Patents

Literature

40results about How to "Avoid impact on mechanical properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Flame-retardant polyester material with high glow wire ignition temperature and preparation method thereof

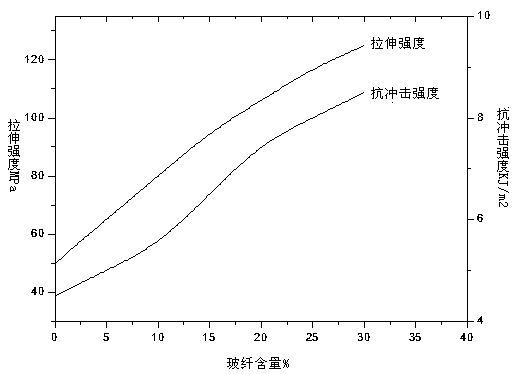

ActiveCN102250450AGWIT performance improvementsMeet performance requirementsPolyester resinUltimate tensile strength

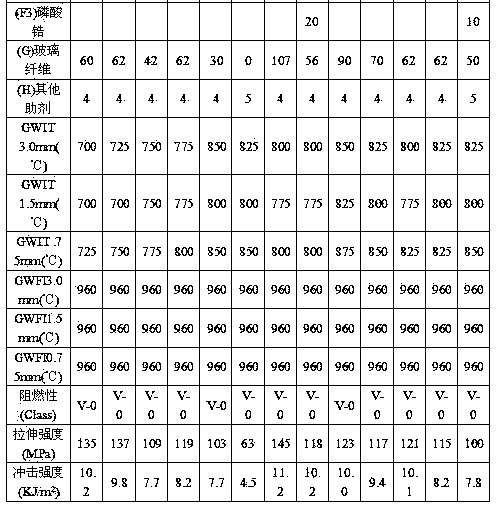

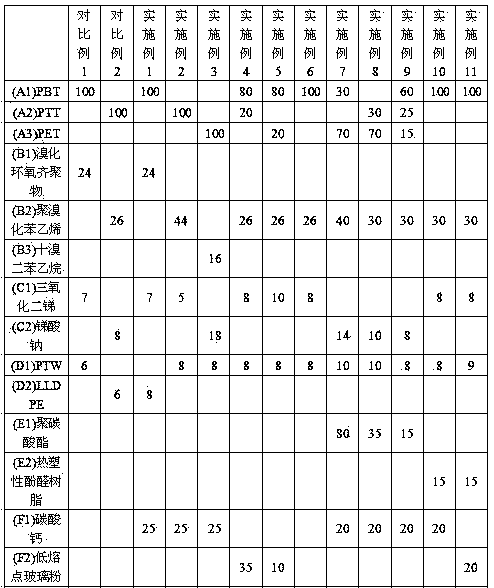

The invention discloses a fame-retardant polyester material with a high glow wire ignition temperature and a preparation method thereof. The flame-retardant polyester material with a high glow wire ignition temperature is composed of the following components in parts by weight: 100 parts of polyester resins, 15-50 parts of bromine-series flame retardant, 5-20 parts of synergistic flame retardant, 0-20 parts of toughening agent, 0-80 parts of carbon forming agent, 5-40 parts of hot oxygen barrier agent, 0-120 parts of fibrous reinforcing agent and 0-10 parts of processing aid. The preparation method of the flame-retardant polyester material with a high glow wire ignition temperature comprises: drying the polyester resins, mixing with other components to obtain a premixed material, then feeding the premixed material into a twin-screw extruder, melting and plasticizing, kneading and mixing, extruding, drawing, cooling, pelletizing, drying and finally packaging. The flame-retardant polyester material with a high glow wire ignition temperature has the advantages of low cost, high glow wire ignition temperature, similar mechanical strength to ordinary flame-retardant polyester and wide application range.

