Patents

Literature

93results about How to "With anti-fouling function" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cambered protective film with multiple functional layers and preparation method of cambered protective film

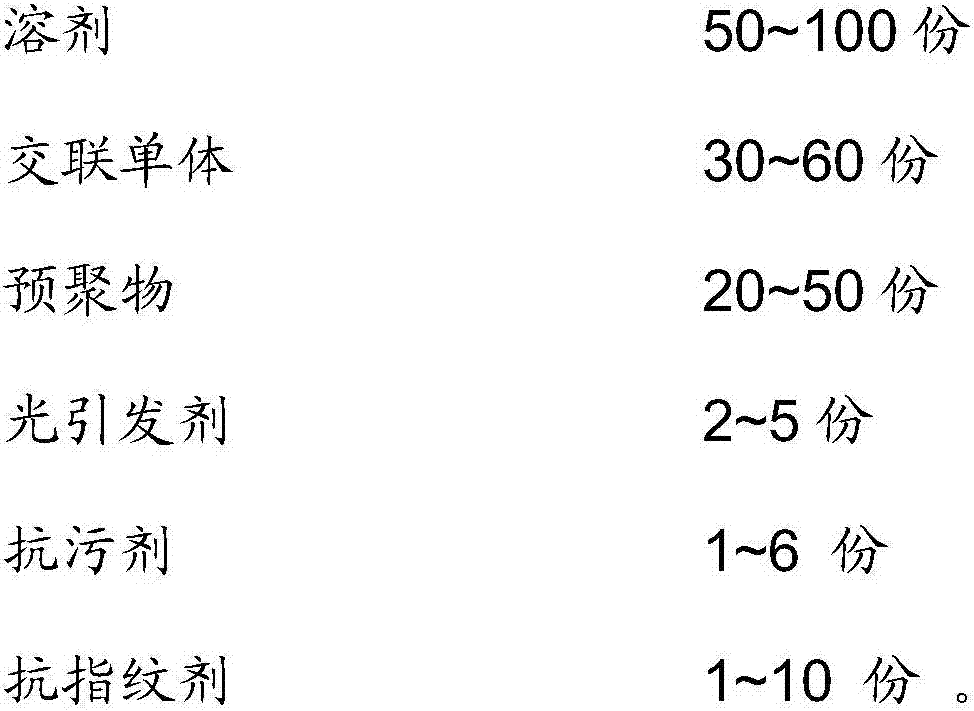

ActiveCN107033799AHydrophobic and oleophobic anti-fingerprintWith anti-fouling functionNon-macromolecular adhesive additivesAntifouling/underwater paintsFluorideSilica gel

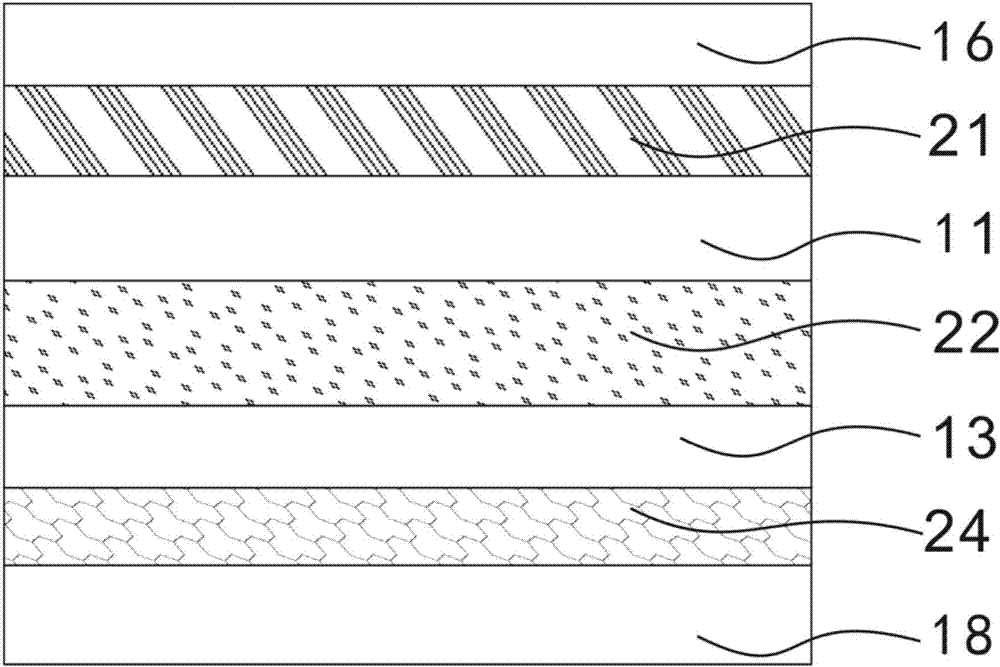

The invention discloses a cambered protective film with multiple functional layers and a preparation method of the cambered protective film. The cambered protective film has stain-resistant and fingerprint resistant effects, and is high in cleanliness. A UV hardened layer is arranged on a first substrate, a film protecting layer is arranged on the UV hardened layer, a silicone layer is arranged on the lower portion of a second substrate, a fluoride-containing release liner is arranged on the lower portion of the silicone layer, a high-tack adhesive layer is arranged on the second substrate, and the high-tack adhesive layer is attached to the other side, away from the UV hardened layer, of the first substrate. The cambered protective film has a blue light resisting effect so as to care the eyes; double-layer PET is used so as to increase the thickness of a using layer, and accordingly, the buffer capacity is improved.

Owner:NALI OPTICAL MATERIAL DONGGUAN

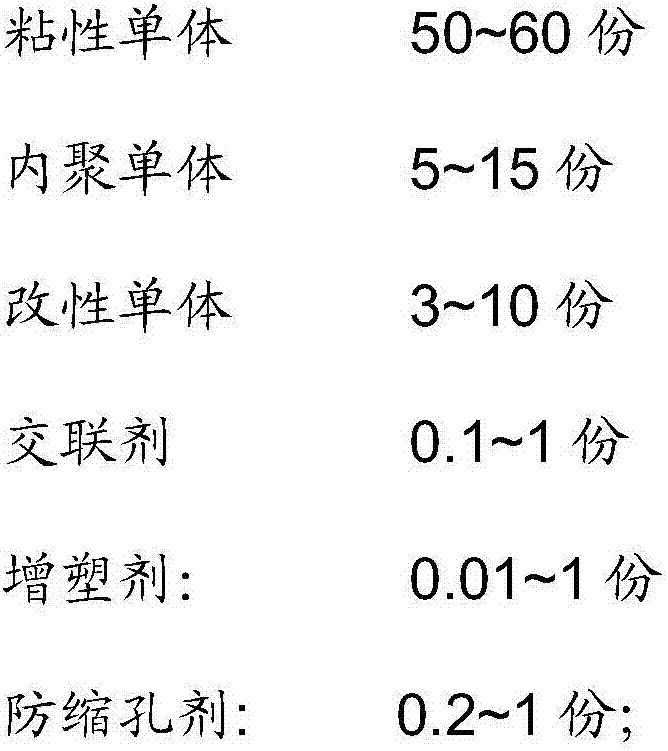

Textile auxiliary containing antibiotic constituents and preparation method thereof

InactiveCN105714558AImprove antibacterial propertiesWith anti-fouling functionBiochemical fibre treatmentPolymer sciencePyrrolidinones

The invention discloses a textile auxiliary containing antibiotic constituents. The textile auxiliary comprises, by weight parts, 50-60 parts of sodium diethylhexyl sulfosuccinate, 45-55 parts of polyvinyl pyrrolidone, 40-50 parts of sodium dodecyl sulfonate, 30-40 parts of hydroxyethyl sulfonate, 30-40 parts of 2-hydroxyethyl salicylate, 25-35 parts of lupenyl palmitate, 25-35 parts of styrene maleic anhydride resin, 15-25 parts of trichloro-sym-diphenylurea, 15-25 parts of ethyl vanillin, 5-10 parts of zinc oxide, 5-10 parts of cross-linking agent and 5-10 parts of softening agent. The textile auxiliary containing the antibiotic constituents improves antibiotic effects of textile, and further has antifouling function. A corresponding preparation method is further disclosed.

Owner:WUJIANG FUHUIYUAN HOME TEXTILES CO LTD

TiCuAlCrMoNb high-entropy alloy and preparing method thereof

The invention provides a TiCuAlCrMoNb high-entropy alloy and a preparing method thereof. The component of the high-entropy alloy is TiaCubAlcCrdMoeNbf, wherein a, b, c, d, e and f separately represent the molar rate of each element, a is larger than or equal to 0.3 and smaller than or equal to 1.5, b is larger than or equal to 0.2 and smaller than or equal to 1.2, c is larger than or equal to 0.2 and smaller than or equal to 1.5, d is larger than or equal to 0.05 and smaller than or equal to 1.2, e is larger than or equal to 0 and smaller than or equal to 1.2, and f is larger than or equal to 0.05 and smaller than or equal to 1.2. Through a non-consumable vacuum electric arc melting technology or electromagnetic levitation melting technology, a high-entropy alloy material which is resistant to seawater corrosion and has a certain anti-fouling function is prepared, the microhardness of the high-entropy alloy material is not lower than 600HV, the defects of traditional high-entropy alloy are compensated, and the application requirements of further ship materials are met.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

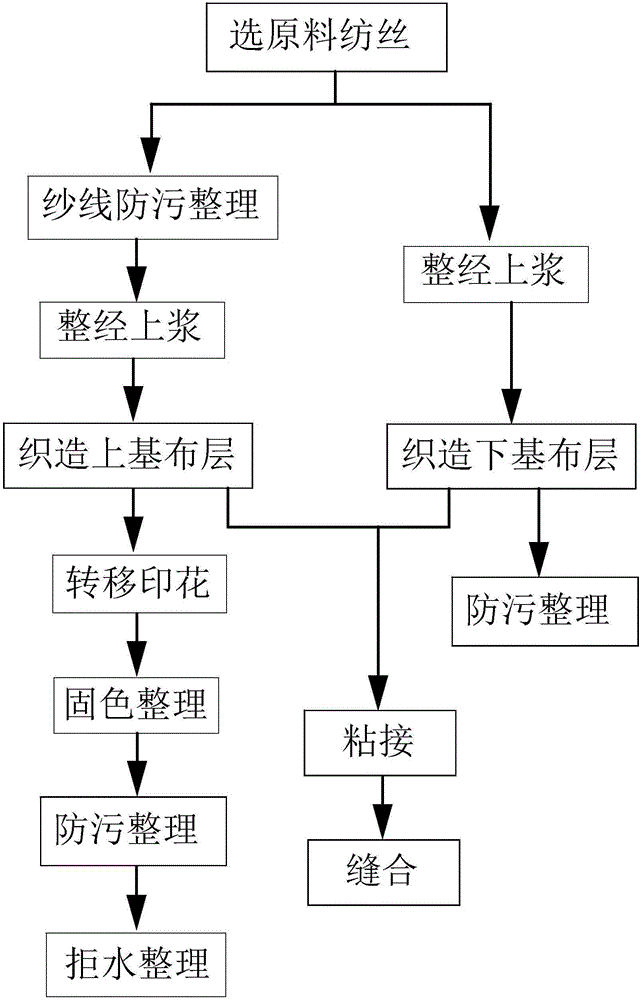

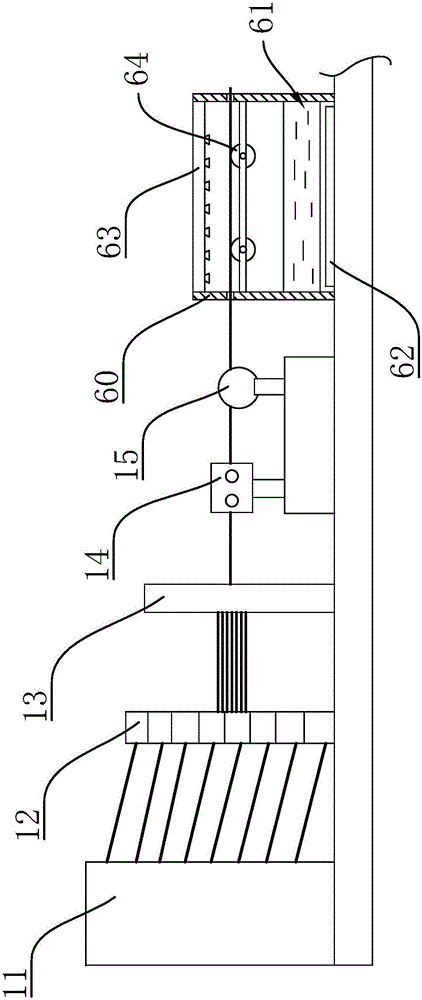

Production method of antifouling sofa fabric

ActiveCN106283340AIncrease sizing rateLess hairyTransfer printing processWarping machinesYarnAdhesive

The invention provides a production method of an antifouling sofa fabric, belonging to the technical field of home textiles. The production method comprises the following steps: (1) selecting raw materials and spinning; (2) performing anti-pollution finishing of yarns; (3) warping and sizing; (4) weaving: weaving an upper base cloth layer and a lower base cloth layer; (5) transferring and printing; (6) fixing color and finishing; (7) performing anti-pollution finishing; (8) conducting water repellent finishing; (9) adhering: coating adhesives on the upper side and the lower side of a sponge respectively, applying pressure to the upper base cloth layer, the sponge and the lower base cloth layer which are superposed vertically, so as to enable the three to be adhered as a whole; and (10) sewing. The yarns treated by a warping and sizing machine are high in sizing rate, and fewer in feathers, so that static electricity generated due to friction among yarns can be reduced, the static electricity of the fabric can be effectively reduced, and the woven fabric is difficult to generate static electricity, thus being relatively difficult to adsorb dust; and the sofa fabric produced by utilizing the method has multiple antifouling capabilities, and has obvious antifouling effect.

