Patents

Literature

476results about How to "Guaranteed heat transfer efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

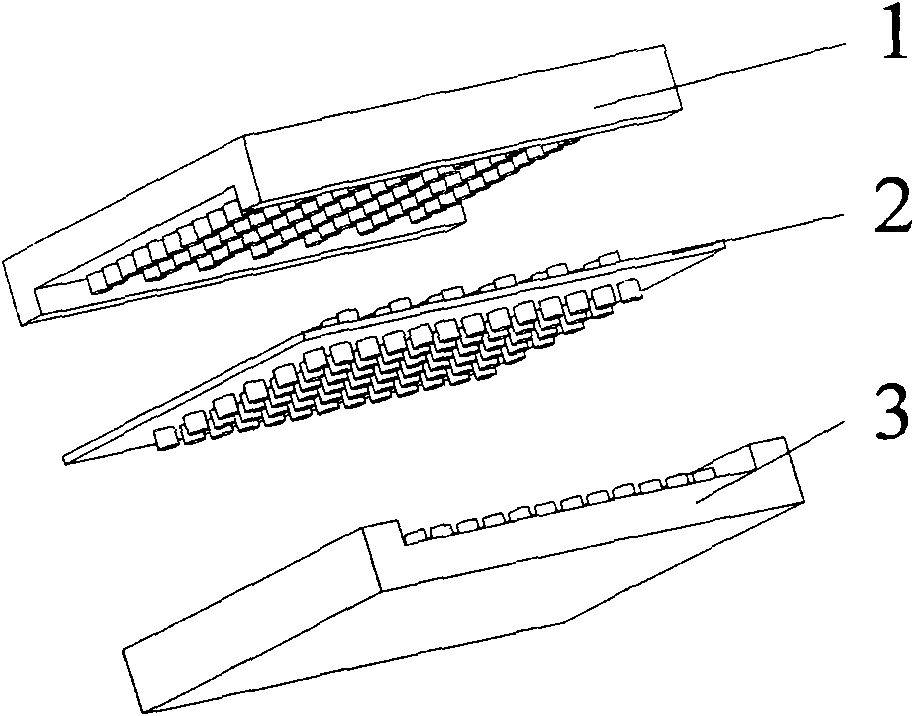

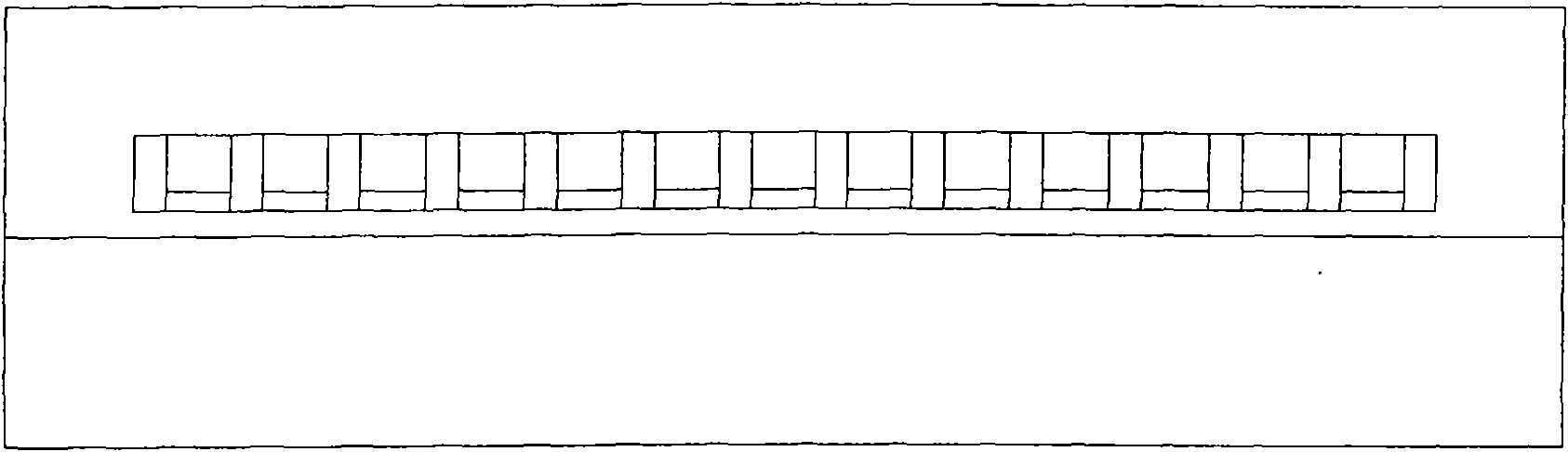

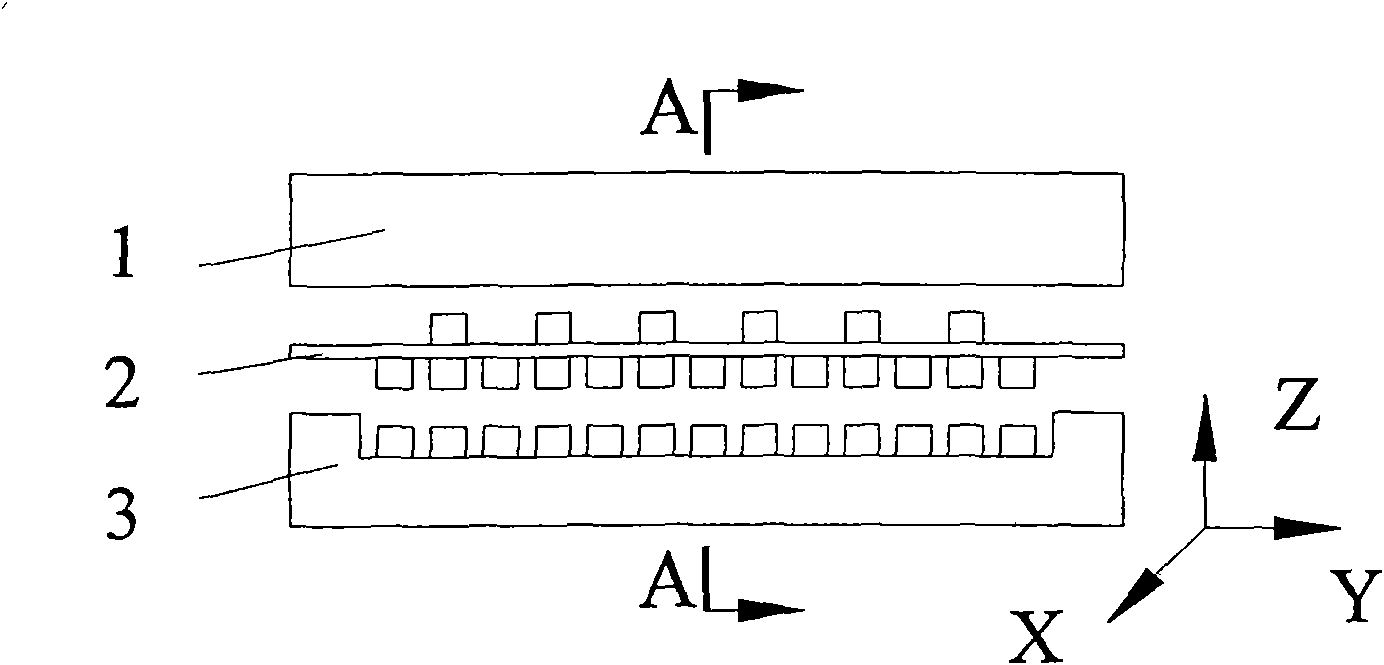

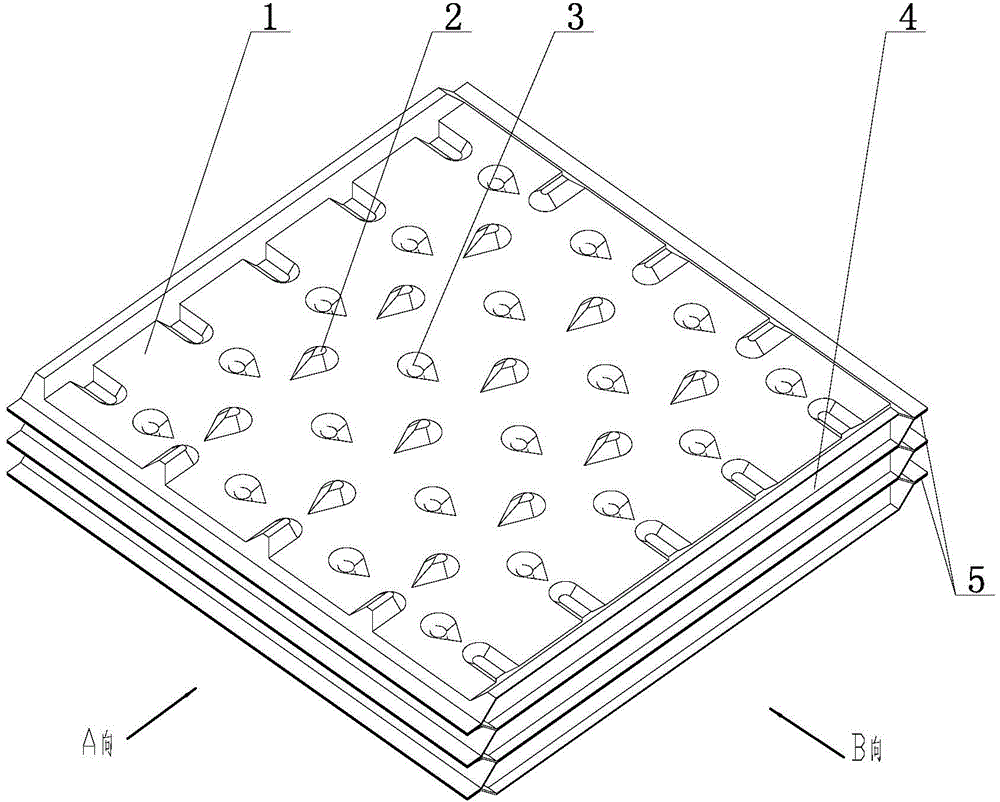

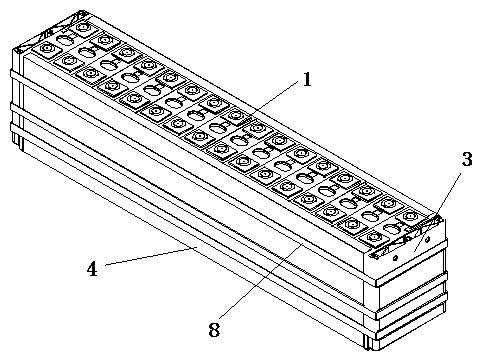

Self-heating type alcohol reforming hydrogen production micro channel reactor with micro-lug boss array structure

The invention discloses a self-heating type alcohol reforming hydrogen production micro channel reactor with the micro-lug boss array structure. Three layers of platy reaction carriers are all provided with micro-lug boss array structures; an upper layer and a lower layer are single-side micro-lug boss array structures; a middle layer is a double-side micro-lug boss array structure; the micro-lug bosses are arranged in the mode of parallel array; the three layers are cascaded to form a reaction channel with an inlet of 90 degrees; both ends of the channel are respectively provided with connector lugs; the gas inlet is provided with a detachable adapter and an outlet is provided with a fixed-type adapter. An upper layer channel is a catalytic reforming hydrogen production channel, and a lower layer channel is a combustion channel. The two layers of channel structures both adopt an open structural type being beneficial for the sediment of the catalytic coating. Fuel gases such as hydrogen and the like are combusted in the combustion channel and generate lot of heat which is transferred into the catalytic reforming hydrogen production channel by the middle layer of the reactor so as to meet the requirement of the steam reforming hydrogen production reaction; the reactor can produce hydrogen in a self-heating type. The invention increases the specific volume of the reactor and increases the yield of the alcohol reforming hydrogen production.

Owner:ZHEJIANG UNIV

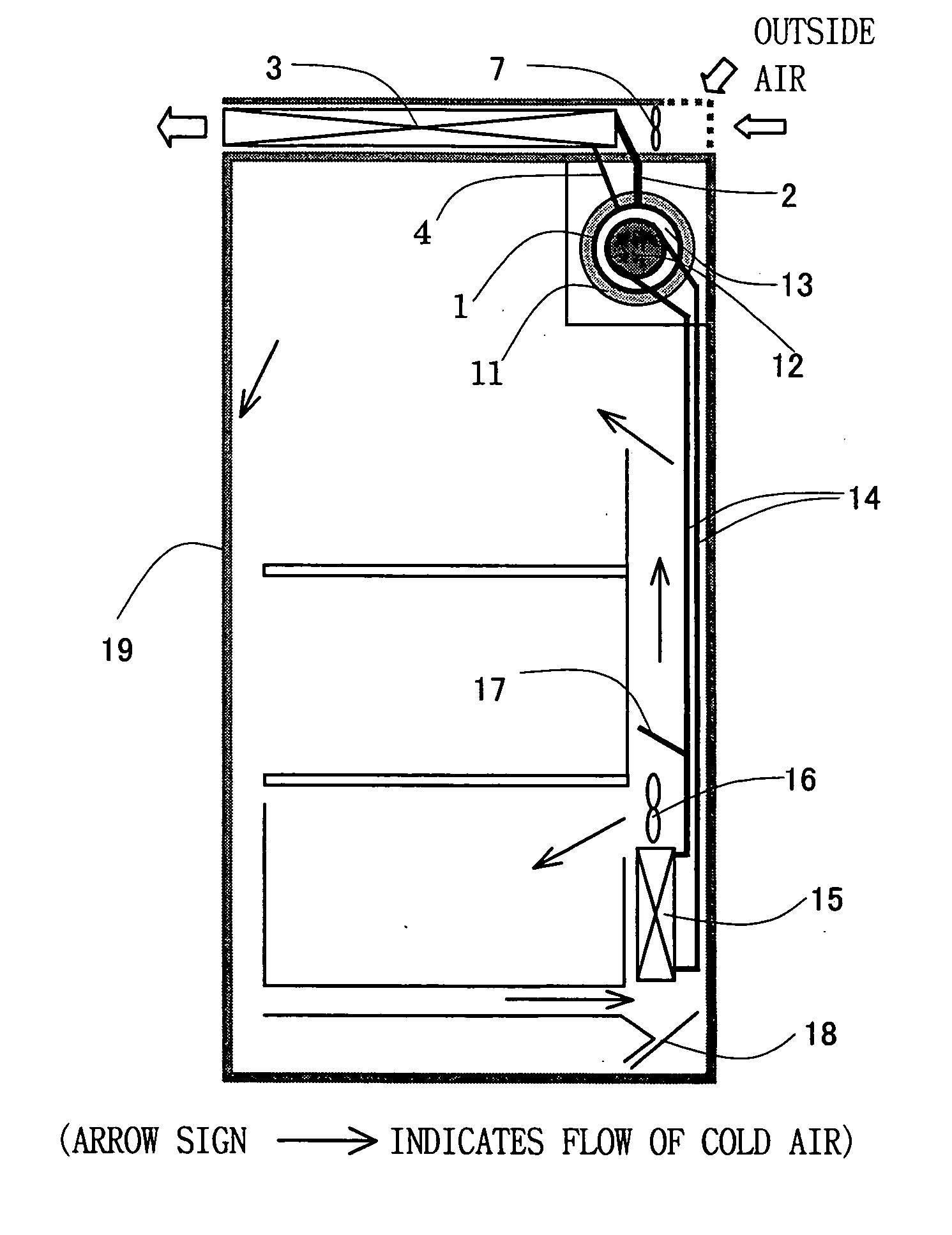

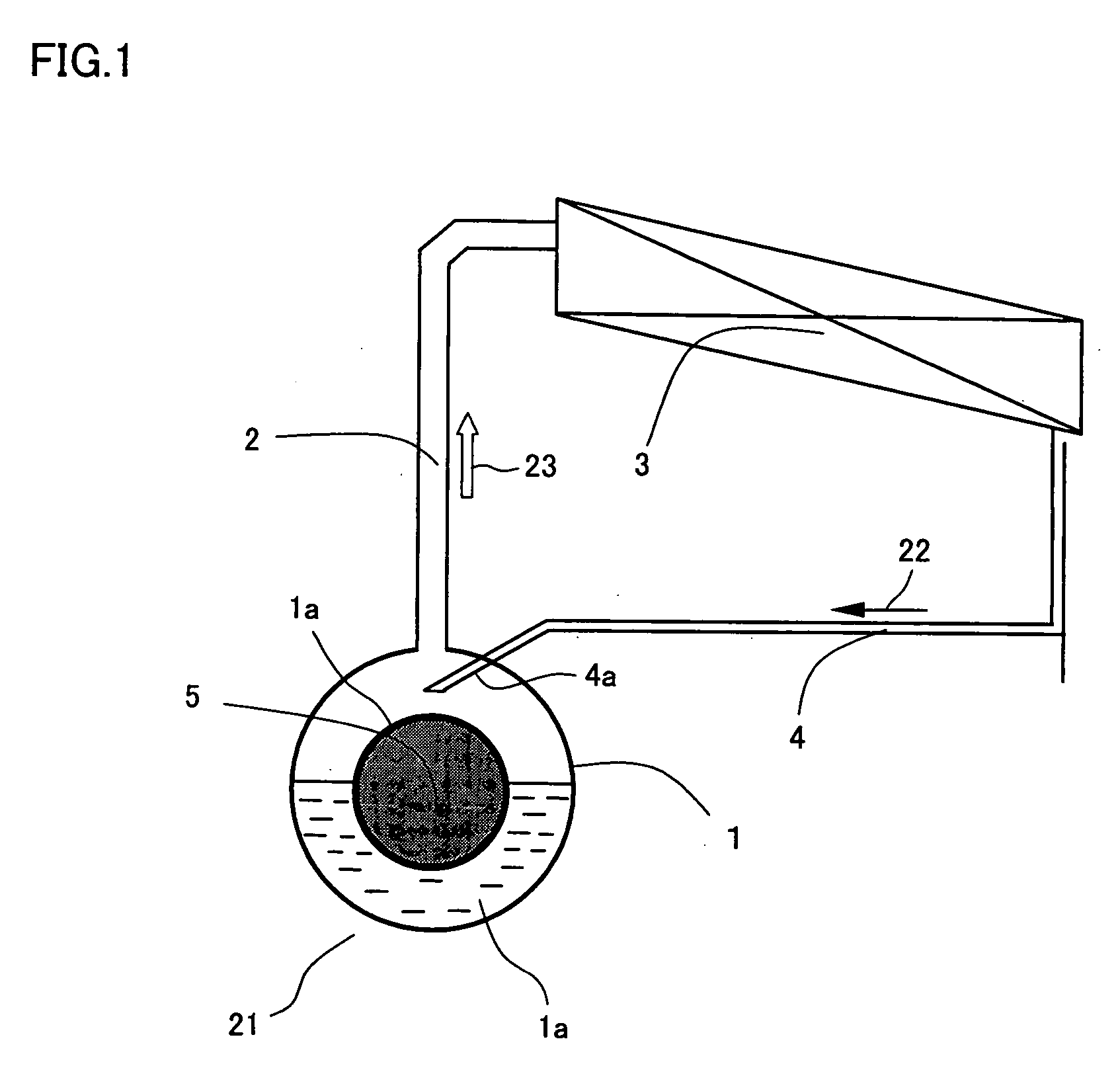

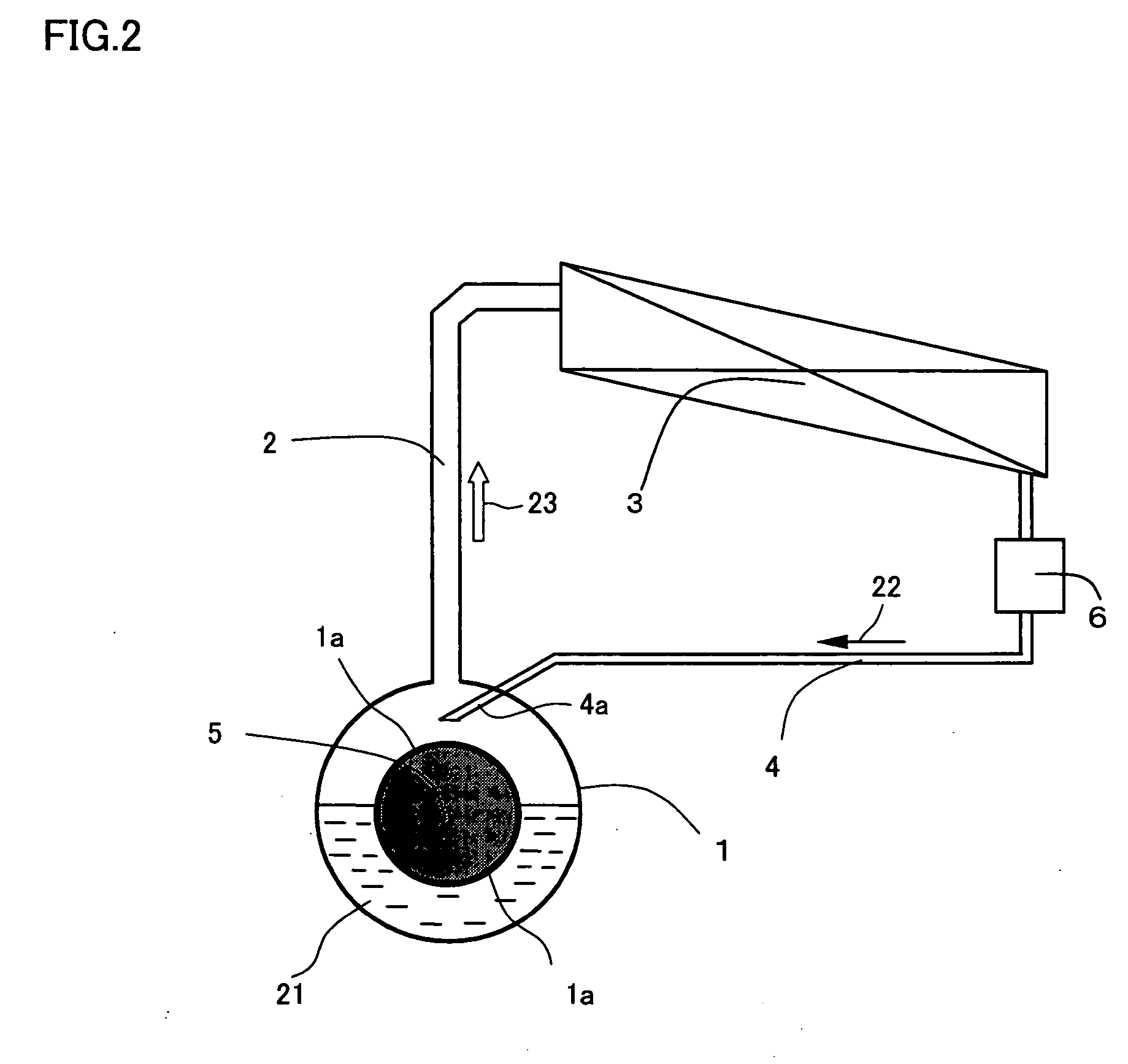

Loop-type thermosiphon and stirling refrigerator

InactiveUS20050172644A1Compact structureEasy to separateCompression machines with non-reversible cycleDomestic refrigeratorsWorking fluidEngineering

A loop-type thermosiphon capable of stable operation regardless of fluctuation of heat load and a Stirling refrigerator using the same are provided. The loop-type thermosiphon transferring heat from a high-temperature heat source using a working fluid includes a evaporator having a heat absorption portion and evaporating the working fluid by depriving the high-temperature heat source of heat through the heat absorption portion, a condenser located above the high-temperature heat source and condensing the working fluid that has evaporated in the evaporator, and a pipe connecting the evaporator and the condenser so as to form a loop. In the loop-type thermosiphon, the working fluid that has passed through the condenser is brought in contact with the heat absorption portion before it is pooled in a liquid pool for the working fluid in the evaporator, so as to exchange heat with the same

Owner:SHARP KK

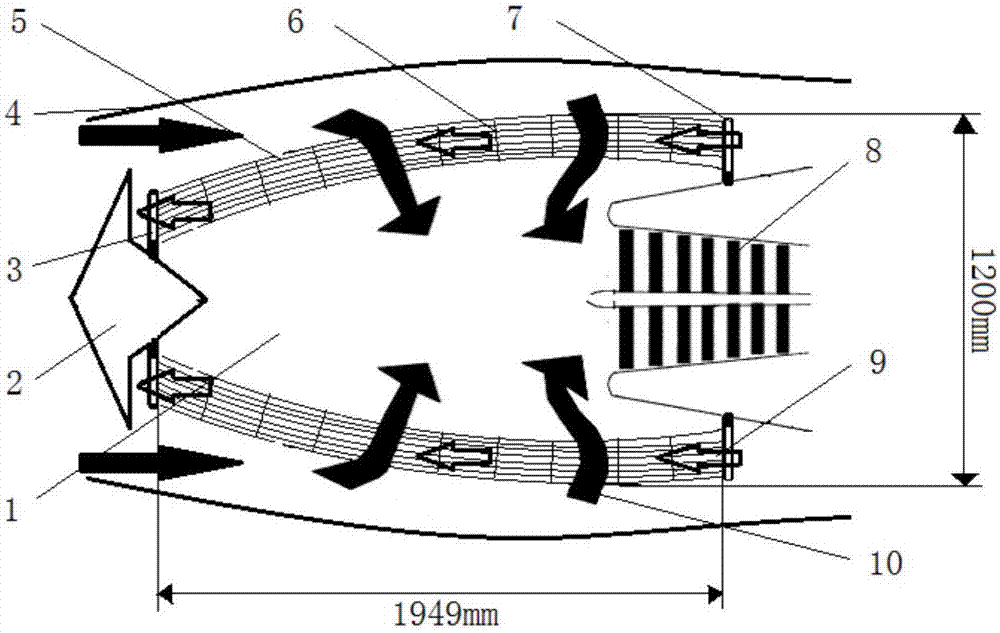

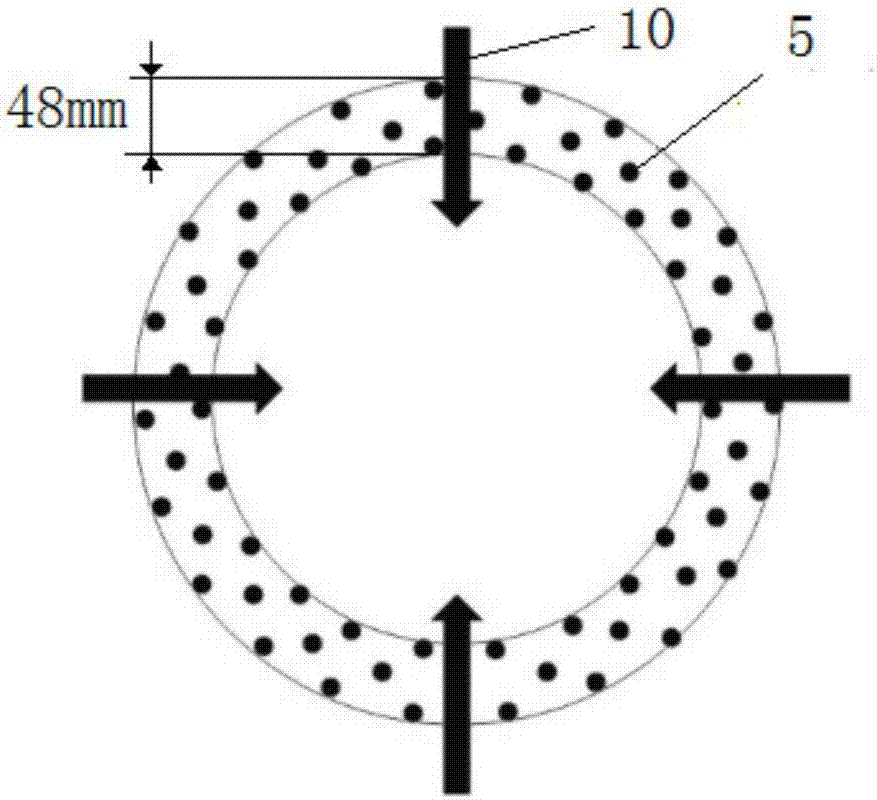

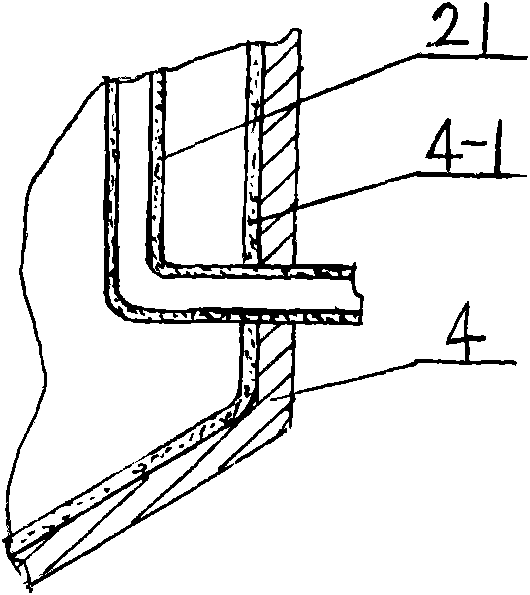

Efficient and compact pre-cooling heat exchanger for pre-cooling gas sucking type engine

ActiveCN107218133AGuaranteed heat exchange effectReduce welding difficultyTurbine/propulsion engine coolingGas turbine plantsEngineeringCurrent technology

The invention discloses an efficient and compact pre-cooling heat exchanger for a pre-cooling gas sucking type engine. The efficient and compact pre-cooling heat exchanger for the pre-cooling gas sucking type engine comprises a pre-cooling heat exchanger body in the shape of a similar cylinder; the cross section of the similar cylinder is in the shape of a ring different in diameter; the longitudinal section of the similar cylinder is formed by two symmetrically arranged arc segments; the center angle of each arc segment is 45 degrees; the pre-cooling heat exchanger body comprises a cold flow outlet pipe, a cold flow inlet pipe and a plurality of heat exchanging pipes; each heat exchanging pipe is in the shape of an arc; the arc-shaped center angle of each heat exchanging pipe is 45 degrees; and the heat exchanging pipes are distributed into the similar cylinder in a crossed manner. The efficient and compact pre-cooling heat exchanger for the pre-cooling gas sucking type engine can have the engineer realizability on the premise that the heat exchanging effect is guaranteed, so that air incoming flow in front of a gas compressor can be pre-cooled, the high temperature over-running problem of gas compressor blades is solved, the engine thrust is increased, the flight envelop is extended, the welding difficulty is effectively reduced, the frosting blockage problem is effectively solved, the engineer realizability is achieved under the current technology, and after the efficient and compact pre-cooling heat exchanger for the pre-cooling gas sucking type engine is applied to the pre-cooling gas sucking type engine, the engine performance can be substantially improved.

