Patents

Literature

1628 results about "Processing aid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A processing aid is a substance used in the production of processed food, and which may end up in the finished product, but which is not, by law, required to be disclosed to the consumer as an ingredient.

Flame-retardant polyester material with high glow wire ignition temperature and preparation method thereof

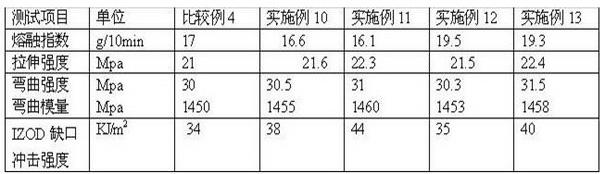

ActiveCN102250450AGWIT performance improvementsMeet performance requirementsPolyester resinUltimate tensile strength

The invention discloses a fame-retardant polyester material with a high glow wire ignition temperature and a preparation method thereof. The flame-retardant polyester material with a high glow wire ignition temperature is composed of the following components in parts by weight: 100 parts of polyester resins, 15-50 parts of bromine-series flame retardant, 5-20 parts of synergistic flame retardant, 0-20 parts of toughening agent, 0-80 parts of carbon forming agent, 5-40 parts of hot oxygen barrier agent, 0-120 parts of fibrous reinforcing agent and 0-10 parts of processing aid. The preparation method of the flame-retardant polyester material with a high glow wire ignition temperature comprises: drying the polyester resins, mixing with other components to obtain a premixed material, then feeding the premixed material into a twin-screw extruder, melting and plasticizing, kneading and mixing, extruding, drawing, cooling, pelletizing, drying and finally packaging. The flame-retardant polyester material with a high glow wire ignition temperature has the advantages of low cost, high glow wire ignition temperature, similar mechanical strength to ordinary flame-retardant polyester and wide application range.

Owner:KINGFA SCI & TECH CO LTD +1

Thin film produced by using starch fiber waste plastic

The invention discloses a thin film produced by using starch fiber waste plastic. The new breakthrough and technical innovative points are applied to an environment-friendly plastic synthesized thin film or sheet. The produced environment-friendly plastic synthesized thin film or sheet comprises the following raw materials of 10-60 percent of high polymer waste plastic (regenerated plastic), 10-60 percent of modified starch, 10-50 percent of natural plant fiber, 5-30 percent of inorganic material and 2-15 percent of modifier, compatilizer and processing aid. In the plastic-synthesized thin film or sheet, the thickness of the membrane is 0.01-0.6mm and the thickness of the sheet is 0.6-3mm. The preparation of the thin film has the advantages that the environment-friendly practical thin film or sheet with degradation time with different efficiencies, transmissivity, stress degrees and the like can be obtained by adjusting the mixture ratio of various materials.

Owner:陈天云

High-temperature resistant thermoplastic polyvinyl chloride cable material and preparation method thereof

ActiveCN103524946AGood physical propertiesHigh strengthInsulated cablesInsulated conductorsProcedure AgentsPolyvinyl chloride

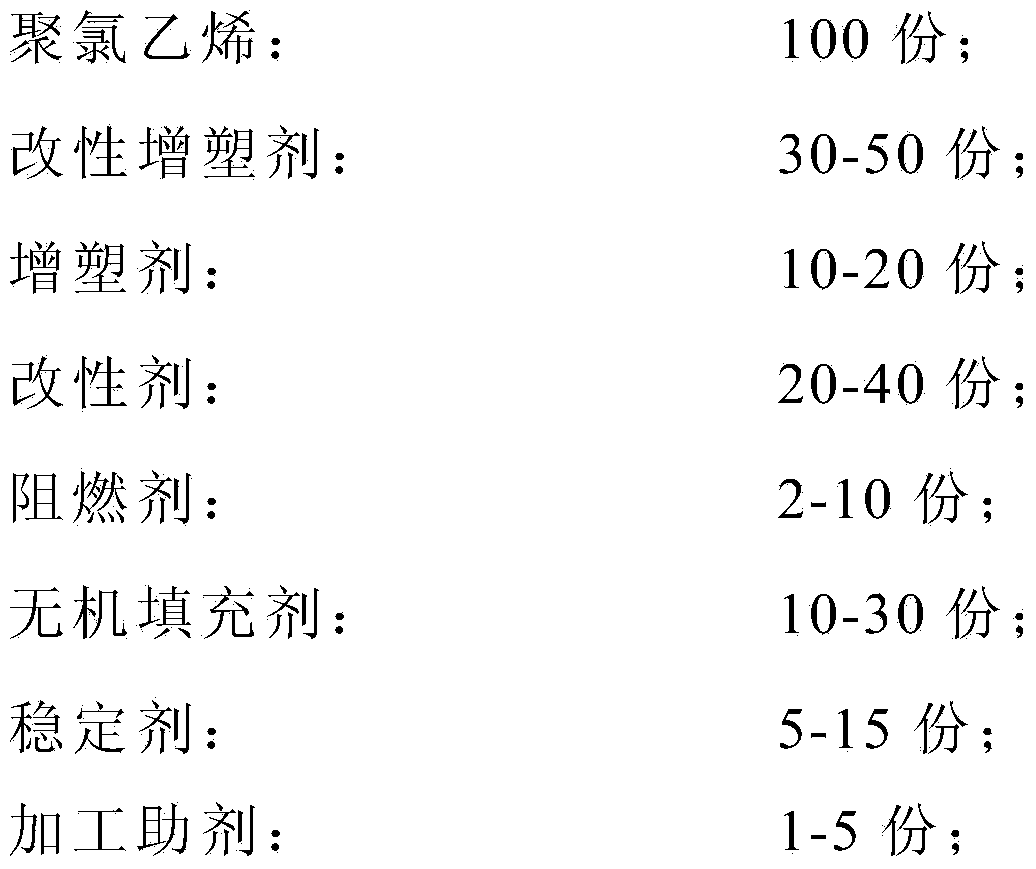

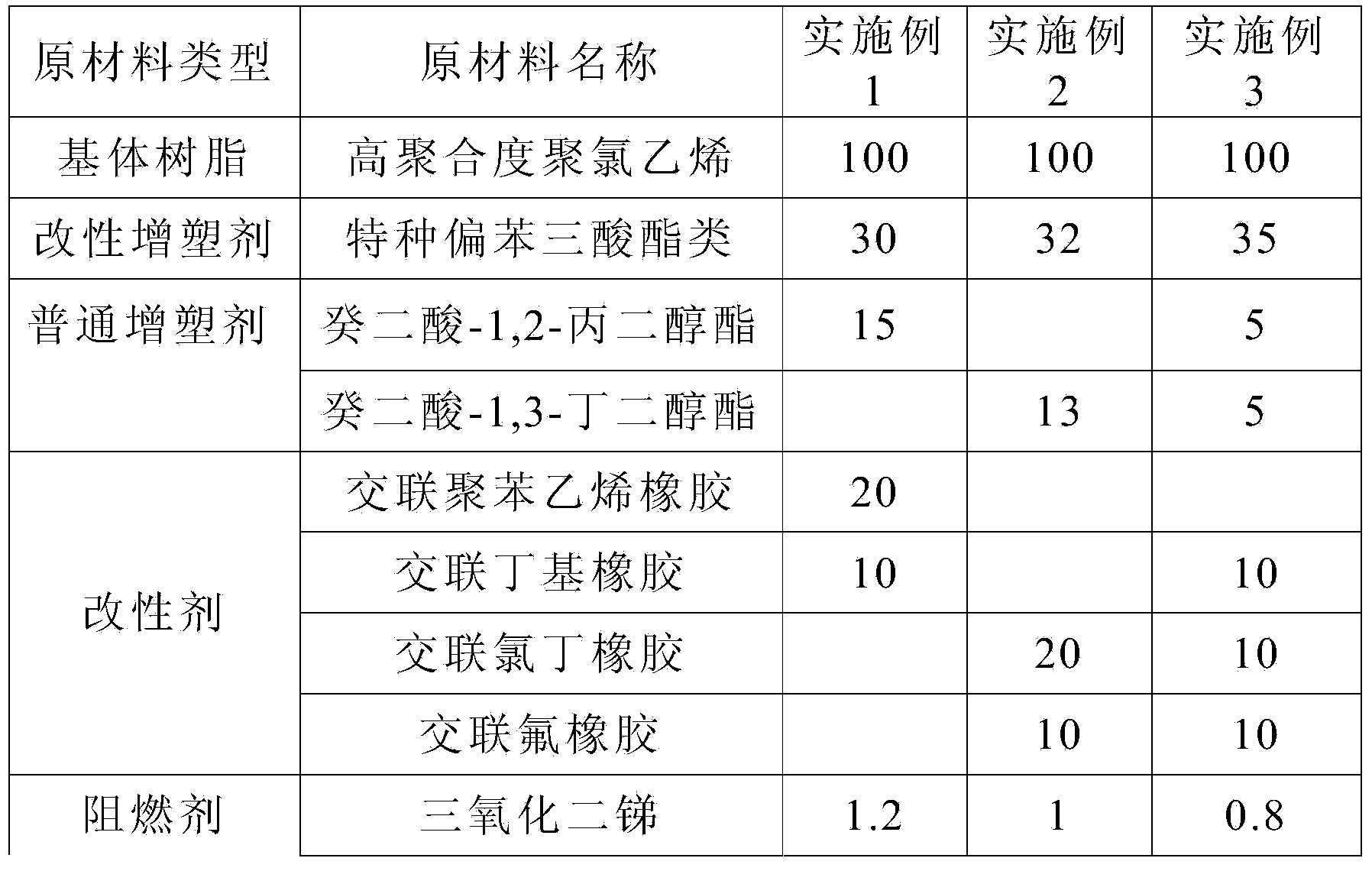

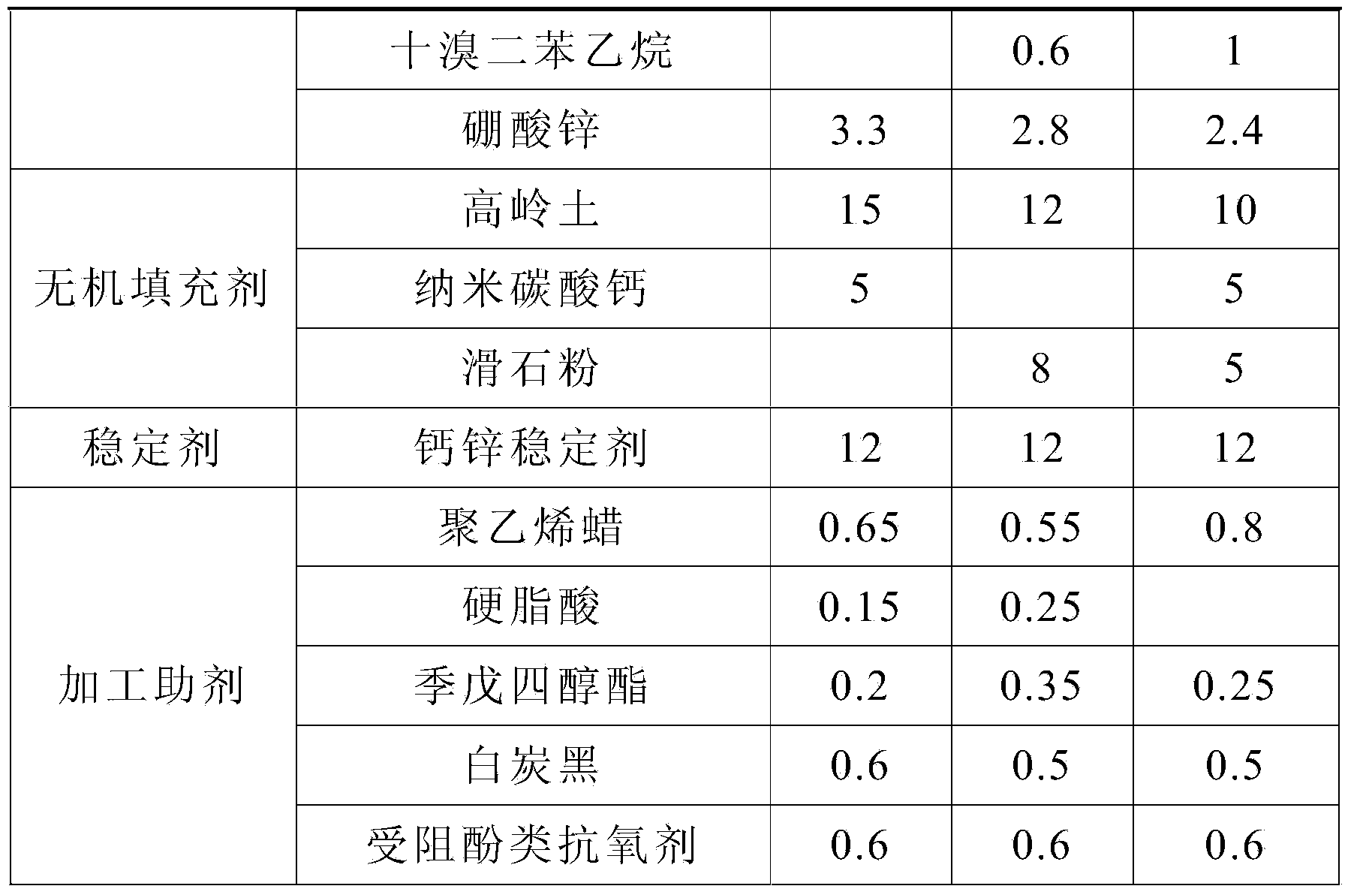

The invention relates to a high-temperature resistant thermoplastic polyvinyl chloride cable material, belonging to the technical field of new materials. The cable material consists of the following components in parts by weight: 100 parts of polyvinyl chloride, 30-50 parts of modified plasticizer, 10-20 parts of plasticizer, 20-40 parts of modifier, 2-10 parts of flame retardant, 10-30 parts of inorganic filler, 5-15 parts of stabilizer and 1-5 parts of processing aid. A preparation method of the cable material comprises the following steps: weighing the raw materials according to the components and weight parts of the cable material; uniformly mixing the polyvinyl chloride and adding the modified plasticizer and the common plasticizer; heating and stirring and adding other raw materials; discharging from a high mixing machine and feeding into a twin-screw extruder for extrusion and granulation; and performing air cooling to obtain the final product. The cable material has the advantages that the physical property is good, the applicable temperature range is wide, little pollution is caused, the flame retardance is good, the smoke output in combustion is low, the preparation method is simple, and the cost is low.