Owner:海宁宝祥布业有限公司

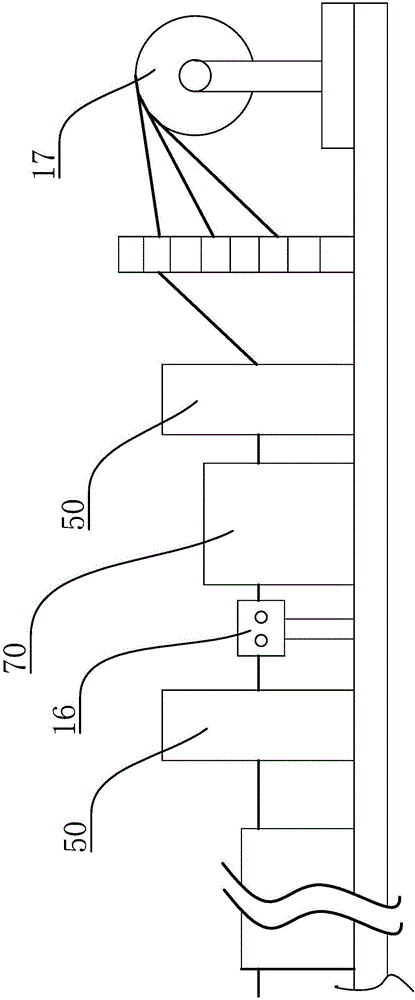

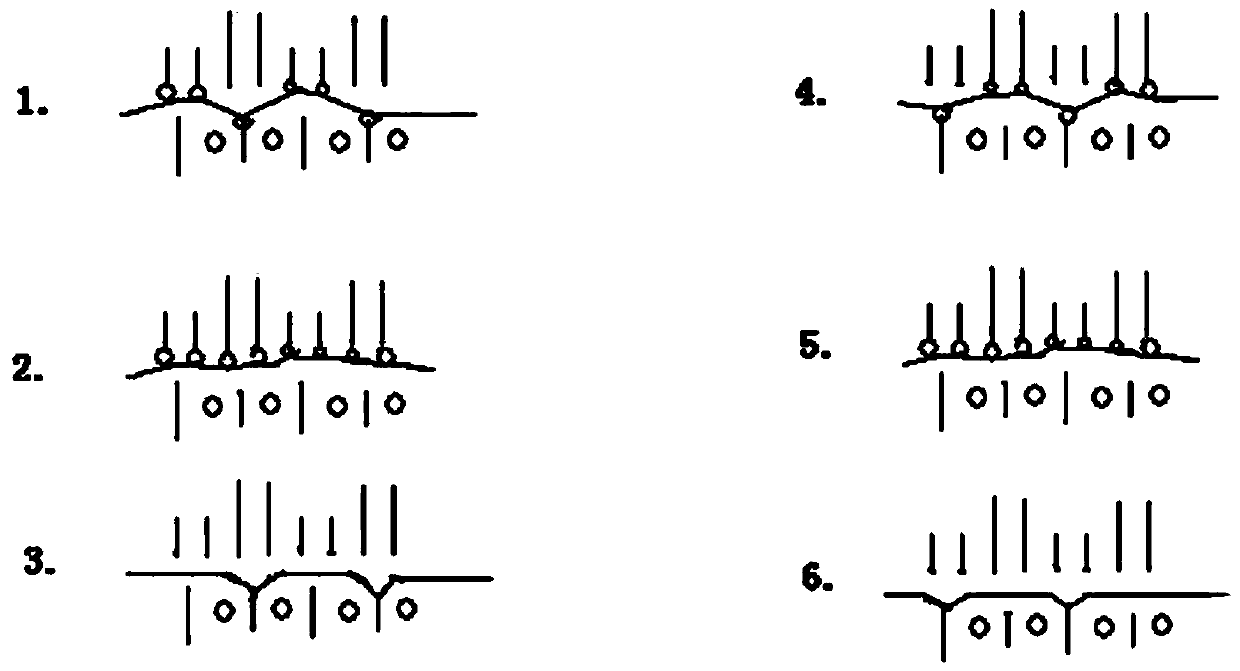

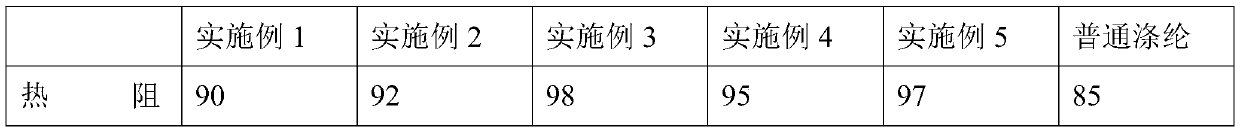

Spinning process of polyester fleece knitted fabric

The invention provides a spinning process of polyester fleece knitted fabric. The spinning process mainly uses polyester filaments and polyester staple fibers as the raw materials to prepare the weft-knitted fabric. The spinning process includes: preprocessing gray fabric; dyeing and printing; softening and pre-forming; napping; carding; shearing; turning naps into granular naps; performing kinetic energy finishing; performing finished-product forming. The polyester fleece knitted fabric spun by the spinning process is soft and fluffy in touch, breathable and warm-keeping, less prone to pilling and fading, excellent in water resistance, oil resistance and fouling resistance and durable in flame retardance and can still have excellent three proofing and flame retardance after being washed at normal temperature.

Owner:森宝(福建)纺织科技发展有限公司

High-entropy TiCuAlCrMoNi alloy and preparation method thereof

The invention discloses high-entropy TiCuAlCrMoNi alloy and a preparation method thereof. The high-entropy alloy is composed of TiaCubAlcCrdMoeNif, wherein a, b, c, d, e and f represent molar ratios of corresponding elements, a is greater than or equal to 0.3 but smaller than or equal to 1.5, b is greater than or equal to 0.2 but smaller than or equal to 1.2, c is greater than or equal to 0.2 but smaller than or equal to 1.5, d is greater than or equal to 0.05 but smaller than or equal to 1.2, e is greater than or equal to 0 but smaller than or equal to 1.2 and f is greater than or equal to 0.05 but smaller than or equal to 1.2. The high-entropy alloy with the microhardness not lower than 550 HV, with the seawater corrosion resistance and with the antifouling function can be prepared through the non-consumable vacuum arc smelting technology or the electromagnetic suspension smelting technology, the shortcomings of traditional high-entropy alloy can be overcome, and the application requirements of ship materials in future can be met.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Anti-glare screen protection film

InactiveCN103507357AEasy to installQuick and automatic exclusionSynthetic resin layered productsVisibilityLiquid-crystal display

The invention discloses an anti-glare screen protection film. The main structure of the anti-glare screen protection film comprises a main film, a mounting adhesive layer, a mounting adhesive protection film, an anti-glare scratch-resistant layer, a protection film adhesive layer and a scratch-resistant layer protection film, wherein the three layers of the main film, the three layers of the mounting adhesive protection film and the scratch-resistant layer protection film are film structures of polyethylene terephthalate (PET) material, and the three layers of the mounting adhesive layer, the anti-glare scratch-resistant layer and the protection film adhesive layer are adhesive structures with different properties. The invention also discloses a making method of the anti-glare screen protection film. The anti-glare screen protection film provided by the invention is easy to mount, and capable of quickly and automatically removing bubbles; no adhesive residue is left on the screen surface after the anti-glare screen protection film is removed; the anti-glare screen protection film can be repeatedly sticked and used after being removed from the screen; the anti-glare screen protection film has the functions of scratch resistance, excellent abradability, stain repellence and the like, and can effectively eliminate reflected light and strong glare in a situation that an extreme brightness contrast exists at a time or in a space so as to cause visual sense uncomfortableness and object visibility reduction; in addition, the anti-glare screen protection film has the characteristics of high fashion property, capability of strengthening liquid crystal picture stereo feeling and making the color more plentiful, and the like, and can be widely applied to screen protection of various liquid crystal display screens. The making method of the anti-glare screen protection film provided by the invention is simple, easy to operate and suitable for industrial production.

Owner:SUZHOU XILIN OPTOELECTRONICS TECH IND

Electromagnetic wave shielding protective film and manufacturing method thereof

InactiveCN102152535AEasy to installQuick and automatic exclusionSynthetic resin layered productsMetal layered productsTectorial membraneInfrared

The invention discloses an electromagnetic wave shielding protective film. The protective film mainly comprises a main film, a composite glue layer, a metal nano layer, a composite PET (polyethylene terephthalate) film, an assembly glue layer, an assembly glue protective film, a scratch-resistant layer, a protective film glue layer and a scratch-resistant layer protective film. The protective film has the following advantages: the protective film is easy to assemble; the bubbles can be rapidly and automatically eliminated; the screen surface is free of residual glue after the protective film is removed; the protective film can be repeatedly pasted and used after being removed from the screen and has the functions of resisting scratch, resisting wear and preventing fouling; and due to addition of the metal nano layer, the screen protective film can shield the electromagnetic waves harmful to the human bodies, has the capabilities of eliminating the static electricity, reflecting infrared rays and ultraviolet rays and can be widely used for protecting the screens of various liquid crystal displays. A manufacturing method of the screen protective film is simple, easy to operate and suitable for industrial production.

Owner:SUZHOU XILIN OPTOELECTRONICS TECH IND

Flash scratchproof protection film and preparation method thereof

InactiveCN102390155ATransparent and brightStrong sense of fashionLiquid surface applicatorsSynthetic resin layered productsPolyethylene terephthalatePolyethylene terephthalate glycol

The invention discloses a flash scratchproof protection film, which comprises a scratchproof layer protection film PET (polyethylene terephthalate) substrate, a protection film glue layer, a scratchproof layer, a composite main film PET substrate, an installing glue layer and an installing flue protection film PET substrate, wherein at least one of scratchproof layer, the composite main film PET substrate and the installing glue layer contains flash powder, or a color transparent material or a mixture containing the flash powder and the color transparent material. According to the protection film, because at least one of the scratchproof layer, the composite main film PET substrate or the installing flue layer is the flash layer or the color transparent layer or the color flash layer, the whole protection film has the characteristics of multiple colors and flashing, transparent brightness, strong fashion sense and the like; the flash scratchproof protection film can be widely used for various liquid crystal displays or automobile protection films and satisfies fashion pursuing trends of young people; and a preparation method of the flash scratchproof protection film is simple and easy to operate and is suitable for industrial production.

Owner:SUZHOU XILIN OPTOELECTRONICS TECH IND

Common anti-scratch protective membrane and manufacturing method thereof

InactiveCN102152569AEasy to installEasy to prepareSynthetic resin layered productsLiquid-crystal displayPolyethylene terephthalate

The invention discloses a common anti-scratch protective membrane. The main structure of the membrane comprises a main membrane, a mounting glue layer, a mounting glue protective membrane, an anti-scratch layer, a protective membrane glue layer and an anti-scratch layer protective membrane, wherein the main membrane, the mounting glue protective membrane and the anti-scratch layer protective membrane are polyethylene terephthalate (PET) membranes; and the mounting glue layer, the anti-scratch layer and the protective membrane glue layer are glue structures with different properties. The invention also discloses a manufacturing method for the common anti-scratch protective membrane. The common anti-scratch protective membrane can be arranged easily, air bubbles can be removed quickly and automatically, no glue is resided after the screen is removed, and the membrane can be recycled after the screen is removed; besides, the membrane has the functions of scratch resistance, high wear resistance, fouling resistance and the like and can be widely applied to screen protection of various liquid crystal displays. The manufacturing method for the common anti-scratch protective membrane is simple, convenient to operate and suitable for industrial protection.

Owner:SUZHOU XILIN OPTOELECTRONICS TECH IND

Superbright high-definition protective film with self luminescence under sunlight or ultraviolet light and manufacturing method thereof

InactiveCN102320174ASelf-luminousWith super bright HDSynthetic resin layered productsUltraviolet lightsLuminescence

The invention discloses a superbright high-definition protective film with self luminescence under sunlight or ultraviolet light which comprises: a scraping-resistant layer protective film PET substrate, a protective film glue layer, a scraping-resistant layer, a composite main film PET substrate, an installing glue layer, and an installing glue protective film PET substrate; wherein at least one layer of the scraping-resistant layer, the composite main film PET substrate, and the installing glue layer comprises fluorescent pigment or phosphor. According to the protective film of the invention, because at least one layer of the scraping-resistant layer, the composite main film PET substrate, and the installing glue layer comprises fluorescent pigment or phosphor, the whole protective film has the characteristics of self luminescence under sunlight or ultraviolet light, superbrightness, and high definition, is widely applicable to screen protective films of various liquid crystal display screens, and meets the trend of fashion pursuit for young people.

