Patents

Literature

157results about How to "Save time in transit" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

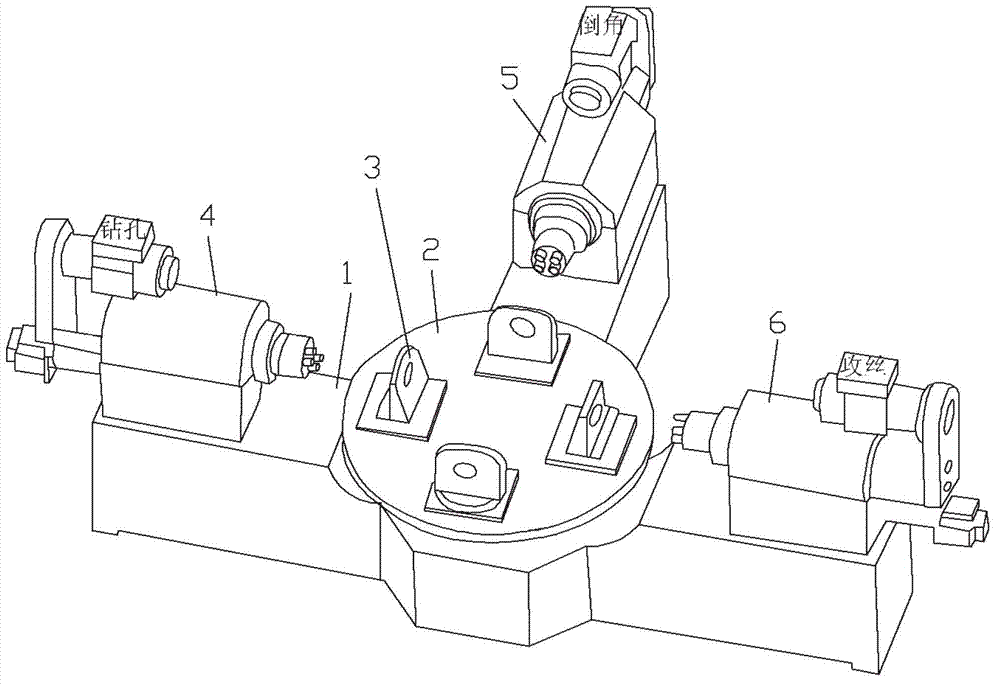

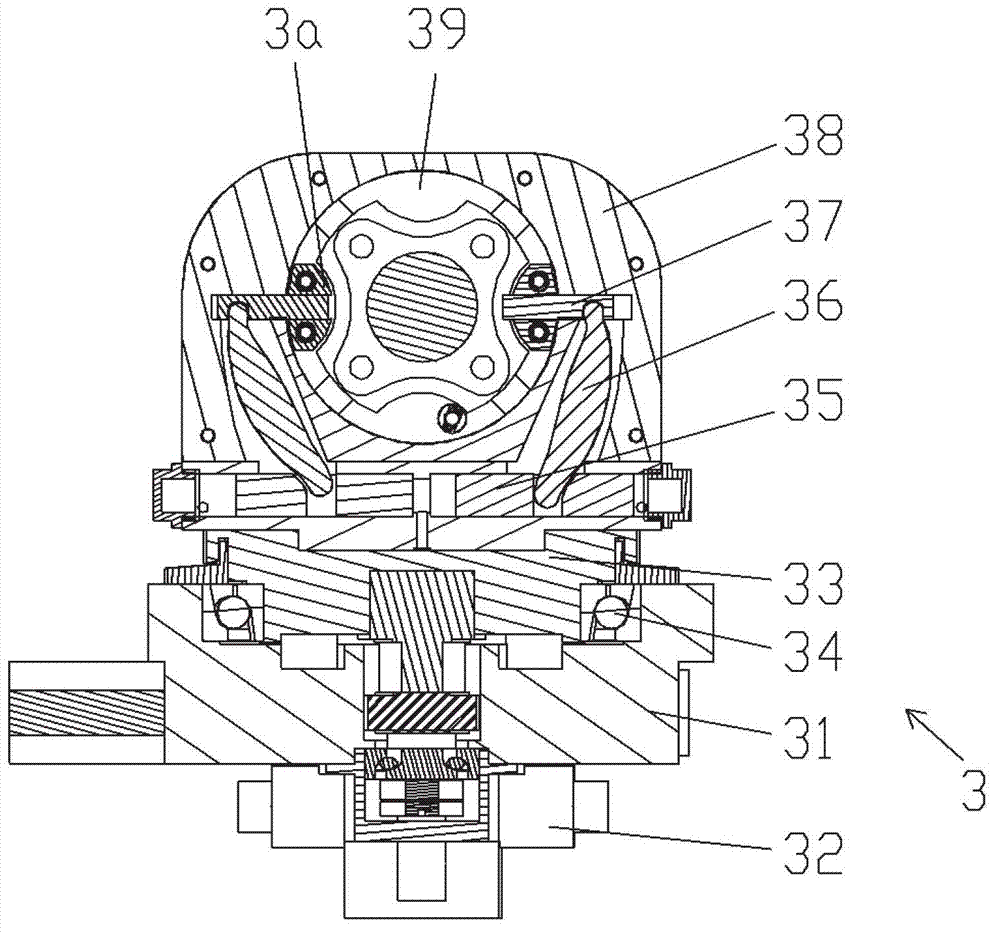

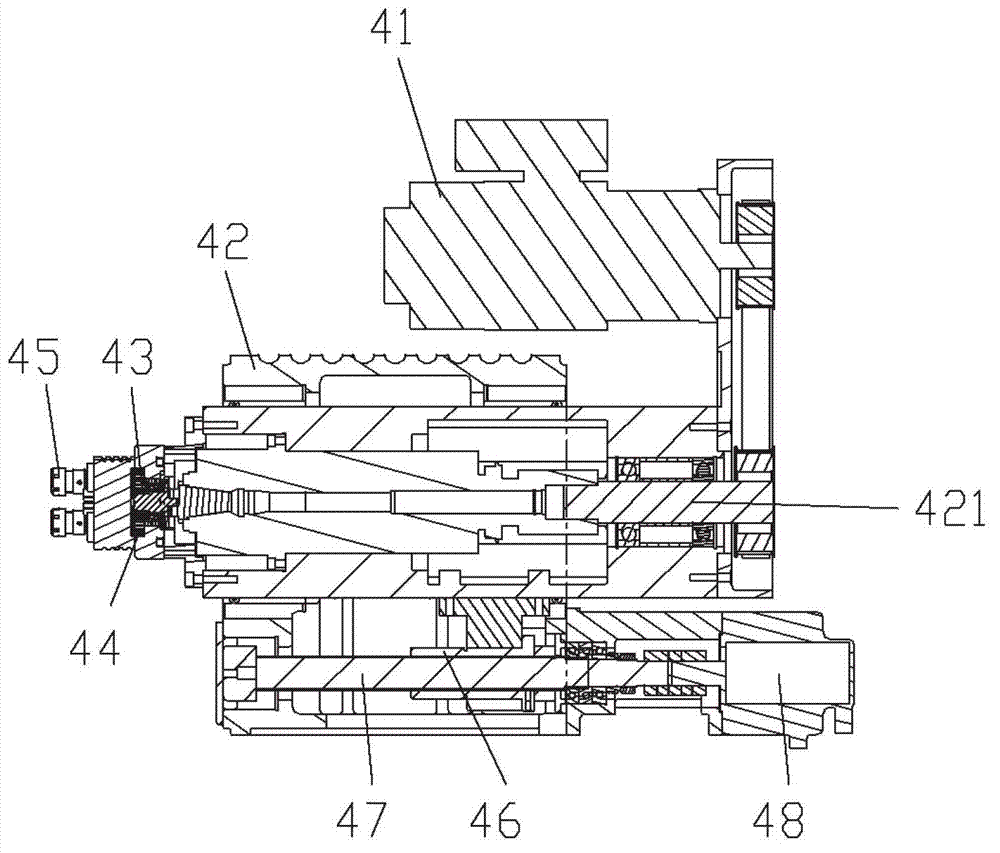

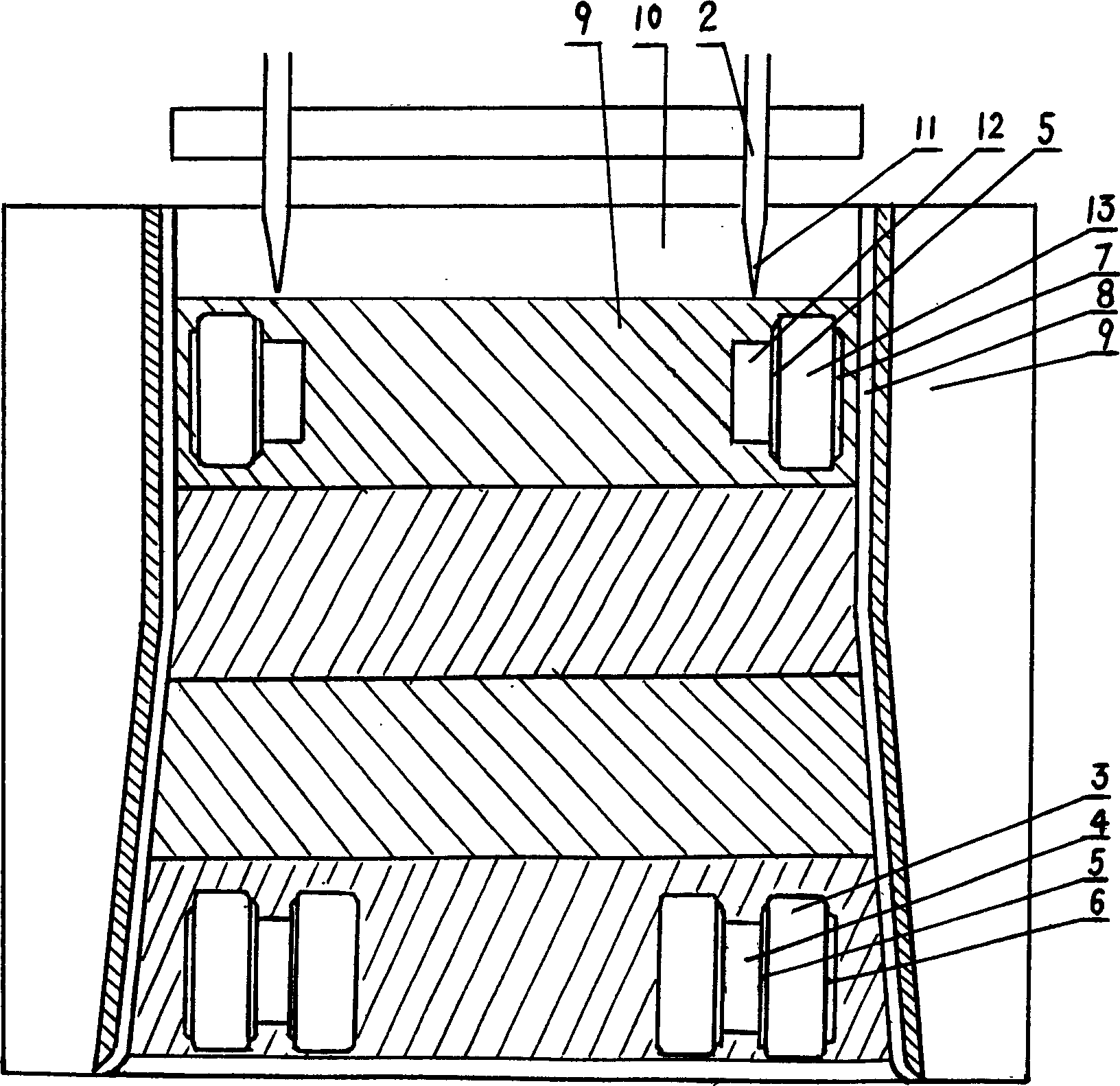

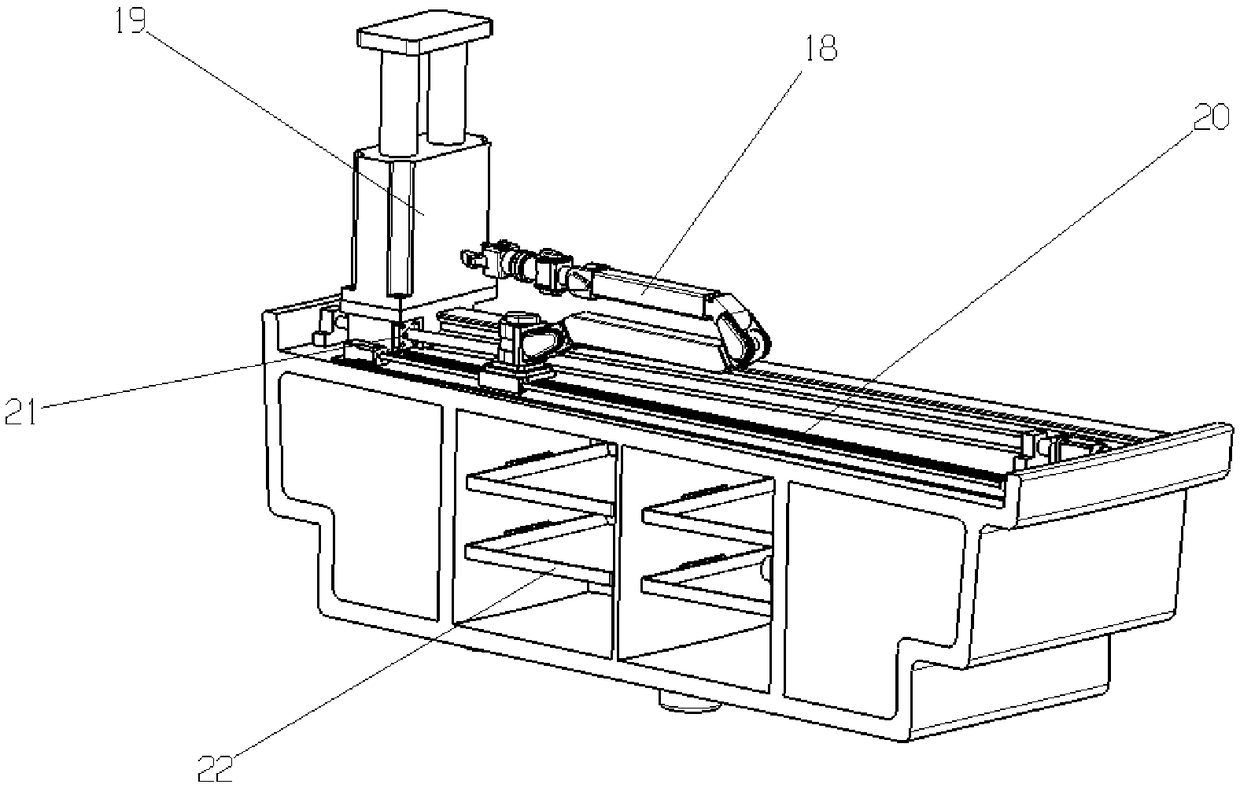

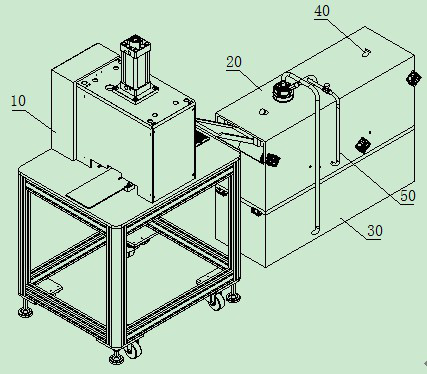

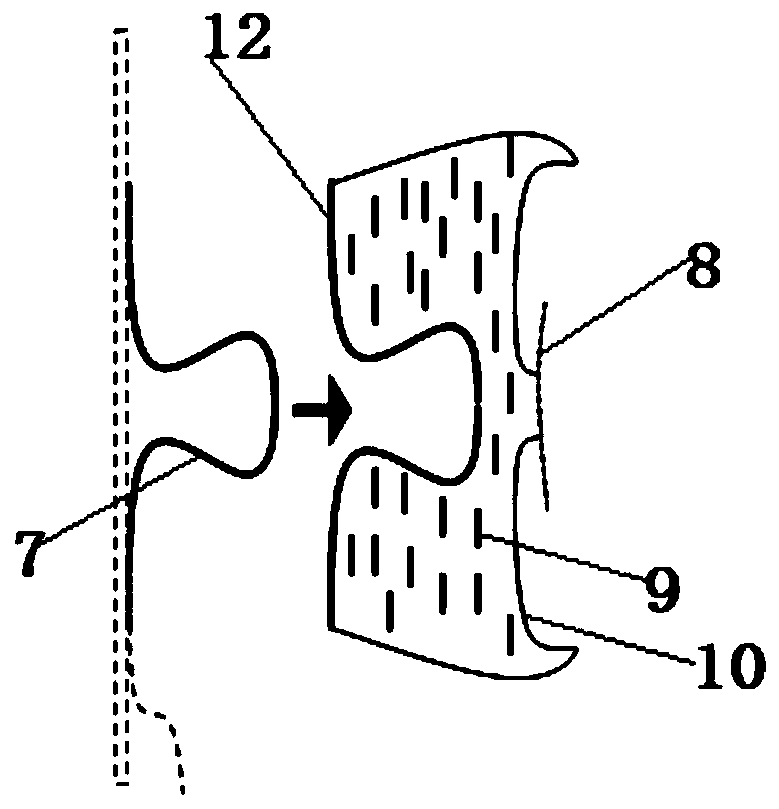

Special machine tool for machining hub bearing shells

ActiveCN102922287ASave time in transitImprove work efficiencyFeeding apparatusOther manufacturing equipments/toolsEngineeringMachining process

The invention discloses a special machine tool for machining hub bearing shells, which is provided with a turntable and a workpiece holder, wherein the turntable rotates the workpiece holder to different working positions, a hub bearing shell is clamped on the workpiece holder through a workpiece clamping lever, a drilling device carries out drilling on the workpiece holder, a chamfering device carries out chamfering on the workpiece holder, and a tapping device carries out tapping on the workpiece holder, so that by using the machine tool, three machining processes of drilling, chamfering and tapping of the hub bearing shell are completed once on a device, thereby improving the working efficiency and reducing the machining cost.

Owner:浙江文源智能科技有限公司

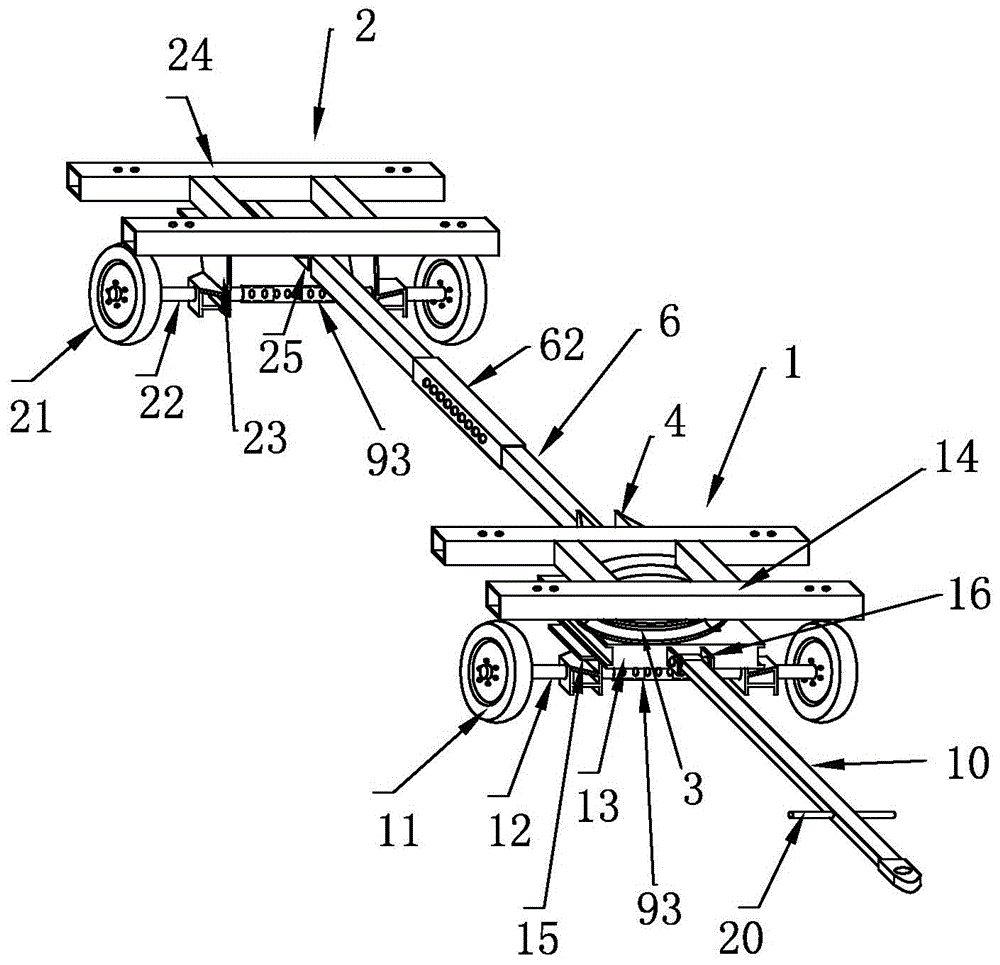

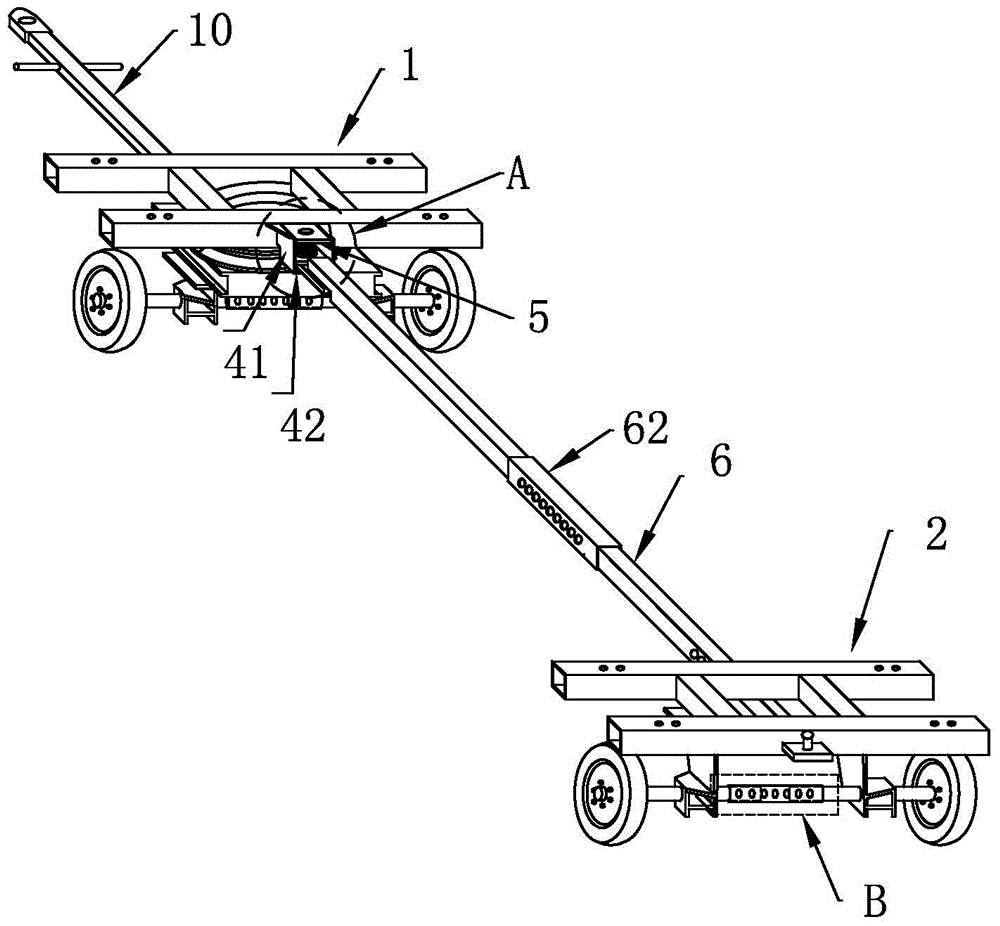

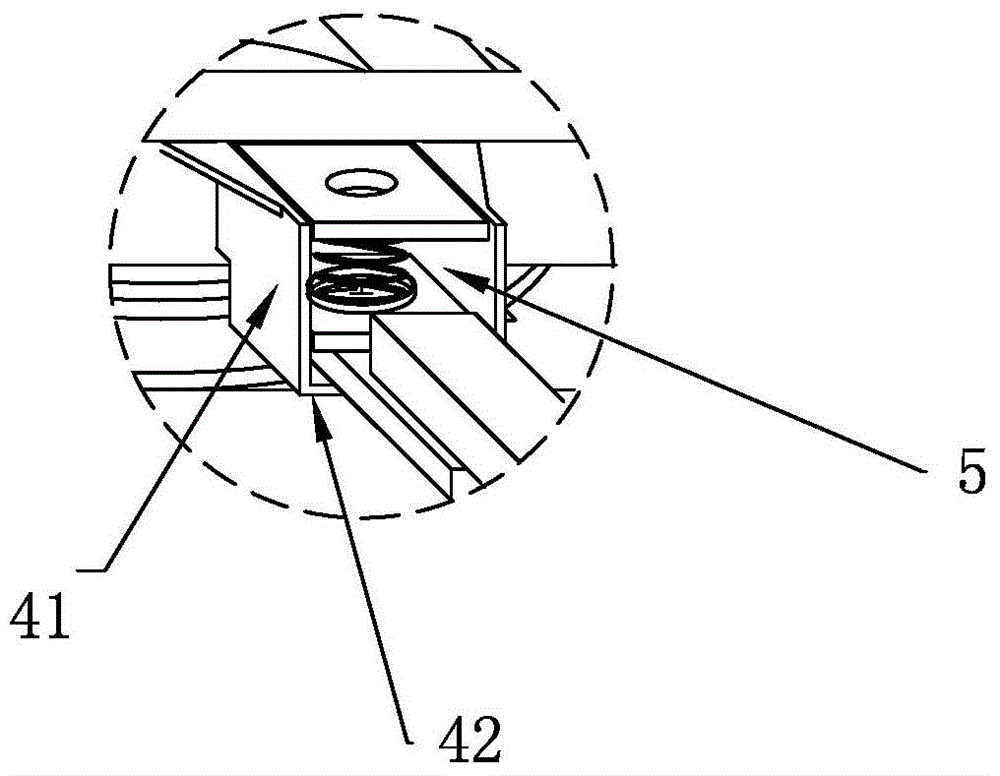

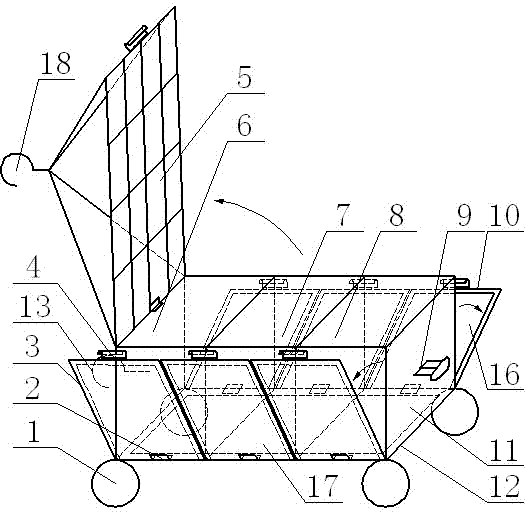

Multifunctional circulation transport cart

ActiveCN104863375AShorten the progressEasy to stackBuilding material handlingBasementSupporting system

Provided is a multifunctional circulation transport cart. The multifunctional circulation transport cart can perform towing in a narrow formwork support system space in the early-stage wall column or formwork removal process in underground structure construction and also can rapidly classify circulation materials and rapidly tow the circulation materials to a discharging port so that the circulation materials can be transferred out by a tower crane in large-scale formwork removal. The multifunctional circulation transport cart comprises a front wheel assembly and a rear wheel assembly, and the front wheel assembly and the rear wheel assembly are connected together through a length-adjustable positioning frame. By the adoption of the spliced adjustable structure, the front wheel assembly, the rear wheel assembly separated from the front wheel assembly, a front frame and a rear frame separated from the front frame form the transport cart of which the size and width are suitable for the narrow space in early-stage formwork removal of a construction engineering basement. The transport cart can play a great role in construction of the construction engineering underground structure or material clearing, transfer the circulation materials and construction materials in or out more rapidly compared with a traditional method, greatly shorten the time for transferring the circulation materials and the construction materials in basement construction, accelerate the progress of the whole basement engineering, lower the construction cost and improve the construction efficiency.