Owner:江西一舟数据技术有限公司

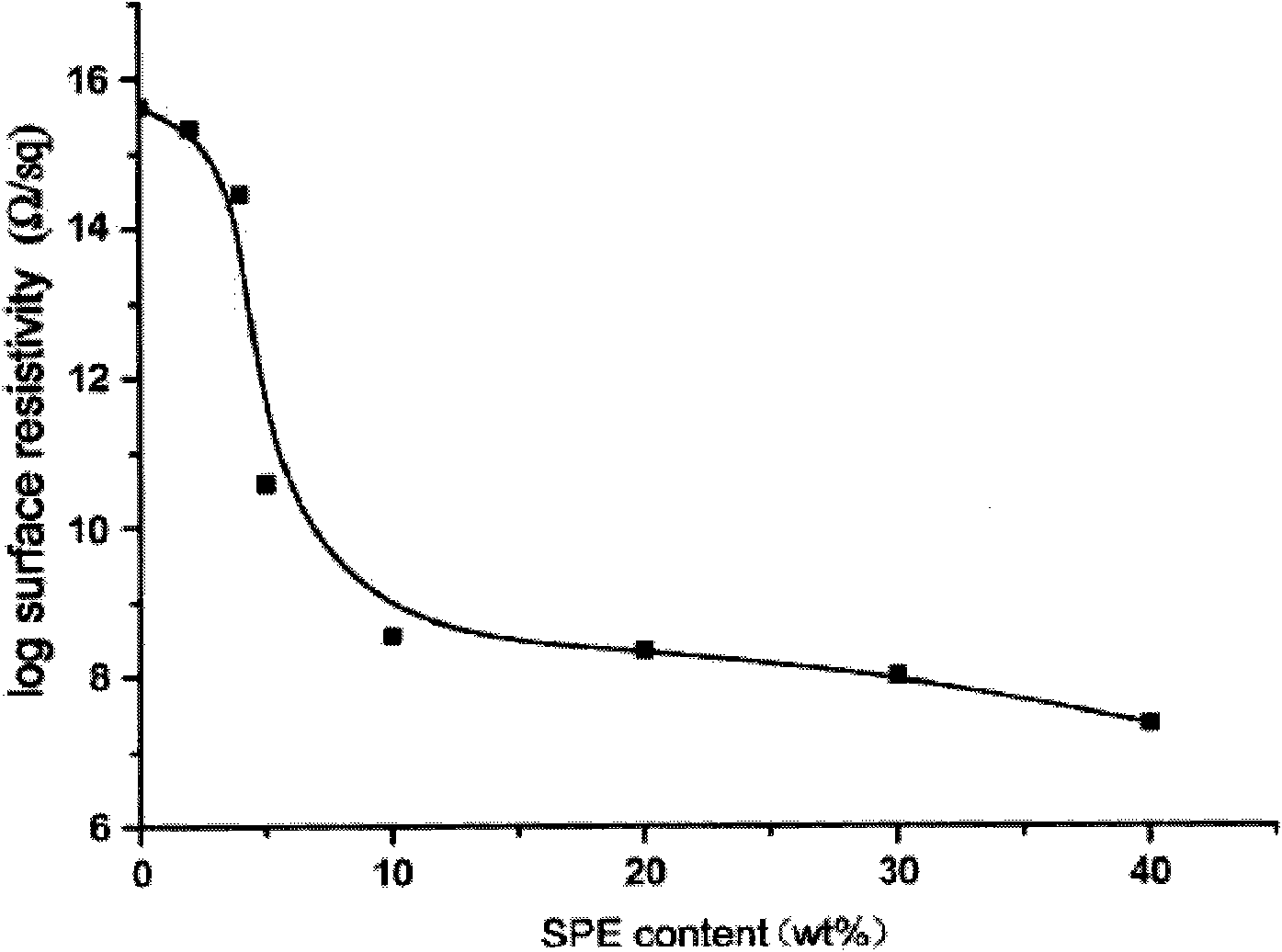

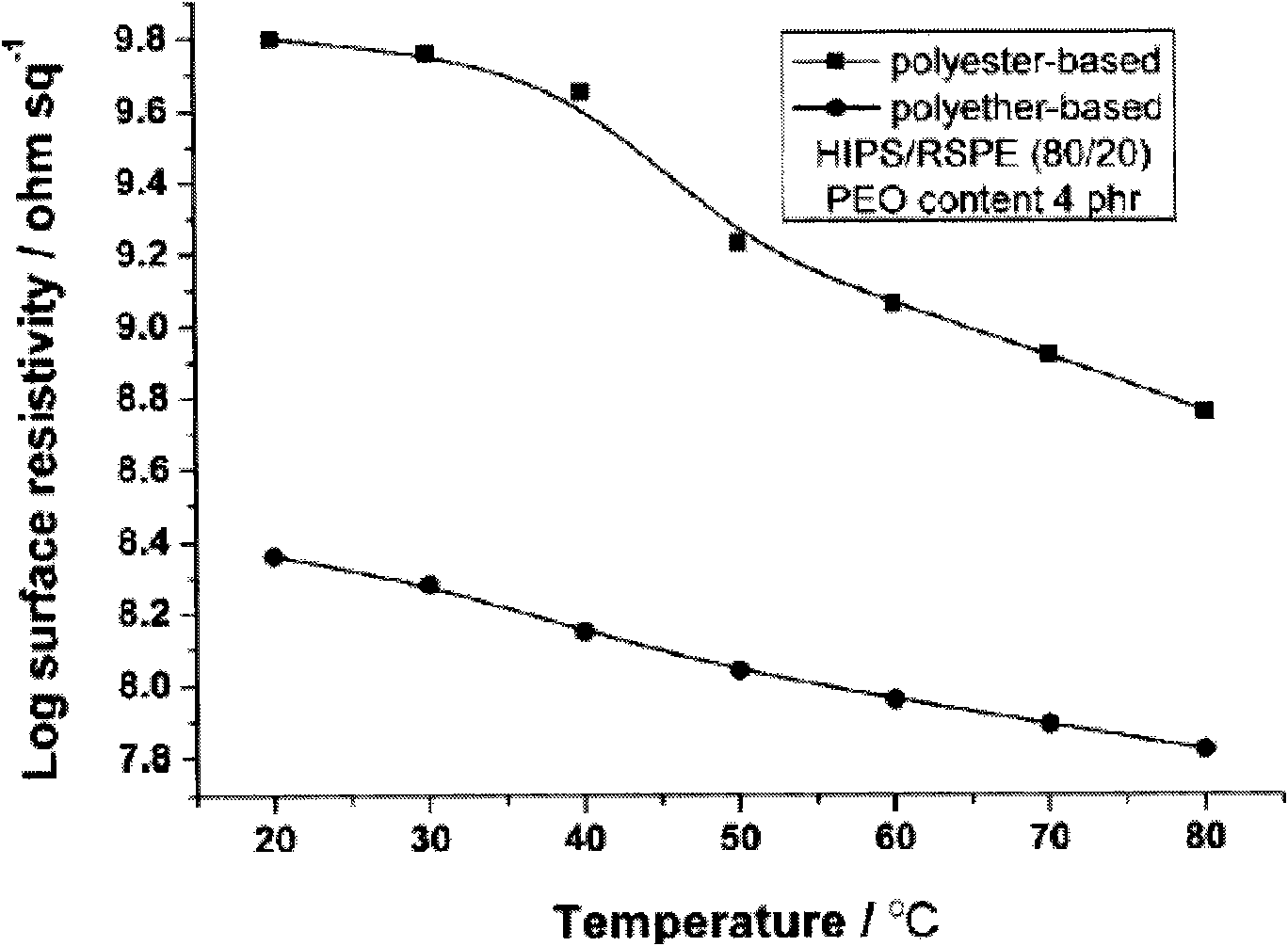

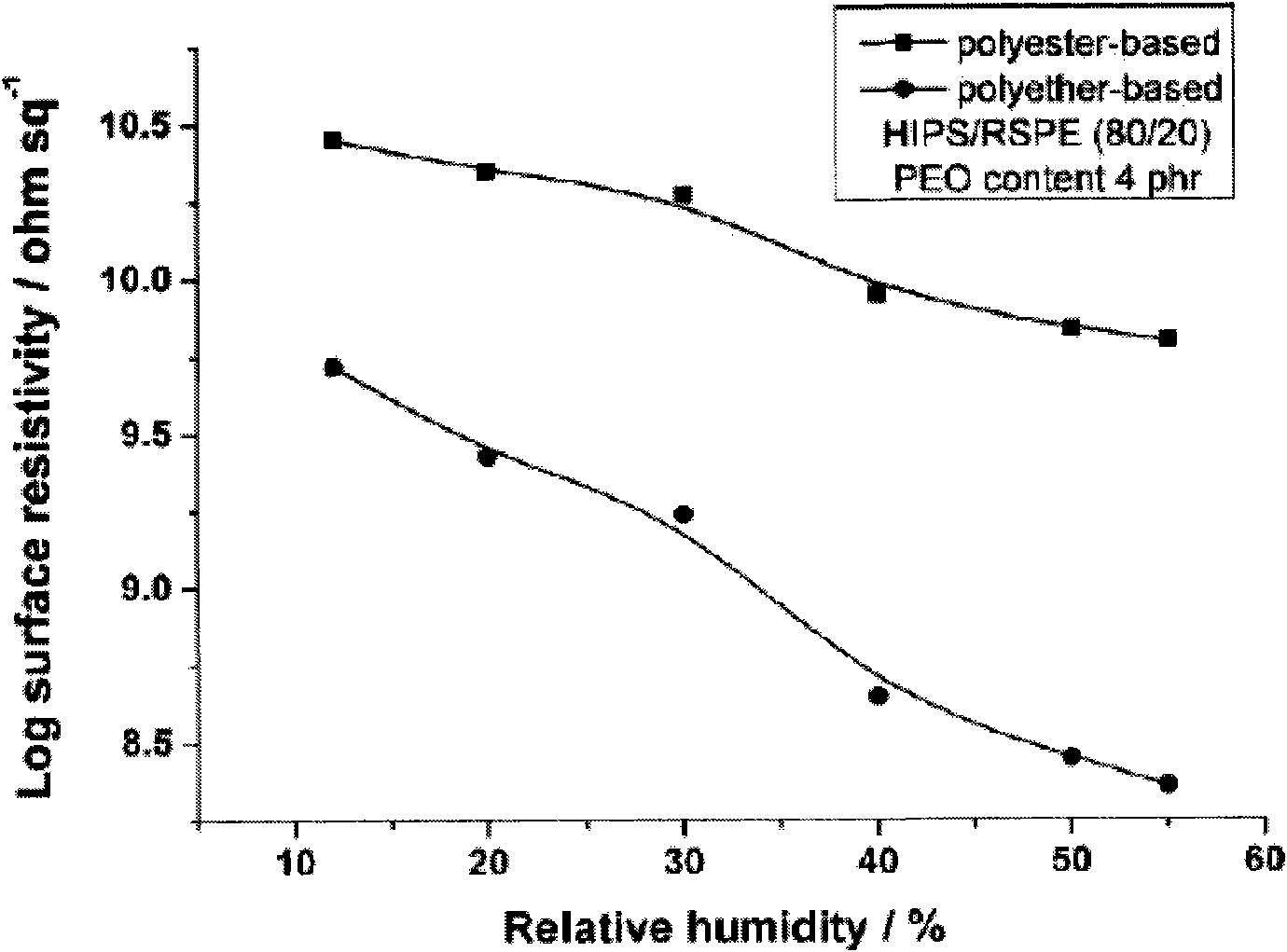

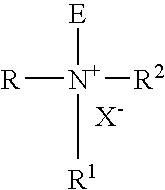

All-weather persistent antistatic master batch capable of being subjected to thermoplastic processing and antistatic composite material

The invention belongs to the field of preparation of macromolecular composite materials and particularly relates to an all-weather persistent antistatic master batch capable of being subjected to thermoplastic processing and an antistatic composite material. The antistatic master batch is prepared by forming of a low-dissociation-energy compounding agent, a processing auxiliary agent and thermoplastic macromolecular resin containing polar groups through macromolecular thermoplastic processing equipment at the temperature of 25-300 DEG C; and the mass ratio of the compounding agent to the thermoplastic macromolecular resin is equal to (1:10)-(1:50). The invention also discloses the antistatic composite material which is obtained after the persistent antistatic master batch and a macromolecular base material are formed through the thermoplastic processing equipment. The antistatic composite material has the characteristics that: 1. the antistatic composite material has light color and dyeability; 2. The master batch of the antistatic composite material and the compounding agent are wider in selection range, low in cost and easy to obtain, and the production process is simple, safe and non-hazardous; and 3. the influence of the ambient environment on the antistatic performance of the antistatic composite material is less, and the antistatic performance is persistent.

Owner:浙江三和塑料有限公司

Ultraviolet-light deeply cross-linked halogen-free flame-retardant polyolefin cable material and method for preparing ultraviolet-light deeply cross-linked halogen-free flame-retardant polyolefin cable insulating or sheathing layer from same

ActiveCN102153802AEnhanced cross-linking efficiencyIncreased uniform photocrosslinking depthPlastic/resin/waxes insulatorsInsulated cablesCross-linkPolyolefin

The invention relates to ultraviolet-light deeply cross-linked halogen-free flame-retardant polyolefin cable material and a method for preparing an ultraviolet-light deeply cross-linked halogen-free flame-retardant polyolefin cable insulating or sheathing layer from the same. The method comprises the following steps: adding a metal hydroxide flame retardant, a cationic photoinitiator, a free radical photoinitiator, a multi-functional cross-linking agent, a compound antioxidant, a flame-retardant synergist, a synergistic smoke suppressant and a processing aid to polyethylene or grafted and modified polyethylene and / or ethylene vinyl acetate or grafted and modified copolymer thereof which are used as base materials, compounding, mixing the materials uniformly according to the proportion, granulating, extruding to prepare the ultraviolet-light cross-linked halogen-free flame-retardant polyolefin cable insulating or sheathing layer, and immediately irradiating with a specific ultraviolet-light source to obtain the deeply cross-linked halogen-free flame-retardant polyolefin cable insulating or sheathing layer. The cross-linking equipment used for preparing the novel material by using anovel technology has low investment, and the process is simple and environmental friendly, saves energy, ensures high production efficiency and low cost and good quality of product and can be widely used for producing high-performance special wire and cable products and the like.