Owner:PLA PEOPLES LIBERATION ARMY OF CHINA STRATEGIC SUPPORT FORCE AEROSPACE ENG UNIV

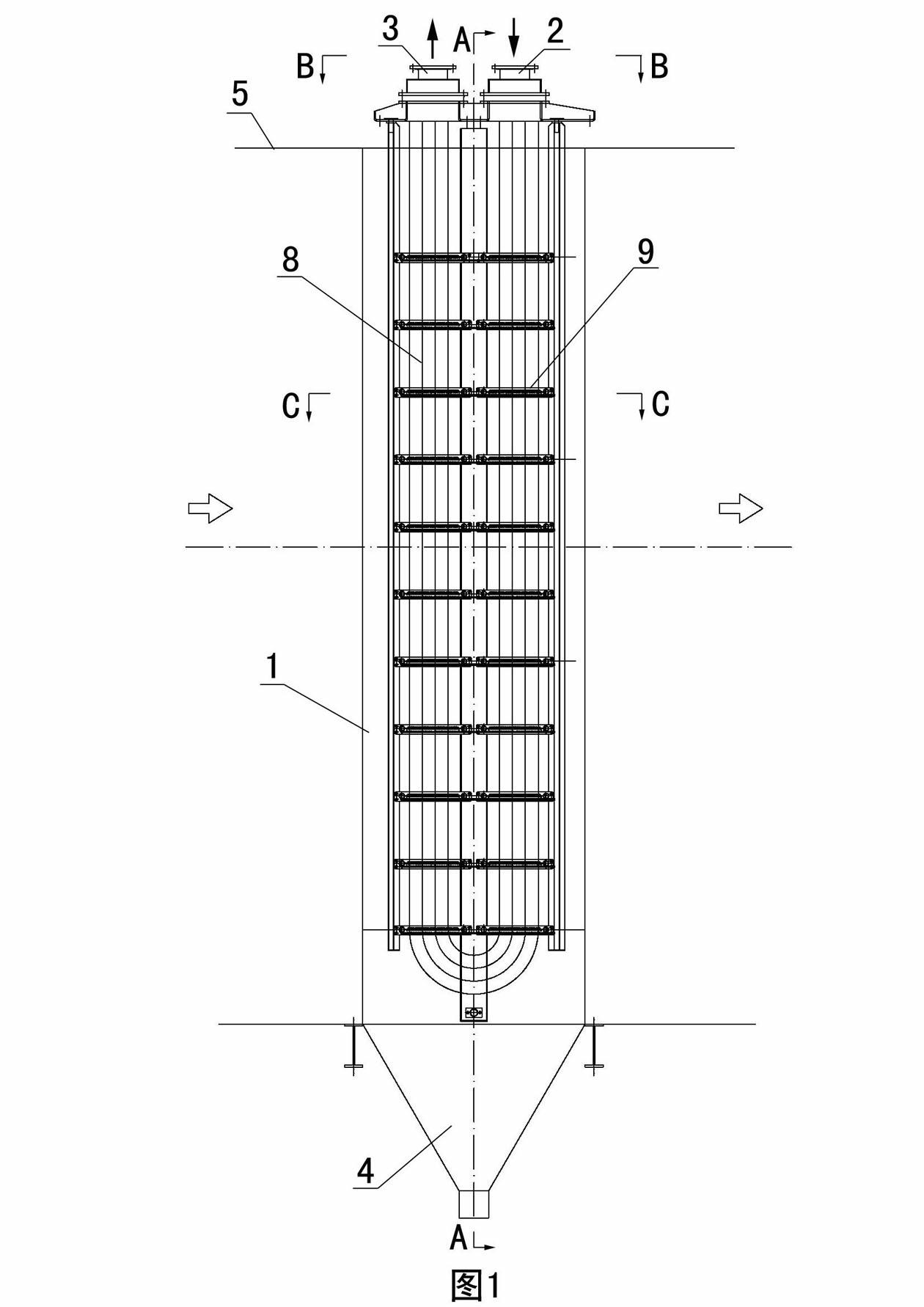

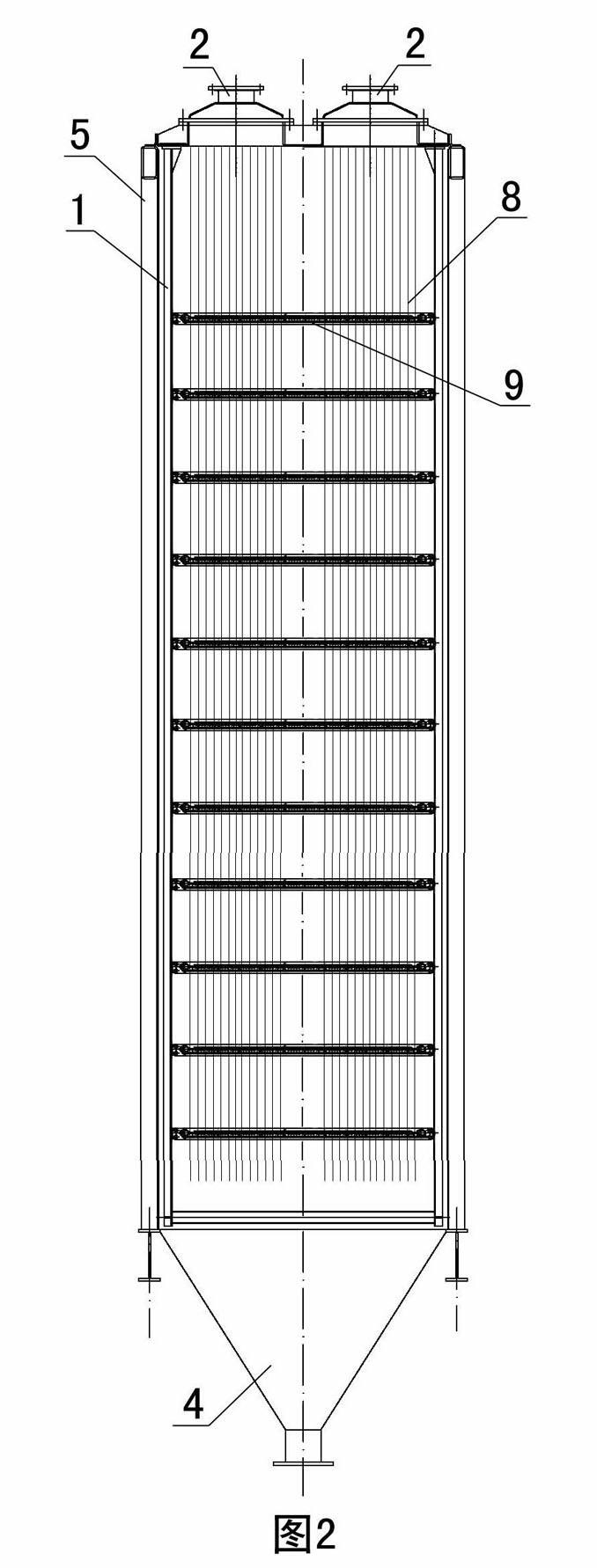

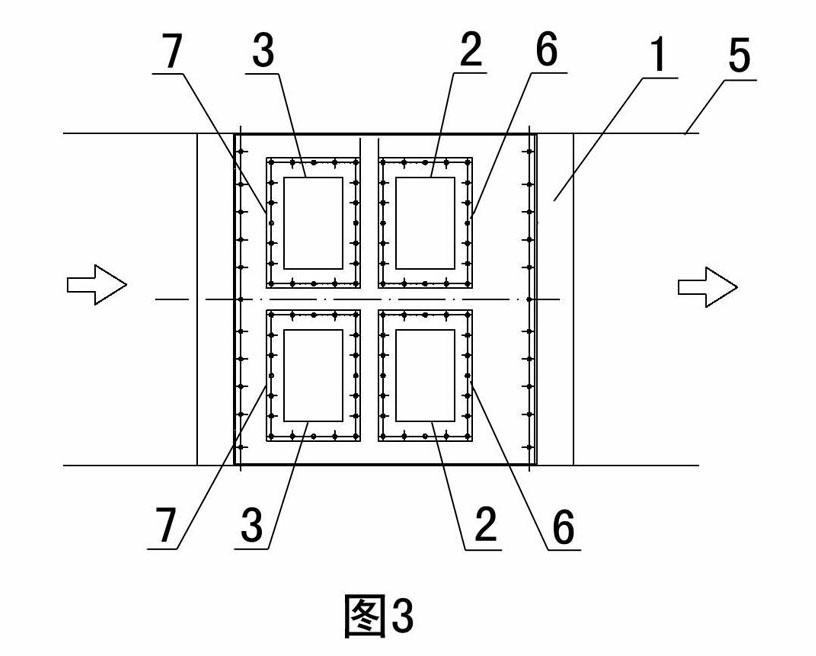

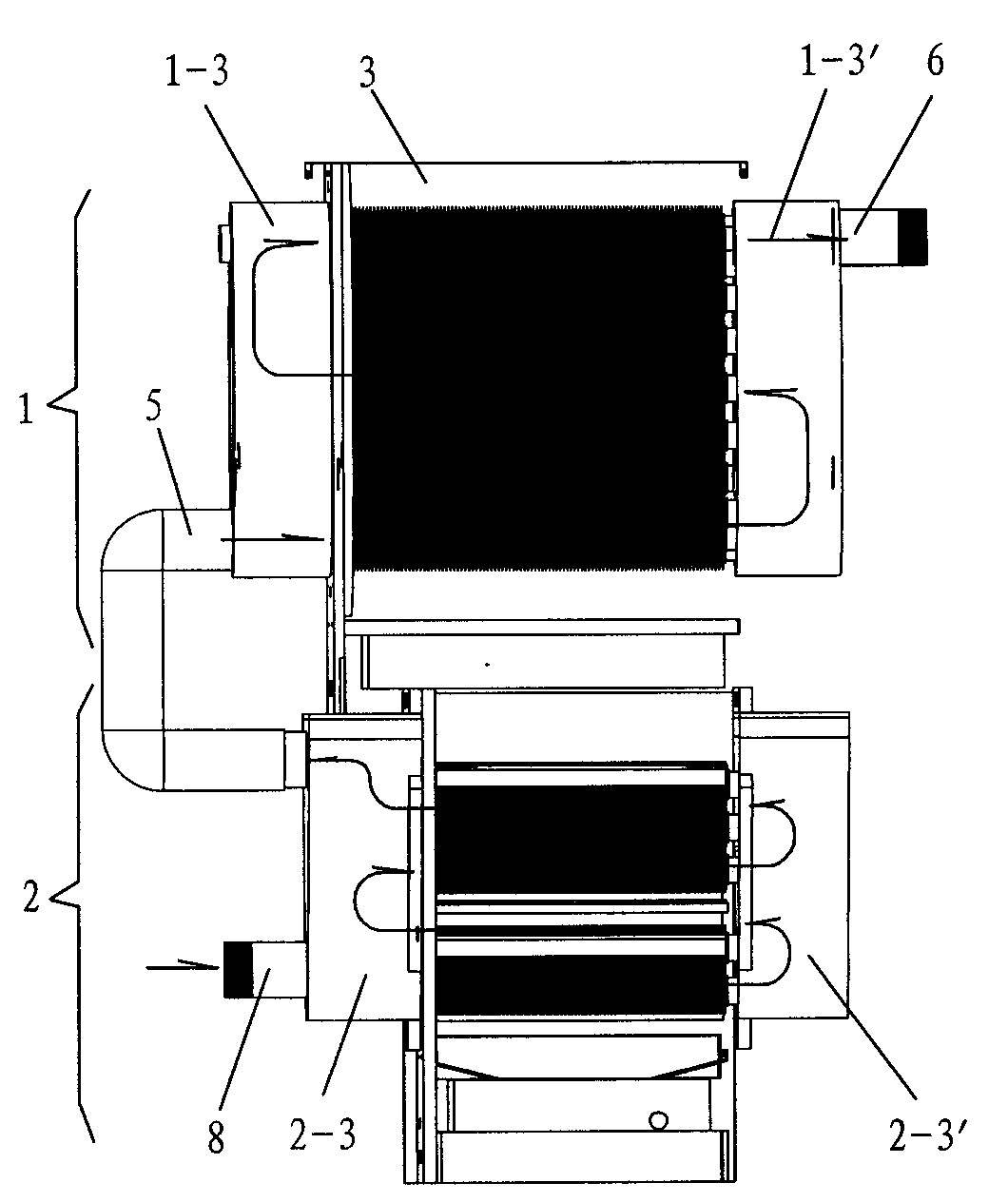

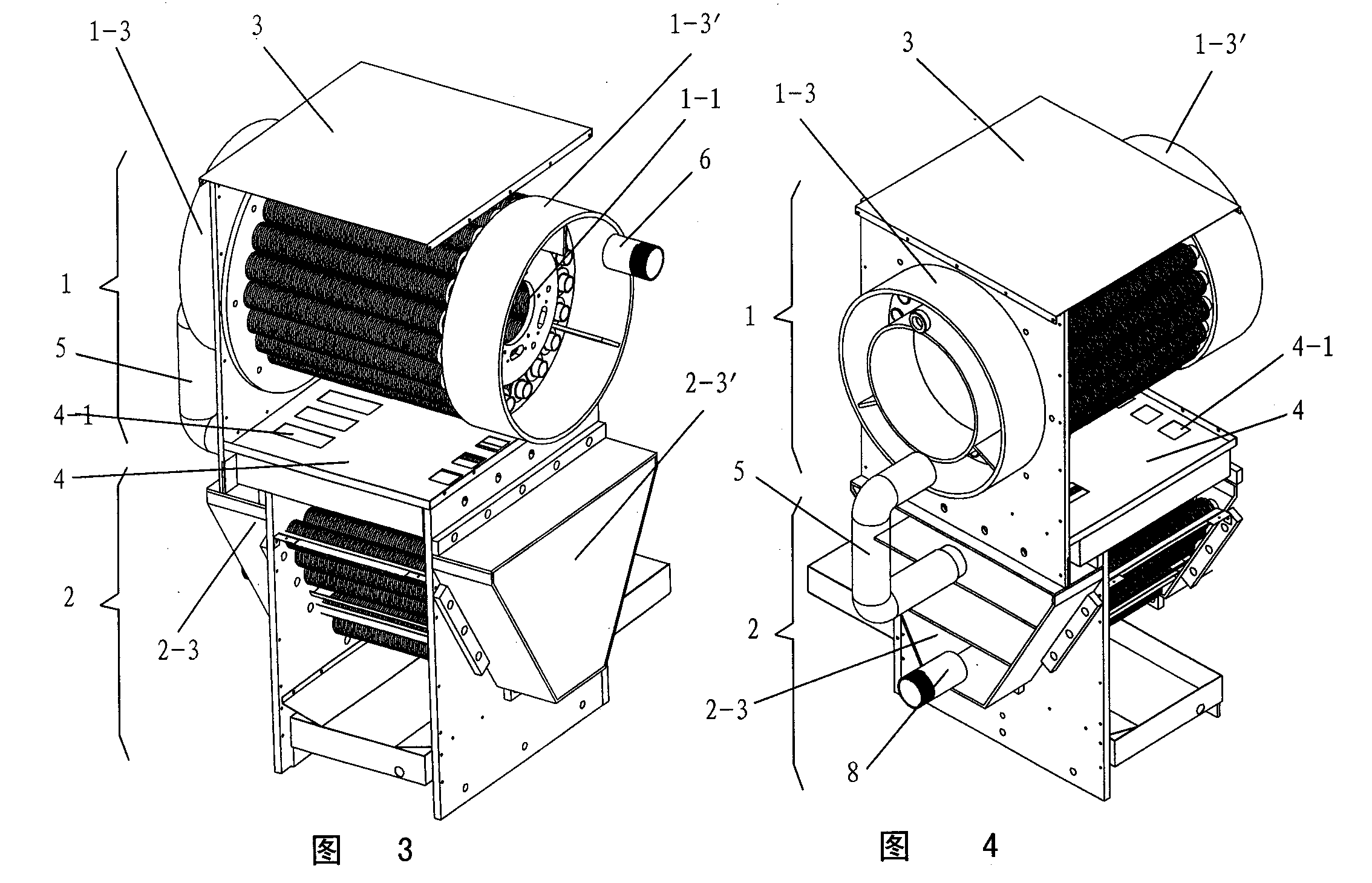

Module type flue gas heat exchanger with fluorine plastic pipes

ActiveCN102607299ALow temperature corrosion resistanceStrong antifoulingHeat exchanger casingsStationary tubular conduit assembliesFlue gasEngineering

A module type flue gas heat exchanger with fluorine plastic pipes comprises a heat exchanger casing and a heat exchange pipe, wherein the upper end of the heat exchanger casing is provided with water inlets and water outlets, and the lower end of the heat exchanger casing is provided with a drain outlet. A water inlet end plate is detachably connected to the position of the water inlets and provided with water inlet holes, and a water outlet end plate is detachably connected to the position of the water outlets and provided with water outlet holes. The heat exchange pipes are U-shaped fluorine plastic heat exchange pipe bundles, water inlet ends of the fluorine plastic pipes in the fluorine plastic heat exchange pipe bundles are communicated with the water inlet holes, water outlet ends of the fluorine plastic pipes in the fluorine plastic heat exchange pipe bundles are communicated with the water outlet holes, and positioning nets are parallelly distributed in the heat exchanger casing from top to bottom at intervals. Module type design is adopted by the flue gas heat exchanger, equipment utilizing rate of the flue gas heat exchanger is greatly improved, the positioning nets are used by the flue gas heat exchanger at a fixed interval so as to fix the fluorine plastic pipes in the fluorine plastic heat exchange pipe bundles, and shaking deformation of the flexible fluorine plastic pipes caused by flowing impact of flue gas can be avoided.

Owner:北京新世翼节能环保科技股份有限公司

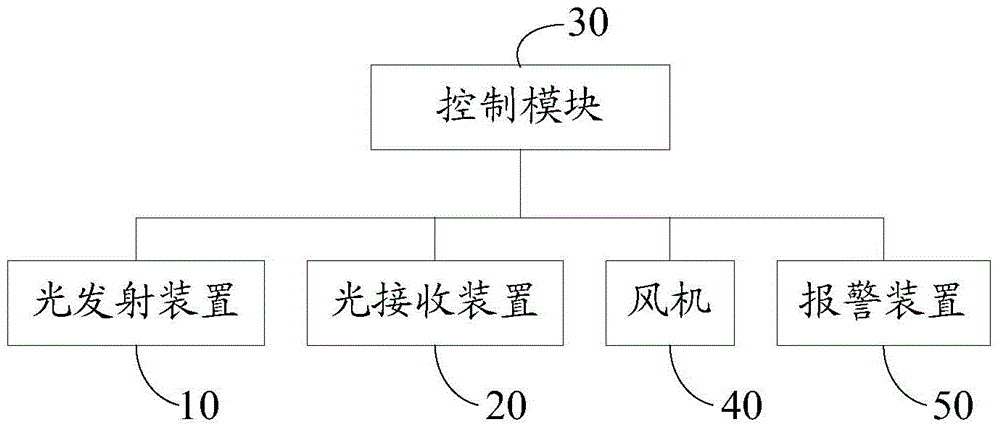

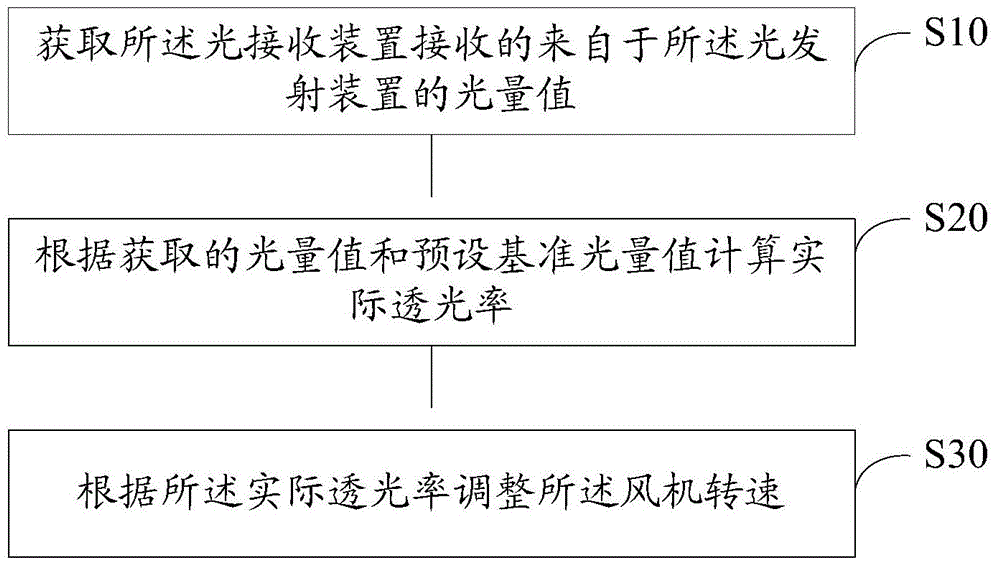

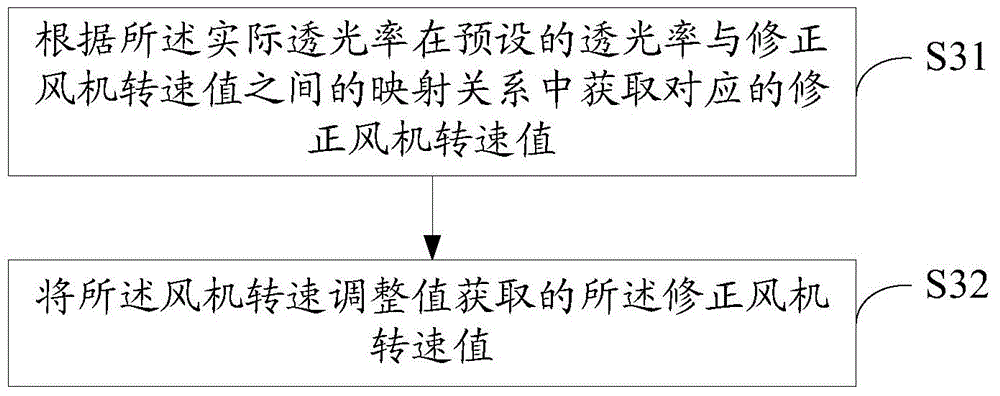

Air conditioner and control method thereof

InactiveCN105783209AGuaranteed heat transfer efficiencySpace heating and ventilation safety systemsLighting and heating apparatusAir volumeEngineering

The invention discloses an air conditioner. The air conditioner comprises a filter screen, a light emitting device arranged on one side of the filter screen, a light receiving device arranged on the other side of the filter screen, a control module connected with the light emitting device and the light receiving device, and a fan connected with the control module; the light receiving device receives light emitted by the light emitting device and transmitting through the filter screen; and the control module calculates actual light transmittance according to the magnitude of the light received by the light receiving device and preset reference light magnitude, and adjusts the rotating speed of the fan according to the actual light transmittance. The invention further discloses a control method of the air conditioner. As the rotating speed of the fan is adjusted according to the actual light transmittance, the circulating air volume of the air conditioner is always kept at a preset level, and the air conditioner also can keep preset heat exchange efficiency under the condition of dust accumulation on the filter screen.

