Patents

Literature

42results about How to "Increase sizing rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

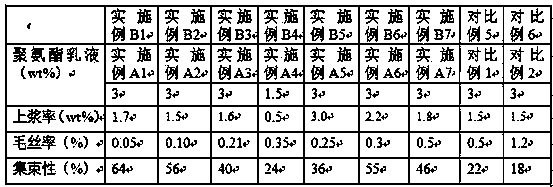

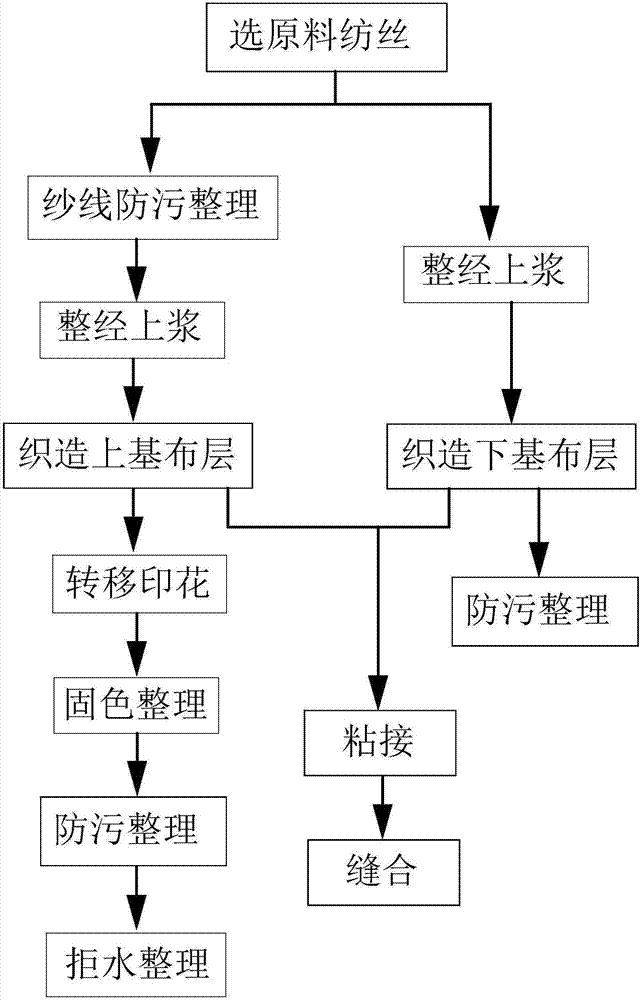

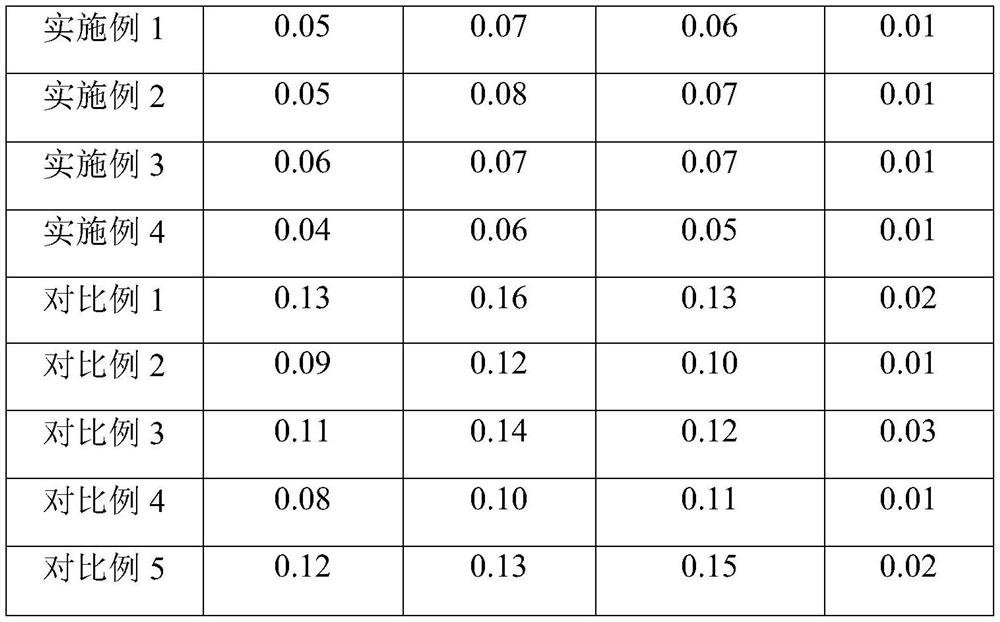

Production method of antifouling sofa fabric

ActiveCN106283340AIncrease sizing rateLess hairyTransfer printing processWarping machinesYarnAdhesive

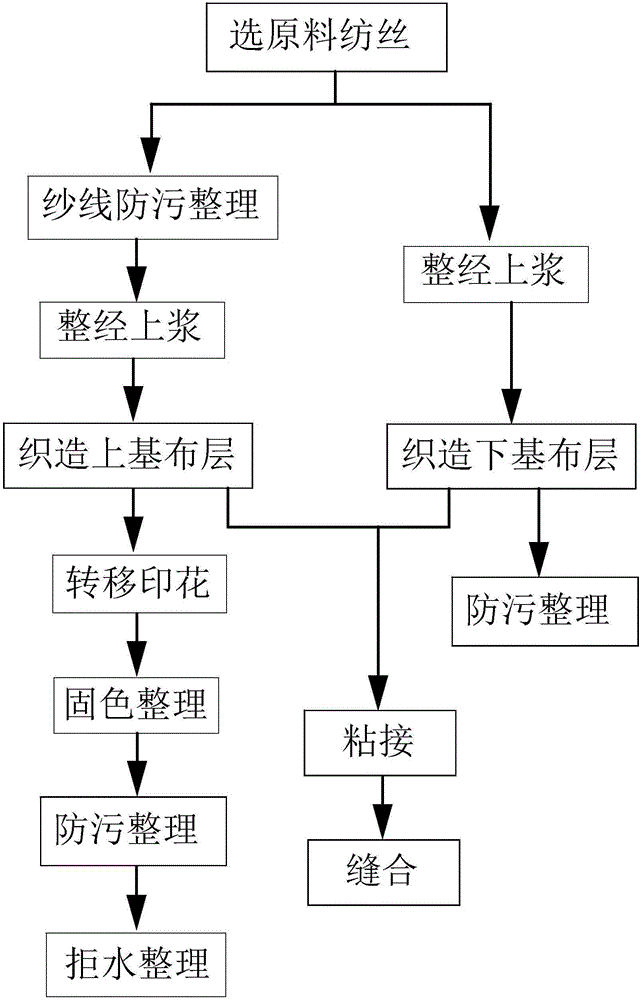

The invention provides a production method of an antifouling sofa fabric, belonging to the technical field of home textiles. The production method comprises the following steps: (1) selecting raw materials and spinning; (2) performing anti-pollution finishing of yarns; (3) warping and sizing; (4) weaving: weaving an upper base cloth layer and a lower base cloth layer; (5) transferring and printing; (6) fixing color and finishing; (7) performing anti-pollution finishing; (8) conducting water repellent finishing; (9) adhering: coating adhesives on the upper side and the lower side of a sponge respectively, applying pressure to the upper base cloth layer, the sponge and the lower base cloth layer which are superposed vertically, so as to enable the three to be adhered as a whole; and (10) sewing. The yarns treated by a warping and sizing machine are high in sizing rate, and fewer in feathers, so that static electricity generated due to friction among yarns can be reduced, the static electricity of the fabric can be effectively reduced, and the woven fabric is difficult to generate static electricity, thus being relatively difficult to adsorb dust; and the sofa fabric produced by utilizing the method has multiple antifouling capabilities, and has obvious antifouling effect.

