Patents

Literature

71results about How to "Does not affect viscosity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

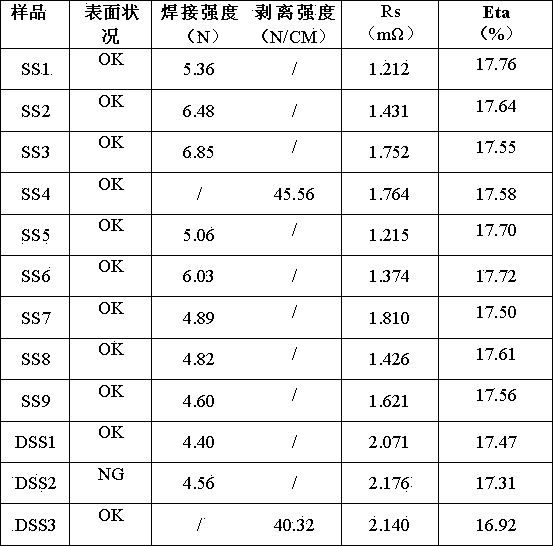

Conductive paste for crystalline silicon solar cell and preparation method of conductive paste

ActiveCN104078090AHigh tear strengthImprove adhesion strengthNon-conductive material with dispersed conductive materialCable/conductor manufactureSilver pasteConductive paste

The invention provides conductive paste for a crystalline silicon solar cell. The conductive paste comprises the following components in parts by weight: 100 parts of conductive metal powder, 1.0-10 parts of inorganic binder, 10-65 parts of organic carrier and 0.05-5.0 parts of conductive carbon. The conductive paste is excellent in conductivity; the photoelectric conversion efficiency of the cell is not influenced; and widely applied conductive paste for the crystalline silicon solar cell such as front-side silver paste, front-side seed layer silver paste, back-side silver paste and back electric field aluminum paste can be prepared.

Owner:BYD CO LTD

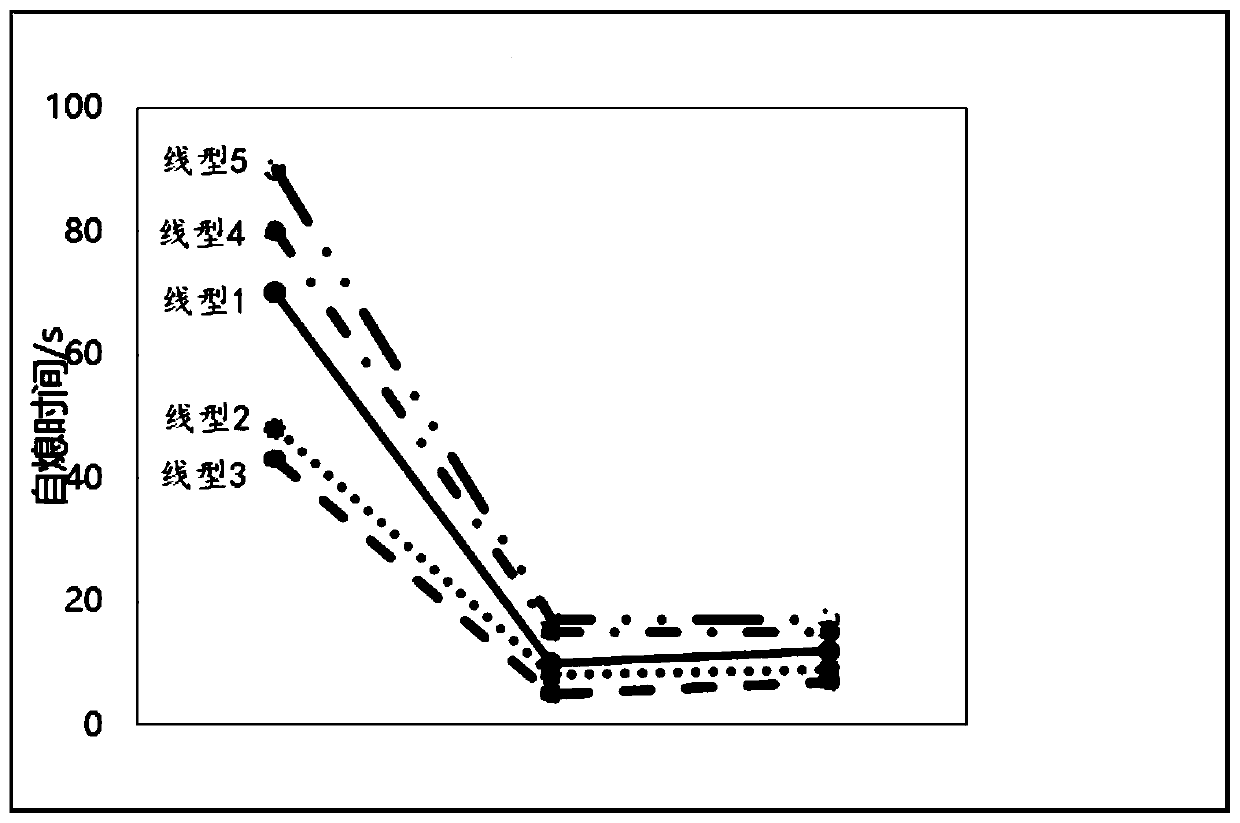

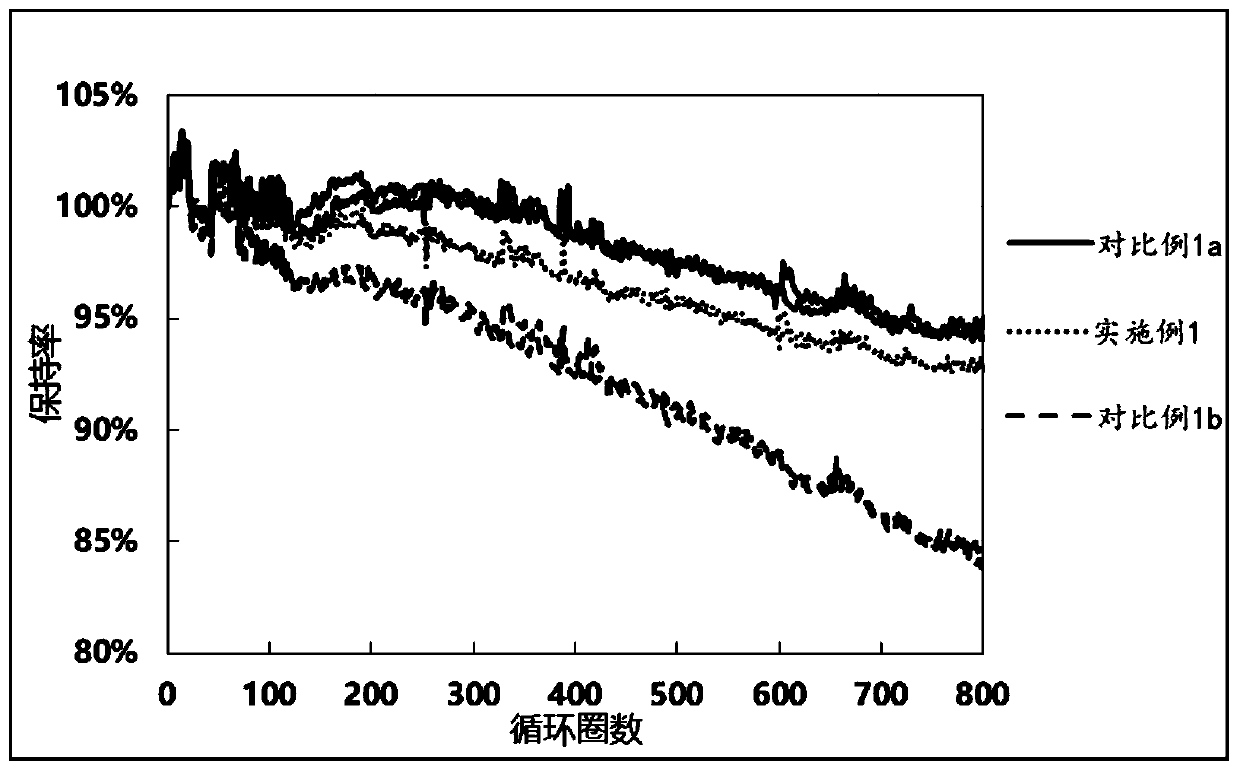

Method for enhancing safety of lithium-ion battery

InactiveCN105742733AIncrease usageGood flame retardant effectCell seperators/membranes/diaphragms/spacersSecondary cells servicing/maintenanceThermal runawayBiomedical engineering

The invention belongs to the technical field of lithium-ion batteries, and particularly relates to a method for enhancing the safety of a lithium-ion battery. The method comprises the steps as follows: a microcapsule is prepared; the microcapsule comprises a capsule core part and a capsule shell part; the capsule core part is coated with the capsule shell part; the capsule core part is a fire retardant for lithium ions; the fire retardant is coated with the capsule shell part to form the microcapsule; the microcapsule is mixed into a solution containing an isolating membrane protecting agent; the surface of an isolating membrane is evenly coated with the solution mixed with the microcapsule; the isolating membrane is used as the isolating membrane for the lithium-ion battery after being dried; and the treated isolating membrane is assembled and applied to the lithium-ion battery in a winding or laminating manner. The method has the beneficial effects that the fire retardant is coated with the microcapsule and is fixed on the surface of the isolating membrane, so that the viscosity of an electrolyte is not affected; the rate and the low-temperature performance of the battery are ensured; protective reaction can be relatively quickly made for the battery when thermal runaway is generated; and the safety improvement effect on the battery is relatively significant.

Owner:HUNAN LIFANG NEW ENERGY SCI & TECH

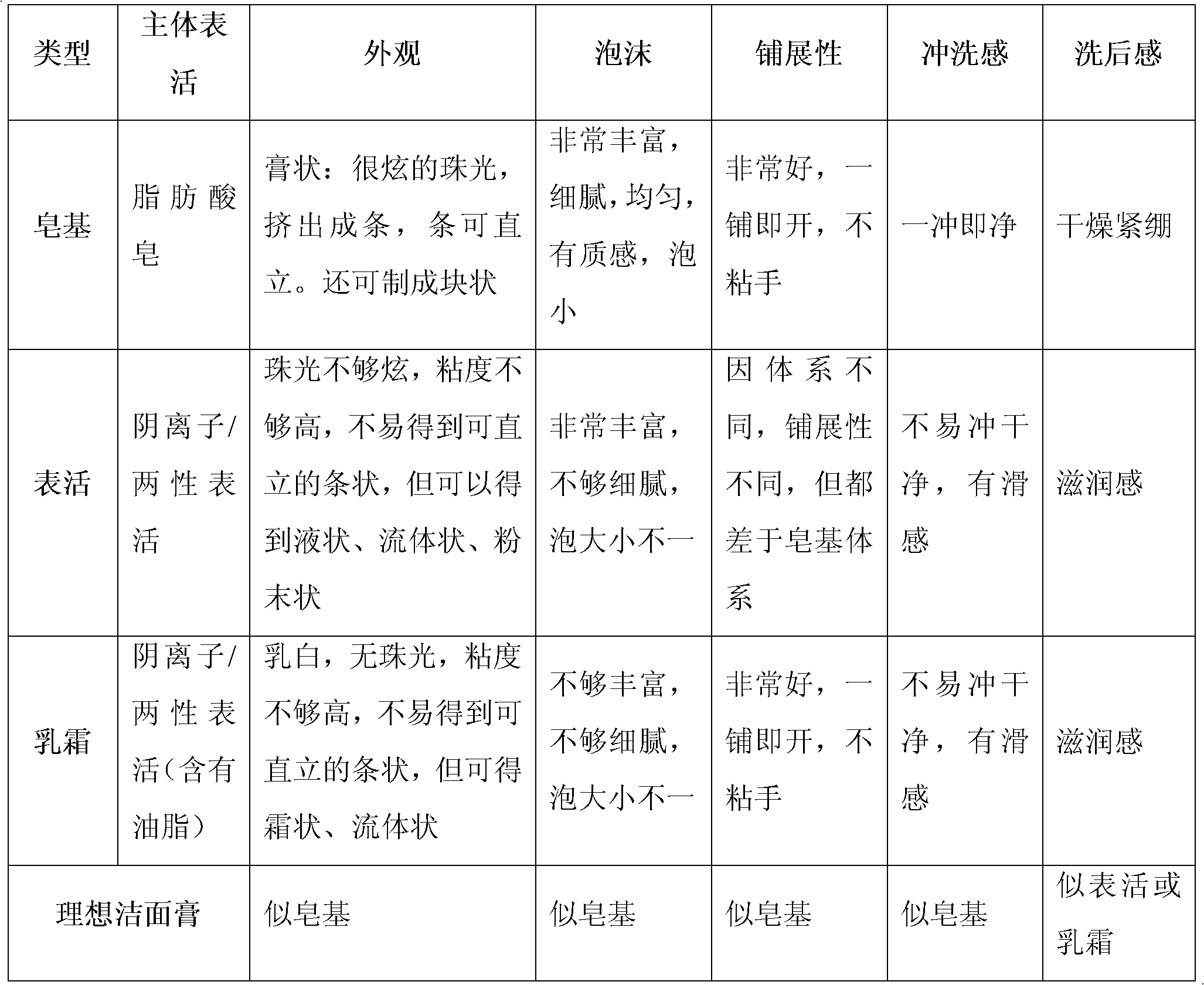

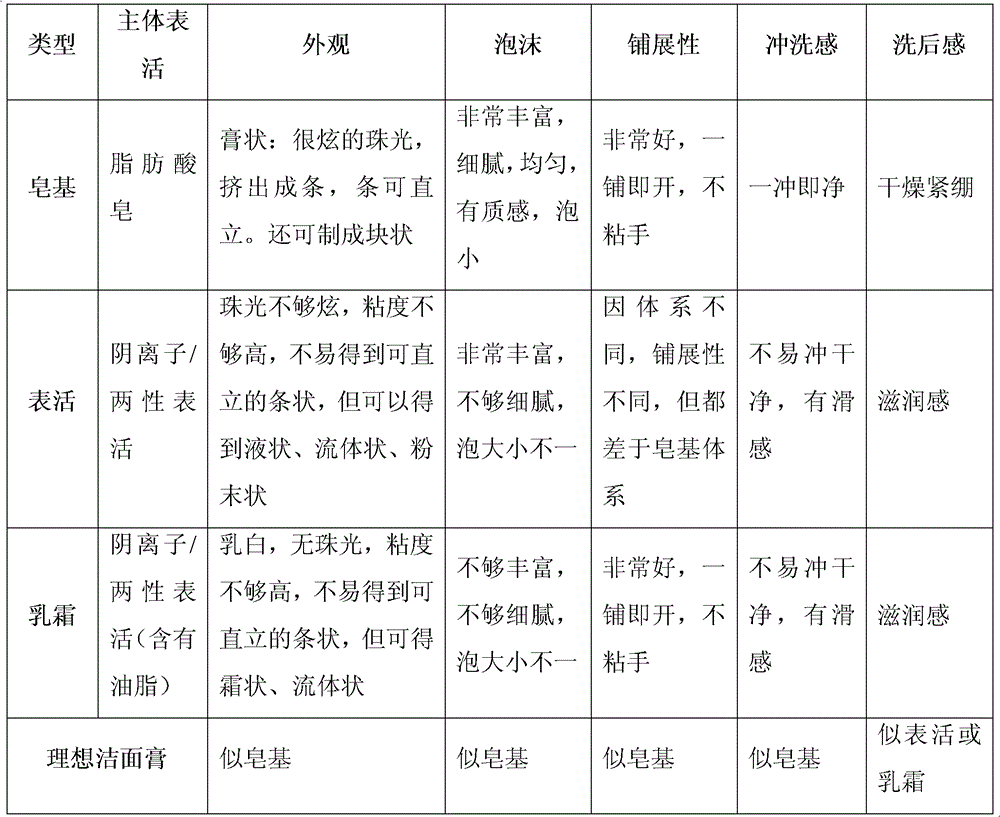

Mild soap base cleansing cream composition and production process thereof

ActiveCN103126911AReduce contentDoes not affect viscosityCosmetic preparationsToilet preparationsSurface-active agentsFatty acid

The invention discloses a mild soap base cleansing cream composition and a production process thereof. The composition comprises, by weight, 2.0% to 50.0% of soap base, 2.0% to 30.0% of negative ion surface active agents, 0.5% to 20.0% of rheolobic modifiers and the balance water. The production process of the mild soap base cleansing cream comprises the following steps: firstly diluting fatty acid with other constituents, compatible with the fatty acid, in the formula and enabling the diluted fatty acid to disperse into fatty acid oil drips through blending; then adding in alkali liquor, so that tiny soap particles are generated after the alkali liquor contacts with the fatty acid oil drips; and finally adding in the constituents which can be added at a low temperature and blending evenly so that materials can be discharged directly. The mild soap base cleansing cream composition has a mild and moistening function, so that a skin can be neither dry nor tight and touches well after being washed. The mild soap base cleansing cream composition also has good high low temperature stability. The production process of the mild soap base cleansing cream is simple and easy to operate, has good repeatability, and can avoid quality problems frequently occurring in the production of a soap base cleansing cream.