Owner:KINGFA SCI & TECH CO LTD +1

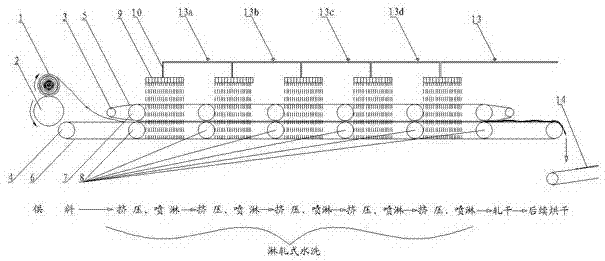

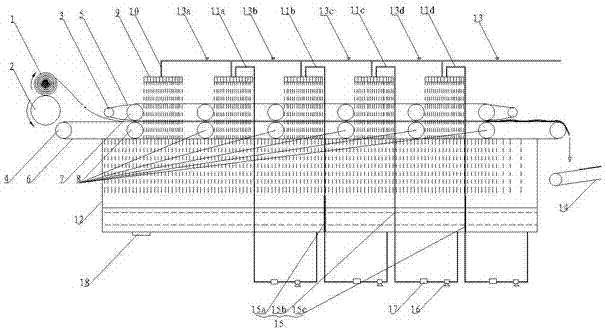

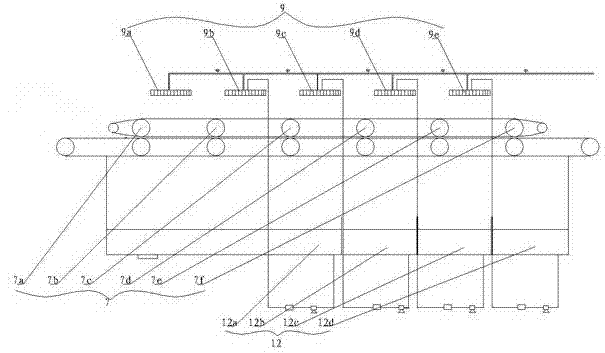

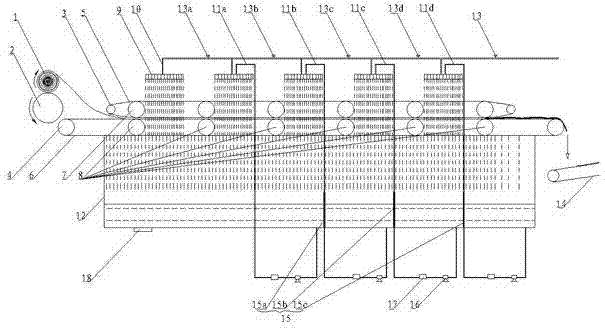

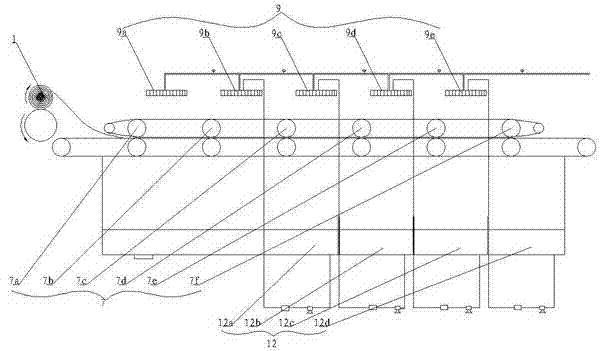

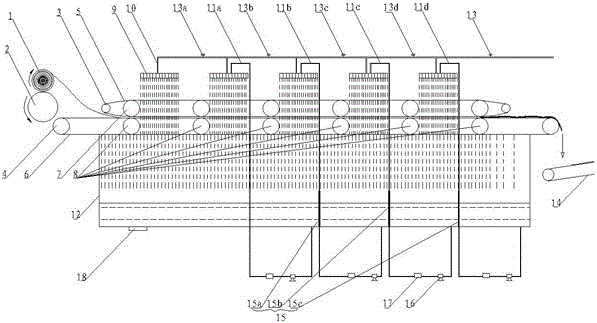

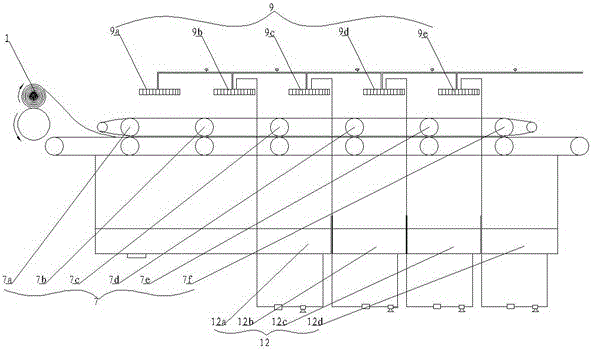

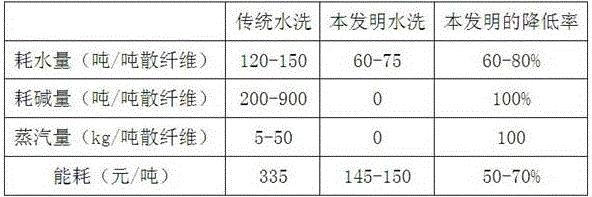

Spray-rolling type loose fiber washing process

ActiveCN103774362ALow water consumptionLow costLiquid/gas/vapor removal by squeezing rollersTextile treatment machine arrangementsDyeingFiber