Owner:海宁宝祥布业有限公司

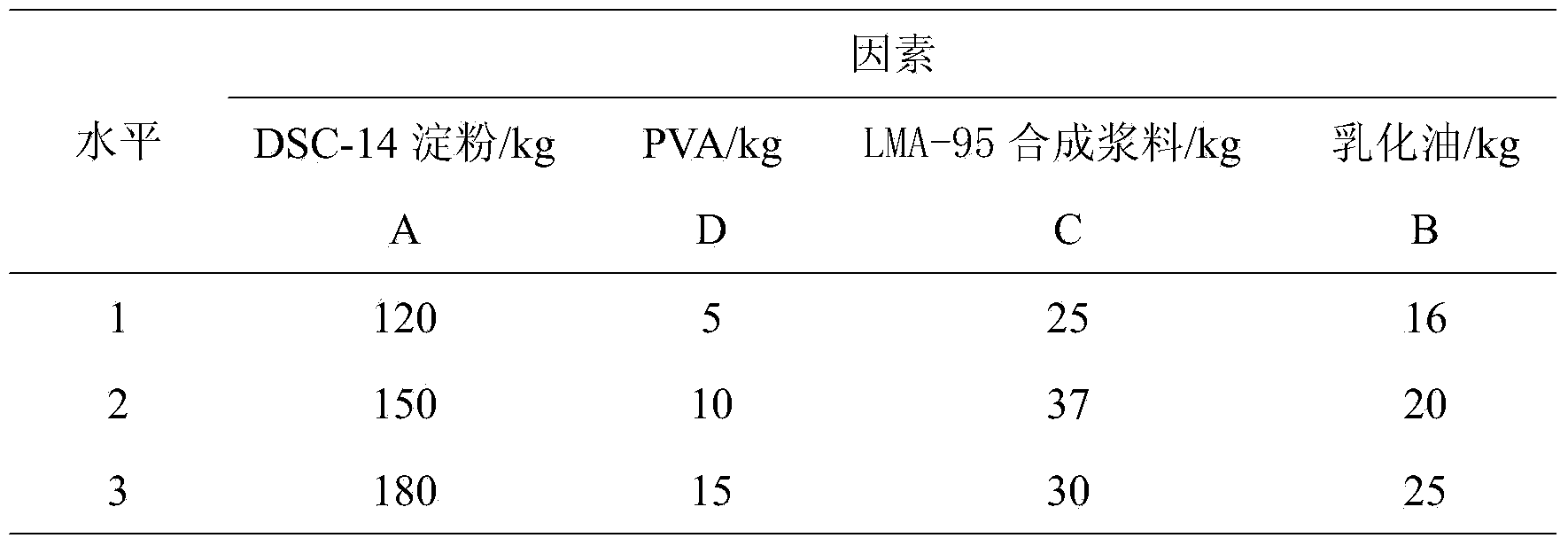

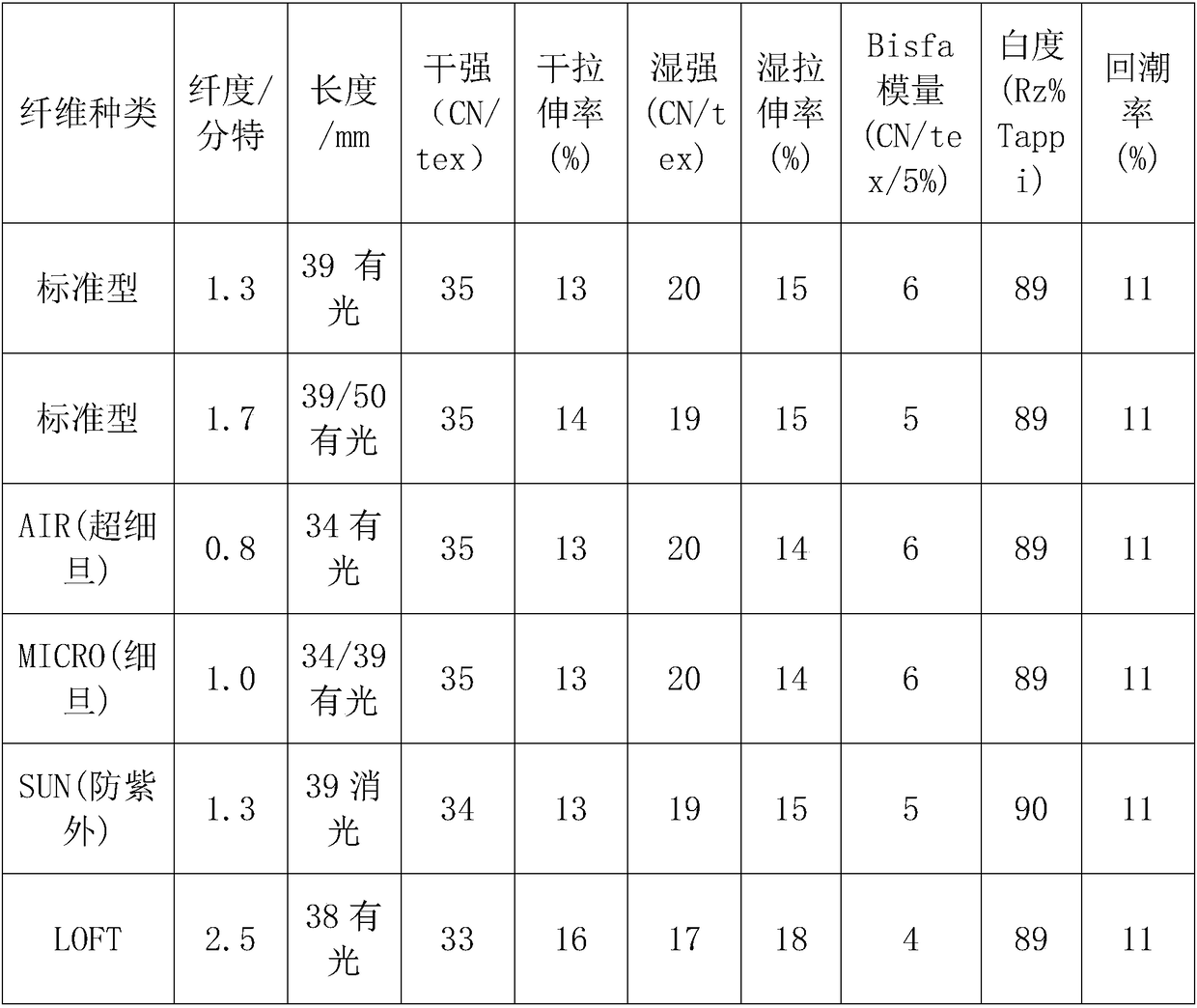

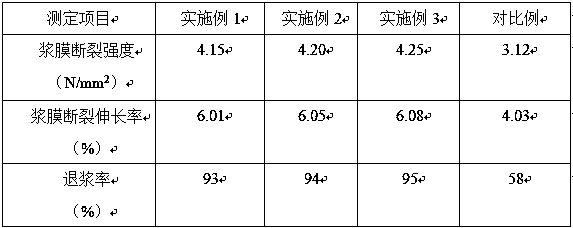

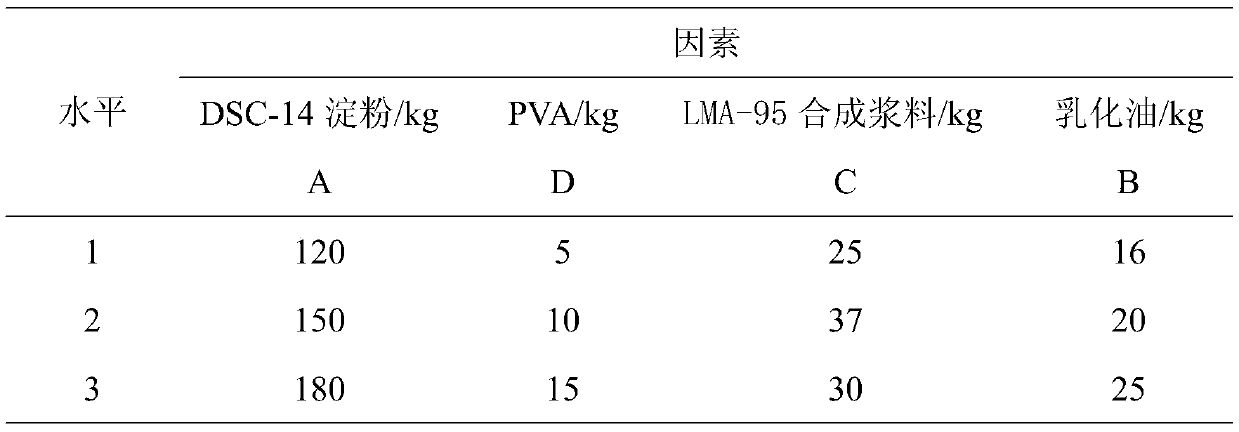

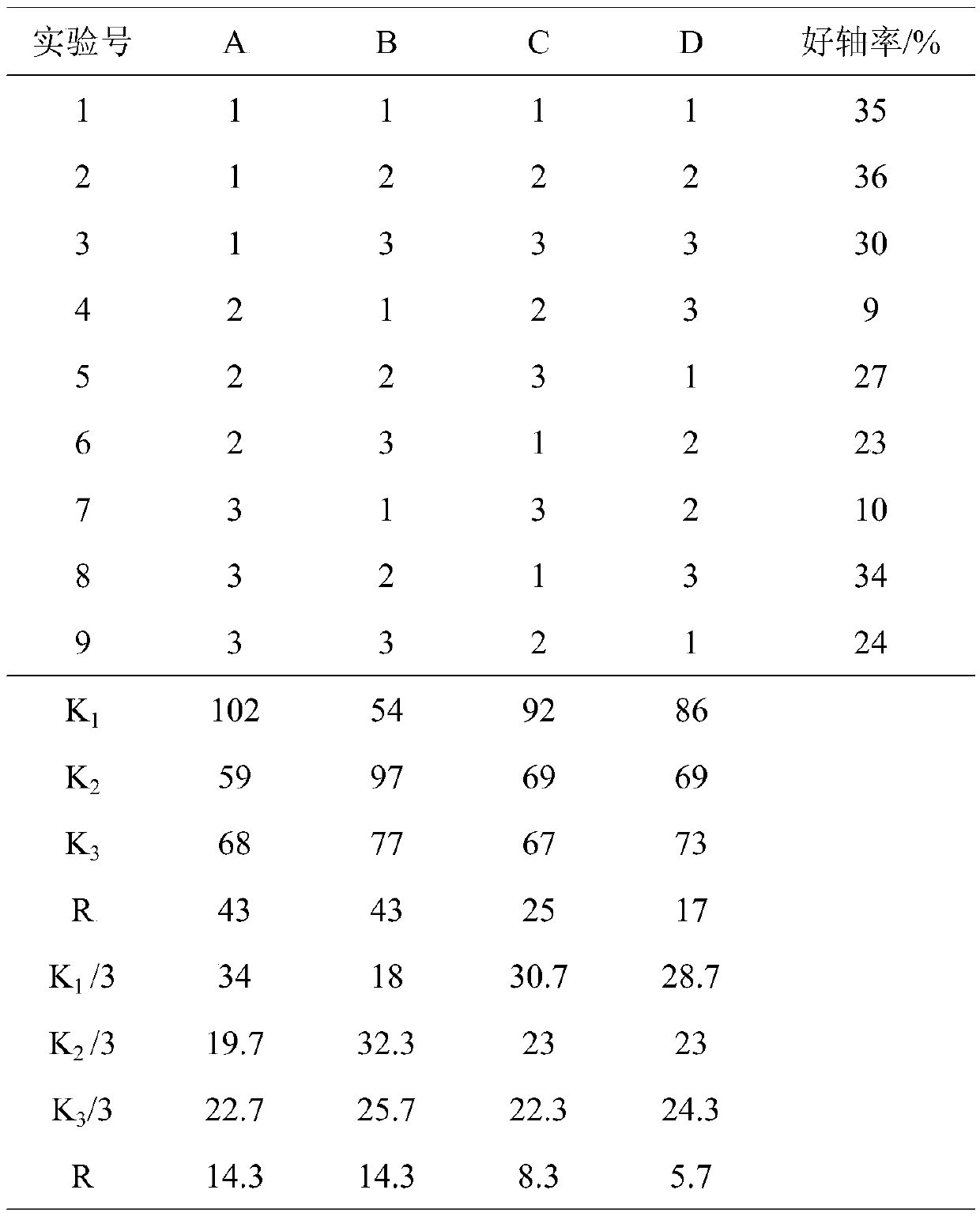

Jean warp sizing slurry and sizing process

ActiveCN103966849AImprove wear resistanceImprove surface propertiesFibre treatmentDenimProcess engineering

The invention provides a jean warp sizing slurry and a sizing process. The slurry is prepared from DSC-14 starch, PVA, LMA-95 synthesis slurry, emulsified oil and a smoothing agent. In comparison with the prior art, the sizing slurry and process ensures that the warp abrasion resistance is greatly improved, the weaving performance is enhanced and the cost is lowered. Besides, the use amount of slurry and pollution are reduced, the existing technological process does not need to be changed significantly, the investment is relatively low and the effect can be taken rapidly.

Owner:ZHEJIANG SANSEN TEXTILE

Manufacturing process of polyester cotton yarn-dyed fabric

InactiveCN107869077ALow staticReduce the probability of static electricitySingeingHeating/cooling textile fabricsYarnPolyester

The invention discloses a manufacturing process of a polyester cotton yarn-dyed fabric. The manufacturing process comprises the following technological steps: selecting a polyester cotton blended yarn; sequentially performing scouring, blanching, dyeing, soap-boiling, water washing and drying, wherein beam dyeing is adopted, and in the dyeing process, the winding density of a warp of a warping machine is 0.46-0.48 g / cm<3>; before dyeing, adding 0.2-0.4 g / L sodium sulfate into water required by dyeing, performing stirring for 8-10 min; adding sodium carbonate first at the water temperature of 35-40 DEG C; after 12-15 min, adding sodium sulfate for 12-15 min; and maintaining for 42-46 min when the temperature rises to 62 DEG C. According to the manufacturing process, the dyeing effect is improved, more uniform dyeing is achieved, the dyeing freshness is guaranteed, the static property of a spun polyester thread is reduced by an anti-static agent, the static ratio of the polyester cottonyarn-dyed fabric which is woven is favorably reduced on the whole, in addition, triple-jump, yarn breakage and yarn sinking are reduced, and the sizing percentage is increased.