Owner:TCL AIR CONDITIONER ZHONGSHAN CO LTD +1

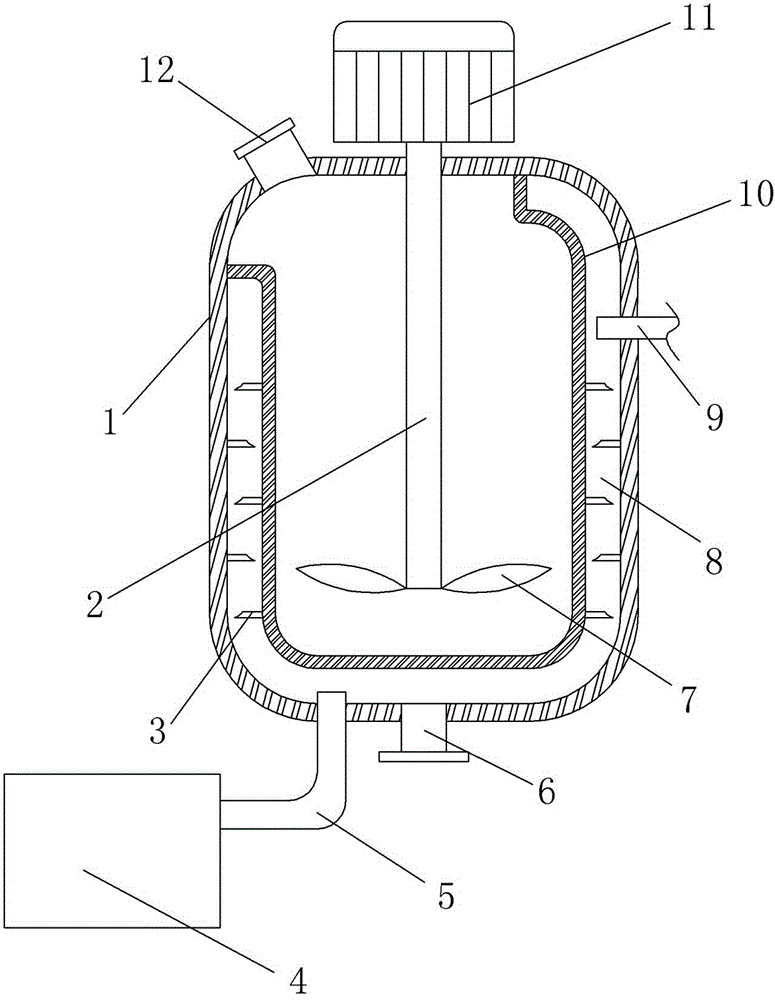

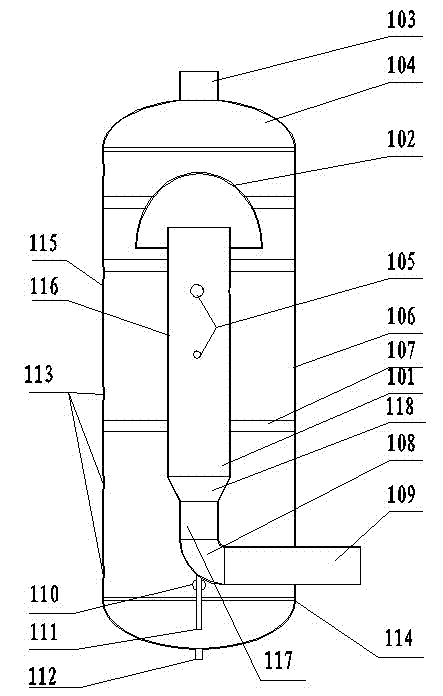

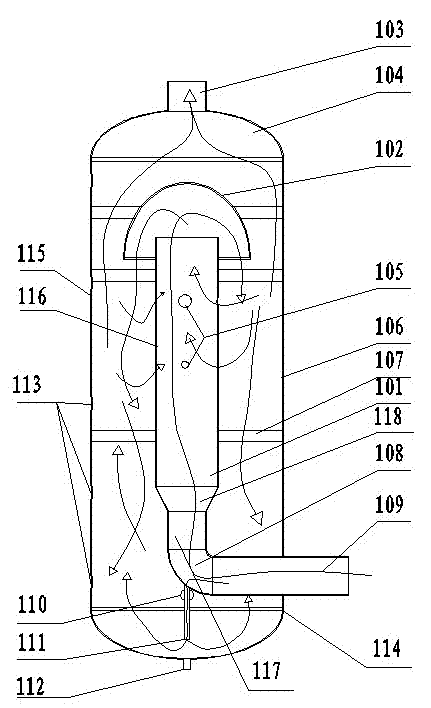

Reaction kettle

InactiveCN104437313AAvoid wastingReasonable useChemical/physical/physico-chemical stationary reactorsIsolation layerWater flow

The invention relate to the technical field of chemical equipment, in particular to a reaction kettle. The reaction kettle comprises a reaction kettle casing, a feeding port, a discharging port, a stirring shaft and a motor, wherein the feeding port is formed in the upper part of the reaction kettle casing; the discharging port is formed in the bottom of the reaction kettle casing; one end of the stirring shaft extends into the reaction kettle casing, and the other end extends out of the reaction kettle casing and is connected with the motor; an isolation layer is arranged in the reaction kettle casing; a water inlet is formed in the upper part of the reaction kettle casing; a water flow channel is formed between the isolation layer and the reaction kettle casing; a hot water outlet is formed in the bottom of the reaction kettle casing and connected with a hot water pipe, a control valve is arranged on the hot water pipe, and one end of the hot water pipe is connected with a hot water tank. According to the reaction kettle adopting the technical scheme, resources are reasonably utilized, and heat energy is recycled.

Owner:CHONGQING YONGCHUAN DISTRICT TIANTANG CHEM PLANT

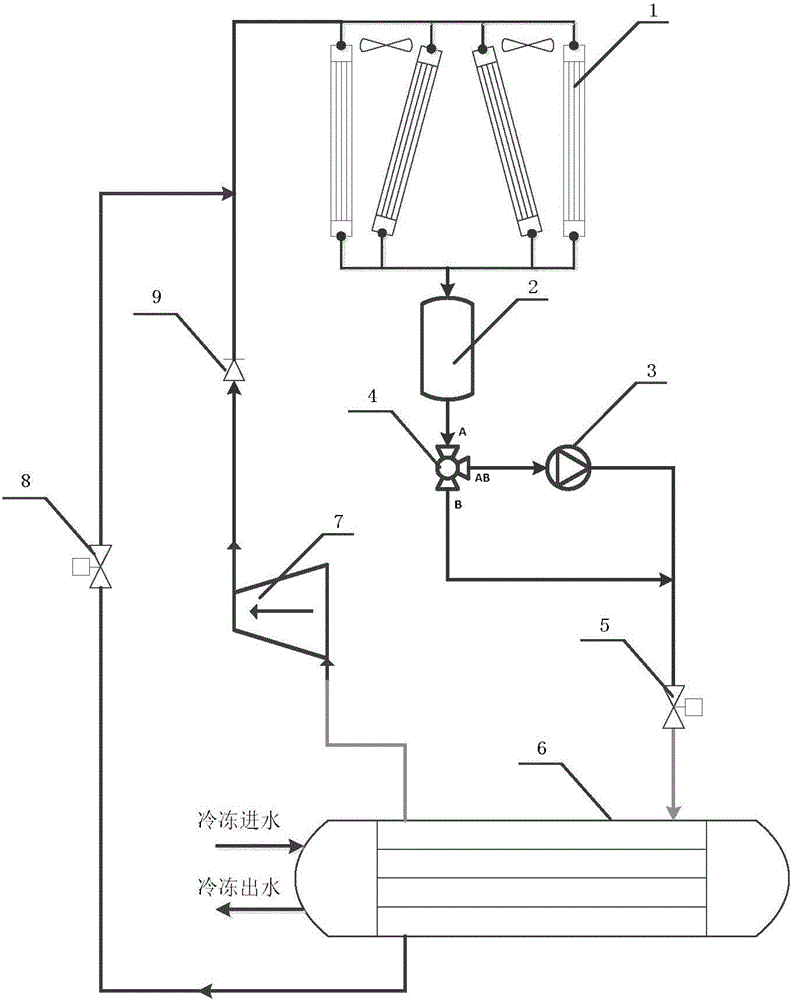

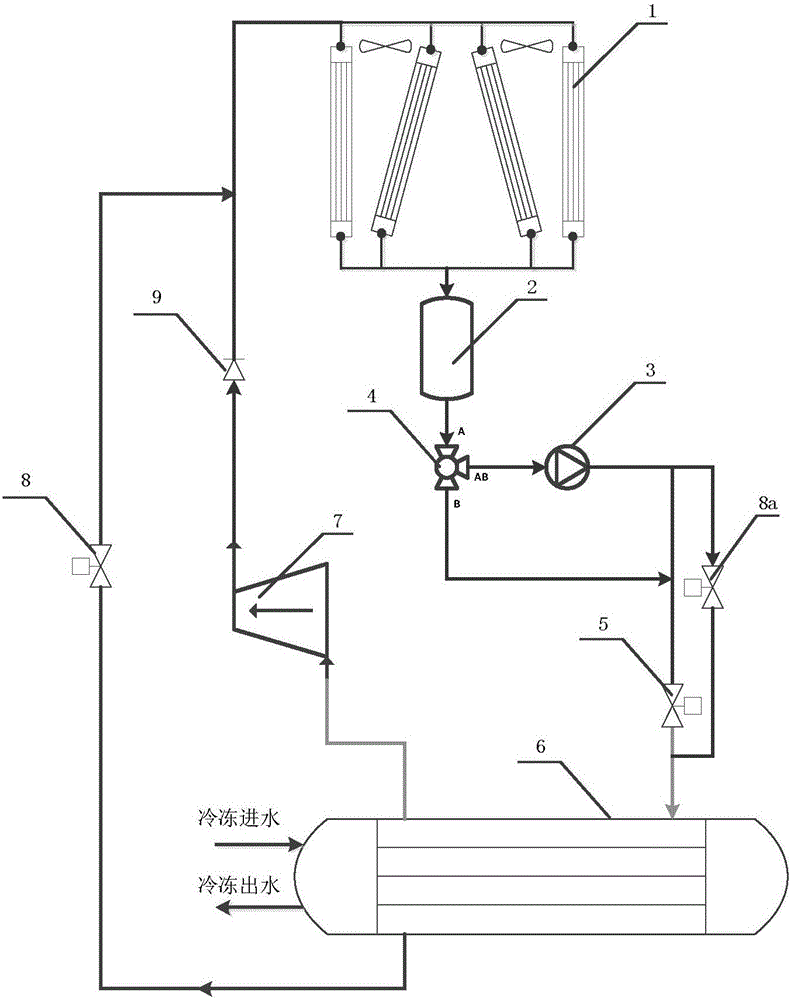

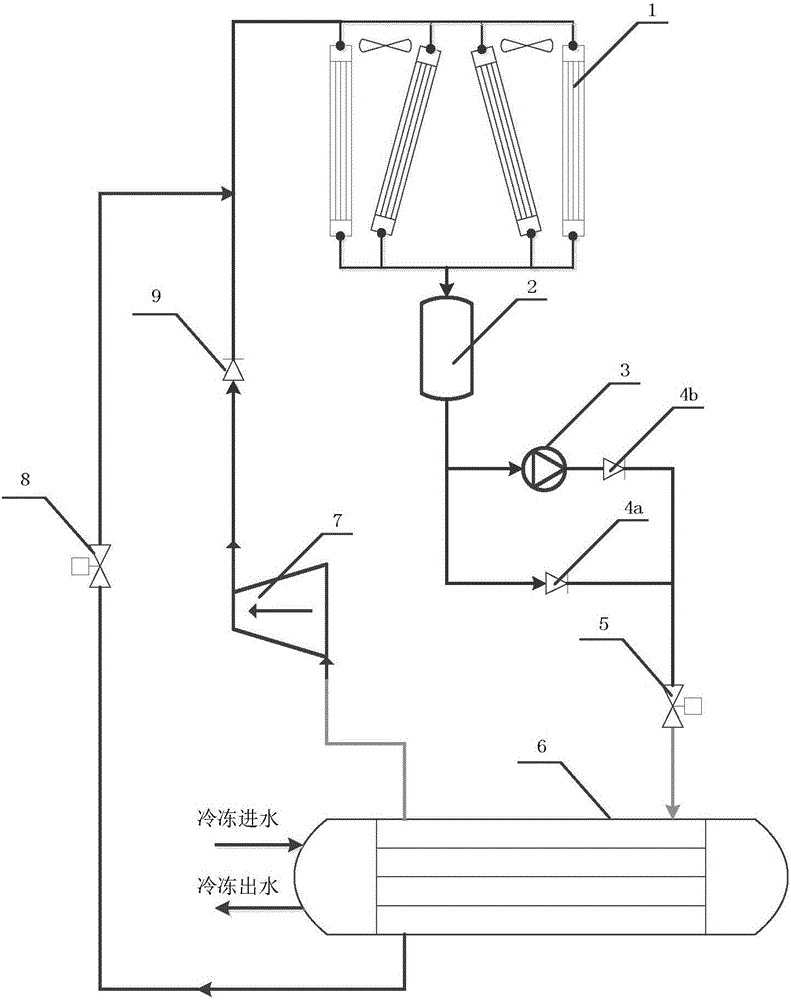

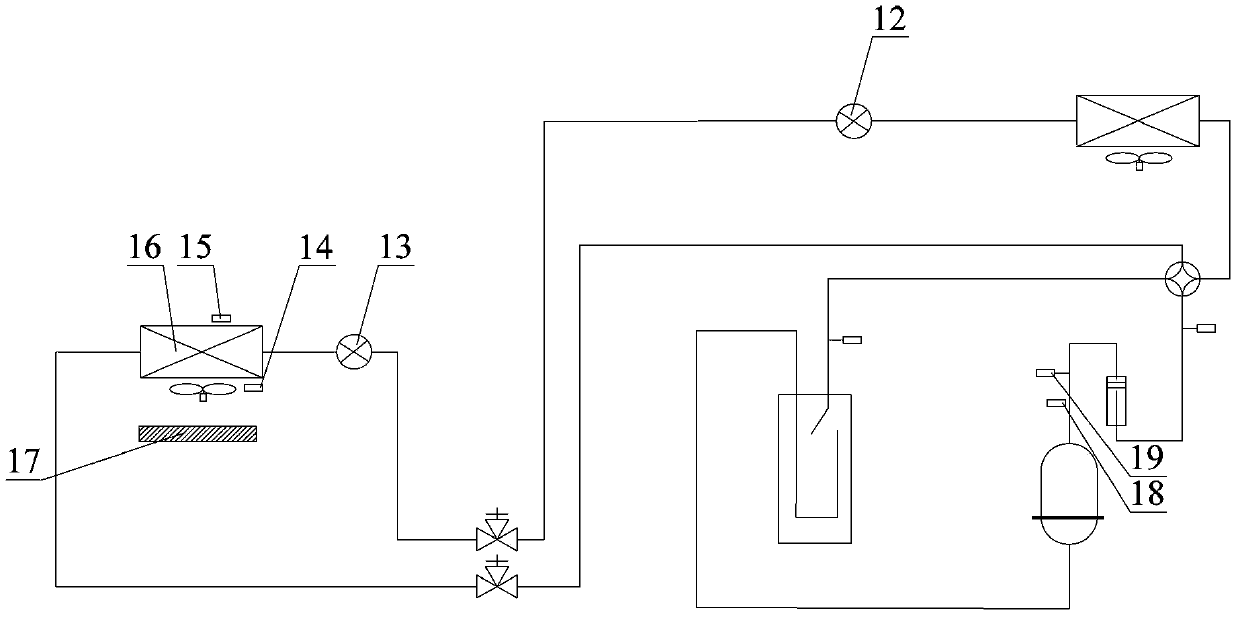

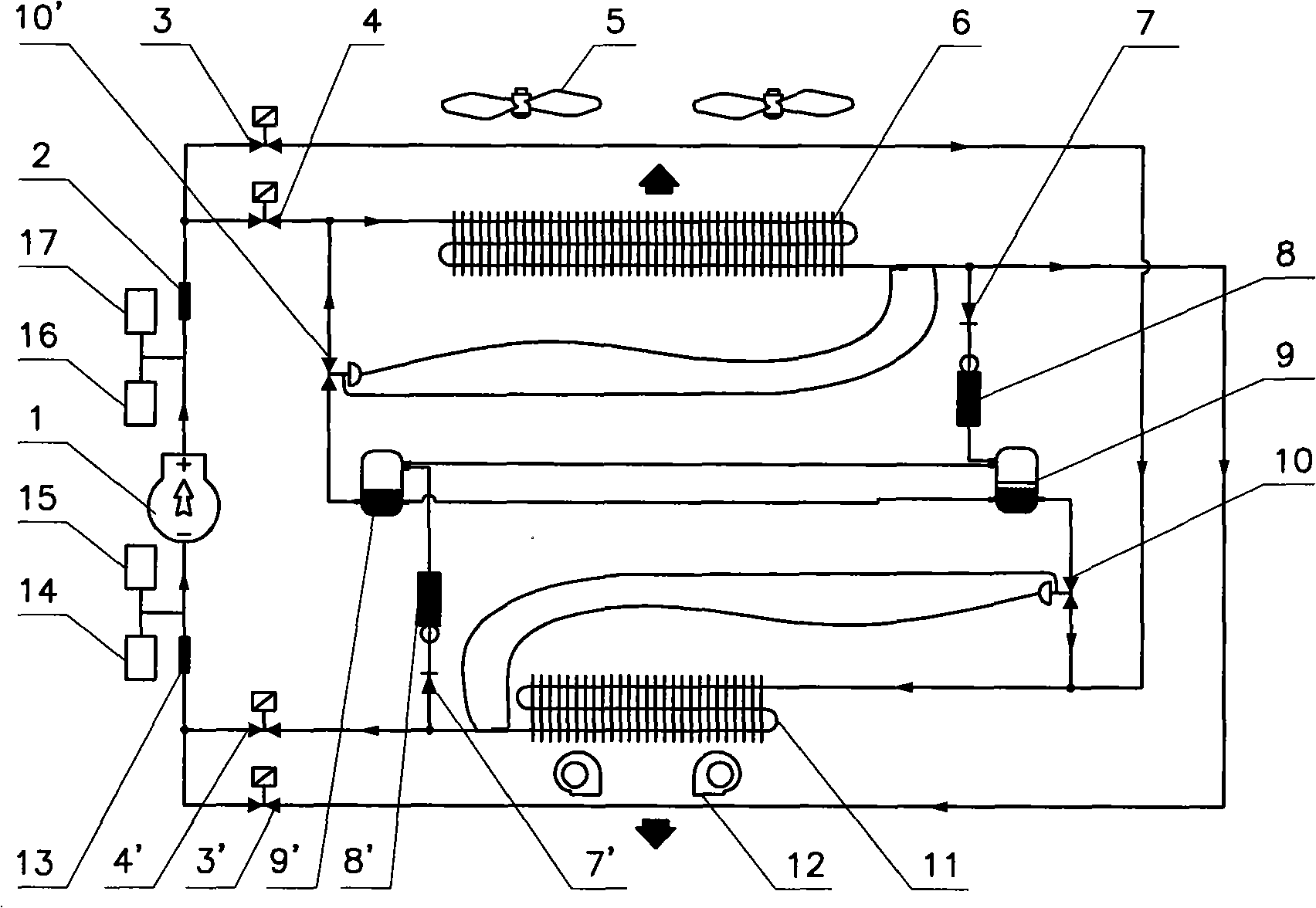

Novel natural cooling resource refrigerating system and control method thereof

ActiveCN106440437ATake advantage ofReduce wind side drag lossCompression machines with non-reversible cycleRefrigeration safety arrangementRefrigeration compressorEngineering

The invention discloses a novel natural cooling resource refrigerating system and a control method thereof. The system comprises a condenser, a liquid accumulator, a freezing medium circulating pump, an electronic expansion valve, an evaporator and a refrigeration compressor. The evaporator, the compressor, the condenser, the liquid accumulator, the freezing medium circulating pump and the electronic expansion valve are connected in sequence to form a circulation loop, wherein the evaporator and the condenser are connected through a first by-pass pipeline, and the liquid accumulator and the electronic expansion valve are connected through a second by-pass pipeline; the refrigeration compressor, the condenser, the liquid accumulator, the electronic expansion valve and the evaporator form an air cooling water chilling unit refrigeration cycle system, and the condenser, the liquid accumulator, the freezing medium circulating pump and the evaporator form a natural cooling resource refrigeration cycle system. Compared with the prior art, a freezing medium is used as a circulating medium, so the novel natural cooling resource refrigerating system has the advantages of an ethylene glycol scheme and a pure water scheme, and no special antifreeze process is needed, the cost can be reduced and the heat exchange efficiency and the convenience of maintenance are improved.

Owner:NANJING CANATAL DATA CENT ENVIRONMENTAL TECH CO LTD

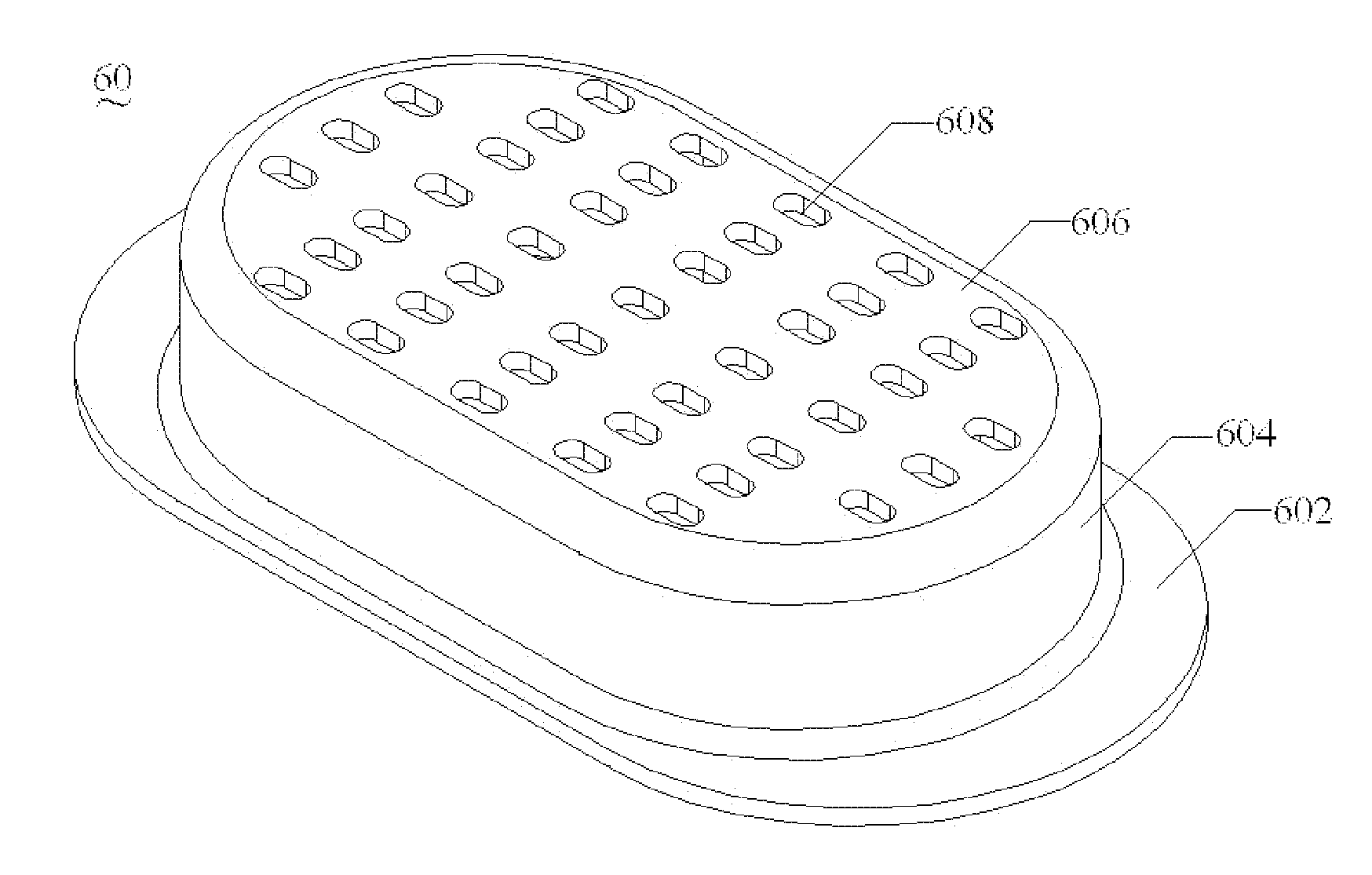

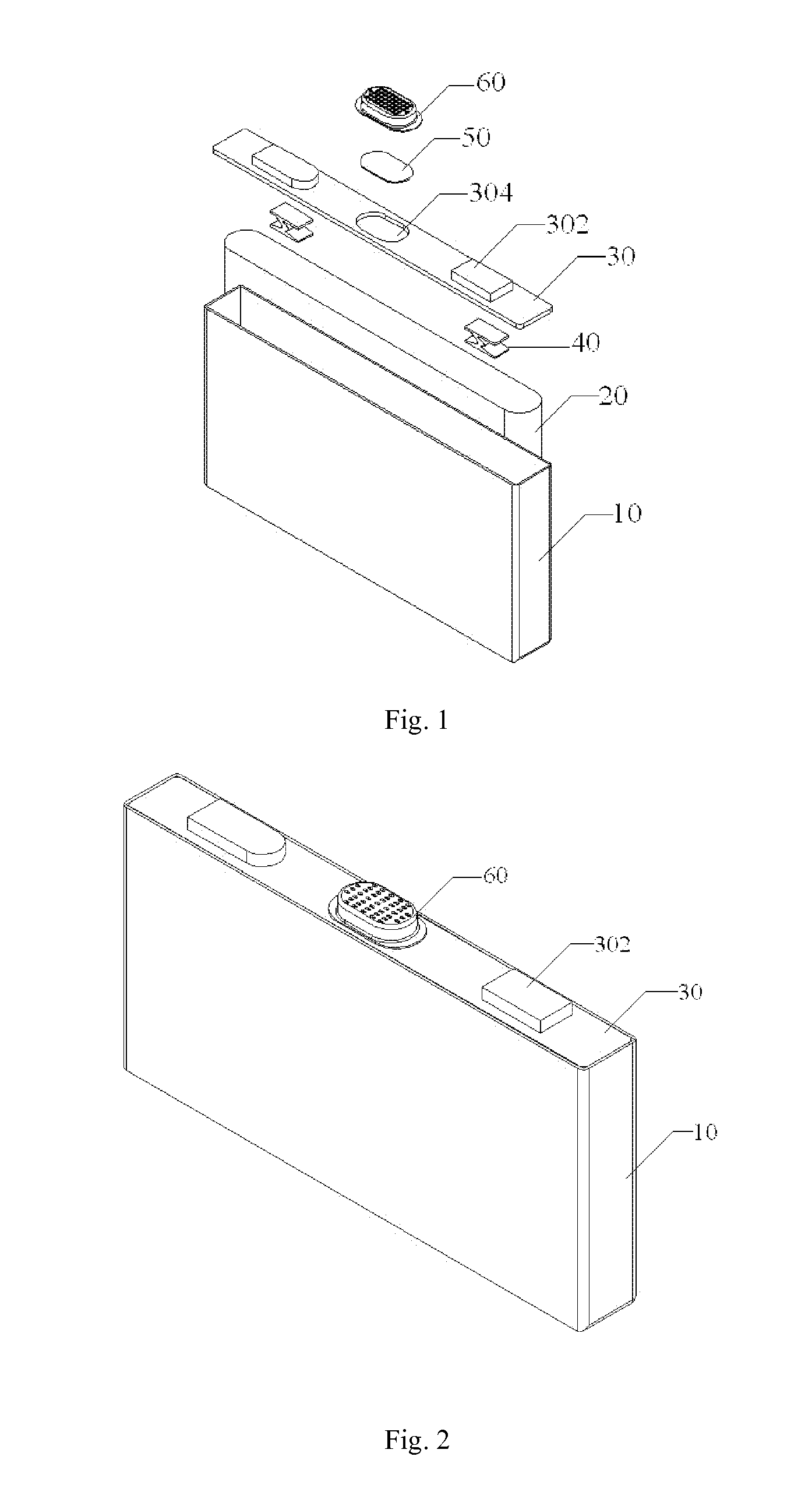

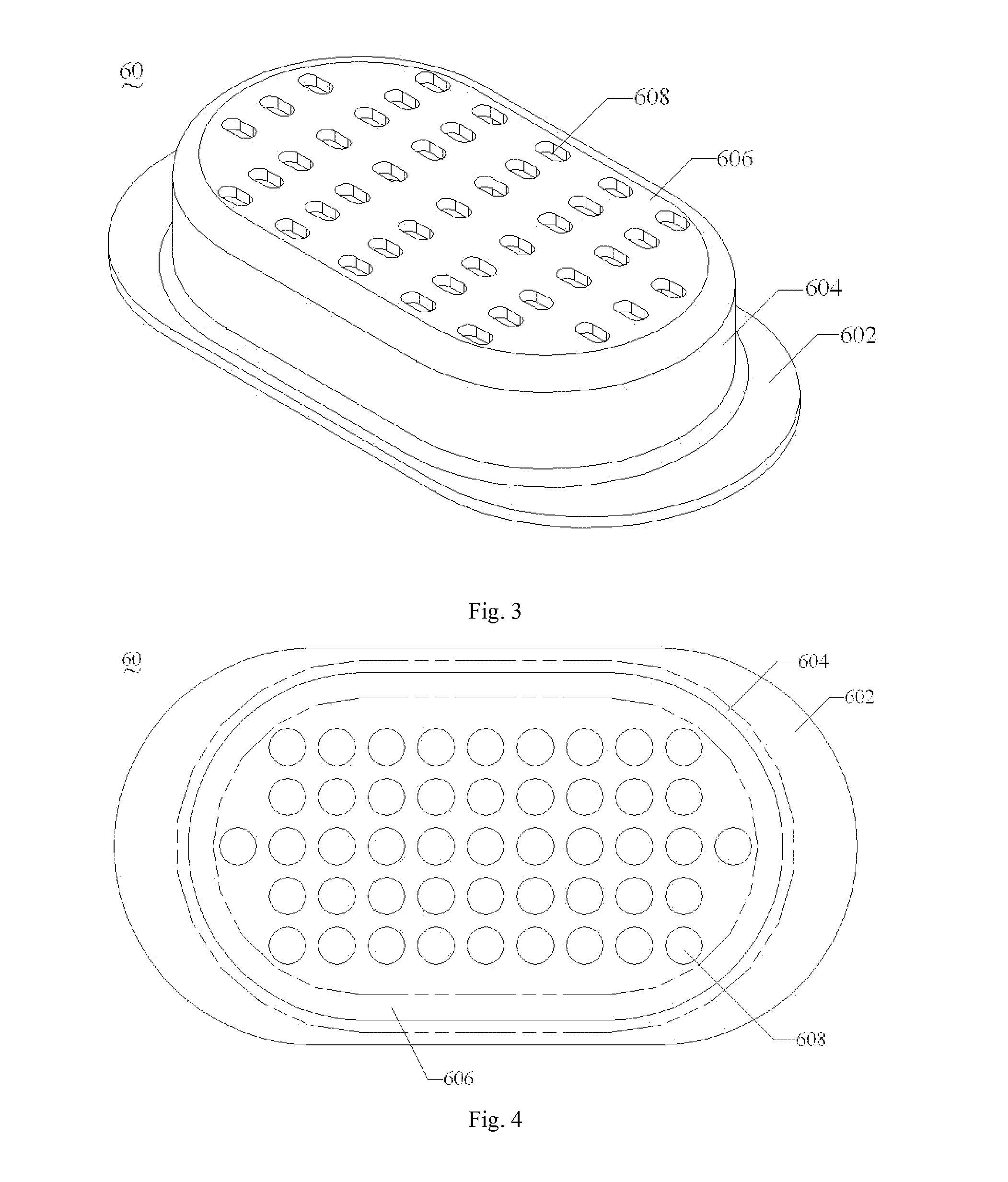

Lithium ion battery having desirable safety performance

ActiveUS20150079426A1Avoid contactAvoid crackingSecondary cellsCell lids/coversElectrical batteryEngineering

Provided is a lithium ion battery including a battery can, a battery core received in the battery can, electrolyte filled in the battery can, and a battery cover assembled to the battery can. The battery can or the battery cover is provided with a pressure relief valve, and the pressure relief valve is coupled with a mesh cover defining a number of through holes therein. According to the present invention, when thermal runaway occurs to the lithium ion battery, the pressure relief valve breaks timely. Only gases and electrolyte vapor can pass through the mesh cover. Solid particles cannot pass through the mesh cover. Therefore, ignition of the flammable gases, the electrolyte vapor and the high temperature solid particles in the surrounding air afar from the pressure relief valve is avoided and the safety performance of the lithium ion battery can be improved remarkably.