Owner:SUZHOU XILIN OPTOELECTRONICS TECH IND

Scratch-resistant color screen protective film and manufacturing method thereof

InactiveCN102152572AEasy to installFast automatic exhaustSynthetic resin layered productsLiquid-crystal displayOrganic dye

The invention discloses a scratch-resistant color screen protective film. The protective film mainly comprises a main film, an assembly glue layer, an assembly glue protective film, a scratch-resistant layer with colors, a protective film glue layer and a scratch-resistant layer protective film. The protective film has the following advantages: the protective film is easy to assemble; the bubbles can be rapidly and automatically eliminated; the screen surface is free of residual glue after the protective film is removed; the protective film can be repeatedly pasted and used after being removed from the screen and has the functions of resisting scratch, resisting wear and preventing fouling; and as different colors of organic dyes and other dispersing aids are added to the scratch-resistant layer, the whole protective film has the characteristics of transparent and bright colors, strong fashion sense and the like after uniform dispersion and can be widely used for protecting the screens of various liquid crystal displays. The manufacturing method of the scratch-resistant color screen protective film is simple, easy to operate and suitable for industrial production.

Owner:SUZHOU XILIN OPTOELECTRONICS TECH IND

Color screen protective film and manufacturing method thereof

InactiveCN102152570AEasy to installEasy to prepareSynthetic resin layered productsTectorial membranePolyethylene terephthalate

The invention discloses a color screen protective film. The color screen protective film mainly comprises a main film, a color composite glue layer, a composite PET (polyethylene terephthalate) film, an assembly glue layer, an assembly glue protective film, a scratch-resistant layer, a protective film glue layer and a scratch-resistant layer protective film, wherein the main film, the assembly glue protective film, the composite PET film and the scratch-resistant layer protective film are of film structure made of PET materials; and the assembly glue layer, the color composite glue layer, the scratch-resistant layer and the protective film glue layer are of glue structure with different properties. The invention also discloses a manufacturing method of the color screen protective film. The color screen protective film has the following advantages: the protective film is easy to assemble; the bubbles can be rapidly and automatically eliminated; the screen surface is free of residual glue after the protective film is removed; the protective film can be repeatedly pasted and used after being removed from the screen and has the functions of resisting scratch, resisting wear and preventing fouling; and as different colors of organic dyes and other dispersing aids are added to the polyurethane resins, the whole protective film has different colors after uniform dispersion. The manufacturing method of the screen protective film is simple, easy to operate and suitable for industrial production.