Owner:JIANGSU MINGYUAN TEXTILE

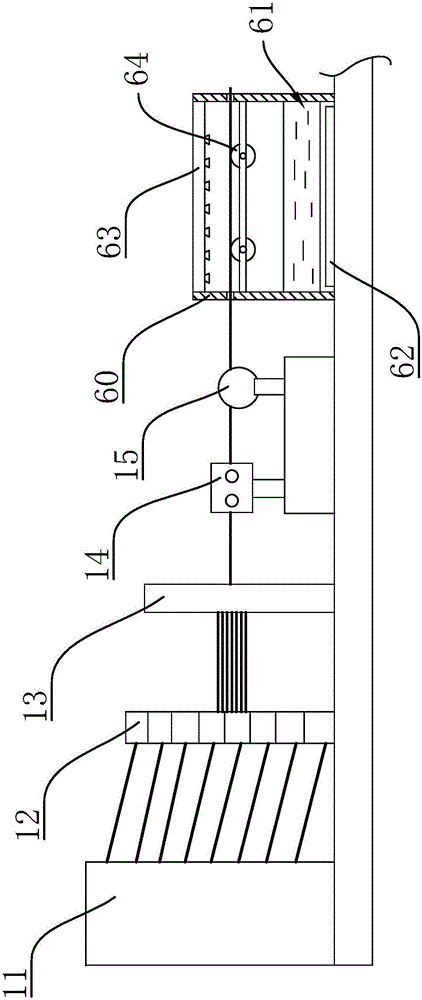

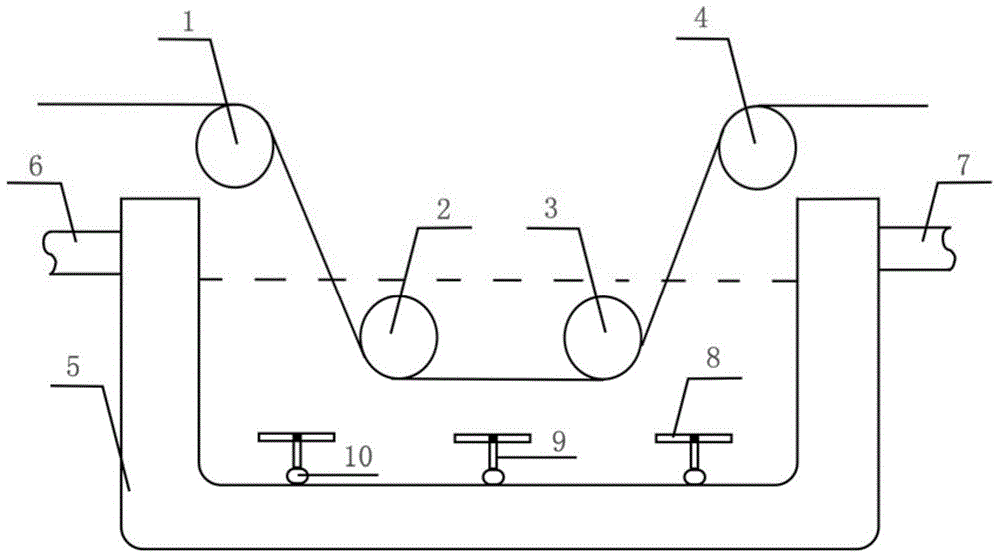

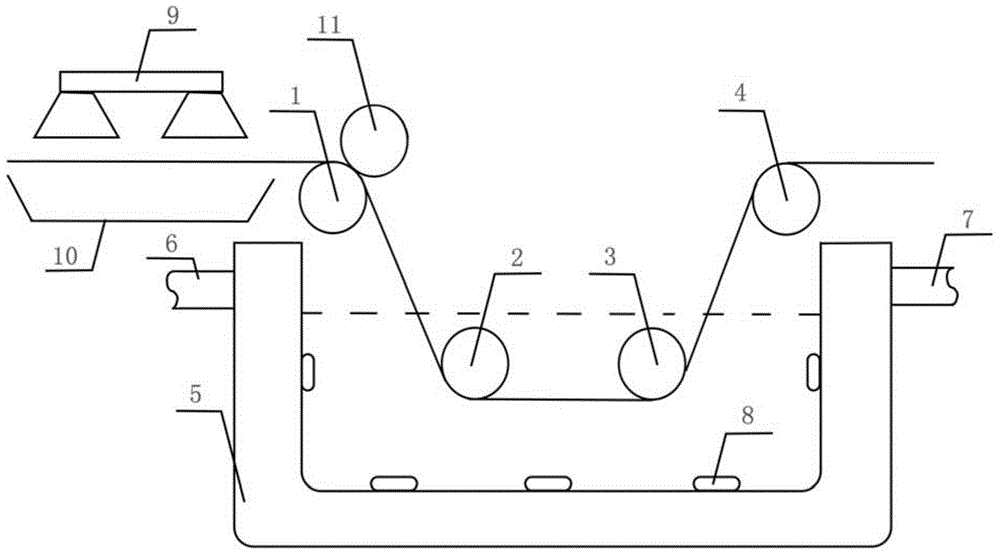

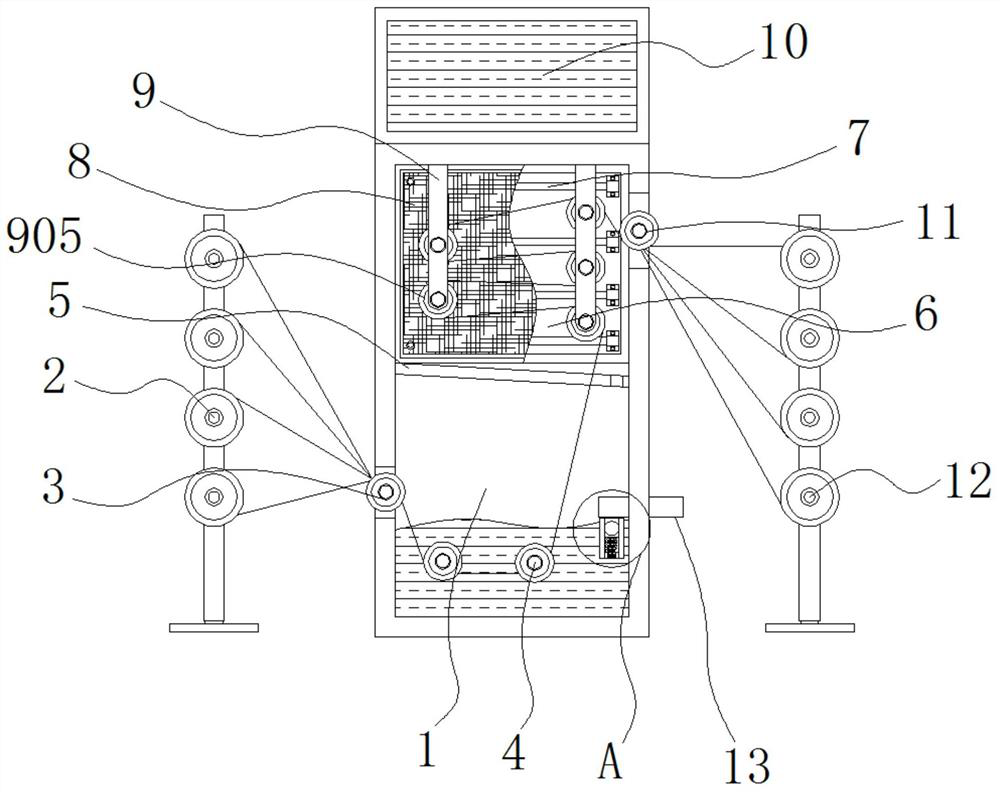

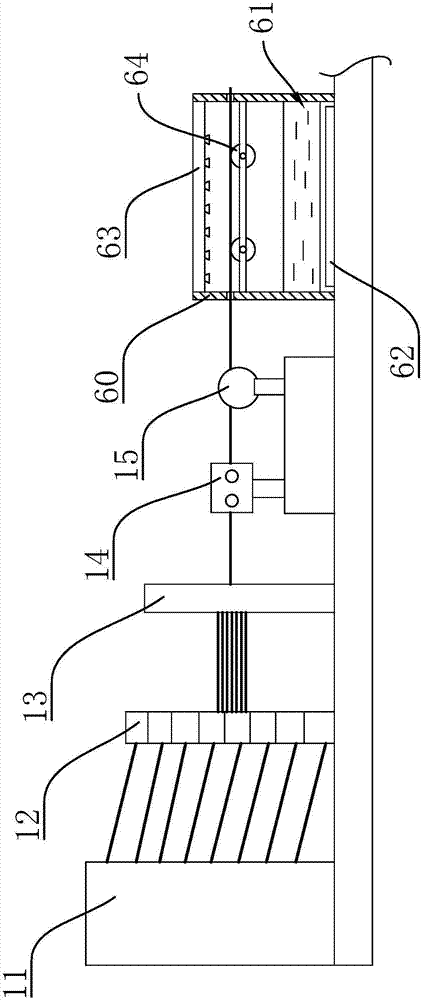

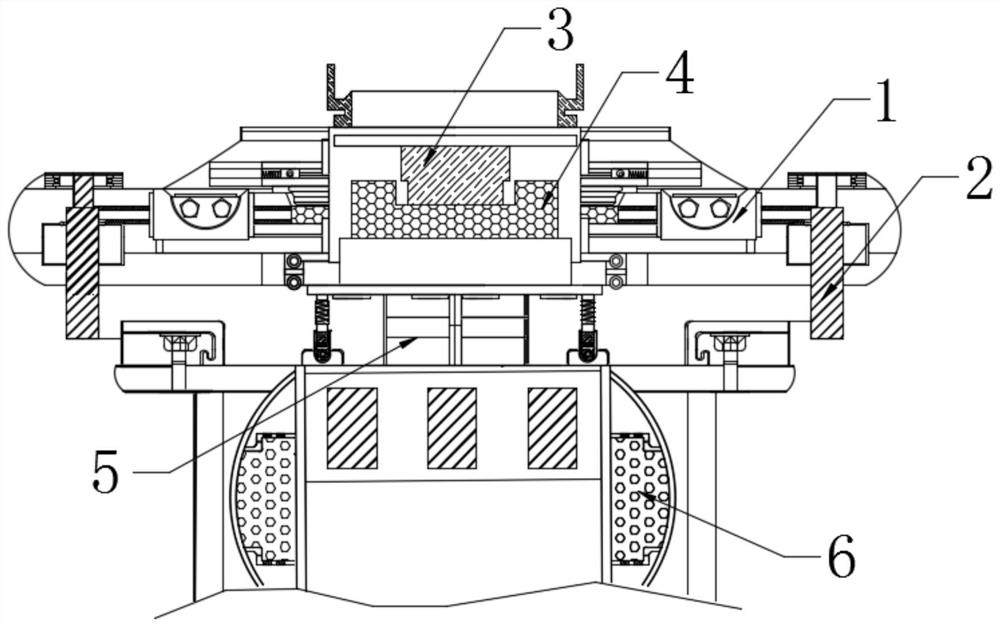

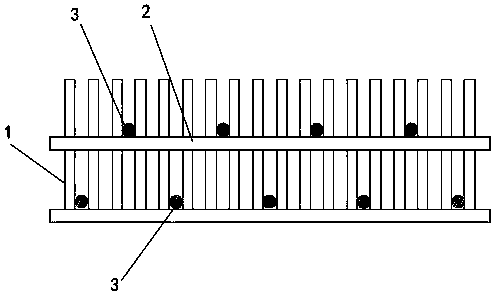

Sizing device

InactiveCN105586737AIncrease sizing rateImprove solubilityTextile treatment containersTextile treatment machine arrangementsYarnPulp and paper industry

The invention relates to the warp sizing machine machinery equipment field, and especially relates to a sizing device comprising a lead in roller, a first immersion roller, a second immersion roller, a lead out roller and a slurry barrel; the slurry barrel comprises an inner wall and an outer wall so as to form a sealed cavity; two sides of the outer wall are respectively provided with a steam inlet and a steam outlet; the inner wall is provided with a stirring device comprising blades, connecting rods and pedestals; the bottom of the pedestal is fixed on the inner wall bottom; one end of the connecting rod is fixed on the top of the pedestal, and the other end of the connecting rod is fixedly connected with the blade; the connecting rods are electrically connected with an external motor. High temperature steam can heat up the slurry in the barrel, so the dissolved matter in the slurry can be fully dissolved; the stirring device can circulate the slurry in the slurry barrel, so the slurry dissolved matter and heat can be evenly distributed in a long time, thus improving yarn sizing rate; the sizing device is simple in structure, and strong in practicality.

Owner:WUXI HONGFEN MACHINERY FACTORY

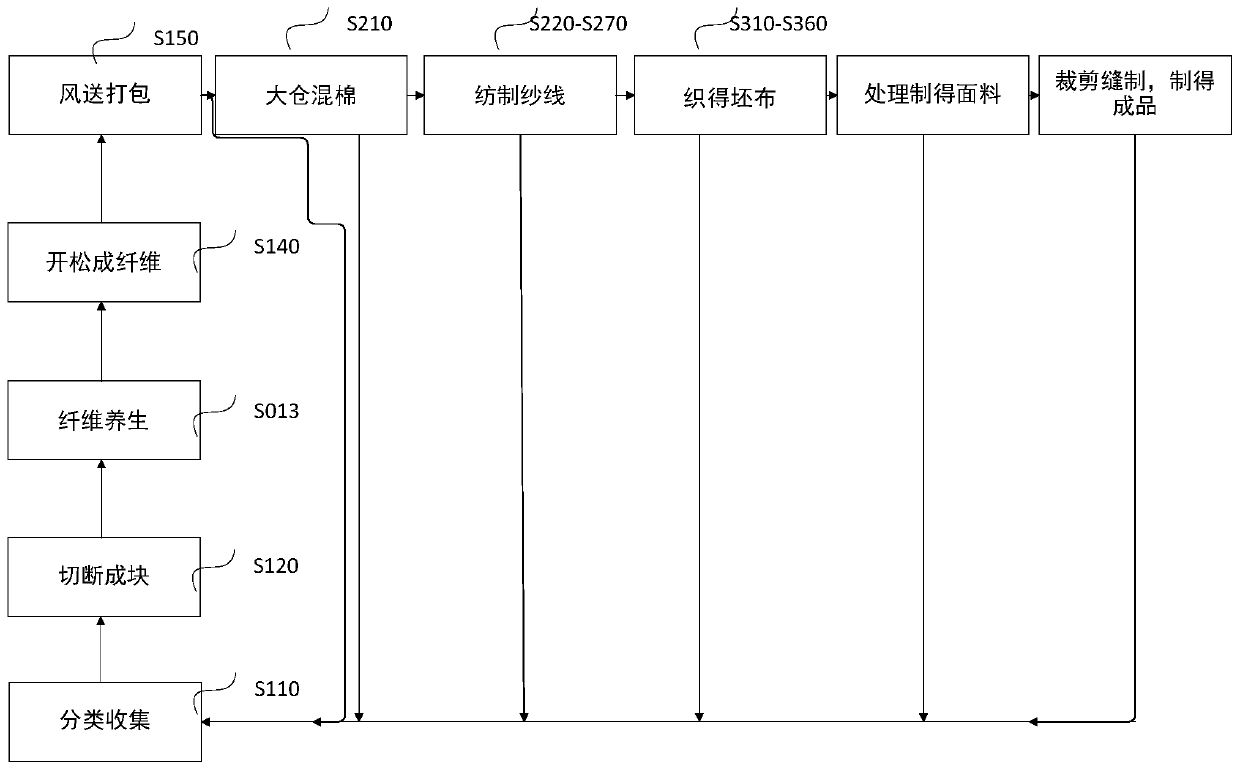

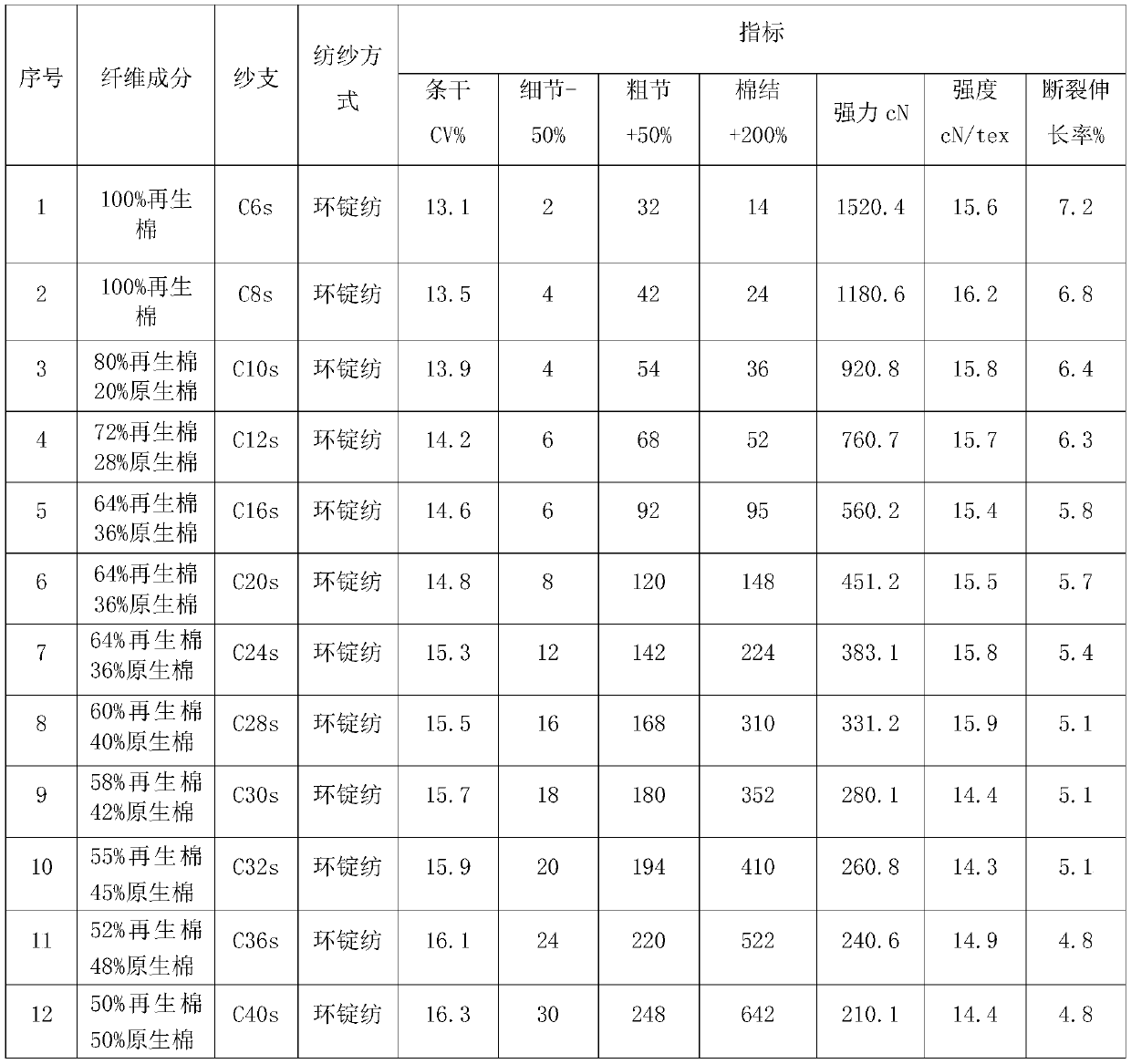

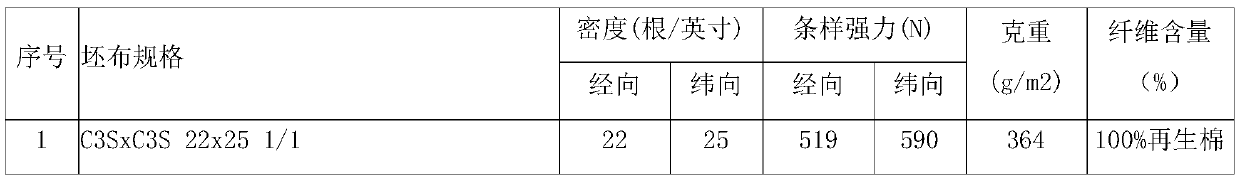

Regenerated cotton fiber and yarn spinning method thereof and textile weaving method

InactiveCN110592732AImprove toughnessHigh strengthBiochemical fibre treatmentUltrasonic/sonic fibre treatmentYarnCotton fibre

The invention discloses a regenerated cotton fiber and a yarn spinning method thereof and a textile weaving method. The regenerated cotton fiber is prepared by using a following preparation method including the steps that large-grained solid impurities in textile wastes are removed first, according to fiber compositions and color features, classification is conducted, and classified textile wastesare obtained; the classified textile wastes are cut into classified textile waste fragments with the length of 2-3 centimeters; a first nourishing solution and a second nourishing solution are addedto the classified textile waste fragments by using a fiber nourishing device in sequence, and a nourished textile fabric is obtained; the nourished textile fabric is subjected to multi-stage opening,the fiber with the length of 14-20 millimeters is collected, and the regenerated cotton fiber is obtained. The length of the regenerated cotton fiber is ensured, the spinnability of the regenerated cotton fiber is improved, and the regenerated cotton fiber is suitable for a ring spinning method.