The invention relates to a spray-rolling type loose fiber washing process, and belongs to the technical field of loose fiber dyeing. Dyed loose fibers are conveyed to a spray-rolling type washing device, while the loose fibers are horizontally clamped by a guide belt to be conveyed, a plurality of groups of spray-rolling type washing with alternative squeezing and spraying is carried out on the loose fibers, and the loose fibers are washed, rolled to be dry, and output. The spray-rolling type loose fiber washing process has the advantages that dyeing is even, water consumption is small, and the working procedure is simple.

Owner:SHAOXING JINYU TEXITLE NEW TECH CO LTD

3004 aluminum foil and preparing method and application thereof

The invention discloses 3004 aluminum foil and a preparing method and application thereof. The aluminum foil comprises chemical elements: by mass, 0.15-0.25% of Si, smaller than or equal to 0.55% of Fe, 0.14-0.2% of Cu, 1.02-1.15% of Mn, 0.95-1.1% of Mg, smaller than or equal to 0.05% of Cr, smaller than or equal to 0.15% of Zn, 0.015-0.025% of Ti, smaller than 0.1% of other chemical elements andthe balance Al. The 3004 aluminum foil is obtained by performing 3004 aluminum alloy smelting, refining, standing, online degassing and deslagging, casting, face-milling, uniform heating treatment, hot rolling, cold rolling, intermediate annealing, cold foil rolling and finished product annealing. With the combination of the various elements and the preparing process, the prepared aluminum foil has high strength and toughness, the thickness is greatly reduced when the aluminum foil is used as a container, use is convenient, and the consumption of the raw materials is reduced; and waste ring-pull cans can be adopted as a raw material, the consumption of the raw material is reduced, resources are reutilized, the source of the raw materials for preparing the aluminum foil is widened, meanwhile the burdens on the environment are avoided, the production cost is reduced, and the 3004 aluminum foil has quite good social economic benefits.

Owner:河南明泰科技发展有限公司

Cyanate resin/ carbon fiber composite material and its preparing process

InactiveCN1970627AHigh strengthIncrease external force transmissionTextiles and paperFiberCarbon nanotube

The invention discloses a making method of cyanate resin / carbon fiber composite material, which comprises the following steps: 1) heating and fusing cyanate resin to form transparent pattern under 80-100 deg.c; insulating 1-3h; adding 1-3% carbon nanometer pipe; insulating under 80-150 deg.c for 2-4h; cooling to indoor temperature; obtaining resin base; 2) adding acetone in the resin base with bulk rate at 1:0.8-1:1.2; allocating glue solution; immersing carbon fiber or carbon fiber cloth in the glue solution; drying; doing hot pressing to mould after the quantity of volatile substance is less than 1%; obtaining the product.