Owner:SUZHOU XILIN OPTOELECTRONICS TECH IND

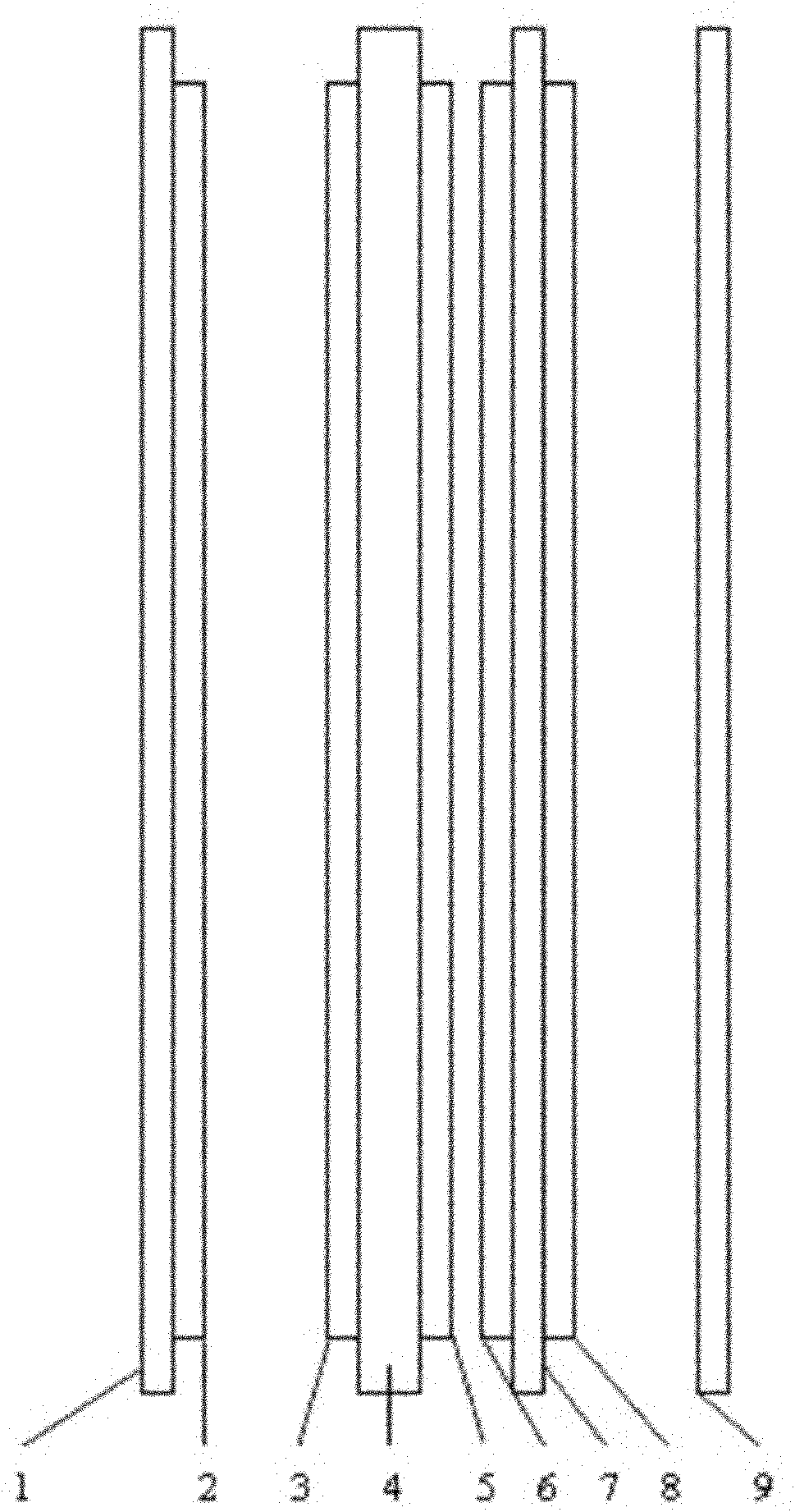

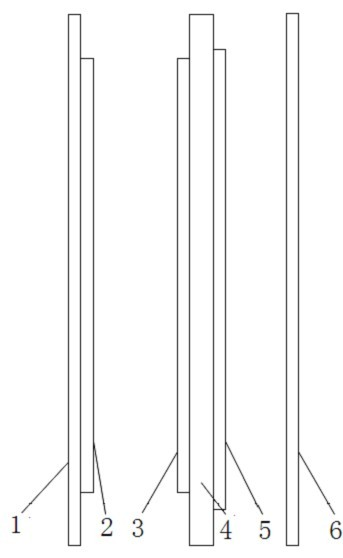

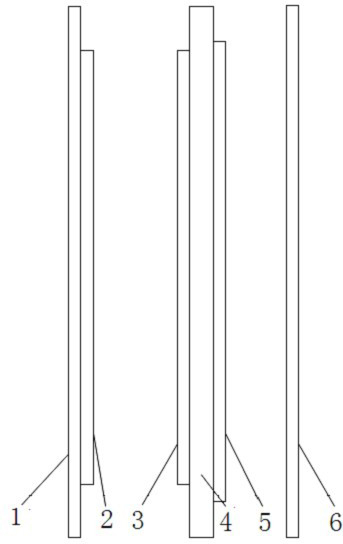

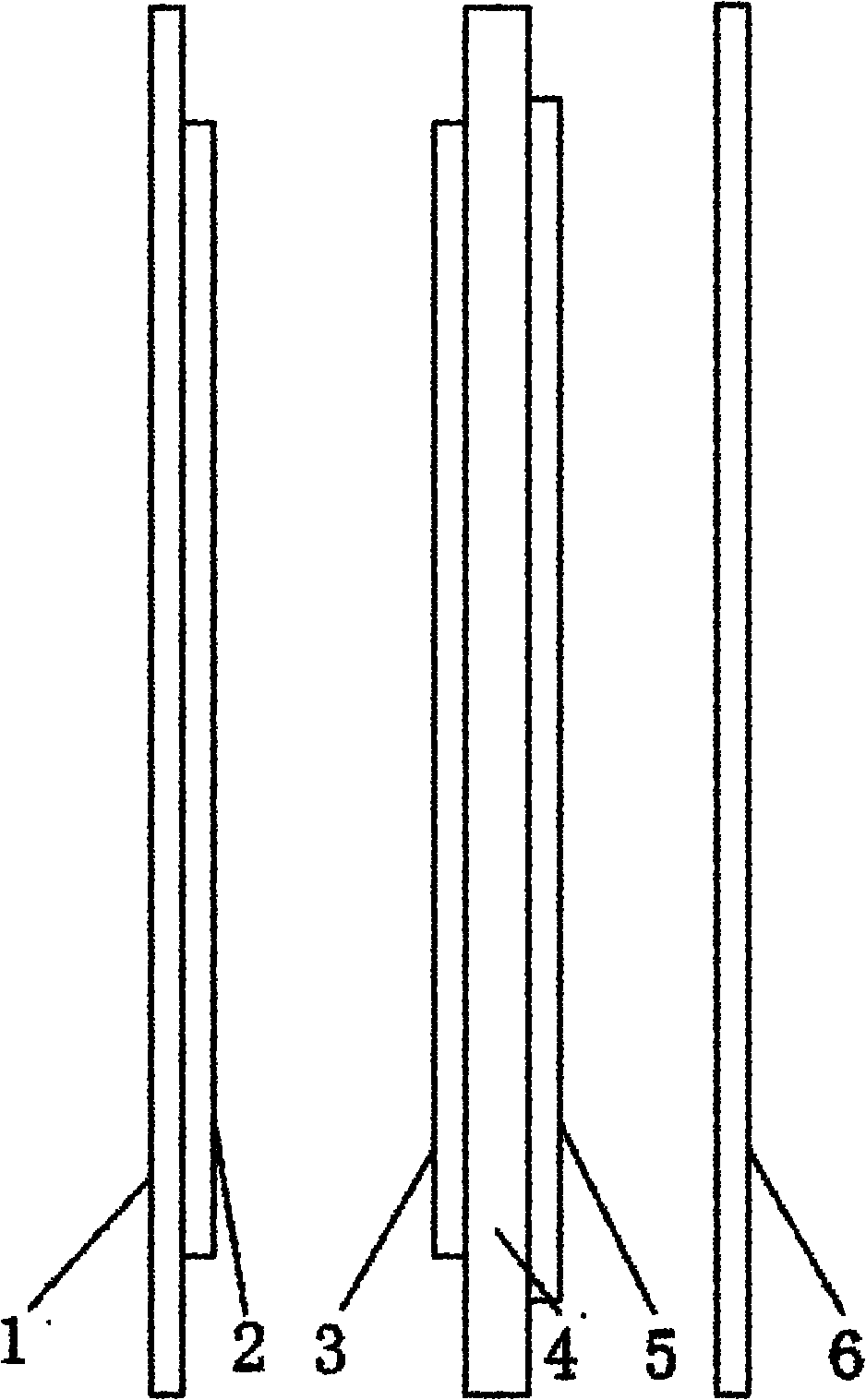

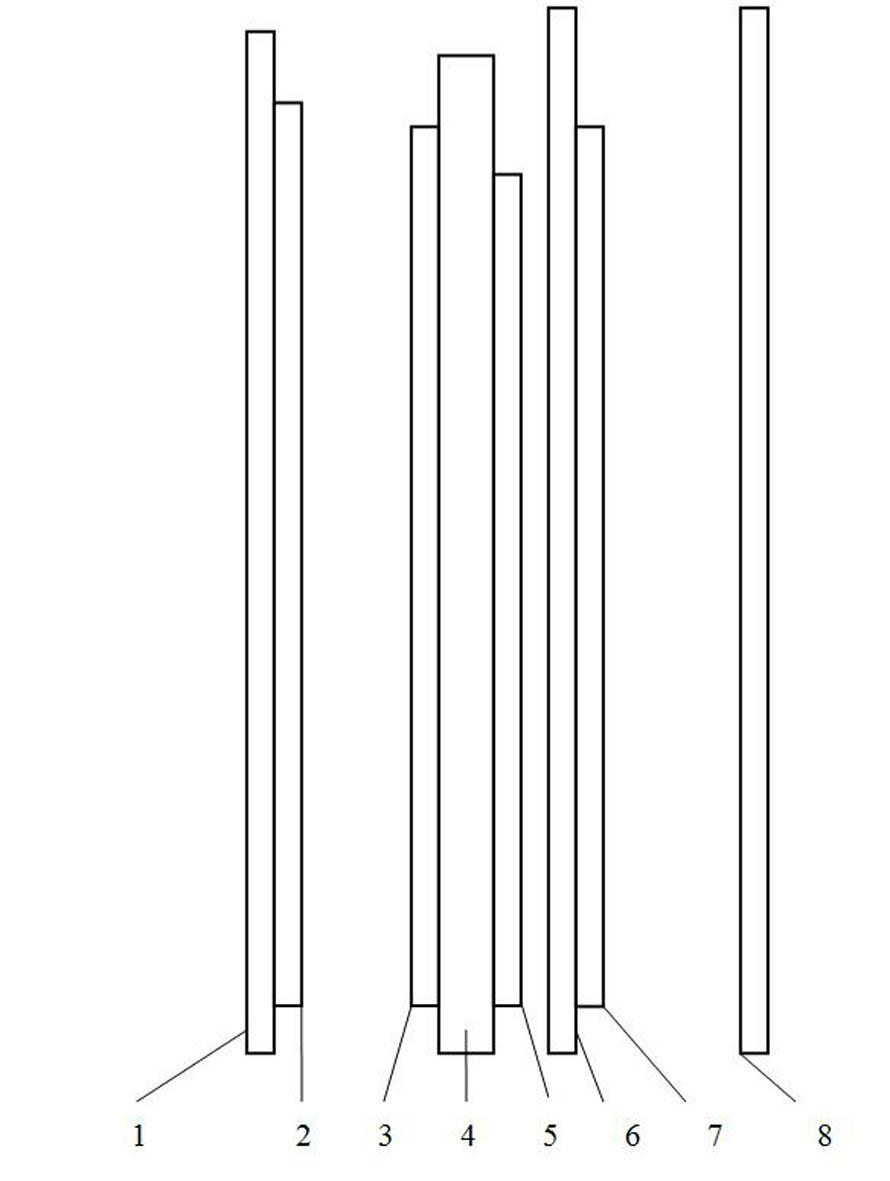

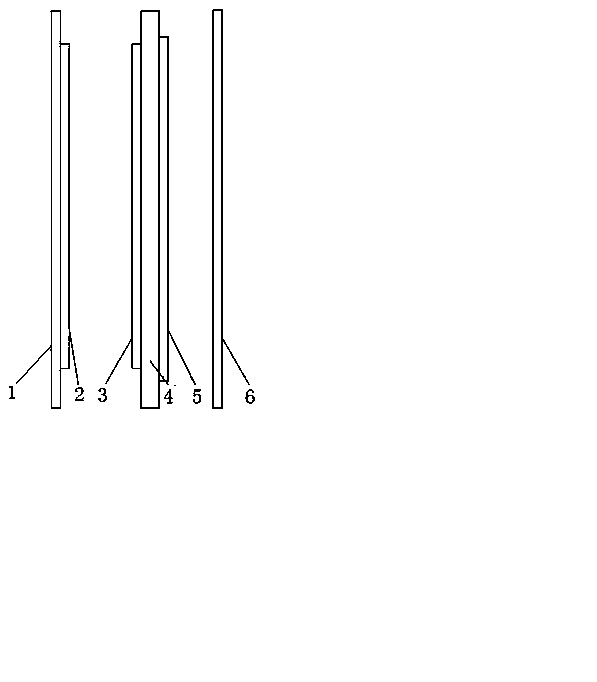

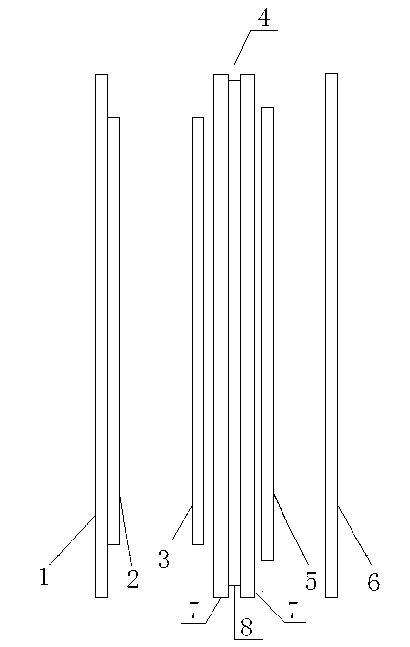

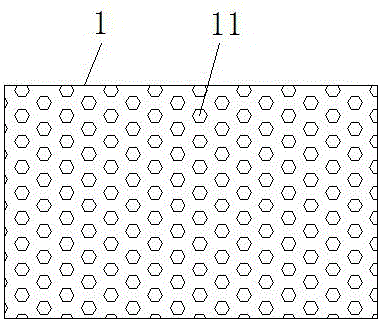

Anti-counterfeiting braided fabric pillowcase fabric with antifouling function

InactiveCN106313751AAntifoulingWith anti-fouling functionLayered productsCoatingsAntibiosisEngineering

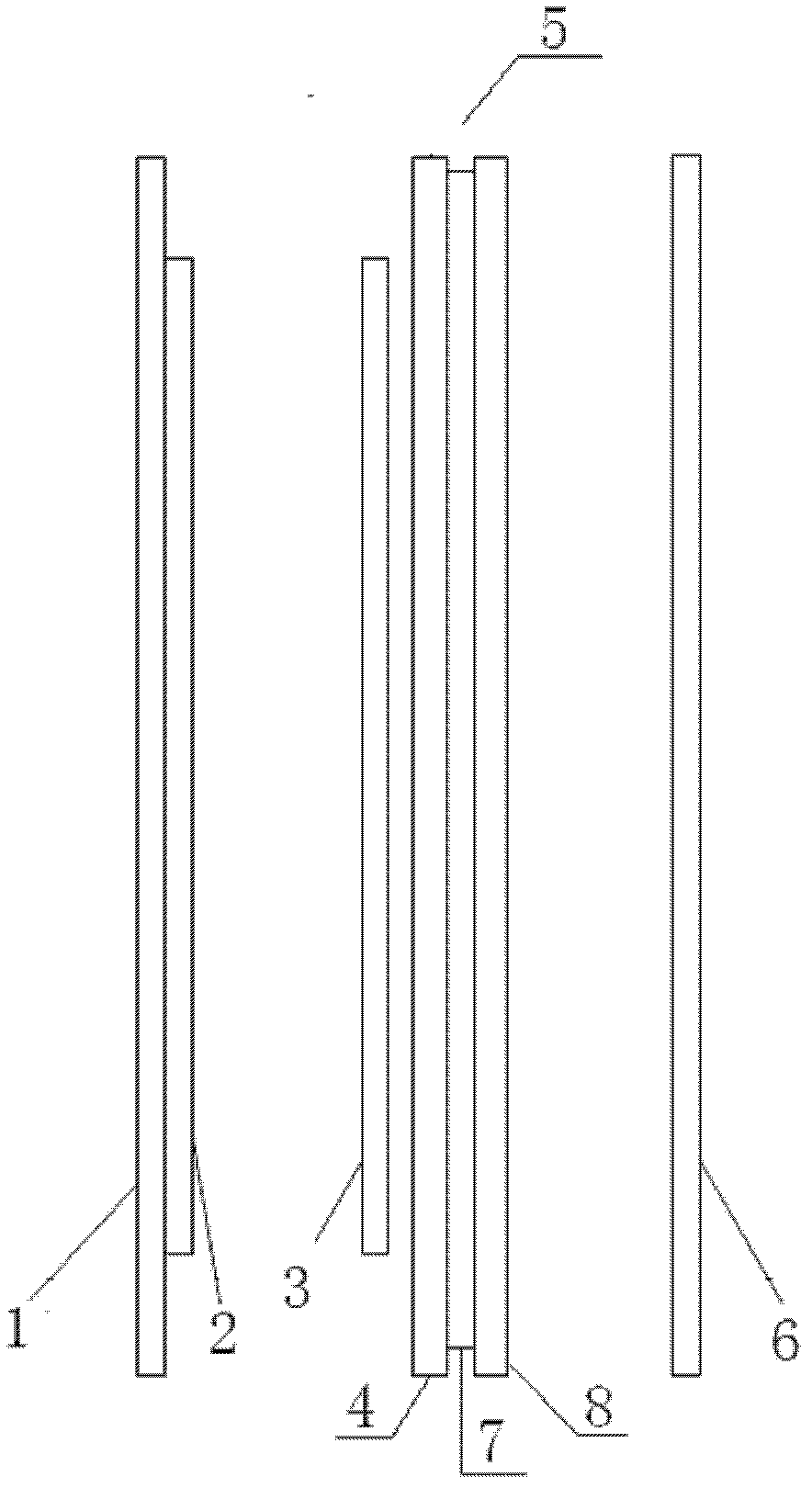

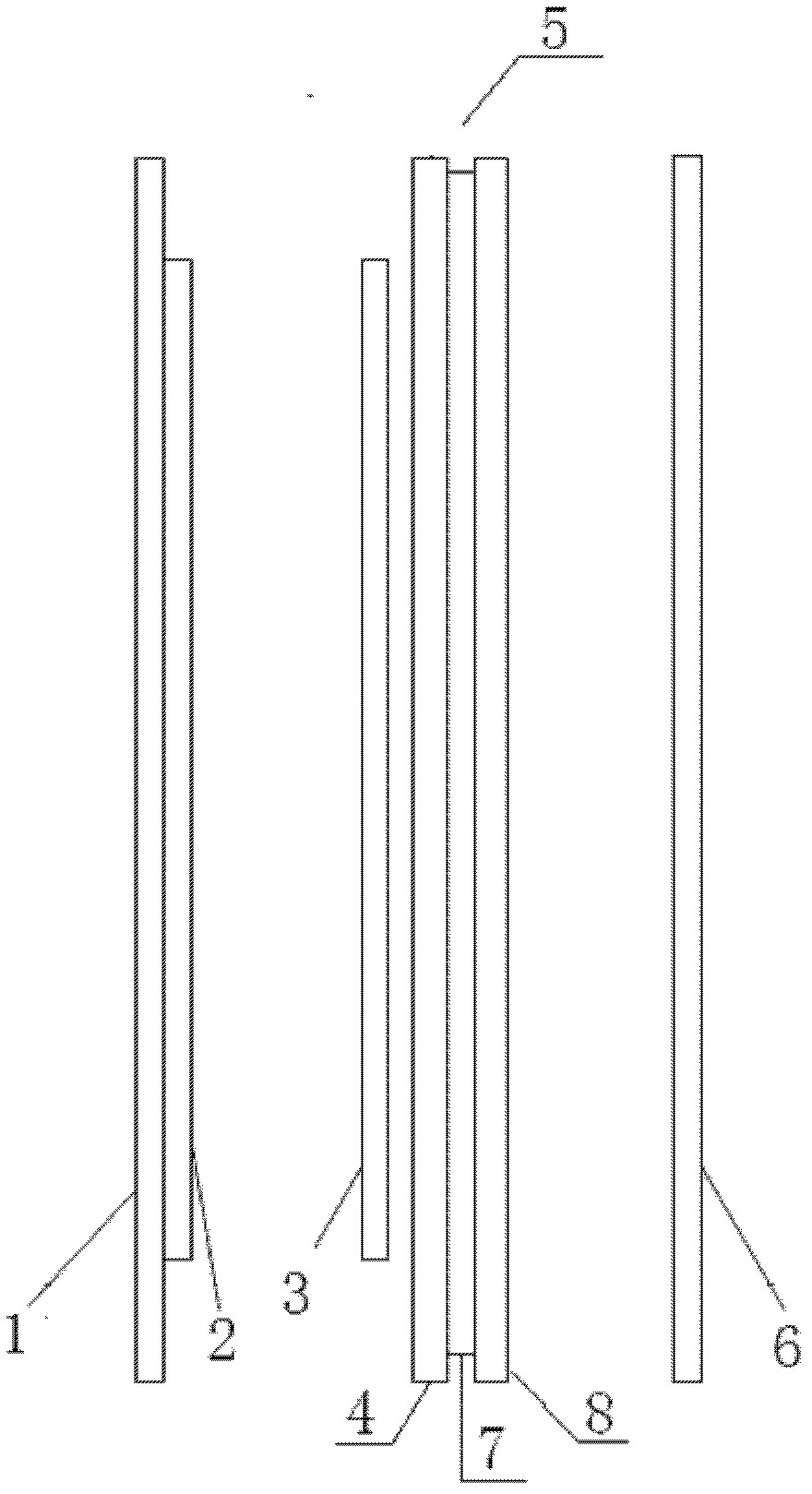

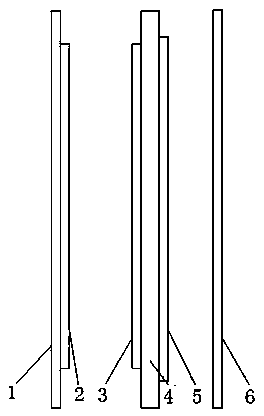

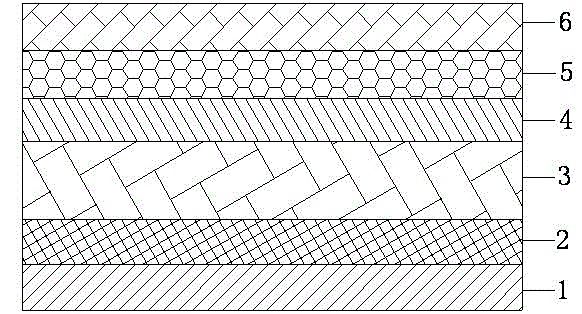

The invention relates to an anti-counterfeiting braided fabric pillowcase fabric with an antifouling function. The fabric comprises a fabric body (1), the upper surface of the fabric body is covered with an air permeable layer (2), the upper surface of the air permeable layer is covered with a waterproof layer (3), the upper surface of the waterproof layer is covered with an antibiosis layer (4), the upper surface of the antibiosis layer is covered with a polyurethane coating layer (5), the polyurethane coating layer is fluorine monomer aqueous polyurethane, and the upper surface of the polyurethane coating layer is covered with a flocked layer (6). The fabric body is made of textile, and the textile comprises a braided fabric and one or more braided filaments printed with anti-counterfeiting labels, braided in the braided fabric production process. The anti-counterfeiting braided fabric pillowcase fabric has waterproof and air permeable effects and good hand feeling, and can effectively prevent others from counterfeiting.

