Thermoplastic water-resistant low-smoke halogen-free flame retardant cable material and manufacturing method thereof

A flame-retardant cable material and thermoplastic technology, applied in the direction of insulated cables, cables, circuits, etc., can solve the problems of public safety hazards, low mechanical properties, cable cracking, etc., and achieve good processability, high mechanical properties, and good flame retardant properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

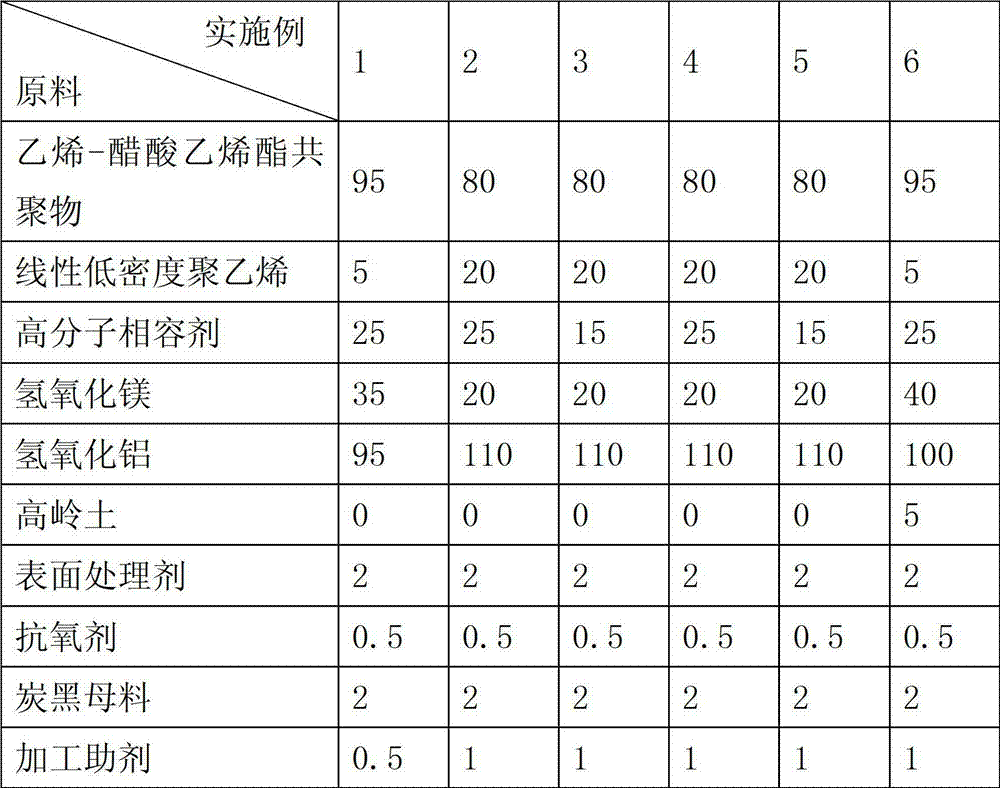

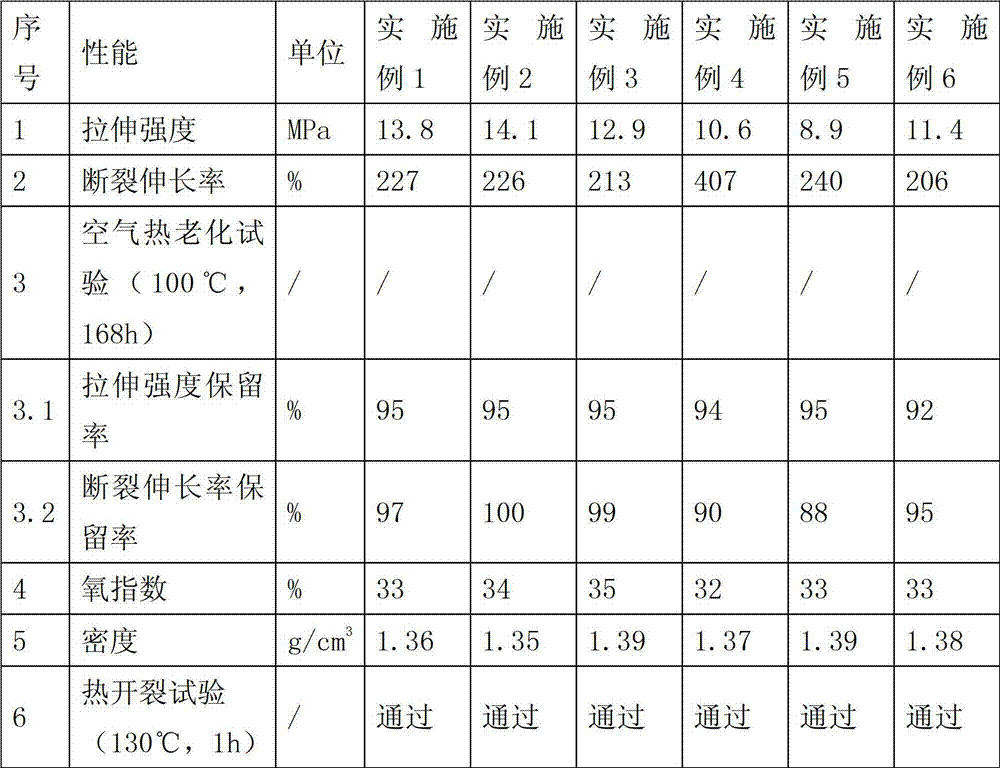

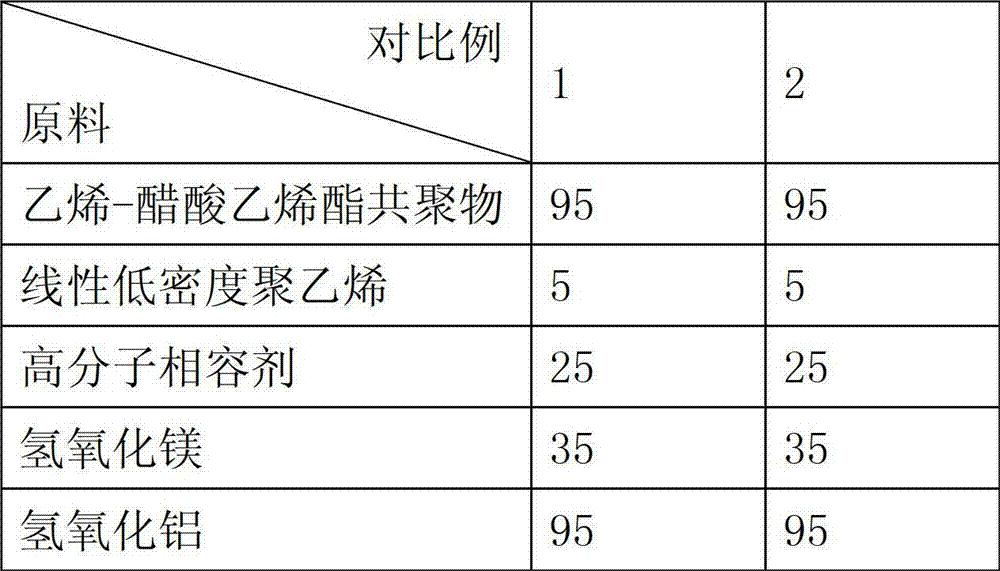

Embodiment 1

[0030] The polymer compatibilizer adopted in embodiment 1 is maleic anhydride grafted polyethylene; the surface treatment agent adopted is aluminate coupling agent; the antioxidant adopted is tetrakis[β-(3,5-di-tert-butyl Base-4-hydroxyphenyl) propionate] pentaerythritol ester; the processing aid used is ethylene bis stearic acid amide.

Embodiment 2

[0031] The polymer compatibilizer adopted in embodiment 2 is maleic anhydride grafted polyethylene; the surface treatment agent adopted is aluminate coupling agent; the antioxidant adopted is tetrakis[β-(3,5-di-tert-butyl Base-4-hydroxyphenyl) propionate] pentaerythritol ester and dilauryl thiodipropionate (ratio: 5:7); the processing aid used is polyethylene wax.

Embodiment 3

[0032] The polymer compatibilizer adopted in embodiment 3 is maleic anhydride grafted polyethylene; the surface treatment agent adopted is a silane coupling agent; the antioxidant adopted is β-(4-hydroxyl-3,5-di-tert-butyl n-octadecyl phenyl) propionate; the processing aid used is polyethylene wax.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com