Owner:SUZHOU UNIV

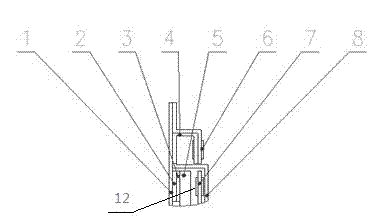

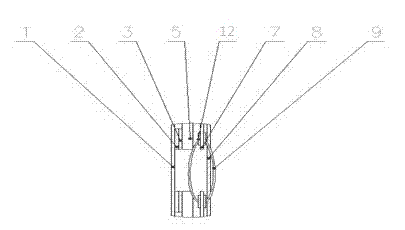

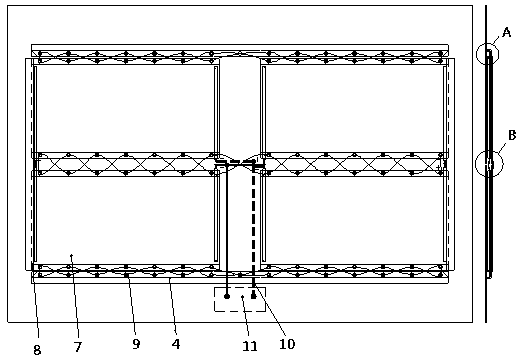

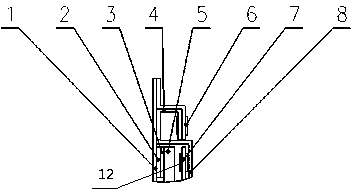

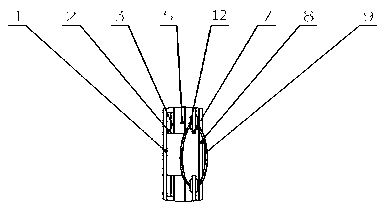

Spray-rolling type loose fiber washing machine

ActiveCN103774359AImprove washing efficiencyLow water consumptionLiquid/gas/vapor removal by squeezing rollersTextile treatment machine arrangementsDyeingEngineering

The invention relates to a spray-rolling type loose fiber washing machine, and belongs to the technical field of loose fiber dyeing. The spray-rolling type loose fiber washing machine comprises a cotton conveying roller, a transmission component and a spraying component. The cotton conveying roller is arranged in front of the transmission component, the transmission component is composed of a guide belt, a roller and a drive roller, the guide belt is horizontally arranged, and the drive roller drives the guide belt to move synchronously with the cotton conveying roller. The spraying component is located above the guide belt and used for washing the loose fibers below the spraying component, and the roller is matched with the guide belt to be mounted and used for squeezing the loose fibers which are conveyed to the guide belt through the cotton conveying roller. The spray-rolling type loose fiber washing machine is used for a loose fiber washing process, and has the advantages of being even in dyeing, small in water consumption, simple in process, and the like.

Owner:SHAOXING JINYU TEXITLE NEW TECH CO LTD

Method for reliably connecting flexible thin-film solar cell and airship envelop

ActiveCN102897330AEfficient power supplyFirmly connectedCosmonautic power supply systemsPhotovoltaic energy generationThermal insulationSolar power

The invention discloses a method for reliably connecting a flexible thin-film solar cell and an airship envelop. According to the method, solar cells are interconnected through brocade silk ropes which penetrate through stainless steel buttonholes, thereby realizing assembly in an array manner; the solar cells and lateral connecting cord fabrics welded on the airship envelop are connected with each other through the brocade silk ropes which penetrate through the stainless steel buttonholes, thereby realizing the reliable connection between a solar cell array and the envelop; and a multi-layer thermal insulation assembly is closely connected with the airship envelop by employing nylon fasteners (groups), thereby realizing the isolation of waste heat of the solar cells and solving the problem of thermal coupling between the solar cells and the airship envelop. The connecting method can be widely applied to various airship platforms which generate power by solar energy and has wide military and civil application prospect.