Owner:NINGDE AMPEREX TECH +1

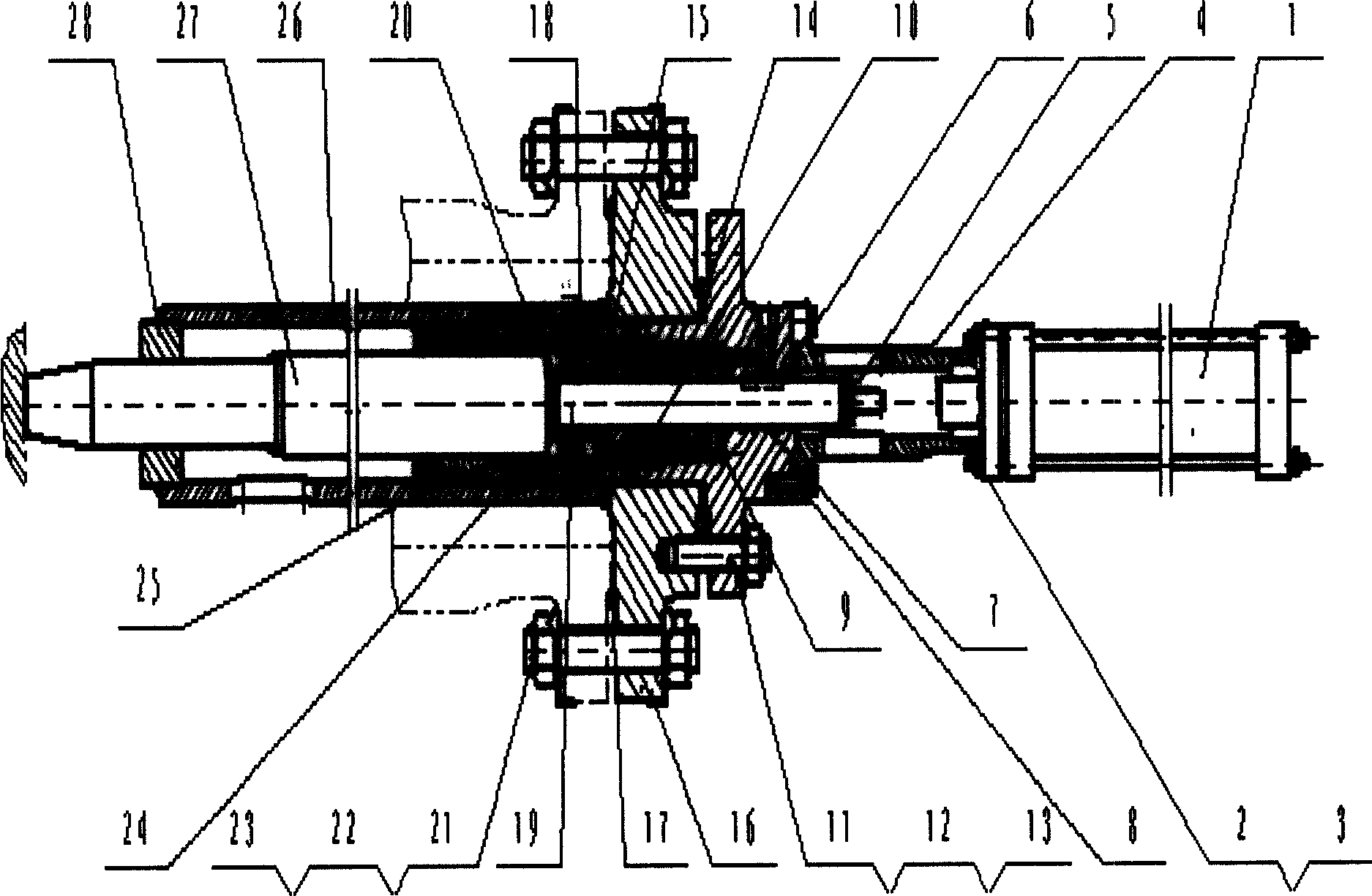

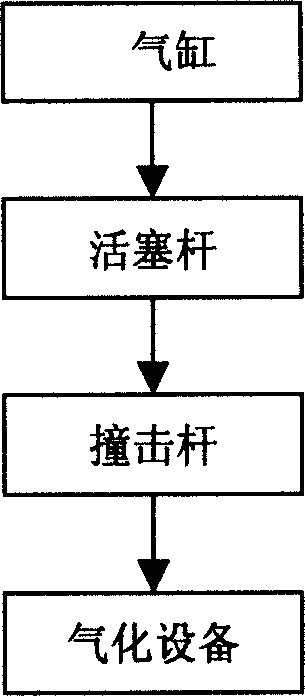

Mechanical rapping apparatus

ActiveCN1686616AAchieve removalGuaranteed continuityElectrodes cleaningEngineeringHeat transfer efficiency

A mechanical shaker is composed of vibrating unit, sealing part, filtering and supporting-connecting unit. The piston rod is impacted by the kinetic energy generated from cylinder. The kinetic energy is then transferred to the impacting rod for impacting against the gasifying apparatus to remove the dust deposit and increase heat transfer efficiency.

Owner:WUHAN JEHOO HIGH TECH

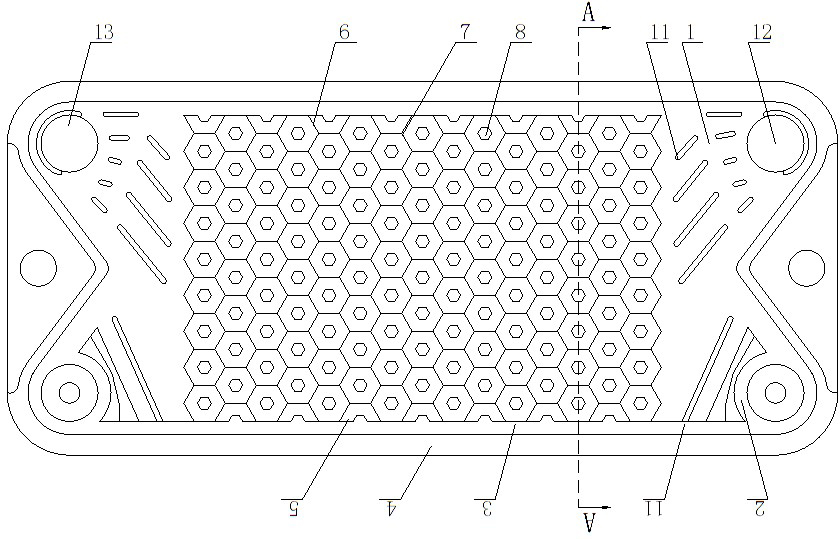

Bionic honeycomb-type plate sheet for plate-type heat exchanger

InactiveCN102435086AEfficient heat exchangeImprove heat exchange efficiencyLaminated elementsConvex structureHoneycomb

The invention discloses a bionic honeycomb-type plate sheet for a plate-type heat exchanger, comprising a flow guiding region, a sealing region, a honeycomb region and a frame, wherein the honeycomb region is composed of a plurality of peripheral regular hexagons which are sequentially connected with each other in longitudinal and transverse directions, so as to form a honeycomb shape; a plurality of peripheral regular hexagons are uniformly and densely distributed on the bionic honeycomb-type plate sheet; a central regular hexagon is arranged at the center of each peripheral regular hexagon and the central regular hexagon is in a protruding structure; a connecting part between two peripheral regular hexagons is in a protruding structure and a ripple-like structure is formed by connection of connecting parts among the plurality of the peripheral regular hexagons; and a flow channel is formed by the peripheral regular hexagons between each protruding central regular hexagon and the ripple-like structure. According to the invention, the fluid is interfered by the flow channel and concave-convex structures of the central regular hexagons and the ripple-like structure in the process of flowing in a hollow cavity, and the heat-exchanging efficiency is improved; and the dense honeycombs such a plurality of I beams, which are mutually limited, can dispersedly bear pressure from a panel, so as to increase the use condition and range of the plate sheet.

Owner:广州汇迪新能源科技有限公司

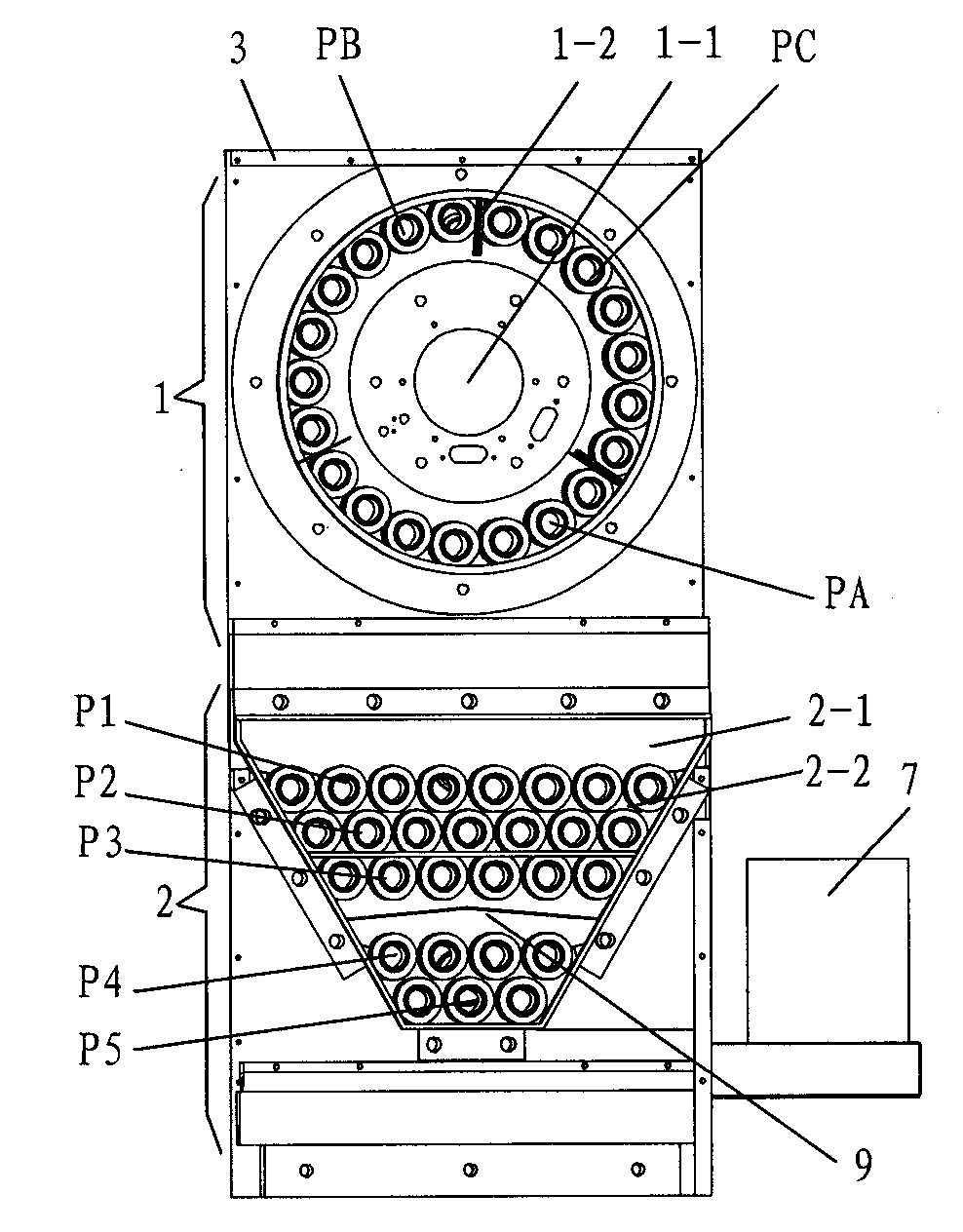

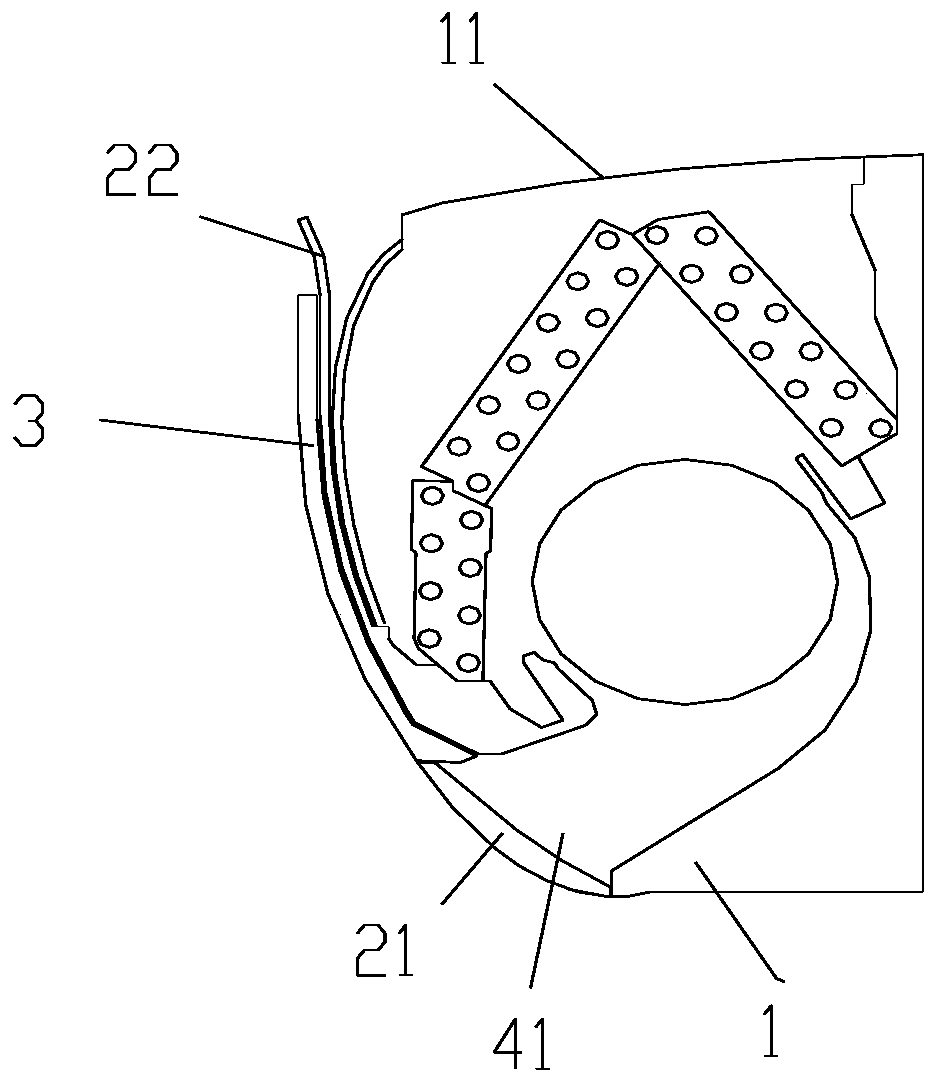

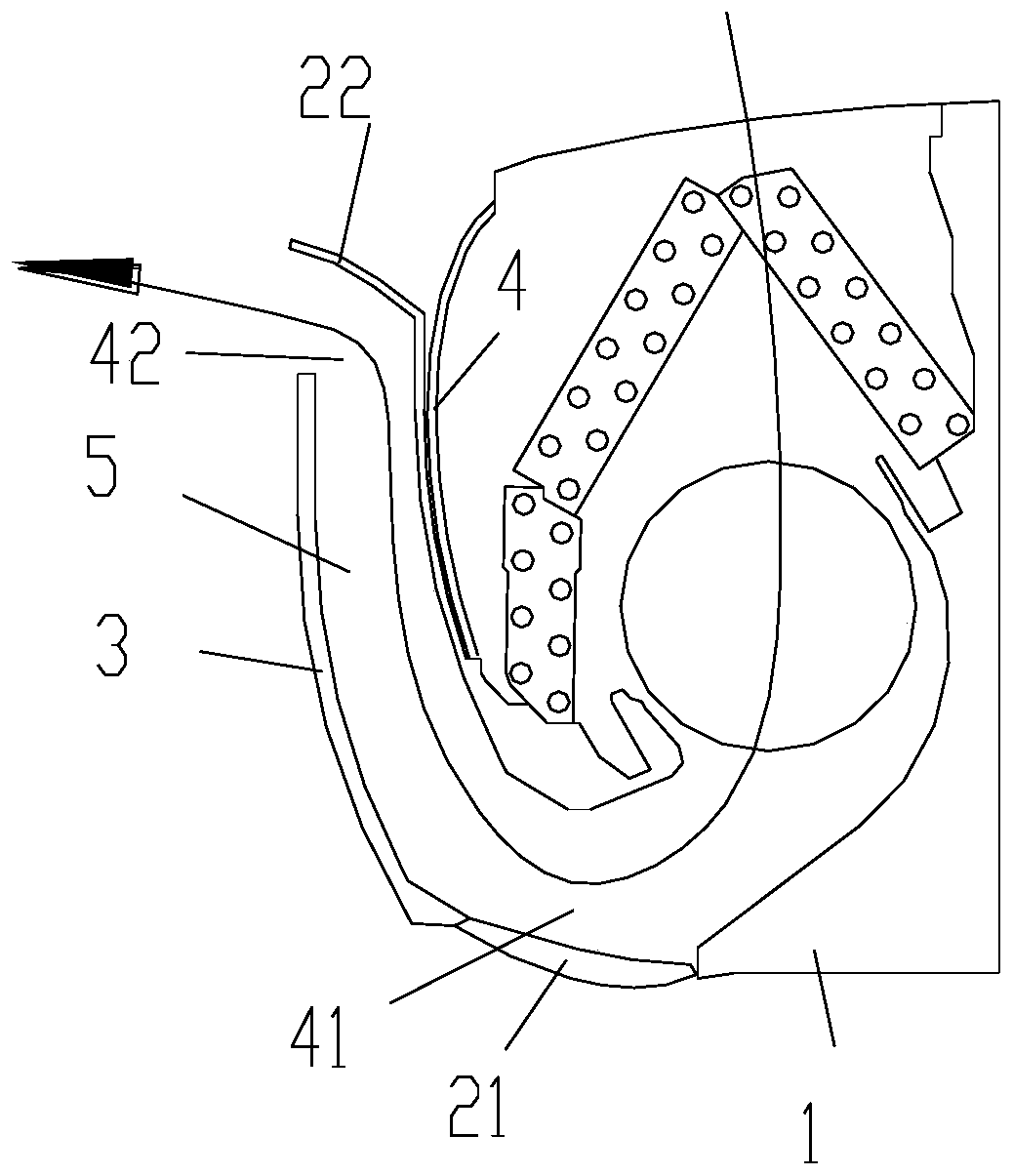

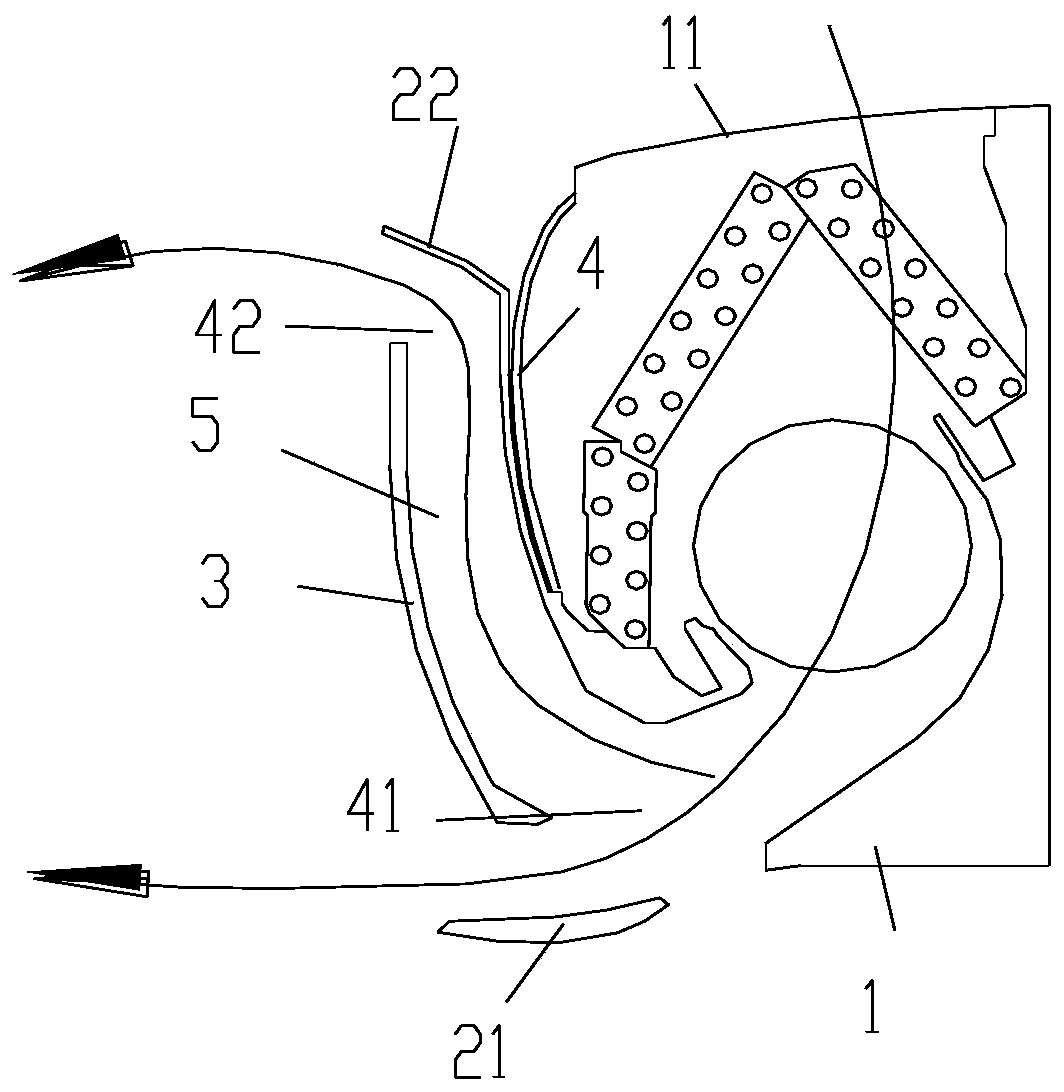

Condensing gas boiler

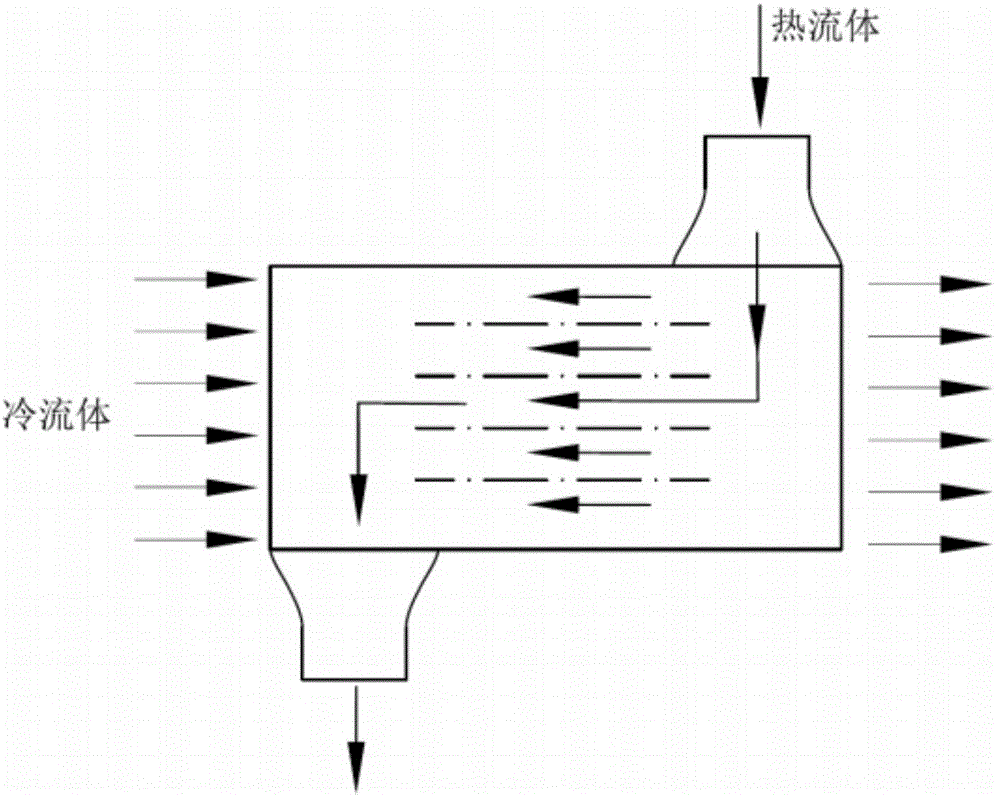

InactiveCN101782270AGuaranteed flow rateSufficient heat exchangeCorrosion preventionWater heatersCombustorCombustion chamber

The invention relates to a condensing gas boiler, which belongs to the technical field of heat exchange facilities. The condensing gas boiler mainly comprises a burner and a heat exchange device with smoke and water passages, wherein the heat exchange device comprises a horizontal heat exchanger and a V-shaped heat exchanger which are mutually connected in series; a first group of water pipes forming a roundabout flow passage are distributed at the circumference of the horizontal heat exchanger, and the middle part of the horizontal heat exchanger is provided with a cylindrical combustion chamber; the burner is arranged at one end of the cylindrical combustion chamber, and the smoke passes through the horizontal heat exchanger and enters the V-shaped smoke passage of the V-shaped heat exchanger through a downward through hole; a second group of water pipes forming a roundabout flow passage are distributed in the V-shaped smoke passage at intervals; and reverse heat exchange is formed between the water first flowing through the second group of water pipes and then the first group of water pipes and the smoke coming from the combustion chamber and flowing through the V-shaped smoke passage. The heat exchange is sufficient, the flow rate of the cooled smoke can be kept to ensure the heat exchange efficiency, and the condensing gas boiler has a reasonable structure and occupies small area.