Owner:陈国银

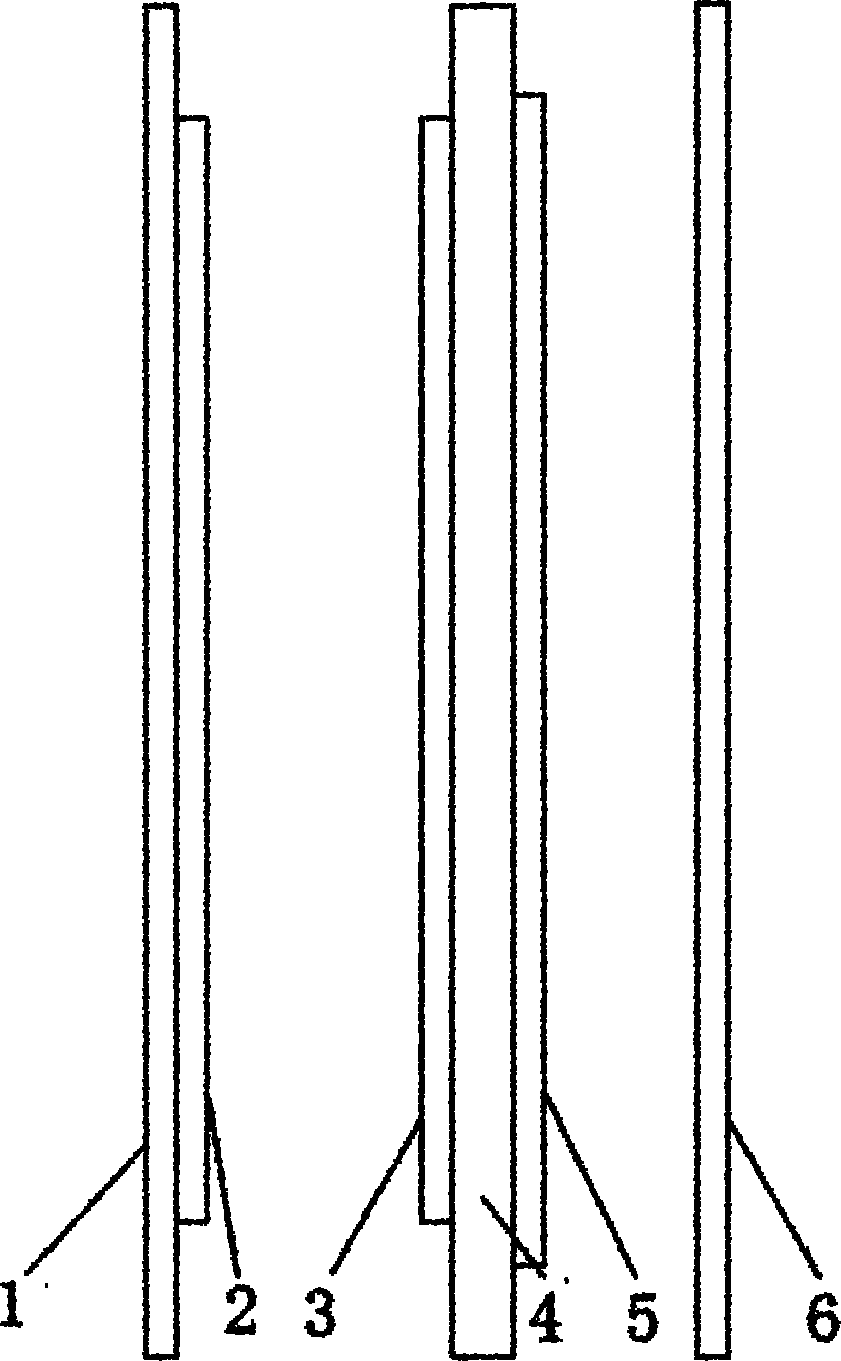

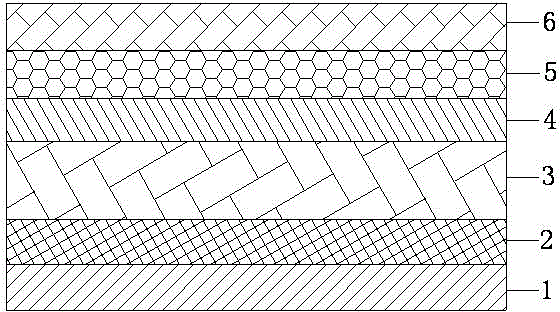

Wear-resisting and washable pillowcase fabric with antifouling function

InactiveCN104856522AReflect the three-dimensional senseImprove wear resistancePillowsSynthetic resin layered productsPolyesterPlain weave

The invention relates to wear-resisting and washable pillowcase fabric with an antifouling function. The fabric comprises a fabric body (1), wherein the upper side of the fabric body is covered with a breathable layer (2), the upper side of the breathable layer is covered with a waterproof layer (3), the upper side of the waterproof layer is covered with an anti-microbial layer (4), the upper side of the anti-microbial layer is covered with a polyurethane coating layer (5), the polyurethane coating layer is fluorine monomer waterborne polyurethane, and the upper side of the polyurethane coating layer is covered with a flocking layer (6); the fabric body is made of textile fabric, the textile fabric comprises warps and wefts, the warps and wefts are interwoven up and down to form a grid structure which is of plain weave or twill weave, and multiple high-gloss polyester yarns parallel to the wefts are arranged in the direction of the warps at intervals. The fabric is resistant to water, high in breathability, good in hand feeling, high in wear resistance, more washable and not prone to fading, and is suitable for making ties or clothes. By means light refraction in multiple directions, the stereoscopic impression of the fabric is reflected.

Owner:JIANGYIN FANRONG YARN DYE FABRIC

Scratch-resistant stain-repellent solar heat insulation membrane

InactiveCN103507370AWith anti-fouling functionEasy to prepareSynthetic resin layered productsArchitectural glassPolyurethane adhesive

The invention discloses a scratch-resistant stain-repellent solar heat insulation membrane. The main structure of the scratch-resistant stain-repellent solar heat insulation membrane comprises a scratch-resistant stain-repellent layer, a first optical thin film layer, a polyurethane adhesive layer, an ultraviolet infrared ray isolated strengthening layer, a metal or metal oxide layer, a second optical thin film layer, a mounting adhesive layer and a release film. The invention also discloses a making method of the scratch-resistant stain-repellent solar heat insulation membrane. The scratch-resistant stain-repellent solar heat insulation membrane provided by the invention is easy to mount, no adhesive residue is left on a screen surface after the scratch-resistant stain-repellent solar heat insulation membrane is removed, and the scratch-resistant stain-repellent solar heat insulation membrane has the functions of scratching resistance, excellent abradability, stain repellence and the like, and can be widely applied to installation and use of automobile glass and construction glass. The making method of the scratch-resistant stain-repellent solar heat insulation membrane provided by the invention is simple, is easy to operate and suitable for industrial production.

Owner:SUZHOU XILIN OPTOELECTRONICS TECH IND

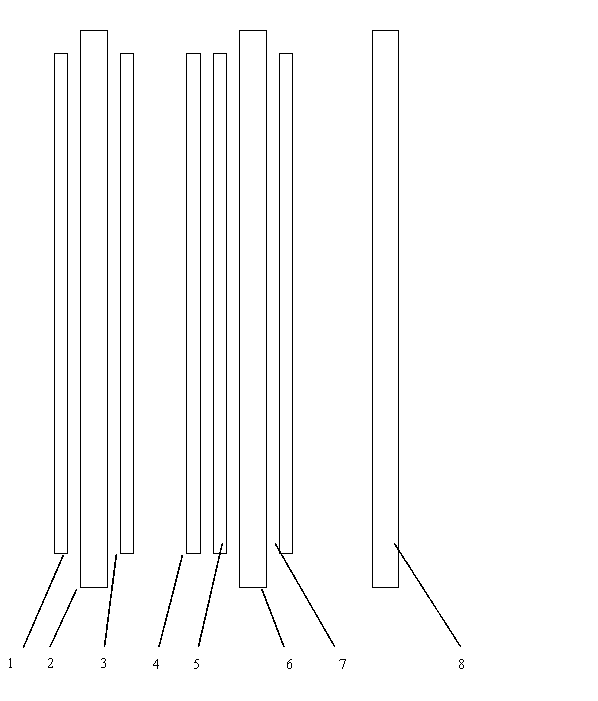

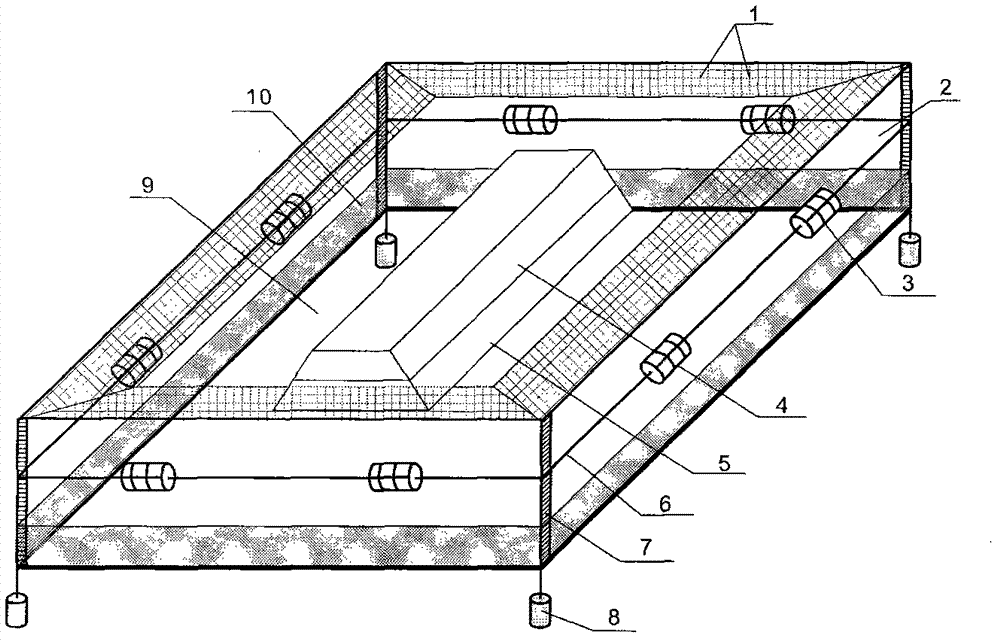

Antifouling and anti-biting cultivation net cage of huangsha (Chinese character) turtle

InactiveCN102763622AEnsure safetyWith anti-fouling functionAnimal husbandryIsosceles trapezoidChinese characters

The invention discloses an antifouling and anti-biting cultivation cage of a huangsha (Chinese character) turtle. The antifouling and anti-biting cultivation net cage comprises a cage body top part, cage sides and a cage bottom. The antifouling and anti-biting cultivation cage is characterized in that the top part of the cage body adopts an anti-biting small-screen ultra-high molecular weight polyethylene net to be sutured into an annular net; the cage side adopts a combined net formed by a copper alloy woven mesh, a netting half-soft state connection, the copper alloy woven mesh, the nettinghalf-soft state connection, the copper alloy woven mesh, the netting half-soft state connection, the copper alloy woven mesh, the netting half-soft state connection and a nylon mesh; a foam floater is arranged on an upper middle line of the copper alloy woven mesh as a buoyancy system; the cage bottom adopts the combined netting of a nylon woven mesh and the copper alloy woven mesh; a cylindricalheavy block is respectively suspended at four corners of the box body for the cage; a back sunning table is arranged inside the cage; the cross section of the back sunning table is an isosceles trapezoid; the distance from an upper bottom to a lower bottom of the isosceles trapezoid is 30cm; and the part of the back sunning table, in the water, is 16-20cm in vertical height, and the cage is fastened on a fixed parking system of an aquaculture area by a connection rope.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI +1

Colorful scratch-resistant screen protection film and its producing method

InactiveCN103507359AEasy to installFast automatic exhaustLiquid surface applicatorsSynthetic resin layered productsTectorial membraneLiquid-crystal display

The invention discloses a colorful scratch-resistant screen protection film. The main structure of the colorful scratch-resistant screen protection film comprises a colorful main film, a mounting adhesive layer, a mounting adhesive protection film, a scratch-resistant layer, a protection film adhesive layer and a scratch-resistant layer protection film. The colorful scratch-resistant screen protection film provided by the invention is easy to mount, and capable of quickly and automatically removing bubbles; no adhesive residue is left on the screen surface after the colorful scratch-resistant screen protection film is removed; the colorful scratch-resistant screen protection film can be repeatedly sticked and used after being removed from the screen; the colorful scratch-resistant screen protection film has the functions of scratch resistance, excellent abradability, stain repellence and the like; in addition, because the used colorful main film is a colorful base film, and at least one of the scratch-resistant layer or the mounting adhesive layer is a colored layer, the colorful scratch-resistant screen protection film has the characteristics of gorgeous colors, transparentness and brightness, high fashion property, and the like, and can be widely applied to screen protection of various liquid crystal display screens. A producing method of the colorful scratch-resistant screen protection film provided by the invention is simple, easy to operate and suitable for industrial production.

