Prepolymer, polyurethane emulsion prepared therefrom for carbon fibers, and applications thereof

A polyurethane emulsion and carbon fiber technology, applied in the directions of carbon fiber, fiber treatment, fiber type, etc., can solve the problems of difficulty in compounding and preparing interface performance composite materials, limiting the use field of carbon fiber, and poor carbon fiber bundling. The effect of low rate and high sizing rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

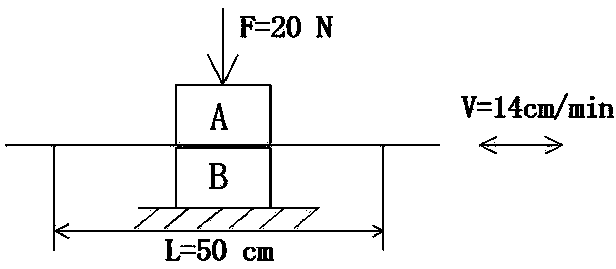

Image

Examples

Embodiment A1~A7 and comparative example 1~2

[0056] Embodiment A1~A7 and comparative example 1~2: the preparation of polyurethane emulsion for carbon fiber

[0057] According to the ratio in Table 1, add the polyether diol into the reaction vessel equipped with electric mixer, thermometer and oil bath, remove water under reduced pressure at 120°C for 1 hour, cool naturally to 50°C, and stir in the oil bath Raise the temperature to 70°C; add aromatic diisocyanate, reflux reaction under nitrogen protection for 2 hours, add organic solvent to reduce the viscosity of the system, cool down to 40°C and discharge to obtain prepolymer; add processing aid, dissolve with organic solvent and add to In the prepolymer, add deionized water to emulsify for 30 minutes after reacting for 1 hour, and distill off the organic solvent under reduced pressure to obtain a polyurethane emulsion for carbon fiber with a solid content of 30~60wt%. , The surface tension properties of the emulsion were tested, and the data are shown in Table 1.

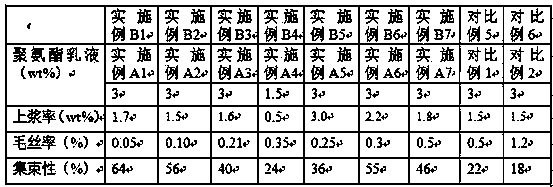

Embodiment B1~B5 and comparative example 5~6

[0068] Examples B1~B5 and Comparative Examples 5~6: Application of Polyurethane Emulsion for Carbon Fiber

[0069] Dilute the above-mentioned carbon fiber with polyurethane emulsion to a mass concentration of 1-10wt%, and infiltrate and modify the surface of the carbon fiber. The temperature of the emulsion is 25°C, and soak for 2 minutes. After ~3 minutes, a polyurethane emulsion modified carbon fiber was obtained, and the sizing rate of the polyurethane emulsion on the carbon fiber was 0.5-3.0wt% for the carbon fiber; the performance test data of the polyurethane emulsion modified carbon fiber is shown in Table 3. Among them, carbon fiber can be purchased in the market, such as: Kingfa Technology Co., Ltd.’s brand T35, the carbon fiber specification is 12k, the tensile strength is 3.53GPa, the tensile modulus is 230~250GPa, and the density is 1.76g / cm 3 carbon fiber.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile modulus | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com