Owner:浙江萃芙化妆品有限公司

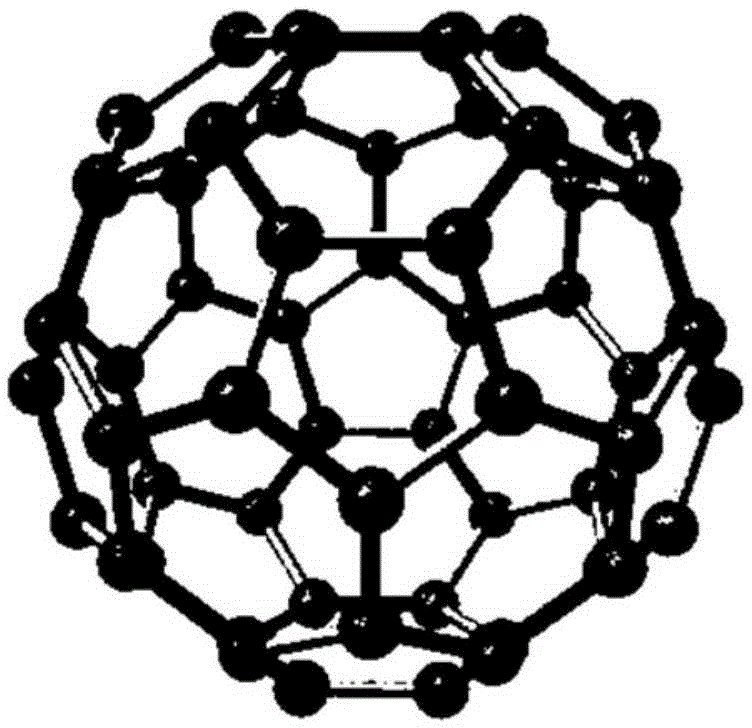

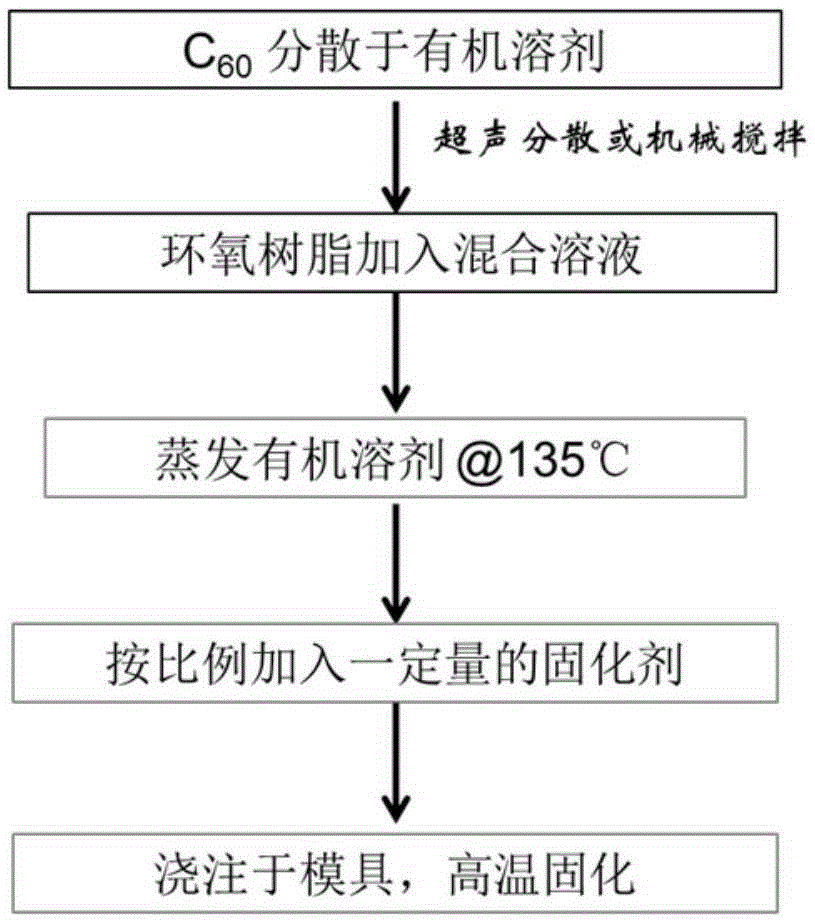

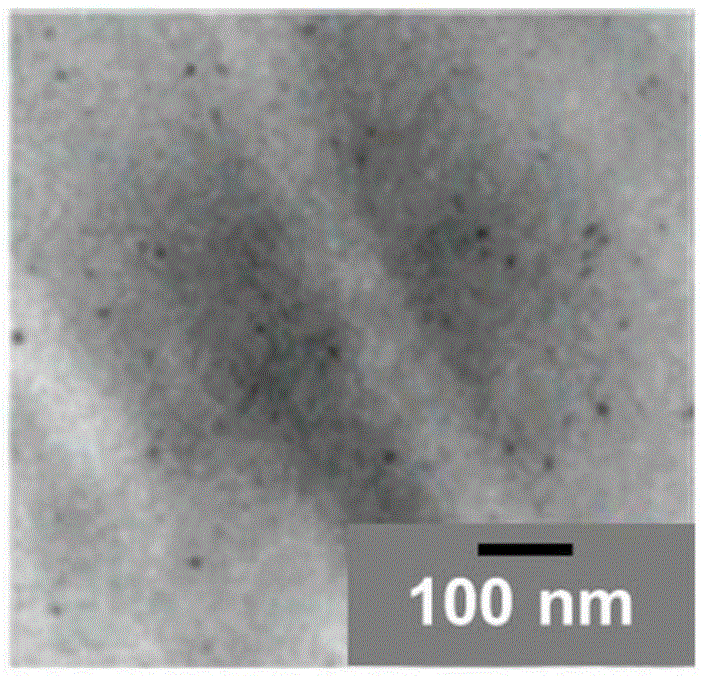

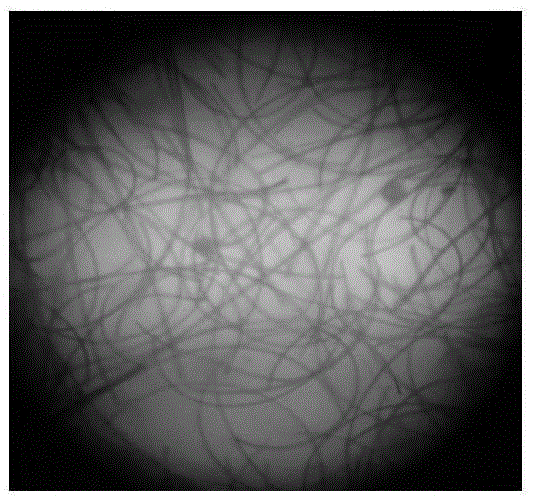

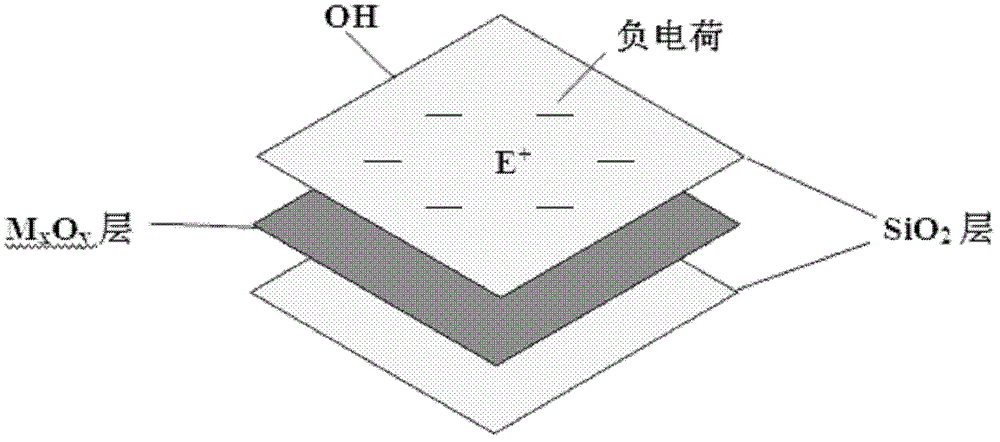

Epoxy resin fullerene composite material and preparation method thereof

The invention relates to an epoxy resin fullerene composite material and a preparation method thereof. The materials of the epoxy resin fullerene composite material include fullerene, epoxy resin and a curing agent. The epoxy resin fullerene composite material has the advantages of remarkably increasing the volume resistivity and breakdown voltage of a polymer matrix, inhibiting the injection of space charges, decreasing dielectric constant and loss, and improving the electrical aging property of the epoxy resin, and moreover, the mechanical strength and toughness of the epoxy resin are also increased to a certain degree.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