Owner:王英春

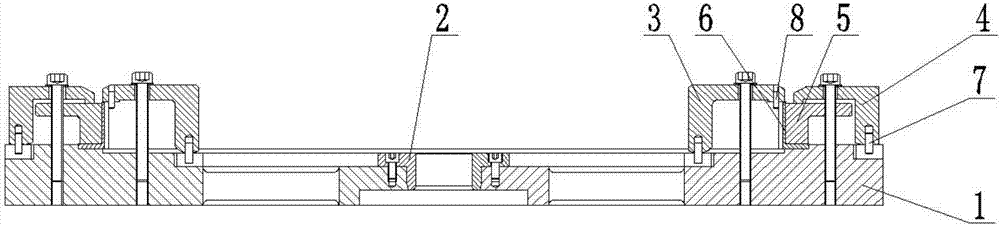

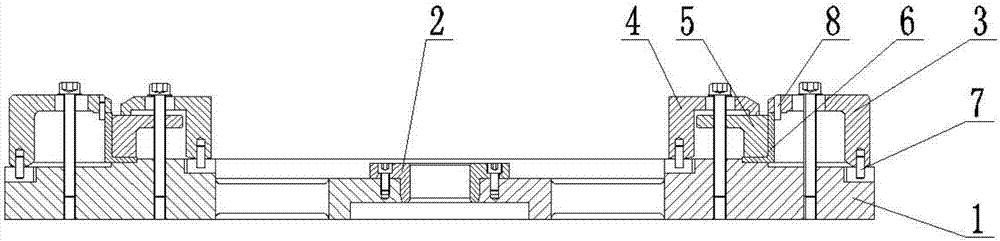

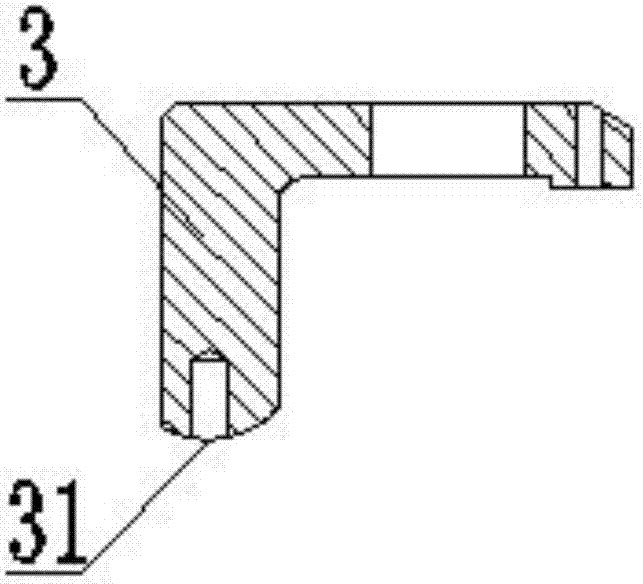

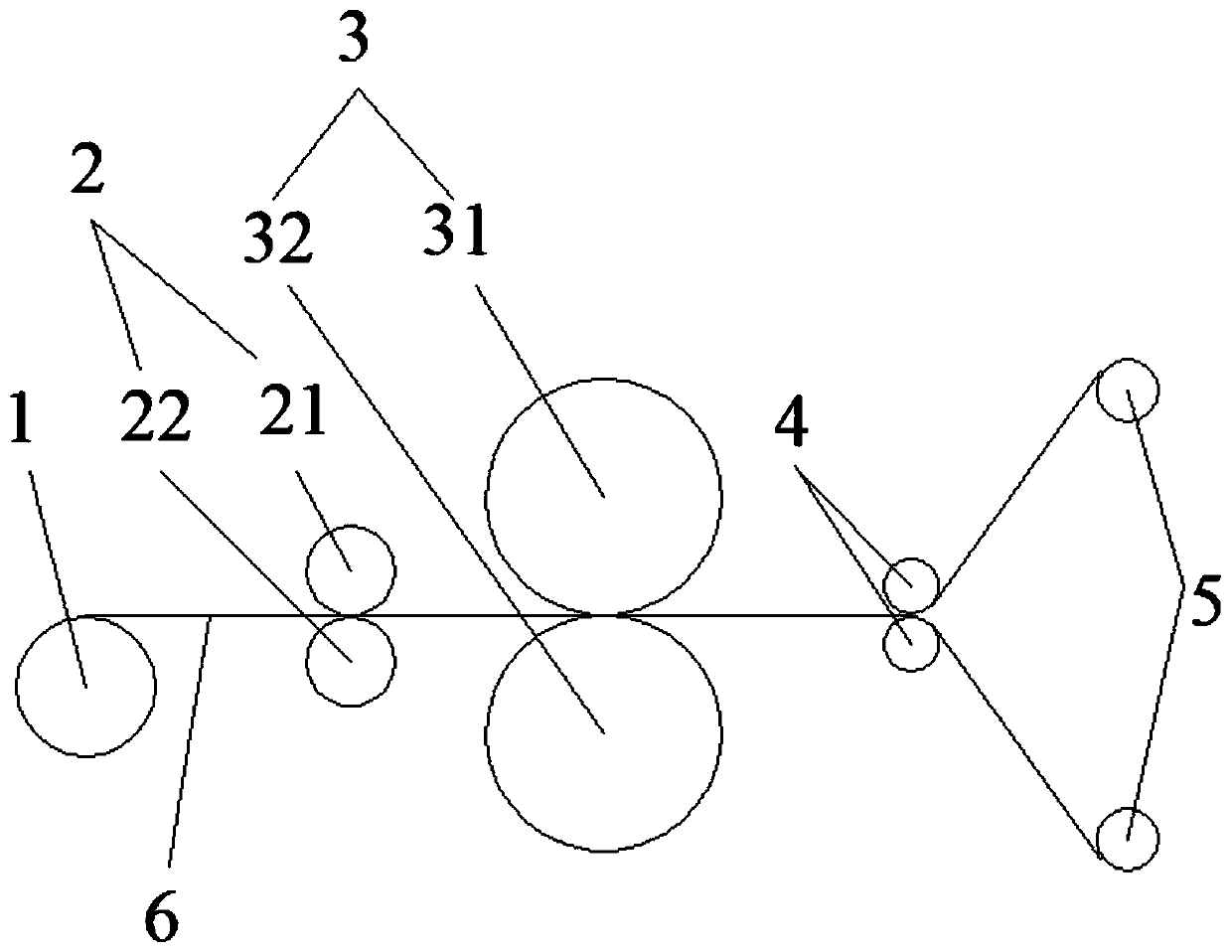

Fixture for L-shaped thin-wall annular part and machining method

InactiveCN107263176AReduce processing stepsReduce time for workpiece transferPositioning apparatusMetal-working holdersEngineeringMachine tool

The invention relates to a fixture for an L-shaped thin-wall annular part and a machining method. The fixture comprises a fixture body, a positioning sleeve, a pressing plate A, a pressing plate B and a pressing sleeve. The positioning sleeve is connected with the center of the fixture body and also connected with a machine tool spindle. The lower end face of the L-shaped thin-wall annular part is flush with the end face of the fixture body. The pressing plate A and the pressing plate B are positioned to the end face of the fixture body through pins and connected with the fixture body through bolts. The upper end face of the L-shaped thin-wall annular part is flatly pressed through the pressing plate A, and the pressing sleeve is flatly pressed on the step face of the L-shaped thin-wall annular part through the pressing plate B. By using the technical scheme provided by the invention, the part is clamped through the fixture and the two pressing plates in sequence, the machining procedures are decreased, and the part transfer time is shortened; and quick positioning and alignment are achieved during clamping of the part, the part rigidity is improved, the wall thickness of the part is machined to be more uniform, the machining precision and the product quality are improved, the production cost is reduced, and the production efficiency is improved.

Owner:GUIZHOU LIYANG INT MFG

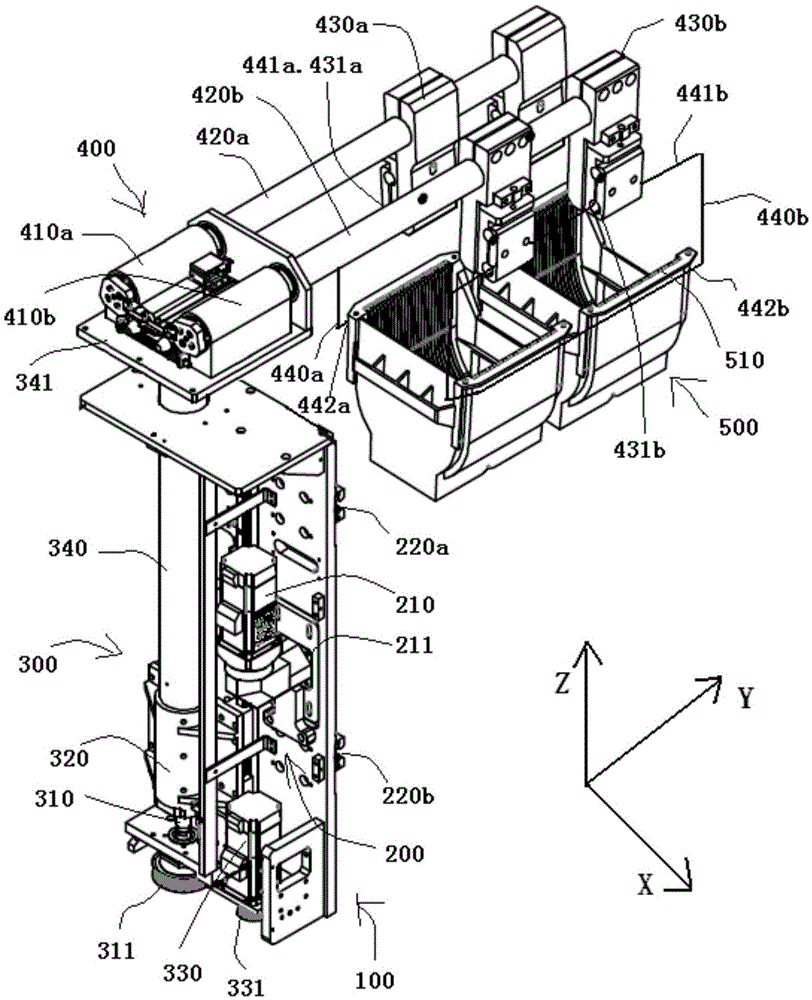

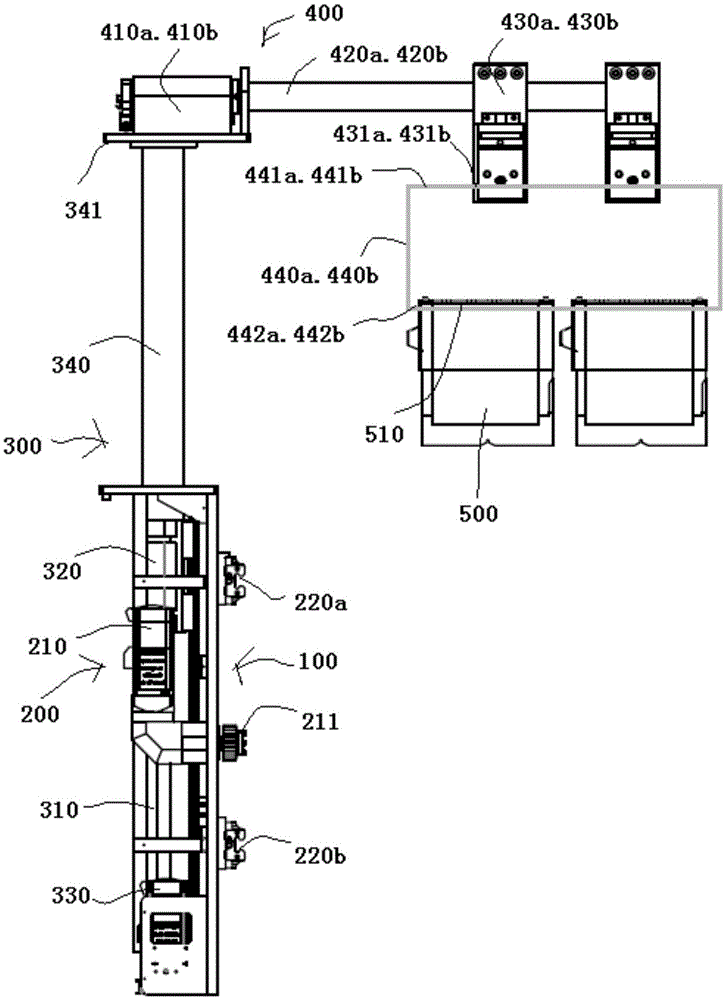

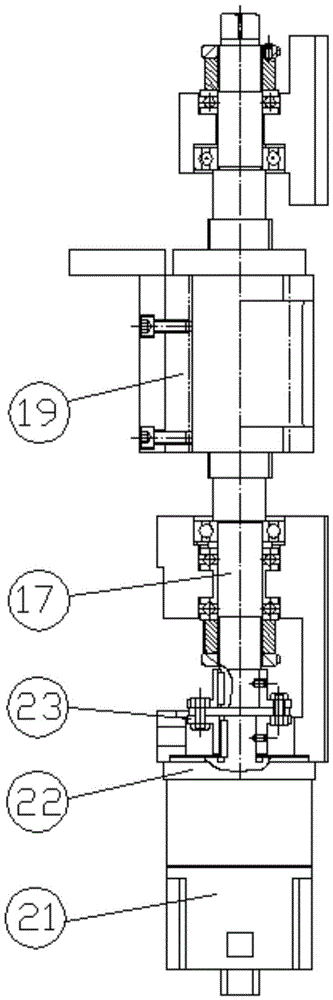

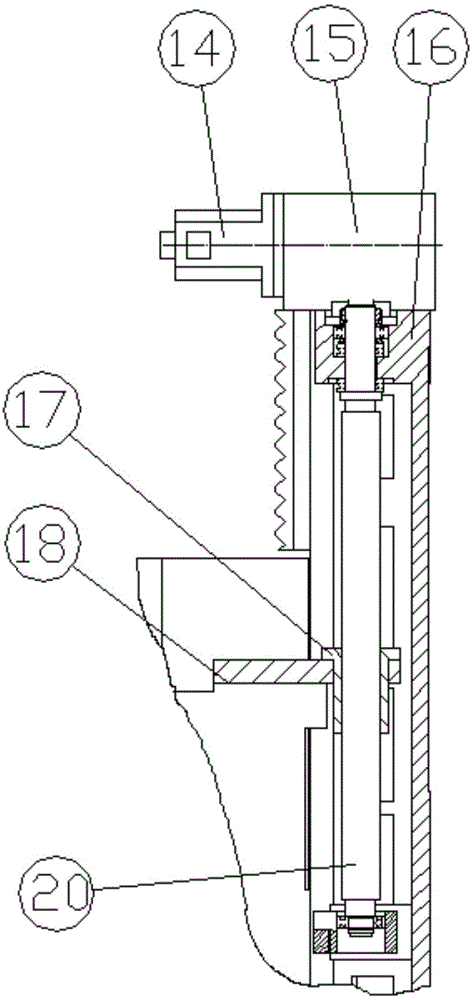

Clamping type manipulator

ActiveCN105459150AGuarantee product qualityAvoid pollutionArmsConveyor partsManipulatorDust particles

The invention discloses a clamping type manipulator. The clamping type manipulator comprises a manipulator base, a lifting driving mechanism arranged on the manipulator base, and a clamping mechanism arranged at the top end of the lifting driving mechanism, wherein the a manipulator base lateral movement driving mechanism is arranged on one side of the manipulator base; the clamping mechanism comprises a pair of rotary driving assemblies which are arranged at the top end of the lifting driving mechanism in a spaced mode; the rotary output end of each rotary driving assembly is connected with a revolving arm; the pair of revolving arms is arranged in parallel and the rotation directions of the revolving arms are opposite; clamping jaw fixing blocks are arranged on the revolving arms; clamping jaws used for clamping the edges of chip containing boxes are arranged on the clamping jaw fixing blocks; position sensors are arranged on the clamping jaw fixing blocks. The clamping type manipulator has the beneficial effects that 1, according to the clamping type manipulator, the chip containing boxes are directly clamped through the clamping jaws, and dust particle pollution and metal pollution are prevented, and thus the production quality of chips is ensured; and 2, clamping and transferring of the chip containing boxes can be achieved conveniently; the transferring speed is greatly increased; the transferring time is shortened; the work efficiency is improved.

Owner:SHANGHAI TUNA ELECTRIC MECHANIC EQUIP CO LTD

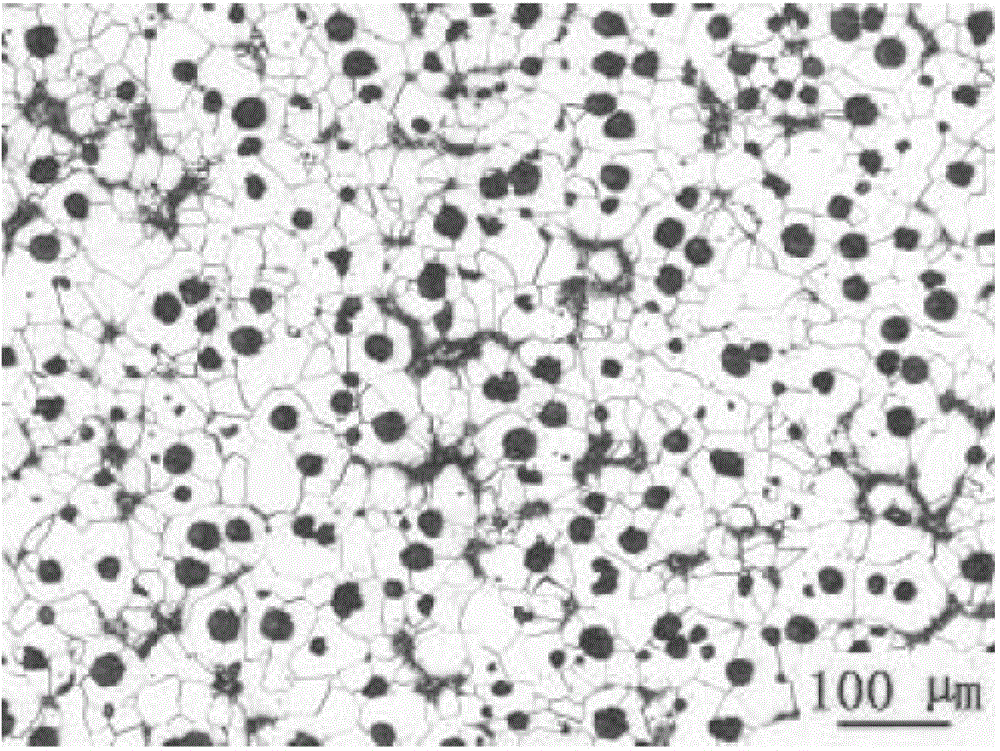

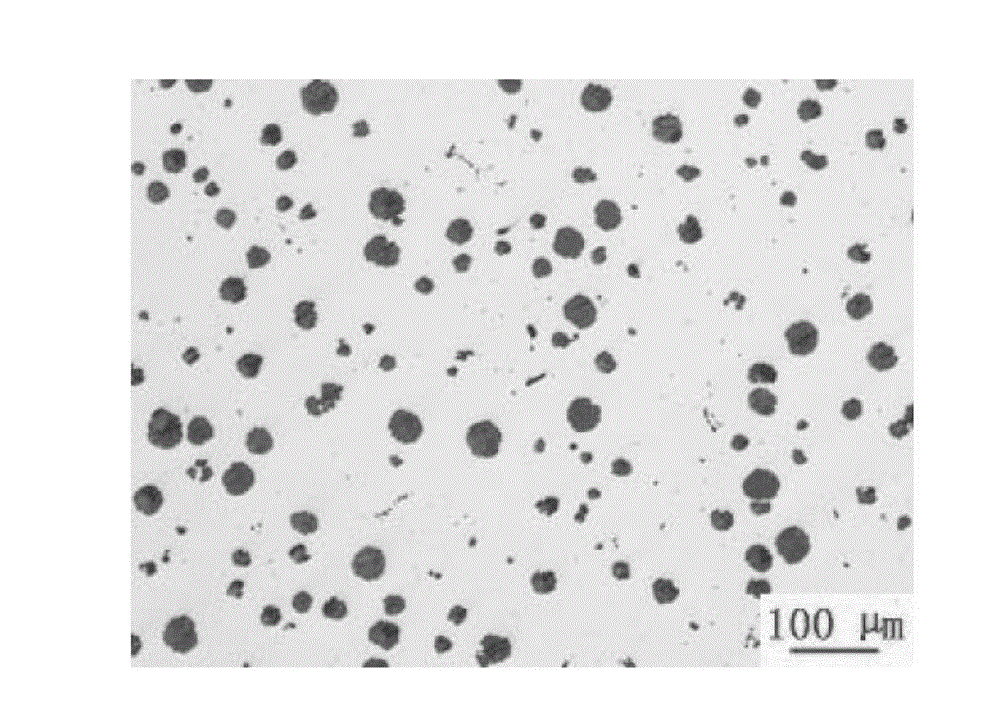

High-silicon-molybdenum ductile iron material and preparation method thereof

The invention discloses a high-silicon-molybdenum ductile iron material and a preparation method thereof. The high-silicon-molybdenum ductile iron material comprises the following components in percentage by weight: 2.90 to 3.35 percent of C, 4.40 to 4.80 percent of Si, 0.50 to 0.75 percent of Mo, 0.30 to 0.50 percentage of Cr, 0.20 to 0.45 percent of V, 0.10 to 0.30 percent of Mn, 0.04 to 0.07 percent of Mg, less than or equal to 0.07 percent of P, less than or equal to 0.02 percent of S, and the balance of Fe. For the high-silicon-molybdenum ductile iron material, the tensile strength is more than or equal to 710 MPa, the yield strength is more than or equal to 500 MPa, the extensibility is more than or equal to 10 percent, and the hardness is 230 to 265 HBW5 / 750. The high-silicon-molybdenum ductile iron material also contains a trace amount of Sn and Sb. The high-silicon-molybdenum ductile iron material eliminates fragmental graphite and graphite deterioration layers, ensures the spheroidization grades of the parts with different wall thicknesses, and the defects of microscopic shrinkage and the like are overcome.

