Tunnel support device of coal mine goaf and construction method thereof

A technology of roadway support and construction method, which is applied in tunnels, tunnel linings, installation of bolts, etc., can solve the problems of difficult detection of goafs, poor self-stabilization ability, and poor support effects, and ensure the safety of operators. , The effect of large working space and high support strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

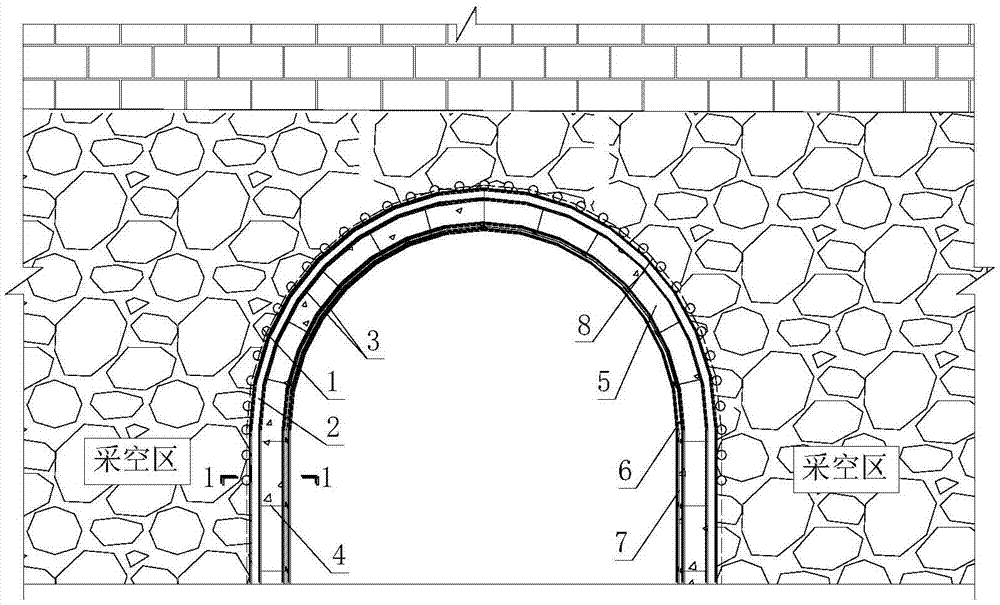

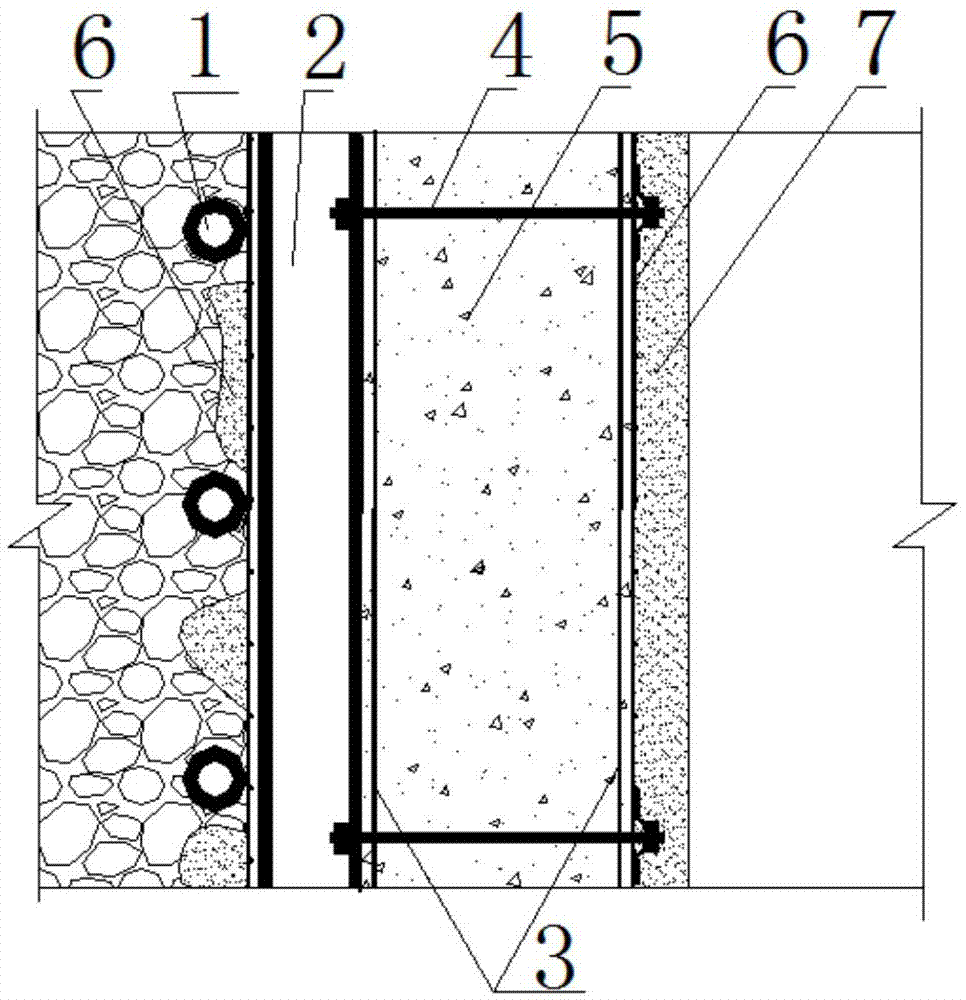

[0029] The invention provides a coal mine goaf roadway support device, such as figure 1 with figure 2 As shown, it includes more than two steel pipes 1 arranged along the roadway peripheral contour line 8 perpendicular to the plane of the roadway peripheral contour line 8, and more than two steel brackets perpendicular to the steel pipe 1 are arranged in the area surrounded by two or more steel pipes 1 2. The steel brackets 2 are parallel to each other and connected sequentially. Each steel bracket 2 is connected to each steel pipe 1 respectively. Each steel bracket 2 is provided with more than two anchor bolt holes, and each anchor bolt hole is equipped with an anchor bolt 4. , the flexible formwork 3 and the steel mesh 6 are sequentially worn on the anchor bolt 4, the flexible formwork 3 is provided with concrete, and two adjacent flexibl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com