Owner:HEILONGJIANG MINGXIANG TECH

Manufacture of bone graft substitutes

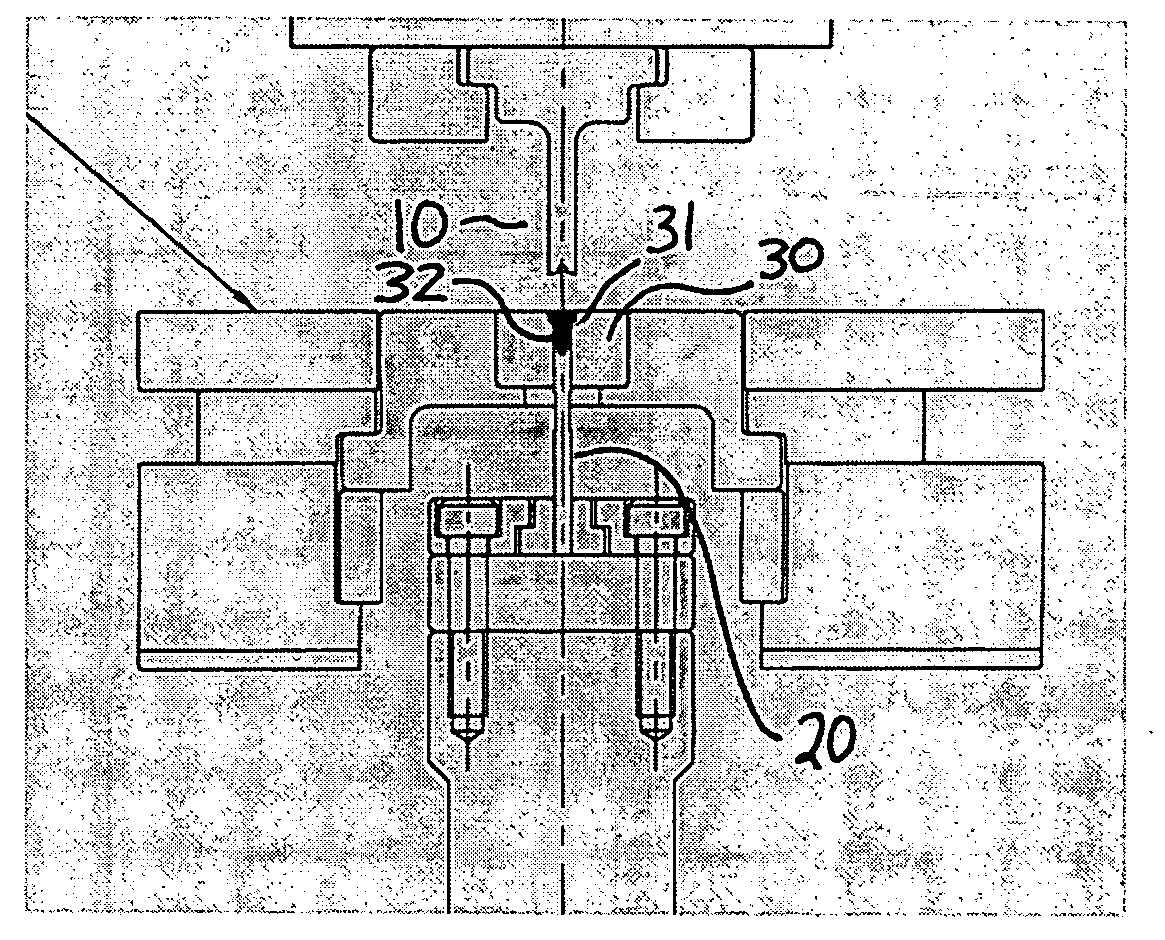

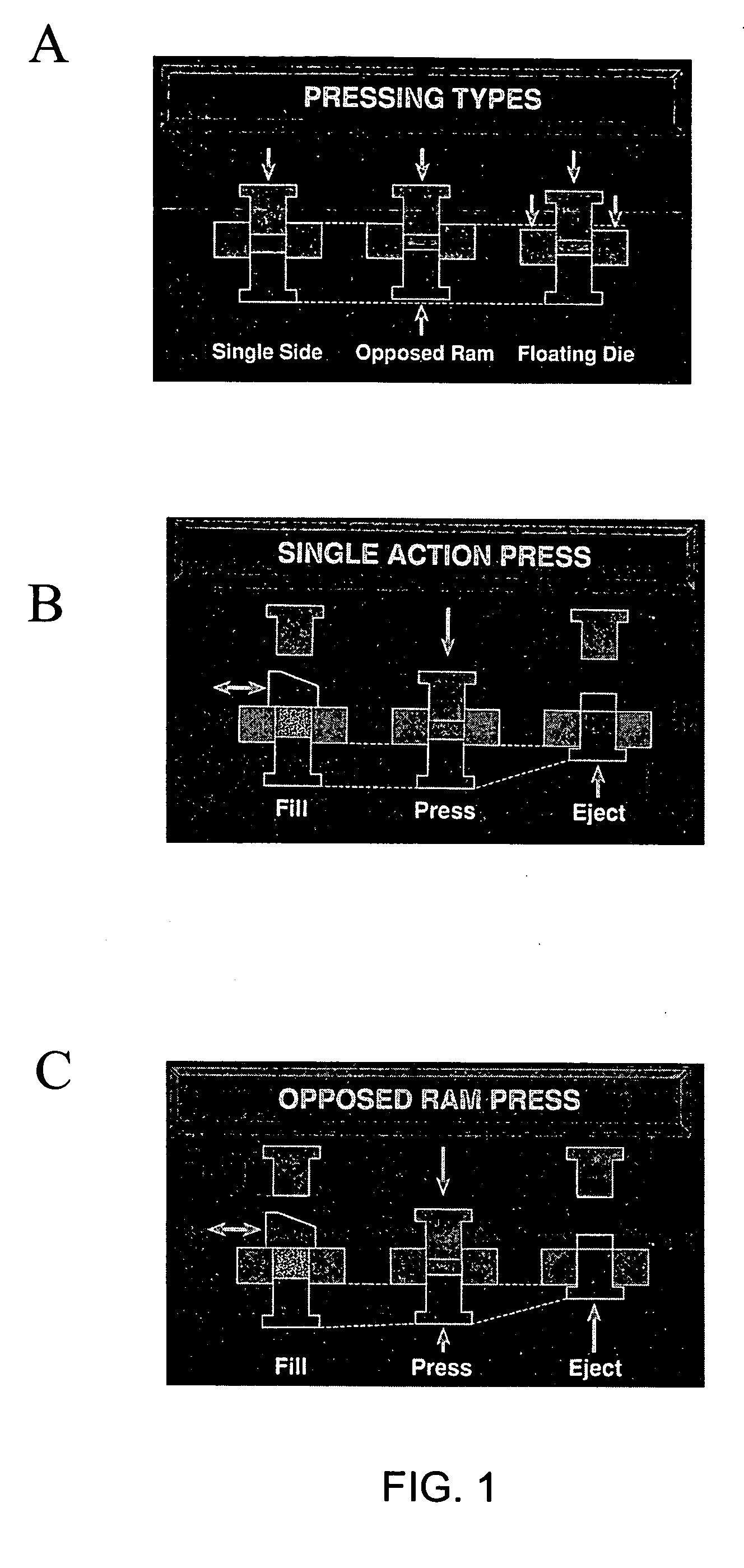

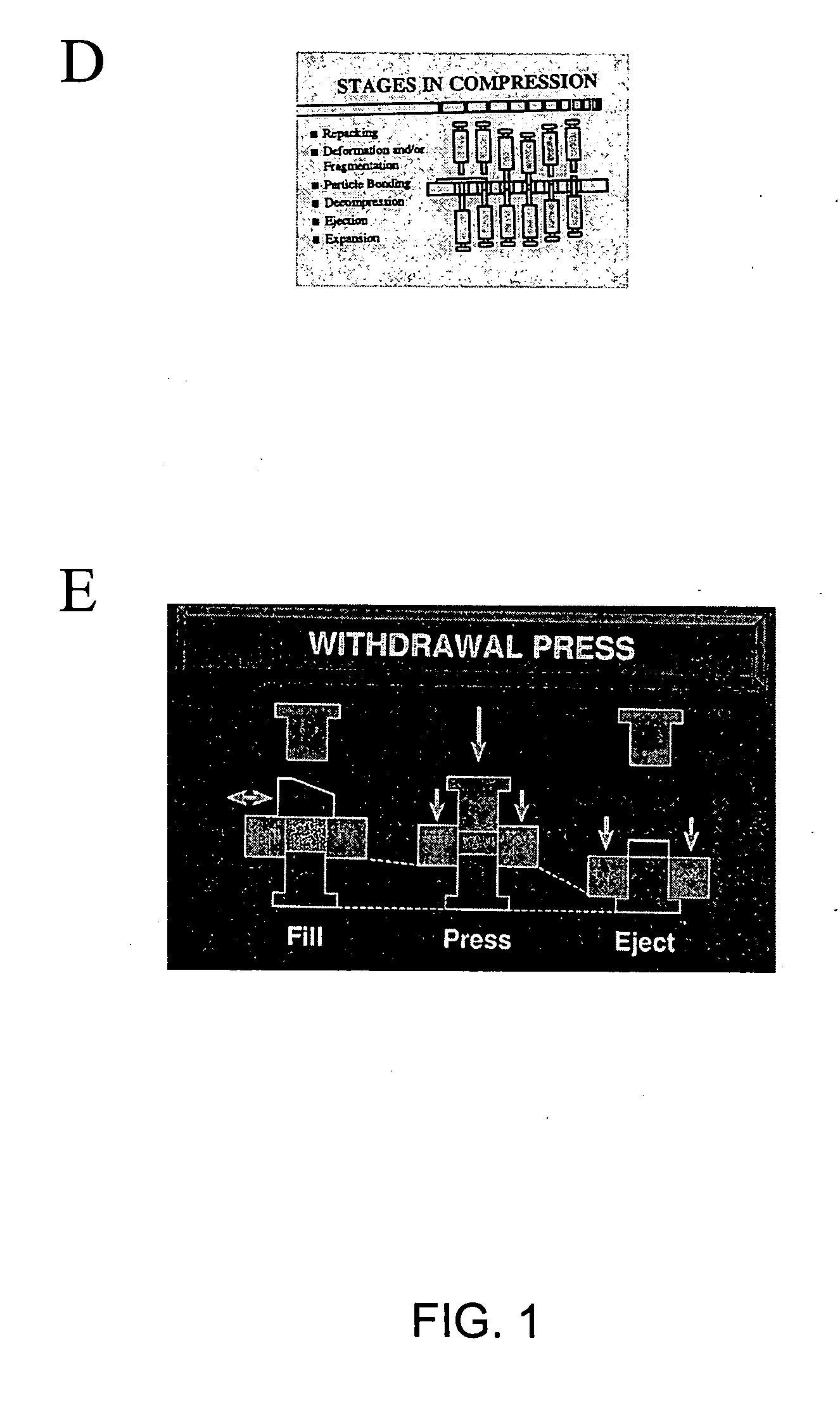

InactiveUS20050098915A1Desired profileEvenly distributedConfectioneryWood working apparatusBiomedical engineeringProcessing aid

The present invention is directed to methods and compositions for manufacturing a bone graft substitute. A powder compaction process is utilized to generate a shaped product comprised of a bone material and in some embodiments a processing aid is utilized to facilitate compaction of the bone material and / or for release of the product from the die. In one aspect of the present invention, the manufacturing process comprises a withdrawal press having a shelf die, a lower punch, and an upper punch, wherein at least both the shelf die and lower punch are configured to impart at least part of the shape of the particle upon the material.

Owner:SMITH & NEPHEW INC

Innerliners for use in tires

The invention discloses tires including innerliners, the innerliners made from at least one polybutene processing aid and at least one elastomer having C4 to C7 isoolefin derived units.

Owner:EXXONMOBIL CHEM PAT INC

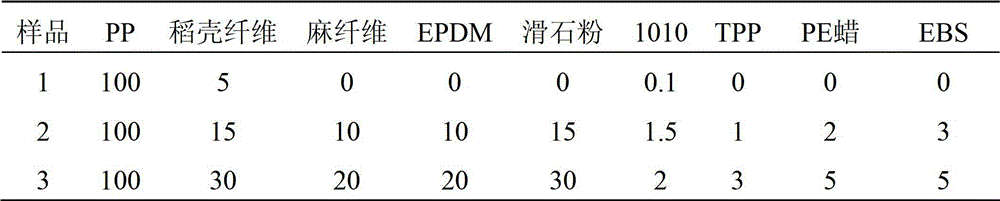

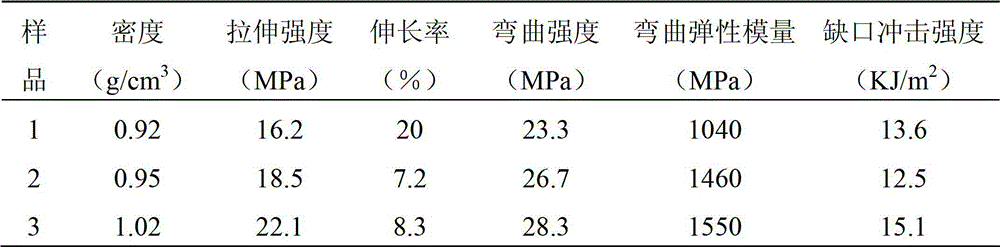

Injecting molding grade natural fiber composite material and preparation method thereof

The invention relates to a natural fiber composite material and a preparation method of the composite material. The composite material comprises the following components in parts by weight: 100 parts of thermoplastic resin, 5-50 parts of natural fiber, 0-20 parts of impact modifier, 0-30 parts of inorganic filler, 0.1-5 parts of anti-aging agent, and 0-10 parts of processing aid. The preparation method of the composite material comprises the steps of adding the natural fiber into an aqueous solution of a saline coupling agent to soak, then drying the natural fiber, mixing the natural fiber with the other processing aids, feeding the mixed material into a double-screw extruder to subject to the melting extrusion, and granulating to obtain the composite material. Compared with the prior art, the preparation method is simple in process and environment-friendly. More importantly, the problems that the composite material, into which a large amount of natural fiber is added, is poor in material mobility, low in intensity of parts, and poor in appearance quality, are solved. The current situation that the natural fiber composite material cannot adapt to the injection moldings of complex structures is changed.

Owner:CHERY AUTOMOBILE CO LTD

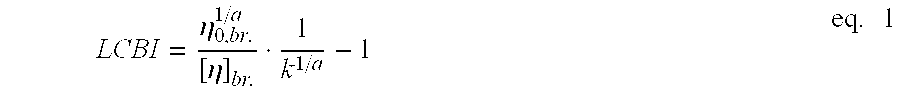

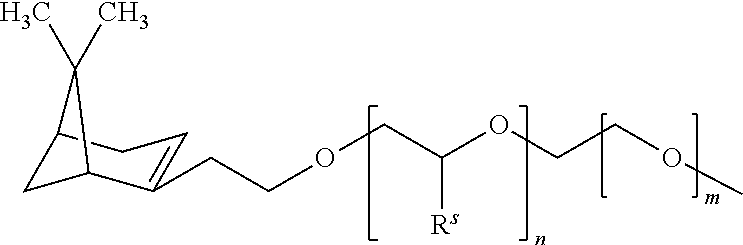

Melt-processible polymer composition comprising fluoropolymer having long chain branches

A polymer melt additive that is suitable for use as a processing aid in the extrusion of a non-fluorinated polymer. The polymer melt additive composition includes a fluoropolymer that has a long chain branching index (LCBI) of at least 0.2 and a zero shear rate viscosity at 265° C. of not more than 107 Pa's. The polymer melt additive may additionally include other compounds such as, polyoxyalkylene polymer or polycaprolactone.