Owner:CRRC CHANGZHOU AUTO PARTS CO LTD +1

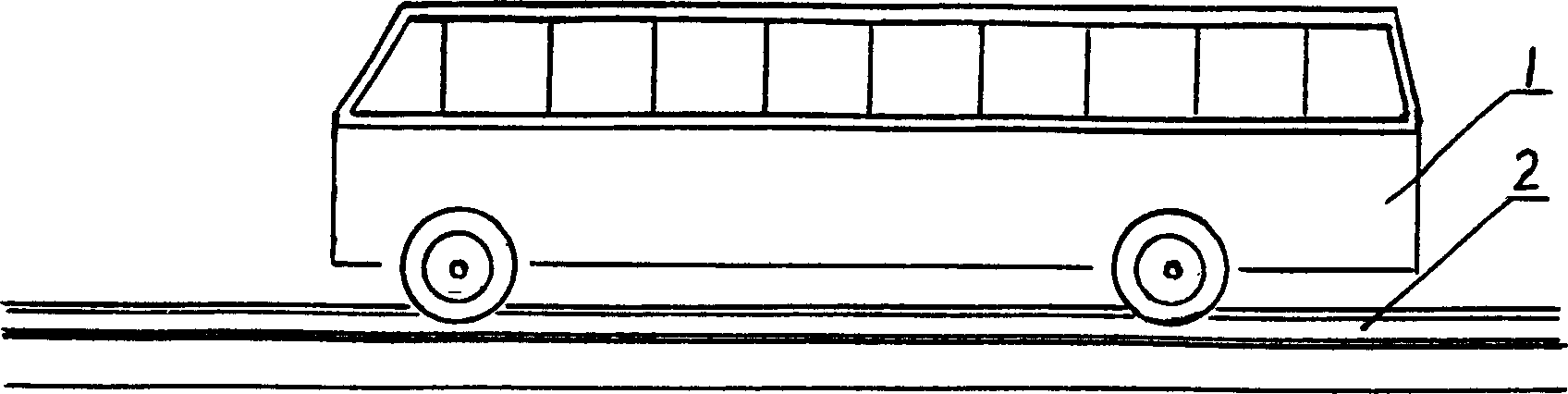

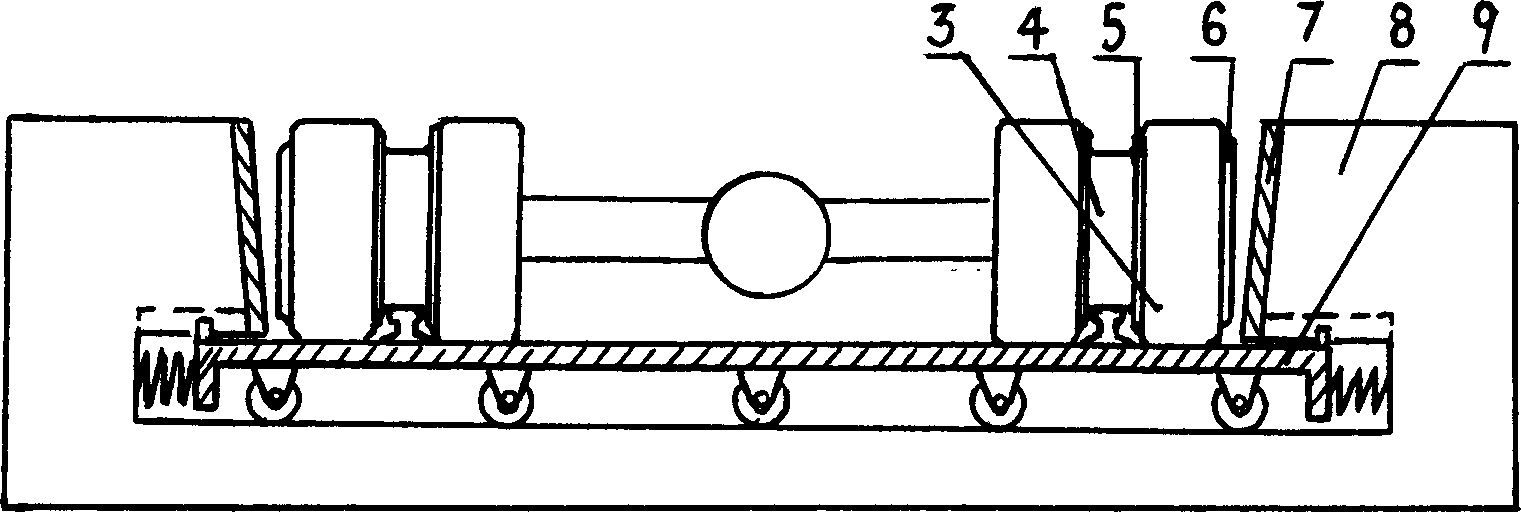

Automobile railroad

InactiveCN1824526AGuaranteed uptimeAchieve conversionRailway tracksRail and road vehiclesEngineeringRail transportation

Owner:HEFEI BOPU HIGH TECH

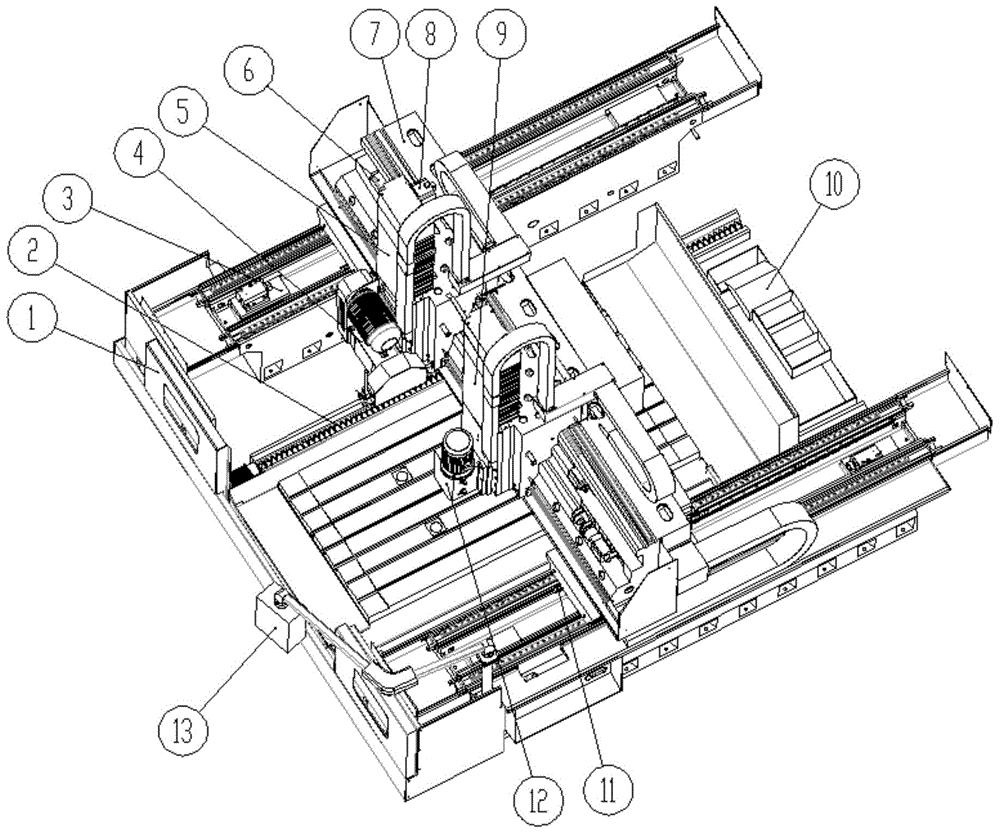

Precise numerical control double housing surface milling and grinding complex machine tool of floor working table elevated horizontal beam movable type structure

InactiveCN104400434ASave setup and transfer timeImprove work efficiencyOther manufacturing equipments/toolsEngineeringMachine tool

The invention relates to a precise numerical control double housing surface milling and grinding complex machine tool of a floor working table elevated horizontal beam movable type structure. The machine tool is composed of a double-width base tool body, a viaduct type movable beam, a vertical transmission mechanism, a milling head and an electric operating system, wherein a horizontal feeding mechanism drives a grinding head to conduct the horizontal reciprocating movement along the viaduct type movable beam through a grinding head dragging board, a vertical feeding mechanism drives the grinding head to conduct the vertical up-down movement along the viaduct type movable beam through the grinding head dragging board, a milling head horizontal feeding mechanism drives the milling head to conduct the horizontal reciprocating movement along the viaduct type movable beam through a milling head dragging board, and a milling head vertical feeding mechanism drives the milling head to conduct the vertical up-down movement along the viaduct type movable beam through the milling head dragging board. The precise numerical control double housing surface milling and grinding complex machine tool of the floor working table elevated horizontal beam movable type structure combines a milling machine and a grinding machine into a whole and combines two processing procedures of milling and grinding into one, so the working efficiency is greatly improved; due to the fact that a working table is fixed, a workpiece is fixed, only a horizontal beam is movable, and a smaller motor can drive, and the complex machine tool is energy-saving and environment-friendly.

Owner:GUILIN GUIBEI MACHINE

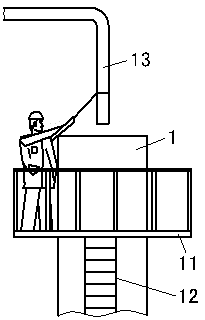

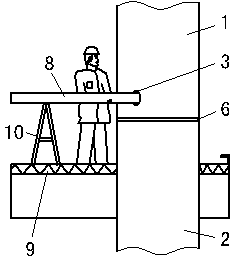

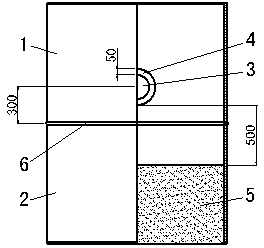

Steel pipe column concrete lateral pouring method and steel pipe column structure used in method

InactiveCN104131704ADoes not affect constructionImprove installation efficiencyStrutsBuilding material handlingArchitectural engineeringPipe

The invention discloses a steel pipe column concrete lateral pouring method and a steel pipe column structure used in the method. A steel pipe column is formed by welding multiple steel pipes. The method includes the steps that a pouring hole is formed in the side wall of the upper steel pipe, and then the upper steel pipe and the lower steel pipe are welded; when concrete in the lower steel pipe is poured, a concrete pumping pipe is inserted into the pouring hole in the upper steel pipe from the side face, and then pouring of the concrete in the lower steel pipe is finished. In the pouring process, construction of an upper-layer steel pipe column, a steel beam and a truss formwork is not influenced, synchronous construction can be achieved, work faces do not interfere with one another, installation efficiency of the steel structure is improved and the construction period is shortened. A worker can stand on an outer-frame horizontal beam and slab structure during pouring construction, safety risks are greatly reduced, pouring is easy and convenient to carry out, pouring can be carried out without a concrete spreader, operation time of the concrete spreader is saved, pouring time of the concrete of the steel pipe column is greatly shortened, the construction period is shortened, and labor expenses are reduced.

Owner:CHINA CONSTR FOURTH ENG DIV

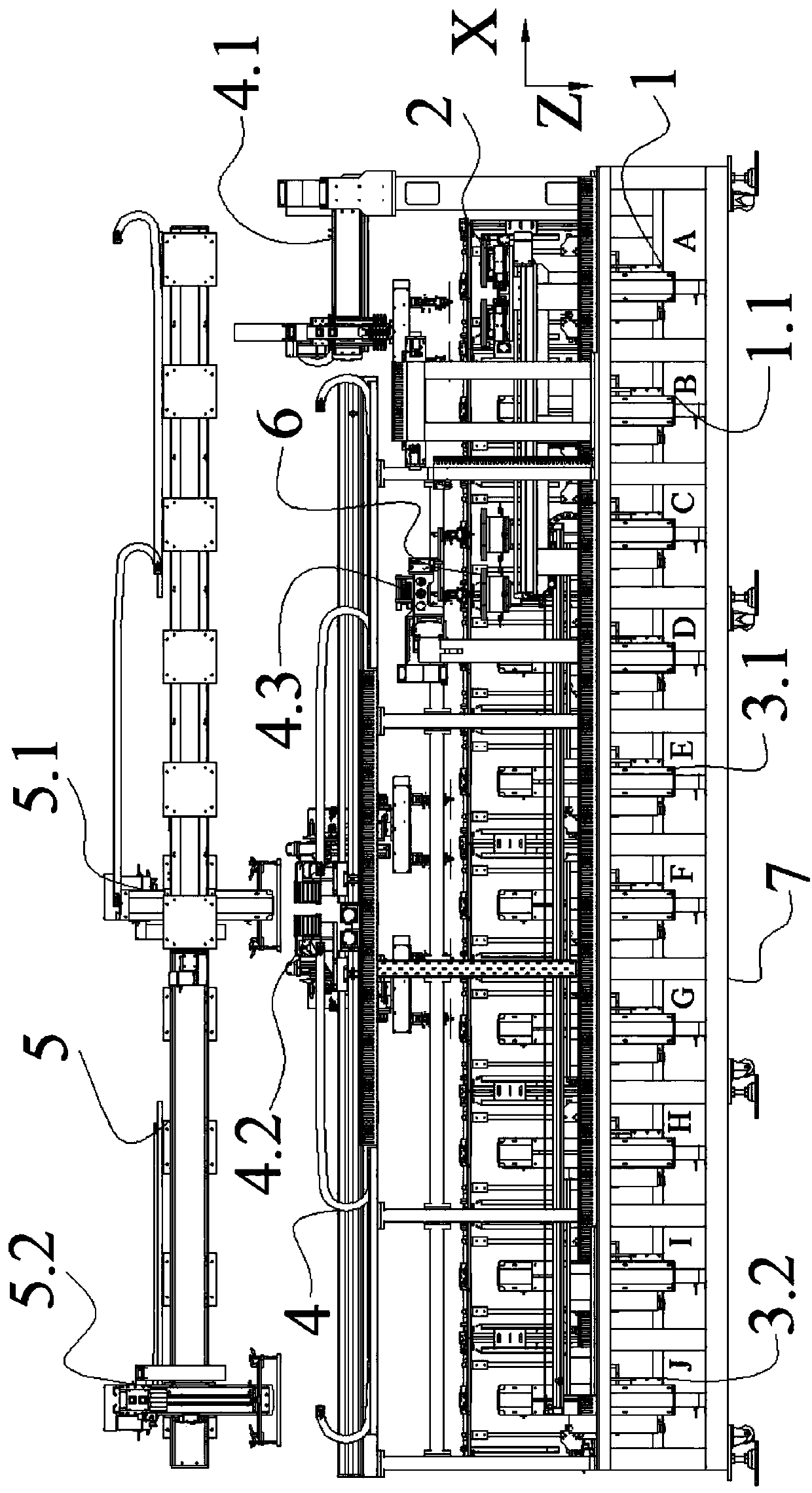

Panel grading device

PendingCN107855285AHigh degree of automationImprove efficiencySortingEngineeringElectrical and Electronics engineering

The invention relates to the technical field of display panel detection, in particular to a panel grading device. The panel grading device comprises a grade judgment position and a charging device, and is characterized in that the charging device comprises a feeding device, a discharging device, a panel taking and placing device and a tray taking and placing device, wherein the feeding device comprises a plurality of feeding positions which are sequentially arranged in the X direction; the feeding device is used for carrying trays for containing panels; the discharging device is adjacent to the feeding device and comprises first discharging positions and a plurality of second discharging positions; the first discharging positions and the second discharging positions are sequentially arranged in the X direction; the discharging device is used for carrying the trays; the panel taking and placing device is arranged on the upper portion of the grading device and used for transferring the panels between the feeding device, the grade judgment position and the discharging device; the tray taking and placing device is arranged above the feeding device and the discharging device and used for transferring the trays on the feeding device onto the discharging device. The panel processing device provided by the invention is reasonable in structure design, compact in arrangement and capableof rapidly achieving discharging, feeding and classifying of the panels.

Owner:KUSN JINGXUN ELECTRONICS TECH

Manufacturing method for multi-color quartz stone board

The invention provides a manufacturing method for a multi-color quartz stone board. The multi-color quartz stone board at least comprises a rack, a stirrer, conveying equipment and a batch hopper, wherein the conveying equipment comprises a feeding conveyor belt and a discharging conveyor belt; the feeding conveyor belt is located under a discharging hole of the stirrer; the discharging conveyor belt and the feeding conveyor belt are parallel and are located on the same plane; the feeding conveyor belt and the discharging conveyor belt are subsection type roller beds; a wagon balance is mounted under the roller bed, located just under the stirrer, in the feeding conveyor belt; the roller bed just under the stirrer is fixed on the wagon balance; rails are arranged at the two ends of the conveying equipment; a supporting frame capable of sliding along the slide rails is erected on the rails; the supporting frame is provided with a movable roller bed and a motor for driving the movable roller bed to operate; the rack is provided with a controller; and the controller controls each section of each roller bed to operate in sequence. The device can accurately control the quality of all raw materials and the quality of the multi-color quartz stone board is guaranteed; and the transportation time of the materials and the batch hopper can be greatly shortened and the production efficiency is improved.

Owner:湖北宏钊建材有限责任公司

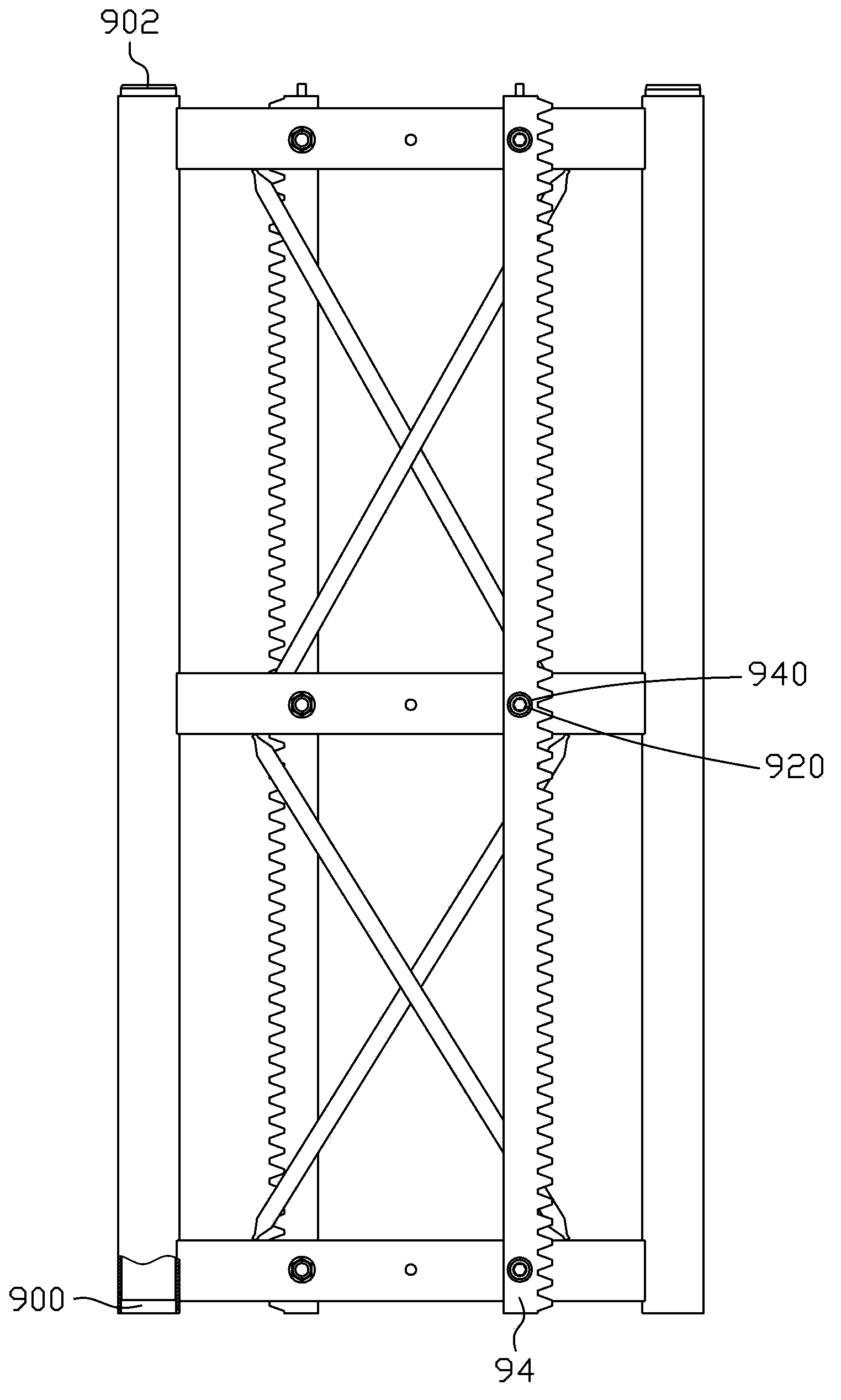

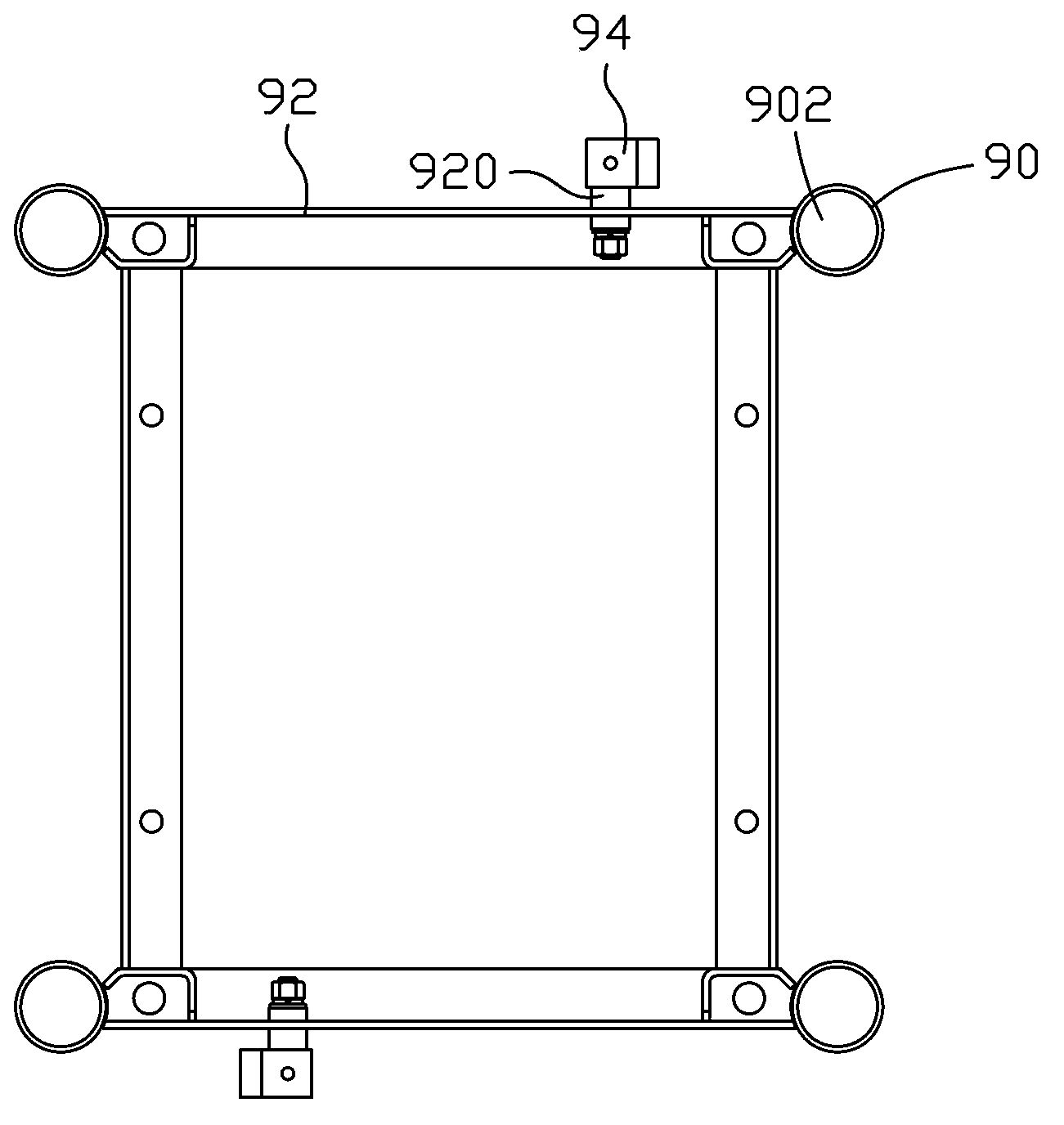

Method and technological equipment for mounting rack on standard section

ActiveCN103846672AEliminate inspection stepsReduce labor intensityAssembly machinesMetal working apparatusEngineeringMechanical engineering

Owner:ZOOMLION HEAVY IND CO LTD

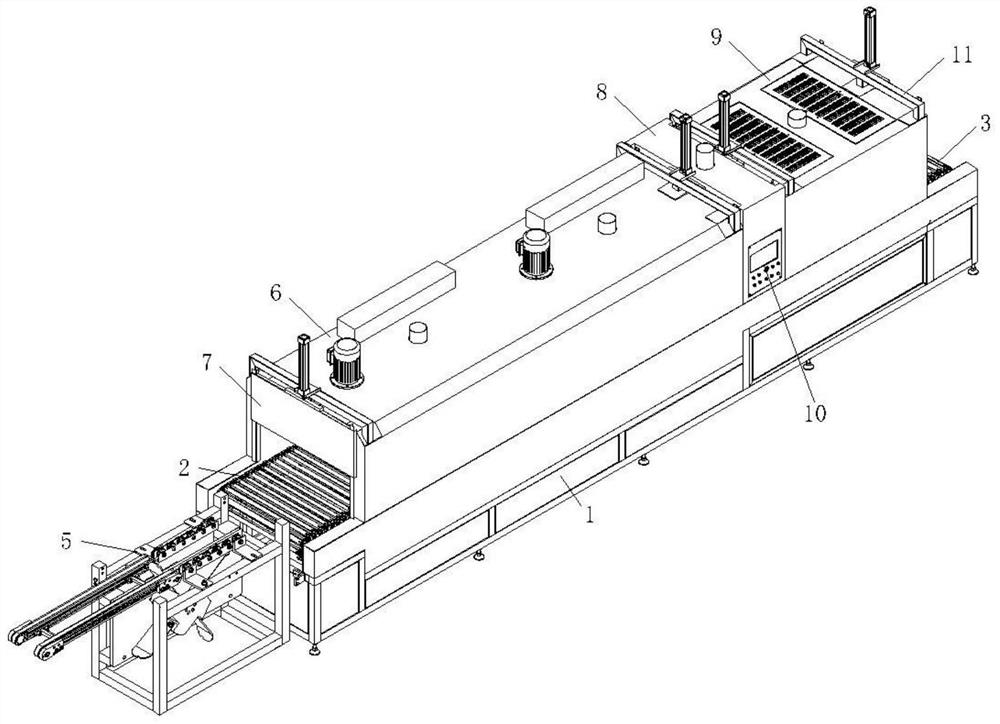

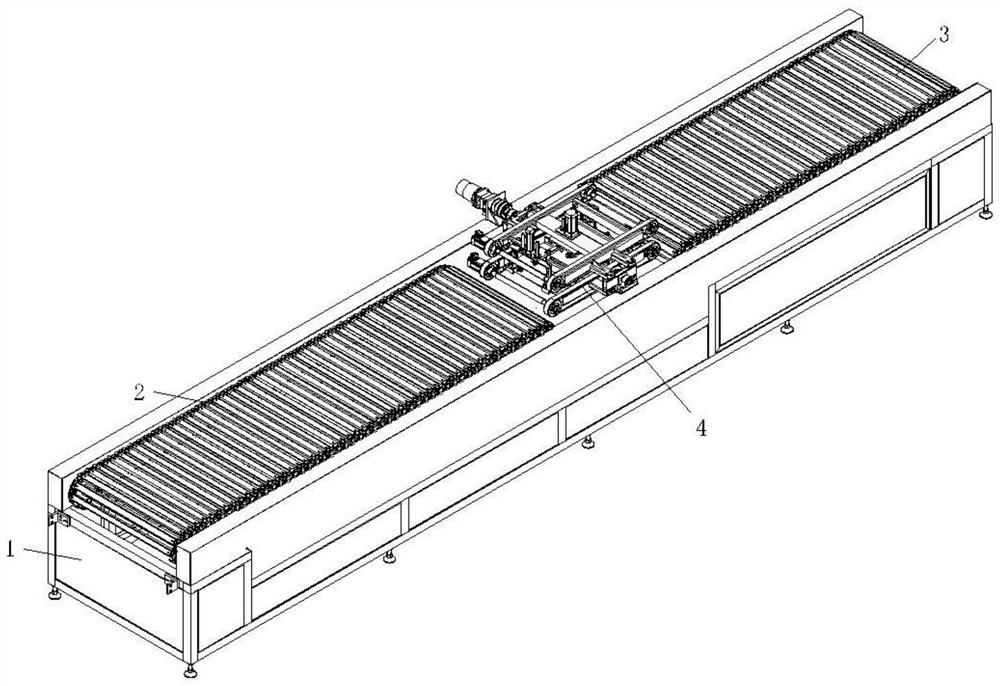

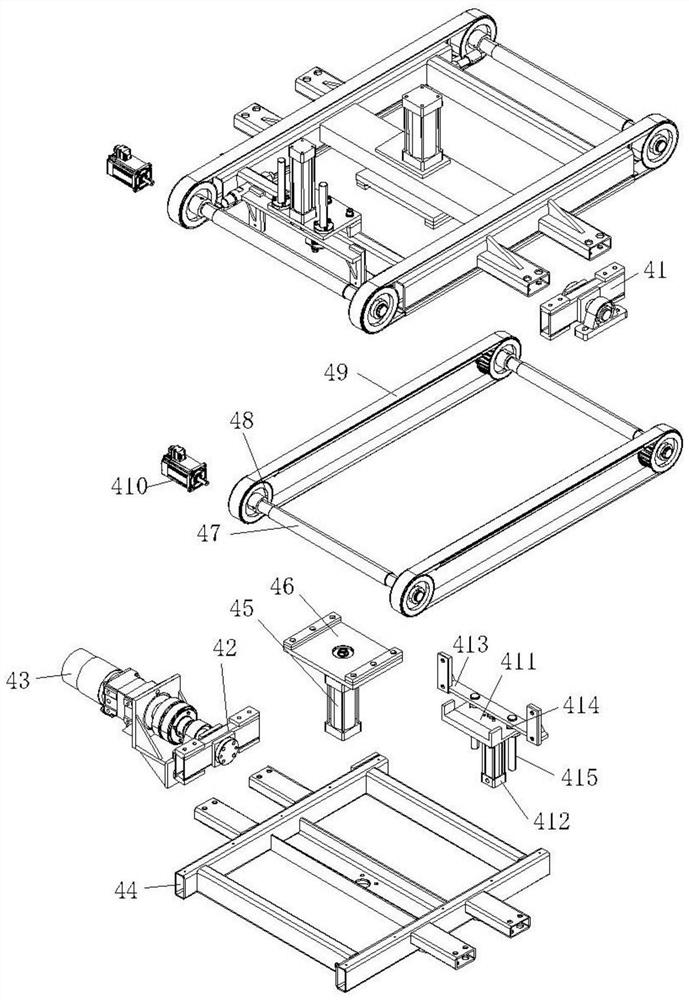

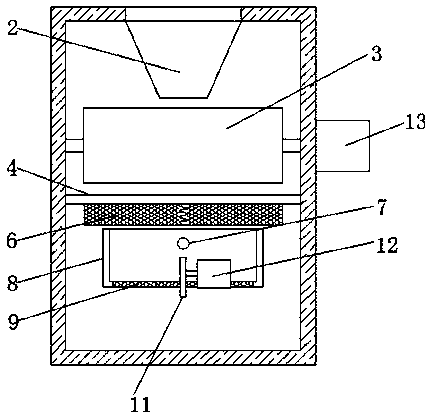

PCB tunnel drying device

InactiveCN112595080ARealize automatic flipSave time in transitDrying machines with progressive movementsDrying solid materialsClassical mechanicsEngineering

The invention discloses a PCB tunnel drying device. The PCB tunnel drying device comprises a base, a first electric conveying belt, a second electric conveying belt, a turnover mechanism, a feeding mechanism, a tunnel drying box, a first electric gate, an infrared grating, a cooling device and a second electric gate plate. The first electric conveying belt is arranged on the front side of the topend of the inner side of the base in the front-back direction. The second electric conveying belt is arranged on the rear side of the top end of the inner side of the base in the front-back direction.The turnover mechanism is arranged in an inner cavity of the base and located on the inner side of the first electric conveying belt and the inner side of the second electric conveying belt. The feeding mechanism is arranged on the front side of the base. According to the PCB tunnel drying device, integrated operation of feeding, drying and cooling of PCBs can be achieved, manual operation itemsof workers and transfer time between different devices are reduced, automatic overturning of the circuit boards during tunnel drying can be achieved, the workers do not need to manually turn over thecircuit boards for secondary drying, the drying period is shortened, and the machining efficiency is improved.