Owner:A O SMITH CHINA WATER HEATER CO LTD

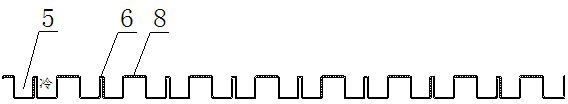

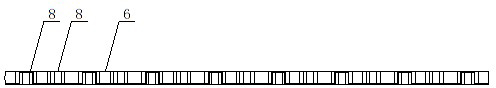

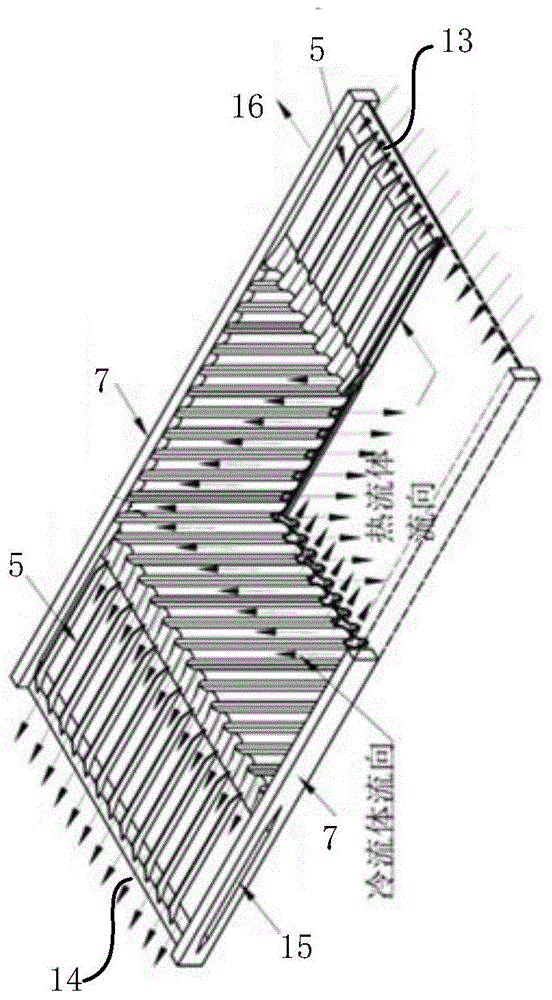

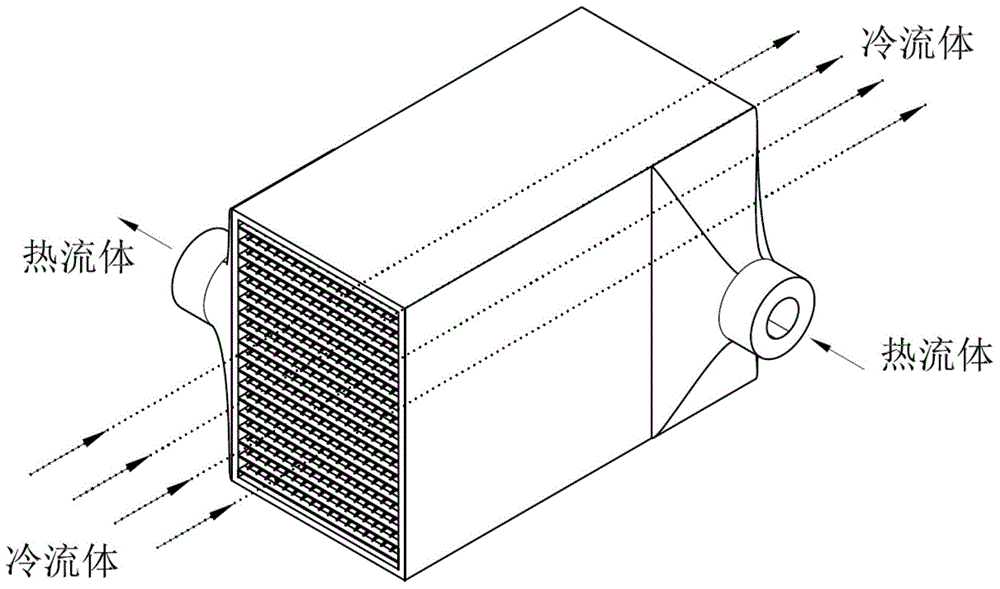

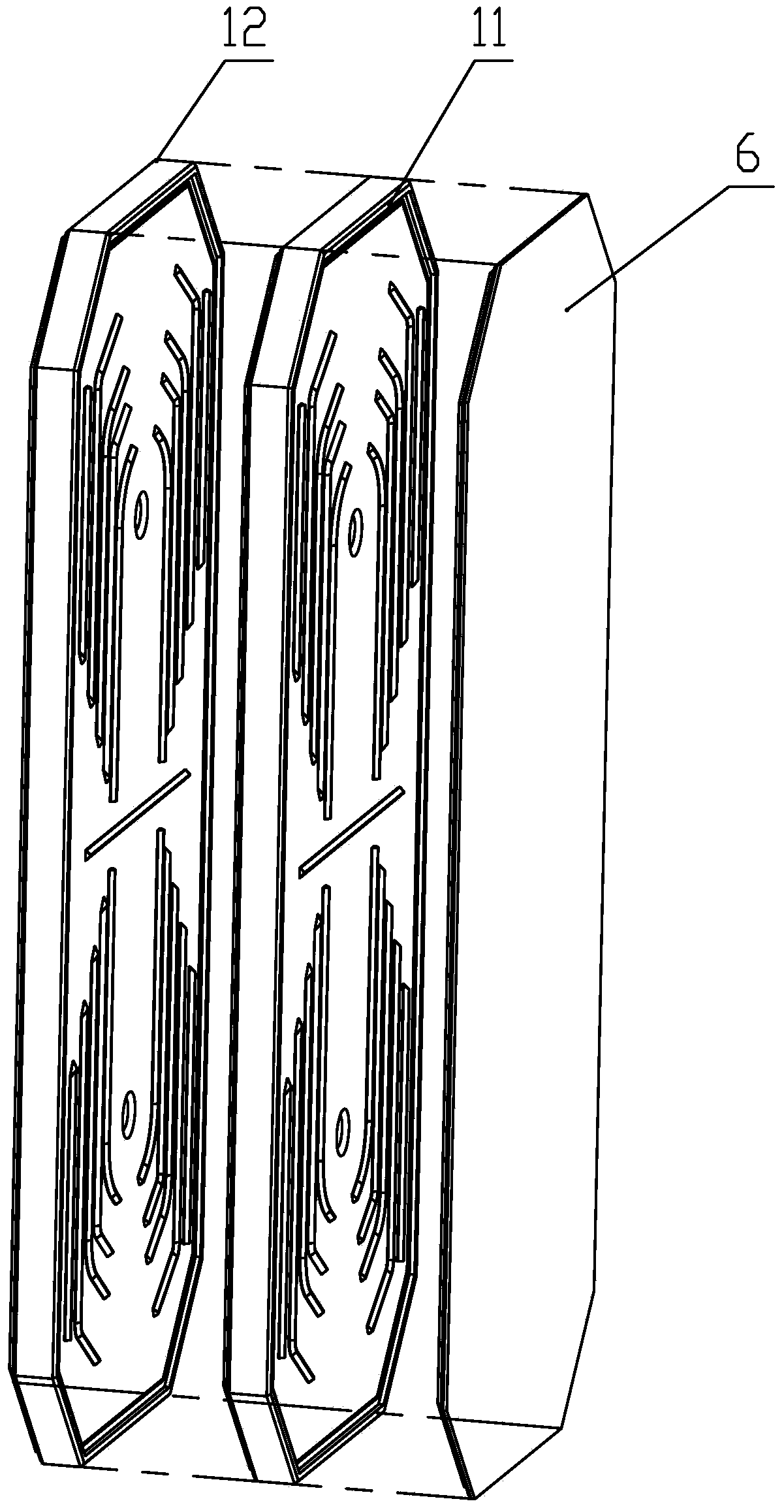

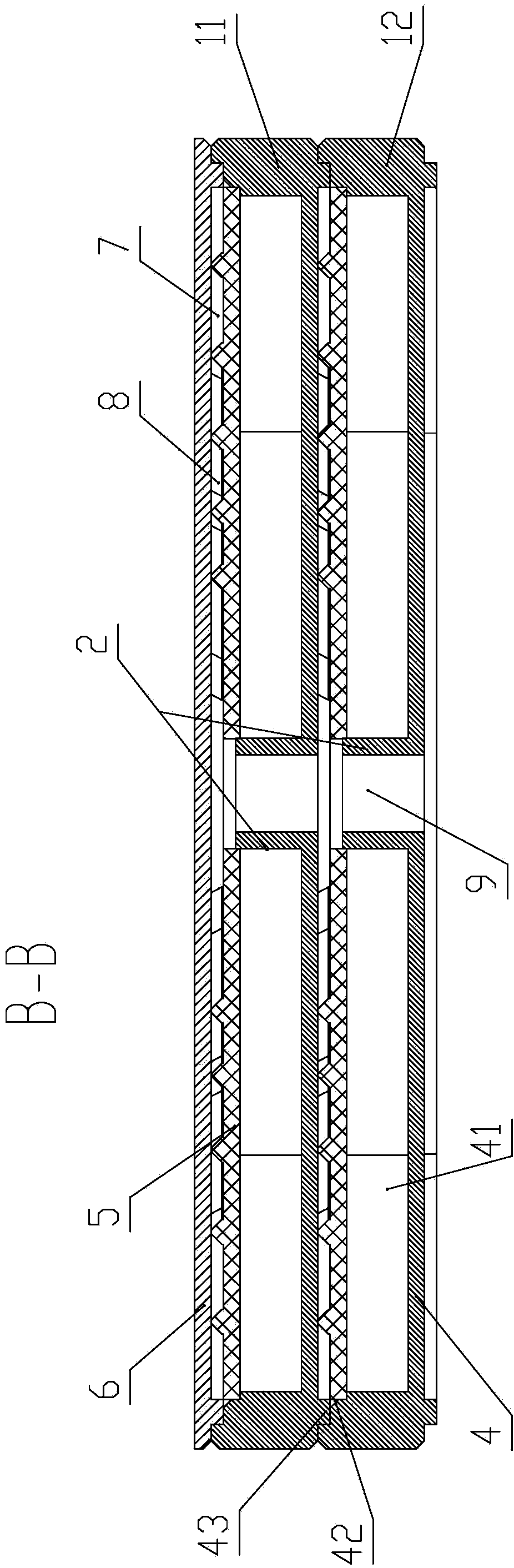

Integrated primary surface micro-channel compact heat exchanger

InactiveCN104896977AIncrease the heat exchange areaLow flow resistanceLaminated elementsStationary plate conduit assembliesPlate heat exchangerEngineering

The invention provides an integrated primary surface micro-channel compact heat exchanger comprising a hot fluid inlet, a hot fluid outlet, a micro-channel compact type corrugated plate heat exchange core body, a cold fluid inlet and a cold fluid outlet. The hot fluid inlet is connected to one side of the micro-channel compact type corrugated plate heat exchange core body and the hot fluid outlet is connected to the other side of the micro-channel compact type corrugated plate heat exchange core body. The cold fluid inlet is connected to one end of the micro-channel compact type corrugated plate heat exchange core body and the cold fluid outlet is connected to the other end of the micro-channel compact type corrugated plate heat exchange core body. The micro-channel compact type corrugated plate heat exchange core body comprises a plurality of mutually stacked cold fluid channels and hot fluid channels. The hot fluid inlet is connected with the hot fluid outlet through the hot fluid channels and the cold fluid inlet is connected with the cold fluid outlet through the cold fluid channels. The cold fluid channels and the hot fluid channels are in solid contact and deformation and sliding therebetween are prevented, so that the overall heat exchange efficiency and the using safety of the heat exchanger are guaranteed.

Owner:SHANGHAI JIAO TONG UNIV

Hydrate sediment CT triaxial testing device

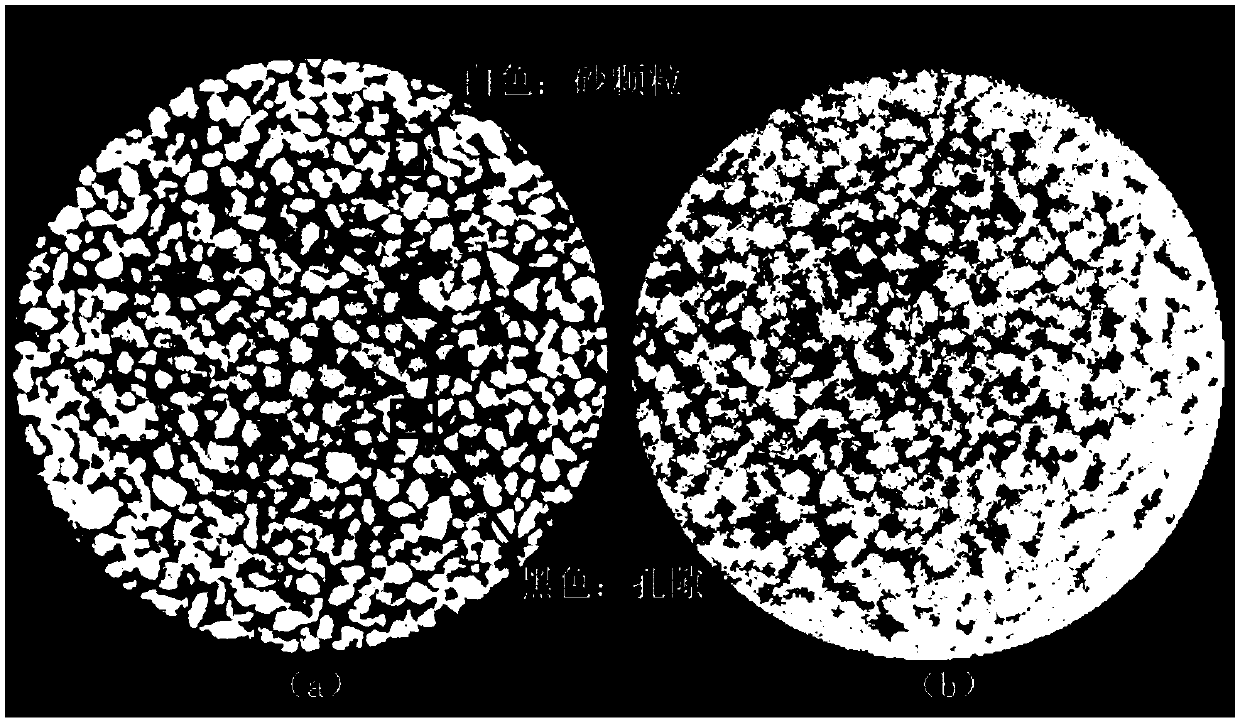

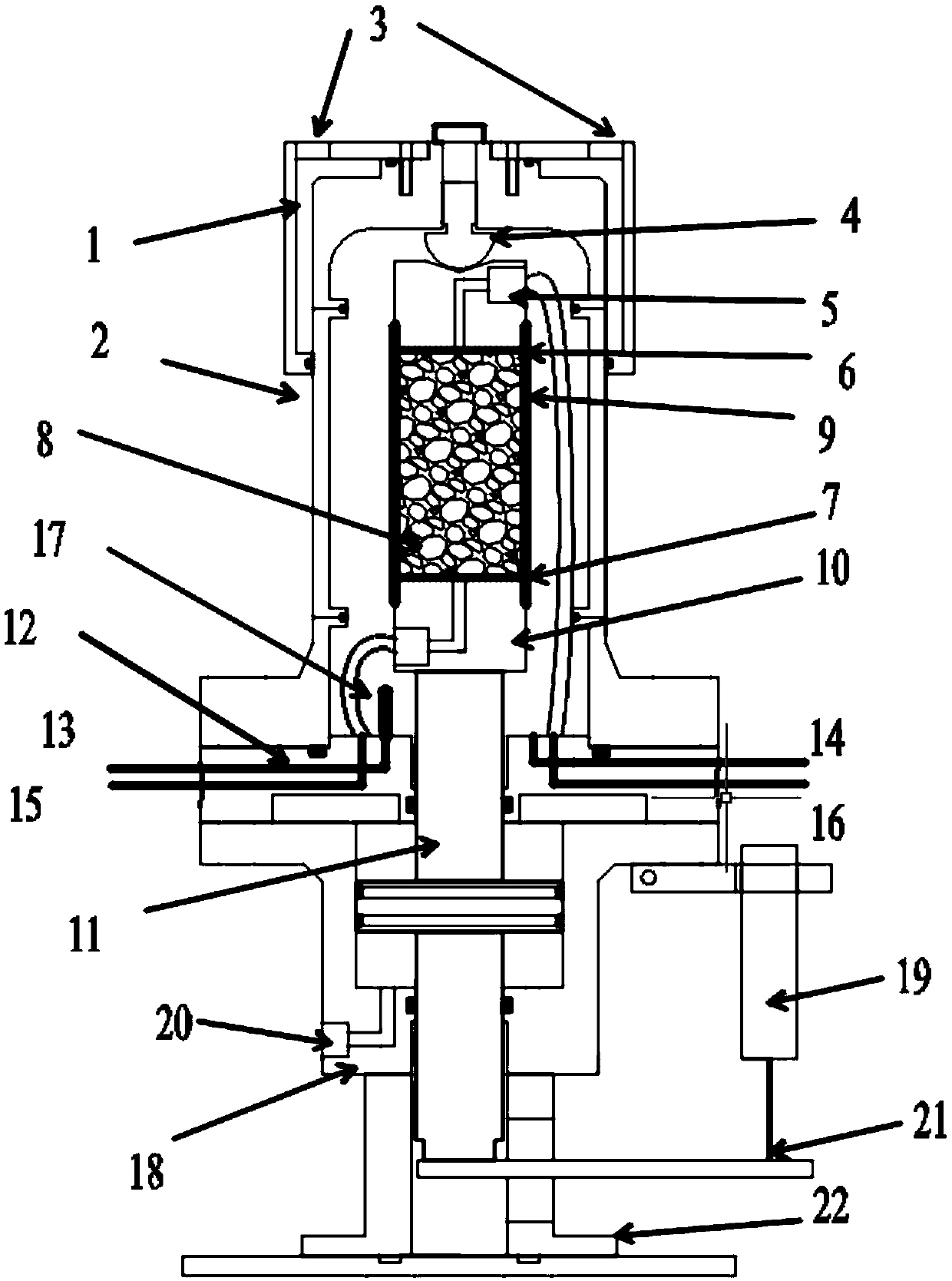

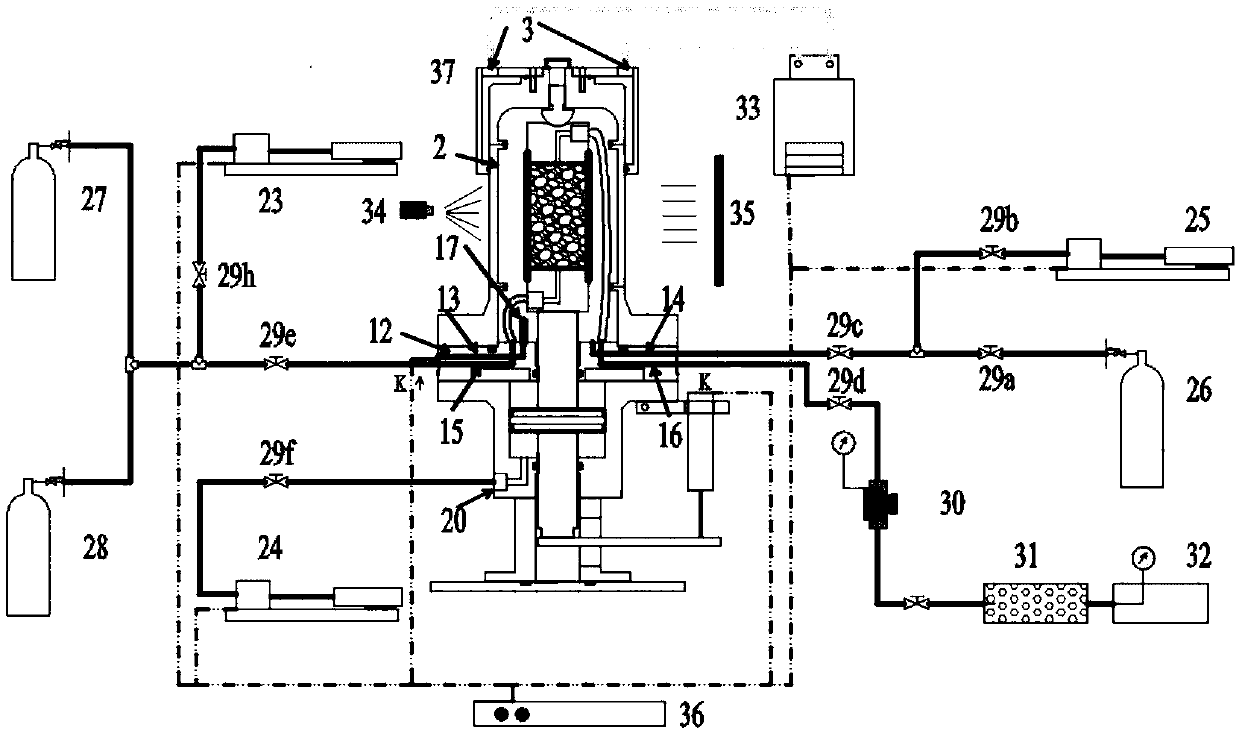

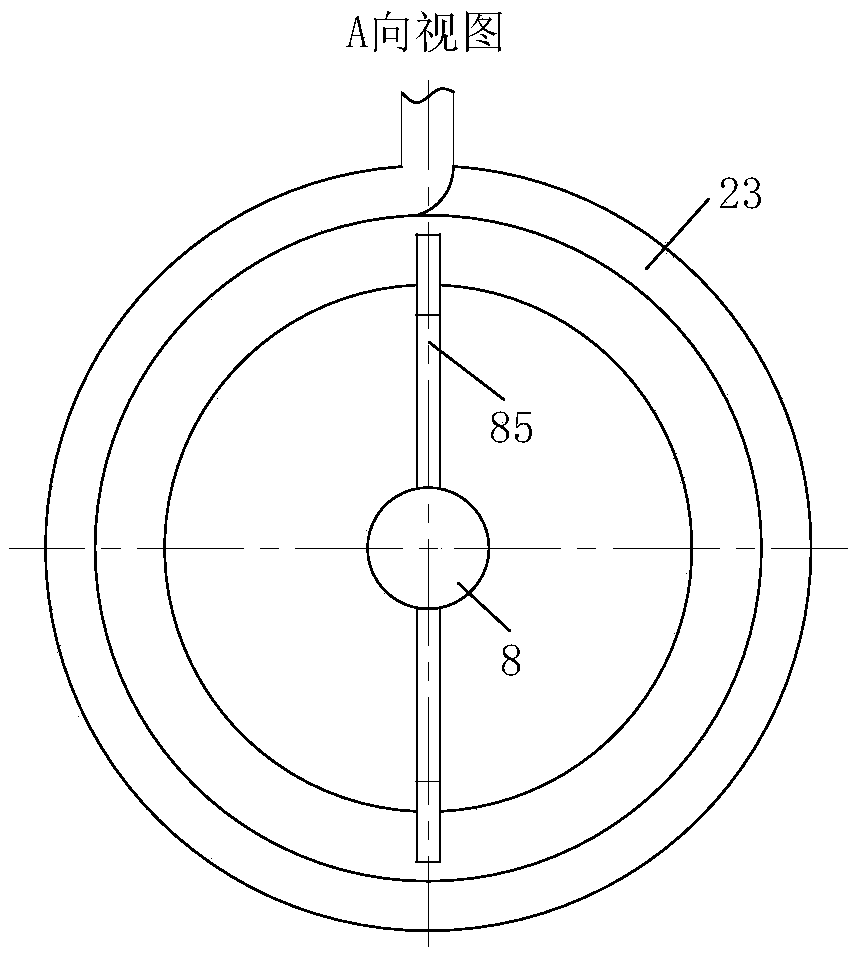

ActiveCN109668916AImprove the stability of the scan rotation processHigh temperature control accuracyMaterial analysis using wave/particle radiationMaterial strength using tensile/compressive forcesDecompositionX-ray

The invention provides a hydrate sediment CT triaxial testing device, and belongs to the technical field of geotechnical engineering foundation physical property measurement. Aiming at the deficiencyof the invention of a visualization testing device for natural gas hydrate sediment mechanical properties, the hydrate sediment CT triaxial testing device is subjected to redesigning and optimization,under the premise that the hydrate reservoir static force, the dynamic properties and the creep property can be obtained, the stability in the scanning rotating process of a triaxial apparatus, the hydrate sample temperature control accuracy and the penetrating property of X-rays of a triaxial apparatus pressure chamber are improved, the optimal CT imaging effect is obtained, and powerful hardware support is provided for the verification of the reservoir deformation mechanism in the decomposition process of a hydrate.