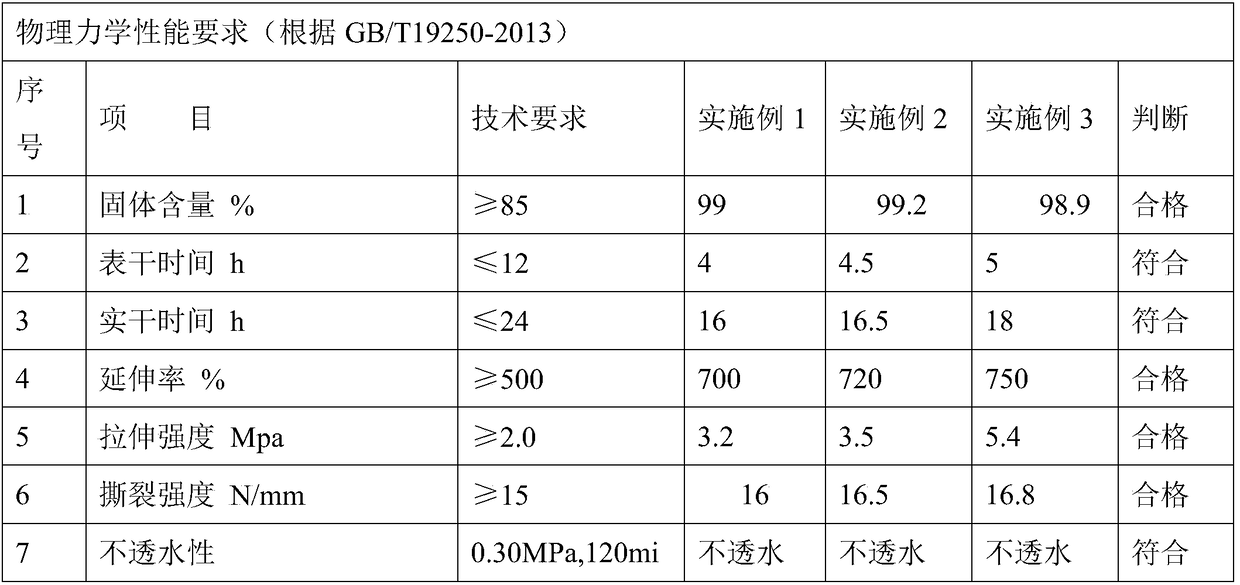

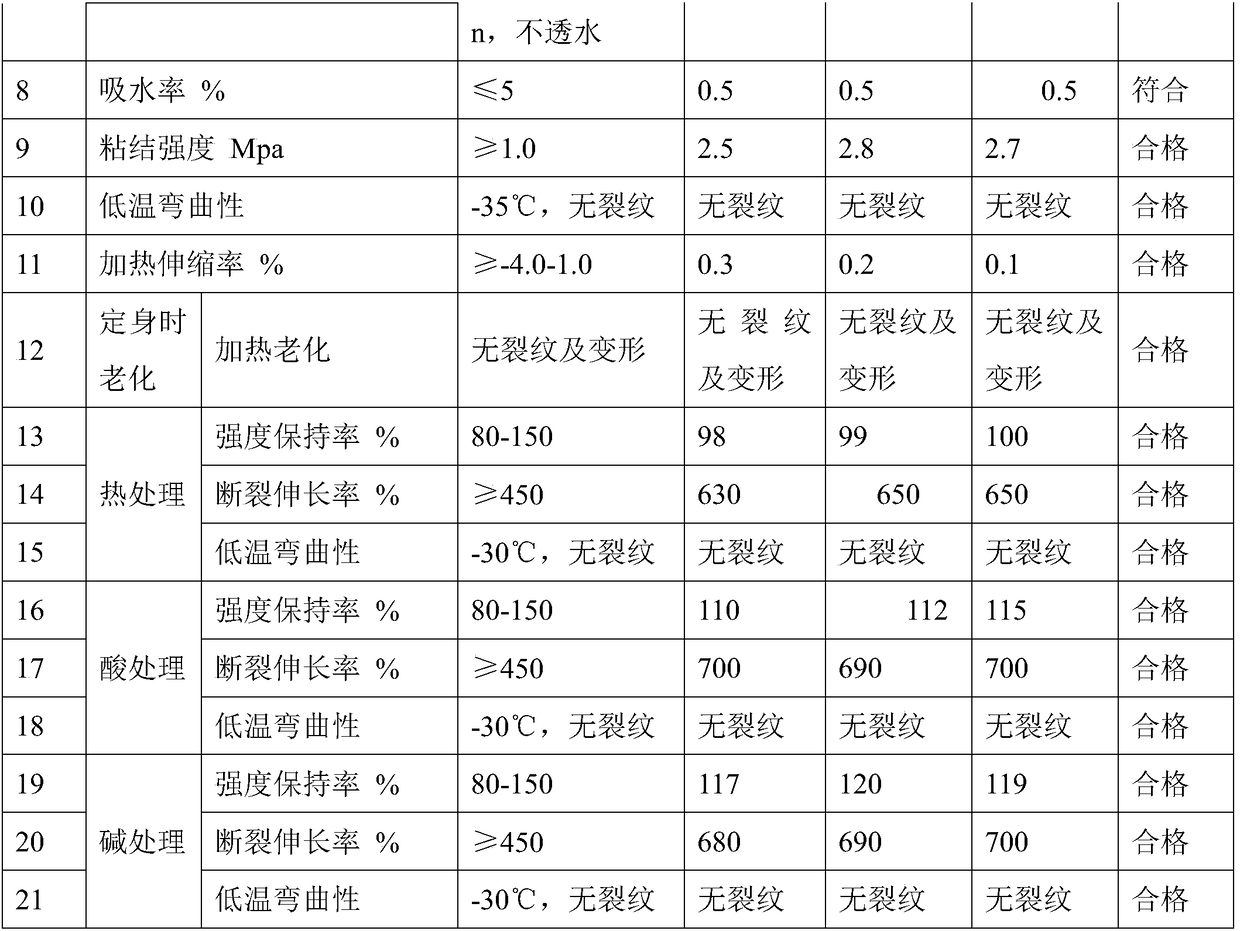

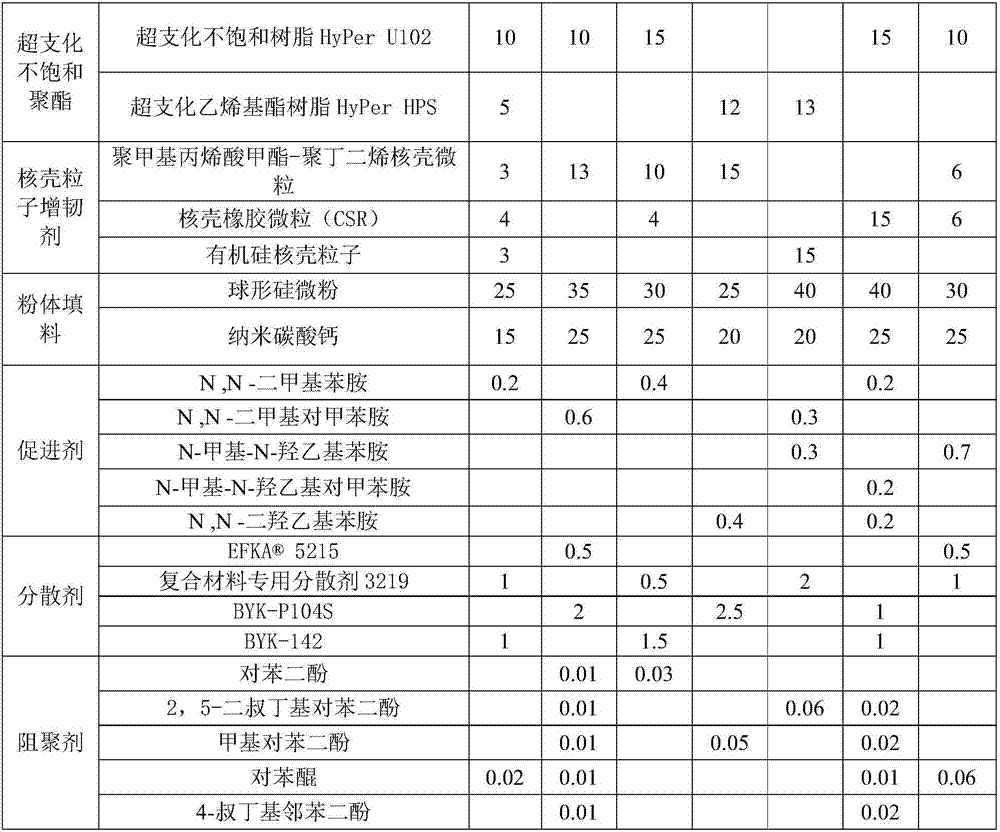

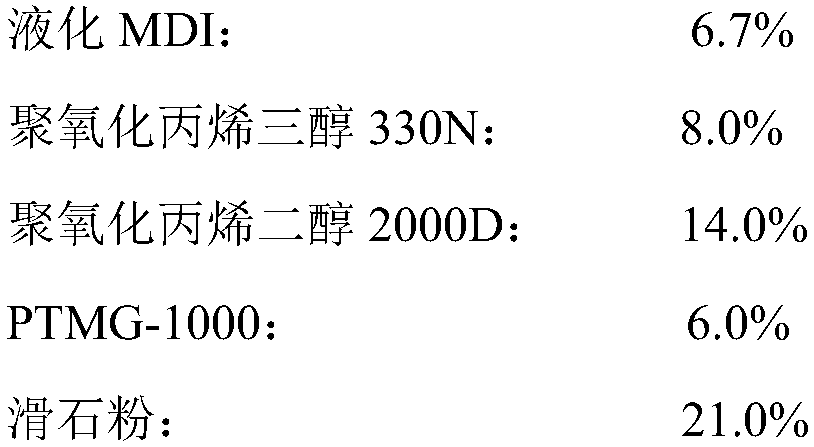

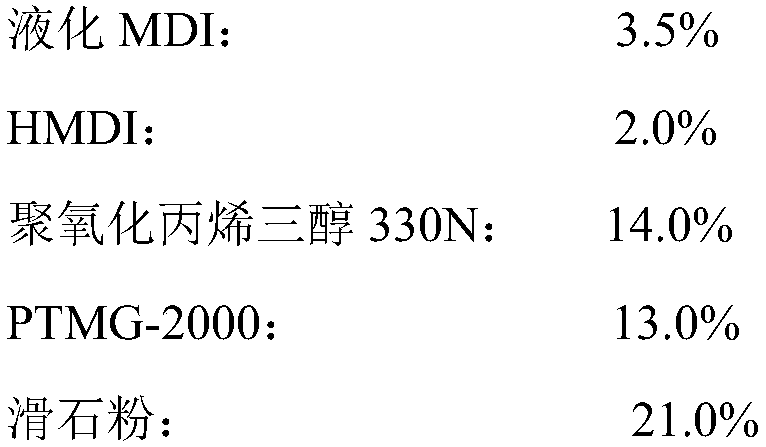

Single-component polyurea modified polyurethane waterproof coating and a preparing method thereof

PendingCN109111834ASmall tasteDoes not affect viscosityInksPolyurea/polyurethane coatingsPolyolPlasticizer

The invention relates to the field of polyurethane waterproof coating and discloses single-component polyurea modified polyurethane waterproof coating. The coating includes, by weight, 22-33 parts ofpolyether polyol, 5.6-7.6 parts of diisocyanate, 20-28 parts of a plasticizer, 34-44 parts of a pigment filler, 0.1-0.5 part of a chain extender, 0.1-0.2 part of a catalyst, and 2-3.5 parts of a self-prepared latent curing agent. A preparing method of the coating is further provided. The method includes uniformly dispersing the polyether polyol, the plasticizer, the pigment filler and the chain extender, then dewatering the mixture under vacuum, then adding the diisocyanate, stirring and reacting the mixture, then adding the self-prepared latent curing agent, stirring and reacting the mixture,finally adding the catalyst, fully stirring the mixture, and discharging a material under nitrogen protection. The self-prepared latent curing agent is adopted so that the coating is free of organicsolvent, low in viscosity and excellent in physical performance, and overcomes a problem that oil returning and insufficient tensile strength are caused by application of a high amount of plasticizers.

Owner:德州科顺建筑材料有限公司

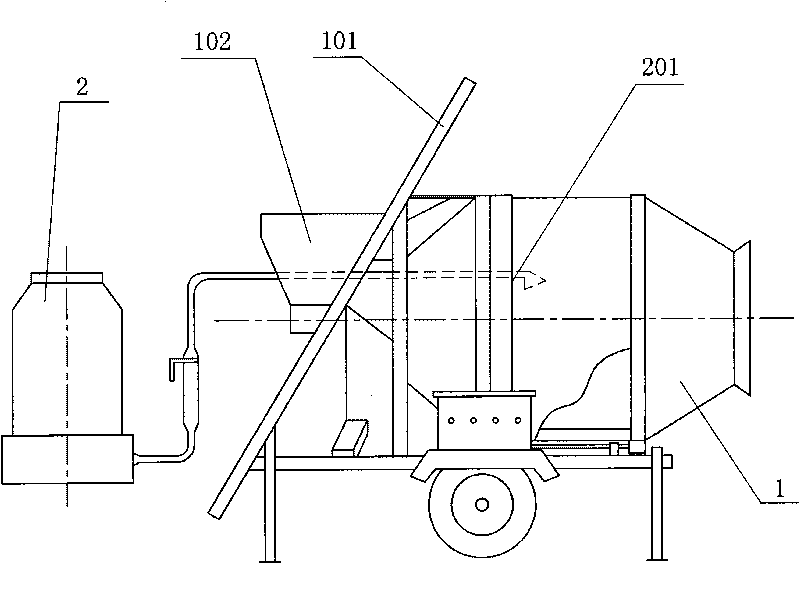

Water reducing agent with concrete workability adjusting function and synthetic method thereof

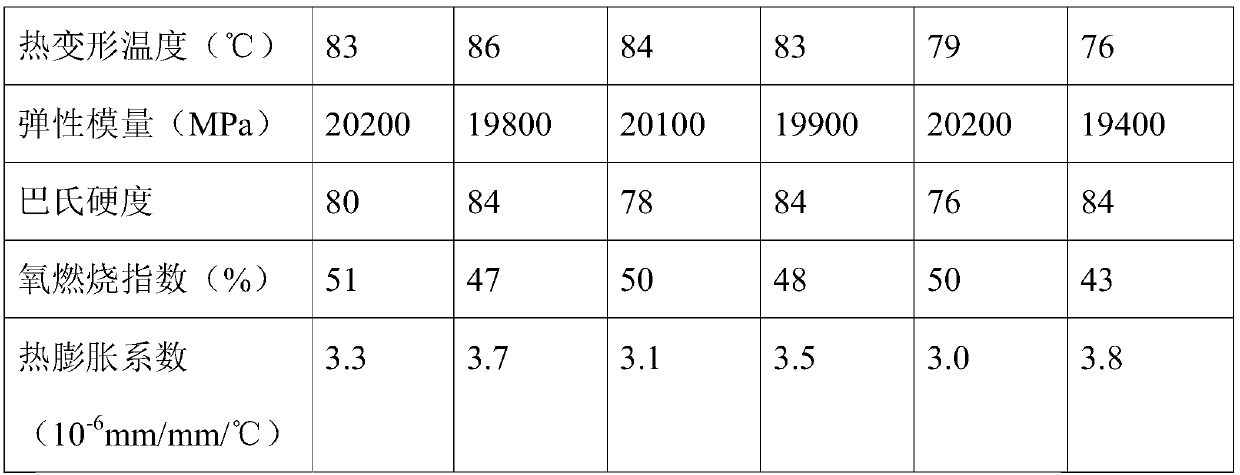

ActiveCN103819628AHas water retention capacityReduce surface tensionPotassium persulfateUltimate tensile strength

The invention discloses a water reducing agent with a concrete workability adjusting function. The water reducing agent is prepared from the following components: a. isopentenol polyoxyethylene ether, b. acrylic acid or methylacrylic acid or a mixture of the acrylic acid and the methylacrylic, c. maleic anhydride, d. sodium p-styrenesulfonate, e. ammonium persulfate or potassium persulfate or a mixture of the ammonium persulfate and the potassium persulfate, and f. sodium methallyl sulfonate, wherein the molar ratio of the using amount of a to b to c to d to f is 1:(1-1.5):(1.5-2.5):(0.2-0.25):(0.3-0.6); the using amount of e is 0.5 to 1.0 percent of the total weight of a, b and c. The water reducing agent provided by the invention has water retention capacity and has the function of reducing the surface tension of concrete so as not to influence the viscosity and the flowability of the concrete, and also can guarantee normal condensation and strength development of the concrete.