Owner:董立喜

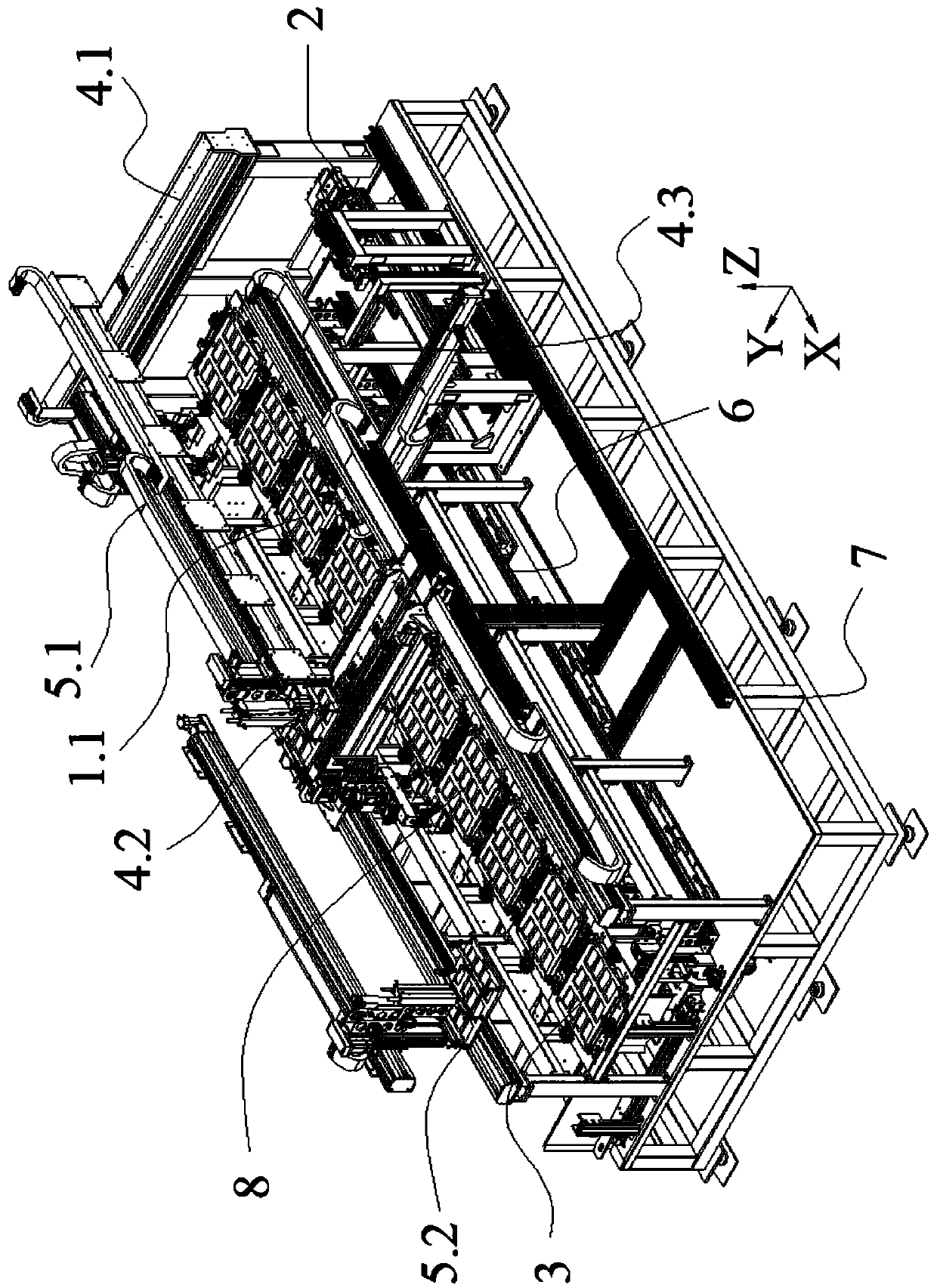

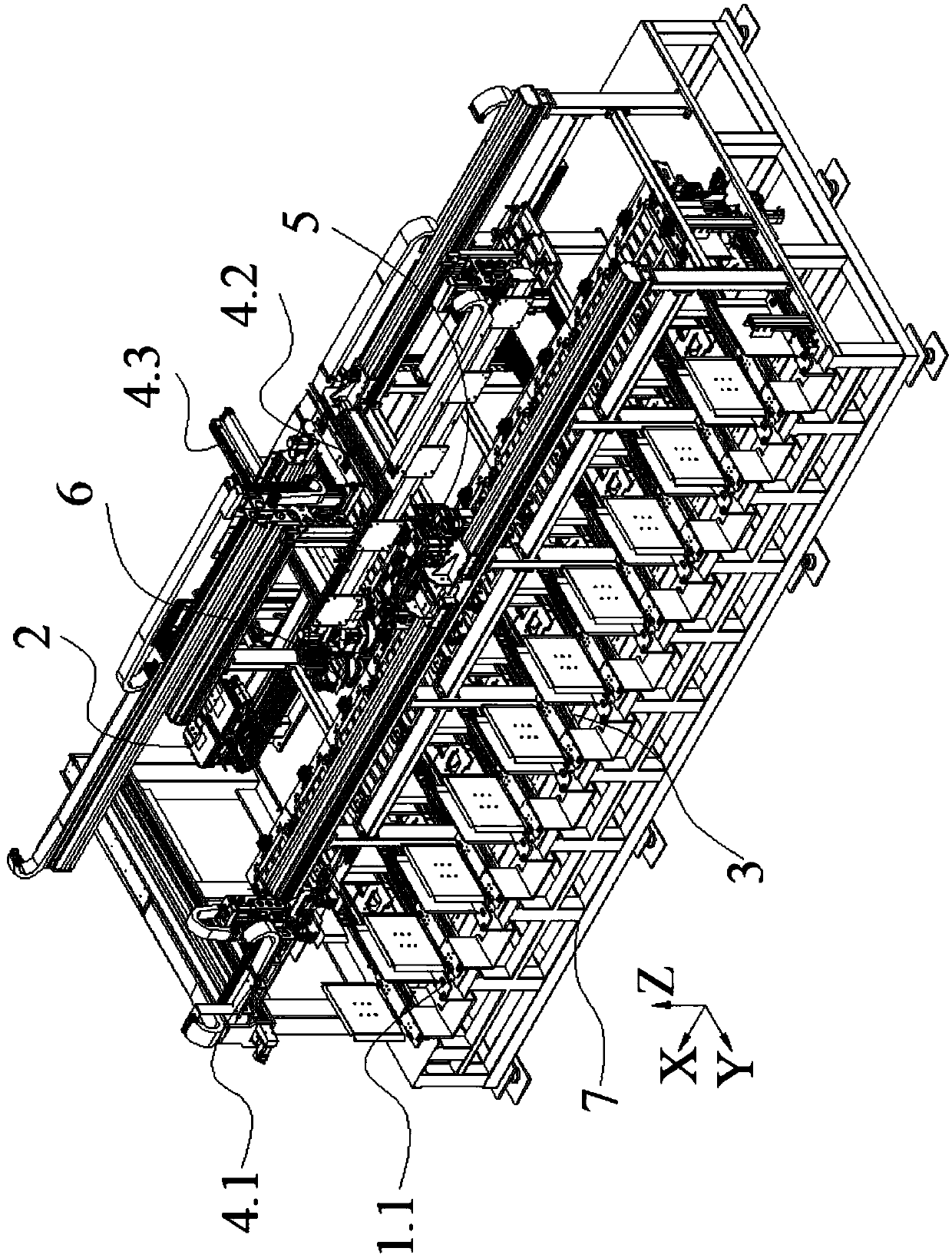

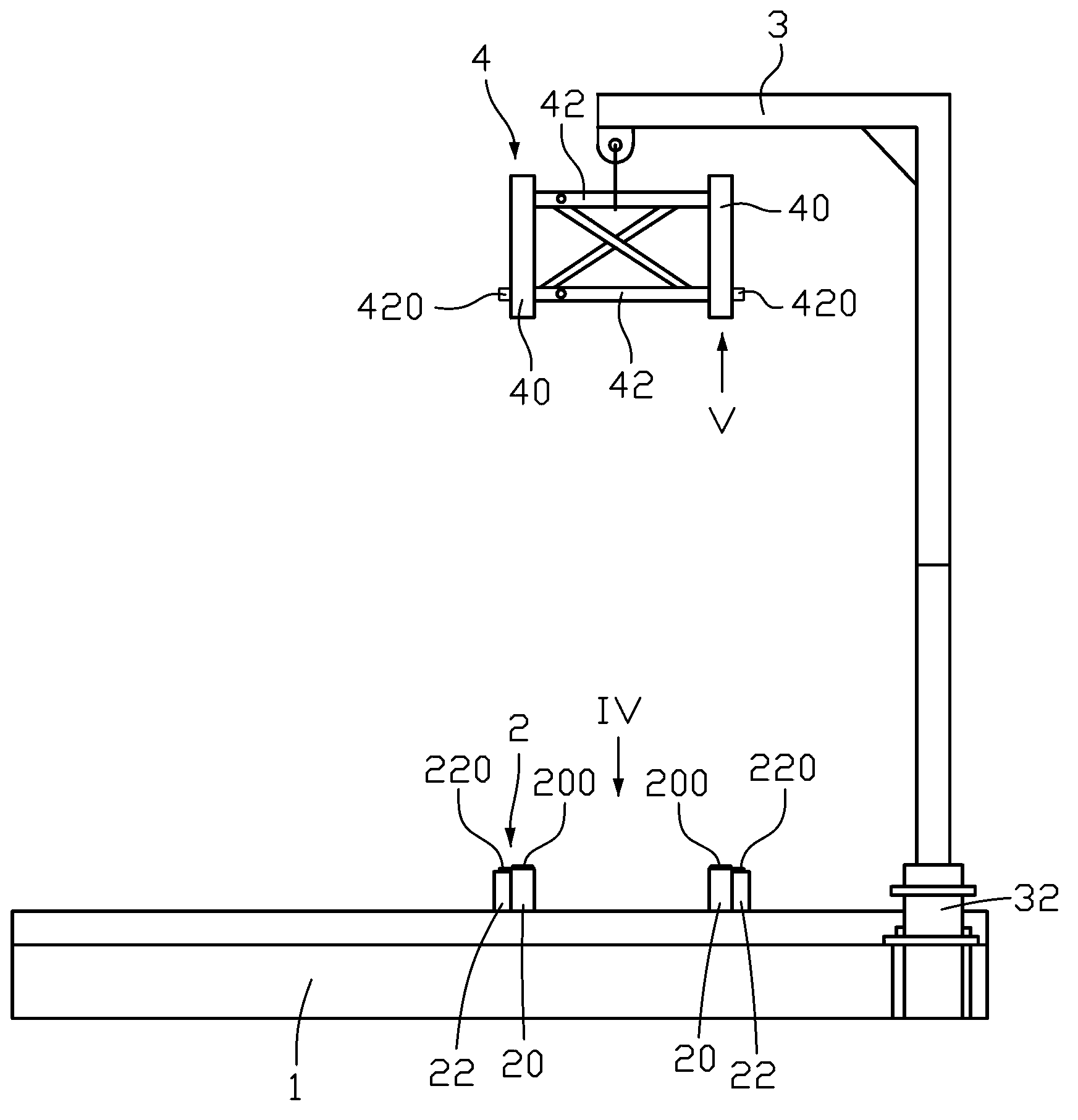

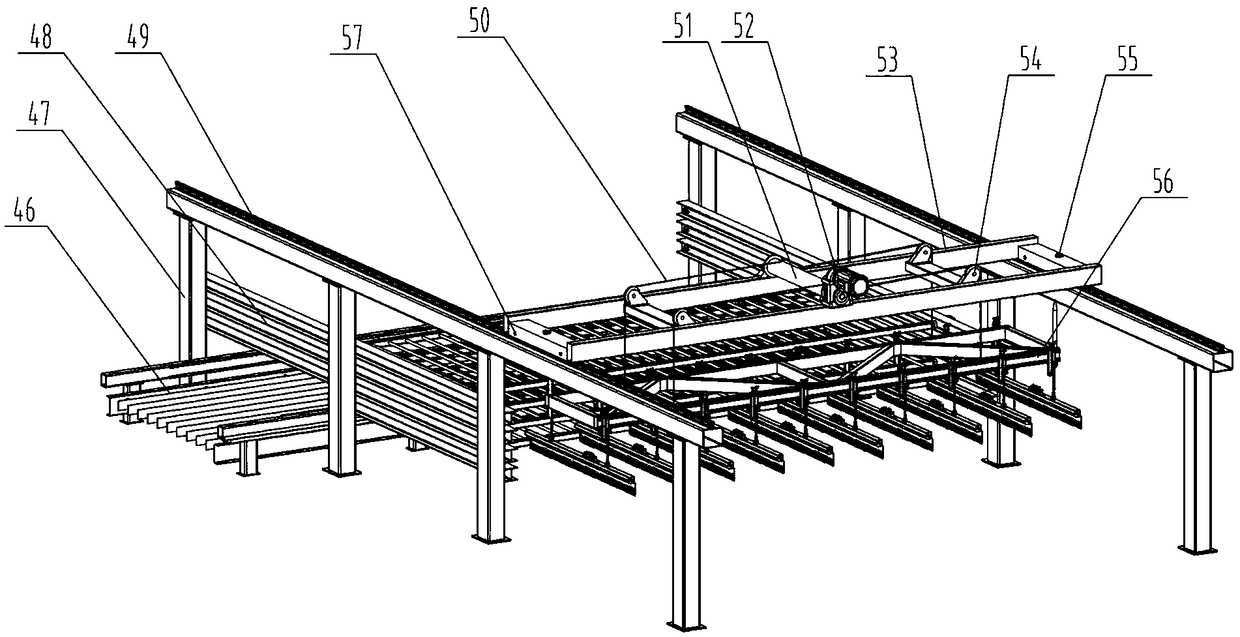

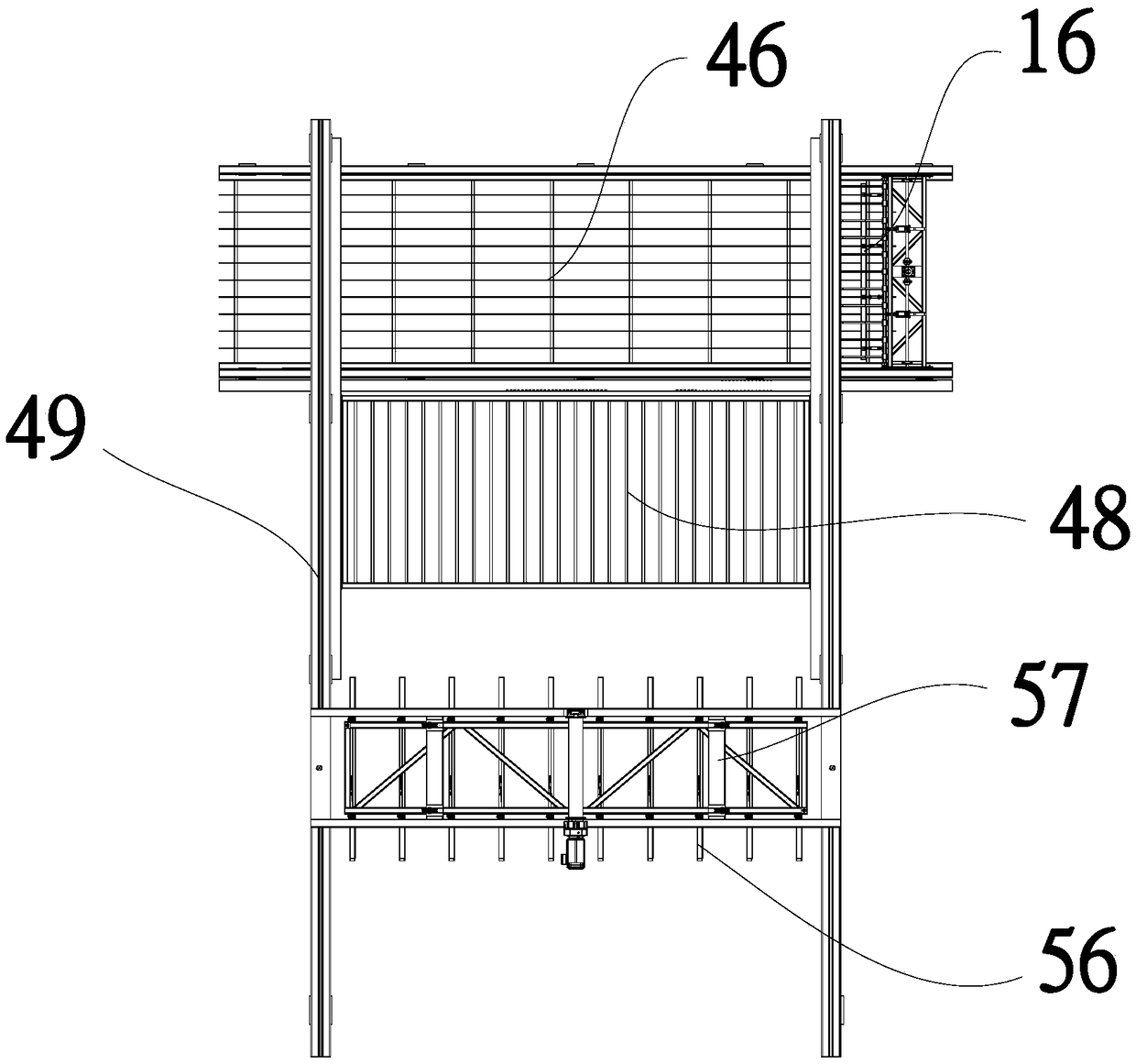

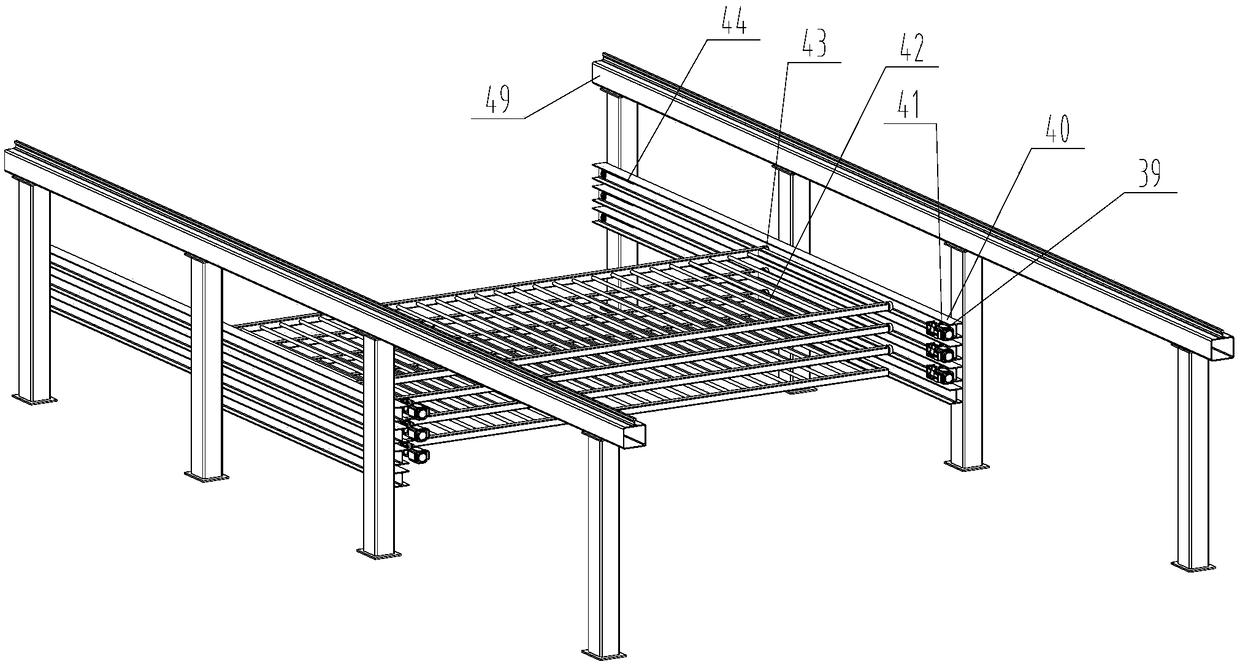

On-line process for reinforcing mesh sheets in prefabricated member production line

The invention relates to an on-line process for reinforcing mesh sheets in a prefabricated member production line. The on-line process comprises the following processes that (1) a mesh pulling processis carried out, specifically, the processed reinforcing mesh sheets are pulled to a preset position in an on-line section; (2) the grabbing process of the reinforcing mesh sheets is carried out, specifically, a reinforcing mesh sheet clamping mechanism moves the upper part of the reinforcing mesh sheets, moves downwards and grabs the reinforcing mesh sheets, and returns to the walking position upwards after grabbing the reinforcing mesh sheets; and (3) the process of storing or putting the reinforcing mesh sheets on line, specifically, the reinforcing mesh sheet clamping mechanism transportsthe grabbed reinforcing mesh sheets to a predetermined production die table, or transports the grabbed reinforcing mesh sheets to a storage mechanism for temporary storage. According to the on-line process, the prefabricated member production line is linked with the manufacture and production of the reinforcing mesh sheets, so that the automatic on-line of the reinforcing mesh sheets in the prefabricated member production line is realized, the on-line process without personnel operation is realized, the transfer time of the reinforcing mesh sheets is saved, the production efficiency is improved, and the problem that a single device cannot directly transport products to the production line is solved.

