Multi-agent collaborative autonomous transfer system for large equipment with heterogeneous characteristics

A technology of large-scale equipment and intelligent bodies, applied in storage devices, transportation and packaging, etc., can solve the system solutions that lack flexibility, flexibility and integration in the transfer mode, and cannot meet the requirements of high quality, high efficiency and flexibility. Intelligent transfer requirements, restrictions on high-end equipment and other issues, to achieve the effect of shortening product transfer time, realizing autonomous health management, and realizing efficient application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

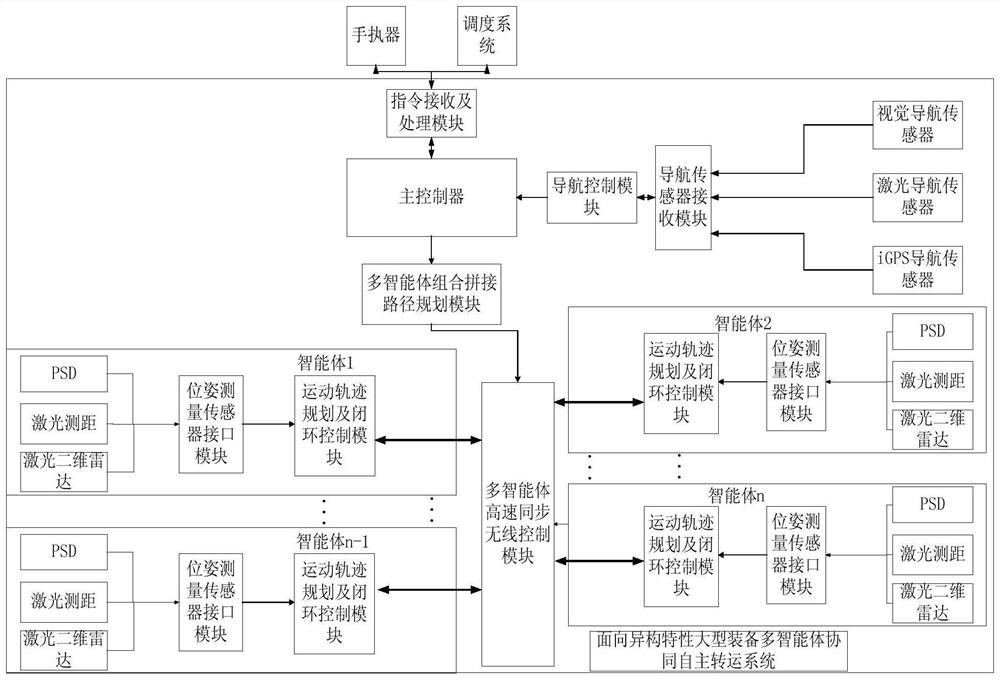

[0061] Specific embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

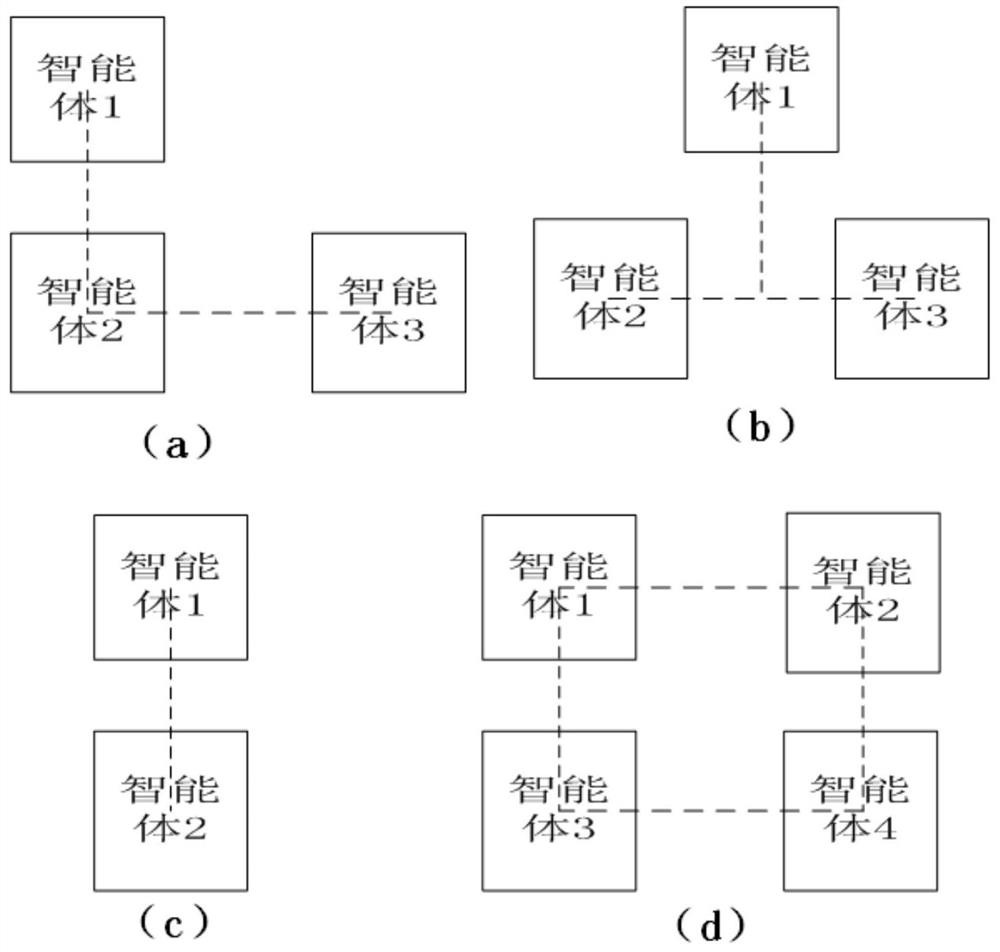

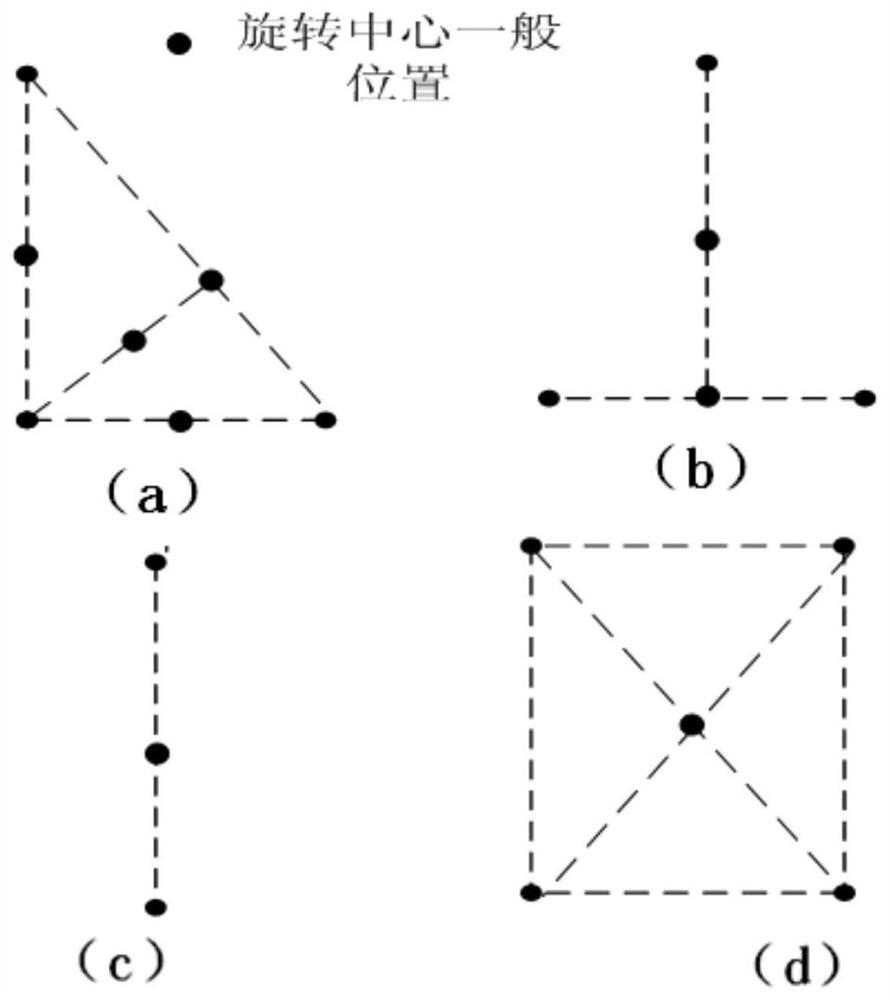

[0062] Facing the needs of ultra-large loads or flexible transfer in narrow heterogeneous spaces, it is necessary to break through the multi-agent cooperation and autonomous heterogeneous formation cooperative control technology based on omnidirectional intelligent equipment, and to have the ability to achieve high-end equipment efficiency based on multi-vehicle heterogeneous formation and cooperative control. , flexible and generalized transfer, and develop a generalized transfer platform to meet the requirements of diversification and heterogeneity in the transfer of high-end equipment products, improve the flexibility and adaptability of equipment transfer, and realize the precise transfer of intelligent equipment collaborative operations.

[0063] In addition, construct a continuous navigation and high-precision spatial positioning ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com