Owner:DALIAN UNIV OF TECH

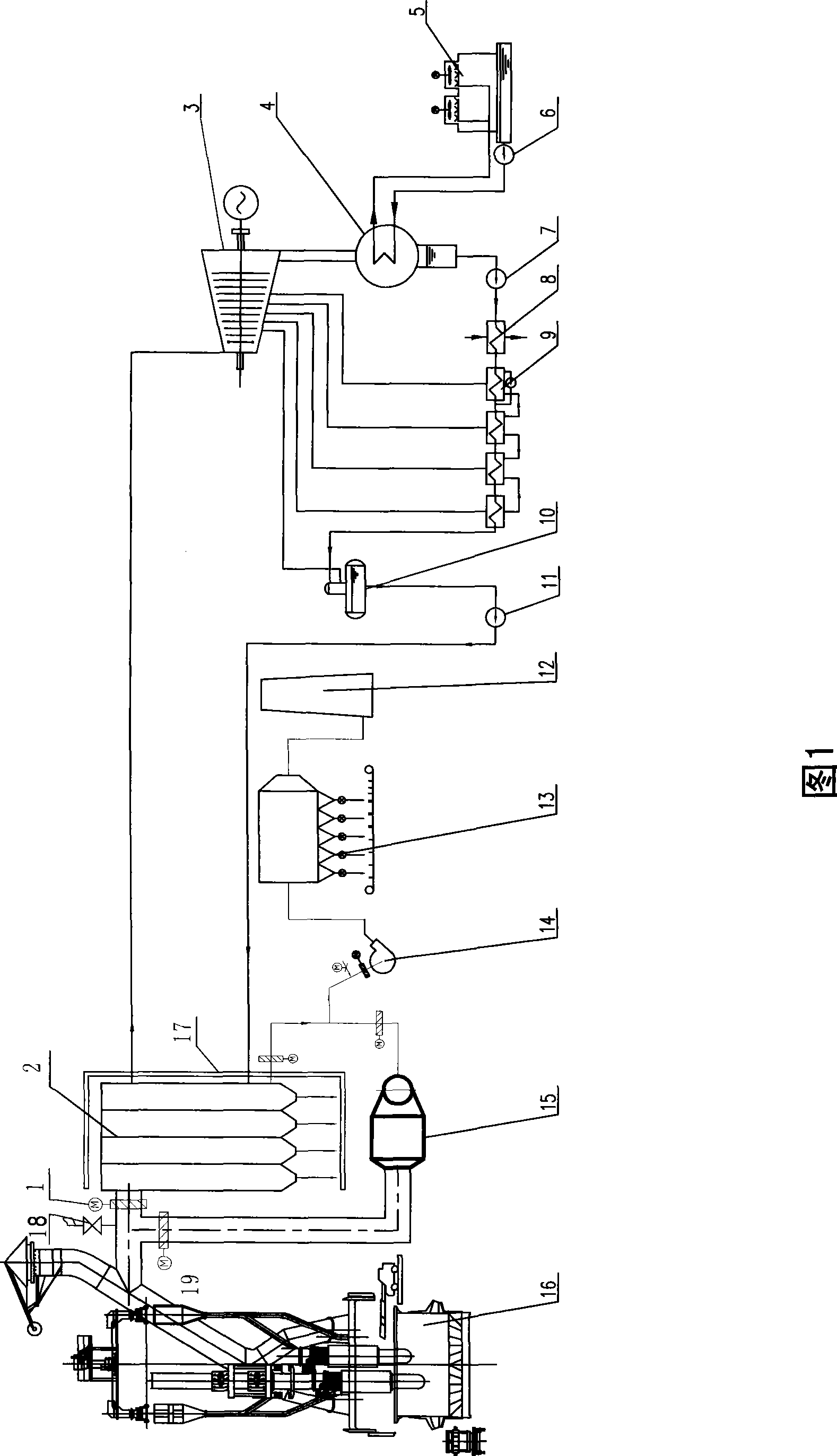

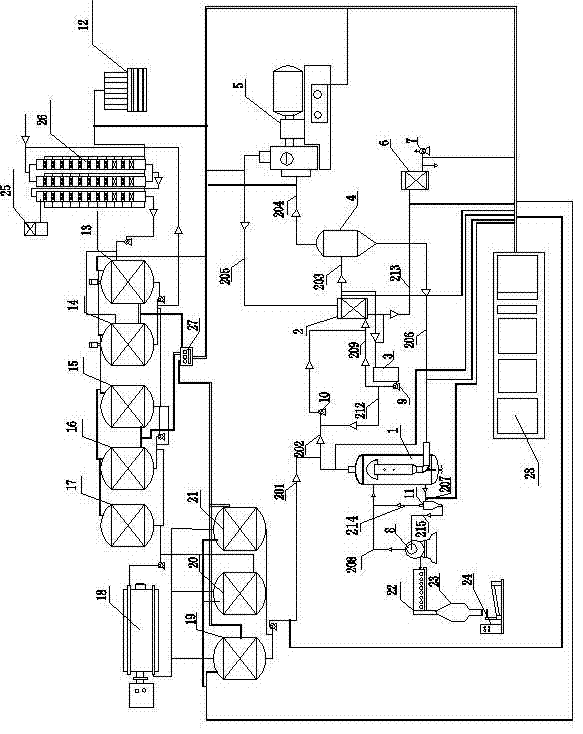

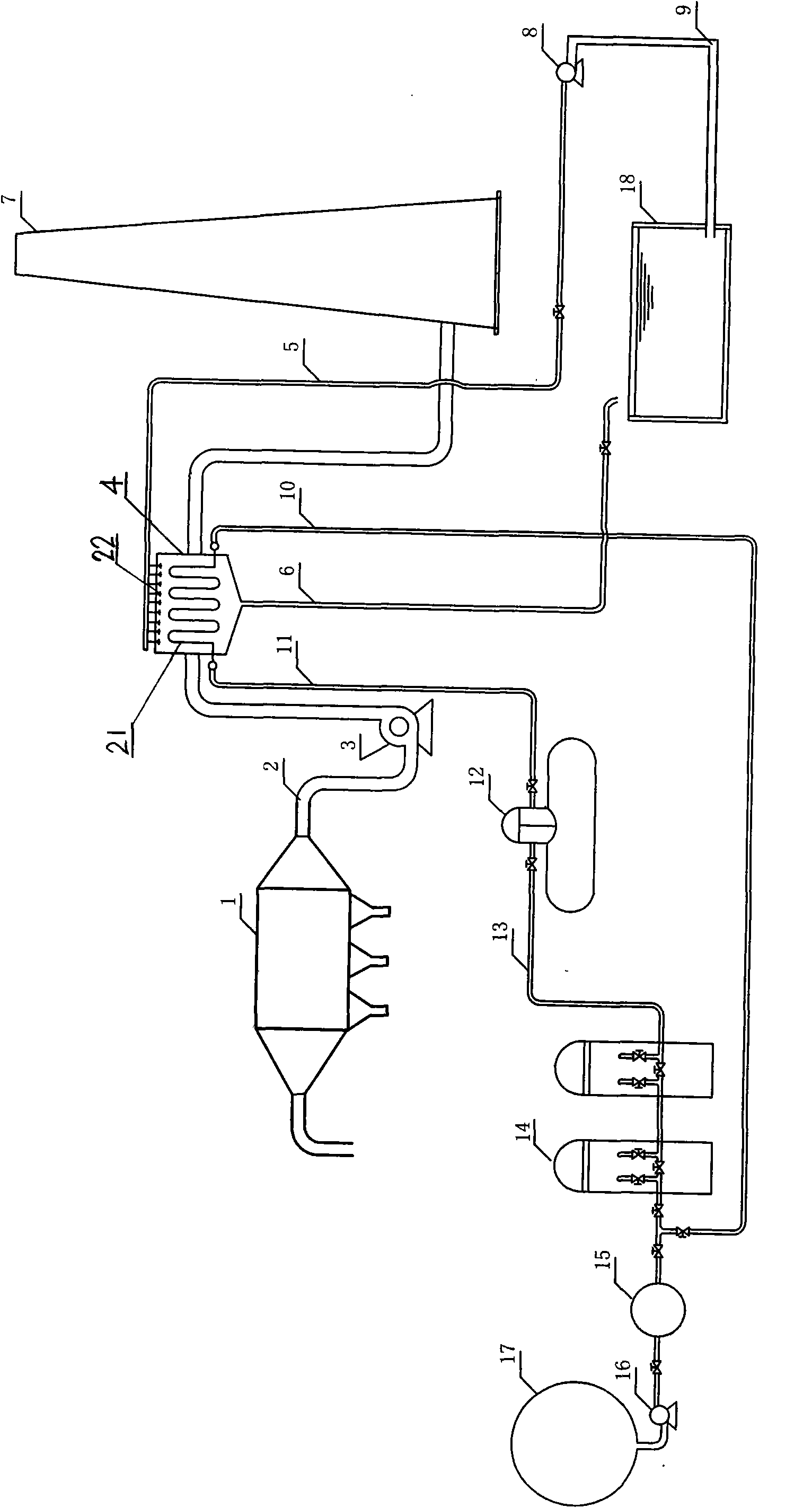

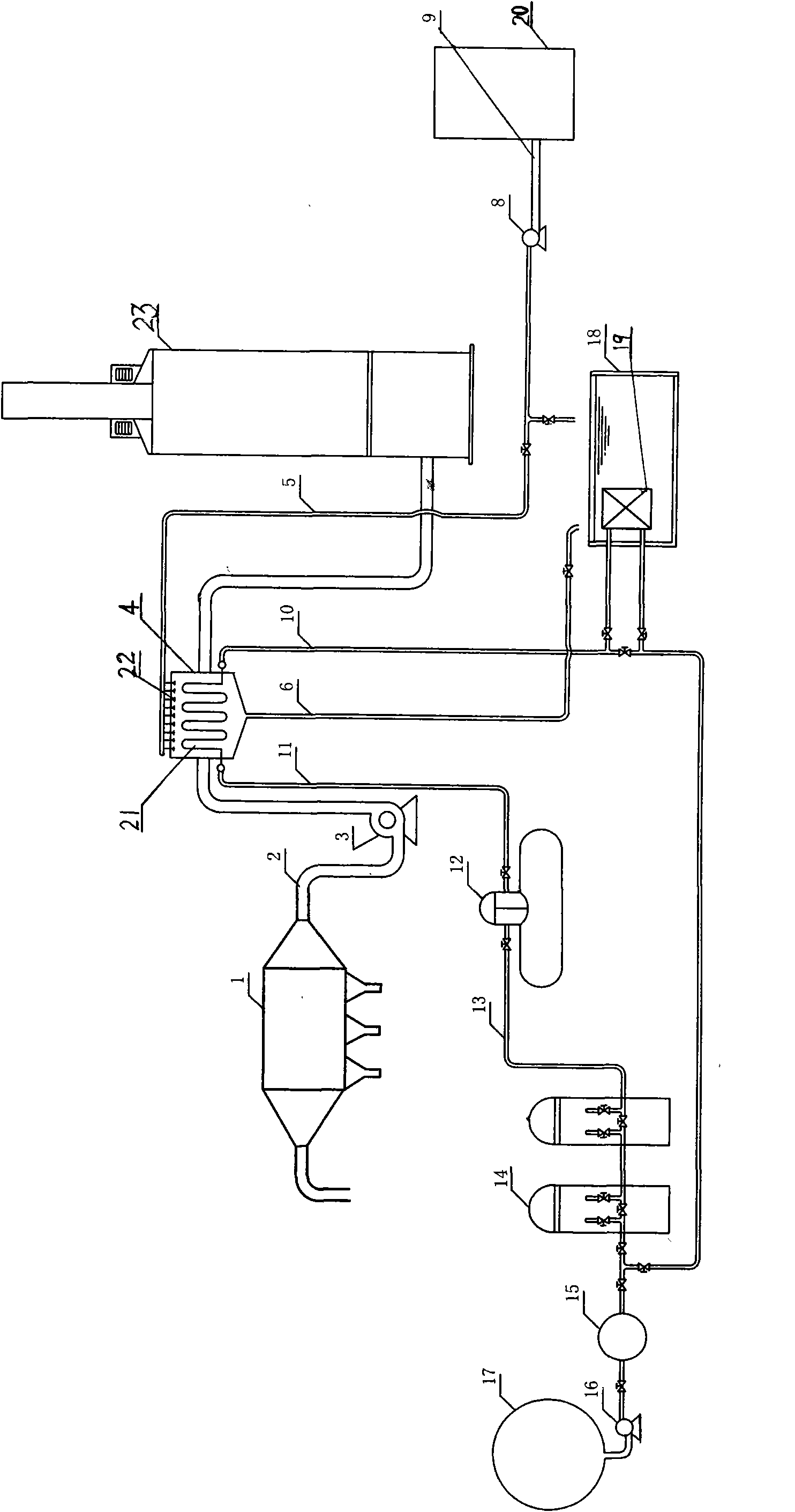

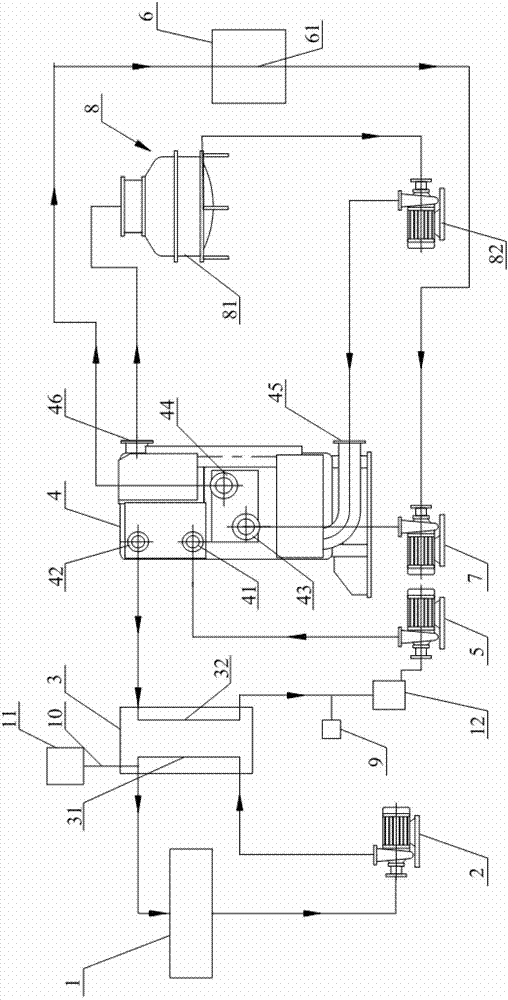

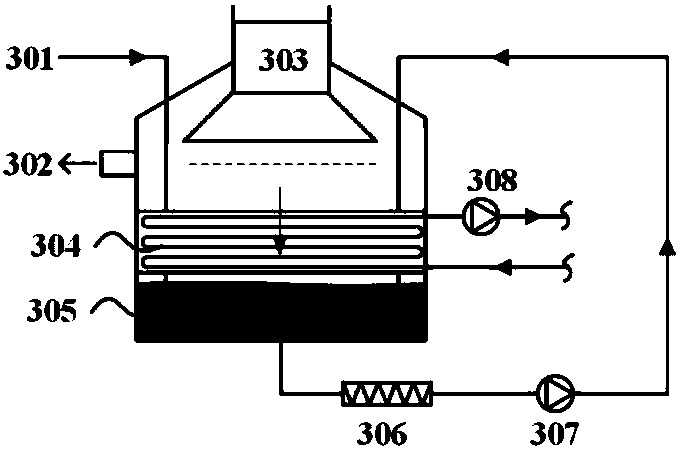

Silicon smelting electric furnace waste heat power generation process flow and configuration

ActiveCN101392992AEfficient extractionIncrease waste heatEnergy industryIncreasing energy efficiencyCooling towerAtmospheric air

The invention provides silicon smelting electric furnace waste heat power generating equipment, which consists of a valve 1, a waste heat boiler 2, a turbo generator 3, a vapor condenser 4, a cooling tower 5, a circulating water pump 6, a condensing water pump 7, a vapor seal heater 8, a low-pressure heater 9, a deaerator 10, a feed water pump 11, a chimney 12, a bag dust collector 13, an induced draft fan 14, a air cooler 15, a steel ball collection conveying distribution lifting device 17, a mixing cold air valve 18 and a by-pass valve 19, wherein waste flue gas discharged by a silicon smelting electric furnace 16 is introduced into the waste heat boiler to release partial heat; and when the temperature of the waste flue gas is reduced to nearly 180 DEG C, the waste flue gas enters the bag dust collector through the induced draft fan, and finally is discharged to atmosphere through the chimney. The desalted water enters the waste heat boiler through the feed water pump, vapor generated by the waste heat boiler enters the turbo generator; and after the vapor does work, the vapor enters the vapor condenser to be condensed into water, and the water enters the deaerator through a condensate removal pump, and the deoxidized water enters the waste heat boiler through the feed water pump. The silicon smelting electric furnace waste heat power generating equipment has the advantages of good energy saving effect, little investment and low cost.

Owner:CITIC HEAVY INDUSTRIES CO LTD +1

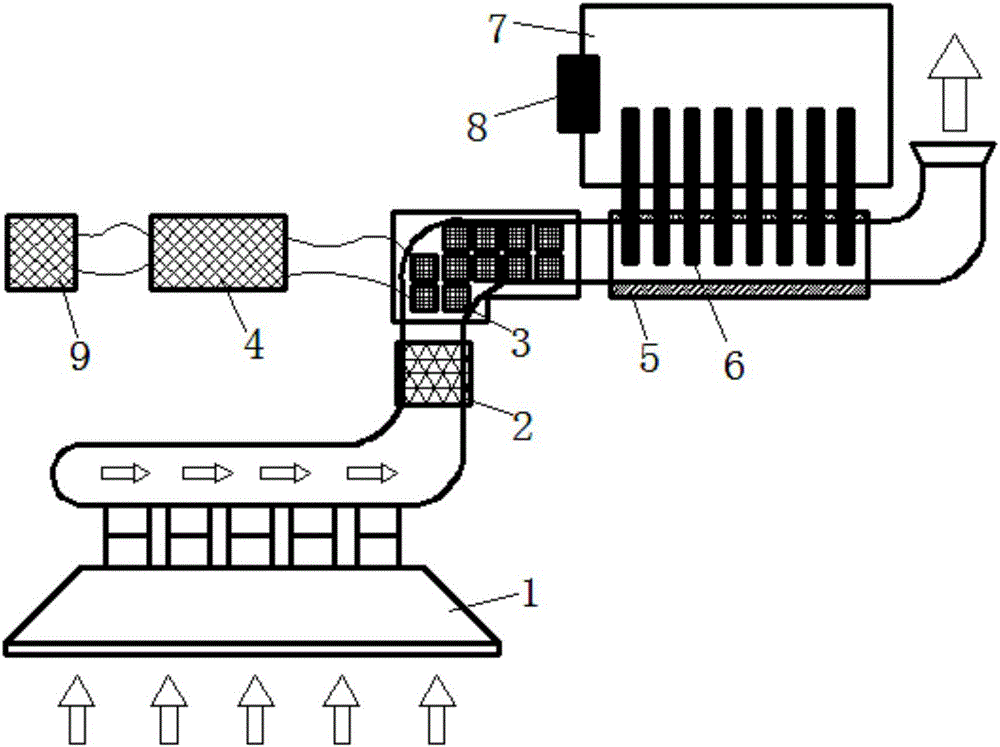

Kitchen fume waste heat recycling system

InactiveCN106196211AReduce settingsReduce layoutDomestic stoves or rangesCooking fumes removalAutomatic controlEconomic benefits

The invention discloses a kitchen fume waste heat recycling system. The system comprises a fume collecting box, a fume purifier, a temperature difference power generating piece, a storage battery, a gravity heat pipe heat exchanger, a water tank, an integrated automatic control device and an inverter. A multi-time graded treatment manner is adopted, the fume collecting box collects kitchen fume, the fume enters the fume purifier firstly to be subject to oil stain removal, the manner of one-side air cooling and one-side convection heat exchange is adopted for generating power through the temperature difference power generation module, and the storage battery is connected for electric amount storage. The cooled fume enters an outdoor heat preservation pipeline again to be subject to heat pipe waste heat recycling, heating of the automatic control water tank is combined, so that constant-temperature domestic water is obtained, and finally low-temperature fume subject to two-stage heat exchange is discharged out of a fume discharging opening. The system can sufficiently utilize the characteristics of the temperature difference power generation and heat pipe waste heat recycling, temperature difference power generation and heat pipe waste heat recycling are effectively combined, meanwhile, energy waste and unnecessary equipment arrangement caused by improper temperature during traditional fume recycling are avoided, and the utilization efficiency and economic benefits of a kitchen fume discharging system are improved.

Owner:XI AN JIAOTONG UNIV

Self-supporting wide gap heat exchanging element

ActiveCN104696983ASelf-supportingReduce manufacturing costCombustion processIndirect carbon-dioxide mitigationFlue gasWide gap

The invention is applicable to the field of air cold medium pre-heating and particularly relates to a self-supporting wide gap heat exchanging element. The self-supporting wide gap heat exchanging element comprises a plurality of plate pairs which are overlapped layer by layer; each plat pair comprises upper and lower plate sheets which are arranged oppositely; a plurality of rows of convex ripples and concave ripples are distributed on the upper surfaces of the plate sheets along the same axis direction; the convex ripples and concave ripples are obtained by upwards and downwards pressing and molding the plate sheets; the convex ripples and concave ripples are distributed at intervals; the positions of the convex ripples and concave ripples on the upper plate sheets in the plate pairs correspond to the positions of the convex ripples and concave ripples on the lower plate sheets in the plate pairs; one group of opposite edges of the plate sheets are upwards folded and are transited into planes; the other group of opposite edges of the plate sheets are downwards folded and are transited into planes; the two adjacent folding edges in each plate pair are welded to form an air channel; the two adjacent plate pairs are symmetrical up and down, and the adjacent folding edges between the two adjacent plate pairs are welded to form a flue gas channel. The self-supporting wide gap heat exchanging element has the advantages that a wide gap channel can be combined, dirt and dust are not easy to deposit, the resistance fall also can be reduced and the heat exchanging efficiency is sufficiently improved.

Owner:SHANDONG WINTECH TECH CO LTD

Battery module

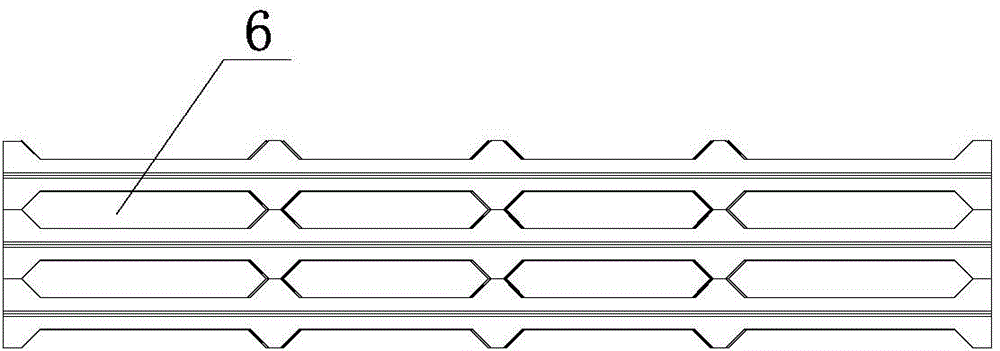

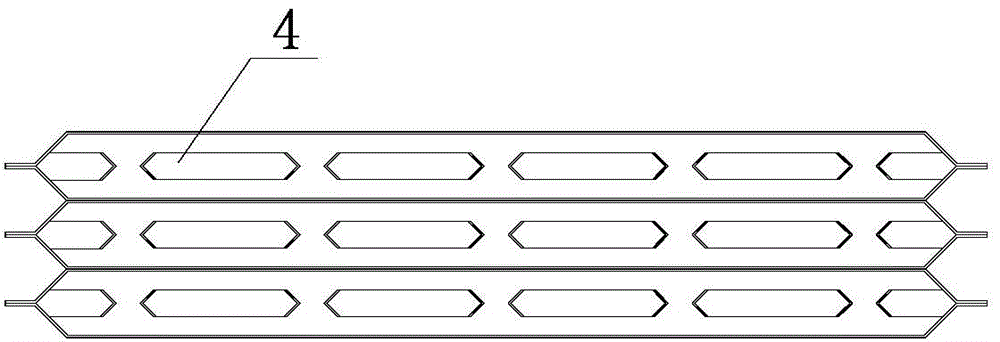

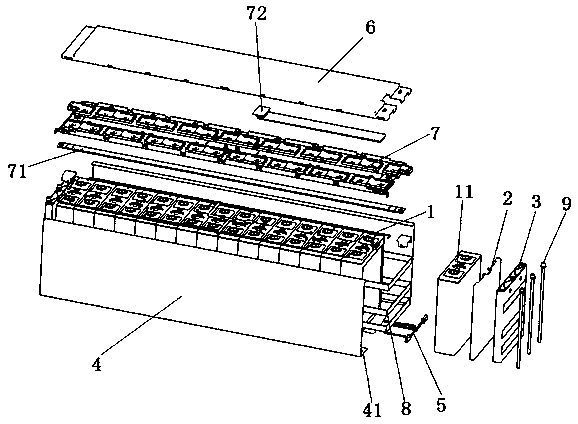

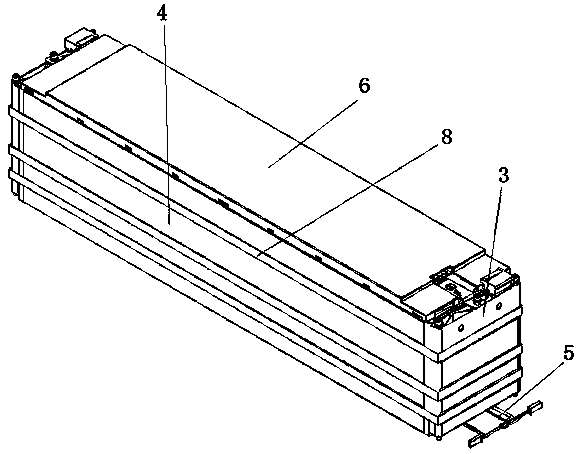

InactiveCN108878702AReduce heat conduction lossLess assembly partsSecondary cellsCell component detailsPower batteryElectrical and Electronics engineering

The invention relates to the technical field of power batteries, in particular to a battery module. The battery module comprises a module framework and a battery pack which is arranged in the modularframework and formed by arranging single batteries and further comprises a temperature adjusting component for heating and / or cooling the battery pack; and an installation hole is formed in the bottomof the module framework, the bottom of the battery pack is exposed in the installation hole, and the temperature adjusting component is arranged in the installation hole and arranged on the bottom face of the battery pack in an attached mode. Due to the fact that the installation hole is formed in the bottom of the module framework, technical staff can directly arrange the temperature adjusting component in the installation hole in the attached mode; due to the fact that the module framework can support the battery pack, the technical staff do not need to arrange a bottom plate forming complete closure on the overall bottom face of the battery module; and due to the fact that the temperature adjusting component directly makes contact with the bottom of the battery pack, the heat conducting loss is reduced, assembly parts of the overall battery module are reduced, and therefore the battery module is lighter and good in heating or cooling effect.

Owner:CHINA AVIATION LITHIUM BATTERY LUOYANG +1

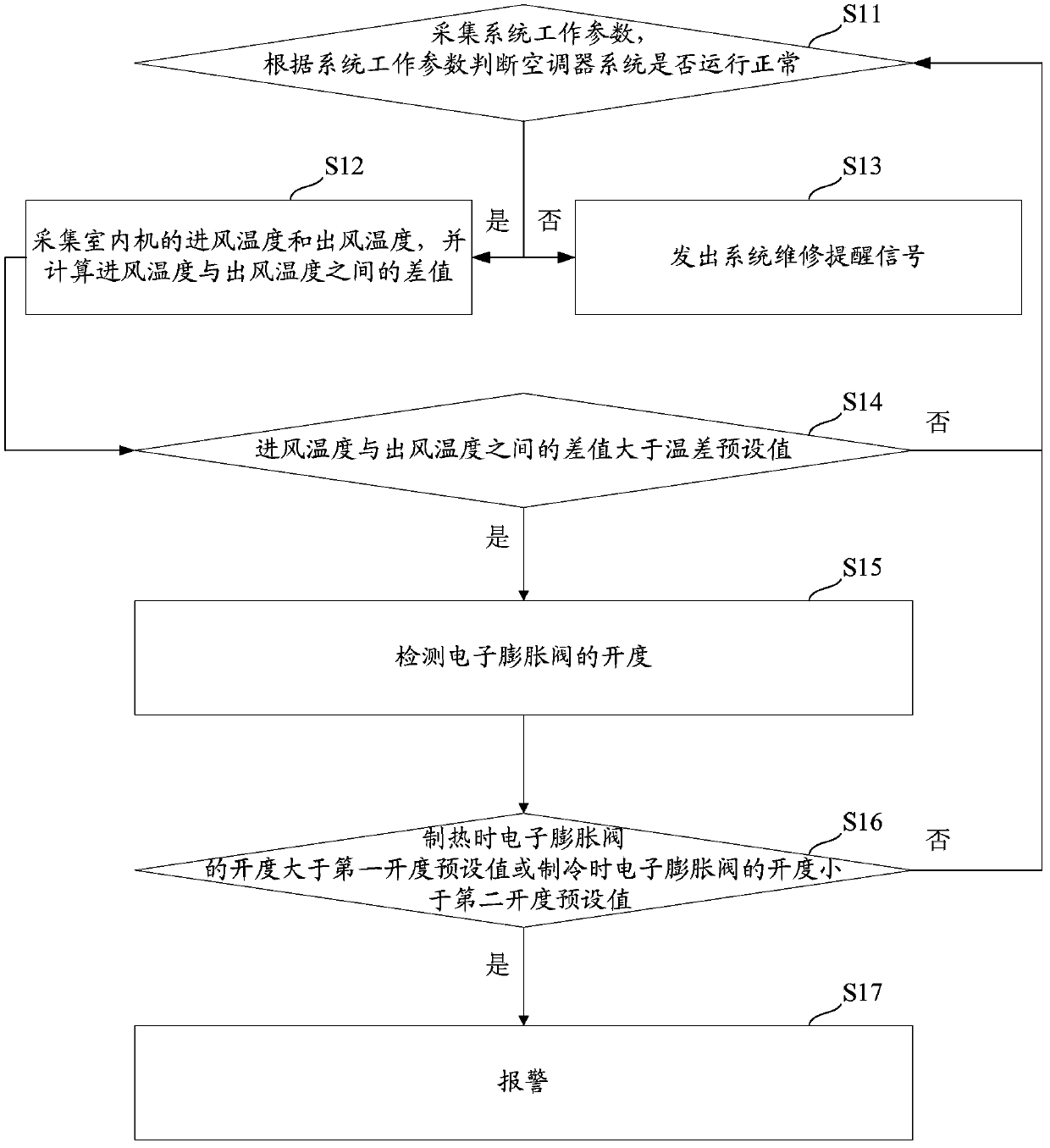

Cleaning reminding method and cleaning reminding device for air conditioner filtering device

ActiveCN104180470AGuaranteed heat transfer efficiencyClean up in timeSpace heating and ventilation safety systemsLighting and heating apparatusTemperature differenceRefrigeration

The invention discloses a cleaning reminding method for an air conditioner filtering device. The method comprises the following steps that S1, the air inlet temperature and the air outlet temperature of an indoor unit are collected, and in addition, a different value between the air inlet temperature and the air outlet temperature is calculated; S2, when the different value between the air inlet temperature and the air outlet temperature is greater than a temperature difference preset value, the opening degree of an electronic expansion valve is detected; S3, when the opening degree of the electronic expansion valve is greater than a first opening degree preset value during heating or the opening degree of the electronic expansion valve is smaller than the second opening degree preset value during refrigeration, warning is carried out. The cleaning reminding method for the air conditioner filtering device disclosed by the invention has the advantages that the cleaning can be carried out according to the actual work condition of the filtering device, further, the labor and material waste caused by regular cleaning can be relieved, meanwhile, the filtering device can be cleaned in time, and the heat exchange efficiency of an air conditioner can be ensured. The invention also discloses a cleaning reminding device for the air conditioner filtering device adopting the cleaning reminding method.