Owner:大连市铭源全科技开发有限公司

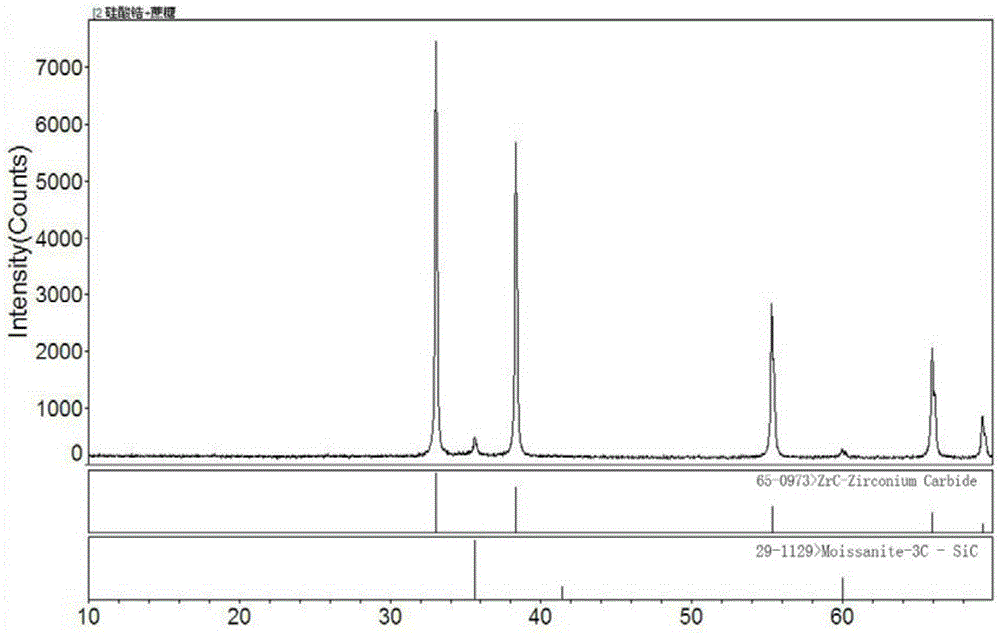

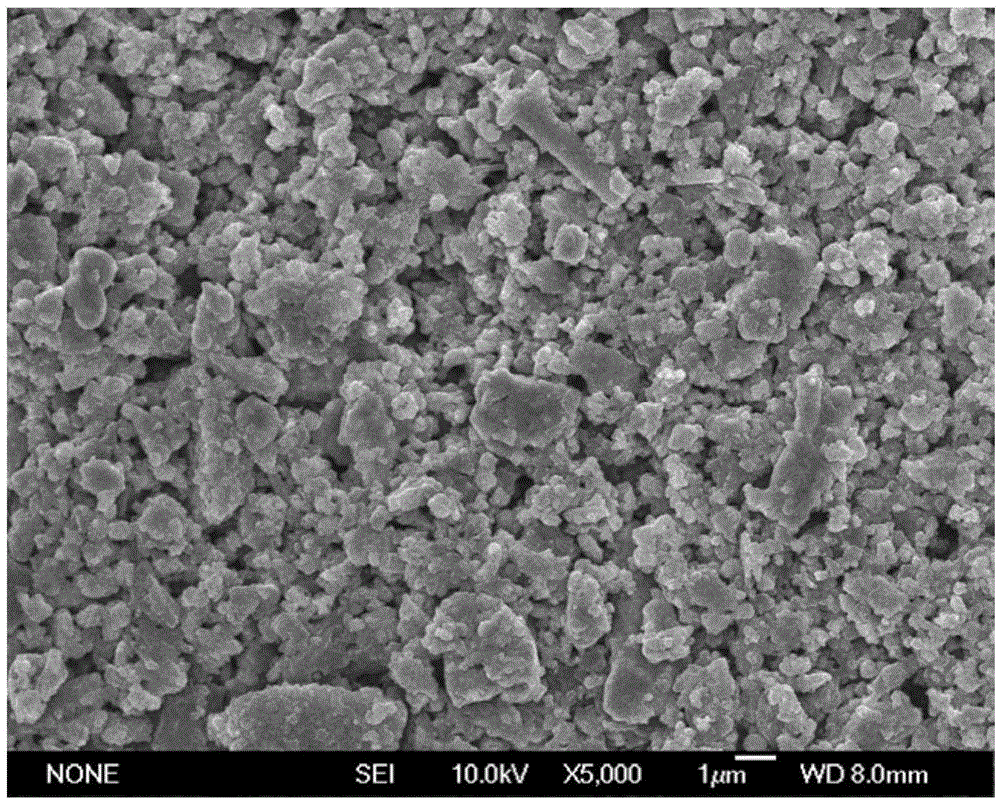

Synthetic method of high-purity ultrafine ZrC-SiC composite powders

The present invention belongs to the field of inorganic nonmetallic materials, and relates to a synthetic method of high-purity ultrafine ZrC-SiC composite powders. The synthetic method comprises the following steps: taking only zirconium silicate or zirconium silicate added with one or both of zirconium oxide or colloidal silica as a zirconium source and a silicon source material, taking sucrose or glucose as a carbon source material, and taking acrylamide monomer and a methylene-bisacrylamide cross-linking agent as a gel material to prepare the high purity ultrafine ZrC-SiC composite powders. The ZrC-SiC composite powders synthesized by the synthetic method provided by the present invention are mixed very uniformly and are quite high in purity, and the purity is greater than or equal to 99%, and the particle size d is less than or equal to 50 [mu]m. An aqueous pulp containing acrylamide monomer and the methylene bisacrylamide cross-linking agent is subjected to in-situ gel curing, C can closely coat the surfaces of solid phase powder particles very uniformly, so that segregation of raw materials in dehydration and reaction processes is avoided, and carbothermal reduction synthesis reaction can be carried out fully.

Owner:SHANDONG ULSTREETCARING FINE CERAMICS

Preparation method of high-flame-retardancy lithium ion battery

InactiveCN109841908AAdd lessAvoid uncontrolled combustionFinal product manufactureCell electrodesSlurryPole piece

The invention discloses a preparation method of a high-flame-retardancy lithium ion battery. The preparation method comprises the steps of: evenly mixing a positive electrode active substance and a flame retardant, adding a conductive agent, PVDF and NMP into the mixture, kneading and stirring the mixture to obtain a positive electrode slurry, and coating the positive electrode slurry on aluminumfoil to obtain a positive electrode pole piece; evenly mixing a negative electrode active substance, a conductive agent, SBR, CMC and water to obtain a negative electrode slurry, coating the negativeelectrode slurry on copper foil to obtain a negative electrode pole piece; winding the positive electrode pole piece, the negative electrode pole piece and a membrane into a pole group, and manufacturing the pole group into a lithium ion battery after performing operations such as baking, shell entering, electrolyte injection, aging and formation on the pole group. According to the preparation method, the flame retardant is directly added into to the positive electrode slurry, and the combustion reaction can be inhibited or prevented by physical or chemical means after thermal runaway of the battery occurs; the flame retardant only forms a film at the positive electrode without loss at the negative electrode, thus the additive amount of the flame retardant is reduced, and the lithium precipitation situation of the negative electrode of the battery is reduced to a certain extent; and since the ignition point of the flame retardant is high, the addition of the flame retardant into the positive electrode slurry does not affect the original performance such as the cycle performance and processing performance of the battery.

Owner:上海力信能源科技有限责任公司

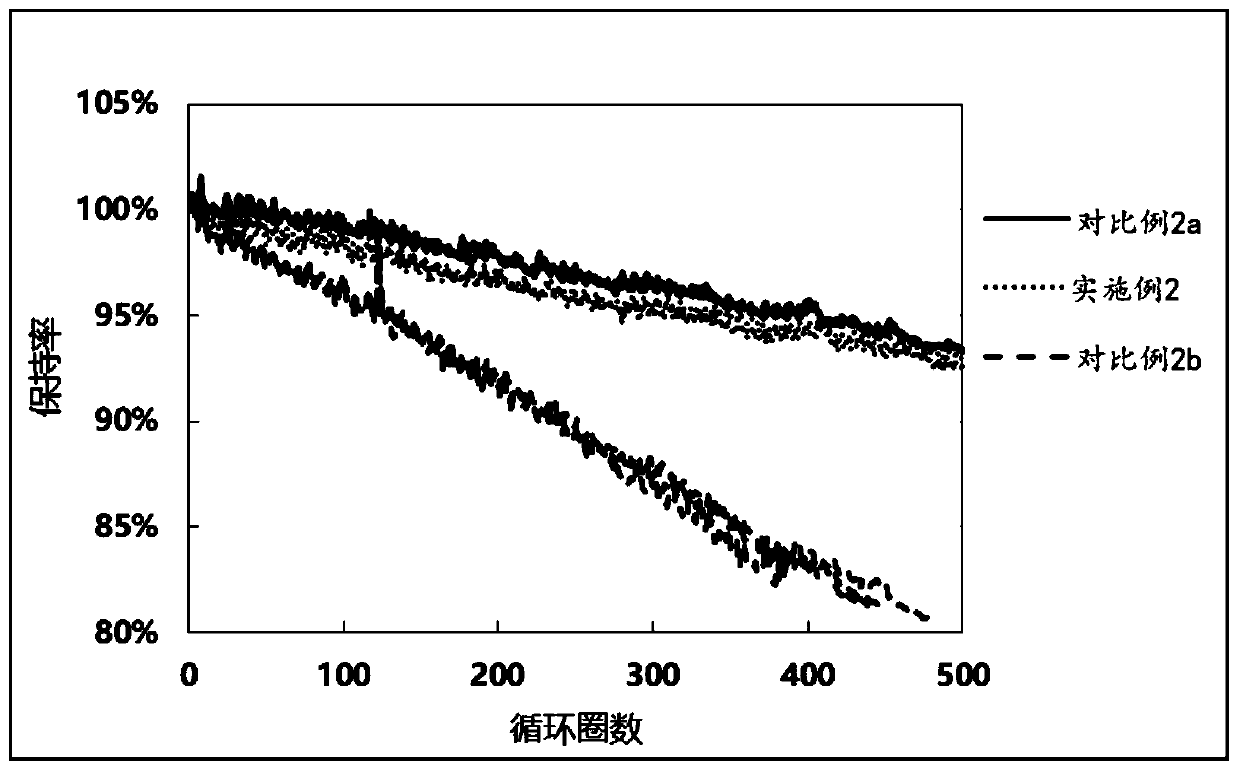

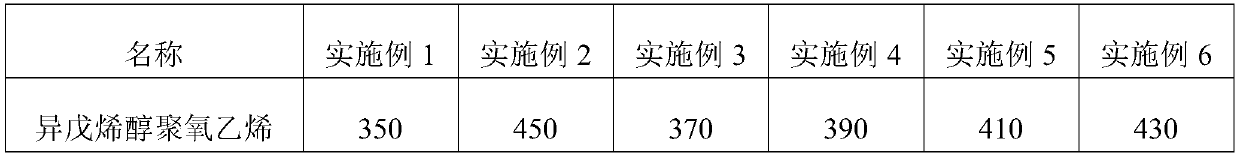

Mud-resistant polycarboxylate superplasticizer as well as preparation method and application thereof

InactiveCN110002784AGood water reduction effectGood collapsibilityMaterials preparationThermal insulation

The invention belongs to the technical field of concrete and proposes a mud-resistant polycarboxylate superplasticizer. The mud-resistant polycarboxylate superplasticizer is prepared from components in parts by weight as follows: 350-450 parts of isoamyl alcohol polyoxyethylene ether, 40-70 parts of acrylic acid, 18-36 parts of hydroxyethyl acrylate, 6-16 parts of an initiator, 1-5 parts of a chain transfer agent, 4-15 parts of a cationic monomer and 10-50 parts of a coagulation adjusting component. The preparation method of the mud-resistant polycarboxylate superplasticizer comprises steps asfollows: material preparation, preparation of materials A and B, dissolution, droplet adding of the materials A and B, thermal insulation ageing, neutralization and the like. The mud-resistant polycarboxylate superplasticizer is applied to preparation of concrete. With the adoption of the technical scheme, the problem that application of the polycarboxylate superplasticizer is affected due to massive adsorption by mud in the prior art is solved.

Owner:兰州同邦建材有限公司

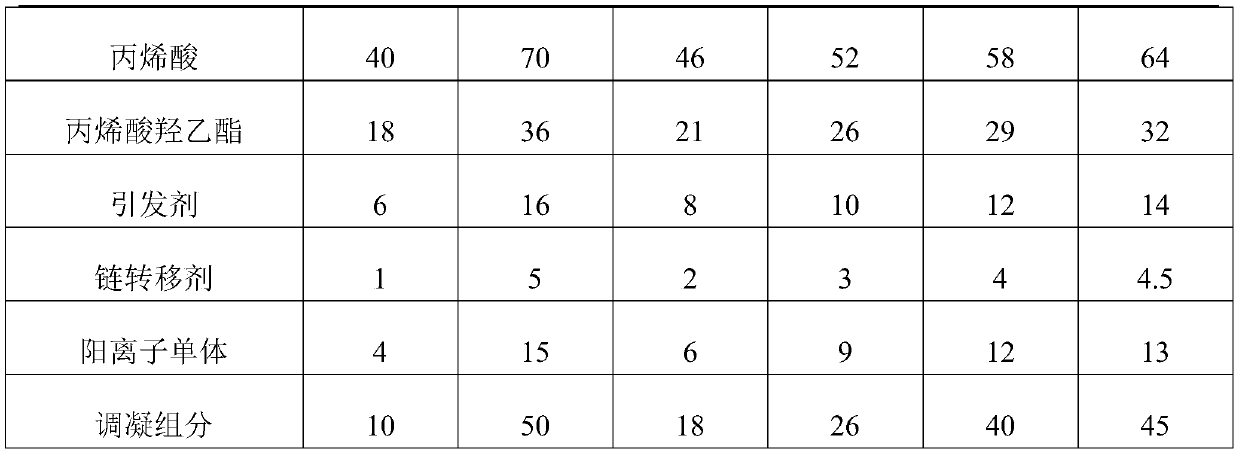

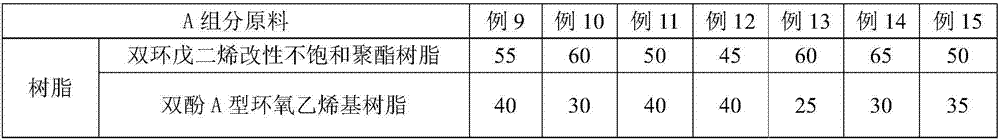

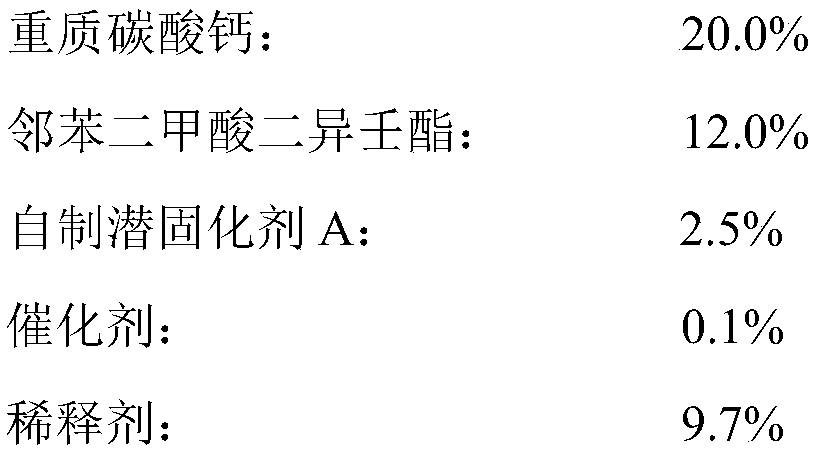

Toughened environmental-friendly back mesh glue as well as preparation method and application thereof

ActiveCN107090264AFast aggregationFast curing at room temperatureNon-macromolecular adhesive additivesMacromolecular adhesive additivesPolyesterToughening

The invention discloses toughened environmental-friendly back mesh glue as well as a preparation method and application thereof. A component A is prepared from the following components in parts by weight: 45-65 parts of dicyclopentadiene modified unsaturated polyester resin, 25-40 parts of bisphenol-A epoxy vinyl ester resin, 10-15 parts of hyperbranched unsaturated polyester, 1-2.5 parts of a dispersant, 5-10 parts of a core-shell particle toughening agent, 25-40 parts of spherical fine silicon powder, 15-25 parts of nano calcium carbonate, 0.2-0.8 part of an accelerator and 0.02-0.08 part of a polymerization inhibitor. A component B is prepared from the following components in parts by weight: 10-70 parts of a solidifying agent, 30-40 parts of a blending agent, 30-50 parts of an inorganic filler and 3-10 parts of a stabilizer. After the component A and the component B are mixed, the solidifying agent accounts for 0.5-3.5 percent of the total weight of the mixture. The back mesh glue is small in viscosity, good in permeability, moderate in rheology and low in content of total volatile organic compounds (VOCs); and the mechanical strength, particularly the impact resistance, of a back mesh stone is remarkably superior to that of the existing product.

