Flame-retardant polyester material with high glow wire ignition temperature and preparation method thereof

A high-glow wire and flame-retardant polyester technology, which is applied in the field of flame-retardant thermoplastic polymers, can solve the problems of high price, limited application space, and not showing too many advantages, and achieve the effect of good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] Further explain the present invention below in conjunction with embodiment, embodiment is only used to further illustrate the present invention, can not be interpreted as the limitation of protection scope of the present invention, those skilled in the art make some non-essential improvements according to the content of the present invention to the present invention And adjustments still belong to the protection scope of the present invention.

[0061] The polyester of embodiment and comparative example is prepared as follows:

[0062] (1) Dry the polyester resin at 100~140°C for more than 3 hours, so that the moisture content does not exceed 0.05% of the weight of the polyester;

[0063] (2) Weigh various raw materials according to the ratio in Table 1;

[0064] (3) The polyester resin is mixed with other components in a high-speed mixer or a rotary premixer to obtain a premix;

[0065] (4) Feed the premix into the twin-screw extruder, under the conveying and shearin...

PUM

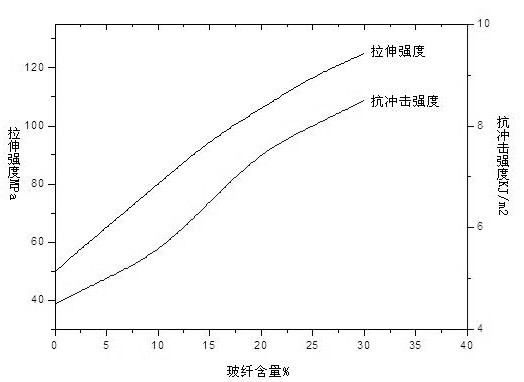

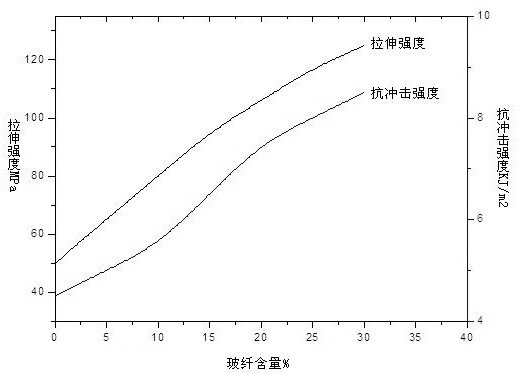

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com