Owner:YUYUE HOME TEXTILE

Method for starching by utilizing ultrasonic waves

InactiveCN102660848AReduce energy consumptionAchieve low temperature sizingVegetal fibresVibration treatmentYarnFiber

The invention relates to a method for starching by utilizing ultrasonic waves. The method comprises the following steps of: (1) pouring starch into a starch tank, unreeling yarns from a warp beam, immersing the yarns in the starch tank directly, and opening an ultrasonic generator, so that ultrasonic oscillation is generated in the starch tank, wherein the bottom of the starch tank contains a plurality of ultrasonic oscillation points, and connecting holes arranged on one edge of a groove are connected with the ultrasonic generator; (2) allowing the yarns in the step (1) to pass through an immersion roller, and extruding by using a roll compacting roller, wherein a 'double-immersion and double-compression' mode is adopted in the integral sizing process; and finally, drying the obtain yarns. According to the method, the temperature of the starch tank is stabilized to 55 DEG C in the starching process, so that energy consumption is reduced, and low-temperature starching is realized; the starched yarns are stable in quality, and the starching rate is improved, so that the strength of the starched yarns is improved, and hairy feather is reduced obviously; and the wear-resisting property is improved, and the starch is high in penetrability and coverage in the yarns by the high moistening of fibers and the starch.

Owner:DONGHUA UNIV

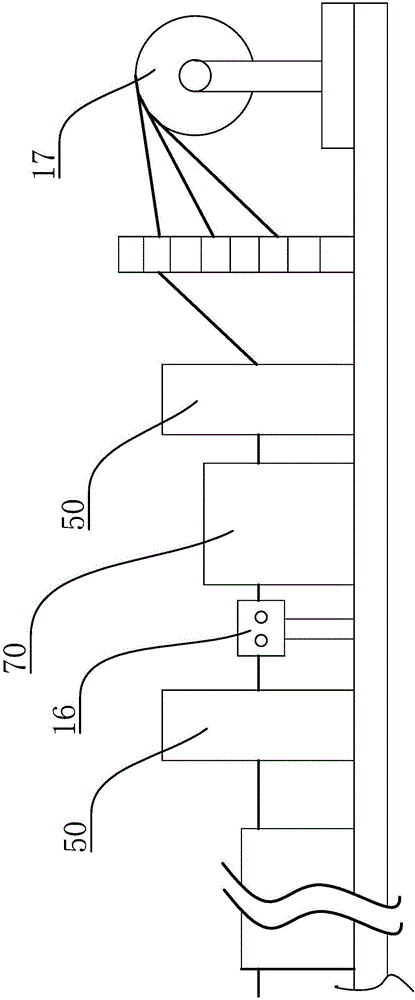

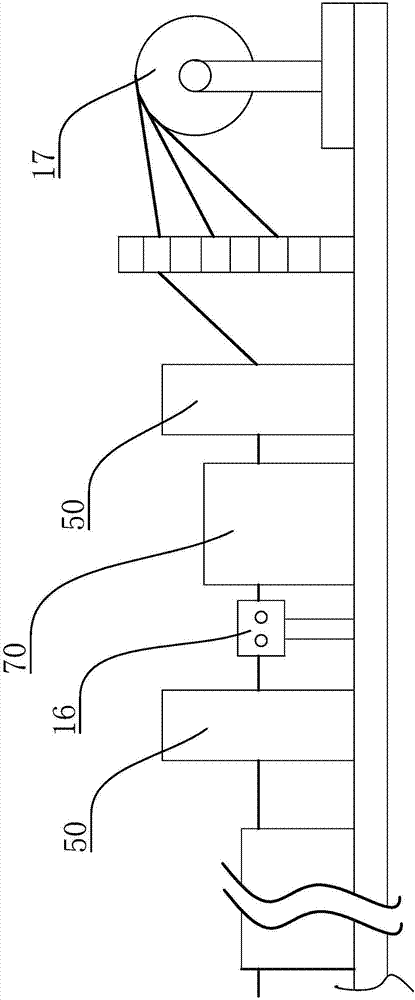

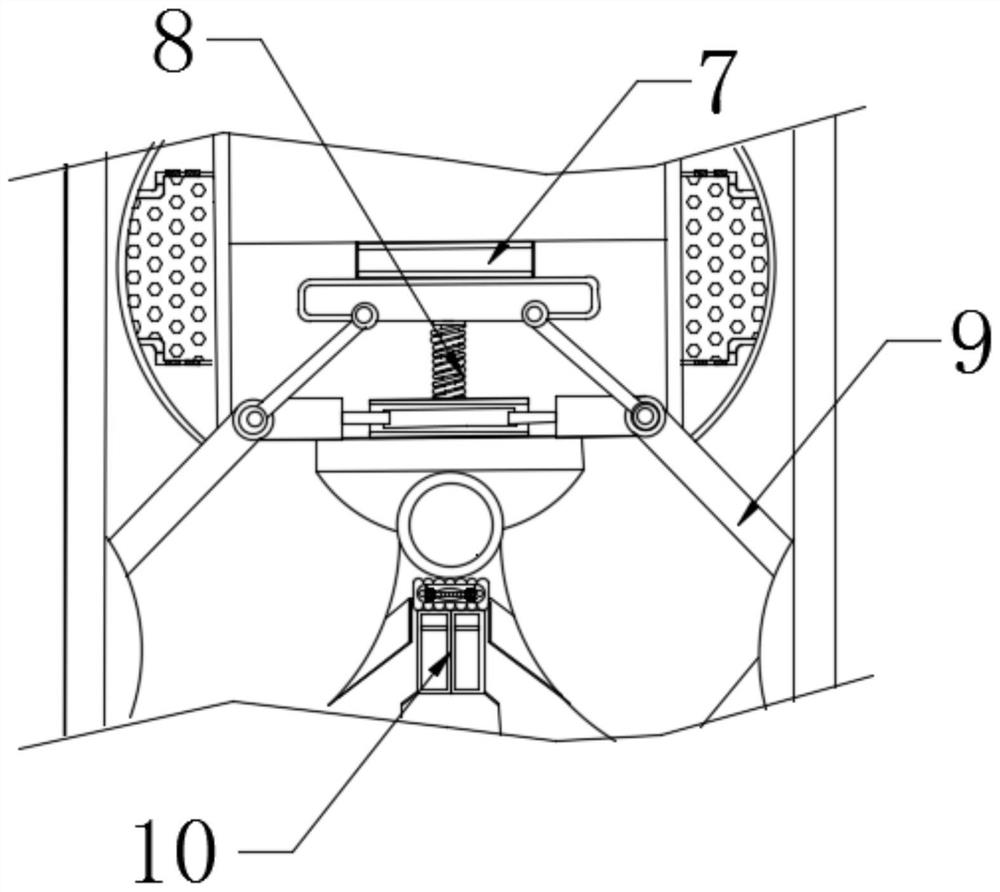

Pre-wetting sizing device

InactiveCN105586744AReduce sizeEvenly distributedSucessive textile treatmentsTextile treatment containersYarnPulp and paper industry

The invention relates to the field of sizing machine and especially relates to a pre-wetting sizing device. The pre-wetting sizing device comprises a drawing roller, a first immersing roller, a second immersing roller, an extraction roller and a slurry bucket. The slurry bucket comprises an inner wall and an outer wall. A sealed cavity is formed by the inner wall and the outer wall. Two sides of the outer side are provided with a steam inlet and a steam outlet. Multiple ultrasonic oscillators are arranged on the inner wall. One side, away from the slurry bucket, of the drawing roller is provided with a spraying device and a liquid recovery device, both of which are arranged horizontally and correspondingly. The upper part of the drawing roller is provided with an extrusion roller. The drawing roller is almost attached to the extrusion roller. The drawing roller and the extrusion roller are used for extruding superfluous pre-wetting liquid in pre-wetting yarns in order to avoid dilute grout.Slurries in the slurry bucket are heated by high-temperature steam such that dissolved matter in slurries can be fully dissolved. The ultrasonic oscillators drive slurries in the slurry bucket to flow such that dissolved matter of slurries and heat can be kept uniformly distributed for a long time. Sizing efficiency of yearns is increased. The pre-wetting sizing device is simple in structure and high in practicability.