Owner:江苏大力士云石护理材料有限公司

Polyurethane latent curing agent, one-component polyurethane waterproof coating and preparation method thereof

ActiveCN109251292AImprove stabilityExtended shelf lifePolyurea/polyurethane coatingsImino compound preparationArylStructural formula

The invention discloses a polyurethane latent curing agent having the structural formula of R1-CH--N-R 2-N--CH-R3, wherein R1 , R2 and R3 are alkyl group or aryl group or alkylaryl group. The molecular weight of the latent curing agent is not higher than 300. The invention also discloses a one-component polyurethane waterproof coating using the above latent curing agent and a preparation method thereof. The invention provides a polyurethane latent curing agent with good stability, and the one-component polyurethane waterproof coating prepared from the polyurethane latent curing agent is more resistant to storage and has a longer shelf life. Unit mass of the polyurethane latent curing agent can provide more -NH2 groups. The dosage is small and the application cost is low. The polyurethane waterproof coating disclosed in the invention has little damage to human body, is environmentally friendly, has excellent storage stability, has excellent coating performance, excellent tensile strength and tear strength, and can be prepared directly by existing production process and production equipment. The production costs are low.

Owner:重庆科顺新材料科技有限公司

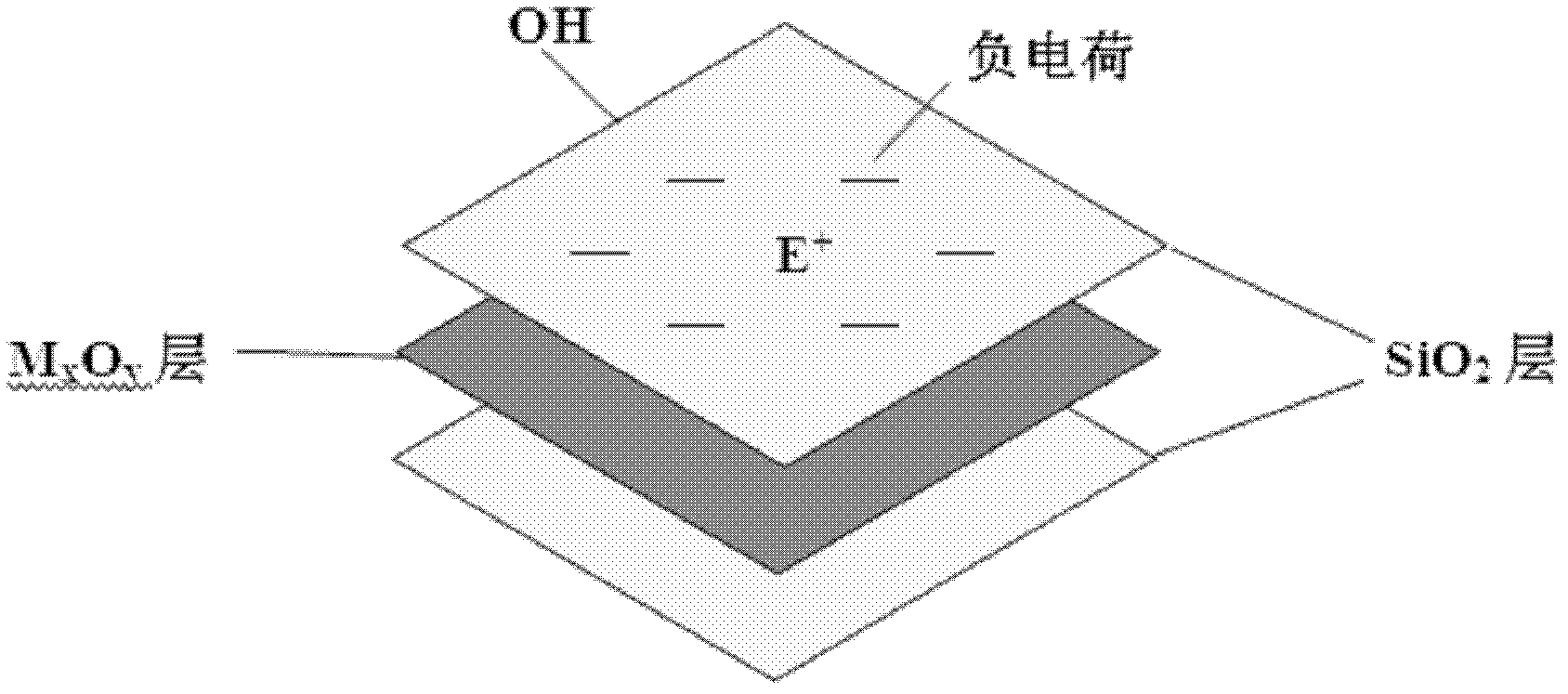

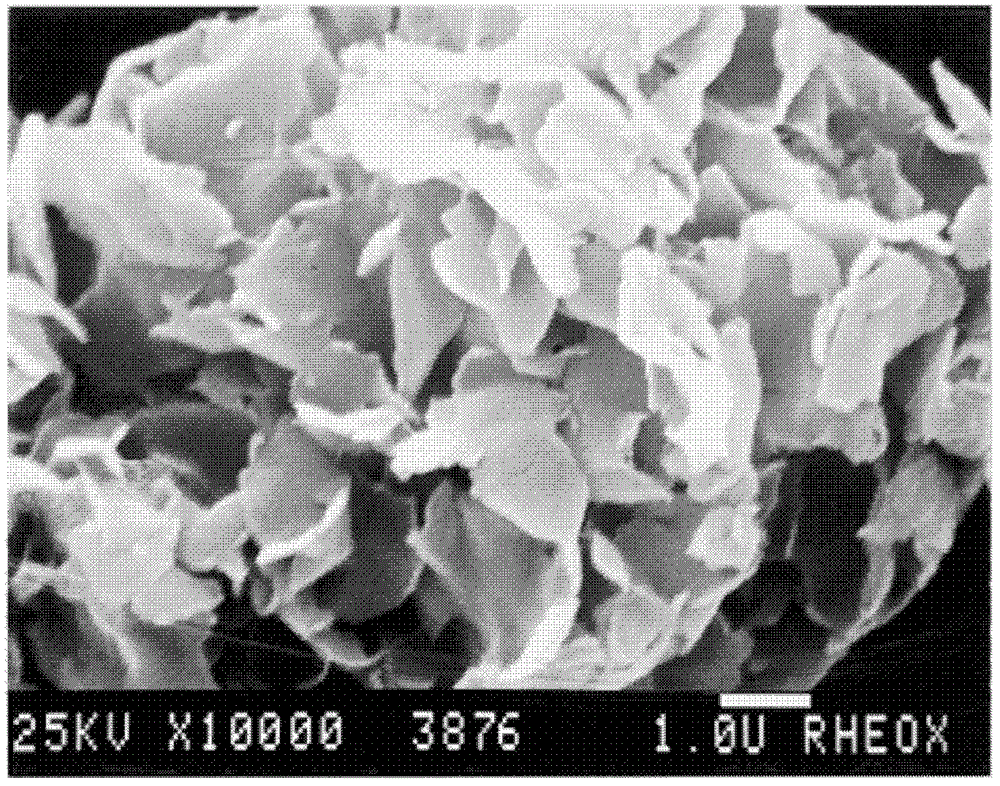

Method for purifying montmorillonite from bentonite ore by twice dispersion method

InactiveCN101391779AReduce viscosityImprove purification efficiencySilicon compoundsSodium BentoniteMontmorillonite

The invention relates to a method for purifying montmorillonite from bentonite ore by using double dispersion method; the method adopts the hydrogen peroxide as dispersant of 'I'-shaped structure, then the hydrogen peroxide is fully mixed with the pulp so as to cause the hydrogen peroxide to be completely infiltrated into each film layer of the 'I'-shaped structure, later sodium pyrophosphate dispersant is added and conclusion is opened so as lower the pulp viscosity, ease the impurities gravity settlement, and provide a relatively 'smooth' path for the impurities settlement inside and outside the 'I'-shaped structure. As the added gas dispersant is provided with stronger oxidation, the hydrogen peroxide is decomposed into gas under slightly-heating circumstance, and the gas is expanded for distracting the 'I'-shaped structure so as to cause the hidden impurities to be precipitated due to the loss of support, thereby eliminating a small amount of organic substances in the natural bentonite by oxidation and simultaneously playing a bactericidal action, and purifying montmorillonite by separation as any pollution is not brought. The method is non-toxic, has simple operation process, and can easily achieve batch production.

Owner:XINJIANG TECHN INST OF PHYSICS & CHEM CHINESE ACAD OF SCI

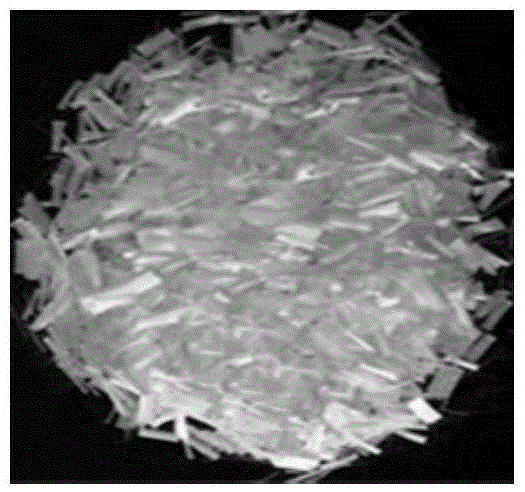

Scattering treatment method for hydrophilic chopped fiber for fracturing

ActiveCN105401446AImprove fracturing effectImprove sand carrying capacityFibre typesDrilling compositionWater basedFiber

The invention provides a scattering treatment method for hydrophilic chopped fibers for fracturing. The method comprises steps as follows: the hydrophilic chopped fibers for fracturing are sent to a degglomerator for degglomeration; the hydrophilic chopped fibers for fracturing are obtained by drying to-be-treated chopped fibers after the to-be-treated chopped fibers are subjected to spraying, immersion and / or moisture treatment through a fiber surface treating agent. The surface treating agent comprises 5%-30% of a hydrophilic oil agent, 0.05%-2.0% of a coupling agent, 0.2%-1.0% of a wettable surfactant, 0.05%-10.0% of an aid, 0.1%-0.8% of a densifier and the balance of water, and the sum of all the components is 100%. The degglomerated hydrophilic chopped fibers, prepared with the method, for fracturing easily enter a water-based fracturing fluid, can be uniformly dispersed in the water-based fracturing fluid and are not clustered, the sand carrying performance of the water-based fracturing fluid is enhanced, and the fiber fracturing effect is improved.

Owner:PETROCHINA CO LTD

Scale inhibitor used for oilfield alkali-surfactant-polymer flooding and application method thereof

InactiveCN105219368AGood anti-scaling effectEnhanced inhibitory effectDrilling compositionPollutionAluminosilicate

The invention discloses a scale inhibitor used for oilfield alkali-surfactant-polymer flooding and an application method thereof, belonging to the technical field of oil production and scale inhibition in oil fields. The scale inhibitor used for the oilfield alkali-surfactant-polymer flooding comprises the following components by mass: 1 to 5 parts of polyepoxysuccinate, 1 to 2 parts of hydroxyethylidene diphosphonate, 1 to 2 parts of amino trimethylene phosphonate, 1.5 to 3 parts of polymaleic anhydride and 3 to 5 parts of water. The scale inhibitor used for the oilfield alkali-surfactant-polymer flooding provided by the invention has good scale inhibition effects on calcium carbonate, calcium sulfate, barium sulfate, calcium phosphate, etc., specifically has strong inhibition effect on aluminosilicate scale, and can reduce or even completely prevent the formation of the aluminosilicate scale; under an economic and practical treatment concentration, the scale inhibitor used for the oilfield alkali-surfactant-polymer flooding is added into an alkali-surfactant-polymer flooding well, and hardly affects viscosity and interfacial tension of an alkali-surfactant-polymer system; meanwhile, the scale inhibitor has the advantages of simple production process, mild reaction conditions, no pollution problems in application process, greenness and environmental protection.