Owner:CHINA MINSHENG ZHUYOU

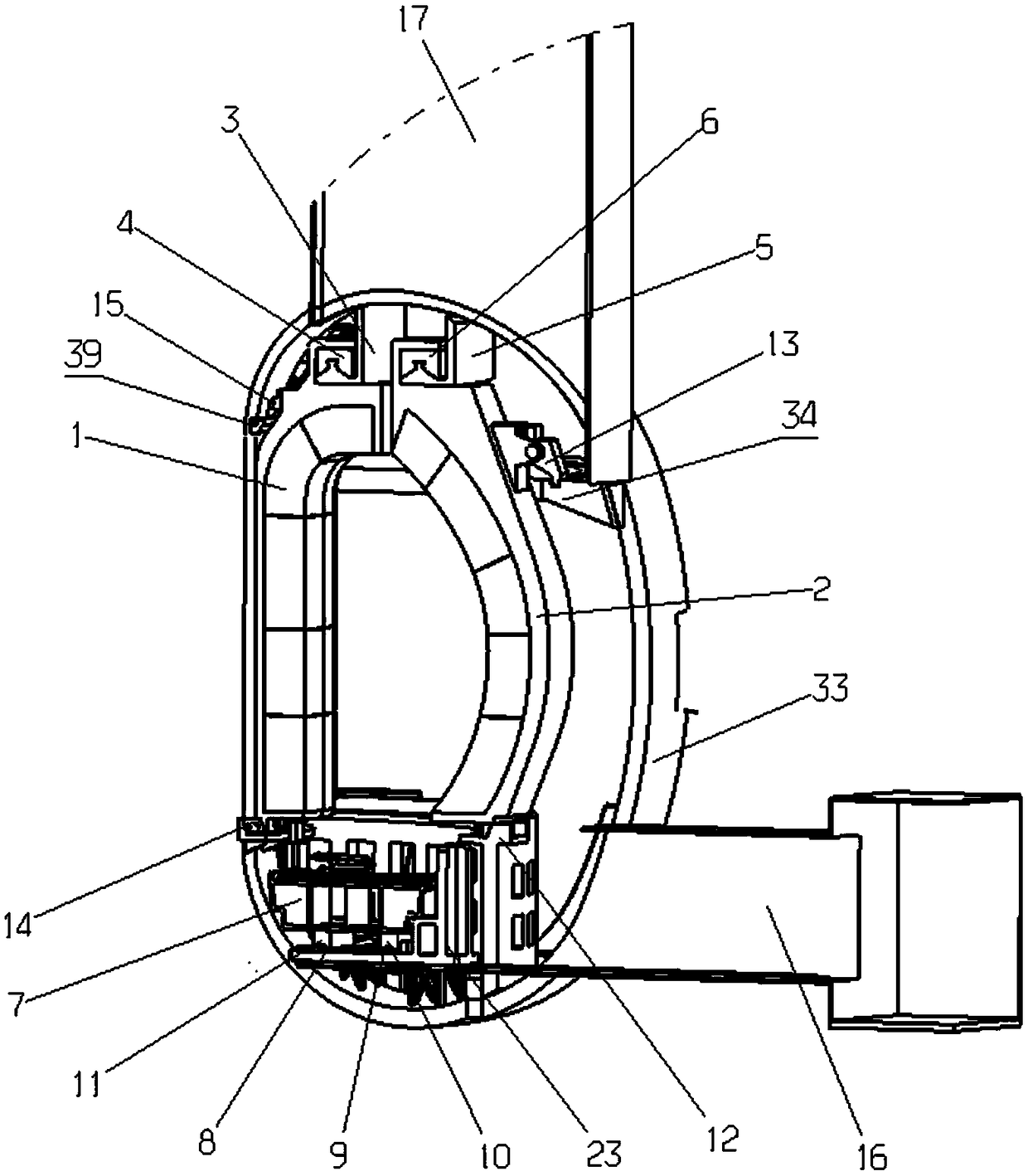

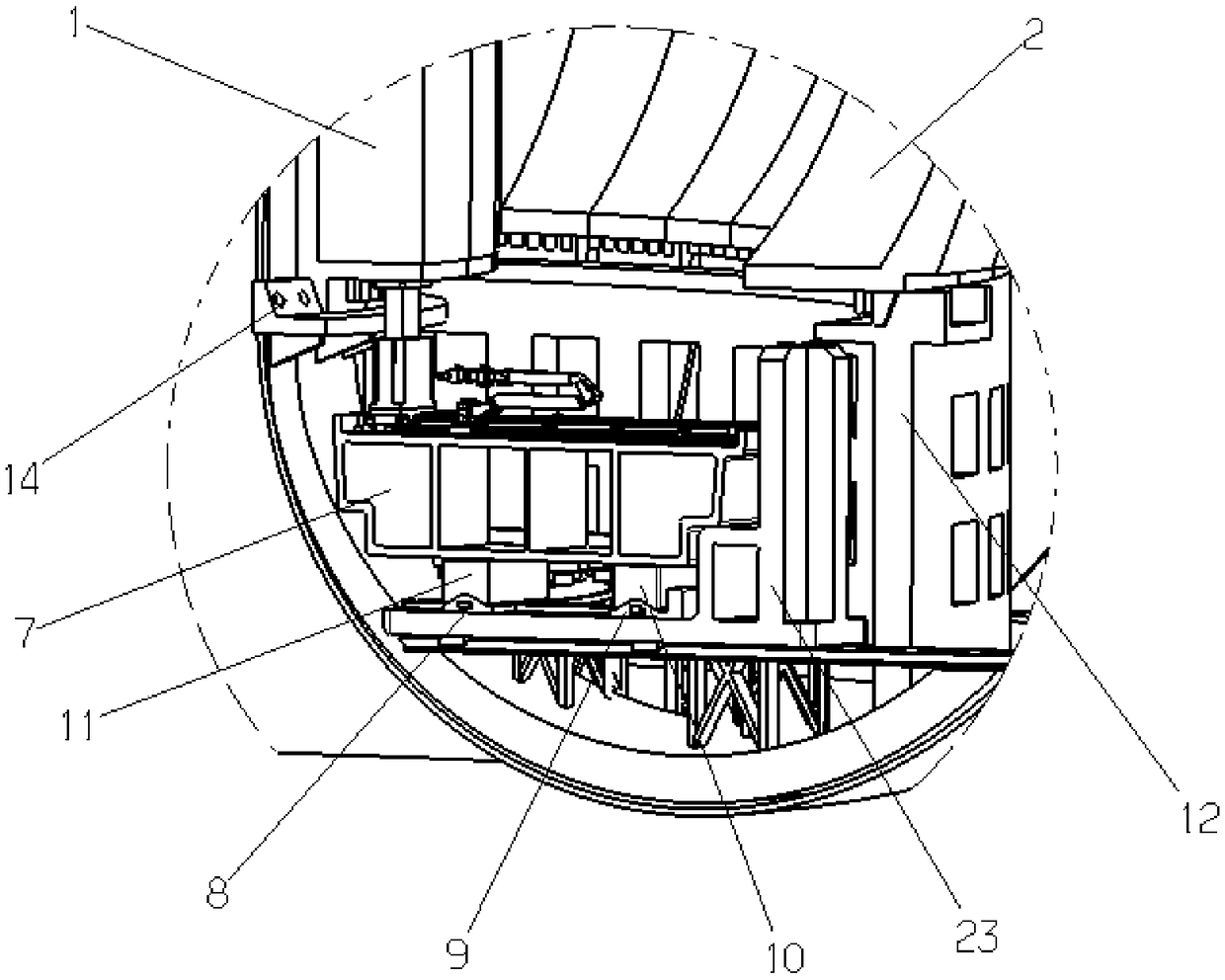

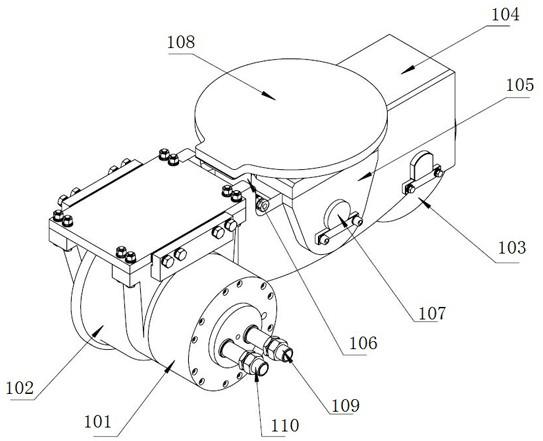

Nuclear fusion device cladding teleoperation transfer device

ActiveCN109346194ALower center of gravityGuaranteed uptimeNuclear energy generationThermonuclear fusion reactorNuclear fusionTeleoperation

The invention discloses a nuclear fusion device cladding teleoperation transfer device. The device includes an annular vacuum cavity, wherein the annular vacuum cavity is internally provided with an annular cladding. Firstly, the pipeline and fixing of the cladding are removed through a multi-joint mechanical arm at the bottom, the cladding is lifted through a hydraulic ejector mechanism at the bottom and an upper cladding annular transfer device, upper and lower cladding annular transfer devices cooperate to realize annular transfer of the cladding, movement to the window position is performed, an upper lifting mechanism cooperates with the hydraulic ejector mechanism to transfer the cladding in the radial direction to the portion under an upper window, and lastly, the cladding is liftedout of the vacuum cavity by an upper crane. The device is advantaged in that the large modular cladding structure is employed, the transfer time is effectively shortened, the center of gravity of transfer equipment is low, the operation process is more stable, and the device is safe and reliable.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

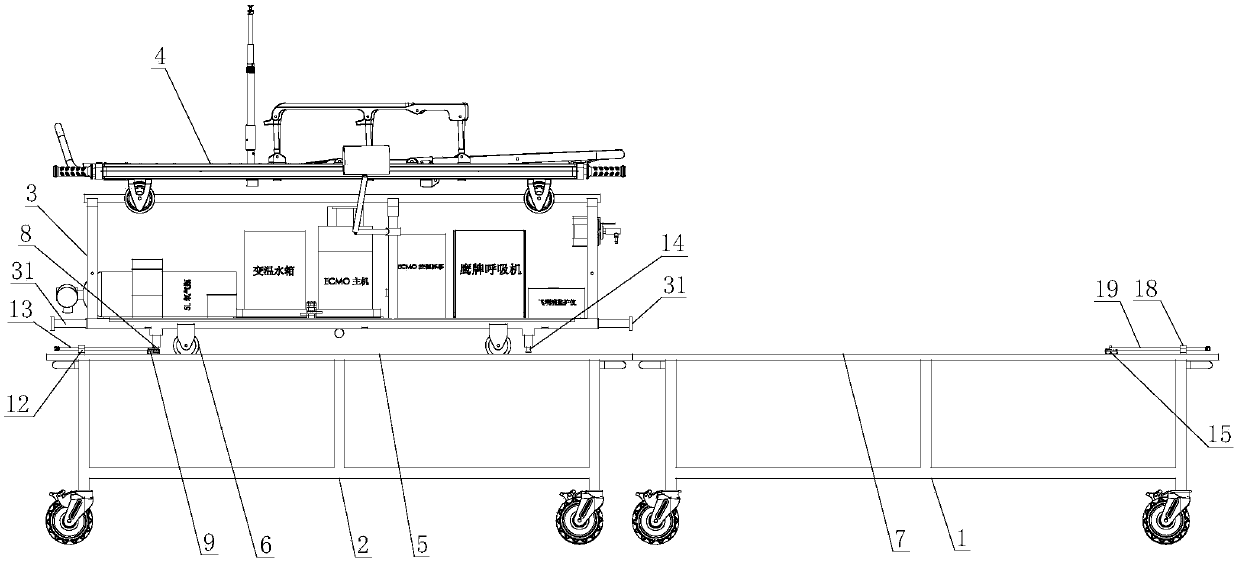

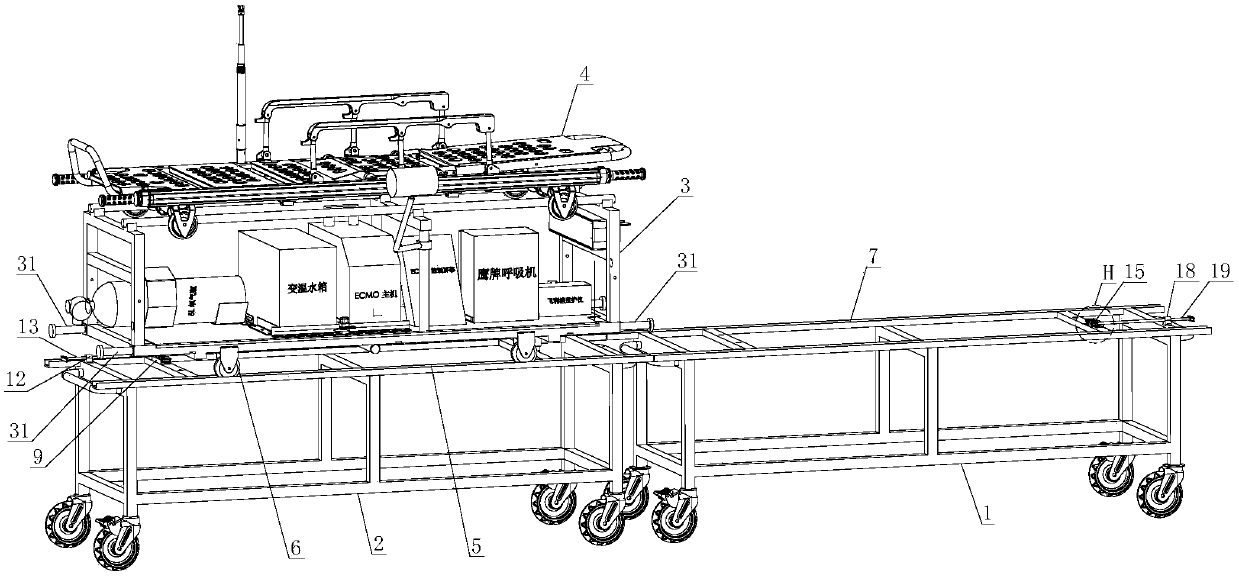

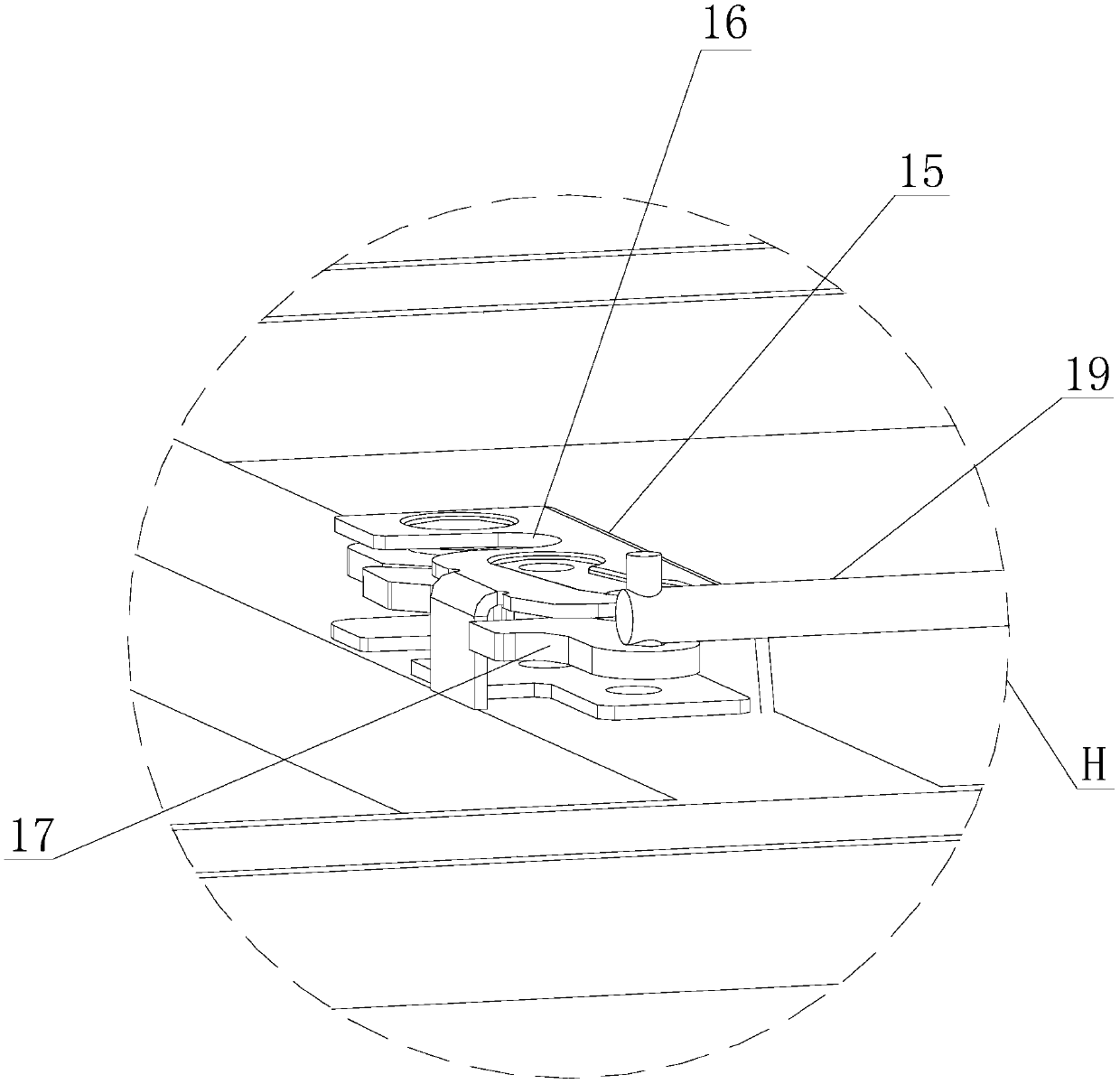

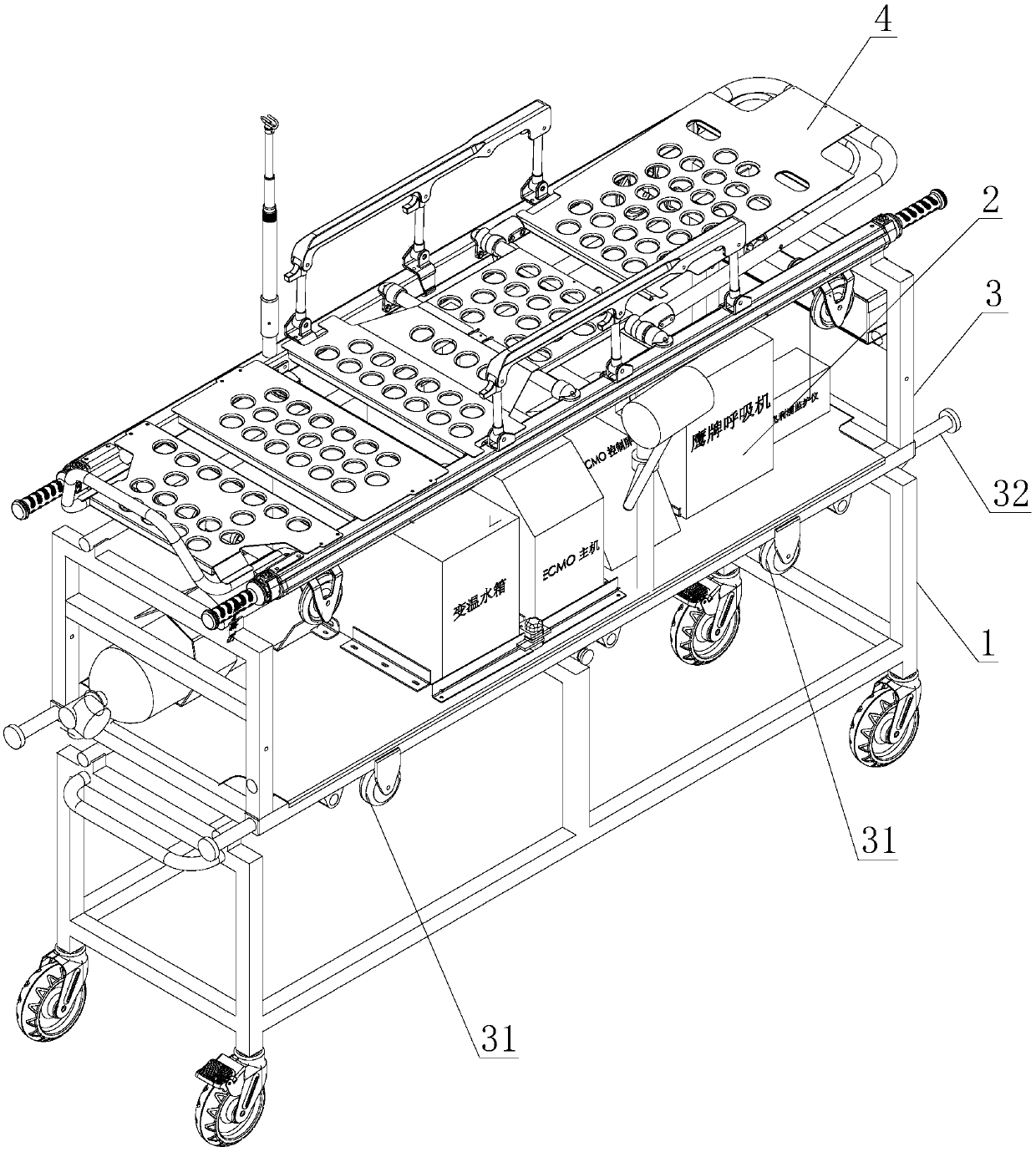

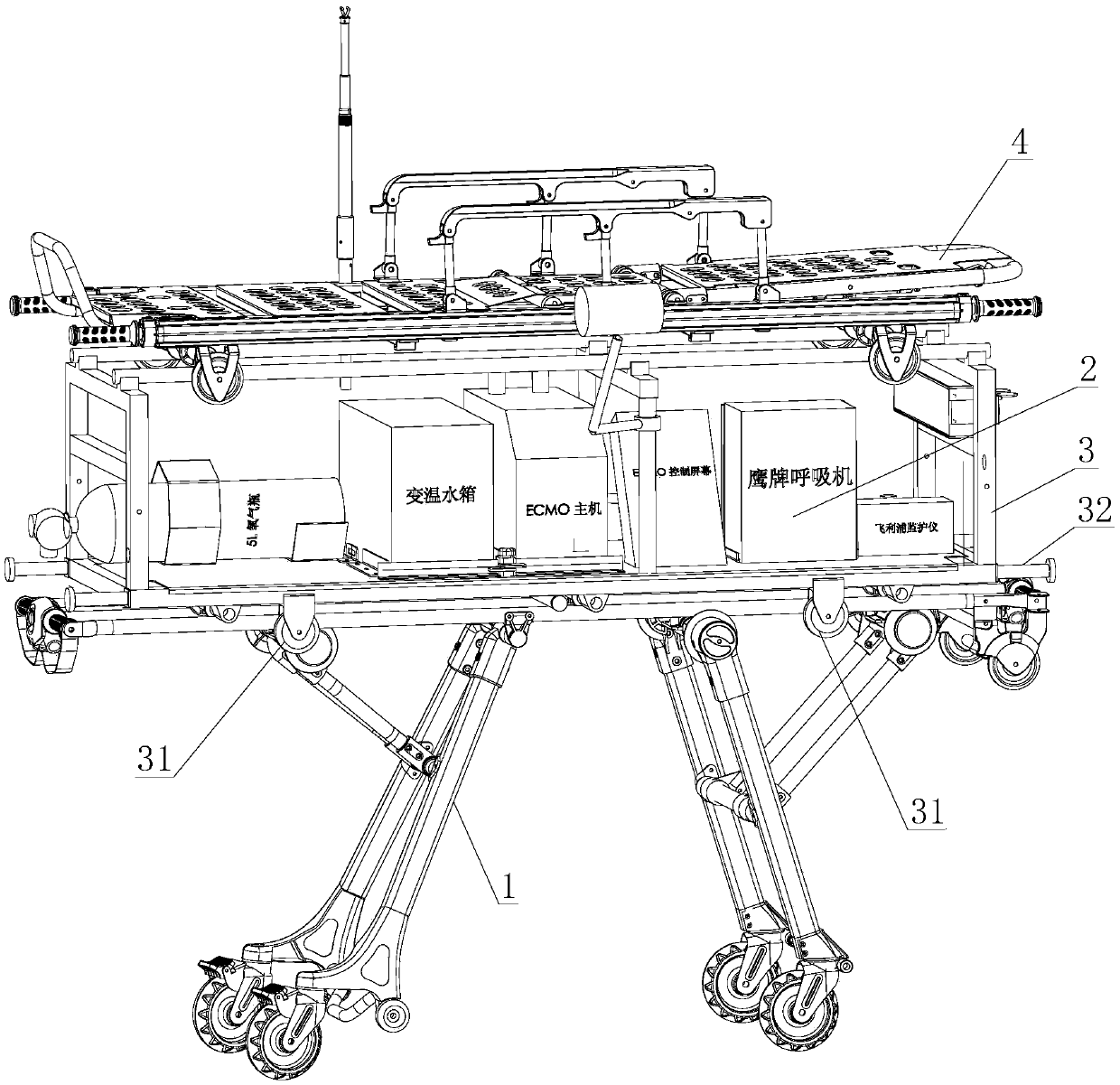

Transport system for severe patients

PendingCN108670588AFacilitate first aid treatmentSave time in transitStretcherHand carts with multiple axesTransport systemEmergency treatment

The invention discloses a transport system for severe patients. The transport system comprises an emergency ambulance stretcher and a transport trolley used in hospitals, wherein the emergency ambulance stretcher structurally comprises a lower stretcher capable of sliding on the ground, an emergency equipment storage rack for storing emergency equipment is arranged at the top of the lower stretcher, and an upper stretcher allowing patients to lie is arranged at the top of the emergency equipment storage rack; the transport trolley can be butted with the lower stretcher of the emergency ambulance stretcher and transport the emergency equipment storage rack and the upper stretcher of the emergency ambulance stretcher. The transport system has the advantages as follows: severe patients cannotbe pressed by emergency equipment in the transport process, and emergency treatment of the severe patients is facilitated; besides, winding of pipelines of emergency equipment can be avoided, the original step of sorting pipelines of emergency equipment before transport is omitted, the patient transport time is greatly shortened, and the severe patients can be treated timely.

Owner:JIANGSU RIXIN MEDICAL EQUIP

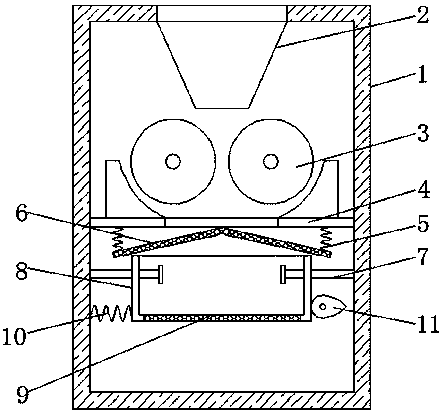

Ore raw material processing device

The invention discloses an ore raw material processing device comprising a smashing box with the top being provided with a feeding inlet. A feeding hopper welded to the inner wall of the top of the smashing box is arranged on the lower portion of an opening of the smashing box; two rotatably-connected smashing rollers are arranged below the feeding hopper; a fixed plate vertically welded to the side walls of the smashing box is arranged below the smashing rollers; first springs are symmetrically connected to the bottom surface of the fixed plate; the ends, away from the fixed plate, of the first springs are connected with first screen nets, and the ends, close to each other, of the two first screen nets are both hinged to the fixed plate; and two fixed rods vertically welded to the side walls of the smashing box are arranged below the first screen nets, and second springs connected with the inner walls of the smashing box are arranged below the fixed rods. The structure is compact, thedesign is novel, and smashing and screening are integrated, so that not only is the occupied space saved, but also the ore transferring time is reduced, the processing efficiency is improved, and theore raw material processing device is suitable for being popularized in the market.

Owner:新昌县恒新机械有限公司

Aluminum profile electrolytic coloring method

The invention discloses an aluminum profile electrolytic coloring method which comprises the coloring step and the washing step. After the coloring step of an aluminum profile is completed, the aluminum profile is transferred to the washing step through a crane, in addition, the traveling speed of the crane in the vertical direction is controlled to be 0.2-0.4 m / s, and the traveling speed of the crane in the horizontal direction is controlled to be 0.2-0.4 m / s. Meanwhile, the technological parameters of an electrolytic cell in the coloring step are controlled as below, the concentration of stannous mono-sulphate is 4-8 g / l, the concentration of nickel sulfate is 23-30 g / l, the concentration of sulfuric acid is 6-12 g / l, and the pH value is controlled to be 1-1.6. According to the electrolytic coloring method, the coloring function of residual cell liquid to the edge of the aluminum profile can be effectively restrained by adjusting the technological parameters of the electrolytic cell, and through the combination of controlling the transfer speed of the crane, the technical problem that the color of the edge of an aluminum profile product is too dark is solved while the electrolytic coloring effect is maintained.

Owner:GUANGDONG JMA ALUMINUM PROFILE FACTORY GRP

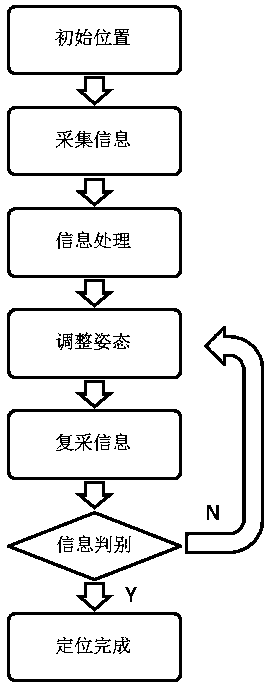

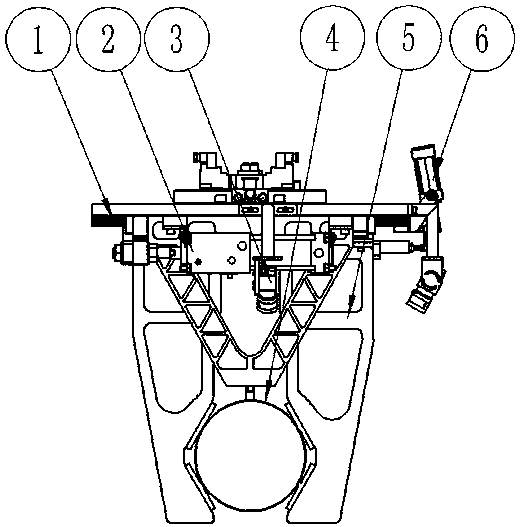

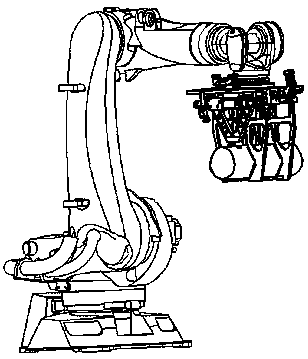

Actuator of binocular vision positioning system

InactiveCN109227577ASolve precise positioningSave time in transitManipulatorControl systemEngineering

The invention discloses an actuator of a binocular vision positioning system, which comprises a binocular vision system and a clamping mechanism, wherein the binocular vision system consists of two cameras and a control system; a clamping mechanism comprises clamping jaws, a linkage mechanism, a clamping cylinder and a linear sliding rail; the linkage mechanism is arranged between the clamping jaws at the two sides, the clamping jaw at one side is connected with the clamping cylinder and retracts and moves along the sliding rail under the driving of the cylinder, the clamping jaw at the otherside is driven to carry out the motion with an opposite direction through the linkage mechanism until the clamping jaws at the two sides are completely attached to a workpiece. The invention has the advantages that: according to the actuator of the binocular vision positioning system, the accurate positioning of the actuator and work piece is better, the transfer time of the work piece is shortened, the universality is strong, the automation rate of production is improved by combining with the use of a control system of a robot, the labor intensity of workers is reduced, the function of humanfactors in the system is reduced, and the production efficiency is improved.