Owner:GREE ELECTRIC APPLIANCES INC

Anhydrous sodium sulfate production system and production method

ActiveCN103241749AReduce manufacturing costImprove economyAlkali metal sulfite/sulfate purificationSolution crystallizationFluidized bedEvaporation

The invention discloses an anhydrous sodium sulfate production system and a production method and aims to solve the problems that the conventional anhydrous sodium sulfate is high in production cost and low in production quality. The anhydrous sodium sulfate production system comprises a multistage reduction tower, a neutralization reaction kettle, a flocculent precipitate tank, a crystallizing tank and a vapor compressor, wherein evaporation and crystallization are finished in one unit; the chromium salt denitration liquid is subjected to reduction, neutralization reaction, flocculent precipitate and multistage filtering and is pumped into the evaporation and crystallization system, the crystal product is discharged and is pumped into a centrifugal machine through a crystal slurry pump, the centrifuged crystal product is fed into a fluidized bed dryer through a spiral conveyer, and the dried finished product enters a storage bin and is packaged. The anhydrous sodium sulfate granules can be effectively and freely controlled, and the technical problems that the anhydrous sodium sulfate is high in production cost, the evaporator is short in operation cycle and bad in heat exchange effect are solved.

Owner:GANSU LANPEC TECH +3

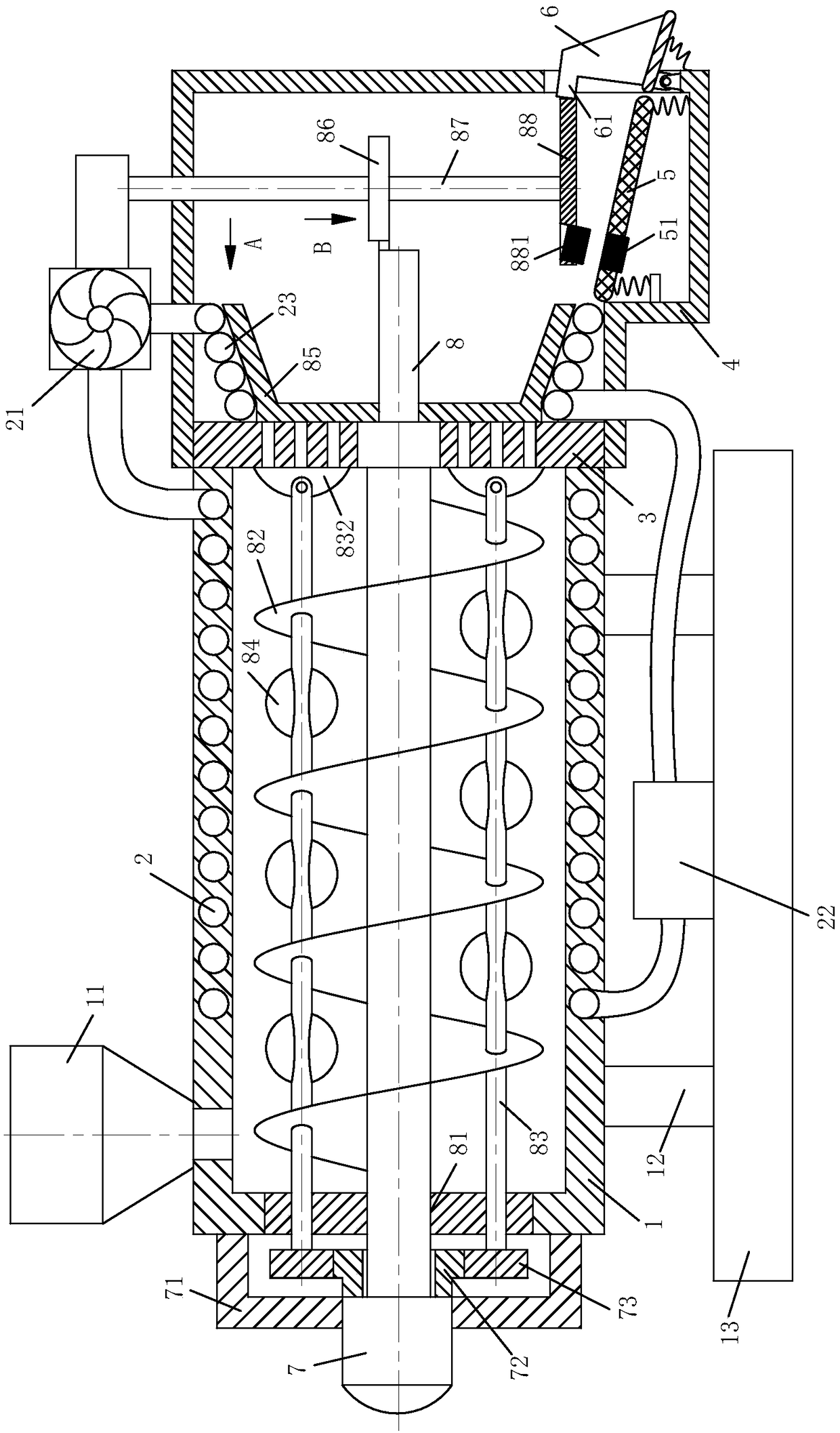

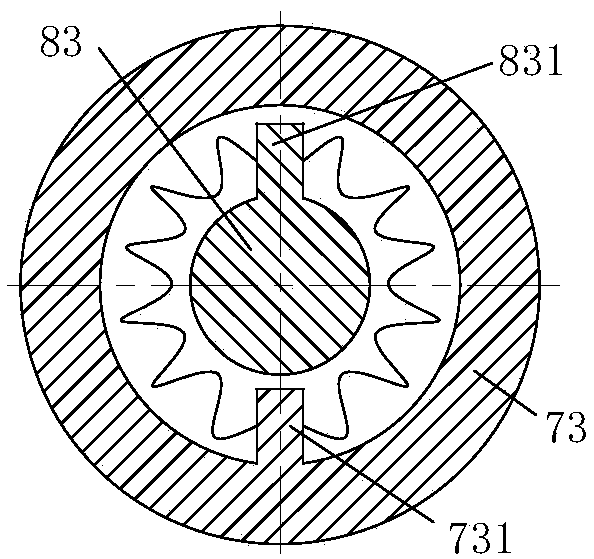

Large rubber production granulator

The invention belongs to the technical field of rubber production, and particularly relates to a large rubber production granulator which comprises a granulator cylinder, a heating water pipe, a granulating mould, a drying box, an elastic plate, a discharge hopper, a transmission shaft, a spiral plate, rotating rods and stirring plates. A group of rotating rods are horizontally arranged on the spiral plate, first rectangular projections on the rotating rods are connected with second rectangular projections on driven gears through two symmetric springs, a group of stirring plates are arranged on the rotating rods, rubber raw materials at the center of the granulator cylinder and on the inner wall of the granulator cylinder are exchanged, so that the rubber raw materials in the granulator cylinder uniformly contact with the inner wall of the granulator cylinder and are uniformly heated, the heat conducting efficiency of the heating water pipe is ensured, and heat use ratio is increased.Besides, the rotating rods are flexibly connected with the driven gears, impact force applied to the stirring plates is reduced, and the service life of the stirring plates is prolonged.

Owner:阜阳市金地橡塑股份有限公司

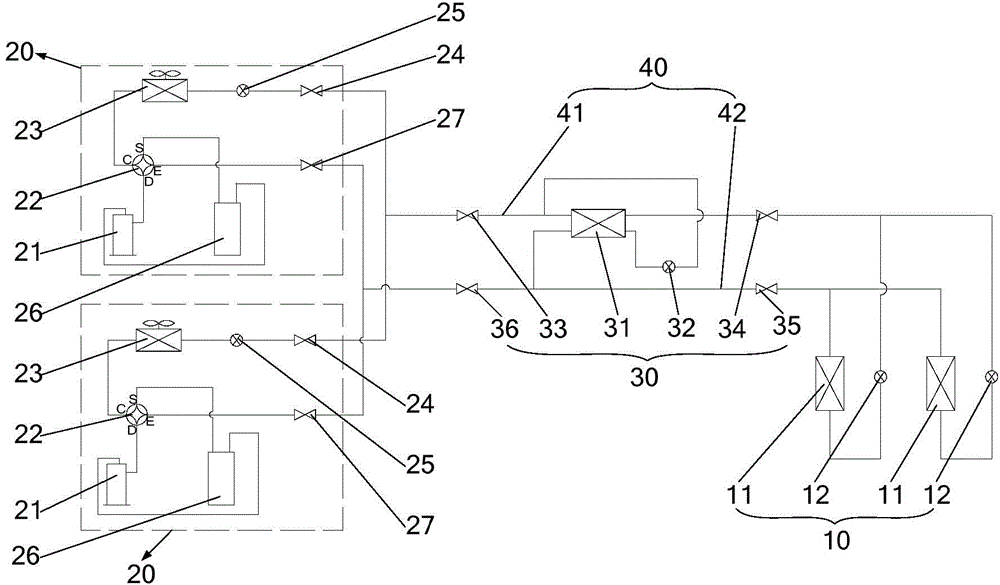

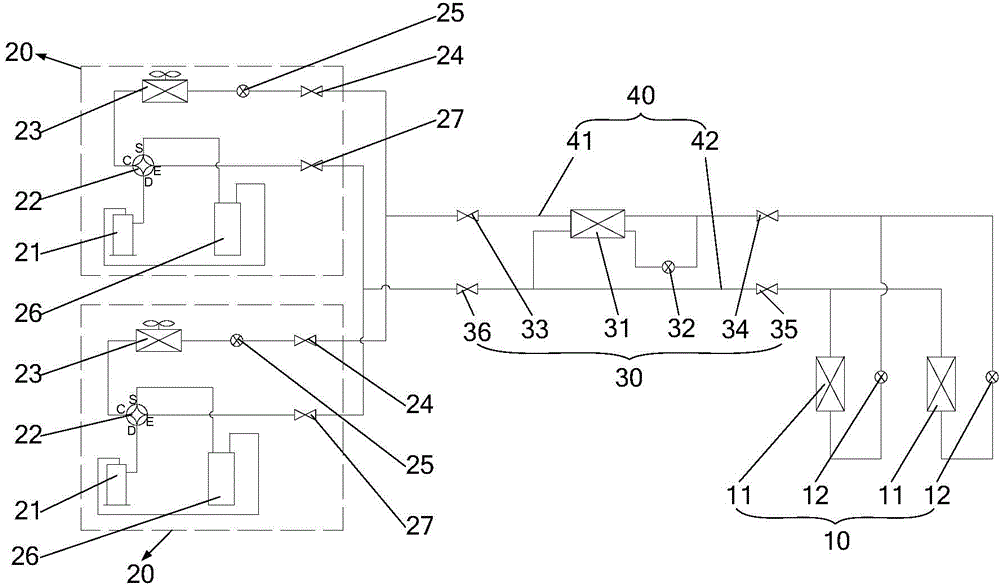

Multi-split air conditioning system

ActiveCN103982943AReduce manufacturing costReduce volumeLighting and heating apparatusSpace heating and ventilation detailsSuper coolingAir conditioning

The invention provides a multi-split air conditioning system. The multi-split air conditioning system comprises an indoor unit, multiple outdoor units and super-cooling devices, wherein the multiple outdoor units are communicated with the indoor unit through pipelines after being connected in parallel, the super-cooling devices are detachably arranged on the pipelines, and the super-cooling devices are communicated with the indoor unit and the multiple outdoor units which are connected in parallel. The multi-split air conditioning system provided by the invention is provided with the multiple outdoor units which are connected in parallel, the super-cooling devices are detachably arranged on the pipelines, whether the super-cooling devices need to be arranged or not can be selected by a user according to self needs, and the super-cooling devices can be arranged in any positions on the pipelines; compared with a mode of arranging the super-cooling devices in the outdoor units in the prior art, the super-cooling devices are detachably arranged on the pipelines, on one hand, the using amount of the super-cooling devices is effectively reduced, the problem of resource waste is avoided, and thus the production cost of the multi-split air conditioning system is effectively reduced; on the other hand, the size of the outdoor units is effectively reduced, thus the conveying amount of the outdoor units is increased, and the conveying cost is reduced.

Owner:GD MIDEA HEATING & VENTILATING EQUIP CO LTD +1

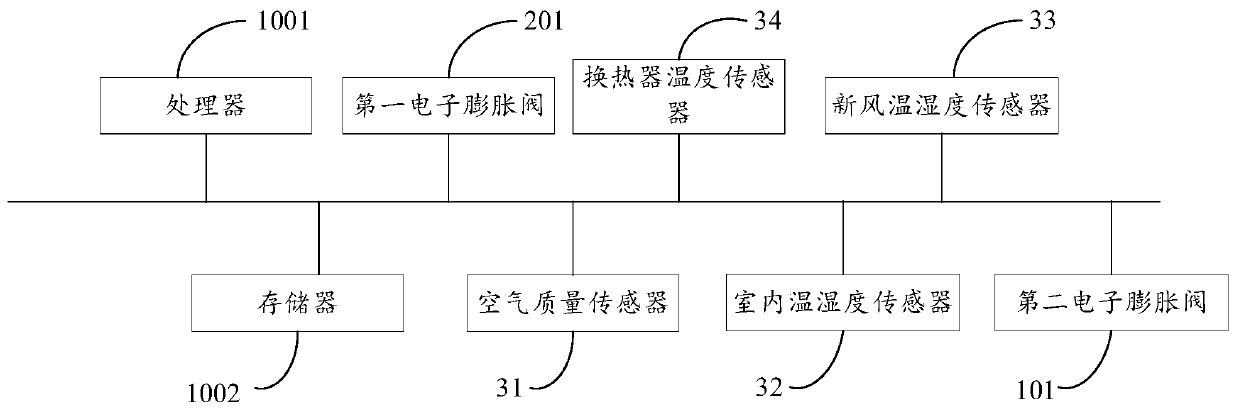

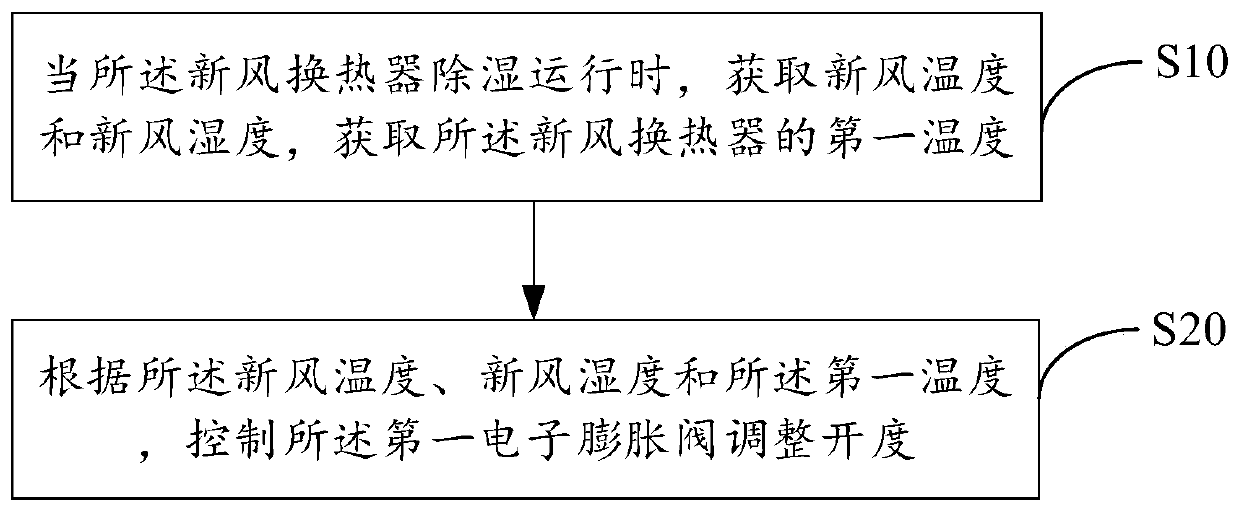

Fresh air conditioner, air conditioner control method and control device thereof and readable storage medium

ActiveCN111536592AAccurately reflect the dehumidification effectGuaranteed dehumidification effectMechanical apparatusLighting and heating apparatusTemperature controlFresh air

The invention discloses an air conditioner control method which is applied to a fresh air conditioner. The fresh air conditioner comprises a fresh air heat exchanger and a first electronic expansion valve, and the fresh air heat exchanger is connected with the first electronic expansion valve in series. The air conditioner control method comprises the following steps that when the fresh air heat exchanger is in dehumidification operation, the fresh air temperature and the fresh air humidity are obtained, and the first temperature of the fresh air heat exchanger is obtained; and according to the fresh air temperature, the fresh air humidity and the first temperature, the first electronic expansion valve is controlled to adjust the opening degree. The invention further discloses an air conditioner control device, the fresh air conditioner and a readable storage medium. According to the air conditioner control method, the dehumidification effect is improved while the heat exchange efficiency of the fresh air heat exchanger is guaranteed.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD

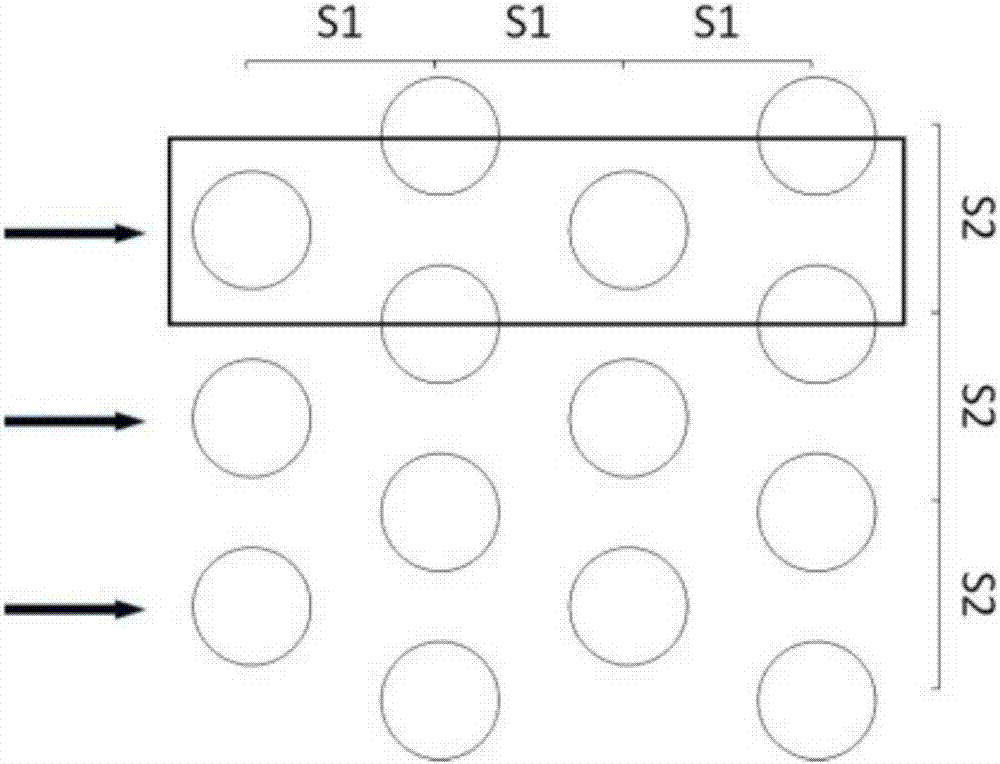

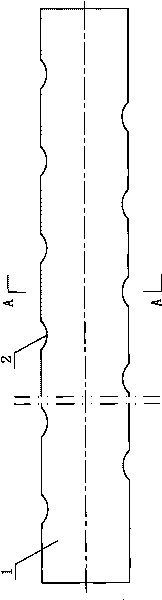

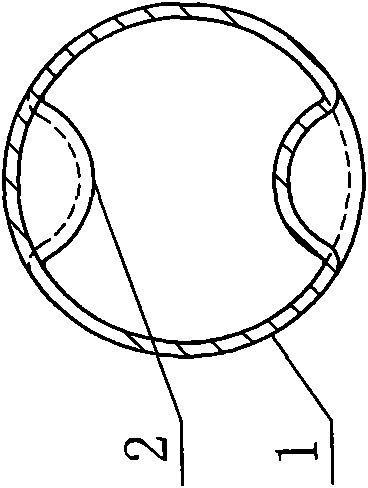

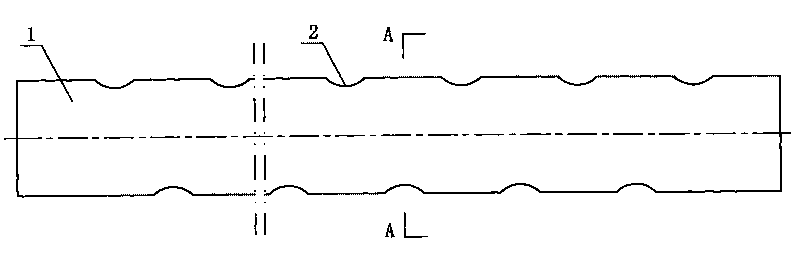

Multi-row pit heat exchange tube

InactiveCN101701779AGuaranteed heat transfer efficiencyEasy to processCorrosion preventionTubular elementsEngineeringImpurity

The invention relates to a multi-row pit heat exchange tube, comprising a stainless steel tube body. The multi-row pit heat exchange tube is characterized in that the surface of the stainless steel tube body is provided with a plurality of rows of pits along an axial direction and the positions of adjacent two rows of pits are staggered. The multirow pit heat exchange tube has the advantages that: 1. the diameter of the heat exchange tube can be produced less than 5 mm while the heat exchange tube ensures the heat exchange efficiency and the heat change tube is easy to process for molding; 2. the tube body has small diameter, relatively high heat exchange surface area ratio and larger heat transfer quantity under the condition that the medium temperature and the temperature needed to be displaced are the same; and meanwhile, the pits on the stainless steel are deeper than spiral grooves on a tube body with the same diameter, thus the turbulence phenomenon of gases passing through the heat exchange tube is enlarged, the heat exchange coefficient is greatly improved and the heat exchange effect is intensified; 3. due to the small diameter of the tube body, the installation space can be saved, and compared with common heat exchange tubes, obviously less heat exchange tubes with small diameter are used in a device with same heat exchange requirements; and 4. the service life is prolonged and the pits can reduce the retention and deposition of the impurities of media in the tube compared with the spiral grooves.