Owner:WUXI HONGFEN MACHINERY FACTORY

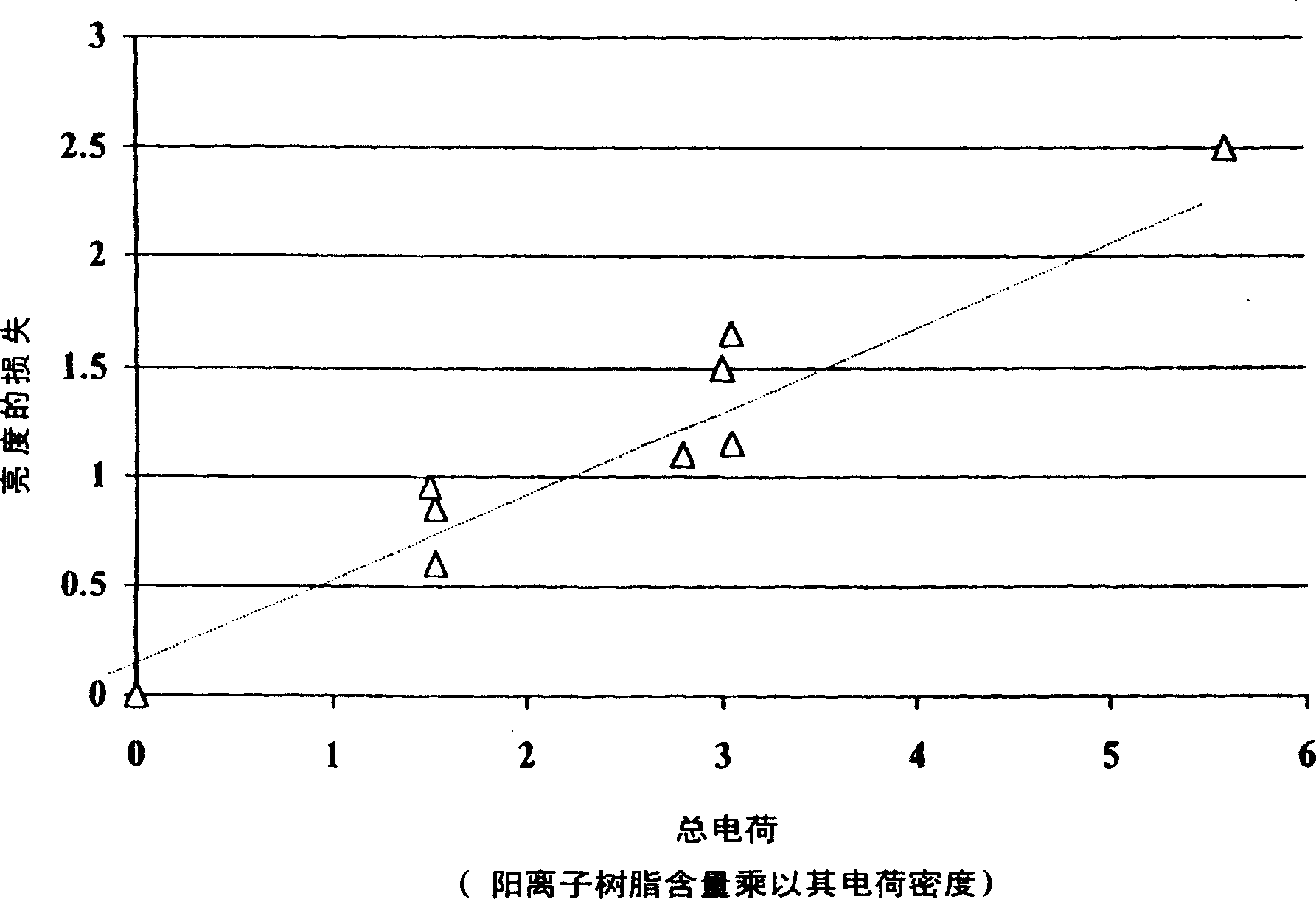

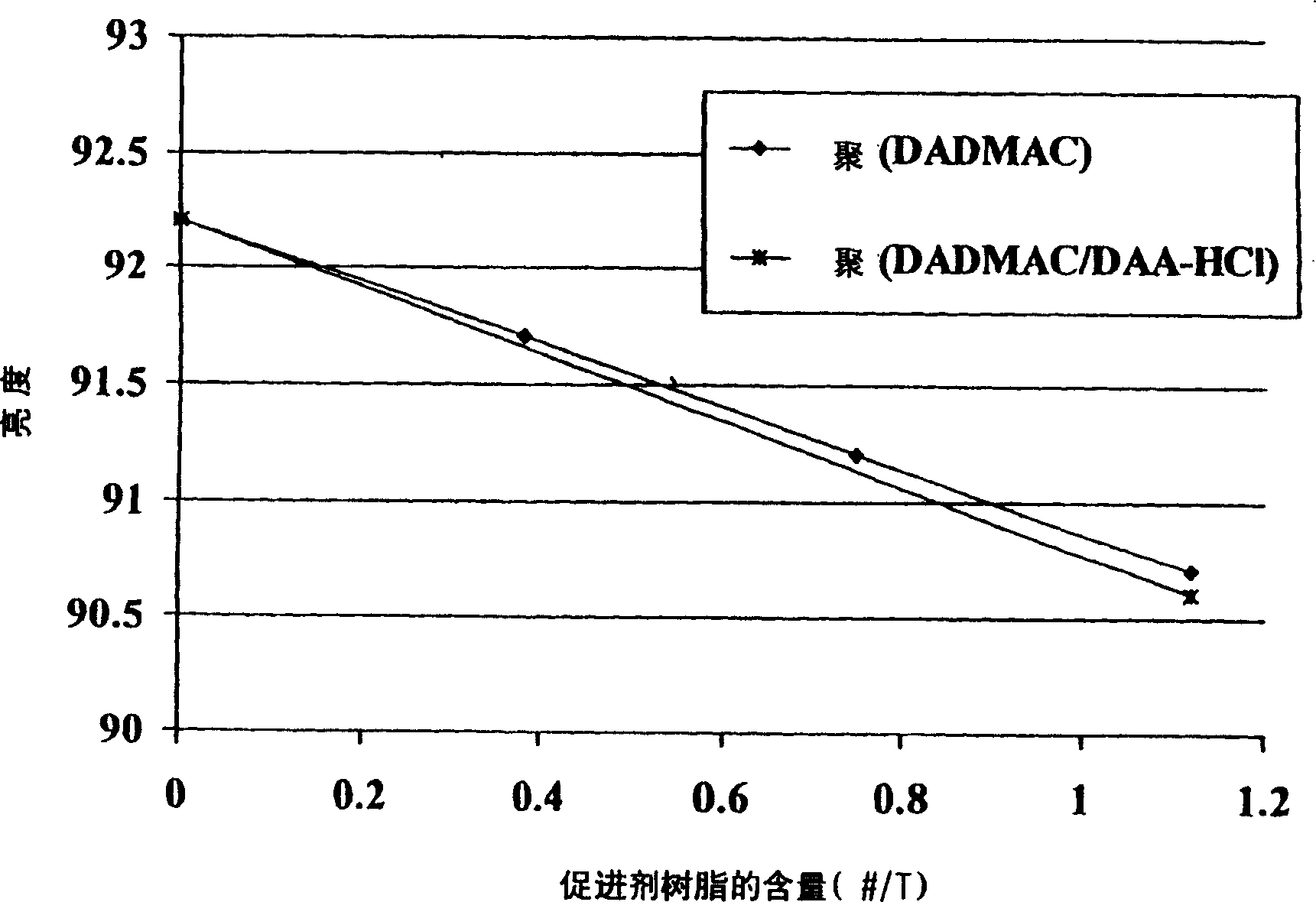

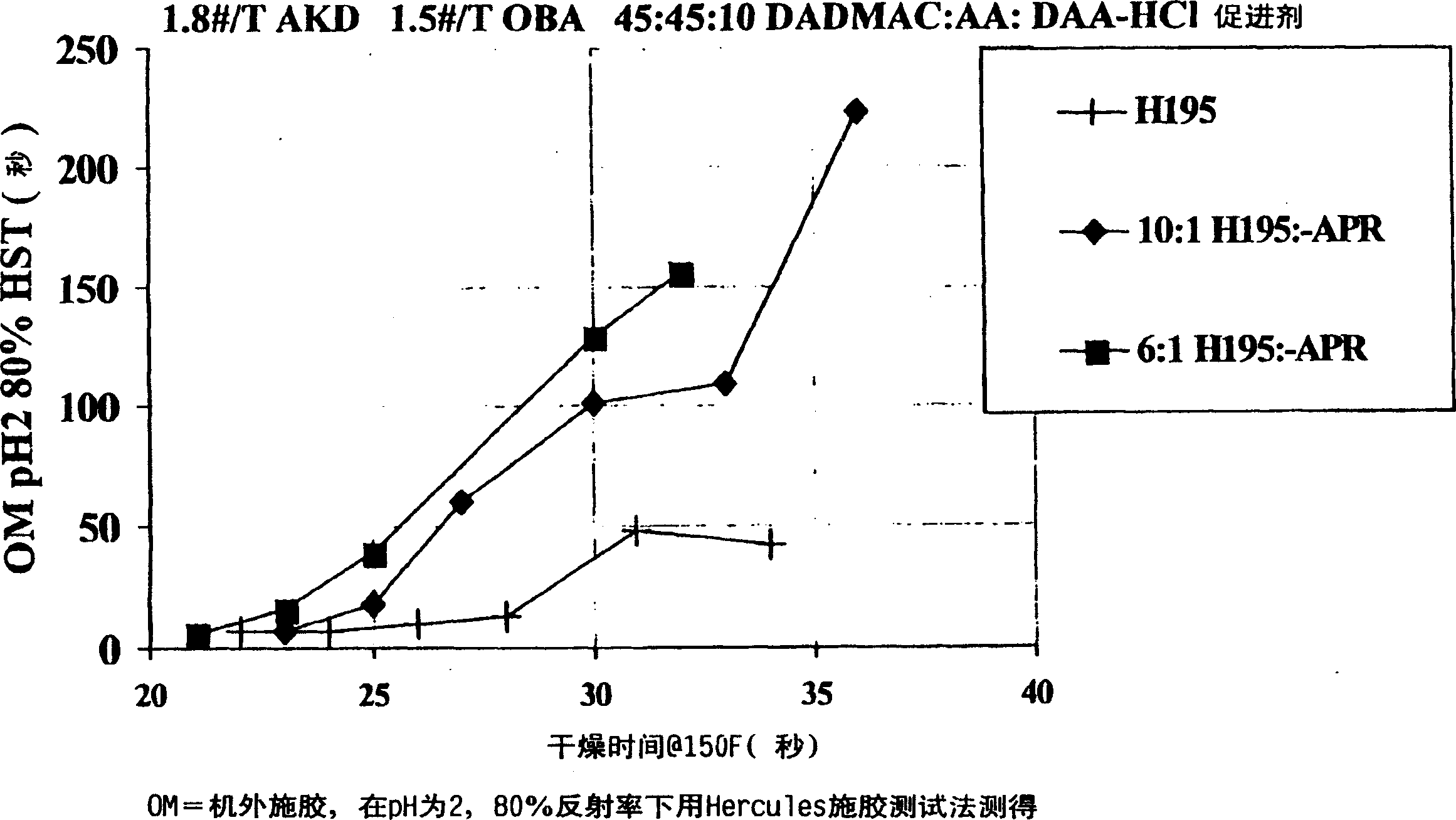

Amphoteric polymer resins that increase the rate of sizing development

InactiveCN1610708AIncrease development rateReduce dosageWater-repelling agents additionPaper/cardboardOrganic acidPolymer resin

Sized paper containing an amphoteric promoter resin that is a polymerization reaction product of a quaternary diallylammonium monomer, optionally a diallylammonium monomer, and an unsaturated organic acid is described. The method of sizing paper with such amphoteric promoter resin compound and a sizing agent provides sized paper with significantly improved sizing property characteristics, and the sized paper exhibits superior retention of brightness due to added optical brighteners.