Owner:大连四达高技术发展有限公司

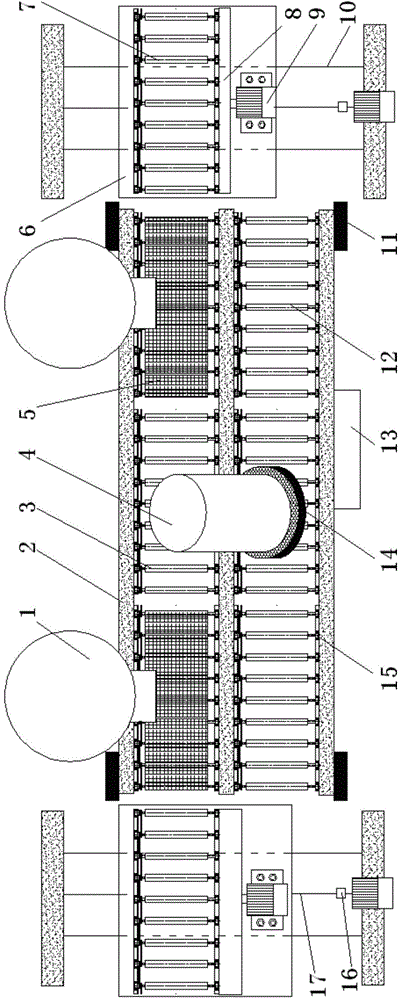

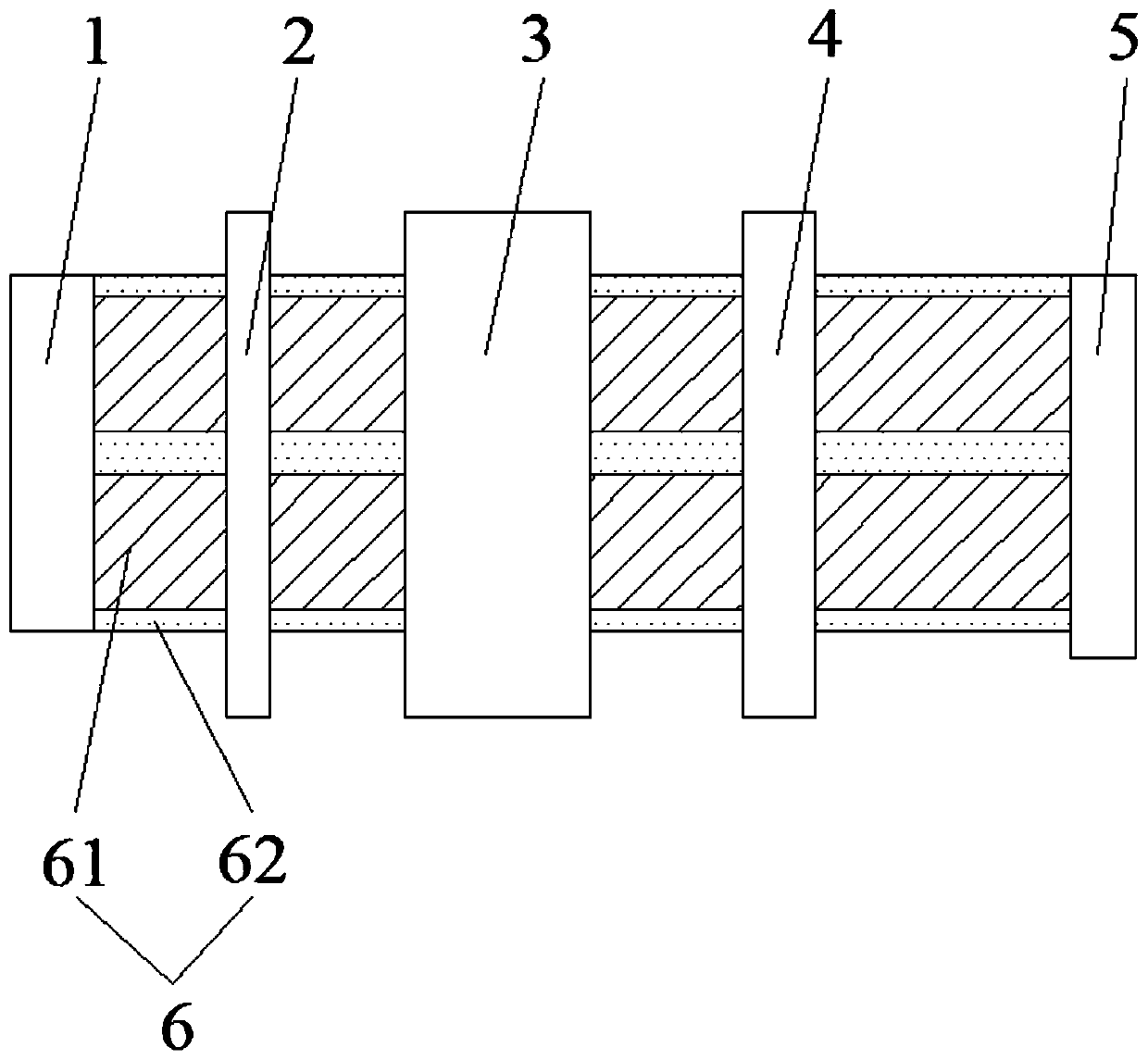

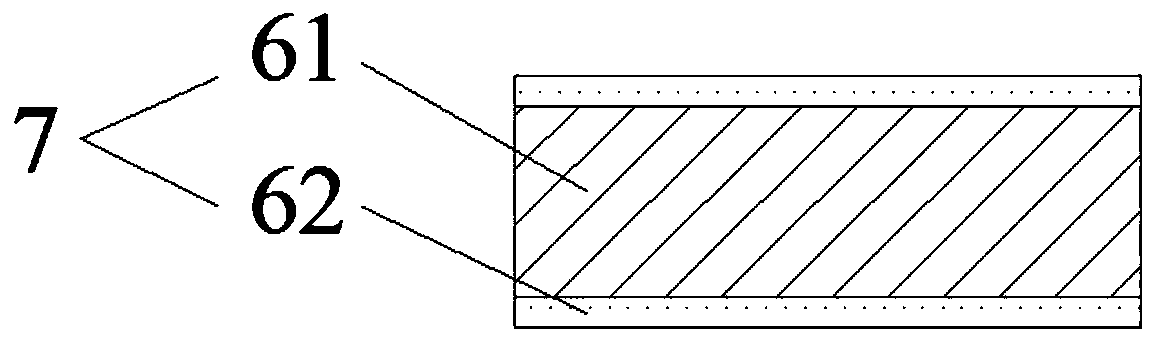

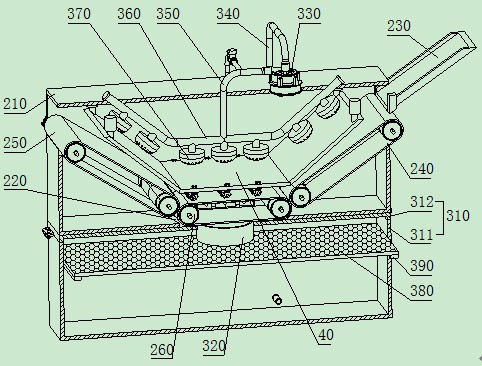

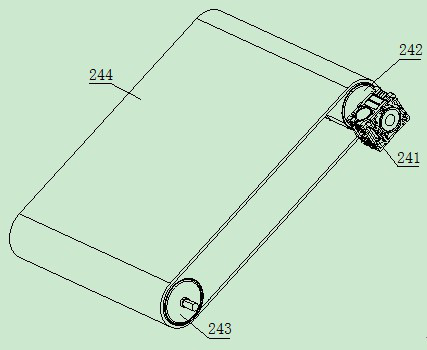

Battery pole piece rolling device and method

InactiveCN110676426AReduce material transfer timesIncrease productivityElectrode rolling/calenderingElectrode collector coatingPhysicsEngineering

The invention belongs to the technical field of lithium ion batteries, and particularly relates to a battery pole piece rolling device. The battery pole piece rolling device comprises an unwinding assembly, a slitting assembly, a rolling assembly, a roller passing assembly and a winding assembly which are in transmission connection in sequence. The slitting assembly comprises a slitting cutter shaft and a plurality of slitting cutters arranged on the slitting cutter shaft. The rolling assembly comprises an upper pressing roller and a lower pressing roller arranged below the upper pressing roller. The invention also relates to a battery pole piece rolling method, which comprises the following steps: coating the surface of a foil with slurry in a zebra coating manner and drying the foil to obtain a single foil with a plurality of dressing areas; slitting the single foil to obtain a plurality of single foil strips; rolling the single foil strips to obtain rolled single foil strips; and winding the rolled single foil strips to complete rolling. According to the rolling method provided by the invention, a pole piece releases stress before rolling, so that the problems of wrinkling and strip breakage of the foil after zebra coating are solved, the production efficiency is improved, and the rework material cost is reduced.

Owner:东莞汇洋动力科技有限公司

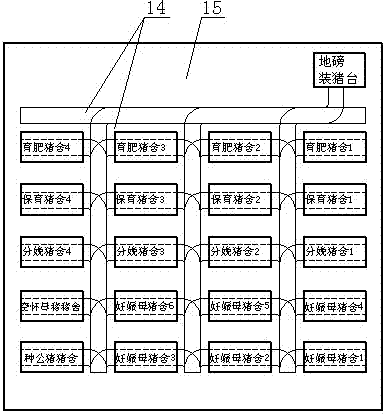

Live pig loading and transportation equipment

Owner:INST OF ANIMAL SCI & VETERINARY MEDICINE SHANDONG ACADEMY OF AGRI SCI

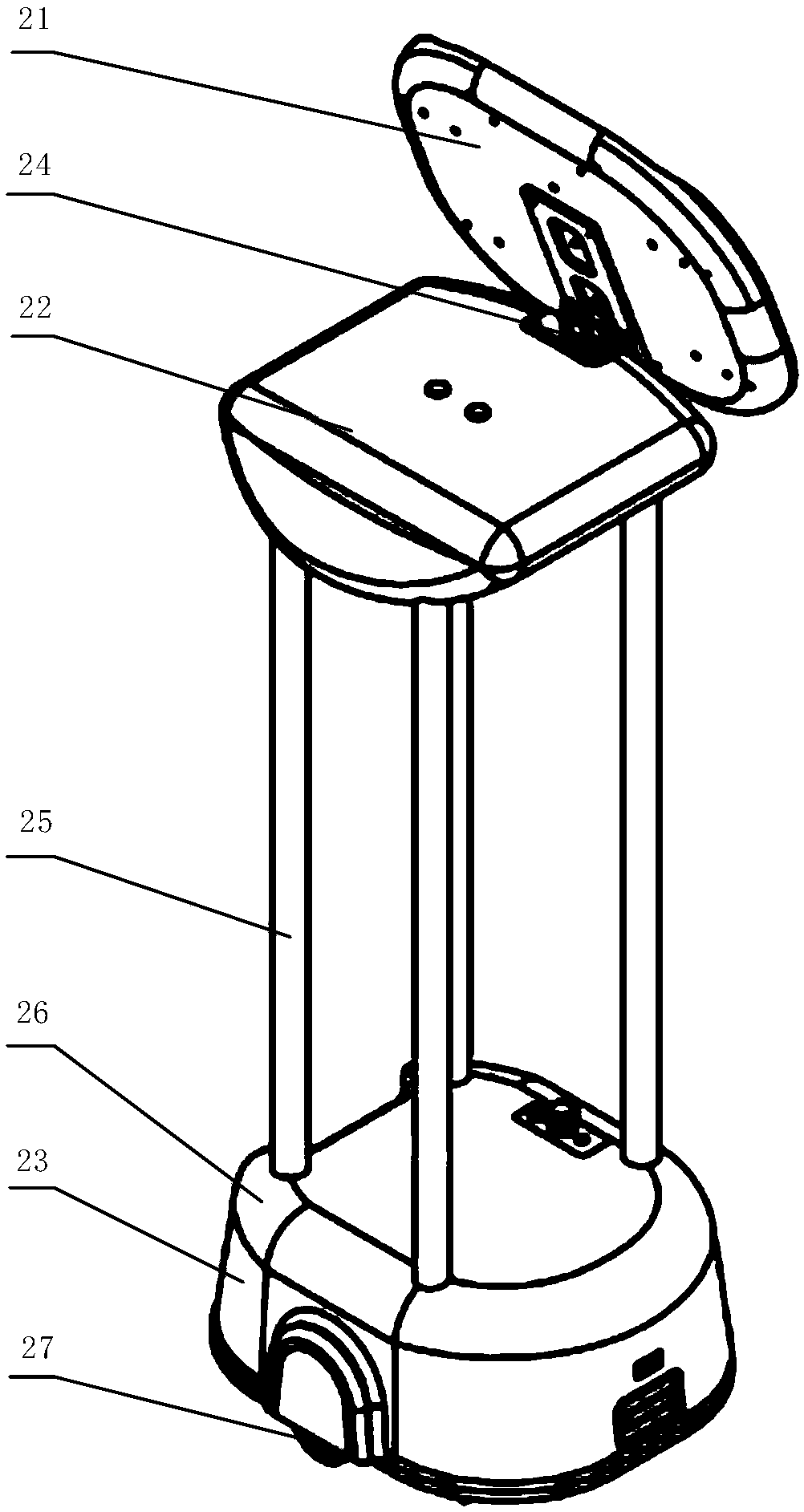

Logistics sorting method and system

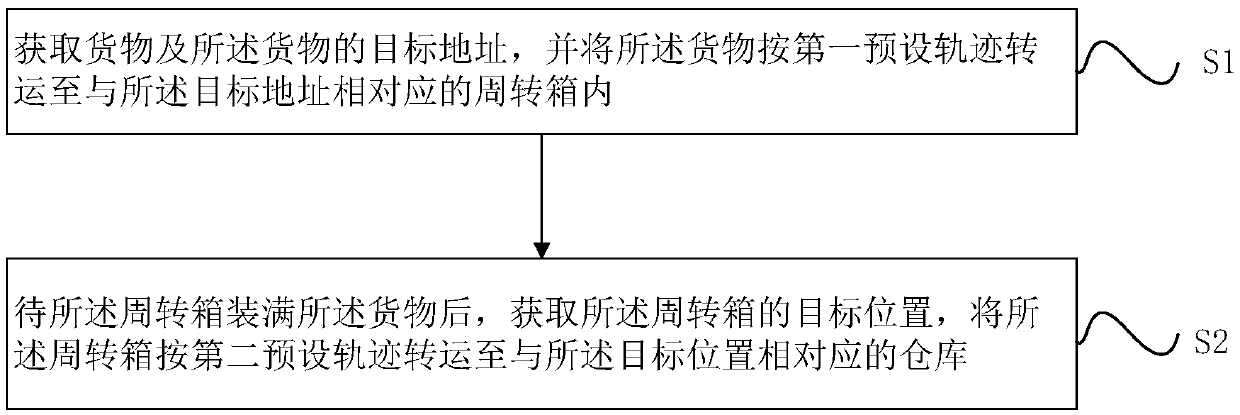

The invention discloses a logistics sorting method. The method comprises the steps that goods and target addresses of goods are acquired, and the goods are transferred into pass boxes corresponding tothe target addresses according to a first preset track; and target positions of the pass boxes are acquired after the pass boxes are filled with the goods, and the pass boxes are transferred to warehouses corresponding to the target positions according to a second preset track. The goods are firstly transferred from initial positions into the pass boxes corresponding to the target addresses of the goods, and then are transferred into the corresponding warehouses from the pass boxes. All logistics equipment is perfectly matched in the whole process, meanwhile, the functions of all the logistics equipment are complete, so that the goods can rapidly reach the warehouses completely without manual transferring in the whole transferring process, the transferring time is shortened, the labor intensity is reduced, and therefore the automation degree is favorably improved. The invention further discloses a logistics sorting system.

Owner:ZHEJIANG GUOZI ROBOT TECH

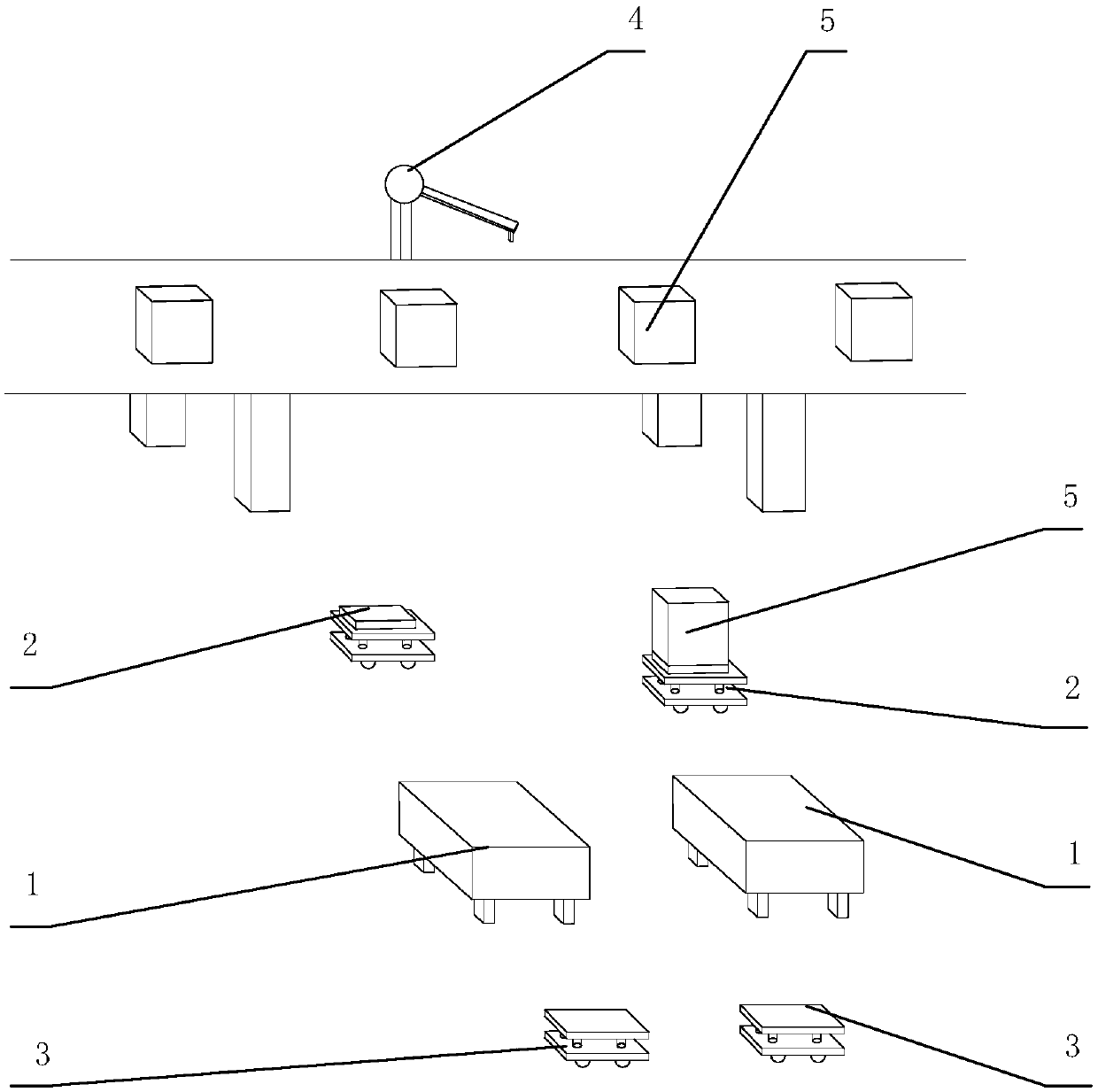

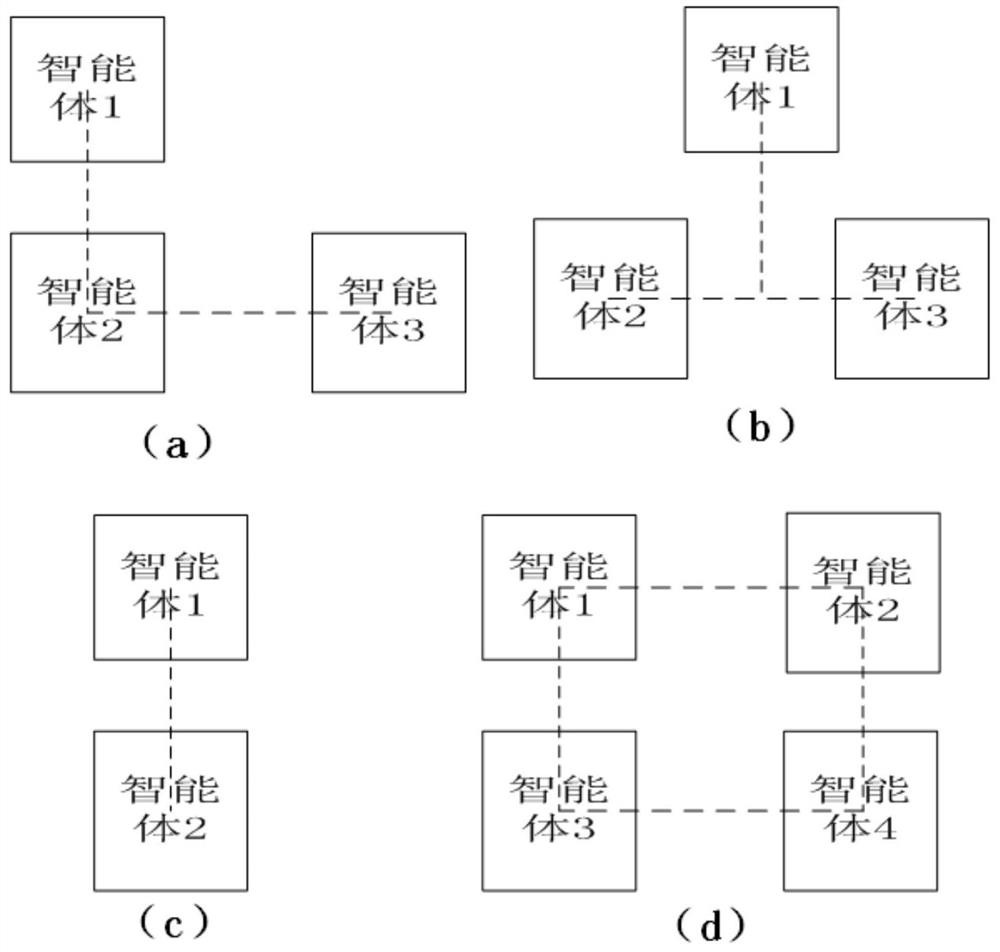

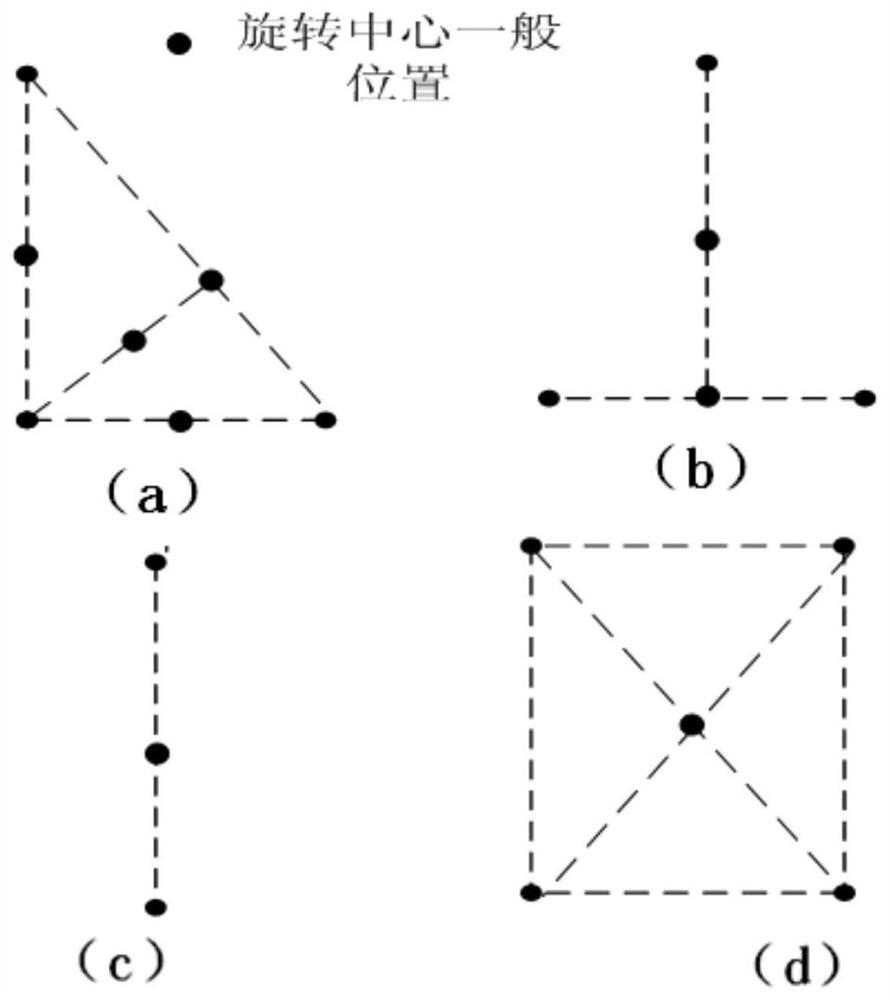

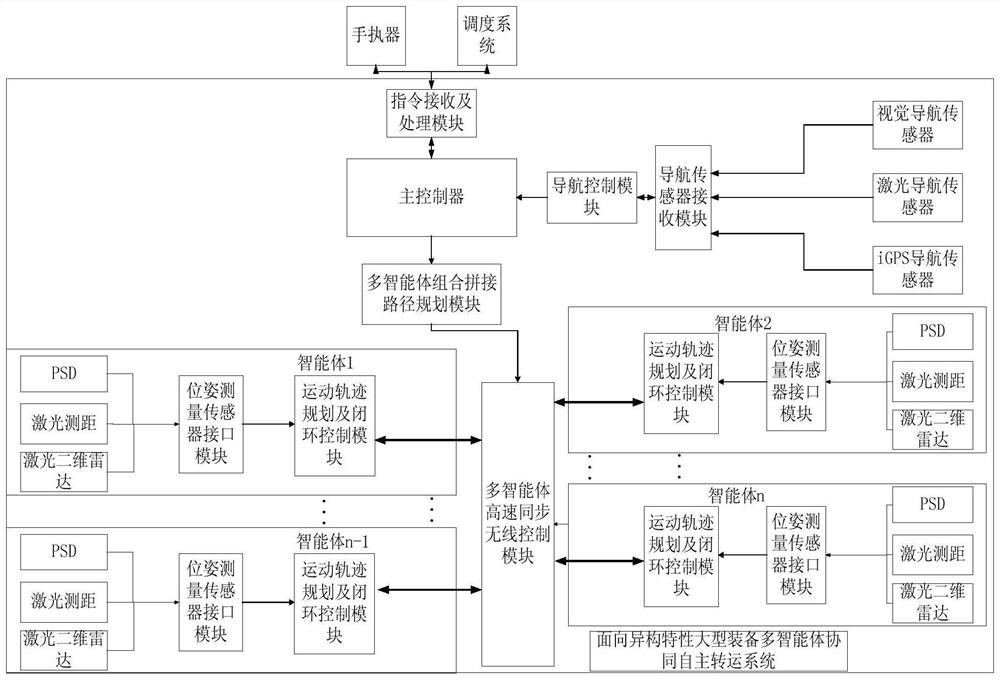

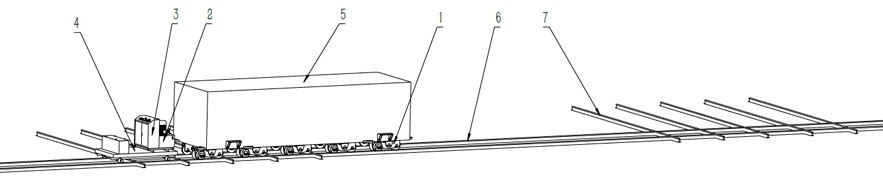

Multi-agent collaborative autonomous transfer system for large equipment with heterogeneous characteristics

ActiveCN113003229AImprove continuityAchieve positioningStorage devicesTotal factory controlPathPingWireless control

The invention discloses a multi-agent collaborative autonomous transfer system for large equipment with heterogeneous characteristics. The multi-agent collaborative autonomous transfer system comprises a main controller, an instruction receiving and processing module, a navigation unit, a combined splicing path planning module, a wireless control module and a plurality of agents. According to the multi-agent collaborative autonomous transfer system for the large equipment with the heterogeneous characteristics, efficient transfer and accurate distribution of high-end equipment are realized through multi-agent autonomous path planning and collaborative operation, so that the diversity and heterogeneous requirements of products in the transfer and accurate distribution process of the high-end equipment are met, the flexibility and the adaptation degree of the equipment are improved, and efficient application of collaborative operation of intelligent equipment in precise transfer, precise distribution and assembly manufacturing links is realized, and the innovative application of the flexible and efficient transfer and accurate distribution process is realized through diversified self-adaptive execution equipment and a transfer mode.