Owner:锦州秀亭制管有限公司

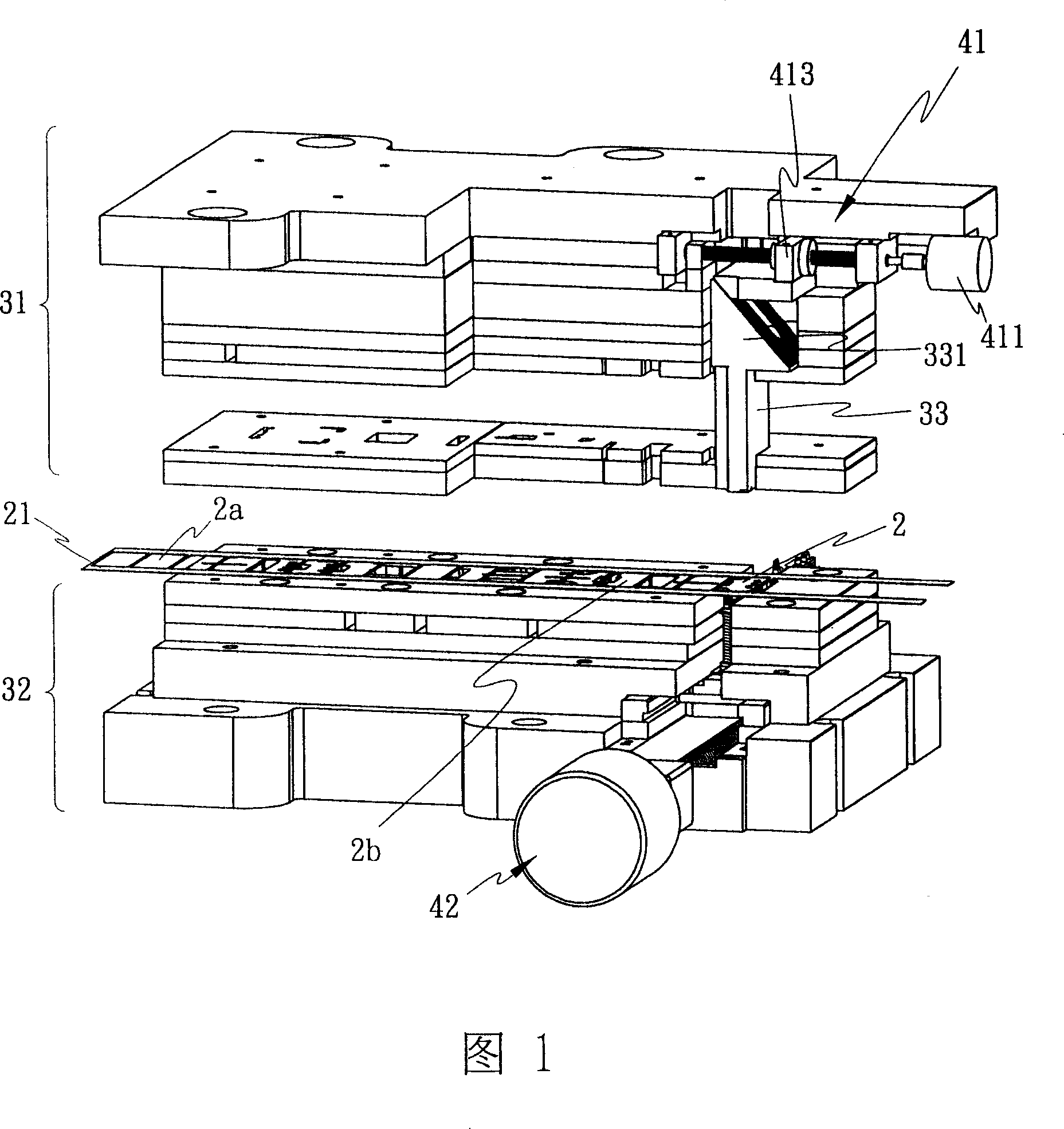

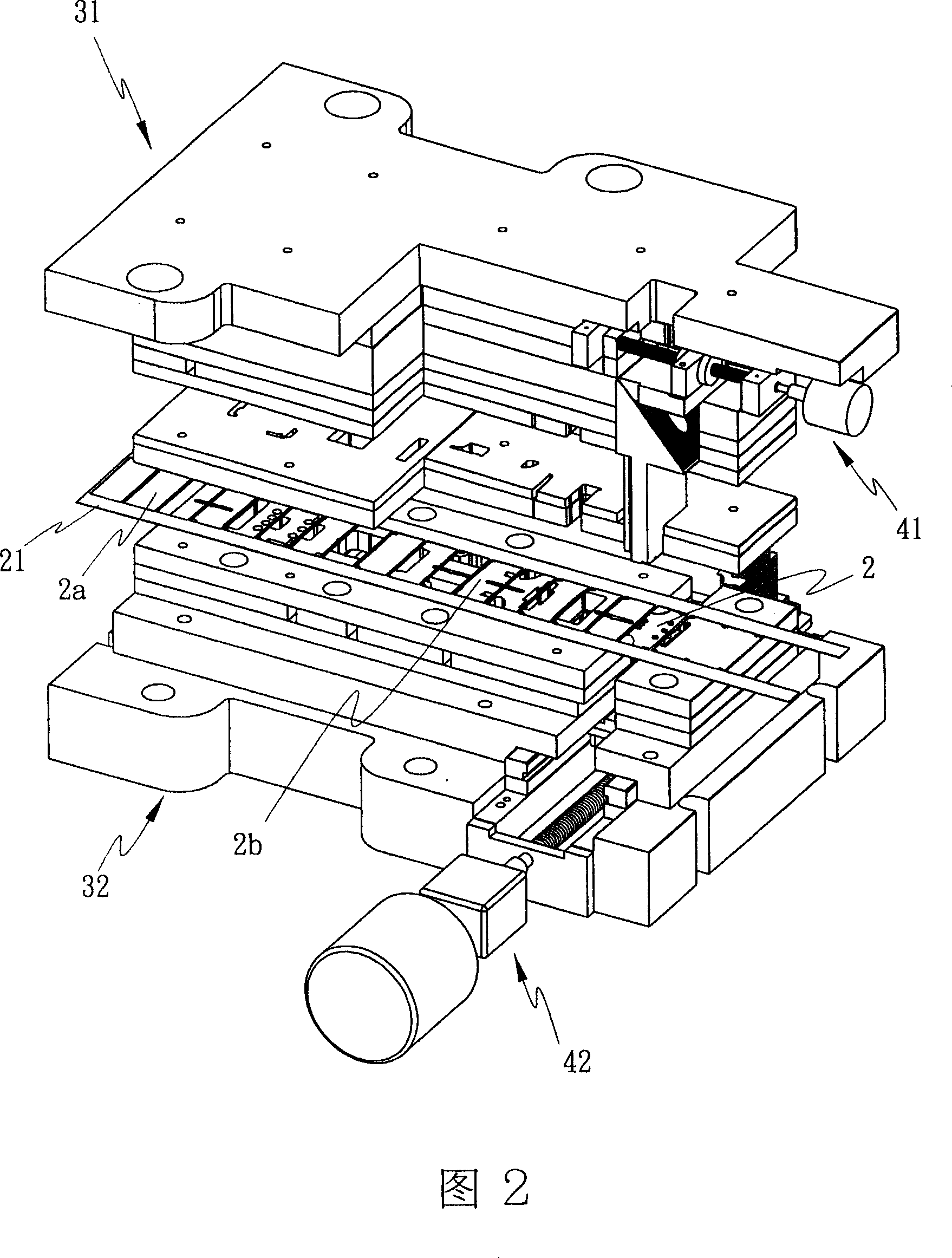

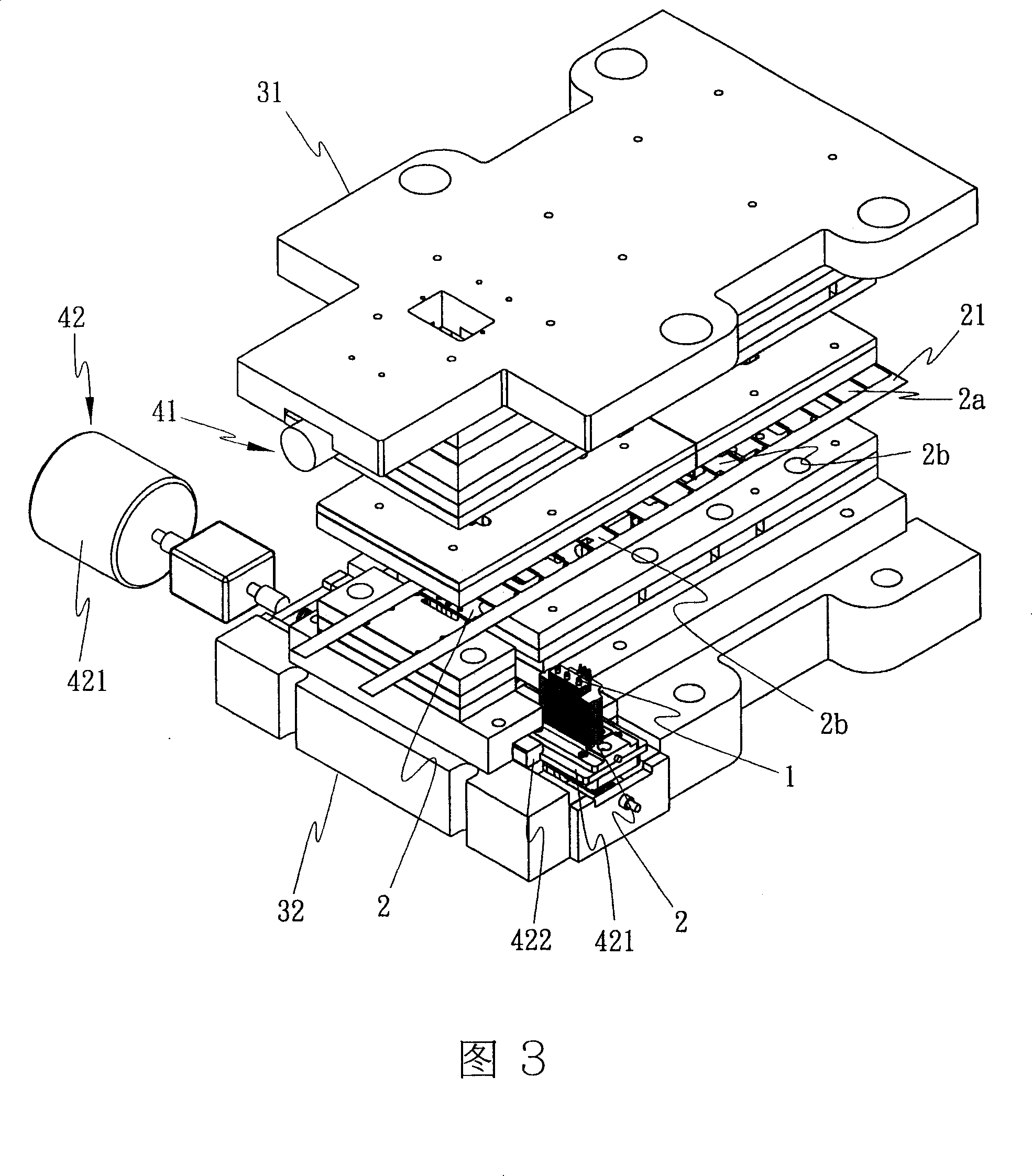

Equipment for automatic assembling of heat conducting tube and radiation fins

ActiveCN101003071AGuaranteed heat transfer efficiencyConsistent and rapid production characteristicsHeat exchange apparatusPunchingHeat conducting

An automatic assembling apparatus for the heat conducting tube and heat radiating fins is composed of a continuous punching die unit with upper and lower dies, and upper and lower drive units arranged respectively in said upper and low dies. Said continuous punching die unit can punch the heat radiating fins and fixing them onto a heat conducting tube. Said upper drive unit can damp the punch head. Said lower drive unit can clamp said tube and move the finished product out.

Owner:HUANG TSUNG HSIEN YUAN SHAN HSIANG

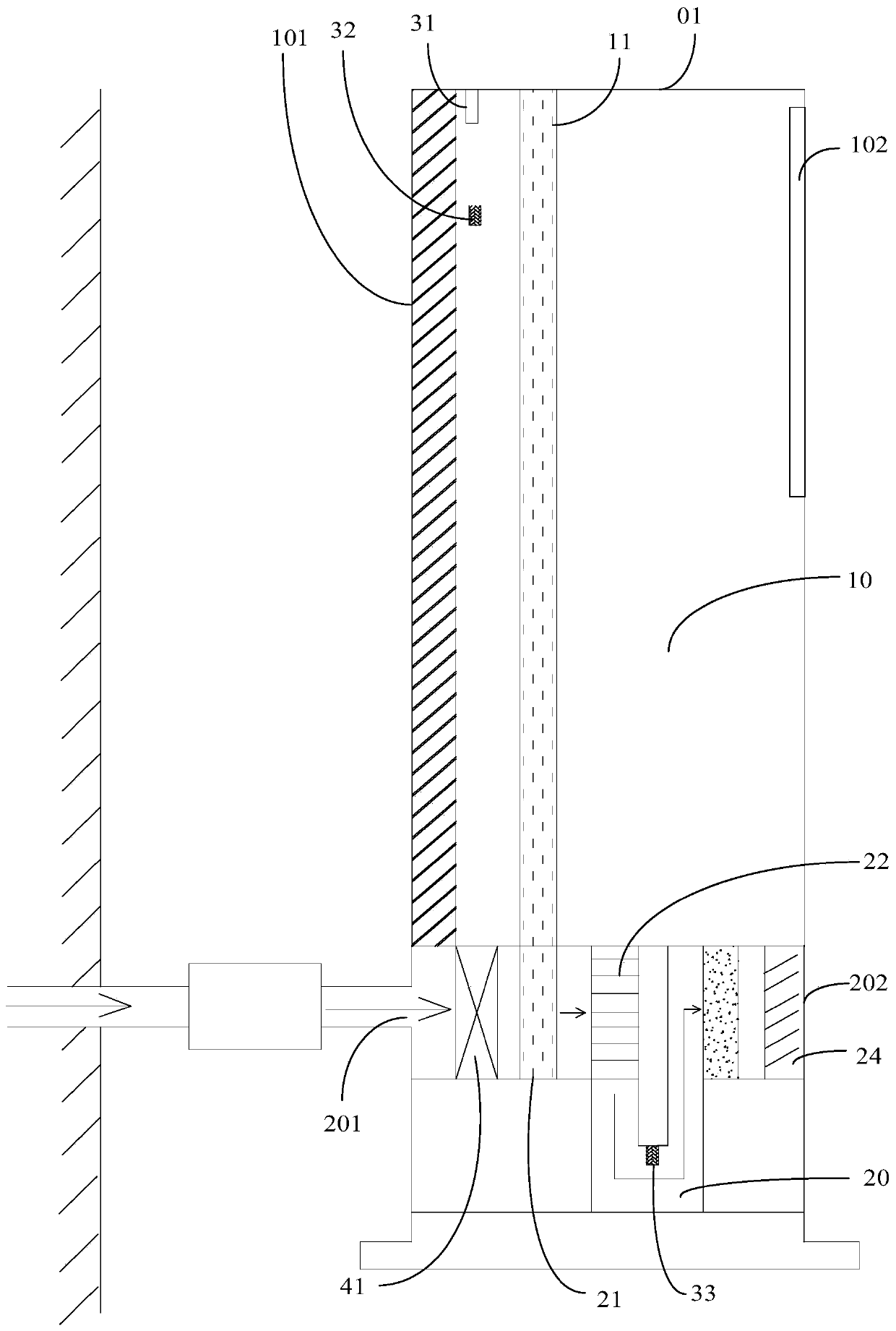

Heat pump -type subway vehicle air conditioner

ActiveCN101290177AReduce failureReduce maintenance costsHeat pumpsRailway heating/coolingEngineeringAir conditioning

The present invention discloses a subway heat pump type air-conditioning structure. An outlet end of a compressor (1) of a heat pump type air-conditioner for a subway vehicle is connected with an input end of a condenser (6) through a refrigeration electromagnetic valve (4) and an exhausting damping pipe (2). An output end of the condenser (6) is connected with an inlet end of the compressor (1) through an air-returning damping pipe (13) and a heating electromagnetic valve A (3'). The outlet end of the compressor (1) is connected with an input end of an evaporator (11) through a heating electromagnetic valve (3) and the exhausting damping pipe (2). An output end of the evaporator (11) is connected with the inlet end of the compressor (1) through the air-returning damping pipe (13) and a refrigeration electromagnetic valve A (4'). The output end of the evaporator (11) is connected with the input end of the condenser (6) through a liquid storage device A (9'), a one-way valve A (7') and a thermostatic expansion valve A (10'). An temperature sensing packet and a capillary of the thermostatic expansion valve A (10') are connected with the output end of the condenser (6). The output end of the condenser (6) is connected with the input end of the evaporator (11) through the liquid storage device (9), the one-way valve (7) and the thermostatic expansion valve (10). The temperature sensing packet and the capillary of the thermostatic expansion valve (10) are connected with the output end of the evaporator (11). The air-conditioning structure is safe, energy-saving, environmentally-friendly and highly effective.

Owner:SHANGHAI HIGHLY AUTOMATIC ELECTRIC

Device for recycling waste heat of flue gas in power station boiler

InactiveCN101825275AReduce consumptionGuaranteed cleanlinessLiquid degasificationFeed water supplyEngineeringDeaerator

The invention provides a device for recycling waste heat of flue gas in a power station boiler, which is characterized in that one end of a water inlet pipe of a heat exchanger is communicated on a pipeline between a gland heater and a low pressure heater; the other end of the water inlet pipe is communicated with a coil in the heat exchanger; the other end of the coil is connected with a deaerator through a water return pipe of the heat exchanger; the deaerator is connected with the low pressure heater through the pipeline; a clean water return pipe is arranged at the bottom of the heat exchanger; a nozzle is arranged at the upper part of the heat exchanger and is communicated with one end of a clean water pipe; the other end of the clean water pipe is connected with a water collecting tank or a desulfurizer storing pot; one end of a flue pipe is connected with an electrostatic dust collector through a draught fan; and the other end of the flue pipe is communicated with a chimney or a desulfurizing tower through the heat exchanger. The device for recycling waste heat can recycle most of heat in the flue gas discharged from the boiler and can convert the recycled heat into the heat of the condensation water of a steam turbine, thereby reducing the steam consumption of the low pressure heater in a heat regenerative system of the steam turbine and saving a large amount of energy sources. A cleaning device is arranged in the heat exchanger, thereby ensuring the cleanness and the heat exchange efficiency of a heat exchange surface.

Owner:史振玺

Method and system for recycling waste heat of ammonia water

InactiveCN102827623AHigh utilization rate of waste heat recoveryGuaranteed to workCoke ovensClimate change adaptationLithium bromideCoke oven

The invention provides a method and a system for recycling waste heat of ammonia water. The method comprises the following steps: circulating circulatory ammonia water into a gas collecting pipe of a coke oven, cooling raw gas for the first time, heating the circulatory ammonia water, feeding the heated circulatory ammonia water into a heat exchange device, and heating the circulating water in the heat exchange device; circulating the circulating water heated in the heat exchange device into a lithium-bromide absorption-type refrigerating machine as a heat source to refrigerate frozen water in the lithium-bromide absorption-type refrigerating machine; meanwhile, circulating a refrigerant into the lithium-bromide absorption-type refrigerating machine; and feeding the cooled circulating water to the heat exchange device and heating again. According to the method provided by the invention, the waste heat in the circulatory ammonia water is effectively recycled and is used for refrigeration, the waste heat recovery rate of the circulatory ammonia water is improved, and the waste of the energy is effectively avoided.

Owner:云南大为制焦有限公司

Air-conditioning indoor unit capable of discharging air up and down, control method thereof and air conditioner

PendingCN111140917AImprove comfortReduce volumeMechanical apparatusLighting and heating apparatusEnvironmental engineeringMechanical engineering

The invention provides an air-conditioning indoor unit capable of discharging air up and down, a control method thereof and an air conditioner. The air-conditioning indoor unit comprises a machine shell, wherein an air inlet is formed in the machine shell, the air-conditioning indoor unit further comprises a panel body, the panel body is connected with the machine shell, a first air outlet is formed between the lower end of the panel body and the machine shell, the first air outlet is further provided with a first air guide plate, the first air guide plate can do translational motion of beingpushed out or retracted into the first air outlet, the air-conditioning indoor unit further comprises a panel, the panel can be covered on the panel body and can be driven to move and can do translational motion away from and close to the panel body, the panel moves in a direction away from the panel body and an air feeding channel is formed between the panel and the panel body, and a second air outlet is formed between the upper end of the panel and the panel body. The air-conditioning indoor unit not only is capable of discharging air up and down, but also can reduce the space size of the air-conditioning indoor unit, especially reduce the space size between the panel to the wall, the volume of the indoor unit is reduced, the demand that the air can be discharged up and down is met whilemaking the structure more compact.

Owner:GREE ELECTRIC APPLIANCES INC

Heat exchanger

ActiveCN104236348AGuaranteed heat transfer efficiencyHeat storage plantsStationary plate conduit assembliesPlate heat exchangerButt joint

The invention discloses a heat exchanger, and relates to the technical field of heat exchanging devices. The heat exchanger comprises at least two heat exchanging plate components which are internally filled with thermal storage materials and are in butt joint with each other, wherein an end cover covers the outside of the heat exchanging plate component on the end part on one side, a closed heat exchanging runner is arranged between every two adjacent heat exchanging plate components, and a closed heat exchanging runner is arranged between the end cover and the adjacent heat exchanging plate component; the heat exchanger is internally provided with at least two through passages which are different in height and penetrate through all the heat exchanging runners; a coolant inlet and a coolant outlet are formed in the end cover and / or the heat exchanging plate component on the end part of the other side, and the coolant inlet is arranged to be higher than the coolant outlet. According to the heat exchanger provided by the invention, the thermal storage materials are arranged in the heat exchanging plate components, the heat exchanging runners are arranged between the heat exchanging plate components as well as between the heat exchanging plate component and the end cover, a coolant enters the heat exchanging runners and forms heat exchange together with the thermal storage materials in the heat exchanging plate components though the wall faces of the heat exchanging plate components, and the heat exchanging efficiency of the heat exchanger is ensured while the sealing requirement is realized.

Owner:GREE ELECTRIC APPLIANCES INC

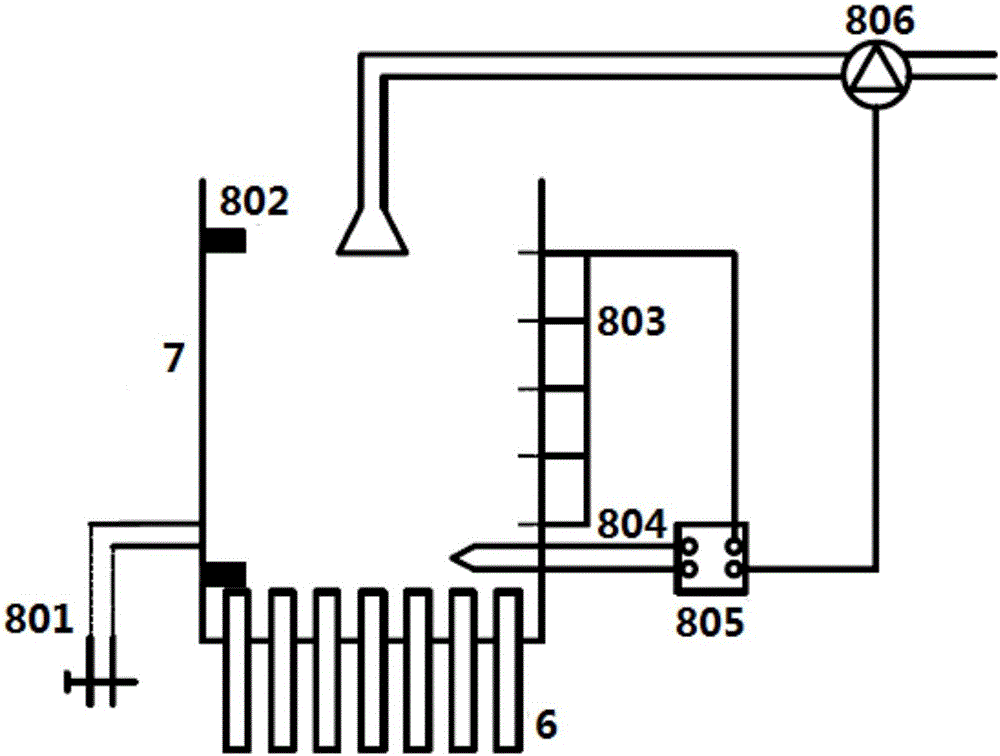

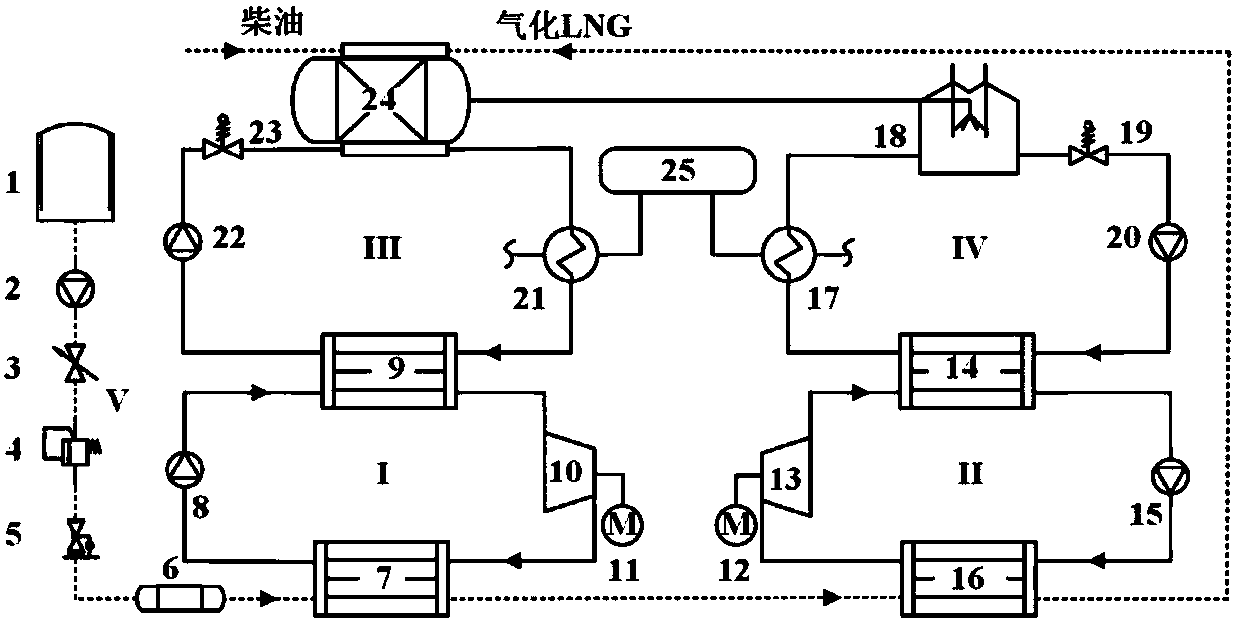

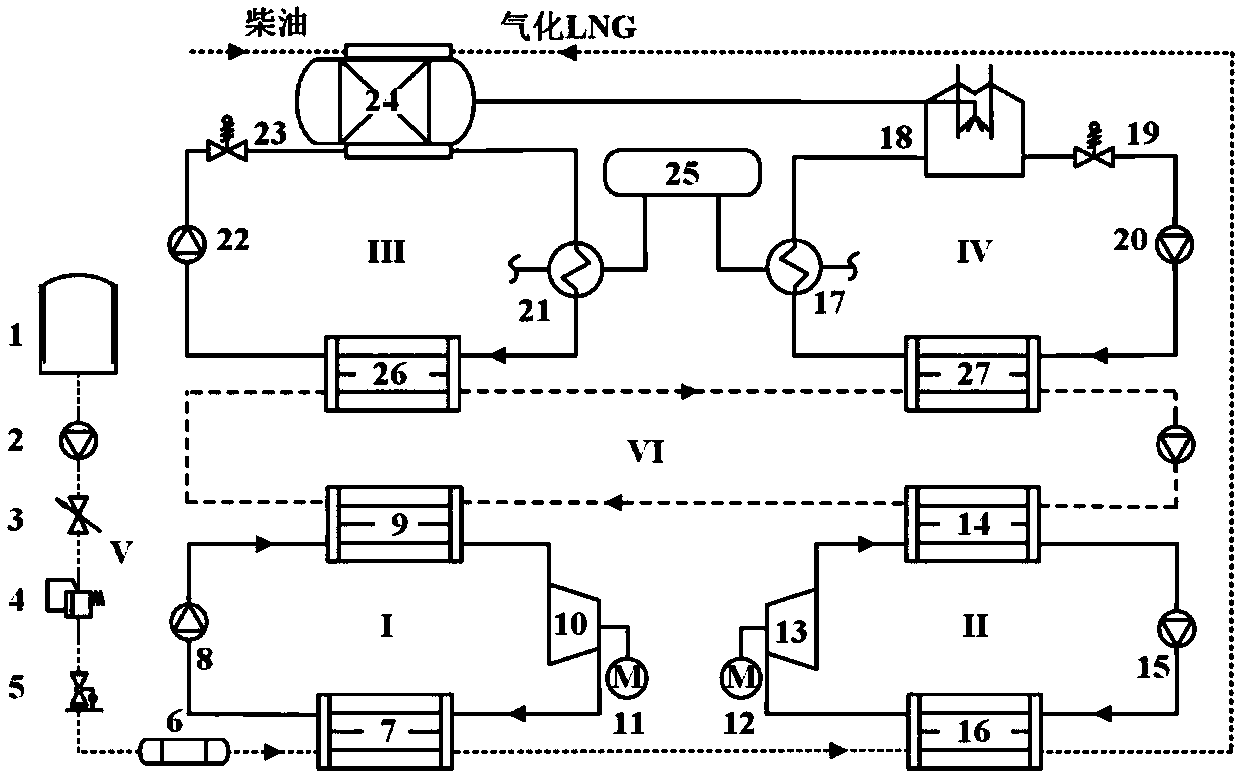

ORC composite power generation system suitable for LNG hybrid power ship

ActiveCN108518288AIncrease profitLower discharge temperatureInternal combustion piston enginesSteam engine plantsTemperature differenceEngineering

The invention is aimed at providing an ORC composite power generation system suitable for an LNG hybrid power ship. The system is characterized in that the system comprises a first-grade ORC loop (I),a second-grade ORC loop (II), an LNG / diesel-oil dual fuel main engine cylinder sleeve water cooling loop (III), a smoke cooling loop (IV) and an LNG gasification loop (V); the first-grade ORC loop (I) takes cylinder sleeve cooling water as a heat source and takes LNG gasification cold energy as a cold source; the second-grade ORC loop takes smoke as a heat source and takes LNG gasification cold energy as a cold source; the first-grade ORC loop is connected with the LNG gasification loop through a first-grade condenser and connected with the LNG / diesel-oil dual fuel main engine cylinder sleevewater cooling loop through a first-grade evaporator; and the second-grade ORC loop is connected with the LNG gasification loop through a second-grade condenser and connected with the smoke cooling loop through a second-grade evaporator. The ORC composite power generation system suitable for the LNG hybrid power ship can effectively integrate heat sources and cold sources at different temperaturein the LNG hybrid power ship and helps avoid loss during a large temperature difference heat transfer process by creating an ORC composite system. Therefore, energy utilization rate of the LNG hybridpower ship is increased.

Owner:SHANGHAI MARITIME UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com