Owner:CHINA PETROLEUM & CHEM CORP +1

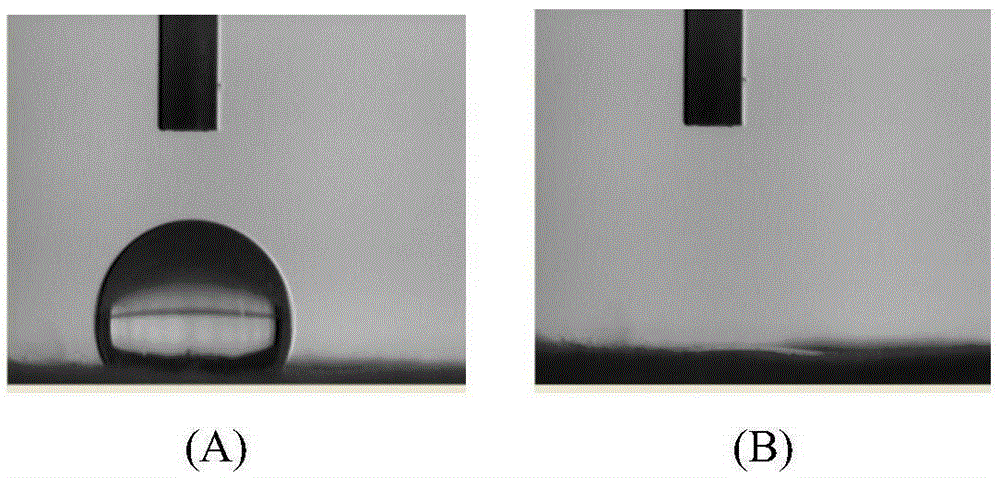

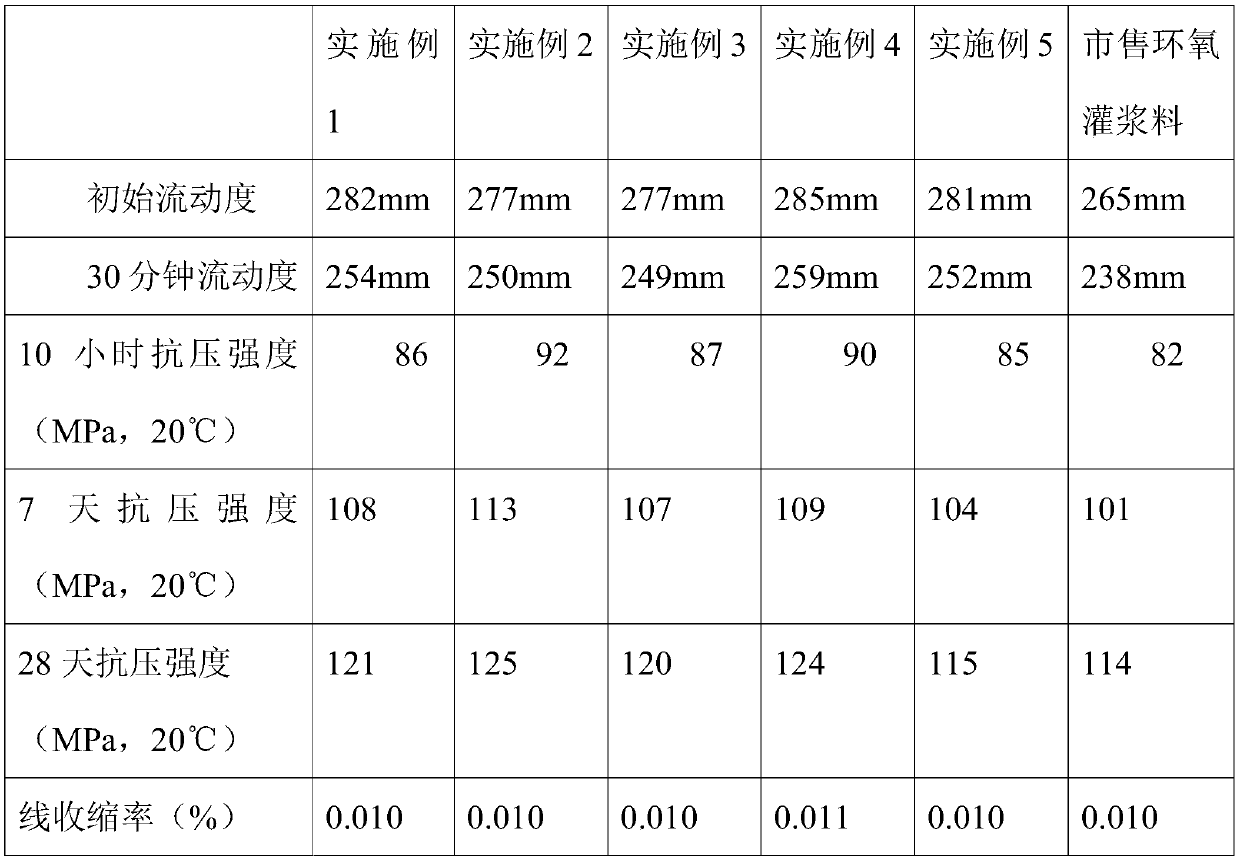

High-penetration non-shrink epoxy grouting material

The invention relates to a high-penetration non-shrink epoxy grouting material. The high-penetration non-shrink epoxy grouting material is formed by a component A and a component B, The component A comprises the following raw materials in parts by mass: 60-80 parts of epoxy resin, 20-35 parts of an active diluent, 10-20 parts of alumina short fiber, and 3-5 parts of an oxidizing agent, the component B comprises the following raw materials in parts by mass: 10-20 parts of a curing agent, 8-12 parts of benzyl alcohol, 4-8 parts of a vinyl modifier, and 2-4 parts of a catalyst. Compared with theprior art, the high-penetration non-shrink epoxy grouting material has the following advantages that alumina fiber is used for enhancement, and the grouting material has good corrosion resisting performance and high intensity; the selected curing agent contains eight amino caged polysilsesquioxanes, and the grouting material after complete solidification has high crosslinking density and intensity; the vinyl modifier is used for modification, and the grouting material has high toughness.

Owner:邢台茂森泡沫塑料有限公司

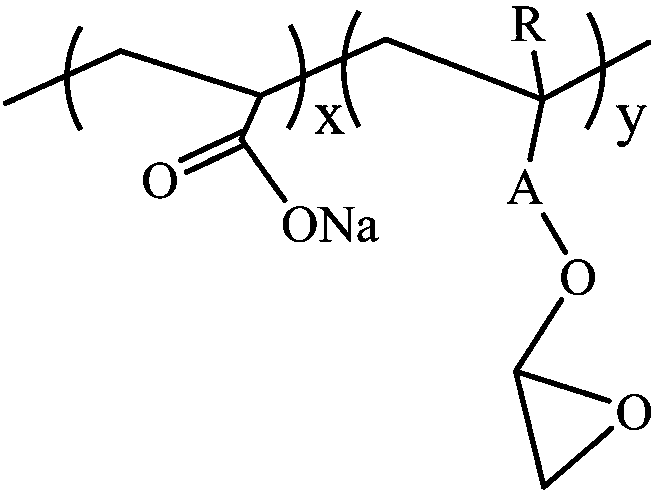

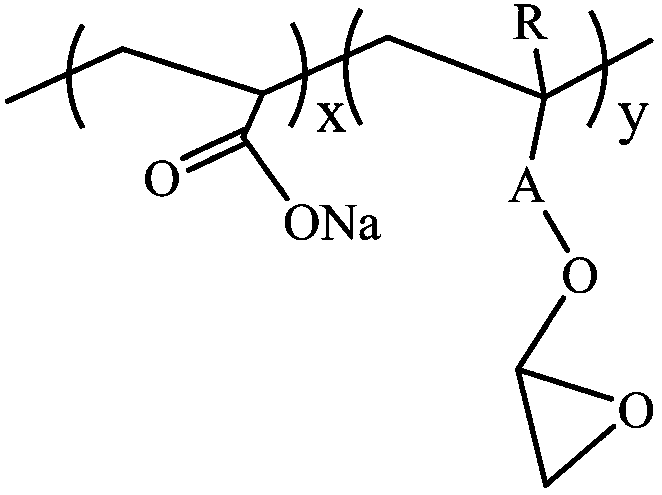

High-efficiency ceramic body reinforcing agent composition and product prepared thereby

ActiveCN107935606AReduce the probability of crackingDoes not affect viscosityClaywaresSlurryPolypropylene

The invention relates to a high-efficiency ceramic body reinforcing agent composition and a product prepared by the high-efficiency ceramic body reinforcing agent composition. The high-efficiency ceramic body reinforcing agent composition comprises the following components in percentage by mass: 4% to 8% of acrylic pressure-sensitive adhesive emulsion, 1% to 3% of a modified natural polymer, 8% to15% of epoxy modified sodium polyacrylate and the balance of water. In the invention, the acrylic pressure-sensitive adhesive emulsion and the epoxy modified sodium polyacrylate are used in the fieldof a ceramic body reinforcing agent to play a high-efficiency reinforcing effect when a body is dried while the viscosity of body slurry is not affected, and test results show that the reinforcing agent can greatly shorten the cracking time and cracking length of a green body and has wide application prospects.

Owner:潮州市潮安区奥特尔陶瓷有限公司

High temperature resistant organosilicone pouring sealant for PCB (Printed Circuit Board)

InactiveCN106833508AHigh tensile strengthHigh hardnessNon-macromolecular adhesive additivesMacromolecular adhesive additivesSodium stearateMetallurgy

The invention discloses a high temperature resistant organosilicone pouring sealant for a PCB (Printed Circuit Board). The high temperature resistant organosilicone pouring sealant for the PCB is prepared from the following raw materials in parts by weight: 40 to 50 parts of vinyl-terminated silicone oil-1, 50 to 60 parts of vinyl-terminated silicone oil-2, 0.38 to 0.5 part of 12 percent platinum catalyst, 0.02 to 0.04 part of ethynylcyclohexanol, 25 to 30 parts of vinyl silicone resin, 14.8 to 16.8 parts of 1-allyloxy-2,3-propylene oxide, 23 to 25 parts of 1,3,5,7-tetramethylcyclotetrasiloxane, 2.7 to 3.6 parts of silane coupling agent A171, a suitable amount of hydrogen-containing silicone oil, 3 to 3.8 parts of sepiolite fibres, 1.7 to 3 parts of aluminium nitride, 2 to 2.5 parts of sodium stearate, 1.5 to 2 parts of dodecylamine and a suitable amount of deionized water. The pouring sealant prepared by the preparation method is simple in preparation process, low in cost and wide in raw material source, has good performance in the aspects of radiating, high temperature resistance, stability, insulating and the like, is wide in application field, and is worth being popularized.

Owner:铜陵安博电路板有限公司

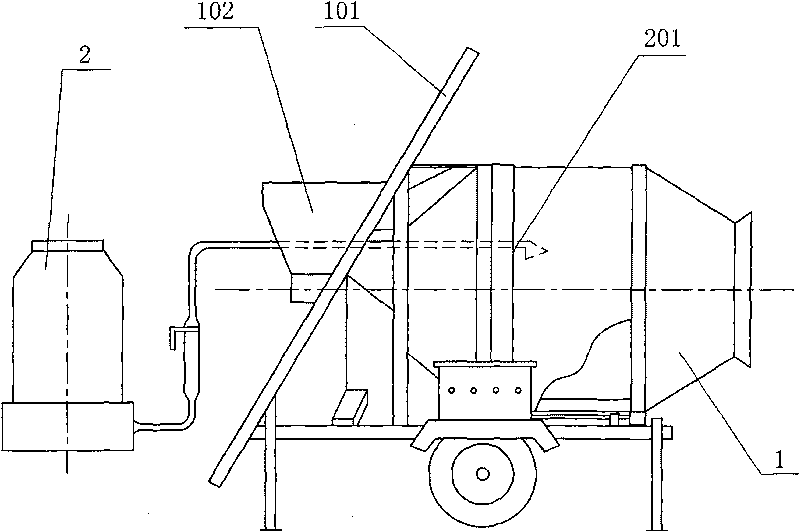

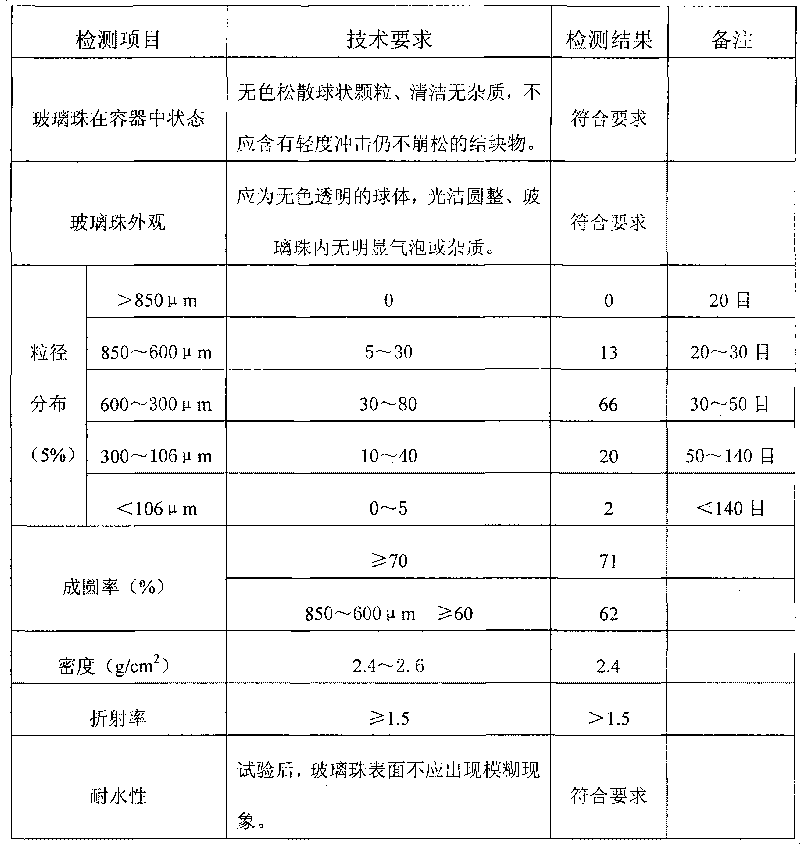

Technology for processing cold coated reflective glass beads

The invention discloses technology for processing cold coated reflective glass beads, which comprises the steps of: dumping qualified glass beads with the diameter between 0.05 and 1.00mm into a feeding funnel of a drum mixer; preparing a medicament, namely taking a silane coupling agent or mixed methyl silicone oil and sodium silicate or mixed thinner and methyl silicone oil as the medicament; adding the medicament, spraying the medicament and stirring the glass beads, namely loading the medicament into a high-pressure sprayer according to the proportion of adding 400 to 600g of the medicament into each ton of glass beads, arranging a nozzle of the high-pressure sprayer above the inside of the drum mixer, downward directly spraying the medicament to the surfaces of the glass beads to form moistureproof protective films, and stirring the glass beads at the same time, wherein the stirring time is between 8 and 10 minutes; and packaging and performing random inspection, namely using packaging bags lined with plastic inner films for packaging, placing the product for 3 days, then performing random inspection, and sending the product into a warehouse after the product is qualified through random inspection. The technology has the advantages that the technology has high production efficiency, raw material conservation, energy conservation, low production cost, good coating effect and strong adhesive power, has no harm to the health of workers, meets requirement of environmental protection, and can be used for pavement markings and various reflective materials and decorative materials.

Owner:张万春

Preparation method of novel ultrahigh-viscosity anionic polyacrylamide

The invention relates to a preparation method of novel ultrahigh-viscosity anionic polyacrylamide. The novel ultrahigh-viscosity anionic polyacrylamide comprises, by weight, 200-270 parts of acrylamide, 80-160 parts of sodium alpha-alkyl sulfonate, 10-22 parts of sodium acrylate, 1-6 parts of a structure modifier, 600-700 parts of deionized water and 0.02-0.08 parts of an initiator. The preparation method comprises the following steps: adding acrylamide, sodium alpha-alkyl sulfonate and sodium acrylate into a reactor, adding the structure modifier in proportion, carrying out nitrogen introducing deoxygenation for 50min, adjusting the pH value to 4-5, adding the initiator, and polymerizing at 2-5DEG C; and taking out the obtained gelly after the reaction, granulating the obtained polymer, drying, and crushing to obtain the above target product. The product changes single linear structure of previous polyacrylamide products, molecular chains are microscopically distributed in an emanative manner along center axis, and all emanative branched chains are mutually associated and wound, so the novel ultrahigh-viscosity anionic polyacrylamide has large viscosity and apparent viscosity, good high temperature and high salinity resistance, and strong viscosity recovery ability after shearing, and can well adapt to requirements of industries of oilfield, joss stick production, buildings and ceramics.

