Method for purifying montmorillonite from bentonite ore by twice dispersion method

A technology of bentonite ore and bentonite, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve problems affecting purification efficiency and difficult removal of associated ore impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

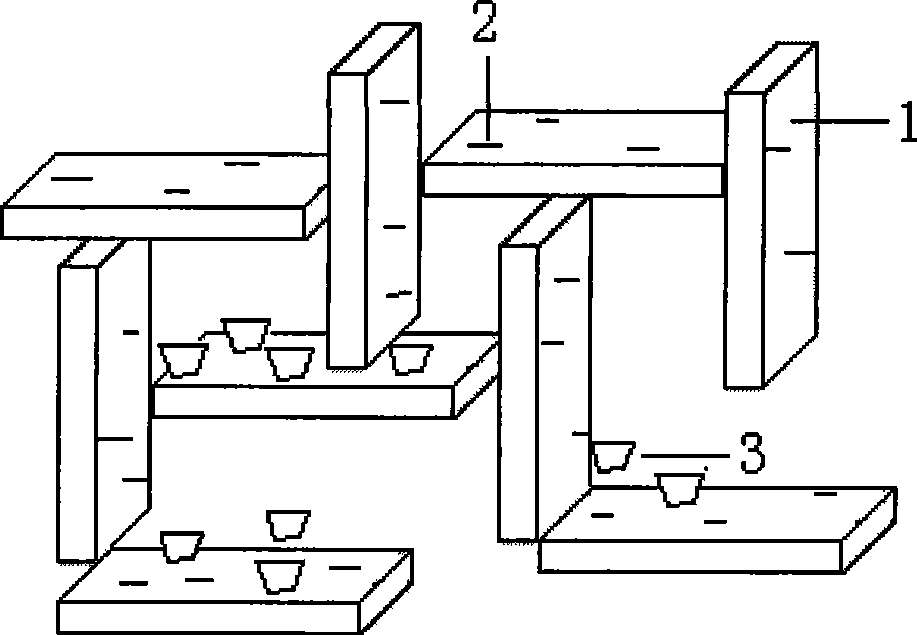

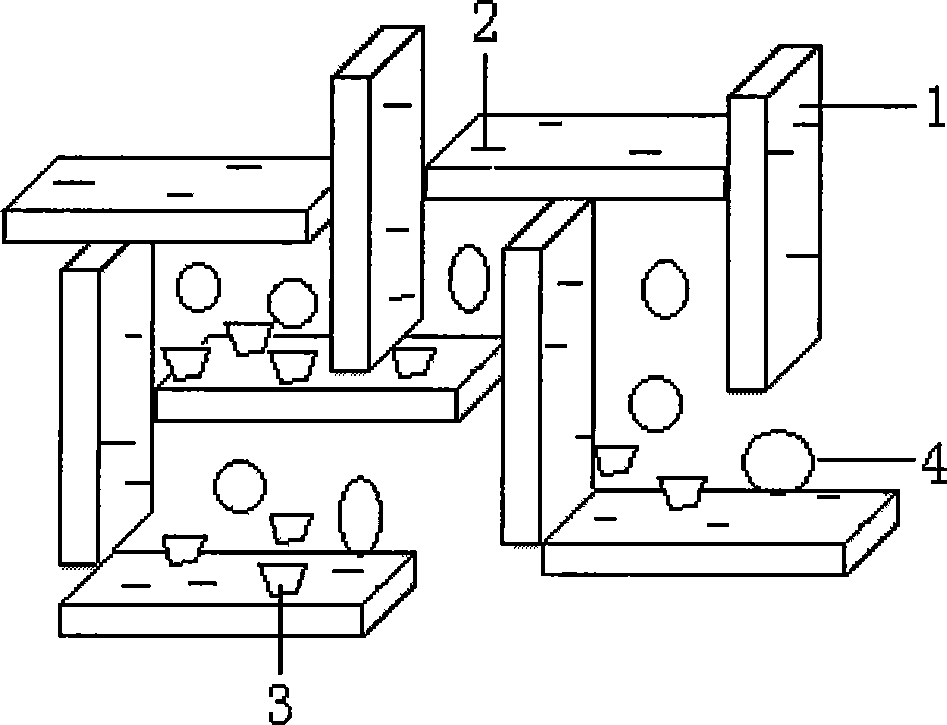

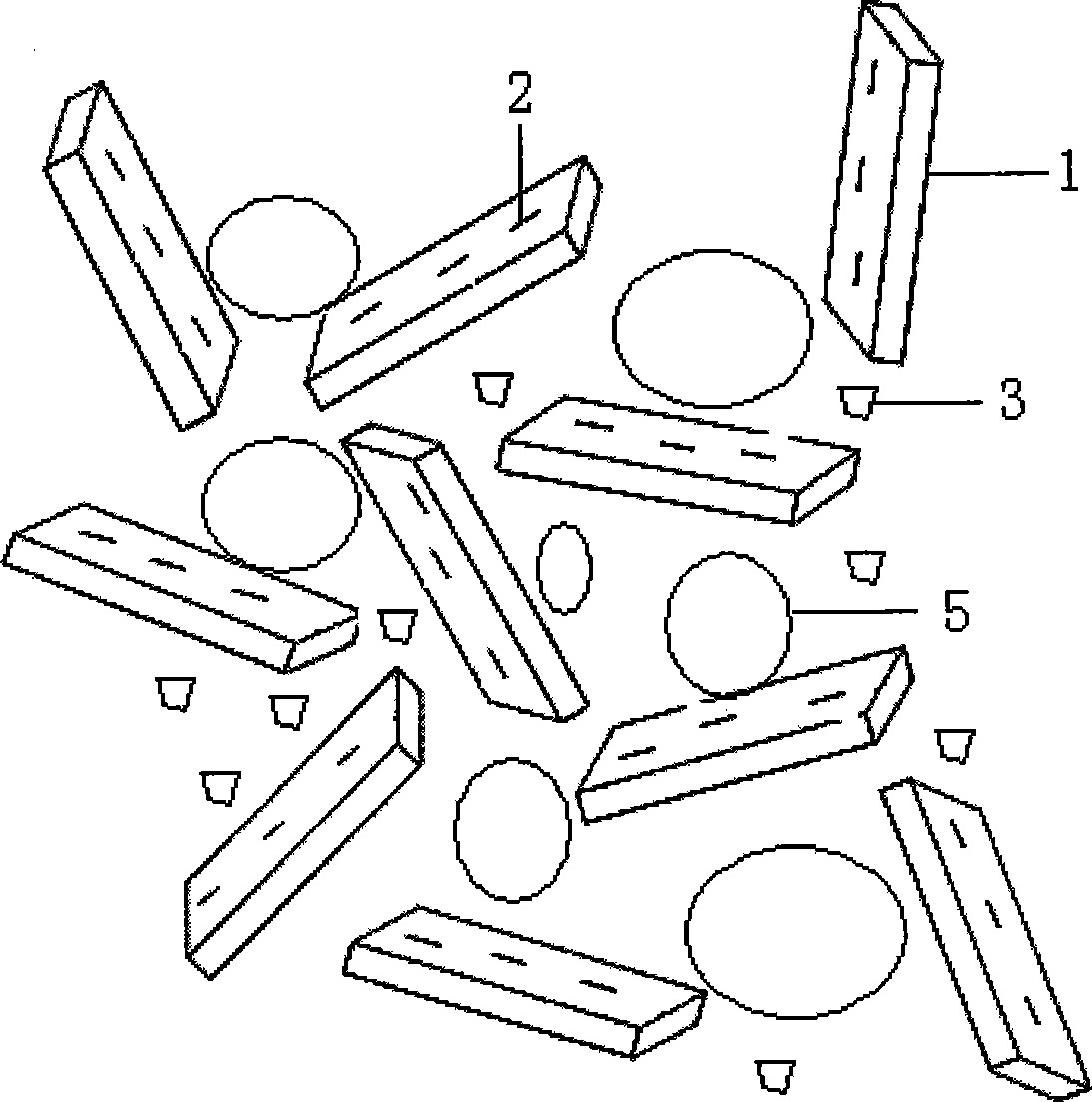

Method used

Image

Examples

Embodiment 1

[0035] Raw ore processing

[0036] Weigh 100g of bulk bentonite raw ore, the content of montmorillonite is 71.4%, crush the bulk bentonite until the volume is less than 1cm 3 , soaked in tap water for 2 hours to make a pulp with a concentration of 20%, passed through a 100-mesh sieve, and then added water to make a 15% pulp;

[0037] add gas dispersant

[0038] Select 17.5ml of 10% hydrogen peroxide aqueous solution and add it to the pulp, stir evenly, and let it stand still for 60 minutes, so that hydrogen peroxide can fully penetrate into the lamellar structure; The color makes it whiter. At the same time, hydrogen peroxide does not produce pollution. Only heating can achieve foaming, expansion and stretching of the "I" structure, so that the tiny impurities hidden in it will slide and precipitate due to the loss of support. Hydrogen peroxide itself has no effect on the performance of montmorillonite due to thermal decomposition;

[0039] Add sodium pyrophosphate dispersa...

Embodiment 2

[0044] Raw ore processing