Owner:BEIJING SATELLITE MFG FACTORY

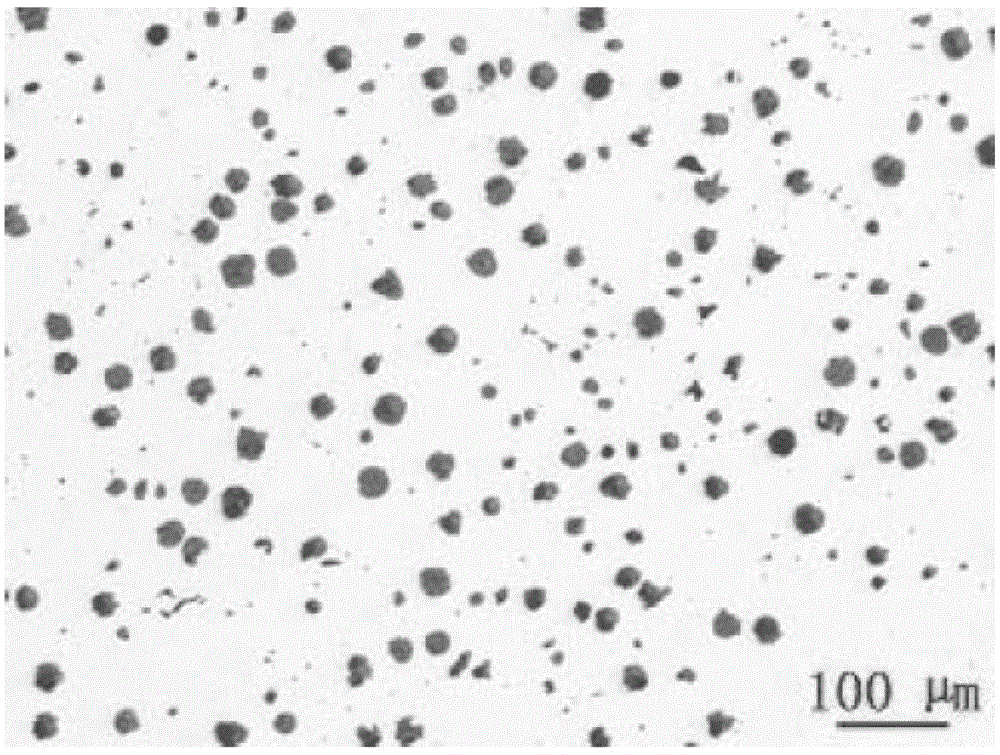

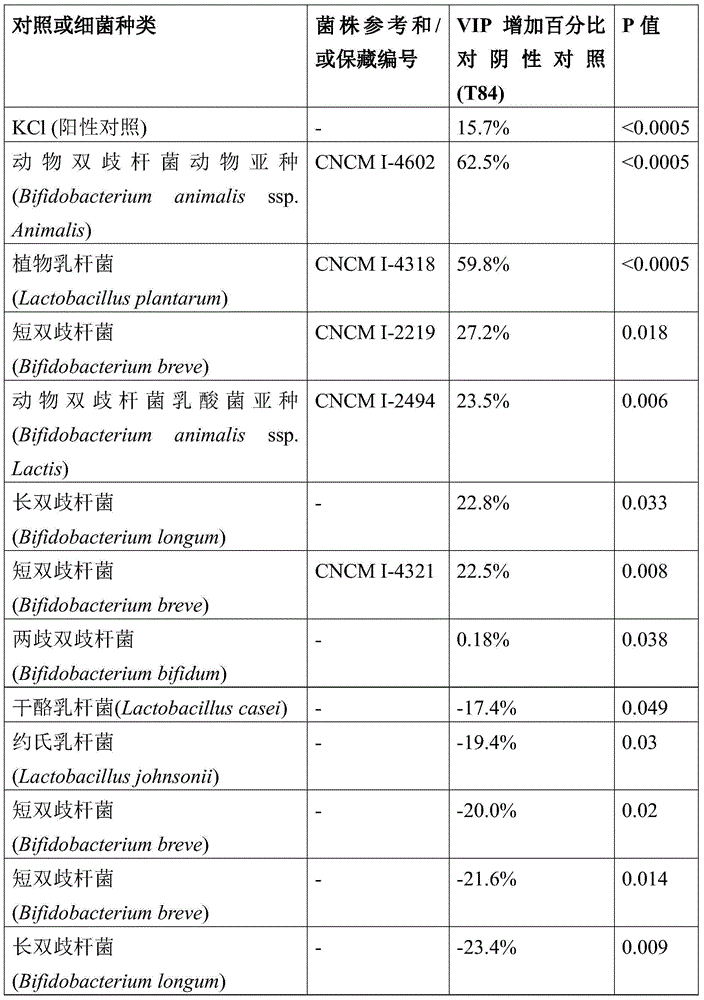

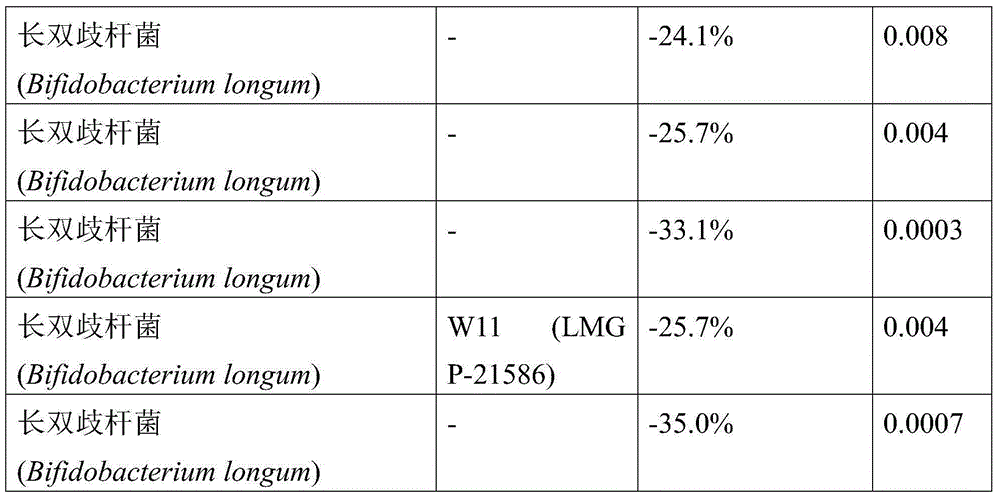

Strain of bifidobacterium animalis ssp. animalis

ActiveCN105025907APromote peristalsisIncreased coordinated contractionMilk preparationMicroorganismsEnteric nervous systemVirology

The invention relates to a novel strain of Bifidobacterium animals ssp. animalis, which is able, inter alia, to improve the function of the enteric nervous system, and to compositions said novel strain.

Owner:DANONE

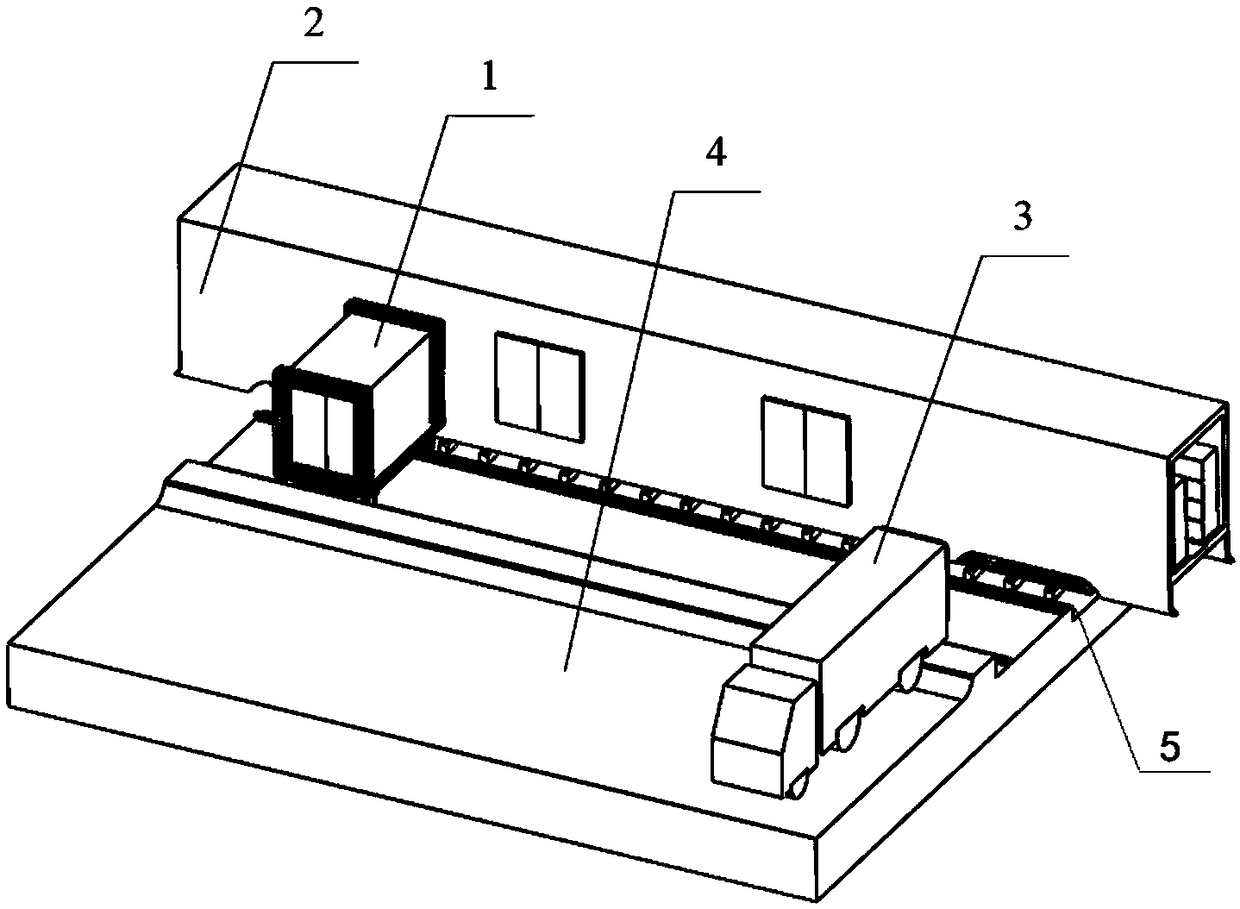

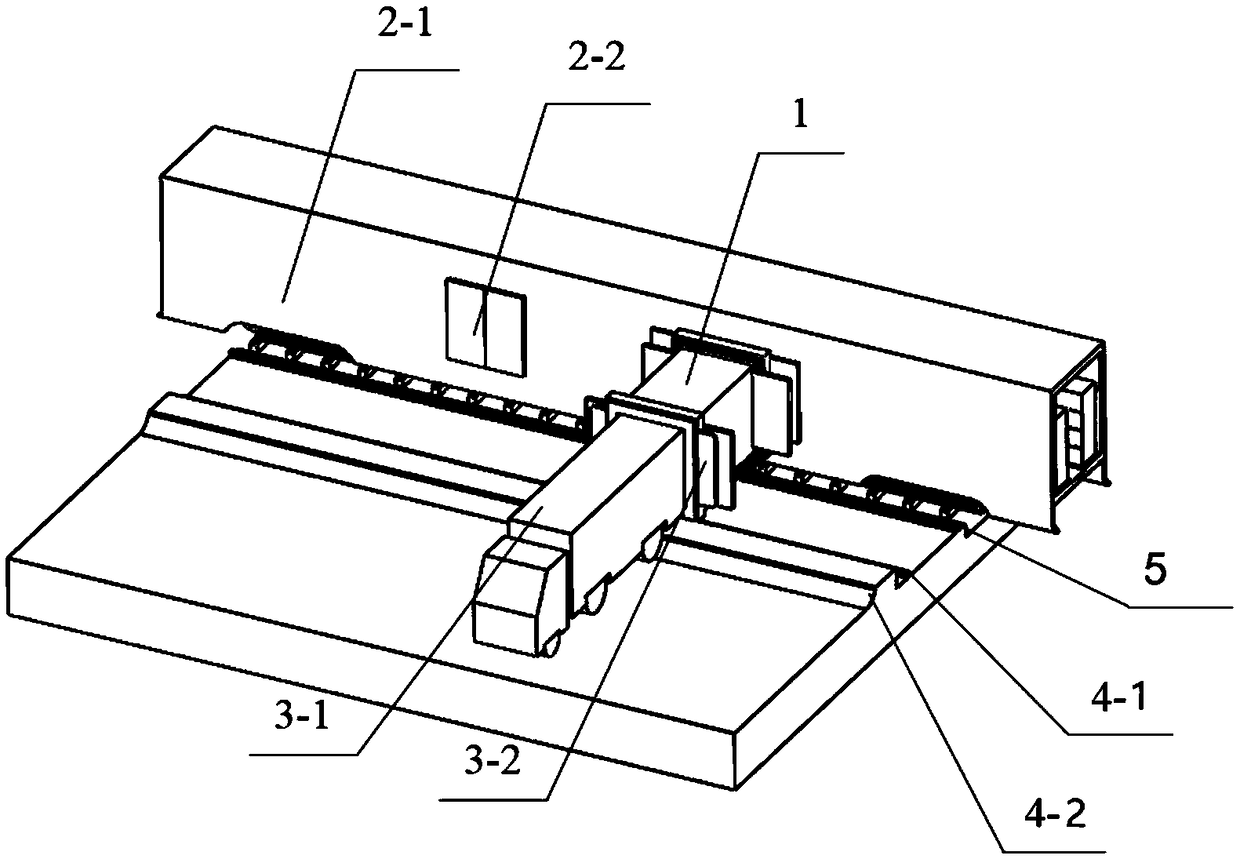

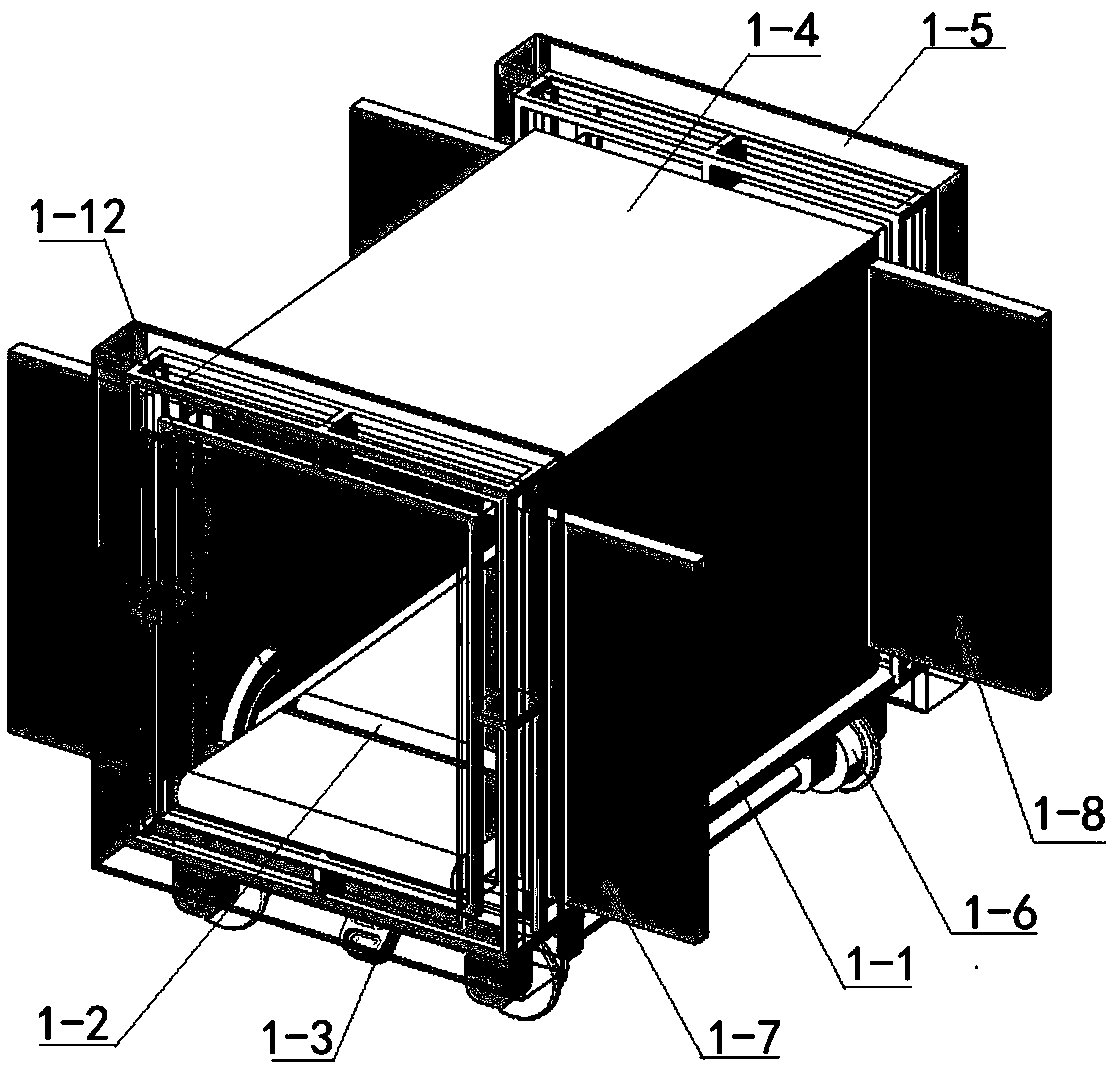

Road-railway combined transportation cold-chain translation butting device and system

PendingCN109081147AImprove docking accuracyAlleviate the problem of docking accuracyLoading/unloadingStorage devicesCold chainRefrigerator car

The invention discloses a road-railway combined transportation cold-chain translation butting device and system. The device comprises a chassis and walking wheels arranged at the four corners of the chassis, wherein a heat preservation butting box is arranged on the chassis; a driving mechanism is arranged between the heat preservation butting box and the chassis and is used for driving the walking wheels to drive the heat preservation butting box to move; elastic buffer devices are arranged at two ends of the heat preservation butting box; detection devices are arranged at the center positions of two ends of the chassis and are used for detecting and judging whether the heat preservation butting box is aligned with a railway heat preservation truck or a cold-chain truck; if the heat preservation butting box is not aligned with the railway heat preservation truck or the cold-chain truck, an offset is calculated, and a first control signal is generated according to the offset, and the walking wheels are driven to drive the heat preservation butting box to move, so as to allow the heat preservation butting box to be aligned with the railway heat preservation truck or the cold-chain truck; and when the heat preservation butting box is aligned with the railway heat preservation truck or the cold-chain truck, a second control signal is sent to control the elastic buffer devices to be inflated to realize sealed butting. The road-railway combined transportation cold-chain translation butting device can effectively avoid direct contact between frozen cargoes and air in a transferring process; and the intelligence and the stability of a frozen cargo transmission process and the parking precision of the railway heat preservation truck are improved.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

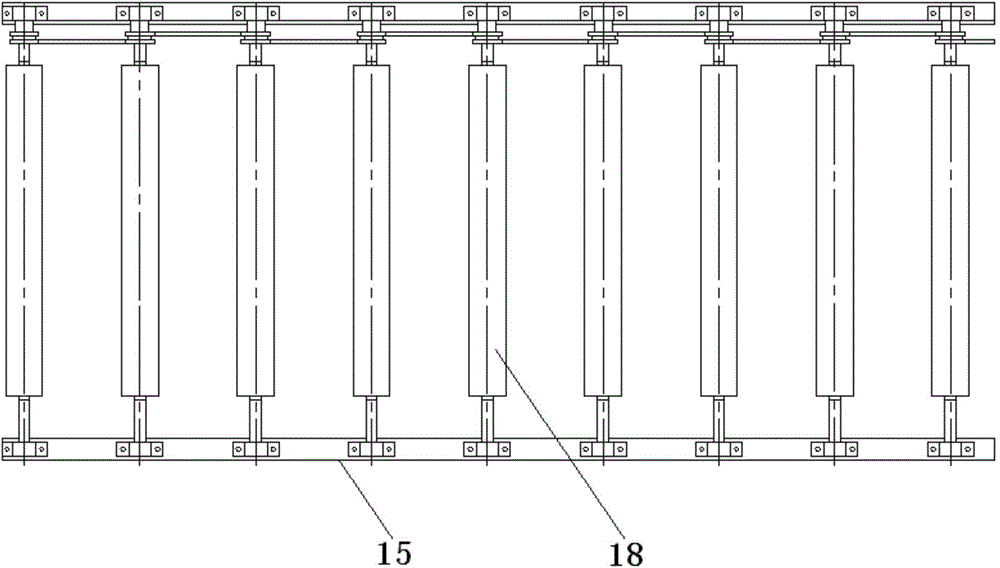

Power semiconductor lead frame production integrated equipment

InactiveCN114433695AGuaranteed cleanlinessSave time in transitCleaning using toolsCleaning using liquidsProcess engineeringLead frame

The embodiment of the invention provides power semiconductor lead frame production integrated equipment, and relates to the technical field of lead frame production and processing equipment. The power semiconductor lead frame production integrated equipment comprises a punching machine, a workpiece conveying mechanism and a workpiece cleaning mechanism. The workpiece conveying mechanism comprises a machine box, a partition plate, a discharging plate, a feeding conveying assembly, a discharging conveying assembly and a middle conveying assembly, the machine box is arranged on one side of the punching machine, and a feeding port and a discharging port are formed in the two sides of the machine box respectively. When the lead frame is conveyed by the feeding conveying assembly, the discharging conveying assembly and the middle conveying assembly, the first water pump operates, and the first water pump pumps a water source in the water tank through a water inlet pipe; a water source passes through a water outlet pipe and a V-shaped drainage pipe and is finally sprayed out from a first spray head to the lead frame transported above the feeding conveying assembly, the discharging conveying assembly and the middle conveying assembly, so that impurities on the surface of the lead frame are cleaned.

Owner:江喜红

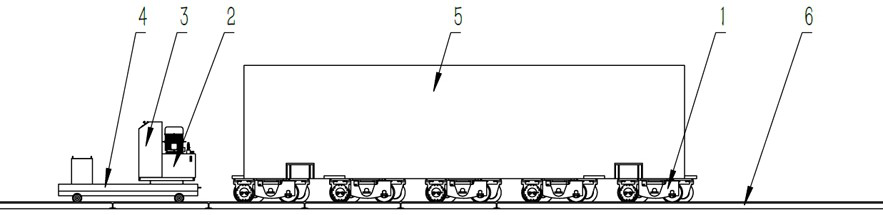

Self-walking device of large transformer

PendingCN112079066ARealize on-orbit self-propelled displacementEliminates many problems with shifting methodsMechanical conveyorsTransformerEconomic benefits

The invention discloses a self-walking device of a large transformer. The self-walking device comprises a walking wheel set, a hydraulic driving system, a control cabinet and a driven walking mechanism, wherein the walking wheel set comprises a plurality of walking wheel mechanisms, the walking wheel mechanisms are uniformly distributed and installed at the bottom of the transformer, the walking wheel mechanisms are power and carriers of the transformer, the hydraulic driving system and the control cabinet are integrated on the driven walking mechanism, the driven walking mechanism is hung onthe transformer through rigid connection, and one end of the hydraulic driving system is in transmission connection with the walking wheel mechanisms. The walking wheel set is provided with the corresponding hydraulic system, so that on-orbit self-walking displacement of the large transformer is realized, and many problems existing in a rope traction displacement mode are eliminated; a ground anchor does not need to be arranged on site, the conveying process is coherent and rapid, and the transfer time of more than ten days can be shortened to one day; and the self-walking device walks stably,safely and reliably, so that the operation efficiency is greatly improved, the engineering construction period or the shutdown maintenance period is shortened, and the economic benefit and the socialbenefit are extremely considerable.