Owner:SHANDONG NUOER BIOLOGICAL TECH

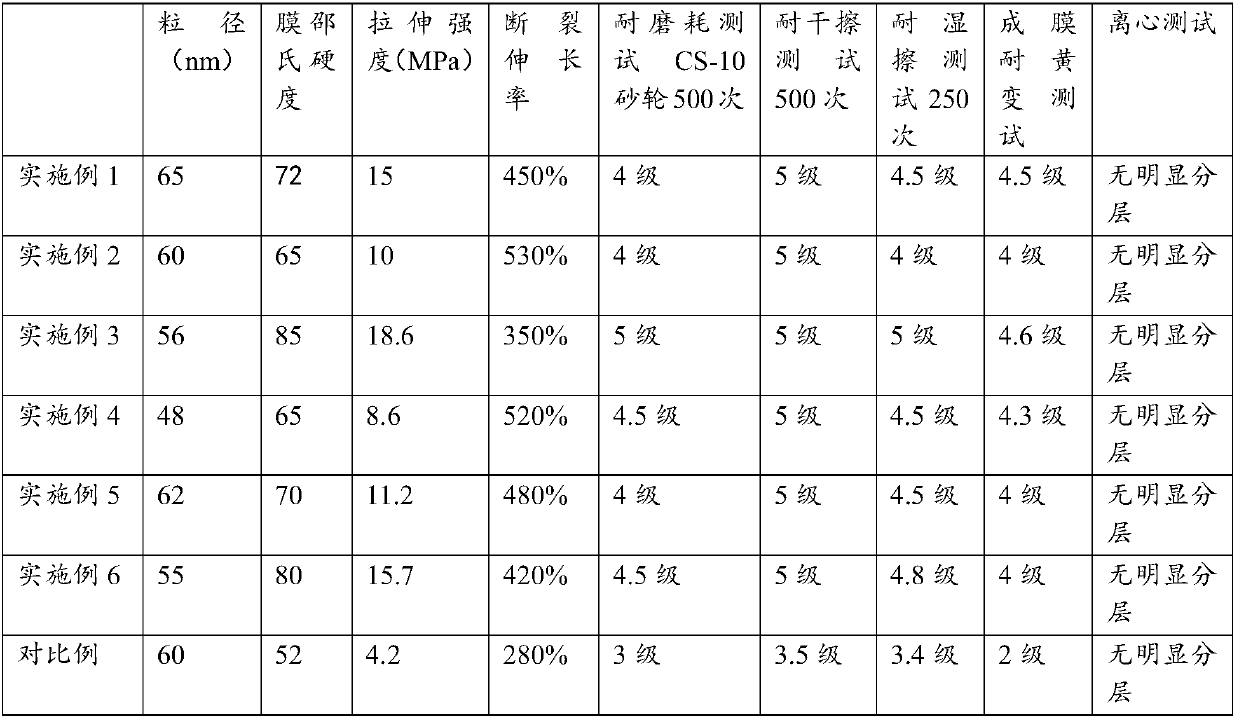

Waterborne polyurethane and preparation method and application thereof

ActiveCN107857869AIncrease softnessDoes not affect viscosityPolyurea/polyurethane coatingsLeather surface finishingHydrophilic monomerCross-link

The invention relates to the field of macromolecular materials and particularly relates to waterborne polyurethane and a preparation method and application thereof. The preparation method comprises the steps: subjecting an HDI trimer or IPDI trimer to a polymerization reaction with polyethylene glycol, then, subjecting the product to a reaction with hexamethylene diisocyanate or isophorone diisocyanate so as to form an isocyanate terminated tri-functionality polymer, and regulating the viscosity of the isocyanate terminated tri-functionality polymer with acetone; subjecting HDI or IPDI to a reaction with a binary alcoholic monomer and a hydrophilic monomer so as to obtain a linear aqueous polyurethane prepolymer, and regulating the viscosity of the linear aqueous polyurethane prepolymer with acetone; subjecting the isocyanate terminated tri-functionality polymer and the linear aqueous polyurethane prepolymer to a cross-linking reaction under the action of a chain extender, and removingthe acetone, thereby obtaining the waterborne polyurethane. After the waterborne polyurethane prepared by the preparation method forms a film, the softness is relatively good, finished, compliant andsoft surface touch feeling of leather is achieved, and meanwhile, the physical properties are relatively good.

Owner:达威水基聚氨酯(上海)有限公司

Waterproof underpad hot melt adhesive excellent in waterproof effect

InactiveCN108219720ADoes not affect viscosityMaintain bonding relationshipNon-macromolecular adhesive additivesMacromolecular adhesive additivesMicrocrystalline waxUrine production

The invention discloses a waterproof underpad hot melt adhesive excellent in waterproof effect. The waterproof underpad hot melt adhesive excellent in waterproof effect comprises an ethylene-vinyl acetate copolymer, a styrene-butadiene-styrene block copolymer, talcum powder, a tackifier, an anti-oxidant, naphthenic oil, paraffin oil, microcrystalline wax, liquid paraffin, and dicyclohexyl phthalate. The viscosity of the waterproof underpad hot melt adhesive is not influenced even the surface of the waterproof underpad is wetted by penetrated urine, the bonding effect among layers of the waterproof underpad is maintained, the raw materials are widely and easily available, and are cheap, and the safety is high.

Owner:苏州市苏宁床垫有限公司

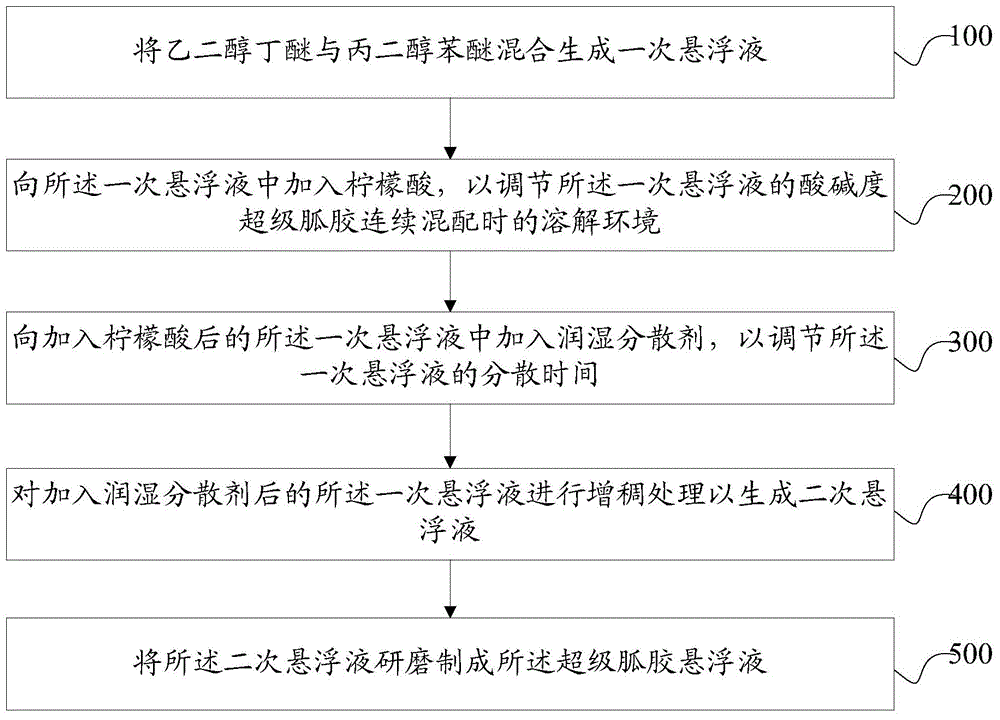

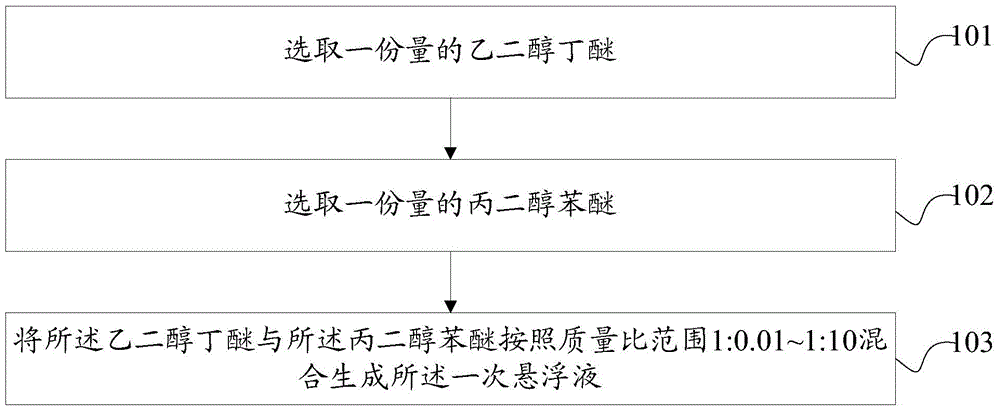

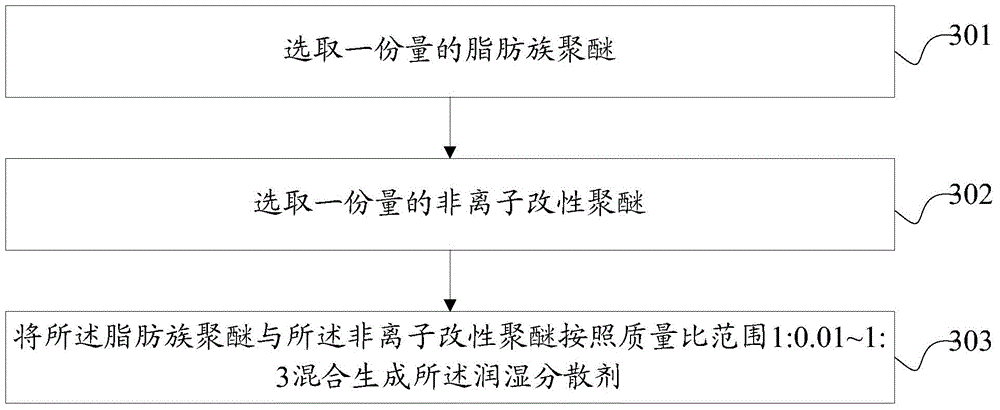

Super guanidine gum suspension and preparation method thereof

ActiveCN104531126ADoes not affect viscosityDoes not affect usabilityDrilling compositionWater based1-Propanol

The invention discloses super guanidine gum suspension and a preparation method thereof. The preparation method comprises the steps: mixing butyl cellosolve and phenoxy-1-propanol to generate primary suspension; adding citric acid into the primary suspension to adjust a dissolving environment of the super guanidine gum when in continuous mixing; adding wetting dispersing agent into the primary suspension after the citric acid is added to adjust the dispersing time of the primary suspension; thickening the primary suspension after the wetting dispersing agent is added to generate secondary suspension; grinding the secondary suspension to form the super guanidine gum suspension. The super guanidine gum suspension has good storage stability and rapid dissolving performance; a fracturing fluid system prepared by adopting the suspension is relatively low in surface and interface tension; when the super guanidine gum suspension is used for preparing water-based fracturing fluid, the viscosity and application performance are not influenced.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

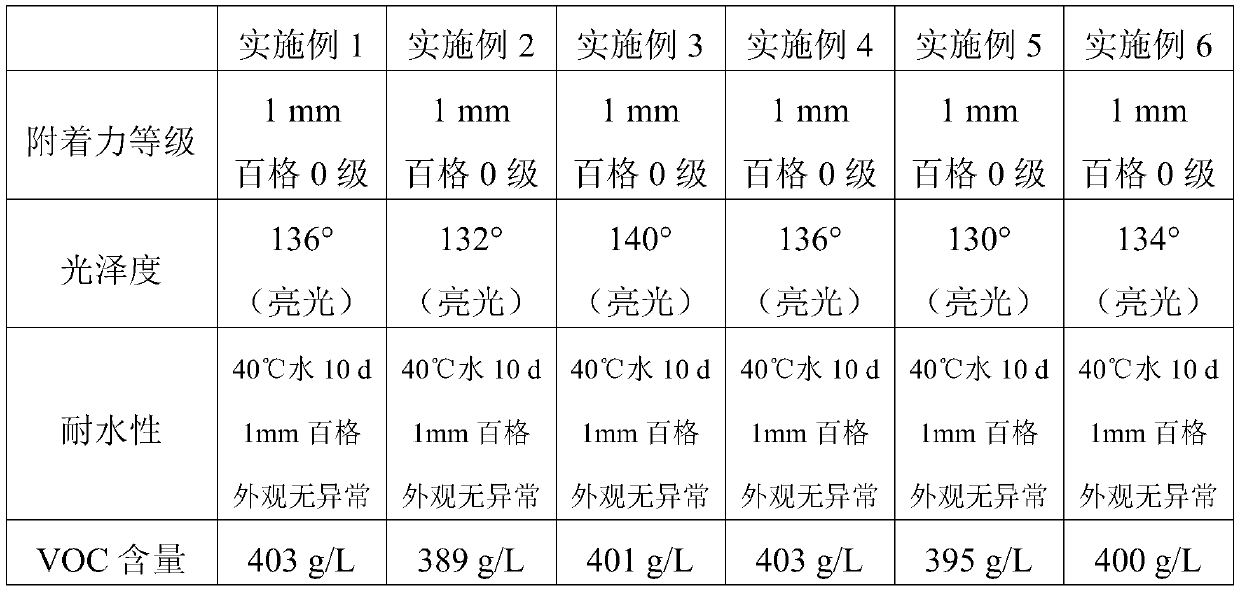

Environment-friendly water-based imitating electrosilvering coating and preparation method thereof

The invention relates to an environment-friendly water-based imitating electrosilvering coating. The coating is prepared from, by weight, 4 to 5 parts of a water-based aluminum paste, 4 to 8 parts ofa coalescing agent, 30 to 50 parts of resin, 3 to 5 parts of a dispersing agent, 3 to 5 parts of an anti-settling agent, 2 to 3 parts of a thickening agent, 0.5 to 1 part of a pH regulator and 30 to 40 parts of deionized water. The preparation method comprises the steps of stirring, standing and dispersing. Compared with coatings in the prior art, the coating of the invention has the advantages oflow cost, strong metal feeling, excellent adhesion to plastic parts, good water resistance, excellent film coating performance, reduction of VOC emission and the like.