Owner:SUZHOU XILIN OPTOELECTRONICS TECH IND

Anti-static PET (Polyethylene Terephthalate) material membrane as well as preparation method and application thereof

InactiveCN103264554AReduce harmPermanent antistaticSynthetic resin layered productsLaminationTectorial membranePolyethylene terephthalate

The invention discloses an anti-static PET (Polyethylene Terephthalate) material membrane as well as a preparation method and an application thereof. According to the anti-static PET material membrane, the anti-static property is achieved by adding conductive polymers into at least one of a scrap resisting layer, a composite adhesive layer or an installing adhesive layer. The anti-static PET material membrane disclosed by the invention can be widely used for preparing products such as screen protective membranes, solar isolating membranes, IMD ((In-mold Decoration) and wall membranes, the products have the permanent anti-static property, the anti-static property is not weakened or even vanished because of environment change, and the products are free of static electricity and do not absorb dust, so that the membrane can be widely applied to various protective membrane products which have rigorous demands on static electricity generation.

Owner:SUZHOU XILIN OPTOELECTRONICS TECH IND

Colored diamond scratch-resistant protective film and manufacturing method thereof

InactiveCN102582179AStrong sense of fashionSatisfy the fashion trendSynthetic resin layered productsNatural mineral layered productsCompound aTectorial membrane

The invention discloses a colored diamond scratch-resistant protective film which comprises a scratch-resistant layer protective film PET (Polyethylene Terephthalate) base material layer, a protective film adhesive layer, a scratch-resistant layer, a mounting adhesive layer and a mounting adhesive protective film PET base material layer, wherein the mounting adhesive layer is formed by compounding a main film PET base material layer, a colored diamond silica gel pre-coating layer coated on the main film PET base material layer and a silica gel layer; transparent or colored diamond powder is contained in the colored diamond silica gel pre-coating layer; the mounting adhesive protective film PET base material layer is compounded with the silica gel layer; the main film PET base material layer is compounded with the scratch-resistant layer; the scratch-resistant layer protective film PET base material layer is compounded with the protective film adhesive layer; and the protective film adhesive layer is compounded with the scratch-resistant layer. The protective film disclosed by the invention has the advantages that as the transparent or colored diamond powder is contained in the mounting adhesive layer, the whole protective film has the characteristics of colored diamond, transparence and brightness, strong fashion sense and the like; and the colored diamond scratch-resistant protective film can be widely applied to protective films of various liquid crystal display screens or automobiles, so that the trend that youths pursue the fashion is satisfied.

Owner:SUZHOU XILIN OPTOELECTRONICS TECH IND

High molecular synthetic material surface hardening technology

The invention provides a high molecular synthetic material surface hardening technology. The high molecular synthetic material surface hardening technology is characterized by comprising the steps that 1, synthetic material surface pretreatment, wherein a UV coating is sprayed to a hardening surfaces of materials by using a UV spraying line, and hardening is conducted through ultraviolet irradiation; 2, ion surface treatment, wherein ionic materials are fixed to a fixture and then put into vacuum cleaning equipment, ionic equipment is used for generating discharging ions, and ionic bombardment is conducted on the UV coating; and surface cleaning is conducted to remove stress between the materials with different properties; 3, optical dielectric thin film hardening, wherein heating is conducted on optical dielectric materials by high-power electron beams generated by an electronic gun in a vacuum environment, and the materials are melted and evaporated to be attached to the surface of the materials to form thin films; 4, stress relieving, wherein bombardment treatment is conducted on dielectric films by using ion source equipment for one minute; and 5, surface anti-fouling protection layer manufacturing, wherein a layer of anti-fouling material is formed on the surface of the materials through evaporation by using resistant heating and prevention evaporating in vacuum. By means of the high molecular synthetic material surface hardening technology, the surface hardness of the high molecular synthetic material can be greatly improved.

Owner:苏盛纳米涂层科技(苏州)有限公司

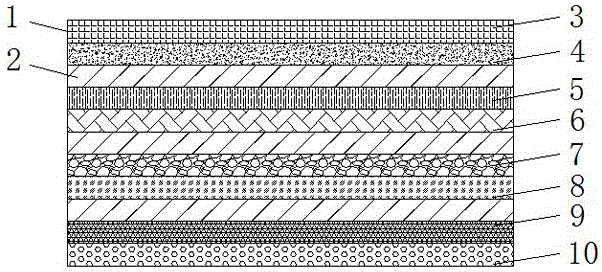

Waterproof fabric for waterproof socks

The invention discloses a waterproof fabric for waterproof socks. The waterproof fabric comprises a fabric main body, wherein the fabric main body consists of an antifouling layer, a wearing layer, a waterproof layer, an insulating layer, an adsorption layer, an absorbent wool layer, a fabric basic layer and a transparent layer; the lower surface of the antifouling layer is provided with the wearing layer; the lower surface of the wearing layer is connected with the waterproof layer by virtue of a hot melting glue layer; the lower surface of the waterproof layer is provided with the insulating layer; the lower surface of the insulating layer is connected with the adsorption layer by virtue of a hot melting glue layer; the lower surface of the adsorption layer is provided with the absorbent wool layer; the lower surface of the absorbent wool layer is connected with the fabric basic layer by virtue of a hot melting glue layer; the lower surface of the fabric basic layer is provided with the transparent layer. By virtue of the transparent layer, the abrasive resistance is favorable; by virtue of arranging the transparent layer, the air permeability is favorable; by virtue of arranging the waterproof layer and the insulating layer, the waterproof fabric has multiple functions of water proofness, insulation and the like, the waterproof effect is ensured, the service life is prolonged, and the production procedure is simplified.

Owner:HAINING YATAI CHEM FIBER

Method for preparing insect bite-prevention antibacterial fiber board

InactiveCN108930191AAnti-mold and sterilizingMoth proofFibreboardVegetable material additionFiberSlurry

Owner:HEFEI HUAGAI PHOTOVOLTIAC TECH CO LTD

Static-free screen protection film and its making method

InactiveCN103507352AReduce harmQuick exclusionSynthetic resin layered productsLaminationPolymer sciencePolyethylene terephthalate

The invention discloses a static-free screen protection film which comprises a scratch resistant layer protection film PET (polyethylene terephthalate) substrate, a protection film adhesive layer, a scratch resistant layer, a composite main film PET substrate, a mounting adhesive layer and a mounting adhesive protection film PET substrate; wherein at least one layer of the mounting adhesive, the composite main film PET substrate layer and the mounting adhesive layer comprises an anionic surfactant. Because at least one layer of the mounting adhesive, the composite main film PET substrate layer or the mounting adhesive layer comprises the anionic surfactant, the static-free screen protection film generates no static, may not adsorb dust, can be widely used as screen protection films of various liquid crystal display screens, and reduces the harm to the human body.

Owner:SUZHOU XILIN OPTOELECTRONICS TECH IND

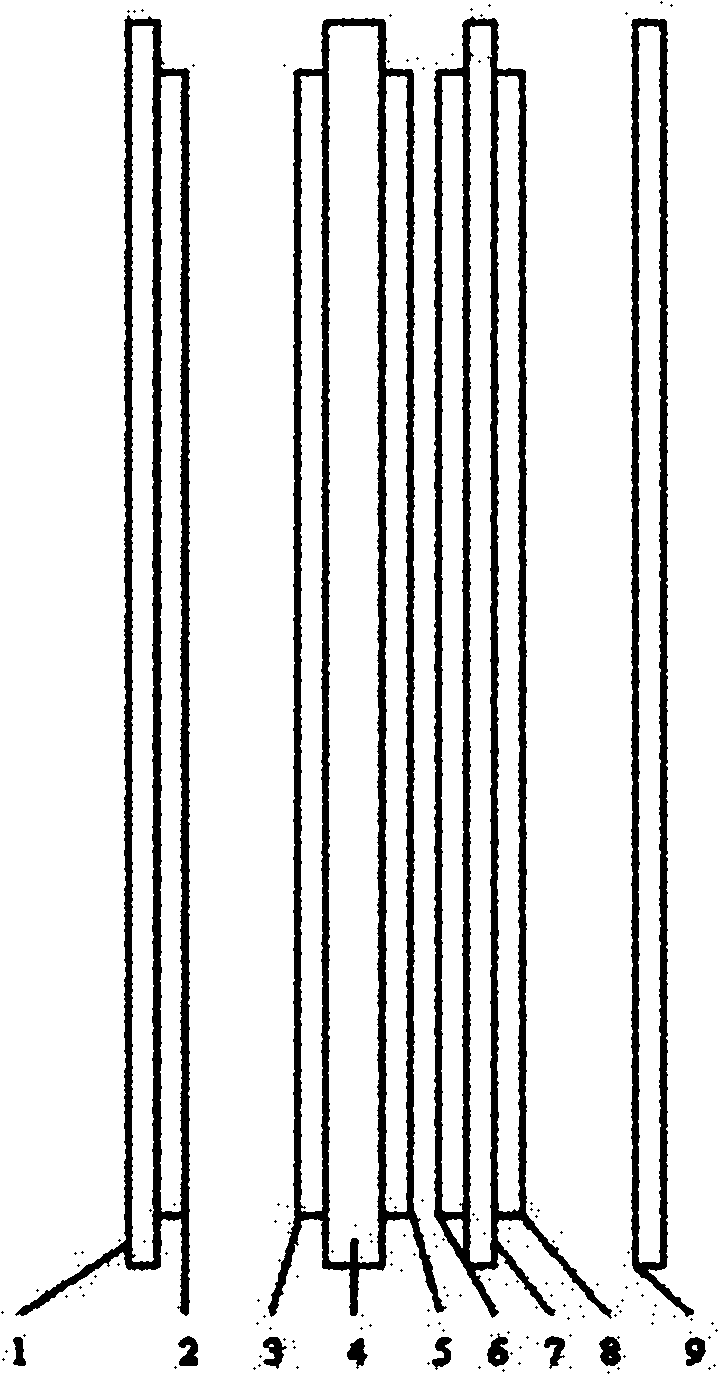

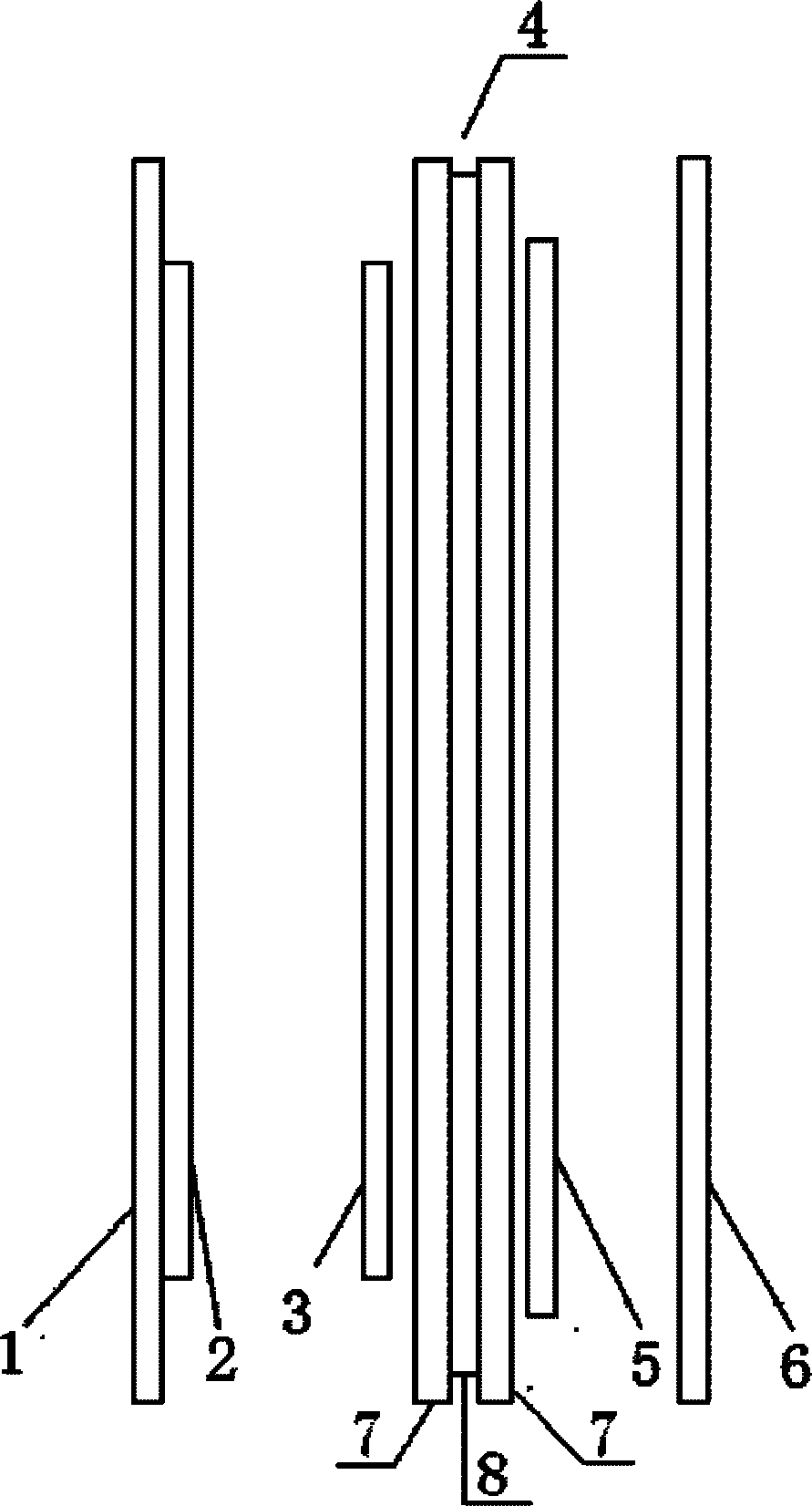

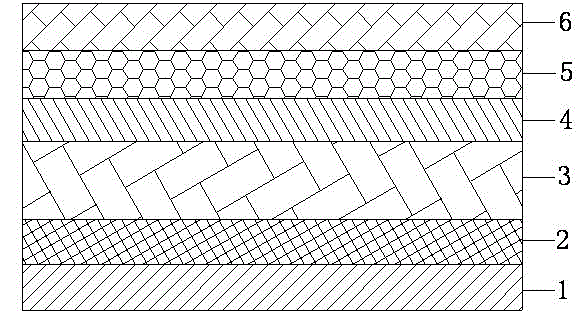

Luminous fabric pillowcase shell fabric with antifouling function

InactiveCN104859257AImprove smoothnessImprove the feelSynthetic resin layered productsAnti bacterialEngineering