Owner:SOLENIS TECH CAYMAN

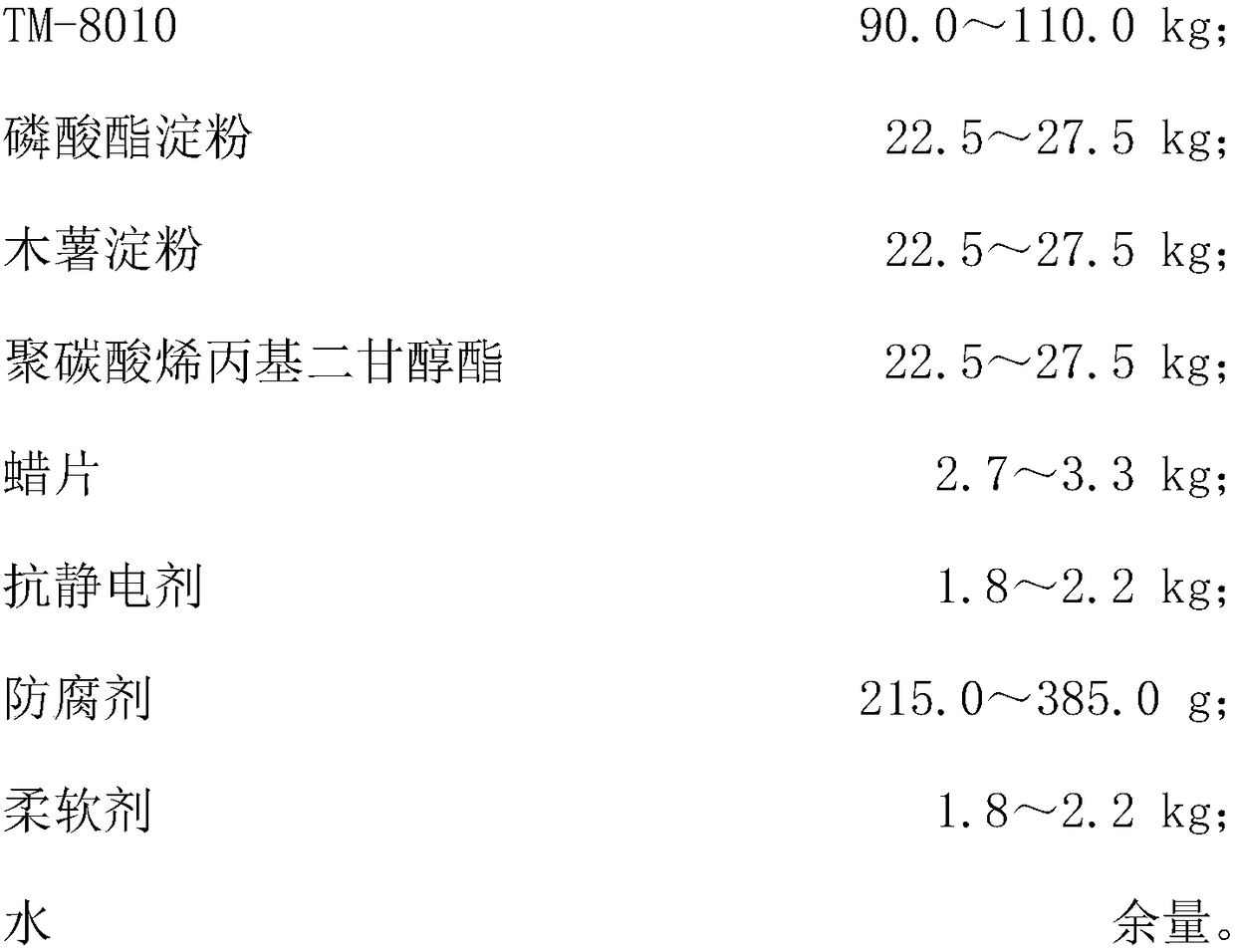

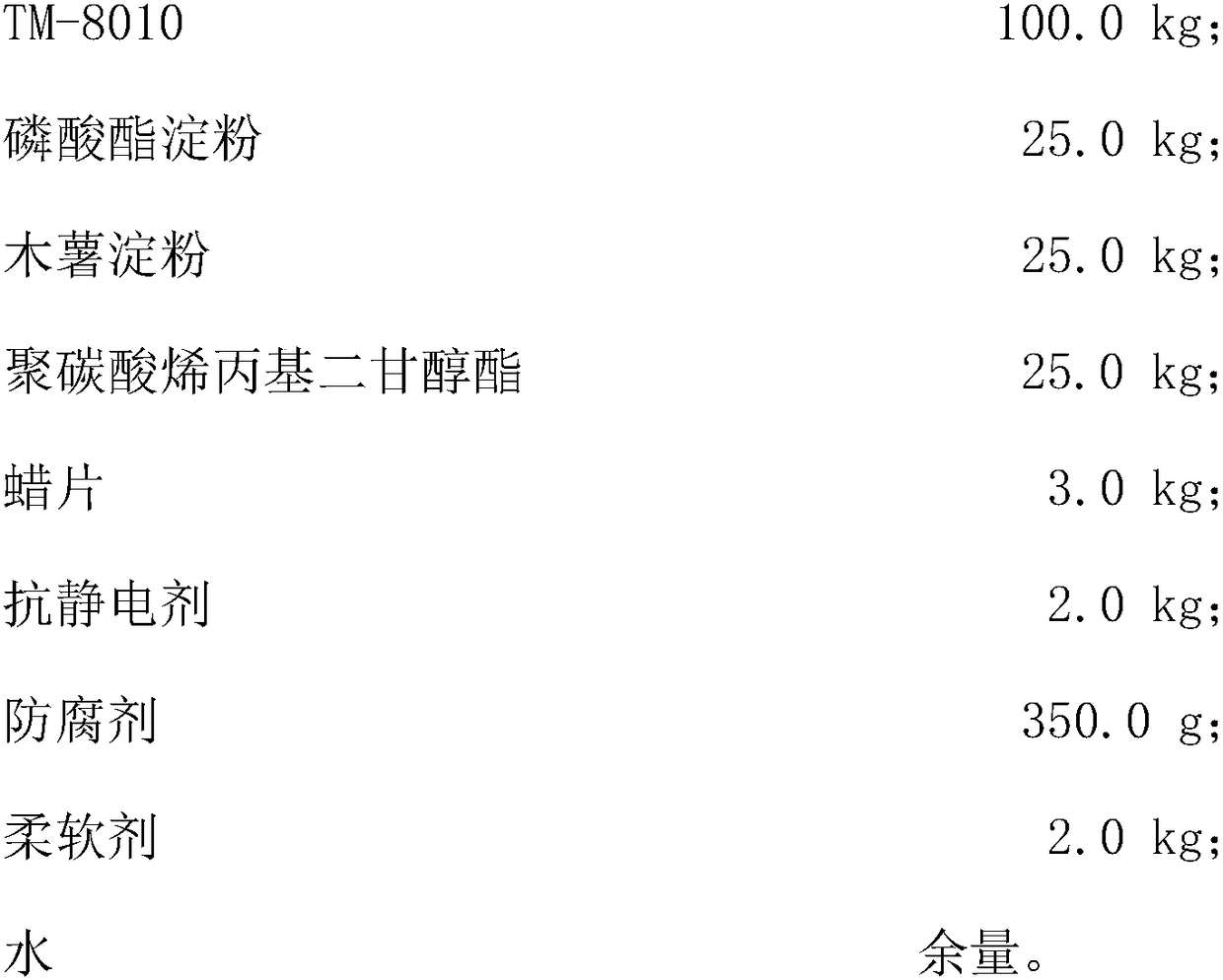

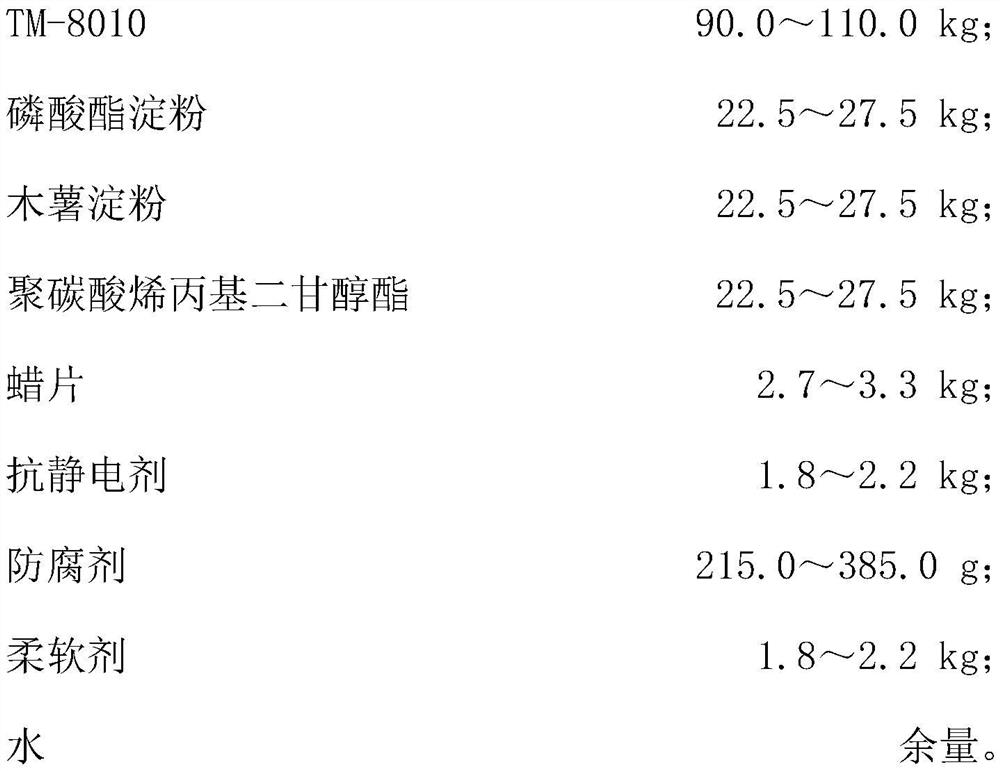

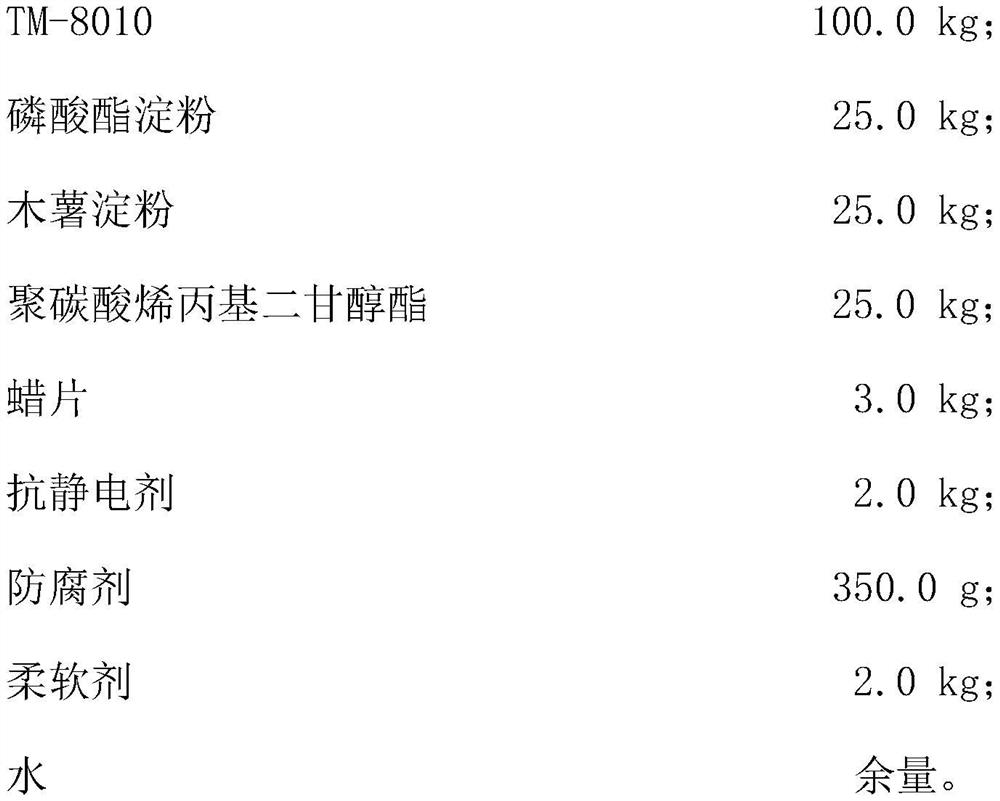

Down-proof shell fabric sizing slurry and sizing method

ActiveCN108239882AIncrease sizing rateImprove cohesionAbrasion resistant fibresVegetal fibresHigh concentrationPhosphate

The invention discloses down-proof shell fabric sizing slurry. The slurry is applied to a sizing technology for a superfine denier modal fiber spinning down-proof shell fabric. Every 780L of slurry isprepared from the following raw materials: 90.0-110.0kg of TM-8010, 22.5-27.5kg of phosphate starch, 22.5-27.5kg of cassava starch, 22.5-27.5kg of allyl diglycerol carbonate, 2.7-3.3kg of a wax sheet, 1.8-2.2kg of an antistatic agent, 215.0-385.0g of preservatives, 1.8-2.2kg of a softening agent and the balance of water. The down-proof shell fabric sizing slurry disclosed by the invention has theadvantages that 'high-concentration and low-viscosity' slurry can be formed, the slurry has excellent cohesive property and abrasion resistance on superfine denier modal fibers, sizing percentage ishigh, and a formed size film is excellent in elasticity, so that the strength and the abrasion resistance of the sized modal fibers are improved, and a risk that the modal fibers are broken during weaving is reduced.

Owner:JIANGSU YUEDA HOME TEXTILE

Beam sizing process of high-count color yarn

The invention discloses a beam sizing process of high-count color yarn. A size mixing formula comprises modified starch, polyvinyl alcohol, acrylic acid, wax sheets and a penetrant. The formula is sized by a double-size sizing machine, and the sizing process parameters of the double-size sizing machine are as follows: the sizing speed is 40-60 m / min-1, the size tank temperature is 95-98 DEG C, thesize viscosity is 6-8 s, the size solid content is 10%-12%, the moisture regain is 4%-5%, the sizing percentage is 10%-15%, the main size press force is 18-24 kN and the auxiliary size press force is8-12 kN. The size formula is simple, high in permeability and high in sizing percentage, the sizing quality is easy to control, the prepared size has high strength, low elongation reduction rate andlittle hairness, and the process is simple, applicable to sizing of high-count pure cotton color yarn and sizing of blended yarn taking cotton yarn as a main material and has very great significance in development of yarn-dyed pure cotton high-count and high-density products.

Owner:南通科沃纺织有限公司 +1

Eggshell modified polypropylene slurry and preparation method thereof

The invention provides an eggshell modified polypropylene slurry and a preparation method thereof. The preparation method comprises the following steps: (1) soaking and washing eggshells, drying at 120 DEG C, and then taking out the inner membranes of the treated eggshells, so as to obtain the inner-membrane-free eggshells; (2) grinding the inner-membrane-free eggshells obtained in step (1) into nanometer eggshell powder, adding the nanometer eggshell powder into an ethanol-water mixed solution, performing ultrasonic treatment for 20-30 min, adding sodium dodecyl sulfate, and heating and stirring to obtain an eggshell solution; and (3) adding the eggshell solution into an acrylic monomer solution, uniformly stirring at 40-50 DEG C to obtain a mixed solution, pouring the mixed solution into a reaction kettle which comprises a reflux condensation device, adding a potassium persulfate initiator for a heating reaction, and adding ammonium hydroxide to adjust the pH value of the mixed solution to be 8.0-9.5, so as to obtain the eggshell modified polypropylene slurry.

Owner:SUZHOU INSILK CO LTD

Compound additive for textile sizing, and preparation method thereof

The invention discloses a compound additive for textile sizing, and a preparation method thereof. The preparation method comprises the following steps: by taking glycol salicylate, fatty alcohol-polyoxyethylene ether, polyvinyl pyrrolidone and sodium dioctylsulfosuccinate as main components, adding sodium sulfite, dimethyl azobisisobutyrate, coconut oil amide propyl betaine, aluminum hydroxide, organic acid, a cross-linking agent and deionized water, and performing ball milling, stirring, emulsification, pH value adjustment, heating, holding, ultrasonic vibration, high-speed shearing and the like, so as to obtain the compound additive. After the prepared compound additive is used, textiles have the effect of remarkably increasing the sizing rate, the tensile strength of the textiles can be enhanced, the adhesion of dust can be decreased to meet the industrial demands, and thus the compound additive has better application prospects.

Owner:WUJIANG BEISHE SHENGYUAN TEXTILE PROD AUXILIARIES PLANT

35D/144F polyester low-stretch yarn fabric production process

ActiveCN104674434AOrderly and smooth movementReduce end break rateWarping machinesLiquid/gas/vapor removalPolyesterYarn

The invention discloses a 35D / 144F polyester low-stretch yarn fabric production process. Through carrying out process adjustment on four working procedures of warping, slashing, re-beaming and weaving, the kinking, the turning and the breaking are reduced, the sizing ratio is improved, the phenomena of rough yarns and cracked ends are reduced, the production efficiency is improved, and the product quality is ensured.

Owner:WUJIANG FUHUA WEAVING

Preparation method of starch-grafted composite glutin sizing

InactiveCN110016808ACatalytic hydrolysisReduce the degree of polymerizationFibre typesFiberMonoglyceride

The invention relates to a preparation method of starch-grafted composite glutin sizing, and belongs to the technical field of textile materials. By adding hydrogenated sheep oil and hydrogenated castor oil, composite sizing is prepared, and hydrogenated sheep oil and hydrogenated castor oil have emulsifying properties under the action of tridecanol polyoxyethylene ether and monoglyceride, can beevenly mixed in the sizing, play roles in plasticizing and improve the sizing percentage of the sizing. When grease is added in an adhesive containing polar groups, grease molecules can destroy physical crosslinking points of adhesive macromolecules and make it impossible for the polar groups of the macromolecules to establish interaction and hydrogen bonds, original non-moving chain segments begin to move, the vitrification temperature of serosas is reduced, and the serosas become softer. Besides, intervals between grease molecules make cohesive force between adhesive molecules reduced, a serosa structure thus relaxes, the strength is reduced, meanwhile the adhesive molecules are kept from fully moving close to fiber due to isolation of the grease molecules, and the desizing percentage ofthe sizing can be effectively improved.

Owner:常州市泰英物资有限公司

A kind of denim warp yarn sizing size and sizing process

ActiveCN103966849BImprove wear resistanceImprove surface propertiesFibre treatmentSlurryPulp and paper industry

The invention provides a jean warp sizing slurry and a sizing process. The slurry is prepared from DSC-14 starch, PVA, LMA-95 synthesis slurry, emulsified oil and a smoothing agent. In comparison with the prior art, the sizing slurry and process ensures that the warp abrasion resistance is greatly improved, the weaving performance is enhanced and the cost is lowered. Besides, the use amount of slurry and pollution are reduced, the existing technological process does not need to be changed significantly, the investment is relatively low and the effect can be taken rapidly.

Owner:ZHEJIANG SANSEN TEXTILE

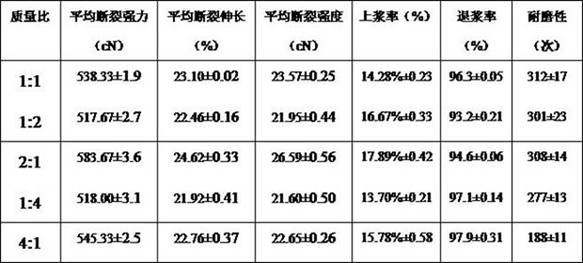

Sizing slurry for jute yarn

The invention discloses sizing slurry for jute yarn. The sizing slurry comprises PVA (polyvinyl acetate) slurry, grafting starch and polyacrylamide slurry, wherein the weight ratio of the PVA slurry to the grafting starch is 1:(1-4), and the weight ratio of the mixture of the PVA slurry and grafting starch to the polyacrylamide slurry is (3-15):1. In the invention, the polyacrylamide slurry is mixed with the PVA slurry and grafting starch in an optimal ratio to realize a perfect coordination effect; and through the invention, the adhesive force of the slurry can be increased, and the slashing flexibility can be obtained, thereby being favorable for splitting yarn and keeping serosa integrity, and improving the comprehensive performance of the slurry as well as the slashing quality.