Owner:3M INNOVATIVE PROPERTIES CO

Novel plastic-base enhanced foaming composite material as well as preparation method and application thereof

The invention relates to a novel plastic-base enhanced foaming composite material which is prepared from the following raw materials in parts by weight: 100 parts of thermoplastic resin, 20-50 parts of continuous fiber, 5-10 parts of filling, 2-8 parts of foaming agent, 2-8 parts of compatilizer, and 0.1-1 parts of processing aid. The invention also discloses a preparation method of the novel plastic-base enhanced foaming composite material, and applications of the material in the preparation of a cue and a table tennis bat. Compared with the prior art, the novel plastic-base enhanced foaming composite material provided by the invention can be directly injection-molded, and the obtained product has the advantages of pretty high strength, pretty high modulus, good toughness, good wear resistance, simple molding and the like.

Owner:HEFEI GENIUS NEW MATERIALS

Polypropylene composite for automobile bumpers, and preparation method thereof

The invention discloses a polypropylene composite for automobile bumpers, and a preparation method thereof. The polypropylene composite for automobile bumpers comprises 60-80% of polypropylene resin, 10-20% of inorganic filler, 5-15% of thermoplastic elastomer, 5-10% of compatilizer, 0.1-1% of antioxidant, 0-1% of light stabilizer and 0-1% of processing aid. The preparation method of the polypropylene composite for the automobile bumpers comprises the following steps of: firstly, adding the polypropylene resin, the thermoplastic elastomer, the compatilizer and the inorganic filler into a high-speed mixing machine for uniformly mixing, then adding the antioxidant, the light stabilizer and a lubricant to continuously stir and mix at high speed, and finally adding the uniformly mixed material into a double-screw extruder for extruding and forming to obtain the polypropylene composite. Due to the addition of the compatilizer, compared with the prior art, the automobile bumpers made of the polypropylene composite provided by the invention have higher impact resistance and lower cost and can better meet the requirement of customers for an automobile bumper material with high cost performance.

Owner:GUANGZHOU SUPER DRAGON ENG PLASTICS

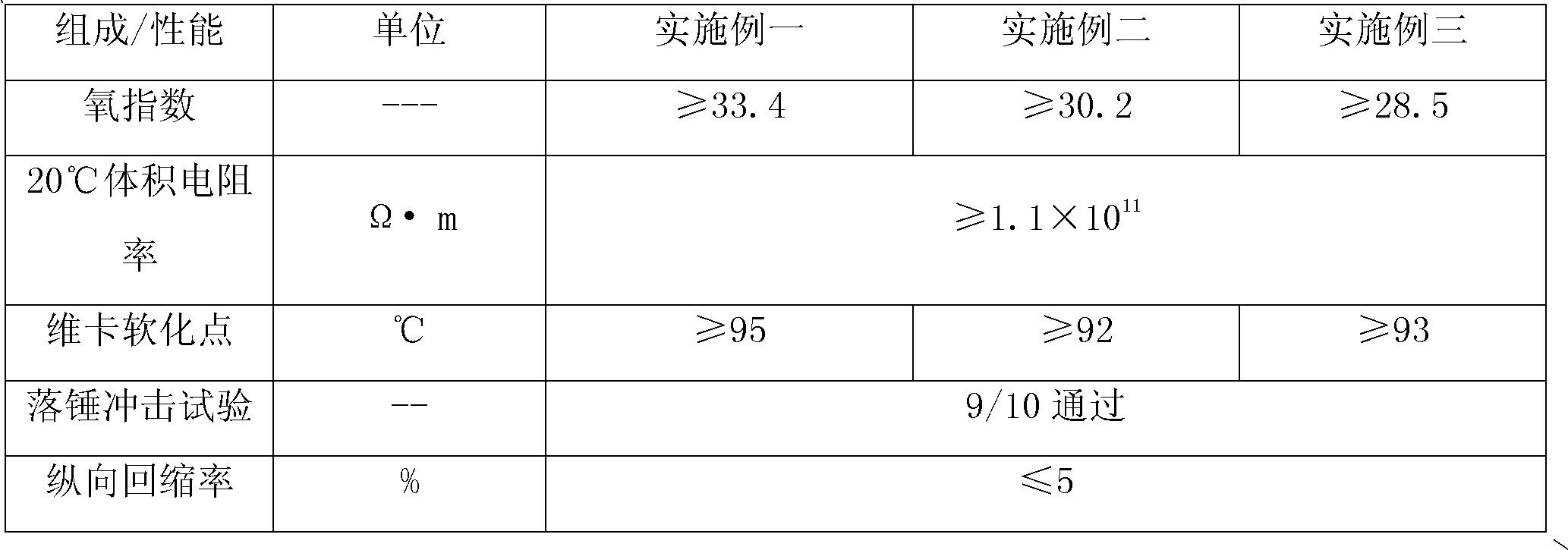

Fire-retardant insulating polyvinyl chloride material and electrical sleeve

InactiveCN102093652AImprove flame retardant performanceImprove insulation performanceInsulating bodiesLow voltagePolyvinyl chloride

The invention discloses a fire-retardant insulating polyvinyl chloride material and an electrical sleeve made from the material. The fire-retardant insulating polyvinyl chloride material comprises the following raw materials in part by weight: 100 to 150 parts of polyvinyl chloride, 0.2 to 5 parts of heat stabilizer, 5 to 20 parts of compatibilizer, 20 to 60 parts of fire retardant master batch, 0.3 to 1 part of lubricant, 1 to 3 parts of titanium white powder, 10 to 20 parts of impact modifier, 2 to 4 parts of processing aid and 5 to 20 parts of calcium carbonate. The fire-retardant insulating polyvinyl chloride material provided by the invention has excellent flame retardant property and insulating property; the oxygen index can be over 33.4; the test is up to V-0 level according to the measurement standard of GB / T2048-2008 plastic combustibility; and the resistivity can be up to 1.1*1,011 Omega.m. Therefore, the material can meet the requirement on insulation and fire retardance of a low-voltage wire cable.

Owner:KANGTAI PLASTIC SCI & TECH GRP

Low-luster polypropylene blending modified material and preparation method thereof

The present invention relates to the blending and modifying field of the polymer material, and discloses a polypropylene blend modified material with the lowered surface gloss. The polypropylene blend modified material of the present invention consists of the following components and weight percentages: 20 to 90 percent of polypropylene, 10 to 80 percent of polyethylene, 0 to 2 percent of peroxide cross-linking agent, 0 to 5 percent of antioxidant, 0 to 5 percent of processing aid, and 0 to 30 percent of filler. The preparation method is: the components are blended in the high-speed mixer for 5 to 15 minutes according to the proportion; the twin-screw extruder is used to melt and blend; the temperature of the extruder is set to be between 100 and 220 Celsius system, and the rotating speed of the screw to be 150 to 400 rounds per minute; after pelletizing and drying, the polypropylene blend modified material can be made. The polypropylene blend modified material of the present invention has the lowered surface gloss and the good extinction effects, and can be used in the fields such as the packaging, daily necessities and building materials, and so on.

Owner:广东波斯科技股份有限公司

Foam control formulations

ActiveUS20150080273A1Lower Level RequirementsInhibition formationDewatering/demulsification with chemical meansDefoamers additionProcedure AgentsWater insoluble

The invention provides a foam control formulation in the form of a microemulsion, the formulation comprising: (a) from S to 70% w / w of primary surfactant, this surfactant having an HLB of from 1 to 12 and / or a cloud point of from 20 to 70° C.; (b) from 2 to 40% w / w of water-insoluble organic carrier liquid; and (c) water. Also provided is the use of this formulation to prevent and / or reduce foam in a fluid system, or as a processing aid to control foam production in a fluid system. The formulation may be used in an aqueous fluid system, such as an oilfield.

Owner:ENERGY SOLUTIONS (US) LLC

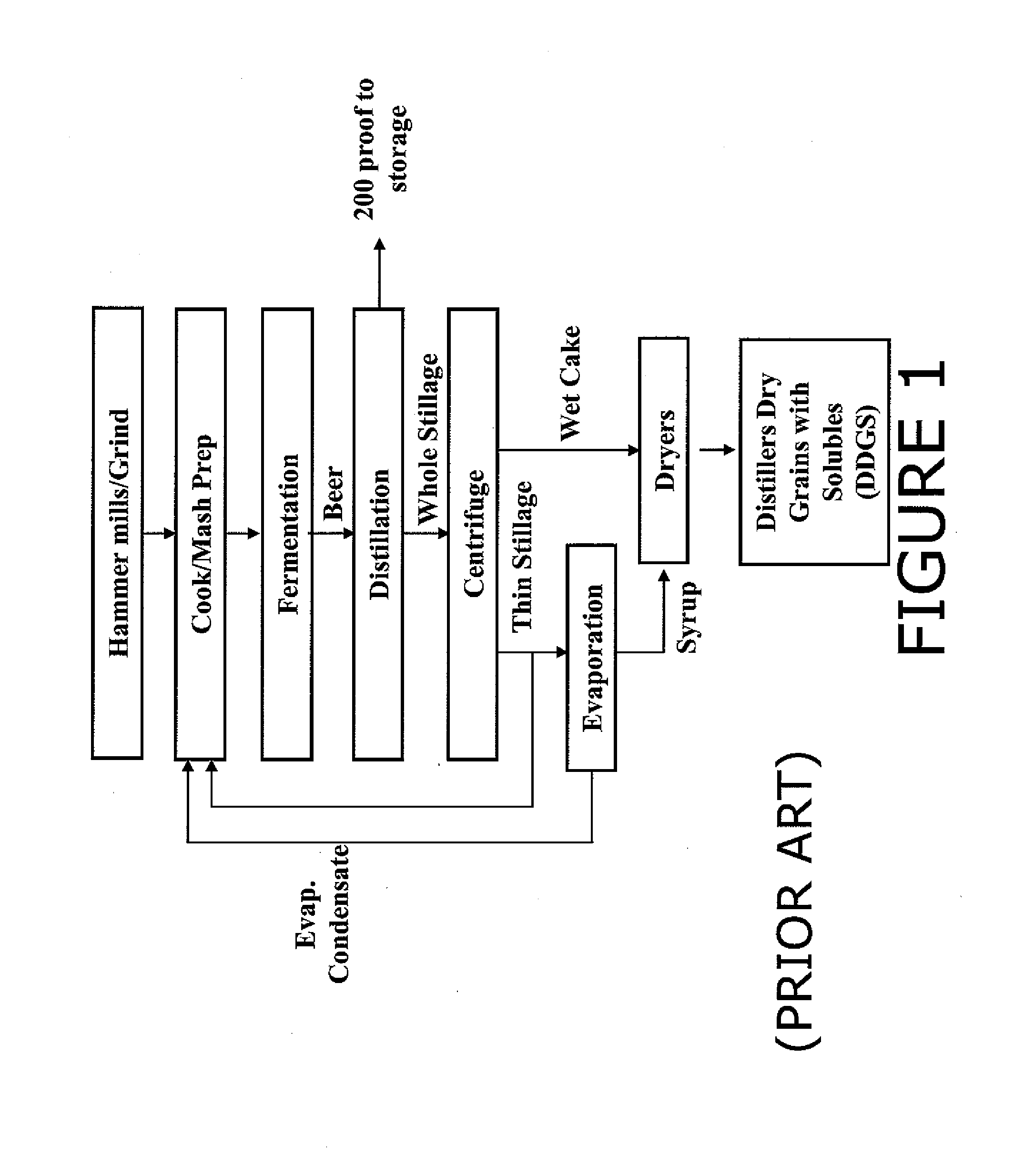

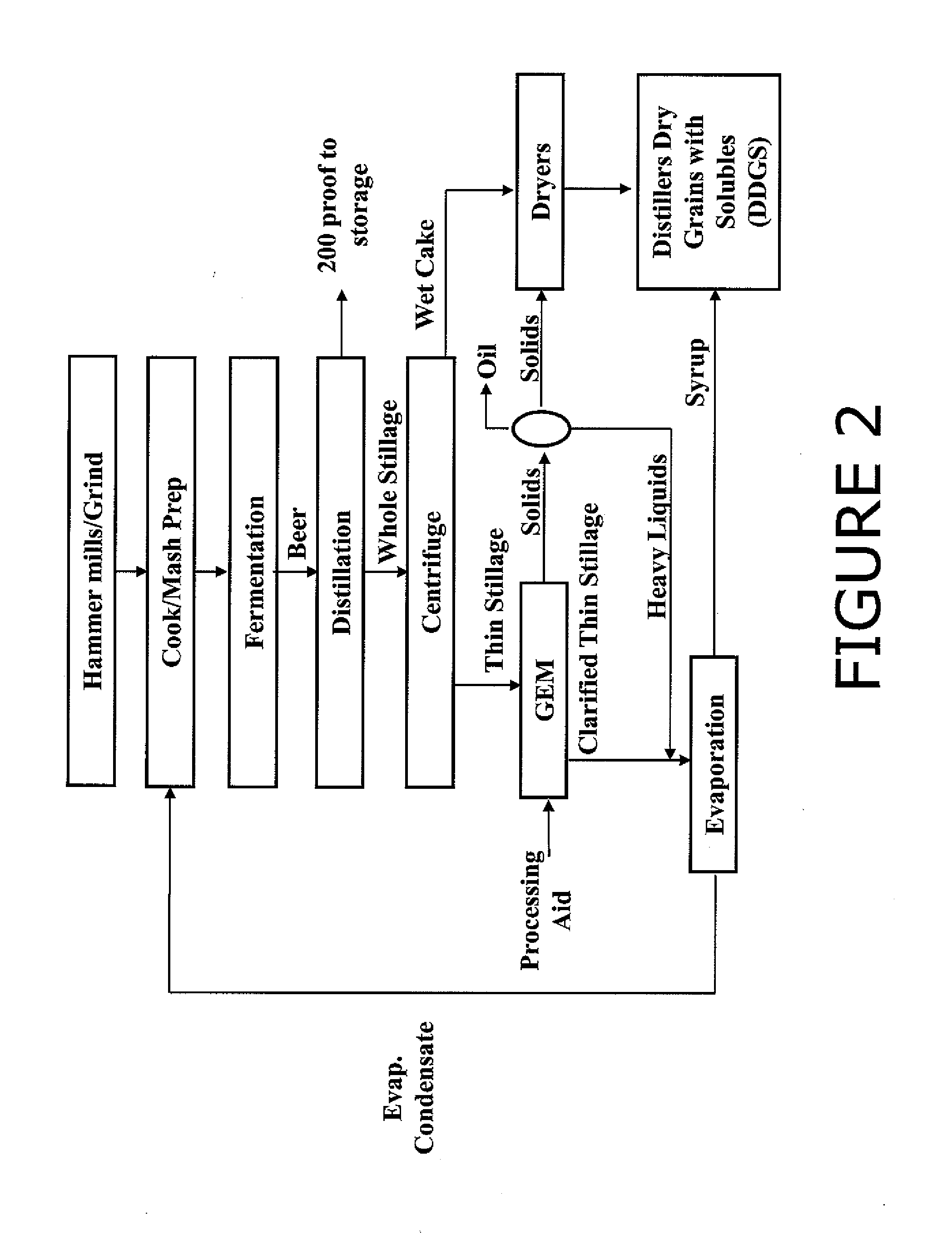

Method for conditioning and processing whole or thin stillage to aid in the separation of and recover protien and oil fractions

ActiveUS20120125859A1Lower energy requirementsFatty/oily/floating substances removal devicesSpecific water treatment objectivesProcedure AgentsProcess engineering

The invention provides a method and apparatus for reducing the energy needed to process stillage in an ethanol refining operation. The method involves adding to stillage an effective amount of at least one processing aid. The flocculant induces the separation of insoluble material that would otherwise remain suspended in water but which impose a high shear energy cost on the refining processes. This allows for the removal of insoluble material that would otherwise be overlooked but which increase energy costs. This allows for more efficient and effective separation and recovery of insoluble fractions of the concentrated thin stillage that would otherwise be overlooked and lost in the process. Loss of these valued fractions as a result of traditional processing techniques and those requiring extensive additional energy input results in the loss of high value co-products to low revenue process streams. This allows stillage to be processed more rapidly with a lower energy cost and improved co-product recovery economics.