The invention relates to luminous fabric pillowcase shell fabric with an antifouling function. The luminous fabric pillowcase shell fabric with the antifouling function comprises a shell fabric body (1); the shell fabric body is covered with a ventilation layer (2); the ventilation layer is covered with a waterproof layer (3); the waterproof layer is covered with an anti-bacterial layer (4); the anti-bacterial layer is covered with a polyurethane coating layer (5); and the polyurethane coating layer is the fluorine monomer waterborne polyurethane, and the polyurethane coating layer is covered with a flocking layer (6). The shell fabric body is formed by the fabric; the fabric comprises a fabric body and luminous threads; the luminous threads are fixed on the fabric body in the manner of knitting or embroidery, and a modeling body is formed on the fabric body. The luminous fabric pillowcase shell fabric with the antifouling function has the characters of good waterproof performance, ventilation effect and good hand feeling. The luminous threads after the luminous processing are used in the luminous fabric pillowcase shell fabric with the antifouling function, namely the luminous threads can shine in the dark. After the structure is used, the luminous threads are alternately woven in the fabric, the structure is stable without the disconnection, and the service life is long.

Owner:江苏红柳床单有限公司

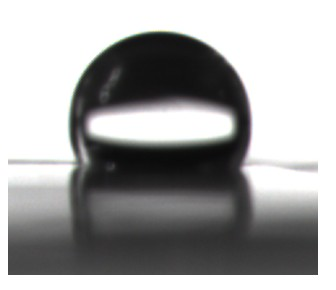

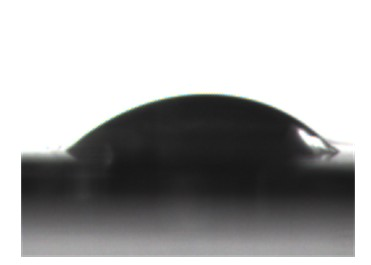

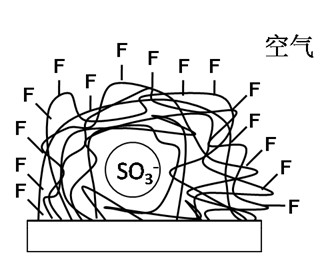

Humidity-sensitive intelligent betaine fluorinated antifouling paint and preparation method thereof

ActiveCN102676015AWith anti-fouling functionGood antifouling functionAntifouling/underwater paintsPaints with biocidesAntifoam agentPolymer chemistry

The invention relates to humidity-sensitive intelligent betaine fluorinated antifouling paint and a preparation method thereof. The paint is mainly made of, by weight, 10%-60% of betaine fluorinated copolymer, 60%-10% of inorganic salt filler, 0.1%-0.5% of water-based paint antifoaming agent, 0.1%-5.0% of dispersing agent and 20%-50% of water. The preparation method includes: firstly, uniformly mixing the betaine fluorinated copolymer solution, the antifoaming agent, the dispersing agent and the water, and secondly, adding the inorganic salt filler while stirring to obtain the humidity-sensitive intelligent betaine fluorinated antifouling paint. The characteristic of foul resistance of fluorinated groups in air and the characteristic of foul resistance of betaine groups in water are integrated to prepare the humidity-sensitive intelligent antifouling paint, and distribution of the fluorinated groups and the betaine groups in coatings can be adjusted according to variation of external media, so that better antifouling function can be kept constantly.

Owner:SOUTH CHINA UNIV OF TECH

Celeste blue glaze with antifouling function

The invention relates to celeste blue glaze with an antifouling function. The celeste blue glaze consists of potassium and sodium feldspar, melilite, boric acid powder, quartz, copper oxide, alkalineearth, green glass, a tin crystal material and copper barium silicate. The celeste blue glaze with the antifouling function has high water tolerance and weather resistance, the added copper oxide andcopper barium silicate have the effects of inhibiting bacteria and decomposing volatile organic compounds, and the antifouling function is high; the celeste blue glaze is suitable for building sanitary ceramic, can be applied to the surfaces of products such as a concrete plate, a plastic plate, a gypsum plate, paint, plastic and textile, has wide application range and has good popularization value; and the celeste blue glaze is simple in preparation process, stable in performance and low in preparation cost.