Owner:JIANGSU REDBUD DYEING TECH CO LTD

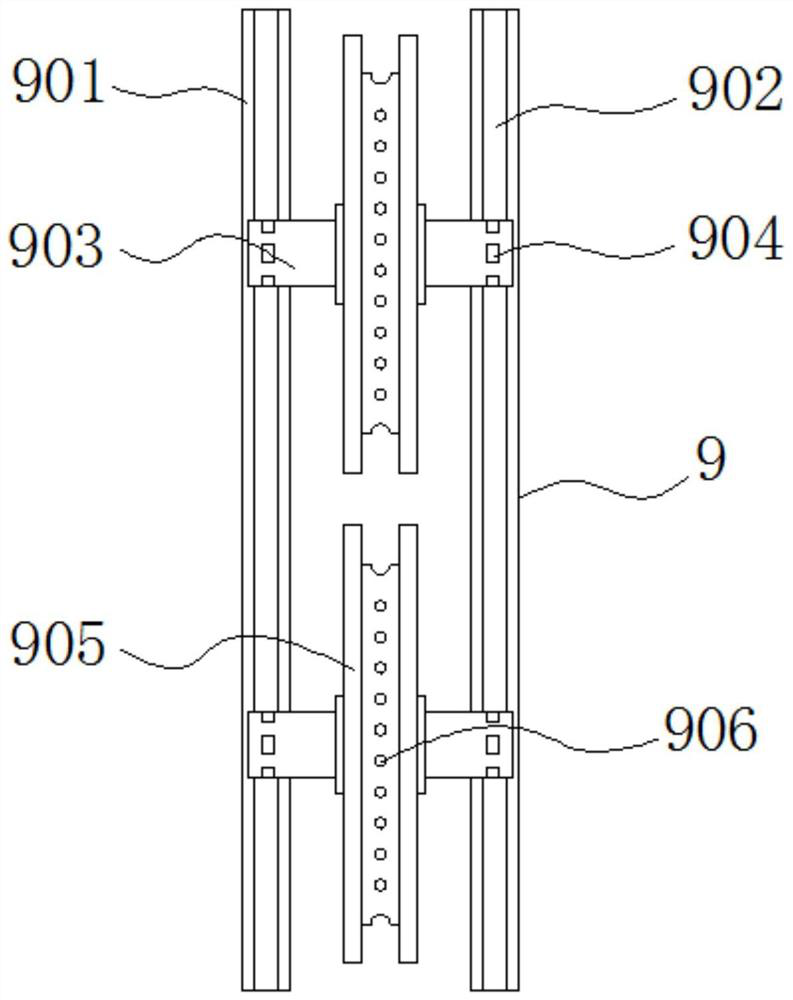

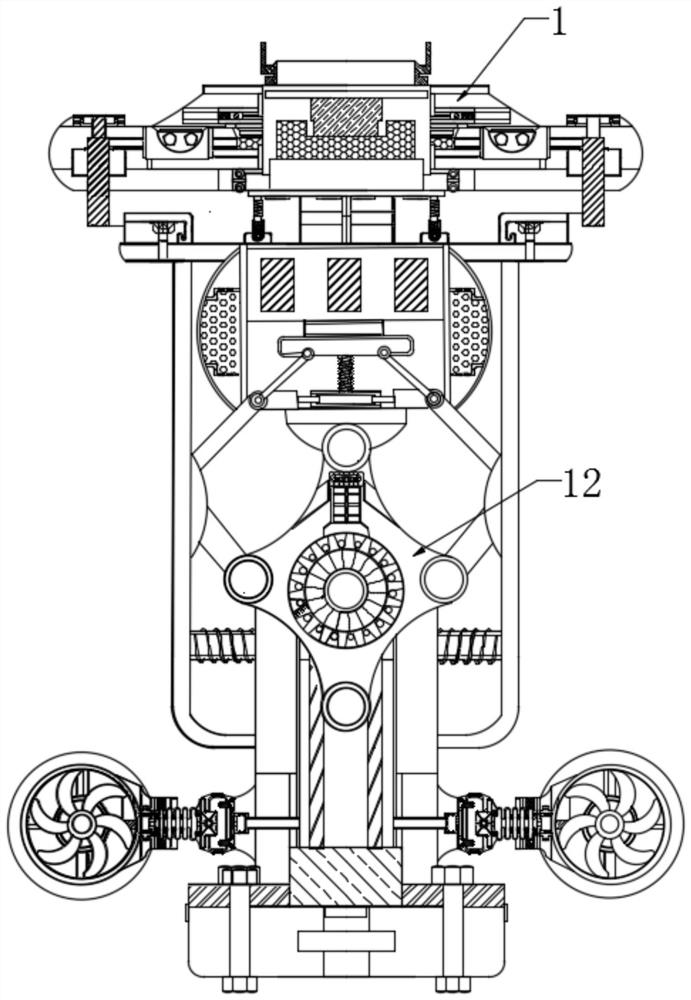

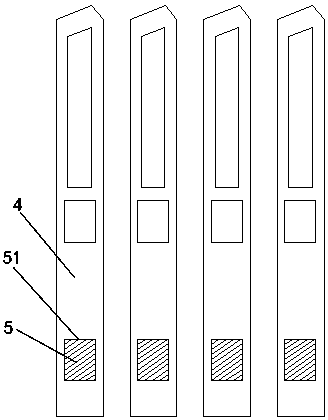

Device and technology for improving sizing rate of T16S yarn

ActiveCN111621939AIncrease sizing rateImprove work efficiencyLiquid/gas/vapor removalTextile treatment machine arrangementsYarnProcess engineering

The invention discloses a device and technology for improving the sizing rate of T16S yarn, and relates to the technical field of sizing machines. The device comprises a first sizing box, a winding group and an automatic adding pipe; a discharging cylinder is arranged on one side of the first sizing box in parallel, a sizing wheel is arranged at the bottom of the inner wall of the first sizing box, a drying chamber is arranged above a heat insulating plate, a protective wire screen is arranged on the outer side of an electric heating wire, the winding group is arranged in the drying chamber, the side face of the drying chamber is connected with a second wire wheel, and the automatic adding pipe is arranged at the bottom of the side wall of the first sizing box. According to the device andtechnology for improving the sizing rate of the T16S yarn, sizing in a second sizing box flows out of the surface of a winding wheel through a discharging hole, so that the friction force between theyarn and the winding wheel is reduced, one-side sizing operation is performed on the surface of the yarn again while falling of the sizing on the surface of the yarn is reduced, missing positions generated due to friction are filled, and therefore the integrity of sizing film on the surface of the yarn is improved.

Owner:武汉裕大华纺织有限公司

Water-based sizing agent for all-cotton spinning and preparation method thereof

The invention relates to a water-based sizing agent for all-cotton spinning and a preparation method thereof. The problems that in the prior art, surface adhesion between water-based sizing agents forall-cotton spinning and cotton fibers is poor, and the tensile property of sizing agents is poor are solved. According to a technical scheme, the water-based sizing agent for all-cotton spinning comprises the following components in parts by weight: 30-40 parts of butyl acrylate, 10-20 parts of methyl acrylate, 10-20 parts of methyl methacrylate, 15-25 parts of acrylonitrile, 10-20 parts of lauryl acrylate, 3-5 parts of a divalent alkaline earth metal compound, 3-4 parts of an emulsifier, 3-5 parts of an initiator, 0.3-0.5 part of an antistatic agent and 1.1-1.9 parts of a penetrant. The acrylonitrile is introduced into a sizing agent monomer, so that the surface adhesive force between the sizing agent and cotton fibers is greatly improved, the sizing rate of the sizing agent is high, andthe antistatic property is good.

Owner:桐乡市星邦科技发展股份有限公司

Prepolymer, polyurethane emulsion prepared therefrom for carbon fibers, and applications thereof

The invention discloses a prepolymer, which comprises the following components: (A) polyether glycol; (B) aromatic diisocyanate; wherein the weight ratio of the component (A) to the component (B) is 5.65:1 to 9.43:1; polyurethane emulsion for carbon fibers comprises the following components in parts by weight: 66.5 to 104.3 parts of prepolymer, 45 to 55 parts of organic solvent, 66 to 184 parts of deionized water, and 2 to 14 parts of processing auxiliary agent. The preparation method comprises the following steps: adding polyether glycol into a reactor, carrying out a water removing treatment at the temperature of 120 DEG C for 1 hour, cooling to 50 DEG C, stirring and heating to 70 DEG C in an oil-bath; then adding aromatic diisocyanate into the reactor, carrying out a reflux reaction for 2 hours under the protection of nitrogen gas, adding an organic solvent into the reactor, and cooling to the 40 DEG C so as to obtain the prepolymer; adding a processing auxiliary agent, dissolving the agent with an organic solvent, then adding the solution into the prepolymer, carrying out the reactions for 1 hour, then adding water to carry out emulsion reactions for 30 minutes, and finally carrying out reduced pressure distillation to remove the organic solvent so as to obtain the target product. The obtained polyurethane emulsion can reduce the surface tension of carbon fibers, improves the wettability and bundling of carbon fibers, reduces the broken filament rate, and can be applied to the fields of automobile, medicine, food processing, and chemical engineering.

Owner:GUANGZHOU KINGFA CARBON FIBER NEW MATERIALS DEV

Manufacturing method of antifouling sofa fabric

ActiveCN106283340BIncrease sizing rateLess hairyTransfer printing processWarping machinesYarnTextile printer

The invention provides a method for making an antifouling sofa fabric, which belongs to the technical field of home textiles and comprises the following steps: (1) selecting raw materials for spinning; (2) yarn antifouling finishing; (3) warping and sizing; (4) weaving (5) transfer printing; (6) solid color finishing; (7) antifouling finishing; (8) water repellent finishing; (9) bonding: on the upper and lower sides of the sponge The adhesive is applied on the sides respectively, and pressure is applied to the upper base cloth layer, sponge and lower base cloth layer stacked up and down, so that the three are bonded into one; (10) sewing; the yarn processed by the warping and sizing machine The sizing rate on the line is high and the hairiness is small, which can reduce the static electricity generated by the friction between the yarns, effectively reducing the static electricity of the fabric itself, so the woven fabric is not easy to generate static electricity, and relatively difficult to absorb dust. The sofa fabric produced has multiple anti-fouling capabilities, and the anti-fouling effect is remarkable.

Owner:海宁宝祥布业有限公司

A kind of multifunctional environment-friendly universal textile size and preparation method thereof

ActiveCN105603750BBulking and loose fibersIncrease sizing rateFibre typesEnvironmental resistanceSlurry

The invention discloses a multifunctional environmentally-friendly universal spinning sizing agent which is prepared from, by weight, 3-9 parts of chitosan, 15-20 parts of acetate starch, 1-3 parts of carboxymethylcellulose, 0.5-1 part of bentonite, 2-3 parts of sodium silicate, 5-10 parts of itaconic acid, 5-15 parts of acrylamide, 4-8 parts of butyl acrylate, 2-6 parts of butyl acrylate, 1-1.5 parts of initiator, 0.8-1.5 parts of a catalyst, 2-5 parts of calcium chloride and 5-10 parts of deionized water. The invention discloses a preparation method of the spinning sizing agent, viscosity of the spinning sizing agent is stable, excellent chemical stability and thermal stability are achieved, sizing and desizing are conducted easily, slurry wastewater is easy to process, the size film property and the sizing property are good, moisture absorption and stickiness viscidity are low, the multifunctional environmentally-friendly universal spinning sizing agent is environmentally friendly, and environmental pollution is reduced.

Owner:嘉兴纳科新材料有限公司

A kind of preparation method of size on wool keratin and sericin yarn

ActiveCN108560261BReduce manufacturing costReduce pollutionPeptide preparation methodsCytokeratinProtein solutionYarn

The invention discloses a method for preparing wool keratin and sericin yarn size. The technical problem to be solved is that silkworm cocoon processing sericin sewage and waste wool cause environmental pollution. The invention includes the following steps: 1) : preparation of sericin solution; 2) preparation of keratin solution; 3) preparation of mixed protein solution: the concentration of sericin in the sericin solution prepared in step 1) and step 2) and the keratin in the keratin solution Adjust the concentration of keratin to the same concentration, mix the keratin solution and sericin solution according to the mass ratio of 4:1‑1:4; 4) add auxiliary reagents: get the prepared wool keratin and sericin yarn Size solution; 5) The prepared wool keratin and sericin yarn size is used for yarn size. At the same time, the invention can realize waste recycling and effectively reduce the pollution of sericin sewage and waste wool to the environment.