Owner:ECOLAB USA INC

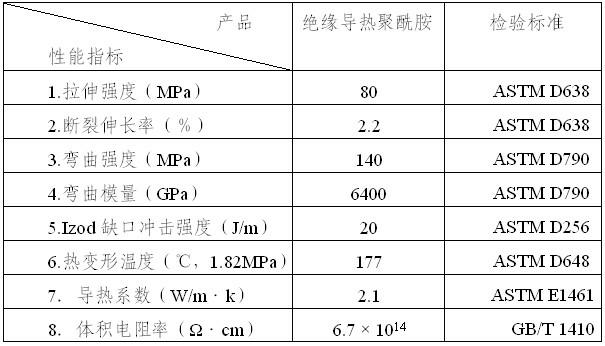

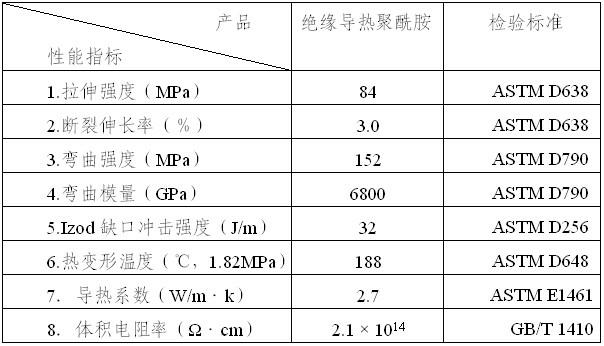

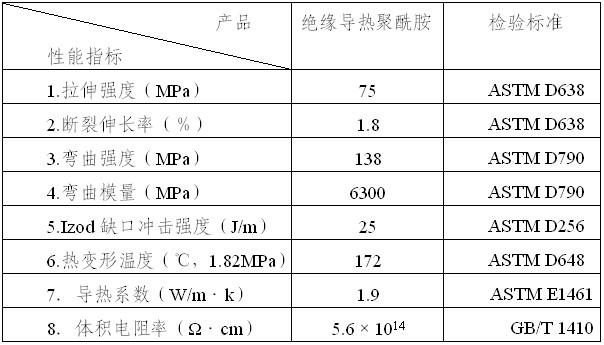

Insulating and heat-conducting polyamide composite material and preparation method thereof

The invention relates to an insulating and heat-conducting polyamide composite material, which is prepared from the following components in part by weight: 60 to 90 parts of polyamide (PA) resin, 10 to 40 parts of polyphenylene sulfide (PPS) resin, 30 to 100 parts of lamellar heat-conducting filler, 10 to 80 parts of whisker-like heat-conducting filler, 1 to 10 parts of nanometer heat-conducing filler, 10 to 20 parts of glass fiber, 1 to 3 parts of coupling agent, 0.2 to 0.5 part of antioxidant and 0.5 to 2 parts of processing aid. The polyamide composite material prepared according to the formula has high heat-conducting property and thermalphysical and mechanical properties.

Owner:GUANGDONG SILVER AGE SCI & TECH CO LTD

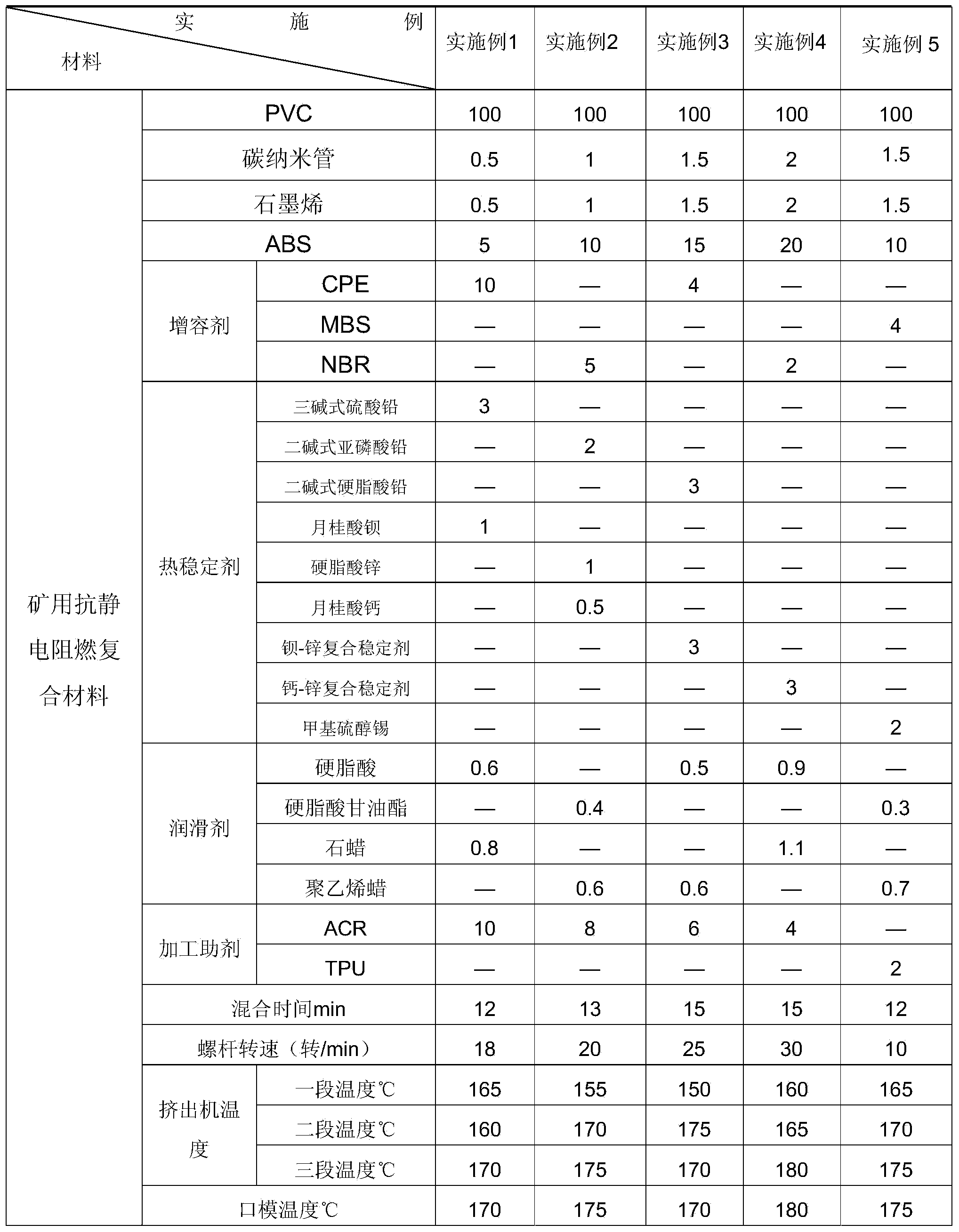

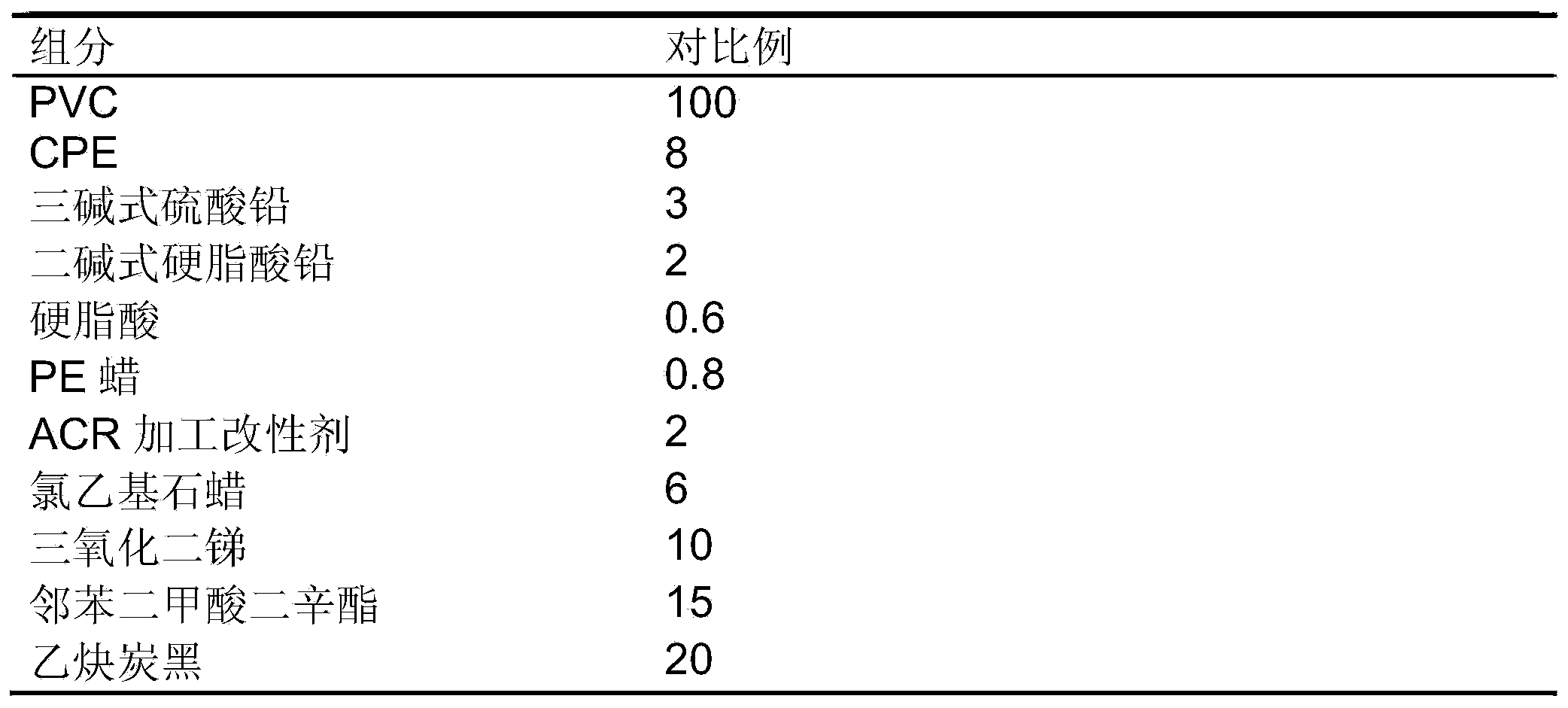

Antistatic flame-retardant composite material for coal mines and preparation method of antistatic flame-retardant composite material

ActiveCN104292699AGood anti-static and flame-resistant propertiesDoes not affect processing fluidityPolyvinyl chlorideCarbon nanotube

The invention discloses an antistatic flame-retardant composite material for coal mines and a preparation method of the antistatic flame-retardant composite material. The antistatic flame-retardant composite material comprises the following components in parts by weight: 100 parts of polyvinyl chloride (PVC) resin, 5-20 parts of acrylonitrile-butadiene-styrene copolymer (ABS), 2-10 parts of compatibilizer, 0.5-2 parts of carbon nano-tubes, 0.5-2 parts of graphene, 2-6 parts of thermal stabilizer, 1-2 parts of lubricant and 2-10 parts of processing aid. The preparation method comprises the following steps: preparing a conducting filler / PVC composite powder material from a mixture of the carbon nano-tubes and the graphene and part of the PVC resin in proportion; performing high-speed mixing on the obtained conducting filler / PVC composite powder material, the residual PVC resin, the ABS, the compatibilizer, the thermal stabilizer, the lubricant and the processing aid to obtain a compound; and putting the mixed compound into a conical twin-screw extruder, setting temperature section by section, and pelleting by extruding, thereby obtaining the antistatic flame-retardant composite material for the coal mines. The prepared PVC composite material has relatively high mechanical properties, excellent antistatic property and flame retardance, is a high-polymer composite material with good processibility, and can be used underground in the coal mines.

Owner:SHAANXI COAL & CHEM TECH INST

Polyvinyl alcohol polarity sponge plastics and method of producing the same

The present invention provides poly vinyl alcohol polar foam. Water is used as foamer and plasticizer. According to weight, water is 15 portion to 55 portion, and poly vinyl alcohol is 45 portion to 85 portion. The material are dissolved for expansion, melted and processed for foaming. The melting and processing foaming comprises a melting and extruding continuous foaming method and a molding foaming method. The poly vinyl alcohol polar foam is a plate material, sheet material, membrane or bead or square block. The poly vinyl alcohol polar foam of the present invention can be added with crosslinker, molecular composite agent, processing aid, nucleating agent and functional additive. According to the weight portion, the crosslinker is 0 portion to 2 portion, the molecular composite agent 0 portion to 10 portion, the processing aid 0 portion to 10 portion, the nucleating agent 0 portion to 5 portion and the functional additive 0 portion to 30 portion. When the poly vinyl alcohol polar foam of the present invention is used as heavy metal particles, adsorption, filtration and separation material of organic pollutant, the poly vinyl alcohol polar foam has the characteristics of rapid adsorption, easy desorption and capacity of being repeatedly washed.