Owner:DONGLAI COATING TECH SHANGHAI

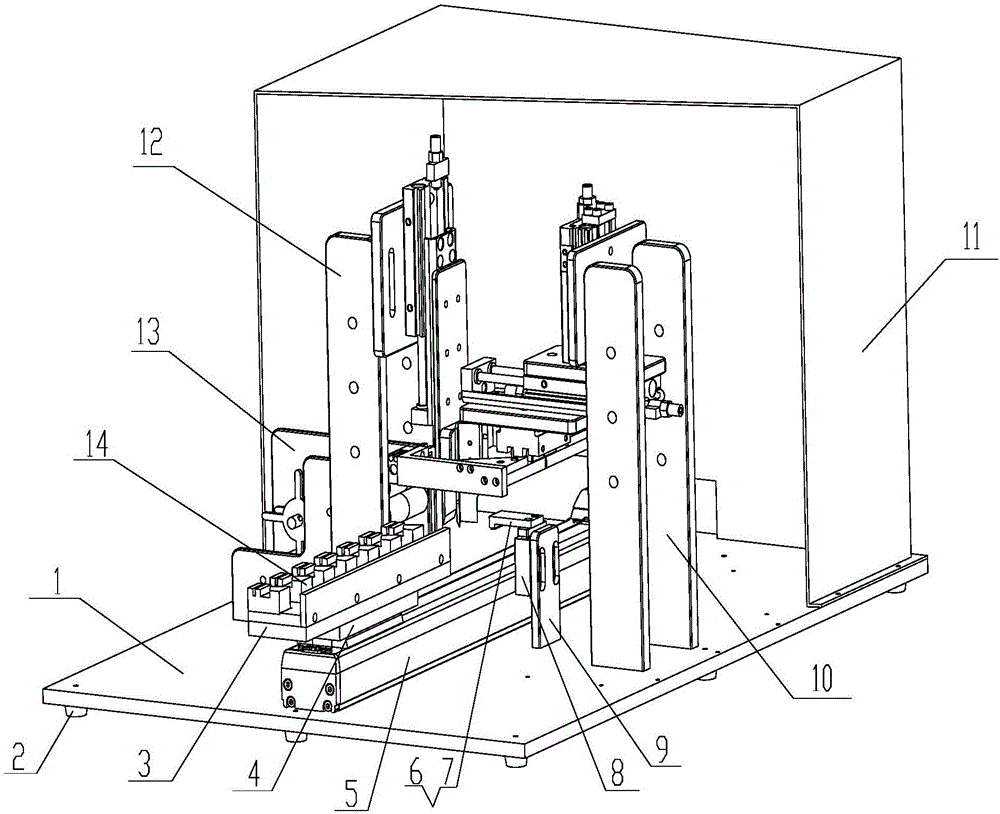

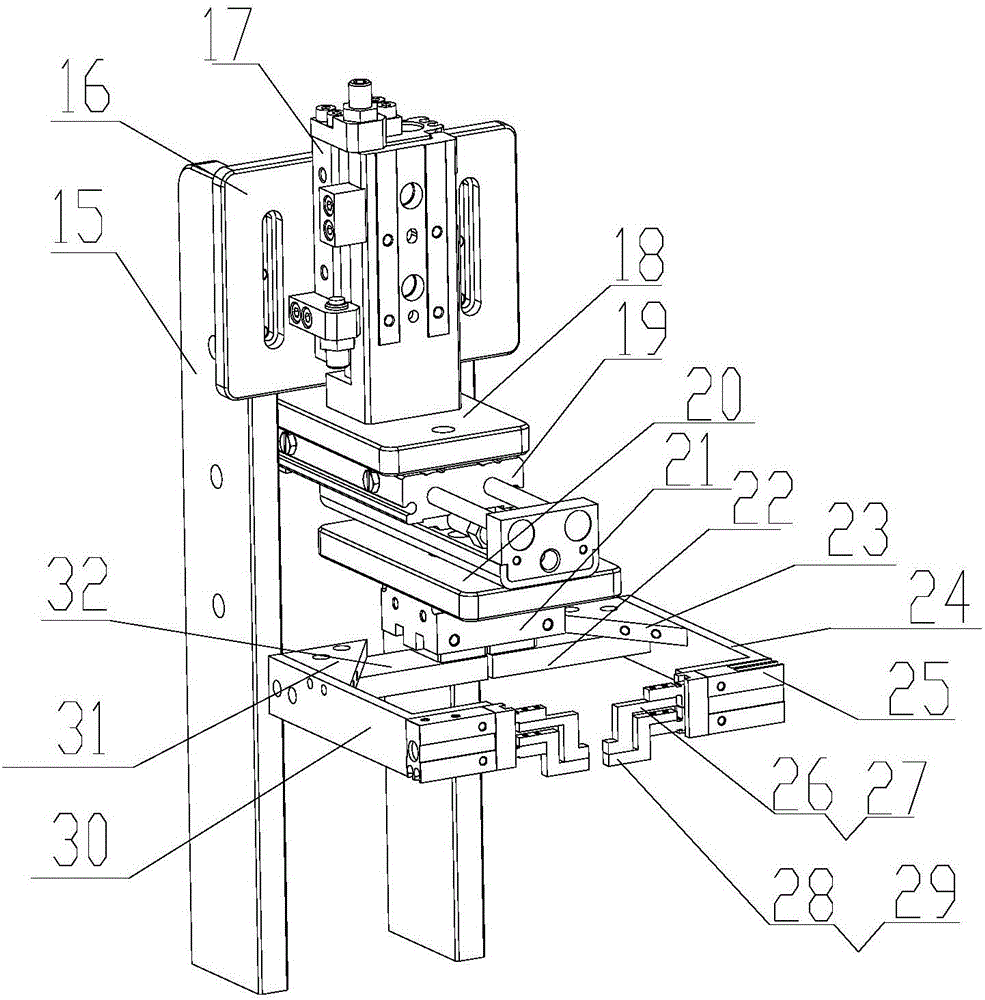

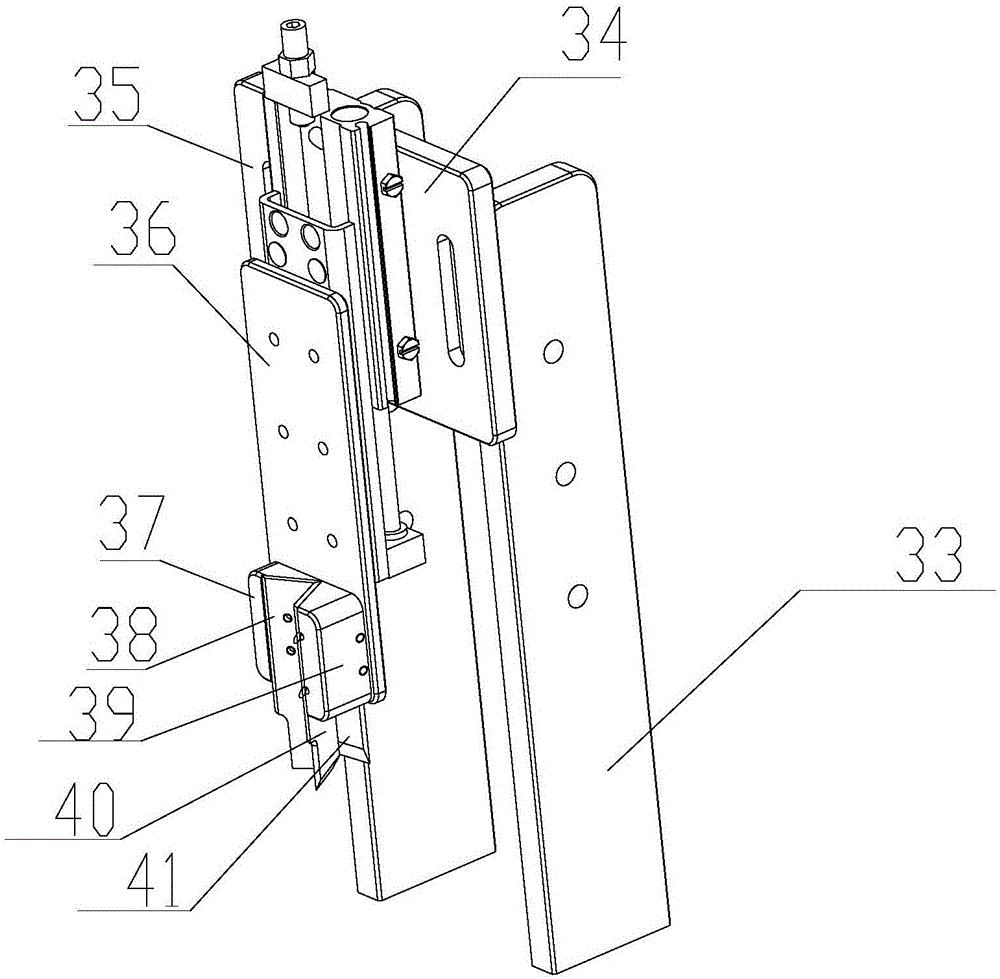

Protective film cutting tool

ActiveCN106217434AEnsure consistencyHigh precisionMetal working apparatusTectorial membraneEngineering

The invention provides a protective film cutting tool. The protective film cutting tool comprises a bottom plate, an air cylinder fixing plate, an electric cylinder, a clamping jaw mechanism, a tool rest mechanism and a protective film placing mechanism, wherein the air cylinder fixing plate is arranged on the upper surface of the bottom plate; a protective film pasting circulating seat is arranged above the electric cylinder, an air cylinder is arranged on the air cylinder fixing plate, and a pressing plate is arranged above the air cylinder; and the protective film pasting circulating seat is driven to move to the protective film placing mechanism by the electric cylinder, one end of a protective film in the protective film placing mechanism is pulled to the position above the protective film pasting circulating seat by the clamping jaw mechanism, the pressing plate is driven to press and limit the protective film on the protective film pasting circulating seat by the air cylinder, and then the protective film in the protective film placing mechanism is clamped by the clamping jaw mechanism, so that the protective film clamped by the clamping jaw mechanism and the protective film limited on the protective film pasting circulating seat are tightened, and the protective film which is pressed and limited is cut by the tool rest mechanism. By utilizing the protective film cutting tool, the problems of bad consistency of angles of the protective film, burrs at corners after cutting, low viscosity and the like in a film cutting process can be solved.

Owner:GOERTEK INC

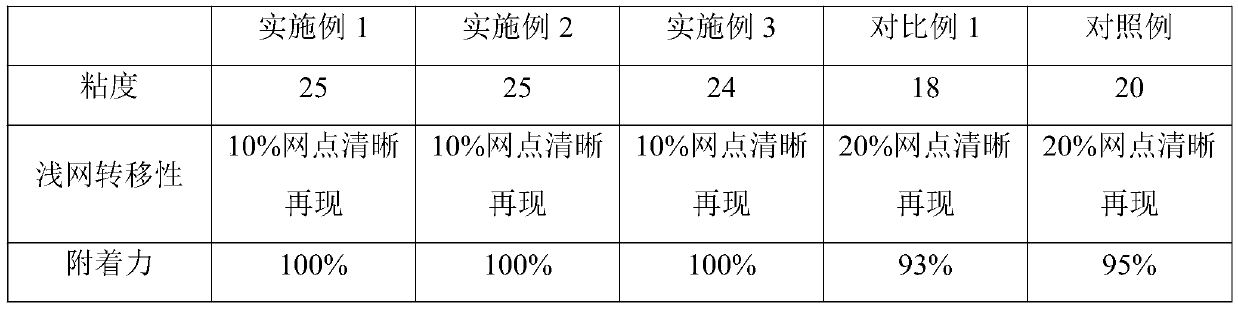

Water-based printing ink with strong shallow screen transferability, and preparation method thereof

The invention discloses a water-based printing ink with a strong shallow screen transferability, and a preparation method thereof. Raw materials of the water-based printing ink comprise a waterborne polyurethane resin, a modified acrylic resin, an aqueous wax paste, an inorganic pigment, a leveling agent, an antifoaming agent and deionized water. The invention also discloses the corresponding preparation method. The preparation method comprises the following steps: adding the waterborne polyurethane resin and the modified acrylic resin into a mixer to prepare a pre-mixture, preparing a mixed color paste from the aqueous wax paste and the inorganic pigment, stirring the pre-mixture and the mixed color paste with the leveling agent and the antifoaming gent in a reactor, and performing dispersing and grinding to obtain the finished ink. The water-based printing ink with the strong shallow screen transferability has an excellent shallow screen transfer performance. The added modified propionic carboxylic acid resin prepared by a specific process and the waterborne polyurethane resin and the inorganic pigment in the ink form a stable dispersion system, so the printing ink has a suitableviscosity and is uniform in coloring.

Owner:陈丽娟

A kind of residual oil hydrogenation antiscaling agent and preparation method thereof

ActiveCN104293393BGuaranteed heat transfer efficiencyNo harmTreatment apparatus corrosion/fouling inhibitionSolubilityPhosphate

A disclosed hydrogenation scale inhibitor of residual oil comprises the following compositions in percent by weight: 10-30% of an organic solvent, 10-25% of ashless phosphate, 10-25% of p,p-di-iso-octyl-diphenylamine, 10-20% of a heterocyclic compound and 10-20% of synthetic calcium sulfonate. Also, the invention discloses a preparation method of the above scale inhibitor. The hydrogenation scale inhibitor gives play to effects of inhibiting fouling and removing a part of formed scale, thereby guaranteeing the heat exchange efficiency of a heat exchanger and the stable and long-term operation of an apparatus. The hydrogenation scale inhibitor has no any damage effects to residual-oil hydrogenation catalysts, does not influence the activity and the stability of the catalysts. Also, the hydrogenation scale inhibitor is good in oil solubility, proper in viscosity, convenient to use, low in addition amount and free of corrosion effect on residual-oil hydrogenation apparatuses. The preparation method is scientific and does not generate any pollution.

Owner:宜兴市星光宝亿化工有限公司

Thixotropic insulating PCB (printed circuit board) organosilicone electronic-pouring sealant

InactiveCN106497510AHigh tensile strengthHigh hardnessNon-macromolecular adhesive additivesMacromolecular adhesive additivesShock resistanceEngineering

The invention discloses a thixotropic insulating PCB organosilicone electronic-pouring sealant. The thixotropic insulating PCB organosilicone electronic-pouring sealant is high in curing hardness, compressive strength and shock resistance, achieves insulation protection of various electronic components and meanwhile obtains rapid thixotropic performance after being mixed, thereby being particularly applicable to pouring-sealed components with tiny gaps and worth popularizing.

Owner:铜陵市超远精密电子科技有限公司

Organosilicon electronic pouring sealant good in impact resistance and used for PCB (printed circuit board)

InactiveCN106634811AHigh tensile strengthHigh hardnessNon-macromolecular adhesive additivesMacromolecular adhesive additivesSealantPlatinum catalyst

The invention discloses an organosilicon electronic pouring sealant good in impact resistance and used for a PCB (printed circuit board). The organosilicon electronic pouring sealant is prepared by vinyl-terminated silicone oil-1, vinyl-terminated silicone oil-2, 12% platinum catalyst, acetenyl cyclohexanol, vinyl silicone resin, 1-allyloxy radicals-2,3-epoxy propane, 1,3,5,7-tetramethyl cyclotetrasiloxane, a silane coupling agent A171, an appropriate amount of hydrogen-containing silicone oil, alkali magnesium sulfate whiskers, (Heptadecafluoro-1,1,2,2-tetradecyl)trimethoxysilane, sodium dodecyl sulfate, ammonium persulfate, maleic anhydride, fluorine silicone resin emulsion, methyl ethyl ketone peroxide, an appropriate amount of deionized water and an appropriate amount of ethanol. The prepared organosilicon electronic pouring sealant is excellent in comprehensive performance, fast in curing, good in adhesion, high in flowability, simple in preparation process, low in production cost, wide in application range and worthy of popularization.

Owner:铜陵安博电路板有限公司

Preparation method of anionic polyacrylamide with ultrahigh viscosity

The invention discloses a preparation method of anionic polyacrylamide with ultrahigh viscosity. The anionic polyacrylamide is a water-soluble high-molecular polymer of a rigid structure and is prepared by copolymerizing cationic monomers and acrylamide and adding structure modifiers to control the polymer structure. The product obtained through the preparation method is good in solubility, higher in adaptability to water purification equipment and water quality and better in flocculation effect.

Owner:东营市诺尔化工有限责任公司

A mild soap-based cleansing cream composition and its production process

ActiveCN103126911BReduce contentDoes not affect viscosityCosmetic preparationsToilet preparationsCleansers skinFatty acid

Disclosed are a mild soap base facial cleanser composition and a production process therefore. The composition comprises: a soap base accounting for 2.0% to 50.0% of the composition by weight; an anion surfactant accounting for 2.0% to 30.0% of the composition by weight; a rheology modifier accounting for 0.5% to 20.0% of the composition by weight, and remaining water. The production process of the composition of the present invention comprises: first, diluting a fatty acid with another compatible component in the formulation, and dispersing the fatty acid by stirring to form fatty acid drips; next, adding a base solution, so that the base solution contacts with the fatty acid drips, to form fine soap particles; and finally, adding components to be added at a low temperature, mixing evenly, and then discharging the product. The mild soap base facial cleanser composition of the present invention is mild and moistening, does not make the skin feel dry and tight after washing, and has good low-temperature and high-temperature stability. The production process is simple and easy to operate, has good reproducibility, and can avoid frequent quality problems in the production of soap base facial cleanser.

Owner:浙江萃芙化妆品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com