Owner:CHINA YANGTZE POWER +1

Stretcher for ambulance

The invention discloses a stretcher for an ambulance. The stretcher comprises a lower stretcher capable of sliding on the ground, wherein a first-aid equipment placement rack allowing placement of first-aid equipment is arranged at the top of the lower stretcher; an upper stretcher allowing a patient to lie down is arranged at the top of the first-aid equipment placement rack. The stretcher for the ambulance has the advantages: when a critical patient is transferred by the stretcher for the ambulance, a medical worker can place accompanying first-aid equipment on the first-aid equipment placement rack orderly, so that the critical patient cannot be compressed by the first-aid equipment in the transfer process, and first-aid treatment of the critical patient is facilitated; pipe winding ofthe first-aid equipment is avoided, after the ambulance arrives at a treatment center, all that is required for the medical worker is to carry the first-aid equipment placement rack and the upper stretcher to a transfer trolley of the treatment center together, the step for untangling pipes of the first-aid equipment before transfer at present is omitted, transfer time for the patient is shortenedgreatly, and the critical patient can be rescued timely.

Owner:JIANGSU RIXIN MEDICAL EQUIP +1

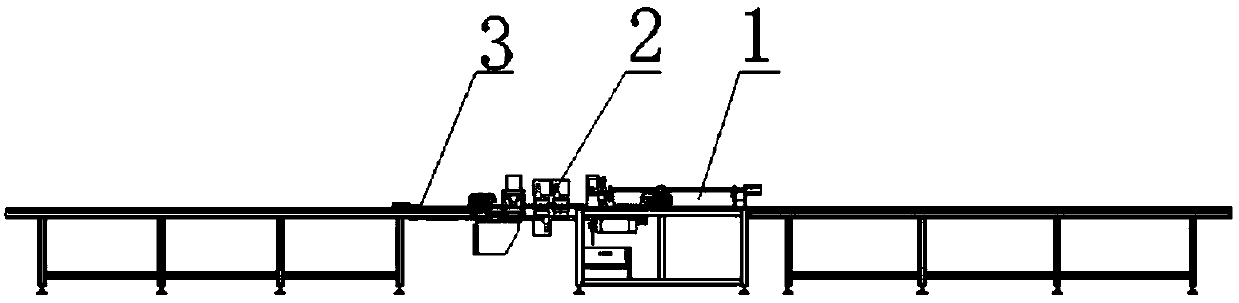

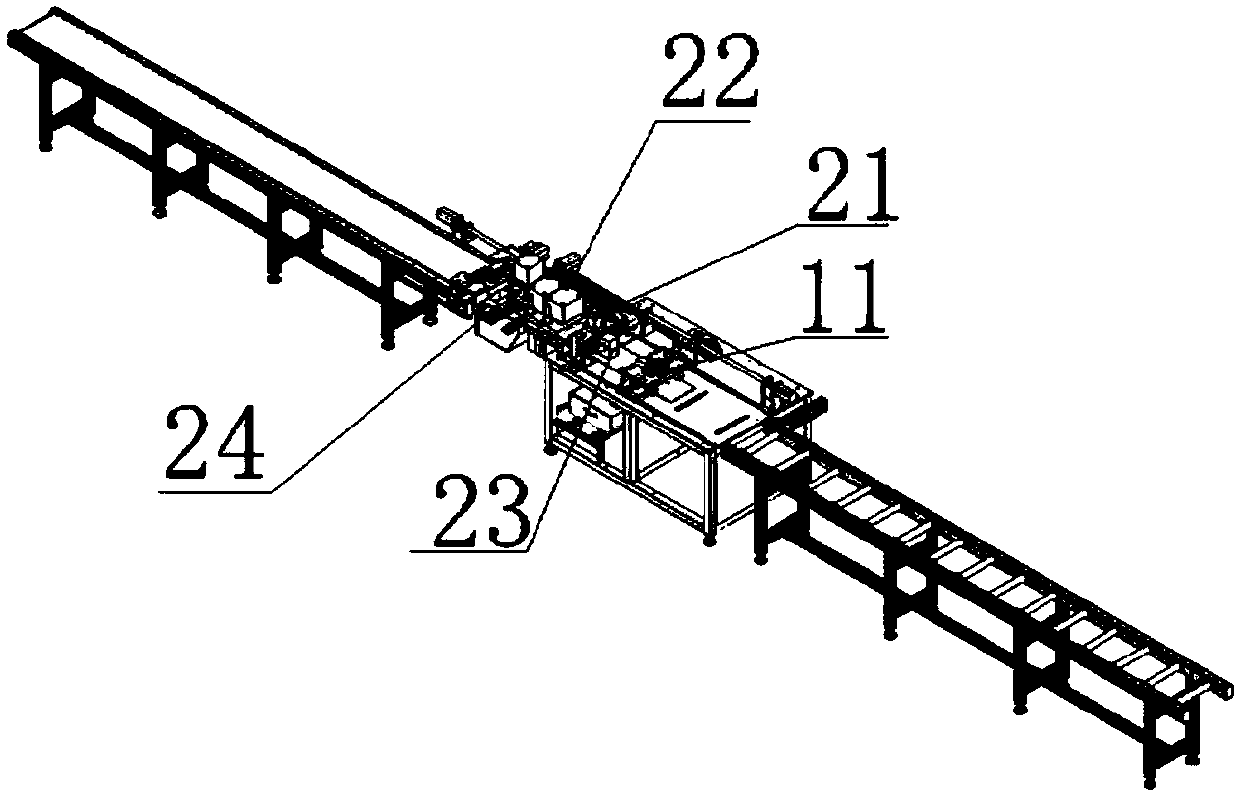

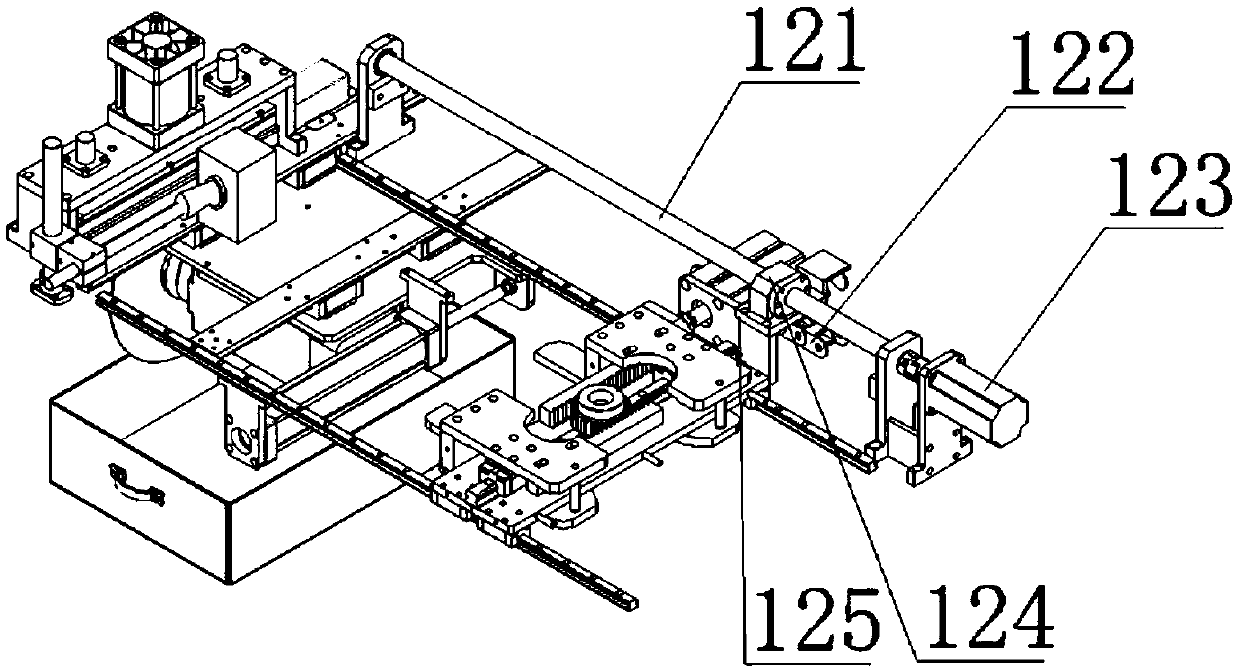

Copper bar machining equipment

InactiveCN110773655AFully automatedIncrease productivityMetal-working feeding devicesPositioning devicesElectric machineryMachining

The invention discloses copper bar machining equipment. The copper bar machining equipment comprises a feeding mechanism, a machining mechanism, a discharging mechanism and a control device, wherein the feeding mechanism, the machining mechanism, the discharging mechanism and the control device are sequentially connected, the control device is connected with the feeding device, the machining device and the discharging device, the feeding mechanism comprises a transmission device, a first positioning device, a second positioning device which are connected with the control device, the transmission device comprises a screw rod, a motor and a roller cylinder, the motor and the roller cylinder are connected with the control device, the motor is connected with the screw rod, the screw rod is arranged at the two ends of the roller barrel in a manner of being perpendicular to the roller barrel, the first positioning module is connected with the screw rod through feed screw nuts, and the secondpositioning device is arranged on the roller barrel in a manner of being perpendicular to the first positioning device. According to the scheme, the structure design is reasonable, the multi-purposemachine can be realized, the full process automation of copper bar production is realized, the production efficiency of copper bar machining is improved, and the labor cost is saved.

Owner:苏州凯艾帝电气有限公司

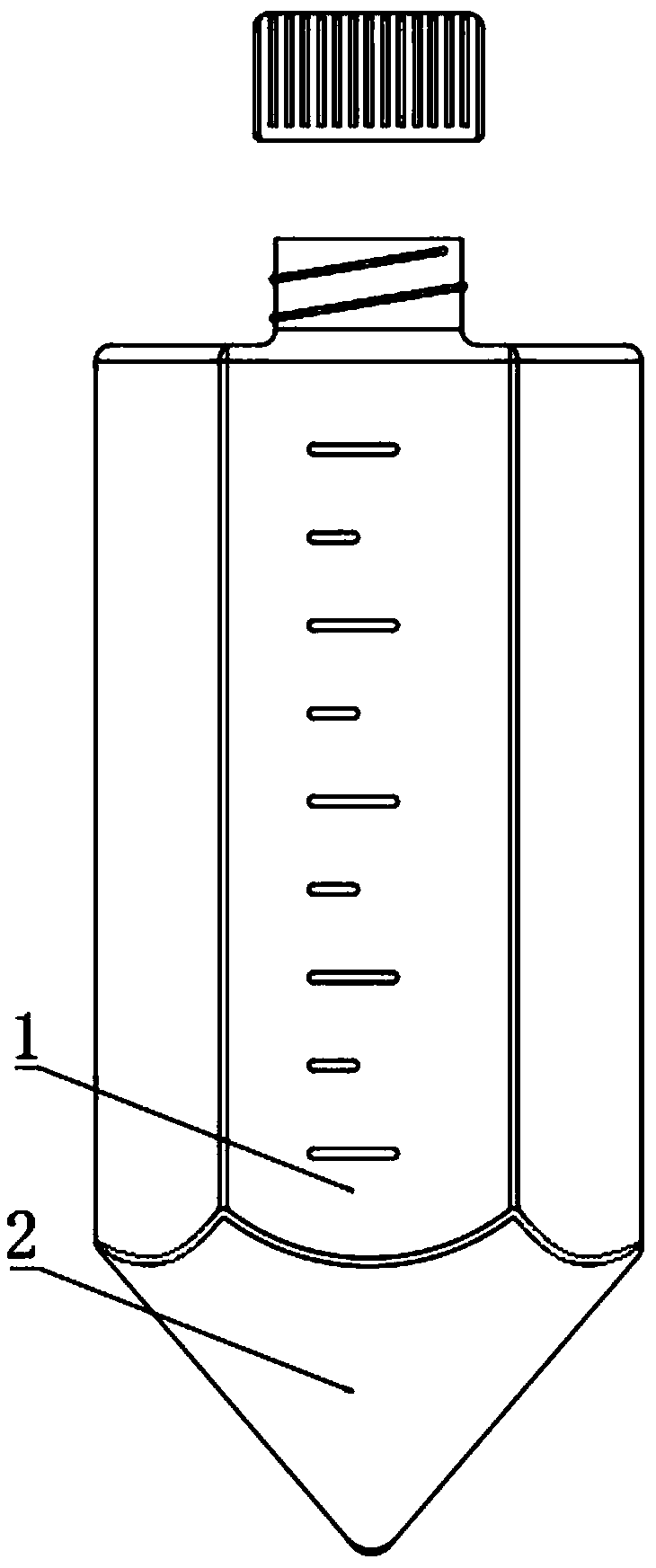

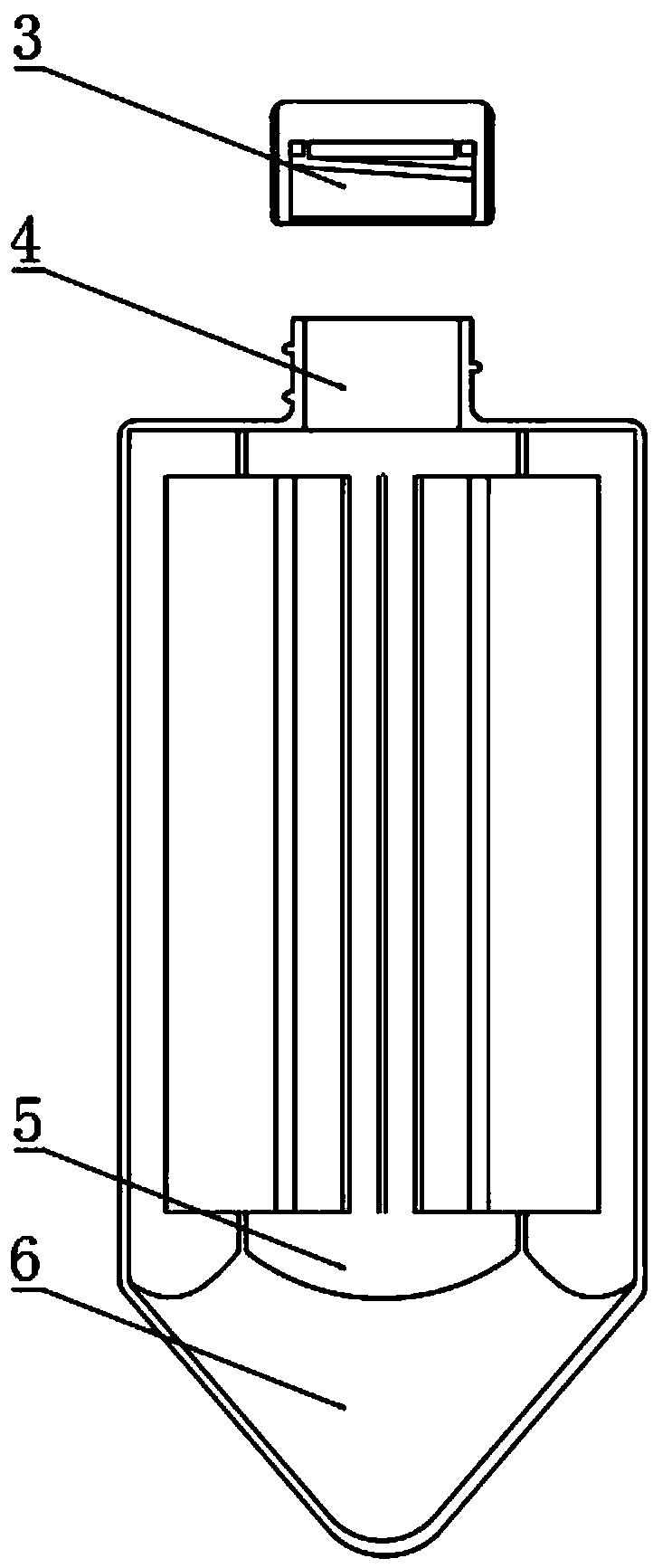

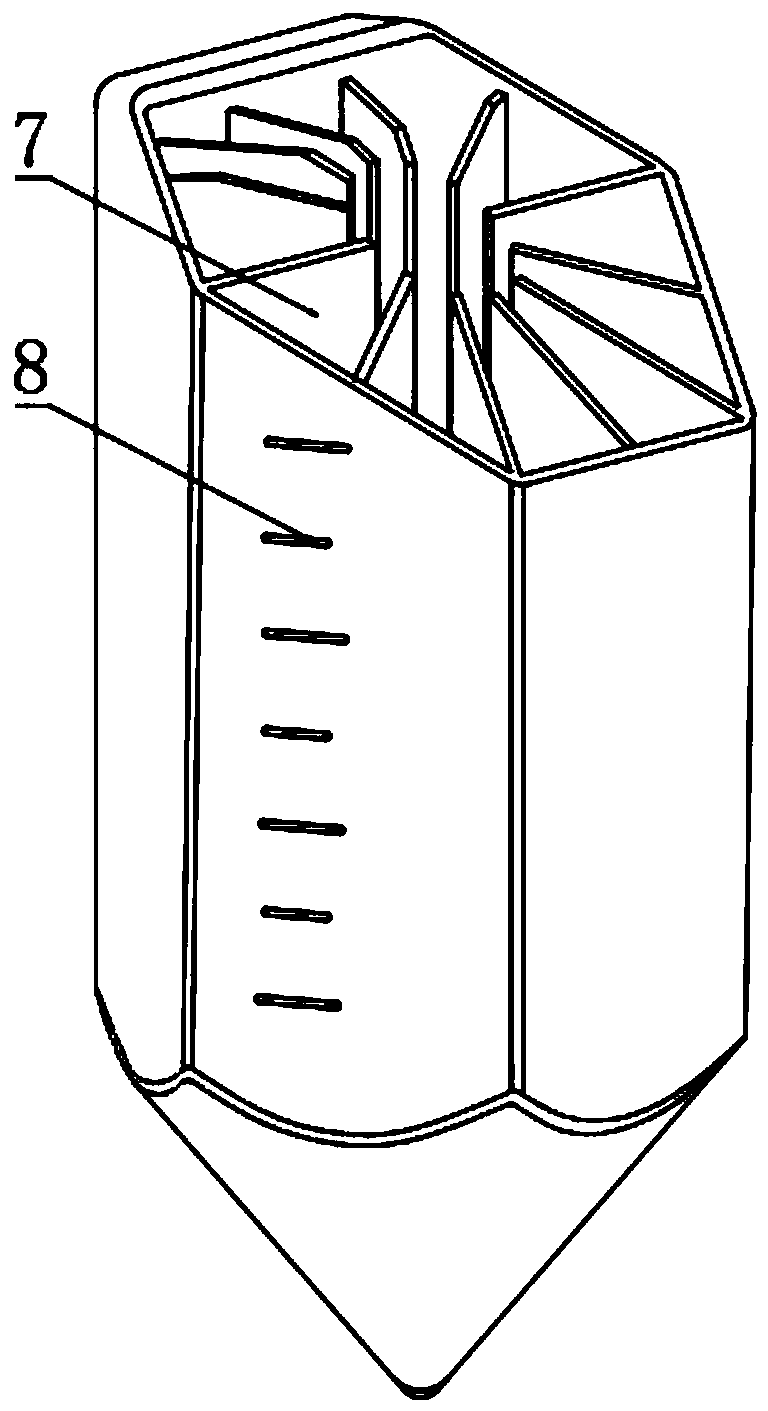

Attached cell culturing container suitable for automatic equipment

InactiveCN109401972AIncrease the wall areaConvenient for compact arrangementBioreactor/fermenter combinationsBiological substance pretreatmentsCentrifugationEngineering

The invention relates to the field of culturing containers, in particular to an attached cell culturing container suitable for automatic equipment. The container comprises a culturing container bottlebody, a fully air-permeable bottle cap and a cell attaching wall panel, the culturing container bottle body comprises a centrifugal bottle bottom collector, a bottle mouth, an inner cell attaching wall, an oblique slope panel and a cell attaching wall panel, the interior of the centrifugal bottle bottom collector is provided with an oblique slope panel, one end of the centrifugal bottle bottom collector is provided with an inner cell attaching wall, the interior of the inner cell attaching wall comprises a plurality of cell attaching wall panels, and a scaling ruler is arranged at the exterior of the culturing container bottle body. The container has the advantages that the container can be used as a single container in the attached cell culturing process for culturing, centrifugation, sample observation, in-process transferring and the like, liquid bottle opening / closing operation, liquid transferring operation, multi-type container storage and multi-type container conversion in thewhole automatic production process are simplified, and the production efficiency and benefits are effectively improved.

Owner:INNOVEL INTELLIGENT TECH CO LTD

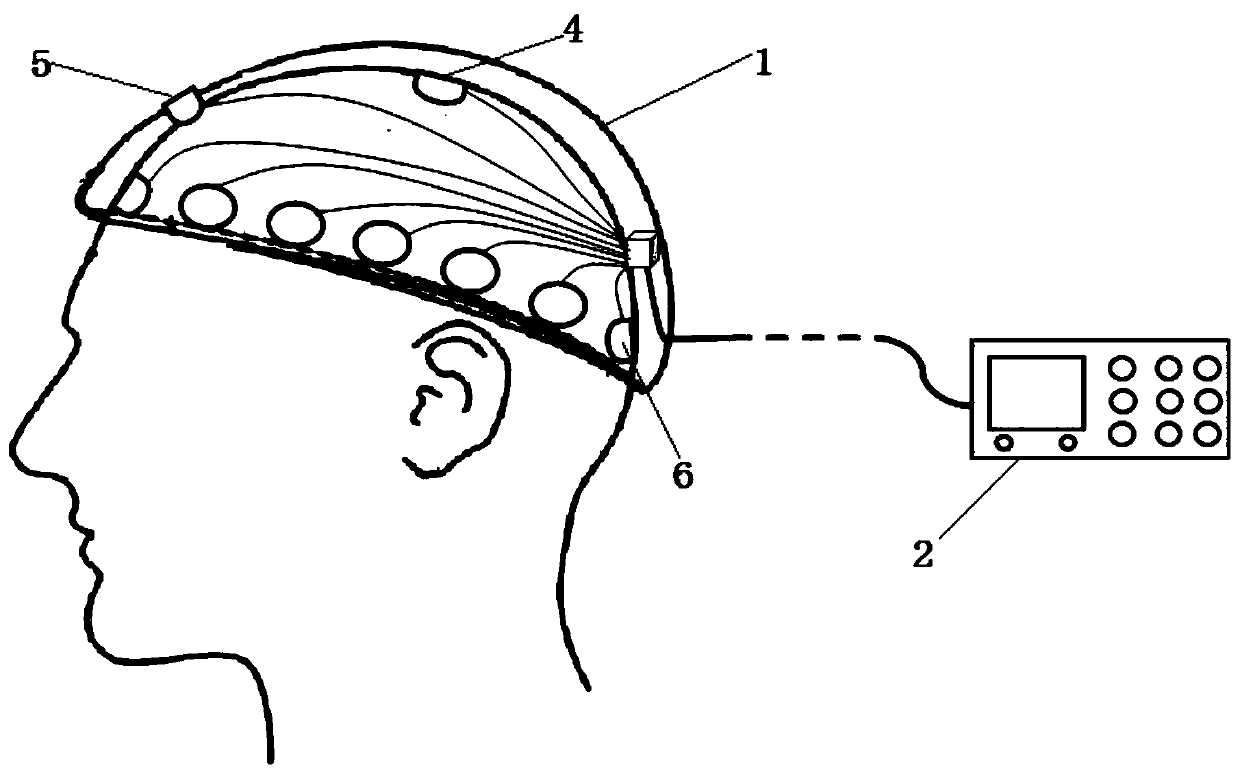

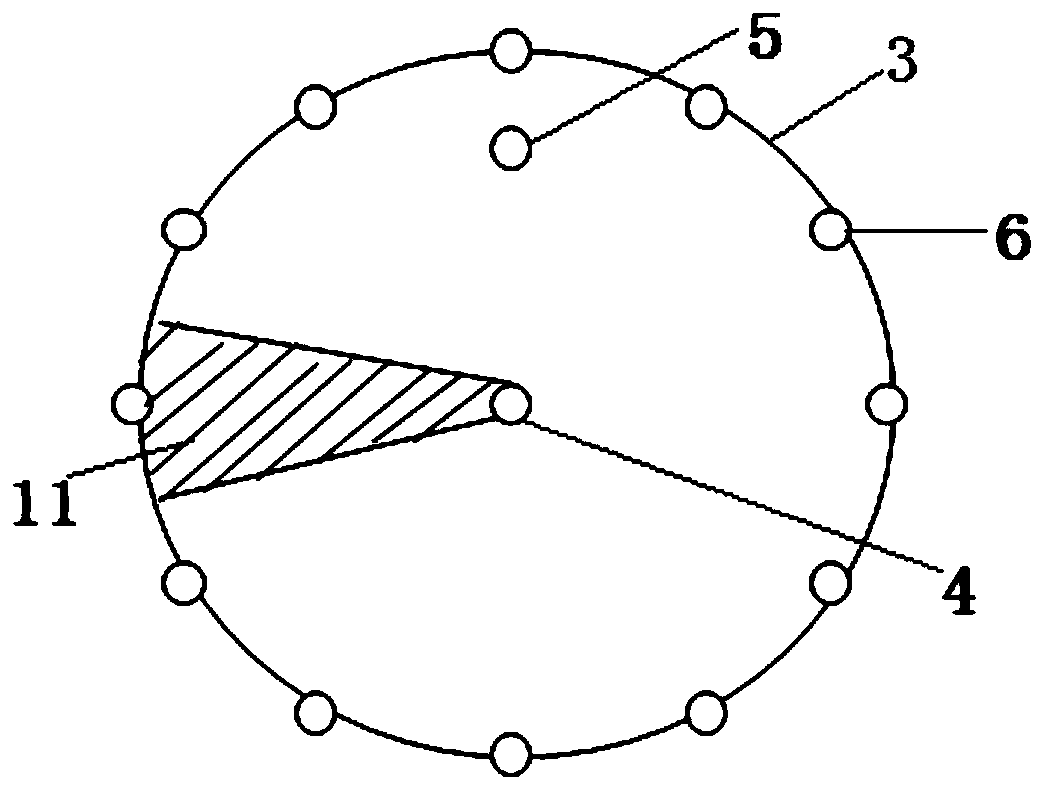

Portable traumatic intracerebral hemorrhage early warning and rapid evaluation device

PendingCN109846460ASave rescue timeSimple structureDiagnostic recording/measuringSensorsTreatment delayEngineering

The invention discloses a portable traumatic intracerebral hemorrhage early warning and rapid evaluation device. The device comprises an electrode head sleeve and a quantitative electroencephalogram analyzer; the electrode head sleeve comprises a head sleeve body and electrodes fixedly arranged on the inner surface of the head sleeve body, the electrodes are metal electrode sheets, the electrodesare connected to the head sleeve body through leads, and each electrode comprises a reference electrode, a grounding electrode and an active electrode; the reference electrode is positioned at the central position of the electrode head sleeve and corresponds to the top of the head of the patient; the active electrodes are evenly distributed around the skull and are used for extracting the brain wave shape of the patient; the position of the grounding electrode corresponds to a position on head top central line one third to the forehead; and the quantitative electroencephalogram analyzer carries out quantitative analysis on the original electroencephalogram shape monitored by the electrode head sleeve. The device can rapidly, simply, conveniently, safely and effectively carry out early warning and rapid evaluation on a trauma patient who is likely to have intracerebral hemorrhage, and avoids misdiagnosis and treatment delay.

Owner:NANJING DRUM TOWER HOSPITAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com