realized, so as to achieve the effect of fast reciprocating movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

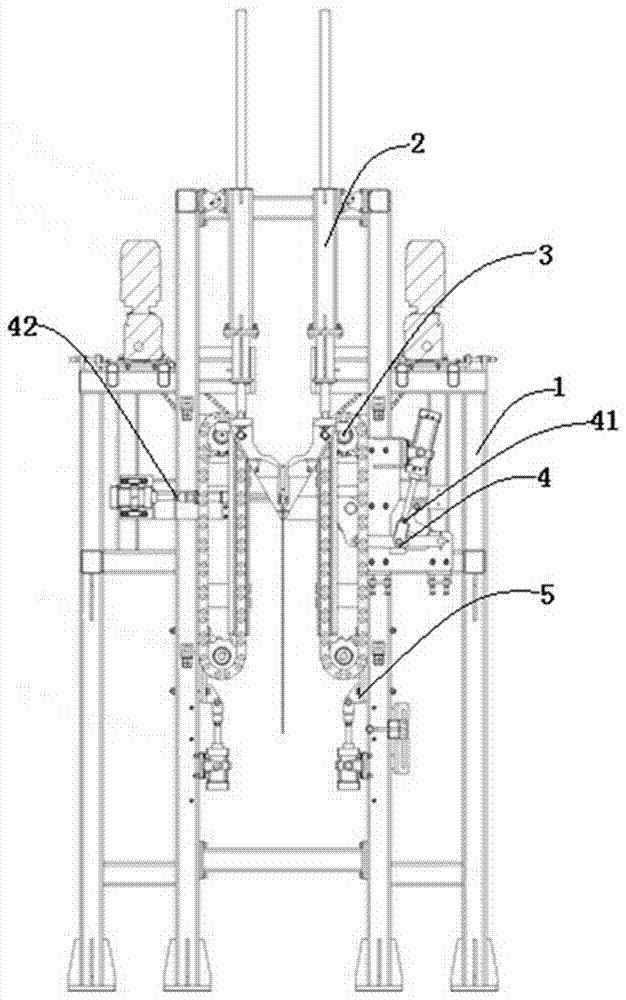

[0036] Such as figure 1 As shown, a stripping device for electrodeposited metal includes a frame 1, a stripping knife part 2 and a driving part 3; the frame 1 is a frame split structure, and is in the form of a left-right symmetrical independent frame;

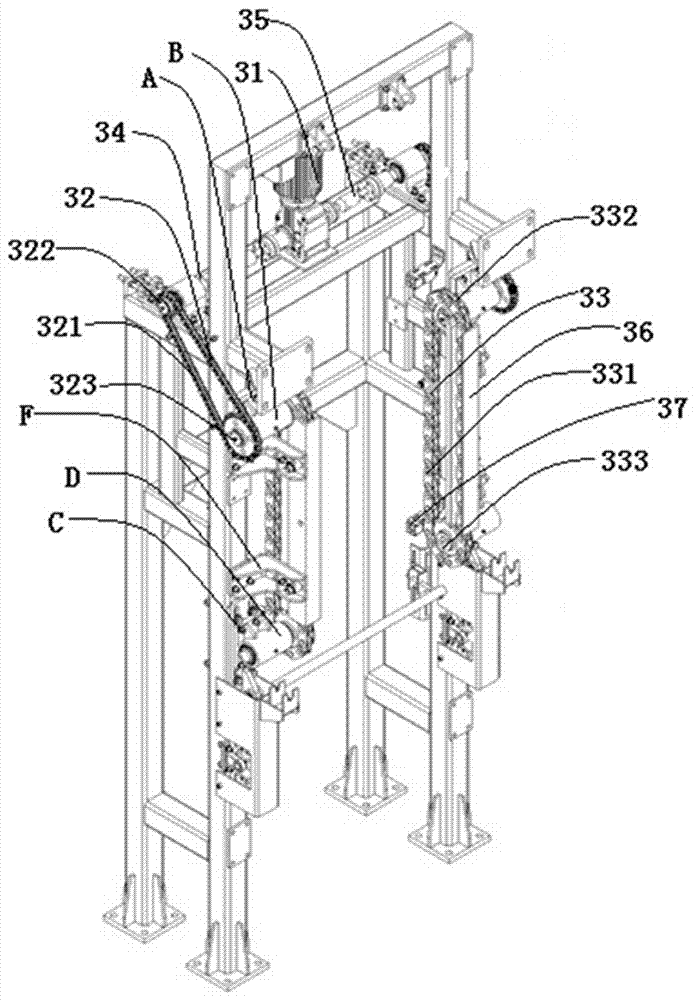

[0037] Such as figure 2 As shown, the driving part 3 includes a power source, a transmission mechanism 32 and a guide mechanism 33 that are arranged on both sides of the frame with the same structure to realize the reciprocating movement of the stripping knife. The power source is a reduction motor 31; 321 connected small sprocket 322 and large sprocket 323, guide mechanism 33 includes driving wheel 332 and driven wheel 333 connected by guide chain 331; small sprocket 322 is connected with power source 31 by power shaft 34, large sprocket 323 and The driving wheels 332 are connected by the transmission shaft B arranged on the mounting seat A, the driven wheel 333 is connected with the transmission shaft 2D, and the transmiss...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com