Module type flue gas heat exchanger with fluorine plastic pipes

A flue gas heat exchanger, fluoroplastic tube technology, applied in the direction of heat exchanger type, heat exchanger shell, indirect heat exchanger, etc. The structure of the device is not reasonable enough, the maintenance is inconvenient, etc., to solve the corrosion problem and scaling problem, to overcome the low-temperature corrosion, and to improve the reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

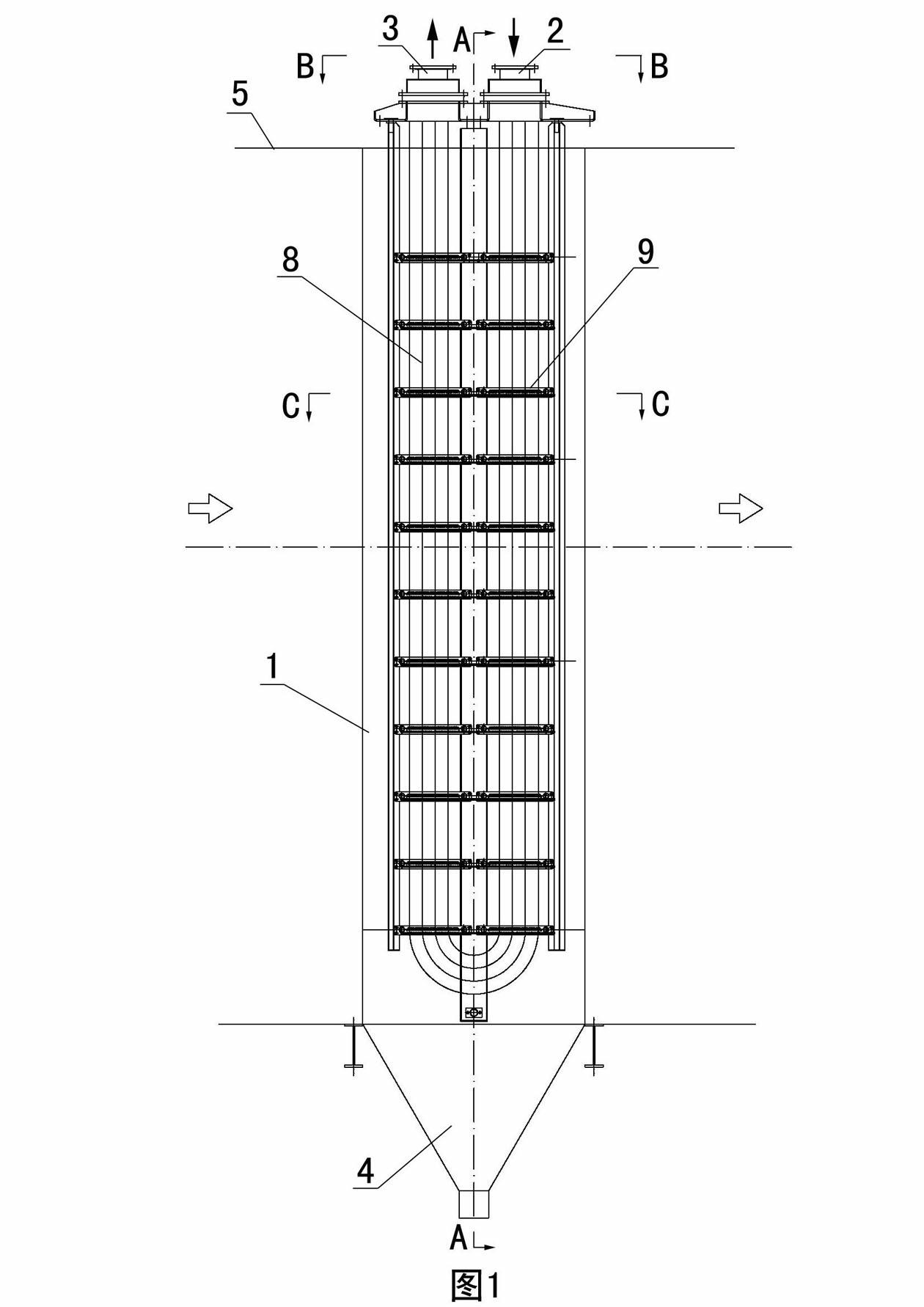

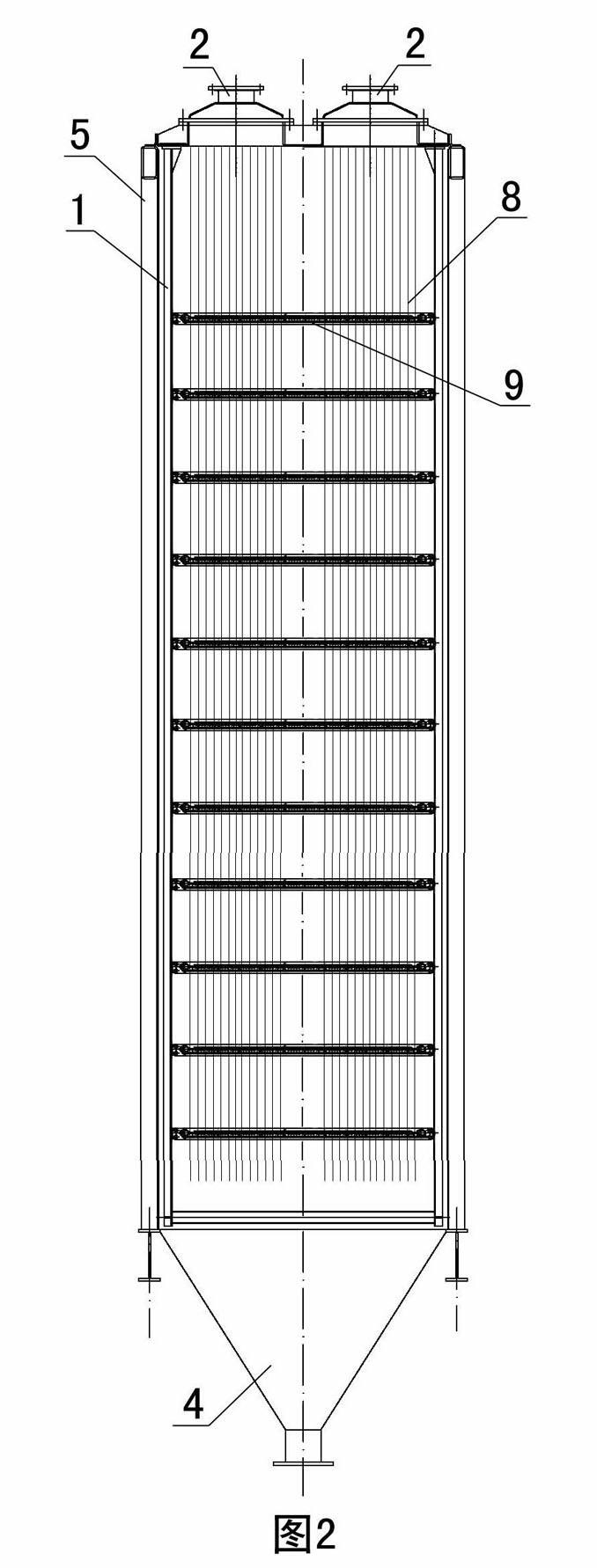

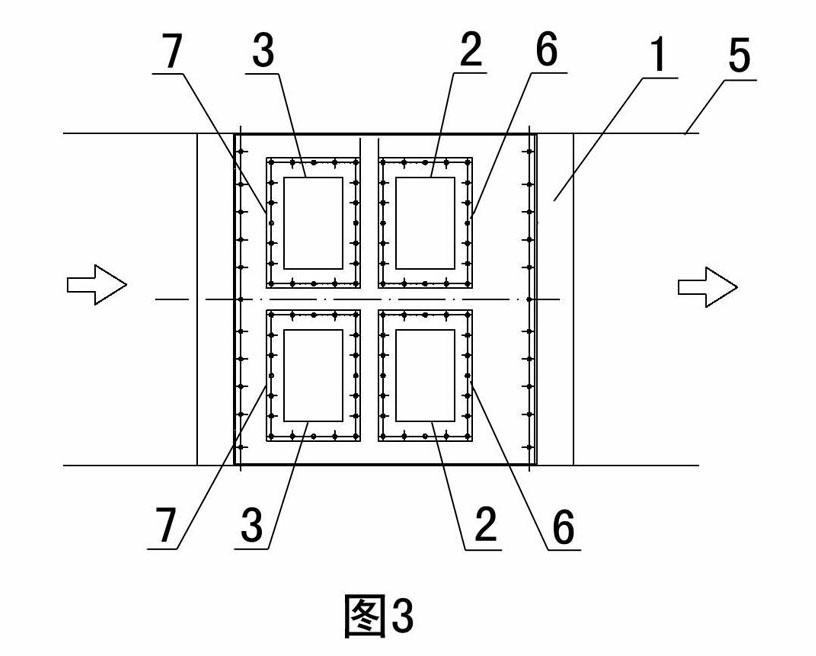

[0032] Embodiment one sees Figure 1-Figure 3 , Figure 6 , Figure 7 As shown, this modular fluoroplastic tube flue gas heat exchanger is arranged in the flue gas channel 5, including a heat exchanger shell 1 with a water inlet 2 and a water outlet 3 at the upper end and a sewage outlet 4 at the lower end, and The heat exchange tubes arranged inside the shell of the heat exchanger and connected between the water inlet 2 and the water outlet 3, the bolts at the water inlet 2 are detachably connected to the water inlet end plate 6, and the water inlet end plate 6 is opened with The water inlet hole 6.1, the water outlet 3 bolts are detachably connected with the water outlet end plate 7, and the water outlet end plate 7 is opened with a water outlet hole 7.1, and the heat exchange tube is a U-shaped fluoroplastic heat exchange tube bundle 8 , and the water inlet end of the fluoroplastic tubes in the fluoroplastic heat exchange tube bundle 8 communicates with the water inlet ho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com