Gravel screening device for building

A screening device, a technology for construction, applied in sieves, solid separation, chemical instruments and methods, etc., can solve problems such as affecting the efficiency of sand production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

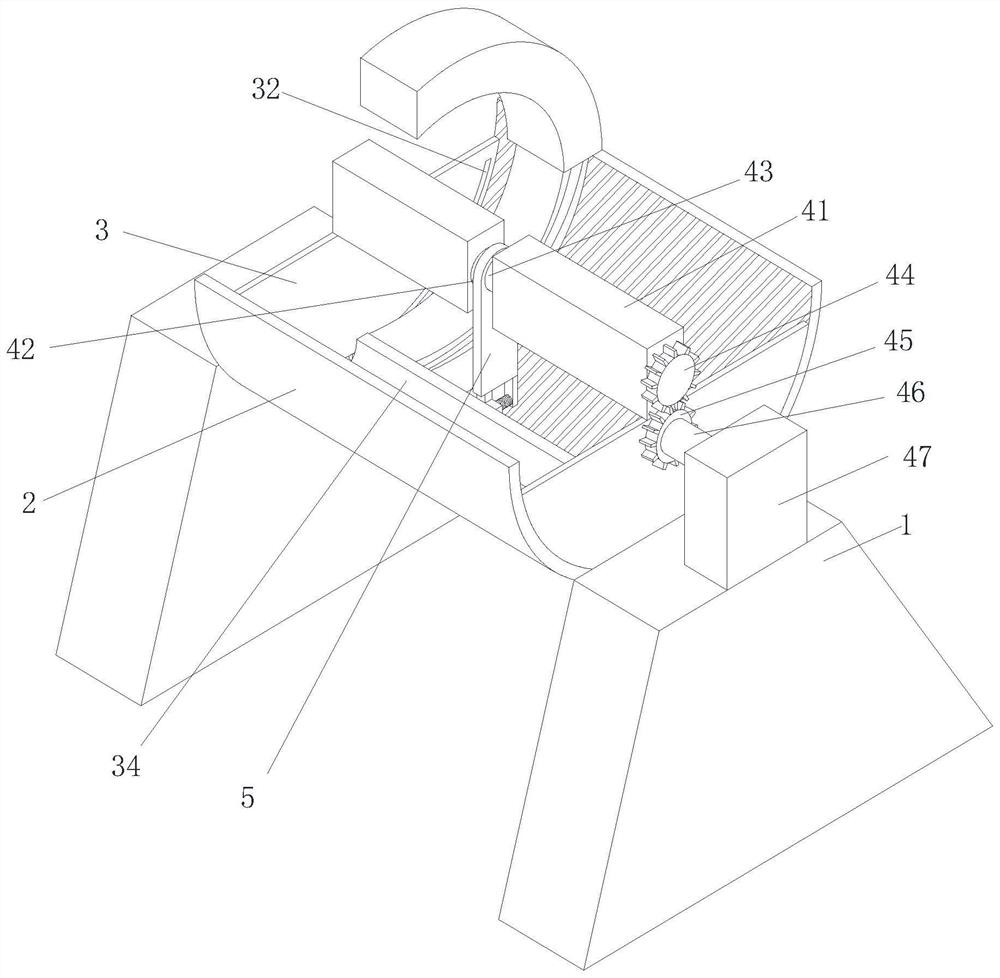

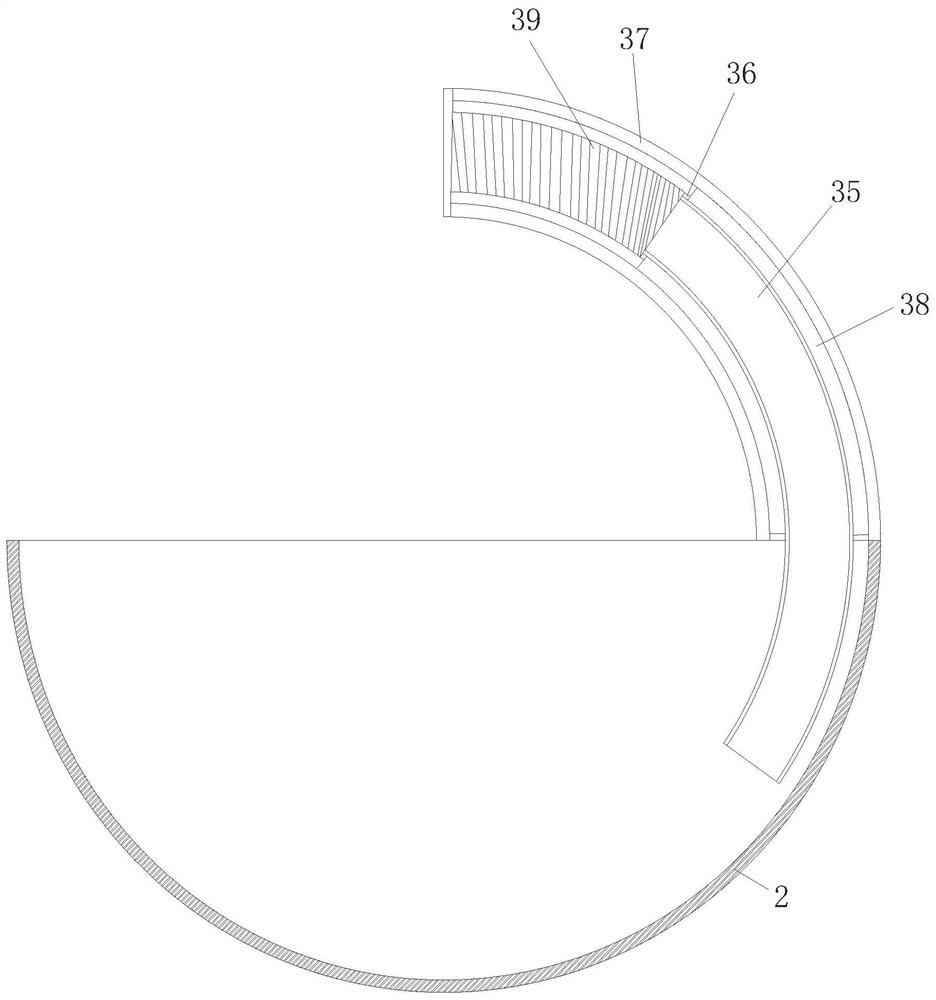

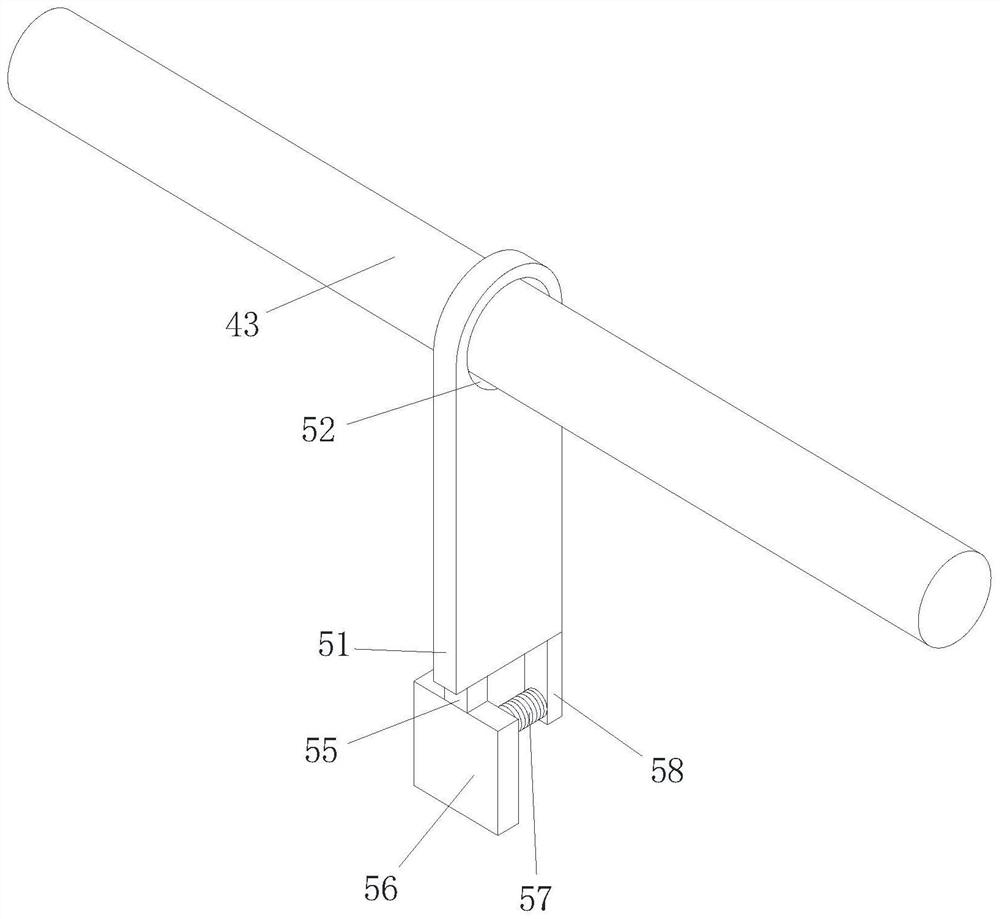

[0031] Embodiment: a kind of sand and gravel screening device for construction, such as Figure 1-Figure 5 As shown, there are two sets of support bases 1, the support bases 1 are trapezoidal blocks, and the sides of the two sets of support bases 1 close to each other are fixed with filter screens 2, and the filter screens 2 are arc-shaped block, the upper end of the filter screen 2 is provided with a sliding device 3, the sliding device 3 includes baffles 31, there are two groups of baffles 31, the baffles 31 are arc-shaped blocks, and the two groups of baffles 31 are on the support base 1 The front and rear sides of the upper end are mirror images, and the upper ends of the two groups of baffle plates 31 are provided with a transmission device 4. The transmission device 4 includes a support block 41. There are two groups of support blocks 41. The support block 41 is a rectangular block. The bottom end of the block 41 is fixedly installed with the upper end of the baffle plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com