[0045] The content of powdered raw ore montmorillonite is 80% bentonite and 100g bentonite is directly mixed with tap water into 5% ore slurry;

[0046] add gas dispersant

[0047] Select 20ml of 15% hydrogen peroxide aqueous solution and add it to the pulp, stir evenly, and let it stand still for 60 minutes, so that hydrogen peroxide can fully penetrate into the lamellar structure;

[0048] Add sodium pyrophosphate dispersant

[0049] Add 2g of sodium pyrophosphate into the pulp, stir evenly, heat at 60°C for 45min, and let stand still for 5 hours;

[0050] Upper slurry treatment

[0051] The dispersed pulp is extracted from the upper layer of pulp, and then dried by a conventional drying method to obtain a dry product with a montmorillonite content of 98.4%.

Embodiment 3

[0053] Raw ore processing

[0054] 100 g of bentonite powder with a montmorillonite content of 79.7% is directly prepared into a 10% slurry with tap water;

[0055] add gas dispersant

[0056] Select 20ml of 10% hydrogen peroxide aqueous solution and add it to the pulp, stir evenly, and let it stand still for 30 minutes, so that hydrogen peroxide can fully penetrate into the lamellar structure;

[0057] Add sodium pyrophosphate dispersant

[0058] Add 1.8g of sodium pyrophosphate into the pulp, stir evenly, heat at 80°C for 45min, and let stand still for 1 hour;

[0059] Upper slurry treatment

[0060] The dispersed pulp is extracted or the upper layer pulp is poured, and then dried by a conventional drying method to obtain a dry product with a montmorillonite content of 96.3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com