Owner:SICHUAN UNIV

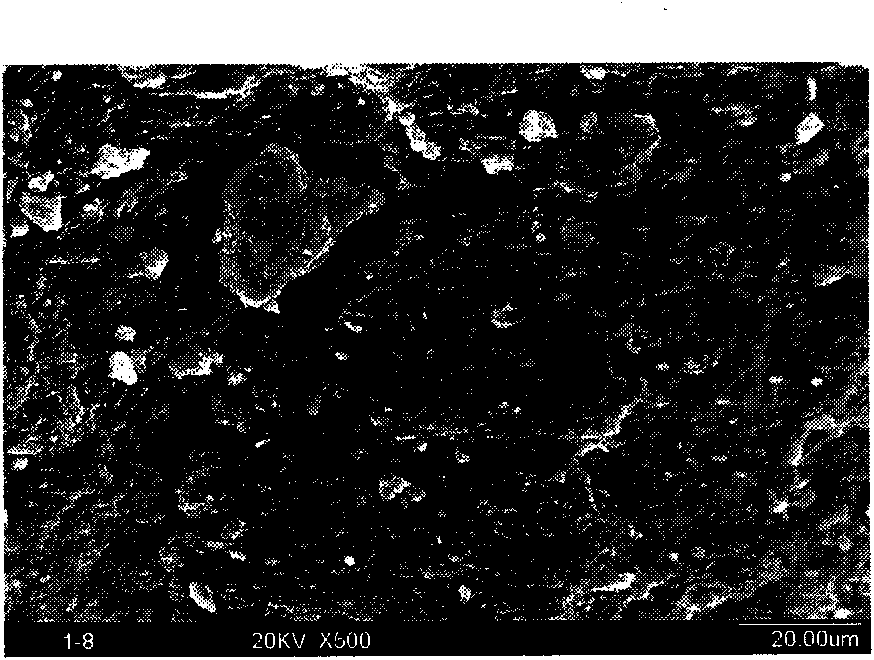

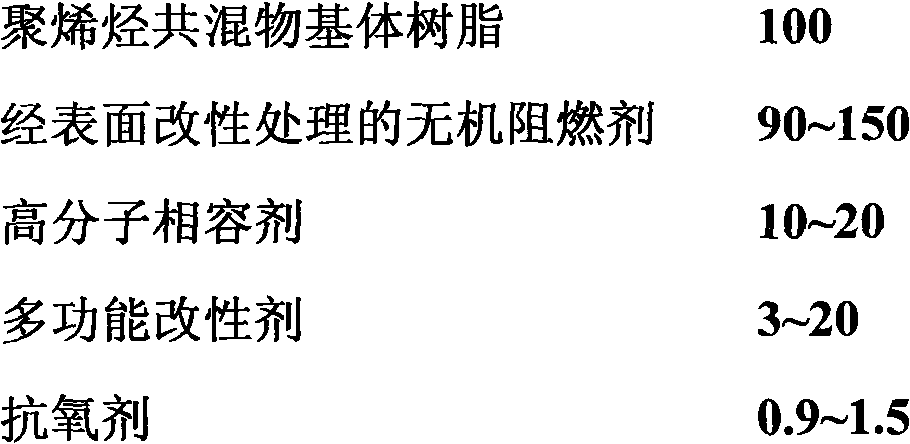

Thermoplastic crack resistant type low smoke zero halogen flame-retardant polyolefin cable sheath material and preparation method thereof

InactiveCN102020804ACrack resistantImprove flame retardant performancePlastic/resin/waxes insulatorsInsulated cablesThermoplasticPolyolefin

The invention discloses a thermoplastic crack resistant type low smoke zero halogen flame-retardant polyolefin cable sheath material and a preparation method thereof. The cable sheath material comprises the following components in part by weight: 100 parts of polyolefin blend matrix resin, 90 to 150 parts of inorganic flame retardant subjected to surface modification, 10 to 20 parts of high molecular compatilizer, 3 to 20 parts of multifunctional modifier, 1 to 1.5 parts of antioxidant and 1 to 2 parts of processing aid. The preparation method of the cable material comprises the following steps of: blending and extruding polyene resin; performing surface treatment on the inorganic flame retardant; preparing materials; mixing; extruding; granulating and the like. Compared with the prior art, the invention has the advantages that: the cable sheath material has crack resistance, high flame retardancy and high processability, is environmentally friendly, is easy to recycle and the like.

Owner:山东安澜电力科技有限公司 +1

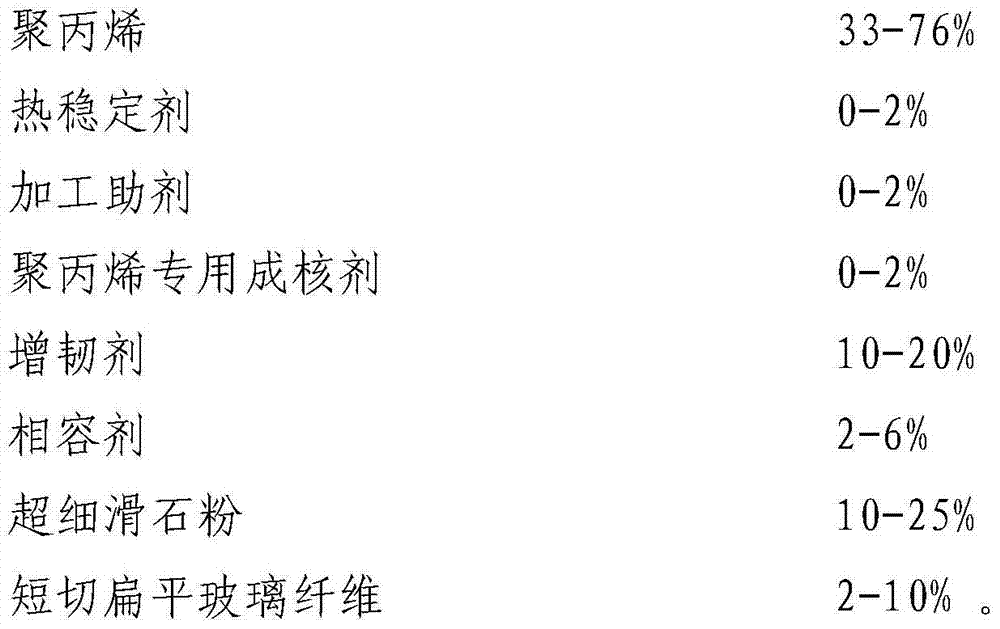

Polypropylene composite material for automobile hard plastic instrument panel and preparation method for polypropylene composite material

InactiveCN103756130AHigh surface hardnessImprove scratch resistanceGlass fiberPolypropylene composites

The invention belongs to the technical field of high polymer materials, and in particular relates to a polypropylene composite material for an automobile hard plastic instrument panel and a preparation method for the polypropylene composite material. The polypropylene composite material is prepared from the following raw materials in percentage by weight: 33 to 76 percent of polypropylene, 0 to 2 percent of heat stabilizer, 0 to 2 percent of processing aid, 0 to 2 percent of nucleating agent special for polypropylene, 10 to 20 percent of plasticizer, 2 to 6 percent of compatibilizer, 10 to 25 percent of superfine talc powder and 2 to 10 percent of chopped flat fiberglass. When the polypropylene composite material for the automobile hard plastic instrument panel is prepared, the chopped flat fiberglass is added, so that the surface hardness of the polypropylene composite material is increased, good scratch resistant effects are achieved without adding any scratch resistant agent, and a matte effect is also achieved; the polypropylene composite material also has the characteristics of high flowability, high rigidity, high heat resistance, high dimensional stability, high impact resistance, low glossiness and scratch resistance, and requirements on a material for the automobile hard plastic instrument panel are completely met.

Owner:SHANGHAI KINGFA SCI & TECH

Biodegradable PE-coated paper material and preparation method thereof

ActiveCN102558797AGood compatibilityImprove bondingSpecial paperSynthetic resin layered productsElastomerAnti ageing

The invention discloses a biodegradable PE-coated paper material which comprises the following components in percentage by weight: 60-90% of polylactic acid, 5-40% degradable toughening resin, 1-10% of elastomer, 0.1-1.0% of processing aid and 0.1-1.0% of anti-aging agent. According to the invention, the compatibility of the polylactic acid and elastic degrading resin can be improved, the adhesion of the material and paper is improved, and the cost of the existing degrading PE-coated paper raw material is greatly reduced.

Owner:SHENZHEN ESUN IND

Antimicrobial composition for pre-harvest and post-harvest treatment of plants and animals