Owner:NANNING SHENGRUN TECH

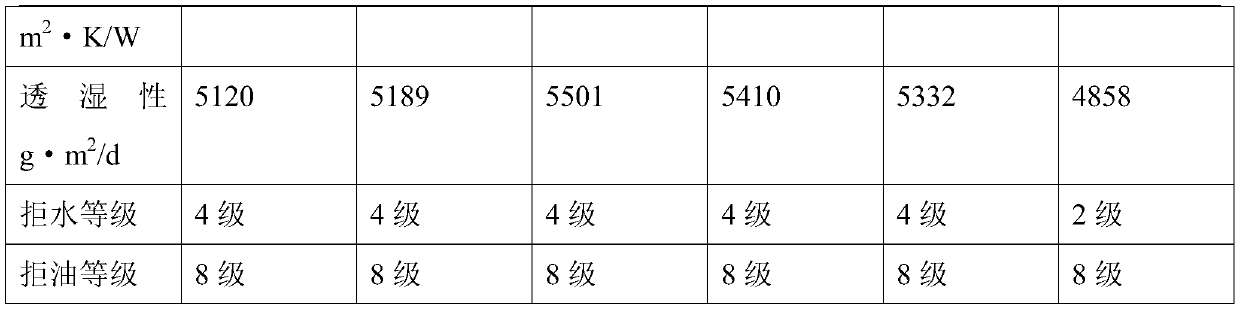

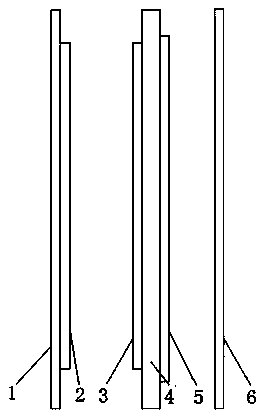

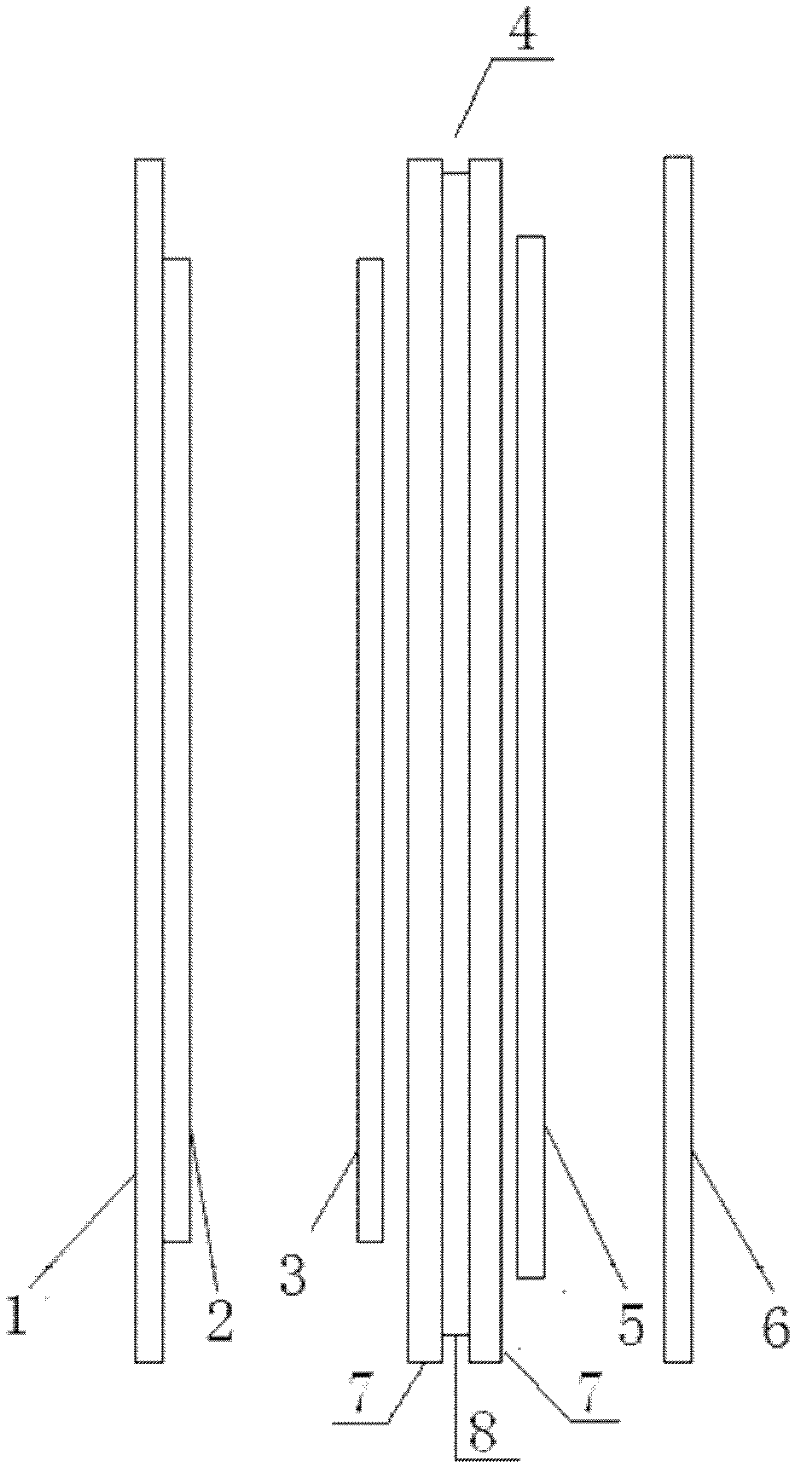

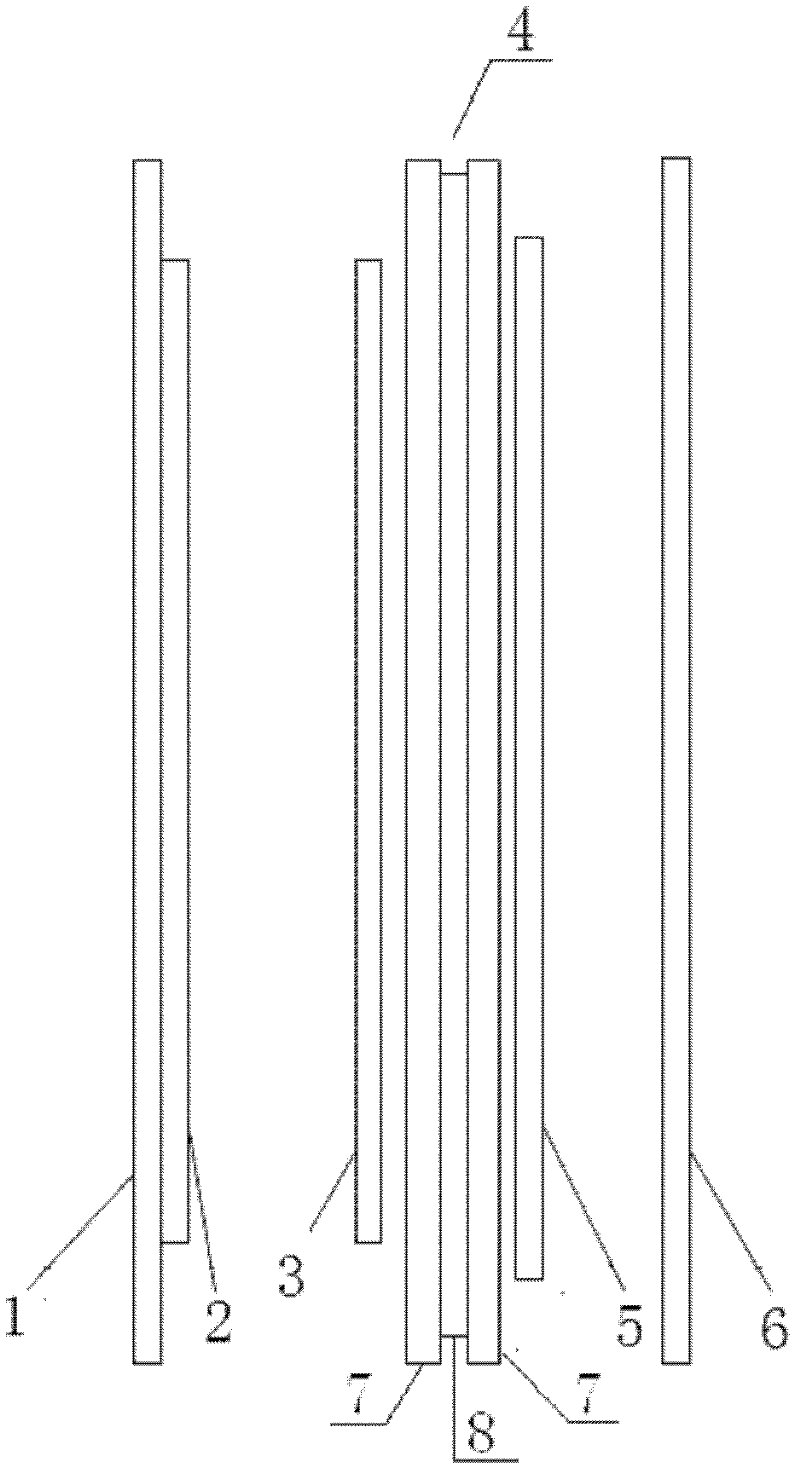

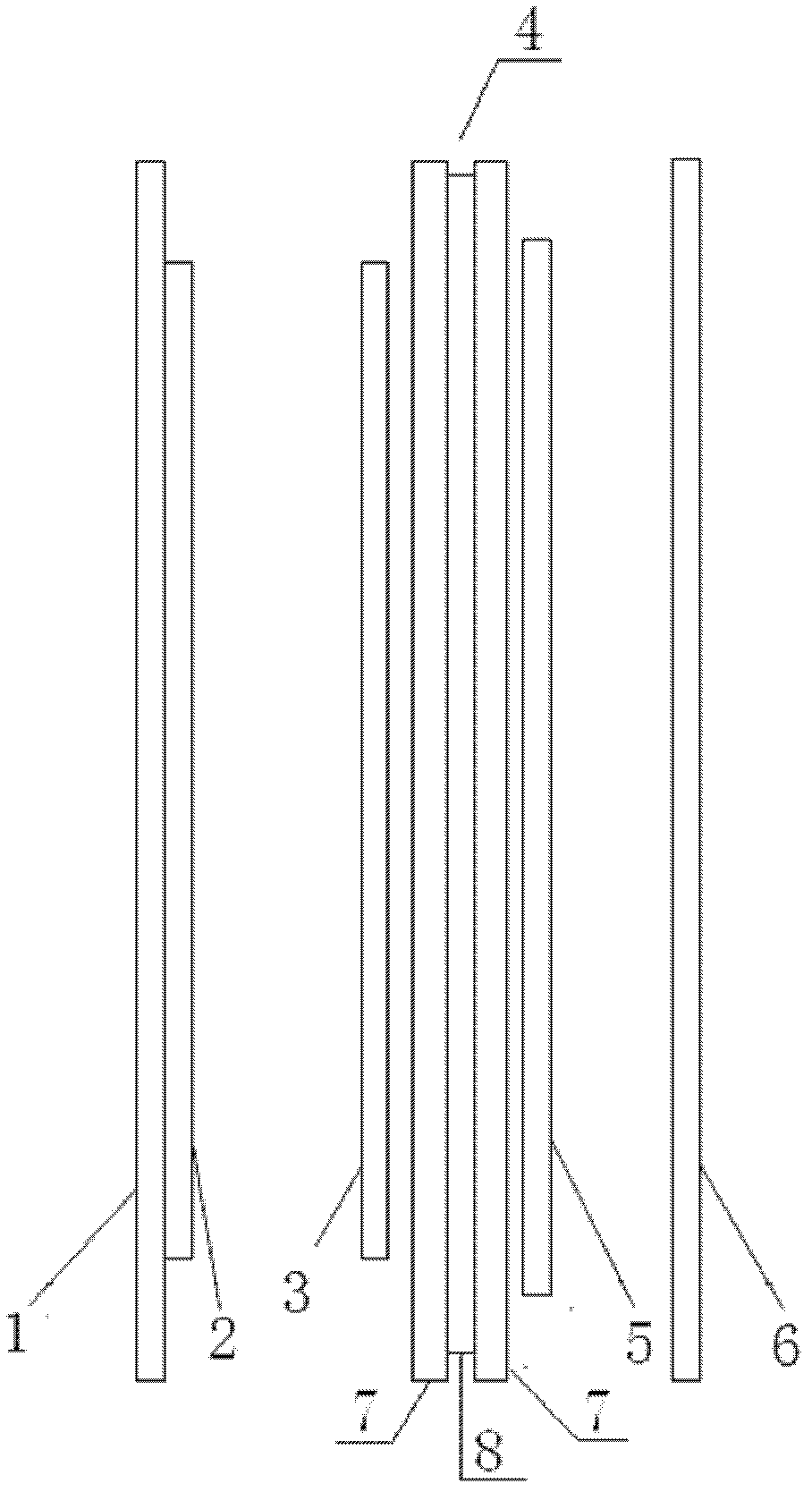

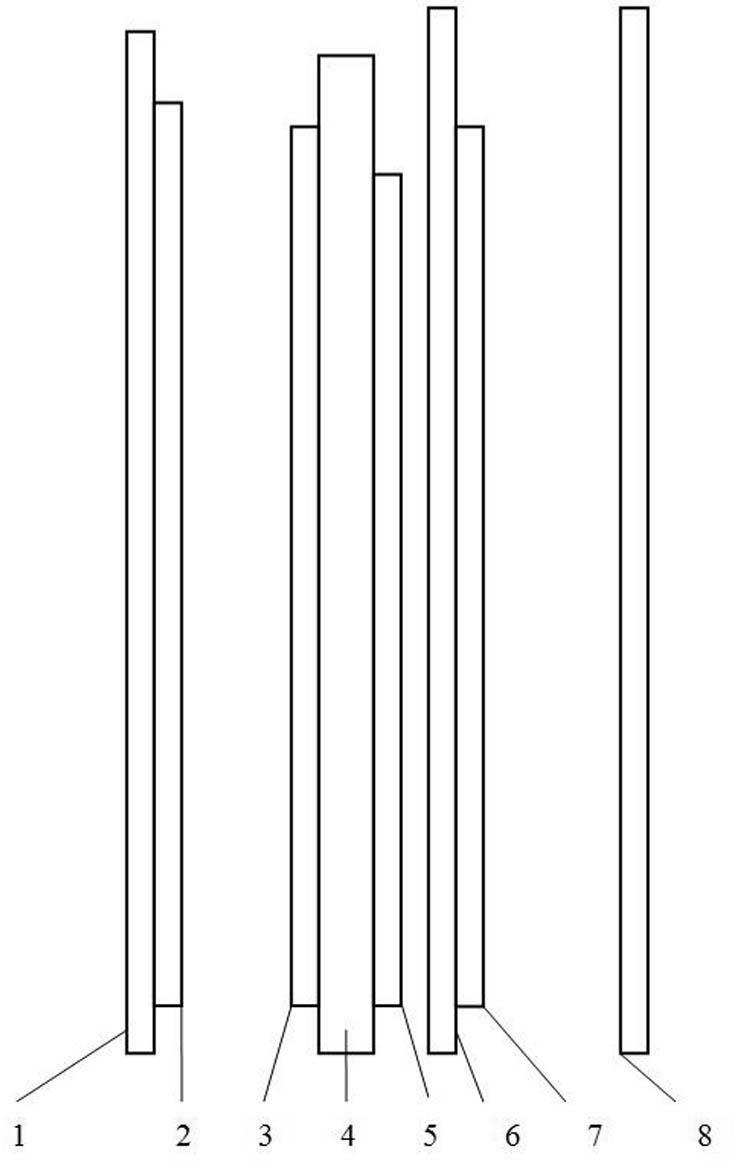

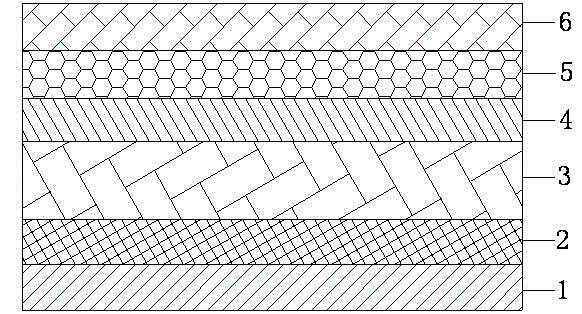

Pillowcase fabric with antifouling function

InactiveCN105690962AAntifoulingWith anti-fouling functionPillowsSynthetic resin layered productsAntibiosisHuman body

The invention relates to a pillowcase fabric with an antifouling function. The fabric is characterized in that the fabric comprises a fabric body (1), the upper surface of the fabric body is coated with a breathable layer (2), the upper surface of the breathable layer (2) is coated with a waterproof layer (3), the upper surface of the waterproof layer (3) is coated with an antibiosis layer (4), the upper surface of the antibiosis layer (4) is coated with a polyurethane coating layer (5), the polyurethane coating layer (5) is fluorine monomer aqueous polyurethane, and the upper surface of the polyurethane coating layer (5) is coated with a flocked layer (6). The upper surface of the fabric body of the pillowcase fabric with an antifouling function is sequentially coated with the breathable layer, the waterproof layer, the antibiosis layer, the polyurethane coating layer and the flocked layer, the waterproof layer can guarantee dryness of the fabric body, the antibiosis layer can block bacteria and prevent the bacteria from traversing the fabric body and being in contact with human bodies, and the polyurethane coating layer can improve the smoothness of the fabric to make the fabric be difficult to contaminate and have waterproof and breathable effects, and the flocked layer can improve the handle of the fabric.

Owner:JIANGYIN YONGTAI PLASTICS CO LTD

Powder coating for building external wall and preparation method of powder coating

InactiveCN107337411AStrong adhesionImprove the decorative effectEster sulfonateHydroxyethyl cellulose

The invention provides a powder coating for a building external wall. The powder coating is prepared from components in parts by weight as follows: 5-20 parts of Portland cement, 10-30 parts of high-alumina cement, 5-25 parts of a terpolymer, 8-30 parts of methyl hydroxyethyl cellulose ether, 2-10 parts of a defoaming agent, 1-8 parts of a dispersant, 8-25 parts of a waterproof agent, 10-18 parts of kaolin, 2-10 parts of diatomaceous earth, 2-12 parts of activated carbon, 5-18 parts of calcium triple superphosphate and 2-12 parts of alkali-resistant glass fiber; the terpolymer is an acrylic acid-acrylic ester-sulfonate terpolymer. The coating not only has the characteristics of ageing resistance and chemical resistance of an inorganic coating, but also has breathable, waterproof and antifouling functions, and the influence of silicate efflorescence on appearance of the coating is avoided. The product is simple to prepare and construct, high in practicability and broad in application range, during use, water is added, and the powder coating is stirred and constructed through spraying, brushing and blade coating.

Owner:ANHUI ZHENXIN PAINT

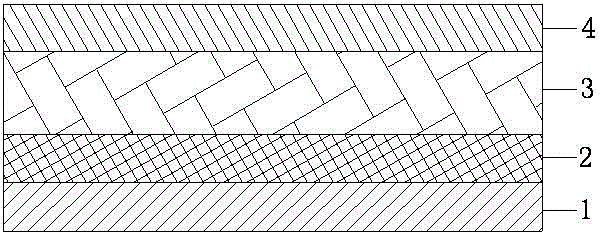

Easy-to-wash quick-to-dry heat insulating fabric with antifouling function

InactiveCN104872877AAntifoulingWith anti-fouling functionSynthetic resin layered productsProtective garmentEngineeringDry heat

The invention relates to easy-to-wash quick-to-dry heat insulating fabric with an antifouling function. The easy-to-wash quick-to-dry heat insulating fabric comprises a fabric body (1), a heat insulating layer (2) covers the fabric body, a waterproof layer (3) covers the heat insulating layer, and a polyurethane coating layer (4) covers the surface of the waterproof layer and is made by fluorine monomer waterborne polyurethane. The fabric body is made by textile which is formed by interweaving warp yarn and weft yarn, each of the warp yarn and the weft yarn is core spun yarn formed by covering polyester filament yarn by cotton, and cross section of is polyester filament yarn is pentacle-shaped. The easy-to-wash quick-to-dry heat insulating fabric is less prone to fouling, waterproof and breathable. Grooves are formed in the polyester filament yarn, so that gas and water can be quickly discharged from the grooves, functions of absorbing moisture and discharging sweat are realized, and the fabric is easy to wash and quick to dry.

Owner:JIANGYIN HANXIN TEXTILE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com