Steel pipe column concrete lateral pouring method and steel pipe column structure used in method

A technology of concrete and steel pipe columns, which is applied in the field of steel pipe column structures, can solve the problems of low turnover efficiency and long time consumption, and achieve the effects of shortened pouring time, simple pouring, and shortened construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0029] This example takes the R&F Yingkai Plaza project located in the core business district of Zhujiang New Town, Guangzhou as an example. The project has 5 floors underground and 65 floors above ground. It is a high-rise building with a frame-core tube structure, and the core tube is reinforced concrete shear force Wall structure, the outer cylinder structure is composed of 16 underground and 20 steel pipe concrete columns on the ground to form a side end support system. Pour 110mm thick concrete slab.

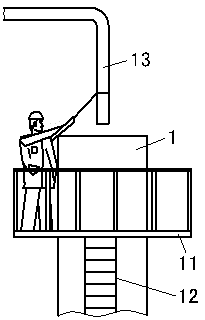

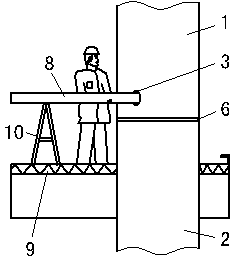

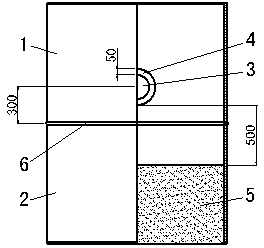

[0030] In this project, the supporting structure of steel pipe columns is used more, the height of steel pipe columns is high, and the engineering volume is large. In order to meet the requirements of the construction period, in this project, the pouring technology of traditional steel pipe column concrete (see figure 1 ) was innovated to use lateral pouring (see figure 2 )technology. This technology is to process a pouring hole 3 on the side wall of one end of ea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com