Owner:湖南航天远望科技有限公司 +1

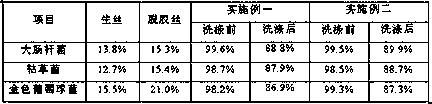

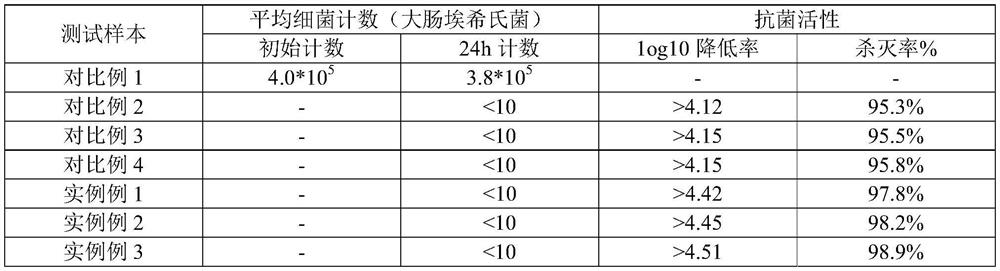

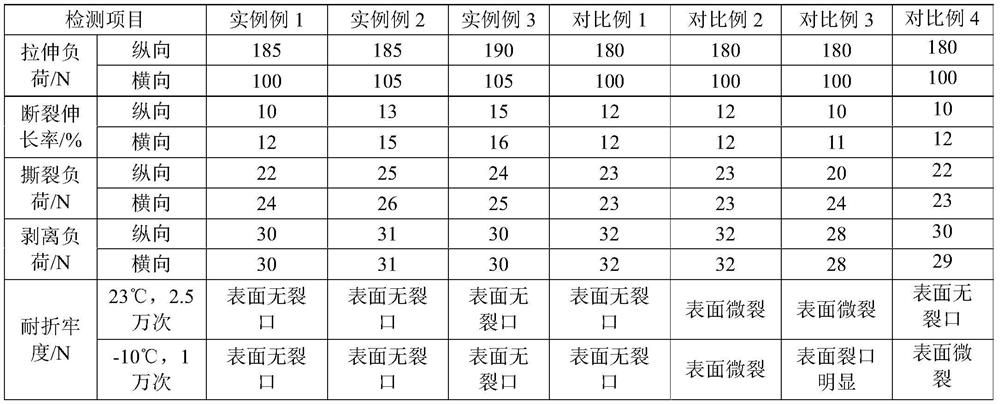

Antibacterial cationic waterborne polyurethane resin and preparation method thereof

ActiveCN108299614AIncrease the degree of cross-linkingImprove water resistanceAntifouling/underwater paintsPaints with biocidesIsocyanateChemistry

The invention provides an antibacterial cationic waterborne polyurethane resin and a preparation method thereof. The preparation method comprises the steps of: reacting macromolecular polyol with polyisocyanate at 80-95DEG C for 2-4h; then adding a small molecular alcohol chain extender and chlorogenic acid for reaction at 75-85DEG C for 1-3h; then adding a catalyst for reaction at 55-65DEG C for2-4h; adding a hydrophilic chain extender by starved charging technique, carrying out reaction at 35-45DEG C for 0.5-1.5h, performing cooling to a temperature ranging from -5DEG C to 5DEG C, adding aneutralizer for neutralizing, adding deionized emulsified water and dispersing the substances uniformly, and then conducting reduced pressure distillation so as to obtain the cationic waterborne polyurethane resin. According to the invention, chlorogenic acid is introduced to a cationic waterborne polyurethane molecular chain by chemical bonding, the influence of functional additives to the mechanical properties of waterborne polyurethane can be avoided, and also a good antibacterial effect can be realized.

