Liquid anti-segregation agent and preparation method thereof

An anti-segregation agent and liquid technology, applied in the field of concrete admixtures, can solve the problems of increased concrete water consumption and slurry-bone ratio, high cohesion performance, and fast concrete settling speed, achieving excellent dispersion performance and reducing surface tension , the effect of excellent salt resistance performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Weigh 5.34g of N,N-dimethylacrylamide and dissolve it in 15g of deionized water, stir well to obtain solution B for use; weigh 2.23g of tristyrylphenol polyoxyethylene ether methacrylate and dissolve it in 10g of deionized In water, stir evenly to obtain solution C for use; weigh 0.4g mercaptoethanol and 0.74gVC to dissolve in 40g deionized water, stir evenly to obtain a chain transfer agent solution for use; weigh 42.43g 2-acrylamide-2-methyl Add propanesulfonic acid and 150g deionized water into the reaction vessel and heat to dissolve. After the temperature reaches 50°C, add 3g of 30wt% hydrogen peroxide solution and keep stirring for 5min. After dropping for h, continue to keep warm for 2 hours. After the reaction, add aqueous sodium hydroxide solution to adjust the pH value of the system to 7.8, and then discharge the product to obtain the product.

Embodiment 2

[0042] Weigh 5.34g of acrylamide and dissolve it in 15g of deionized water, stir evenly to obtain solution B for use; weigh 4.47g of tristyrylphenol polyoxyethylene ether methacrylate and dissolve it in 10g of deionized water, stir evenly to obtain Solution C is ready for use; weigh 0.4g of mercaptoethanol and 0.74g of VC and dissolve it in 20g of deionized water, stir evenly to obtain a chain transfer agent solution for use; put 40.19g of sodium methacrylate and 150g of deionized water into the reaction vessel Heat to dissolve, and when the temperature reaches 50°C, add 1.06g of 30wt% hydrogen peroxide solution and keep stirring for 5 minutes, then start to add solution B, solution C and chain transfer agent solution dropwise at a constant speed, and finish dropping in 3.5 hours, then continue to keep warm for 2 hours, and then After the completion, add sodium hydroxide aqueous solution to adjust the pH value of the system to 7, and then discharge the product to obtain the pro...

Embodiment 3

[0044] Weigh 2.67g of N,N-dimethylacrylamide and dissolve it in 10g of deionized water, stir well to obtain solution B for use; weigh 2.67g of long-chain alkyl alcohol polyoxyethylene ether methacrylate and dissolve it in 15g of deionized In water, stir evenly to obtain solution C for use; dissolve 0.2g mercaptoethanol and 0.74gVC in 40g deionized water, stir evenly to obtain a chain transfer agent solution for use; Put the acid and 150g deionized water into the reaction vessel and heat to dissolve. After the temperature reaches 50°C, add 2.12g of 30wt% hydrogen peroxide solution and keep stirring for 5min, then start to add solution B, solution C and chain transfer agent solution dropwise at a constant speed for 3.5h After dropping, continue to keep warm for 2 hours. After the reaction, add sodium hydroxide aqueous solution to adjust the pH value of the system to 6.4, and discharge the product to obtain the product.

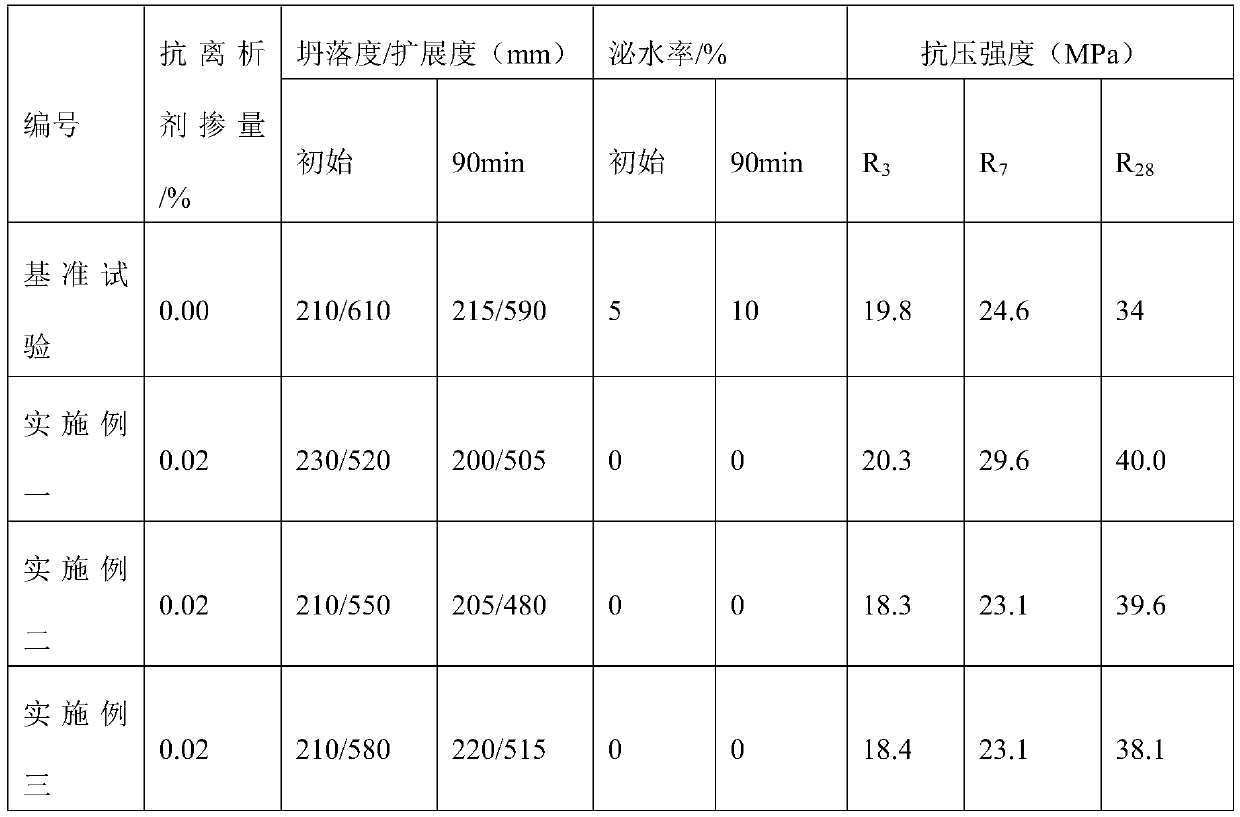

[0045] The application test results of the anti-segregatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com