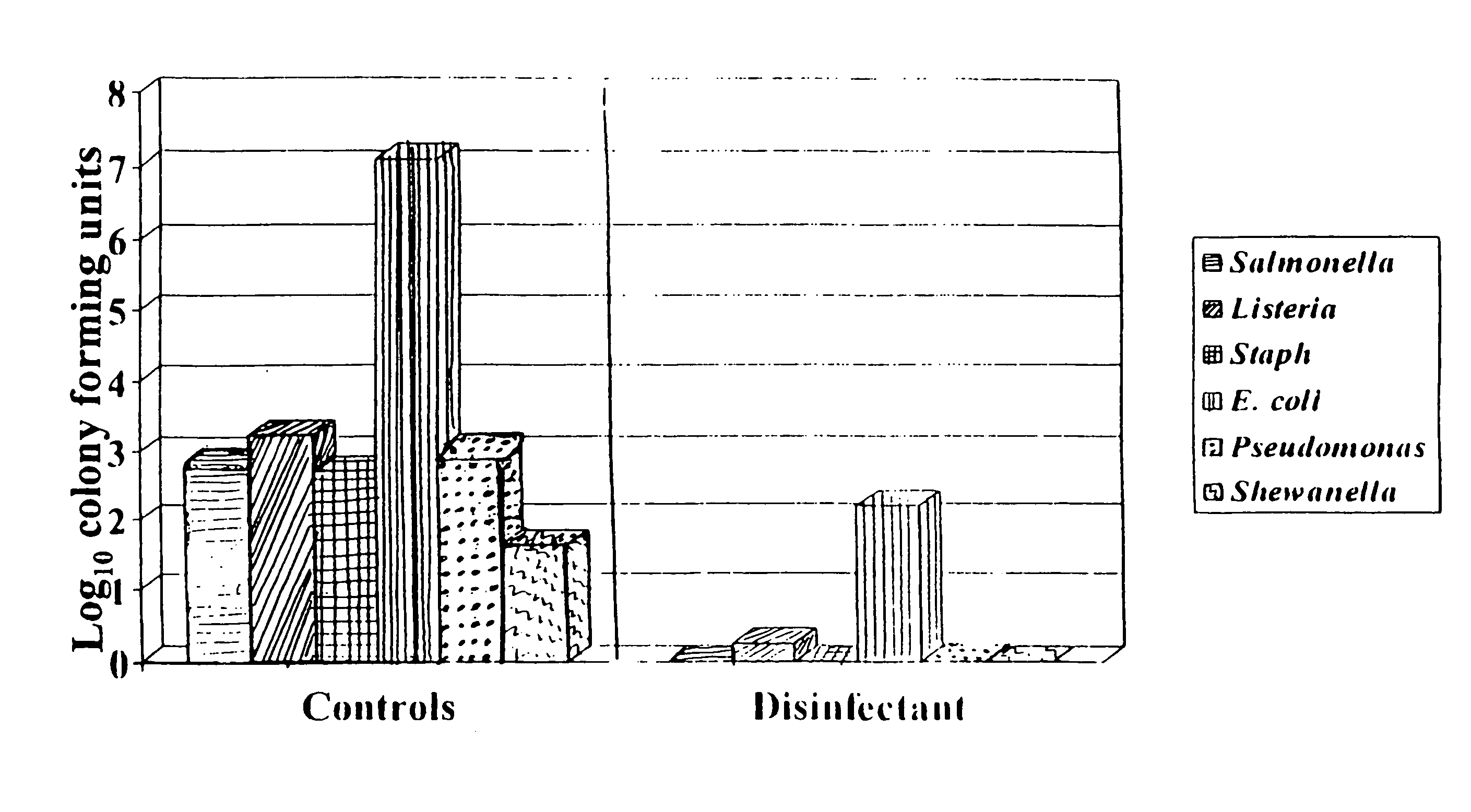

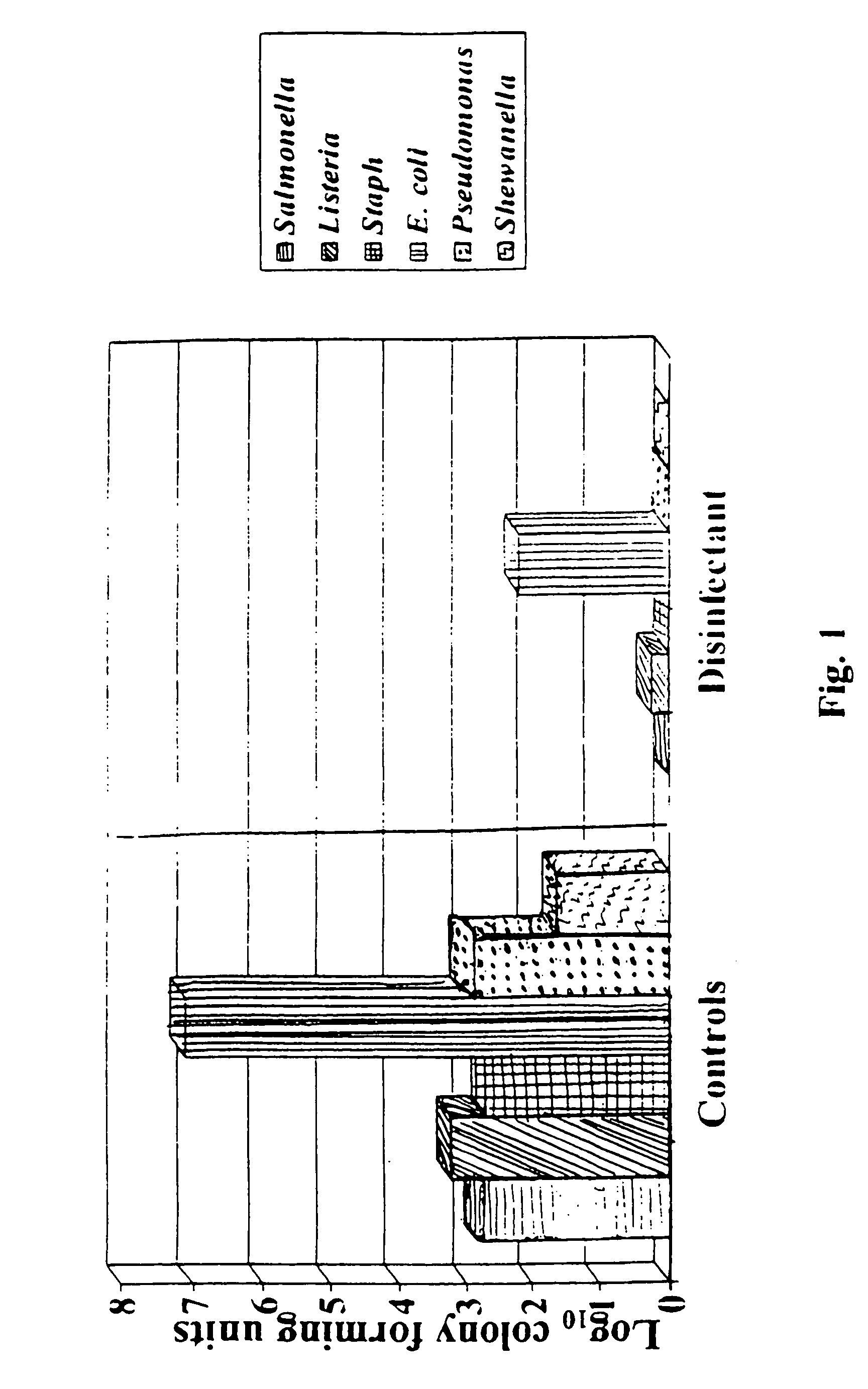

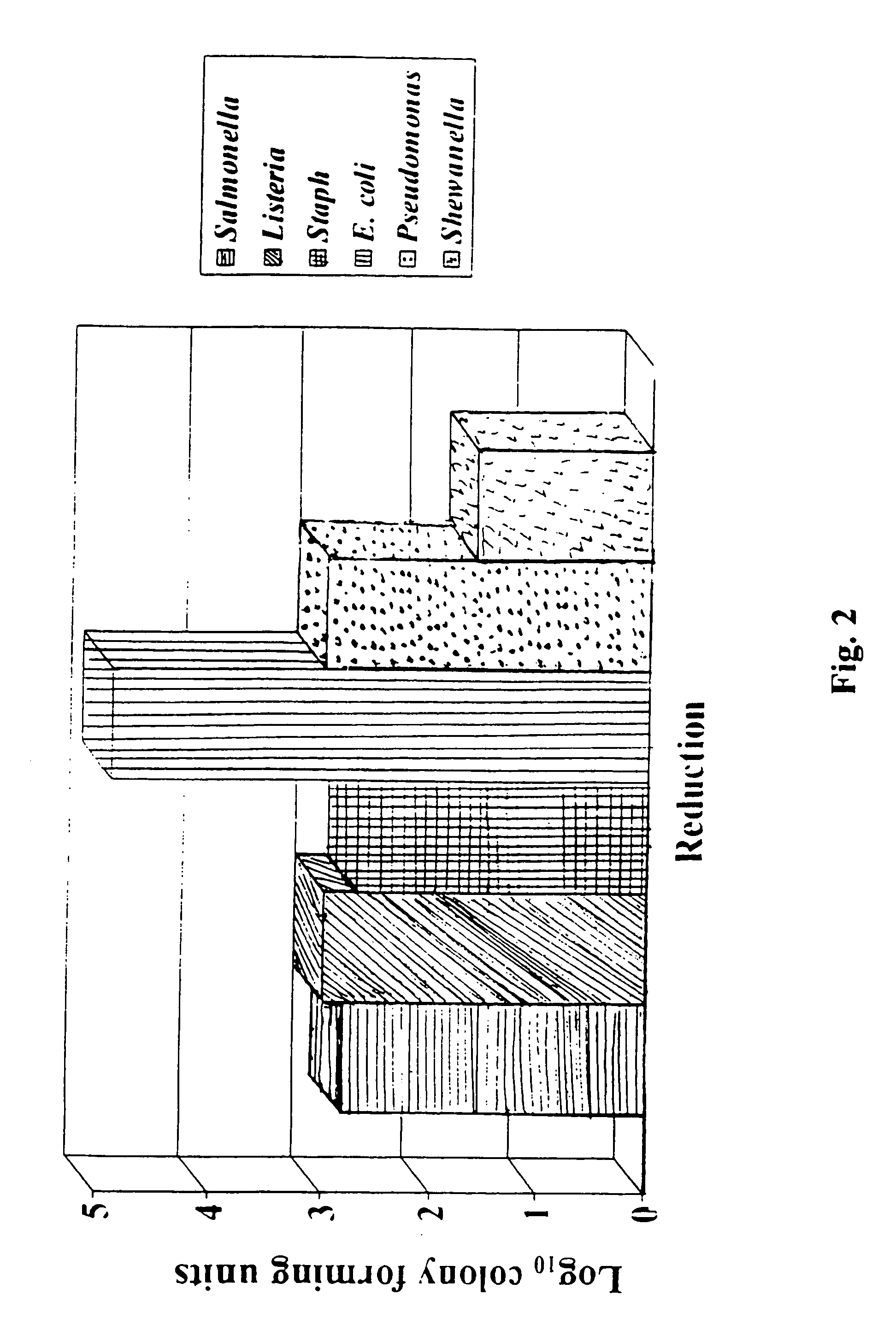

ActiveUS7192618B2Minimize growth and spreadReduce Microbial ContaminationHeavy metal active ingredientsFatty acid chemical modificationFood additiveDisinfectant

Owner:CMS TECH INC +1

Composite material for recycling waste vehicle nylon products and preparation method thereof

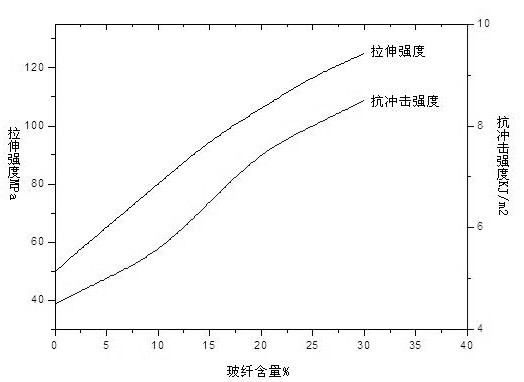

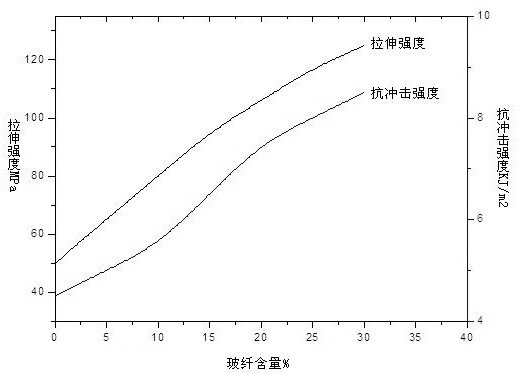

The invention discloses a composite material for recycling waste vehicle nylon products and a preparation method thereof. The composite material comprises the following components by weight percent: 0-85 percent of PA original material, 10-95 percent of recovered PA material, 5-40 percent of glass fiber, 0-2 percent of nucleating agent, 0-0.5 percent of chain extender, 0-5 percent of chain breaking agent, 0-30 percent of toughening agent, 0-2 percent of heat stabilizer and 0-1 percent of processing aid. The method comprises the following steps of: mixing the PA original material, the PA material, the nucleating agent, the chain extender, the chain breaking agent, the toughening agent, the heat stabilizer and the processing aid at high speed to obtain a mixed material; adding the mixed material from a main feeding port of a twin-screw extruder, adding the glass fiber from a second feeding port of the twin-screw extruder, and mixing the mixed material and the glass fiber in the twin-screw extruder; and extruding and pelletizing the mixture to obtain the composite material. The composite material for recycling nylon products is simple and convenient, is easy to control and can protect environment.

Owner:GUANGZHOU SUPER DRAGON ENG PLASTICS +1

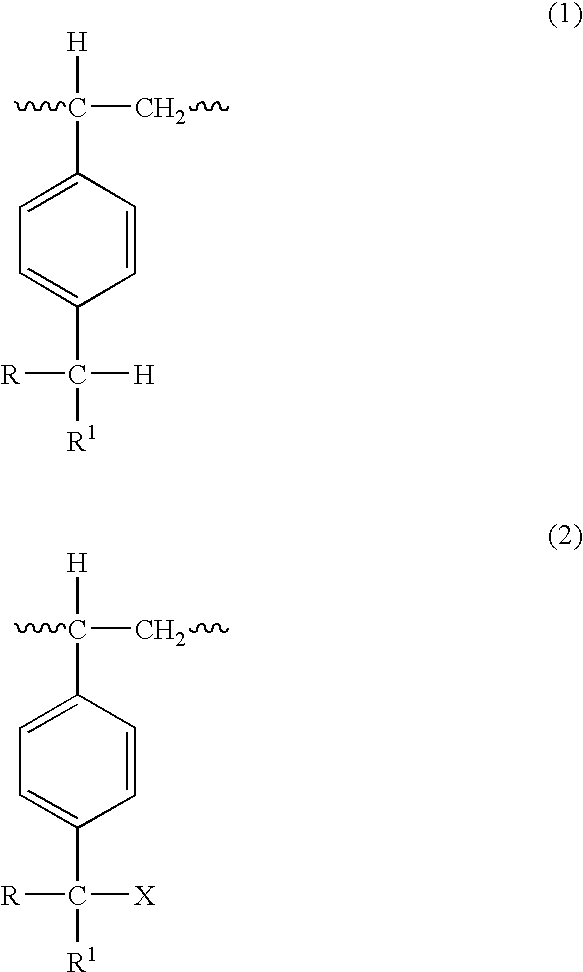

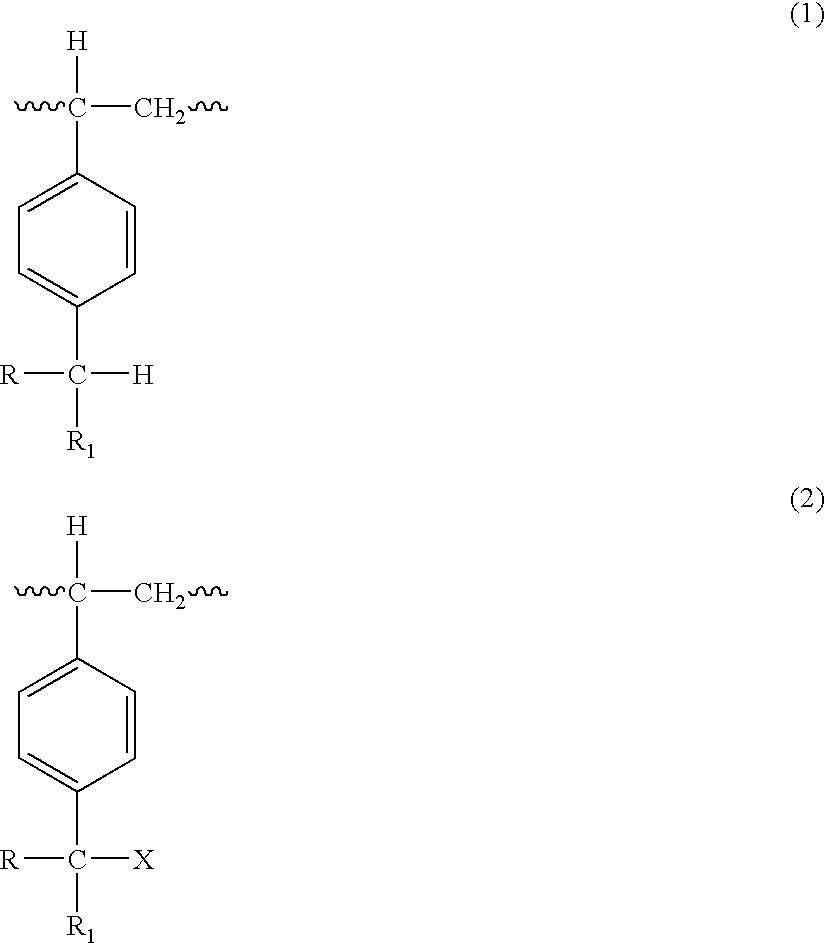

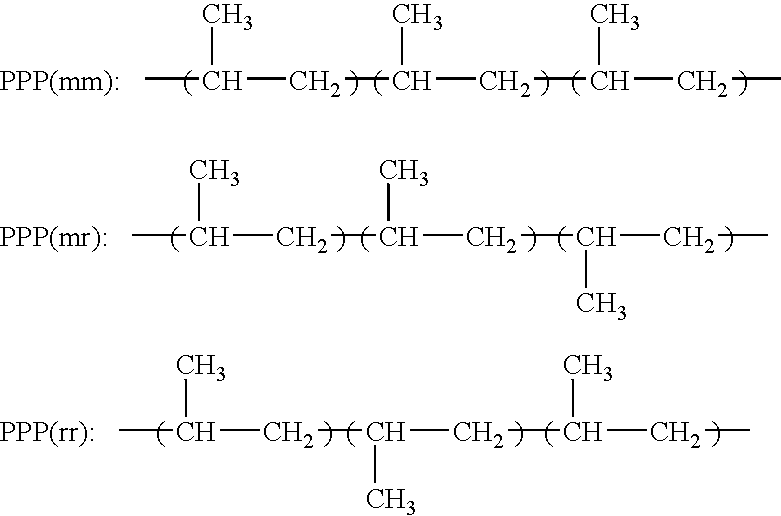

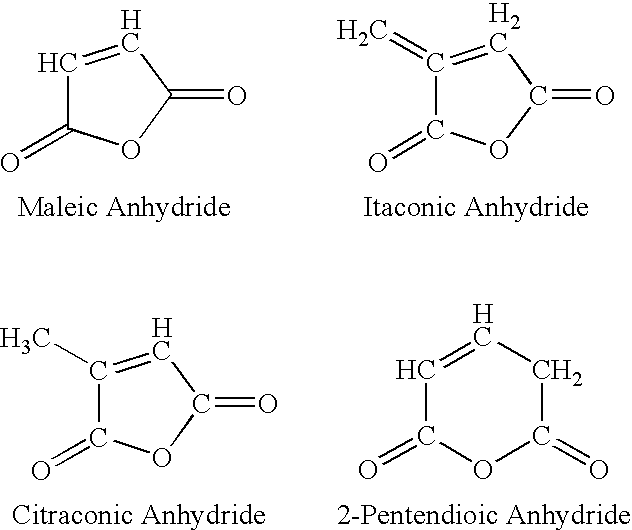

Processing Aids for Elastomeric Compositions

The invention provides for processes to produce elastomeric compositions, the processes including contacting at least one elastomer with a processing aid, wherein the processing aid includes the reaction product of at least one functionalized polymer having at least one anhydride group contacted with at least one polyamine, wherein the at least one polyamine includes at least one primary amine. The invention also provides for articles such as innerliners for tires produced from the aforementioned elastomeric compositions.

Owner:EXXONMOBIL CHEM PAT INC

Preparation method for tea extract

The invention discloses a preparation method for a tea extract, belonging to the technical field of extraction of effective components of tea leaves. The preparation method comprises the following steps: firstly, carrying out low-temperature rapid freezing treatment on high-quality commercial tea leaves; then immediately crushing; then combining a high-voltage pulsed electric field (PEF for short) technology, an ultrasonic treatment technology and a low-temperature enzymolysis technology; and carrying out low-temperature extraction in a whole process. According to the preparation method for the tea extract, the loss of effective components, caused by high-temperature processing, is avoided, and the extraction rate of the effective components of the tea leaves is also improved. The process is simple and low in cost; the introduction amount of extraneous food additives, processing auxiliary agents and chemical substances is reduced; the natural nutritional ingredient and the flavor of the tea leaves are kept to the greatest extent, the low-carbon production is realized and the environment is protected.