Owner:ZHONGYUAN ENGINEERING COLLEGE

A kind of textile size composition and preparation method thereof

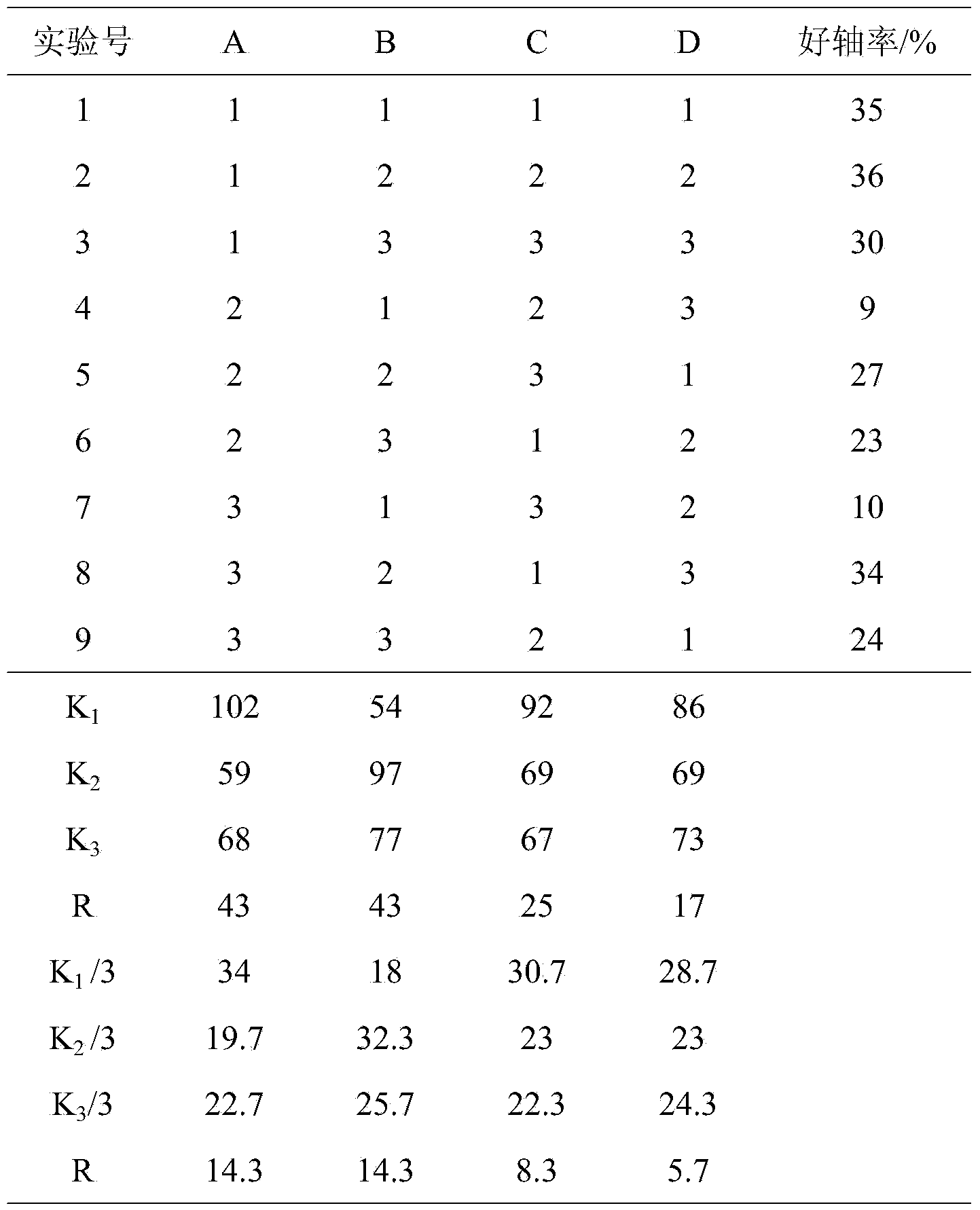

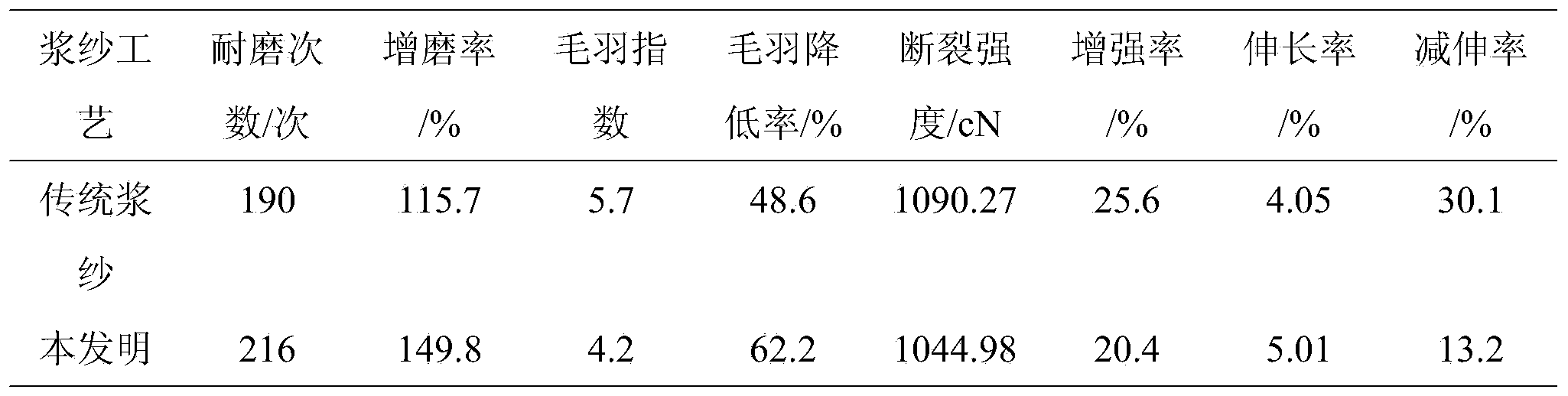

ActiveCN109338725BExcellent shaft ratioExcellent enhancement rateVegetal fibresPolymer scienceSlurry

The invention discloses a textile size composition and a preparation method thereof, belonging to the technical field of sizing. The composition is made of the following raw materials in parts by weight: 45-60 parts of carbamate modified starch, 2-5 parts of sodium alginate, 35-45 parts of PVA, 10-15 parts of LMA slurry, 2-5 parts of sodium silicate 1-4 parts, 1-4 parts of emulsified oil, 3-5 parts of smoothing agent, 1-4 parts of soaking agent and water, and the water adjusts the solid content of the composition to 12-14.5%. The composition is mainly aimed at pure cotton fabrics. From the perspective of the size itself, the viscosity of the size tank is 7.5-8.5s, the viscosity thermal stability is 94-97%, and the viscosity and thermal stability are relatively good; from the quality of the fabric Said that its sizing rate is slightly increased, the reinforcement rate and good axis rate are greatly improved, and the elongation rate is slightly decreased; from the perspective of textile efficiency, the speed and efficiency of the textile have a certain increase; from the cost point of view, the use of more expensive raw materials, but the overall cost has not increased.

Owner:湖北双迅纺织有限公司

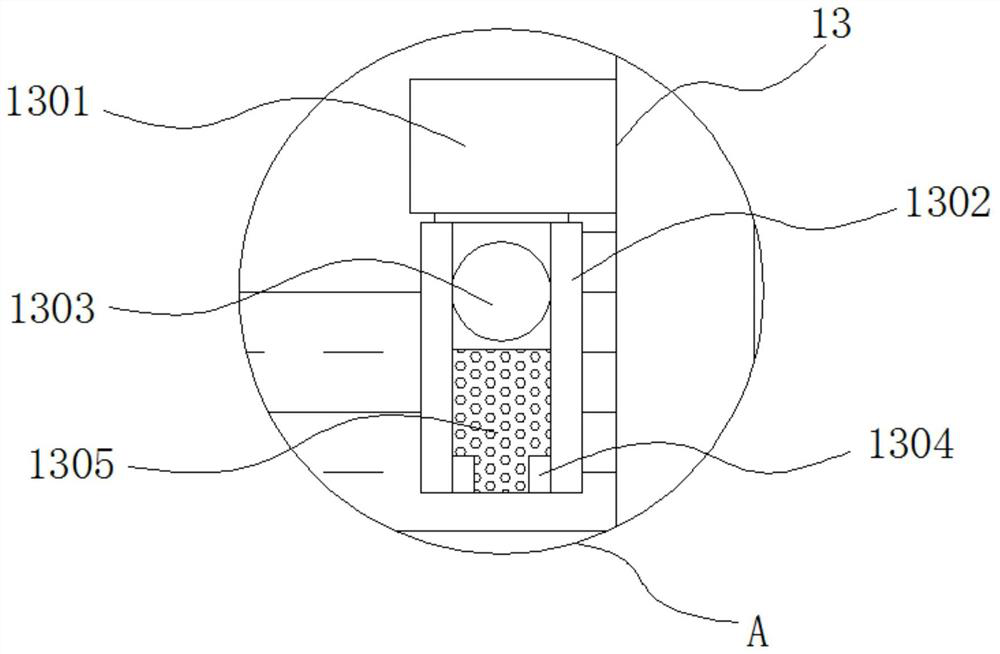

Intelligent manufacturing equipment for increasing sizing rate for bandage production

InactiveCN113046960AIncrease production capacityIncrease rotation rateTextile treatment machine arrangementsLiquid/gas/vapor removal by gas jetsMechanical engineeringBandage

The invention relates to the technical field of bandages, and discloses intelligent manufacturing equipment for increasing a sizing rate for bandage production. In the equipment, stabilizing pieces are fixedly connected to the left side and the right side of a main body. According to the intelligent manufacturing equipment for improving the sizing rate for bandage production, a solution is fed through a feeding port, original sizing in the feeding port moves to the upper end through a conveying part, the feeding port and the conveying part are not equal in height, the conveying part is lower than the feeding port, a supporting rod at the top end of the conveying part moves upwards under the gravity effect, a sliding strip synchronously operates on an internal center seat, a push rod is stressed to gradually move towards the middle, and a round rod accessory accelerates to push a bandage strip, so that the rotating speed of the center seat is increased, meanwhile, the sizing speed can be controlled by controlling the push rod, thus the equipment has the function of controlling the sizing speed, the self-adhesion is improved, the utilization rate is relatively high, and the production of the bandage is promoted.

Owner:胡念兵

A Production Process of 35d/144f Polyester Low Elastic Fabric

ActiveCN104674434BOrderly and smooth movementReduce end break rateWarping machinesLiquid/gas/vapor removalPolyesterYarn

The invention discloses a production process of 35D / 144F polyester low-stretch yarn fabric. Through the process adjustment of the four processes of warping, sizing, paralleling and weaving, kinks, twists and end breaks are reduced, the sizing rate is improved, and the sizing rate is reduced. The phenomenon of hair warp and broken warp improves the production efficiency and ensures the product quality.

Owner:WUJIANG FUHUA WEAVING

A kind of slurry for electronic grade glass fiber cloth and preparation method thereof

ActiveCN114438789BImprove wear resistanceIncrease sizing rateAbrasion resistant fibresGlass fiberYarn

The invention belongs to the technical field of electronic glass fiber cloth, and particularly relates to a slurry for electronic-grade glass fiber cloth and a preparation method thereof. The raw materials of the slurry for electronic-grade glass fiber cloth include the following components: the raw materials of the slurry include 0.5-2% of polyvinyl alcohol, 0.05-0.1% of water-based rosin resin, 0.01-0.05% of water-based phenolic resin, and 0.1-1.0% of gum yarrow, 0.2-2% of stabilizer, 0.1-0.8% of lubricant, and the rest are deionized water. The preparation method is as follows: firstly, adding polyvinyl alcohol, water-based phenolic resin, stabilizer and some lubricants into water, mixing and stirring; then adding water-based rosin resin and tragacanth gum, stirring; finally adding remaining lubricant and stirring. The sizing provided by the invention has good adhesion and strong abrasion resistance, does not need secondary sizing before weaving, can protect the abrasion during the preparation of warp yarns, reduces the generation of broken silk and hairiness, and is easy to desizing.

Owner:清远凯荣德电子专用材料有限公司

A preparation method of flax and tencel interwoven fabric

ActiveCN106435943BPrevent friction fractureUniform sizeWarping machinesAuxillary apparatusYarnSlurry

The invention discloses a preparation method of flax and tencel interwoven fabric, the steps are as follows: (1) winding process; (2) warping process; (3) sizing process; (4) reeding process; (5) Weaving process; (6) Finishing process: Bleaching and packaging the prepared yarn for domestic sale. The invention has the advantages of high weaving efficiency, large production scale, low warp breakage rate and easy finding of warp breakage.

Owner:JIANGSU MINGYUAN TEXTILE

Featherproof fabric sizing size and sizing method

ActiveCN108239882BIncrease sizing rateImprove cohesionAbrasion resistant fibresVegetal fibresFiberHigh concentration

The invention discloses a sizing slurry for feather-proof fabrics, which is used for the sizing process of ultra-fine denier modal fiber textile feather-proof fabrics. Starch 22.5-27.5kg; tapioca starch 22.5-27.5kg; polyallyl diethylene glycol 22.5-27.5kg; wax flakes 2.7-3.3kg; antistatic agent 1.8-2.2kg; preservative 215.0-385.0g; soft agent 1.8 ~ 2.2kg; water balance. The above-mentioned anti-feather fabric sizing sizing can form "high-concentration, low-viscosity" sizing, the sizing has excellent cohesion and abrasion resistance to ultra-fine modal fibers, high sizing rate, and the formed sizing film Excellent elasticity, thereby improving the strength and abrasion resistance of sizing modal fibers, reducing the risk of breakage during weaving.

Owner:JIANGSU YUEDA HOME TEXTILE

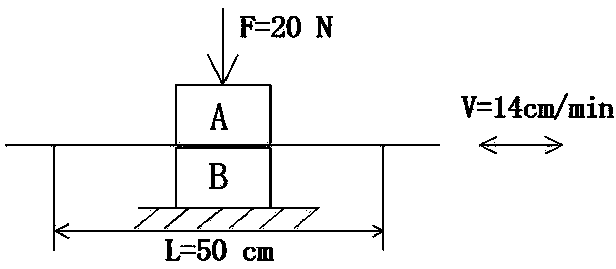

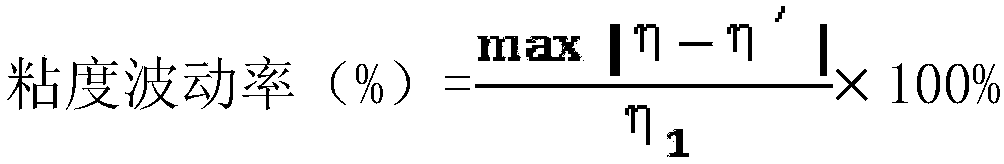

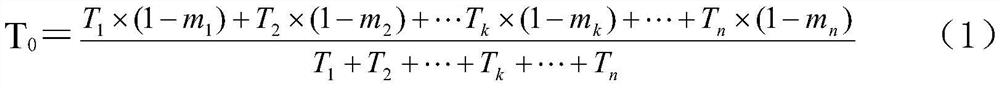

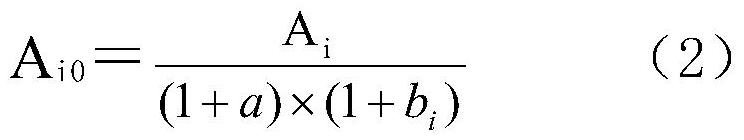

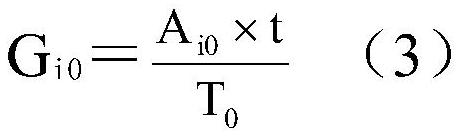

Calculation method of on-machine sizing rate in sizing process

ActiveCN107366118BReduce energy consumptionLow costTextile treatment machine partsYarnTextile technology

The invention discloses a method for calculating the on-machine sizing percentage in the sizing process, and relates to the technical field of textiles. The method comprises the following steps of calculating the average dry weight rate of sizing used for sizing in the sizing process, calculating the dry weight of each piece or each roll of sheet yarn in the sizing process, calculating the standard weight of the sizing needed by each piece or each roll of sheet yarn, and calculating the on-machine sizing percentage at any moment in the sizing process. The defects that in the prior art, blindness and randomness of sizing control of sizing workers are caused and sizing quality is not stable are overcome, and the defects that the sampling analysis process in the prior art is tedious and time feedback obviously lags are overcome; the method has the advantages that the sizing quality is stable, the sizing qualified rate and the weaving efficiency of a cloth machine are improved, the sizing loss is reduced, and the production cost is reduced.

Owner:HUBEI ANMIAN TEXTILE

Wool dip-dyeing technology

The invention relates to a wool dip-dyeing technology. The wool dip-dyeing technology comprises the following steps: vatting reducing dye, preparing a dye bath, adjusting the temperature of the dye bath, dyeing, adding ammonium sulfate to dye for 10-15 minutes under the condition that the original temperature is unchanged, water washing, oxidizing, soap boiling, water washing, and drying. The dyeing step comprises the following processes: firstly, adding 1L of ammonium hydroxide with warm water of 50 DEG C, and 150g of sodium hydrosulfite in a dye liquid; secondly, adding 10L of colloidal solution (a bath ratio of 1:10); thirdly, adding a vat-reduced liquid to perform dyeing, and in the later period of dyeing, adding ammonium sulfate to lower the pH value of the dye bath to 8.5-9. A wool fabric produced by virtue of the technical steps is high in sizing percentage and neither shrinks nor deform easily.

Owner:WUXI YINTAI TEXTILE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com