Owner:LVJIN DEV FUJIAN

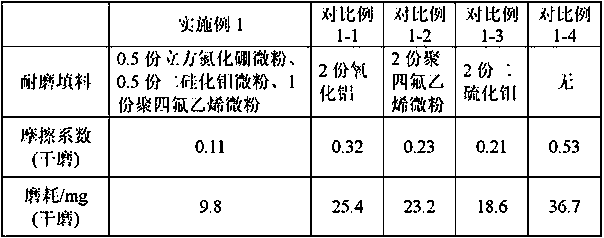

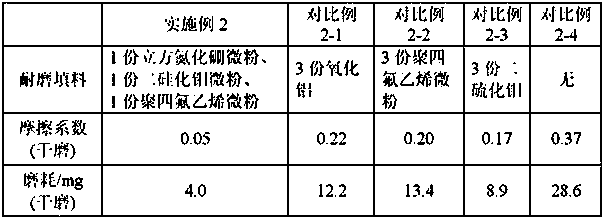

Wear-resistant filling material, wear-resistant composite material prepared from same and preparation method for composite material

The invention discloses a wear-resistant filling material, a wear-resistant composite material prepared from the same and a preparation method for the composite material. The wear-resistant filling material is prepared from the following components by weight: 0.15 to 7.5 parts of cubic boron nitride micro powder, 0.15 to 7.5 parts of molybdenum disilicide micro powder and 0.2 to 10 parts of polytetrafluoroethylene micro powder. The wear-resistant composite material is prepared from the following components by weight: 100 parts of a plastic resin, 0.5 to 25 parts of the wear-resistant filling material, 0 to 2 parts of a coupling agent and 0 to 2 parts of a processing aid. The preparation method for the wear-resistant composite material comprises the following steps: mixing the above-mentioned components at a high speed and carrying out extrusion with an extruder. According to the invention, cubic boron nitride micro powder, molybdenum disilicide micro powder and polytetrafluoroethylene micro powder are compounded to prepare the wear-resistant filling material which is applied to a plastic matrix, so the wear-resistant composite material with good wear resistance, a low friction coefficient and low dry grinding abrasion is prepared; and the application scopes of cubic boron nitride and molybdenum disilicide are broadened at the same time.

Owner:HEFEI GENIUS NEW MATERIALS

Silane cross-linked polyethylene insulating material and production method thereof

InactiveCN102532664AEvenly dispersedIncrease the degree of cross-linkingPlastic/resin/waxes insulatorsSilanesAntioxidant

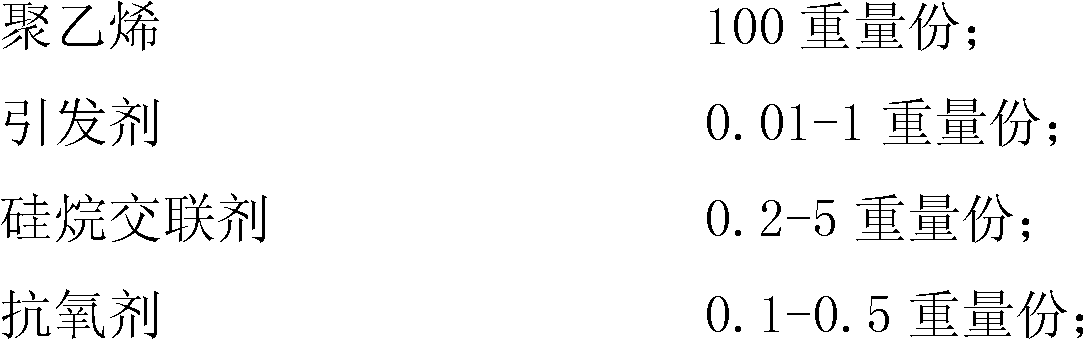

The invention provides a silane cross-linked polyethylene insulating material composition, which comprises a material A and a material B, wherein the material A is composed of the following components in parts by weight: 100 parts of polyethylene, 0.01-1 parts of initiator, 0.2-5 parts of silane cross-linking agent, and 0.1-0.5 parts of antioxidant; the material B is composed of the following components in parts by weight: 100 parts of polyethylene, 0.5-5 parts of catalyst, 0.01-5 parts of processing aid, and 0.1-0.5 parts of antioxidant; and the material A is mixed and extruded by a reciprocating single-screw extruder.

Owner:ORIGIANL DOW ADVANCED COMPOUNDS SHANGHAI

Thermoplastic water-resistant low-smoke halogen-free flame retardant cable material and manufacturing method thereof

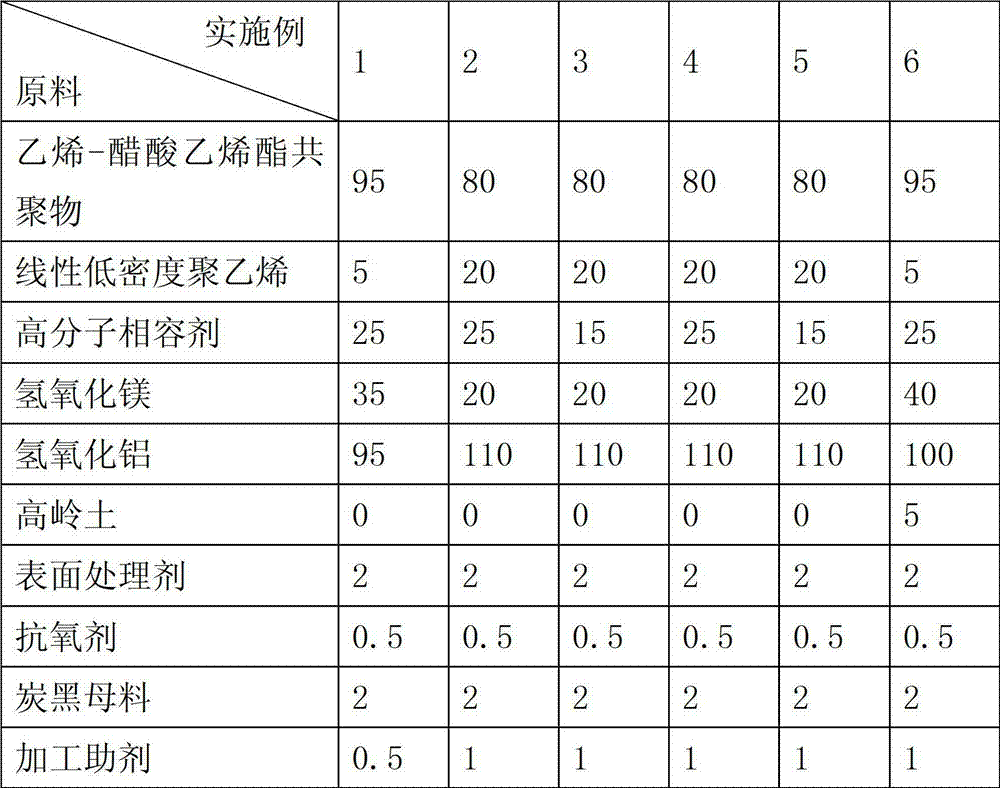

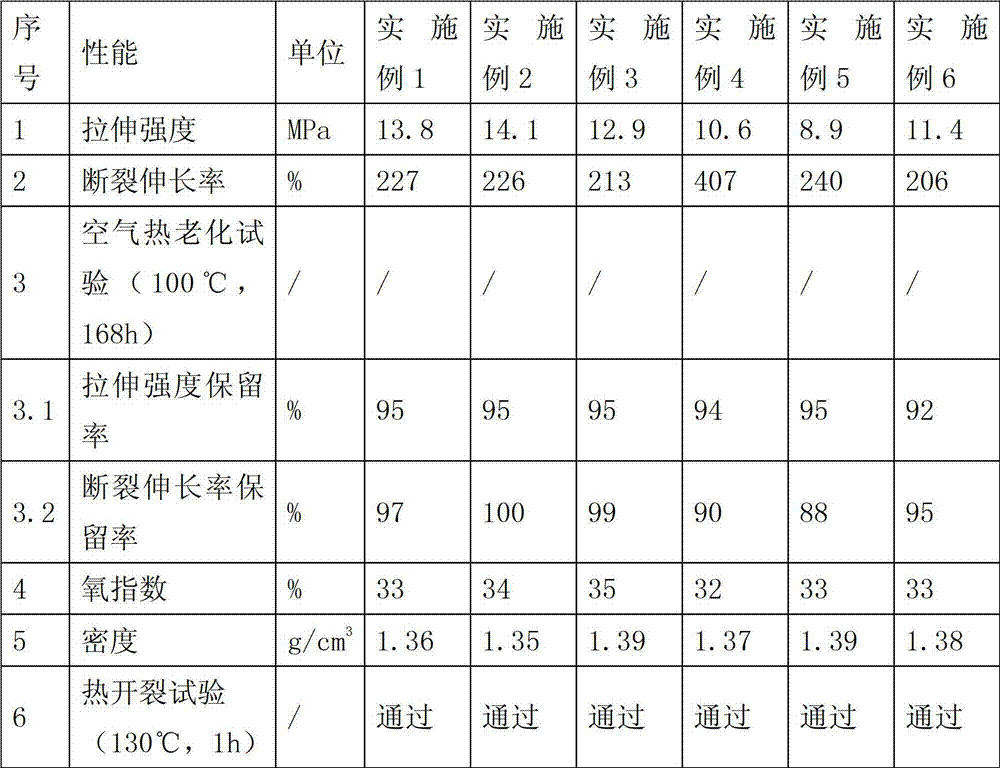

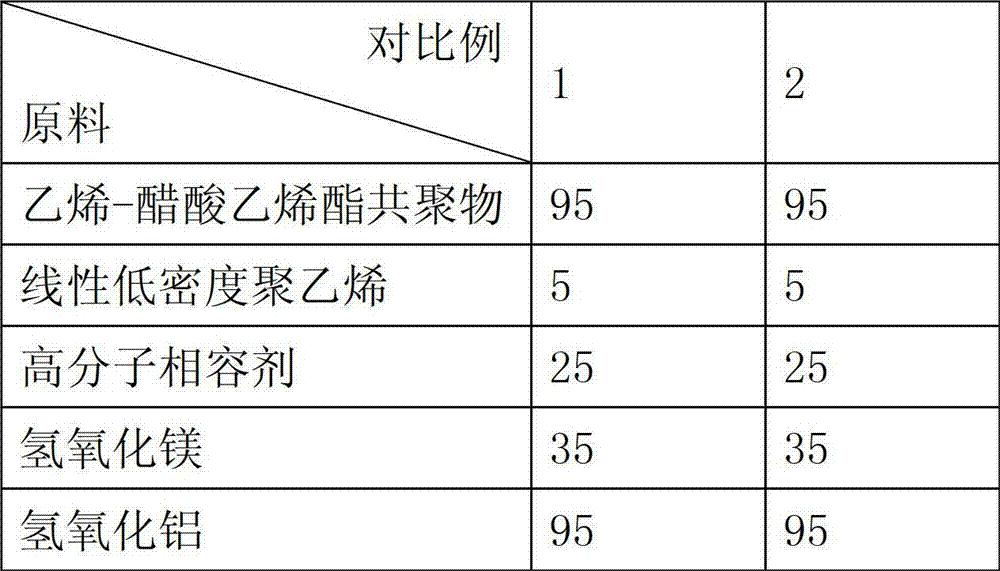

InactiveCN103044758AImprove mechanical propertiesHigh densityInsulated cablesInsulated conductorsLinear low-density polyethyleneCrack resistance

The invention discloses a thermoplastic water-resistant low-smoke halogen-free flame retardant cable material which is prepared from the following raw materials in part by weight: 40-100 parts of ethylene-ethylene vinyl acetate copolymer, 10-60 parts of linear low-density polyethylene, 15-25 parts of macromolecular compatibilizer, 120-160 parts of inorganic filler, 2-4 parts of surface treating agent, 0.5-1 part of antioxidant, 1.5-2 parts of carbon black masterbatch and 2-5 parts of processing aid. The manufacturing method of the cable material comprises the following steps of matrix resin blending and extrusion, inorganic filler pretreatment, extrusion granulation and the like. The thermoplastic water-resistant low-smoke halogen-free flame retardant cable material and the manufacturing method thereof have the characteristics and the advantages of excellent water resistance, heat resistance and mechanical performance, better toughness and bending resistance, better cracking resistance and flame retardant property, low density, low smoke, low toxicity and environment friendliness.

Owner:ORIGIANL DOW ADVANCED COMPOUNDS SHANGHAI

Special color master batch for refrigerator plate and preparation thereof

The invention discloses masterbatch special for a refrigerator plate and a preparation method thereof. The masterbatch comprises the following compositions by weight portion: 15 to 30 portions of carrier resin, 50 to 75 portions of titanium pigment, 0.1 to 5 portions of coloring agent, 0.5 to 20 portions of dispersing agent, 0.1 to 4 portions of stabilizer and 1 to 10 percent of processing agent. The preparation method comprises: firstly, mixing various compositions according to the proportion; secondly, mixing the various compositions in a high-speed kneader for 15 to 30 minutes or mixing the various compositions in a Banbury mixer for 20 to 60 minutes, and discharging and crushing a mixture, wherein the banburying temperature is between 170 and 230 DEG C; thirdly, fusing, mixing and granulating the mixture by a double-screw extruder, wherein the temperature of various areas of screws is between 190 and 230 DEG C, and the rotating speed of the screws is between 100 and 450 revolutions per minute; and fourthly, drying the mixture to obtain the masterbatch. The plate manufactured by the masterbatch special for the refrigerator plate is difficult to change color and crack, and has high finished product rate during plastic sucking.

Owner:常州市改性塑料厂有限公司

Wood/plastic building template

The invention relates to a wood / plastic building template, which is characterized by being prepared by taking polyvinyl chloride (PVC) SG700-8, PVC SG1000-5, wood meal, light calcium carbonate, a foam control agent 530, a compound stabilizing agent, a processing aid ACR401, a lubricating modifier LS-303, polyethylene wax, paraffin, stearic acid 1801, high-density polyethylene wax, a foaming agent AC150P azobisformamide, a foaming agent NC azobisformamide, an impact modifier chlorinated polyethylene and 1-1.4% of soybean oil as the raw materials and carrying out high-temperature mixing, cooling and extrusion molding on the raw materials. The wood / plastic building template replaces the plywood and the bamboo templates in the building templates, has the characteristics of environmental protection, zero pollutant discharge, high use frequency, long use period, etc, conforms to the ideals of low-carbon discharge, forest protection and production environment improvement and is an environment-friendly material for building.

Owner:ANSHAN SENYU BUILDING MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com