Owner:HEFEI KETIAN WATERBORNE TECH CO LTD +1

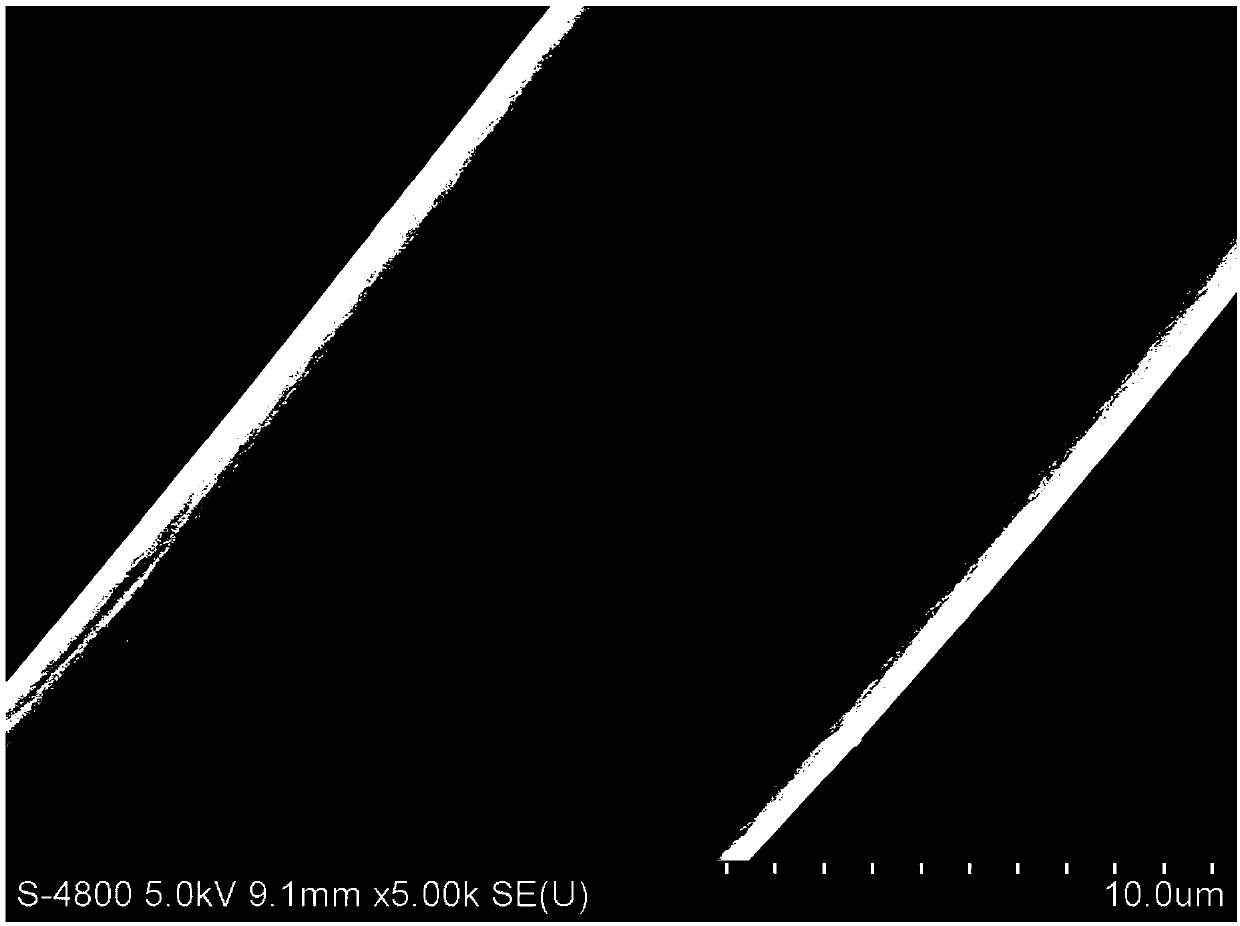

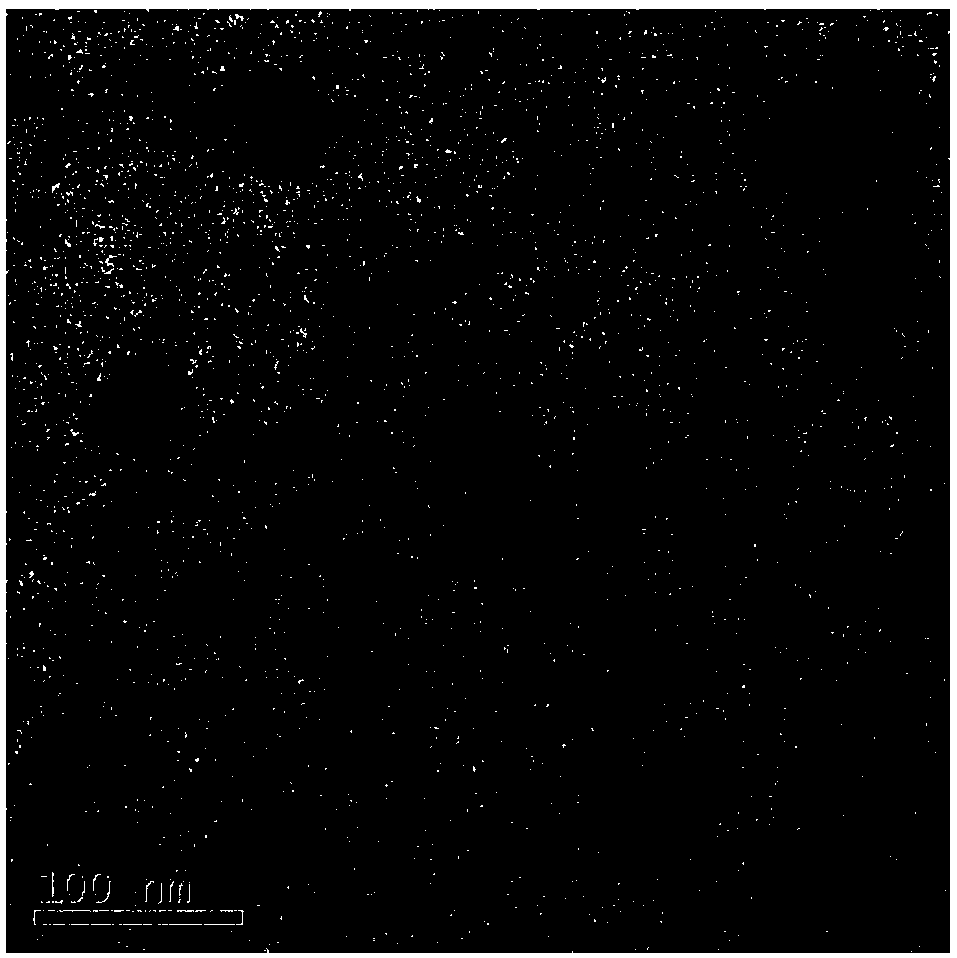

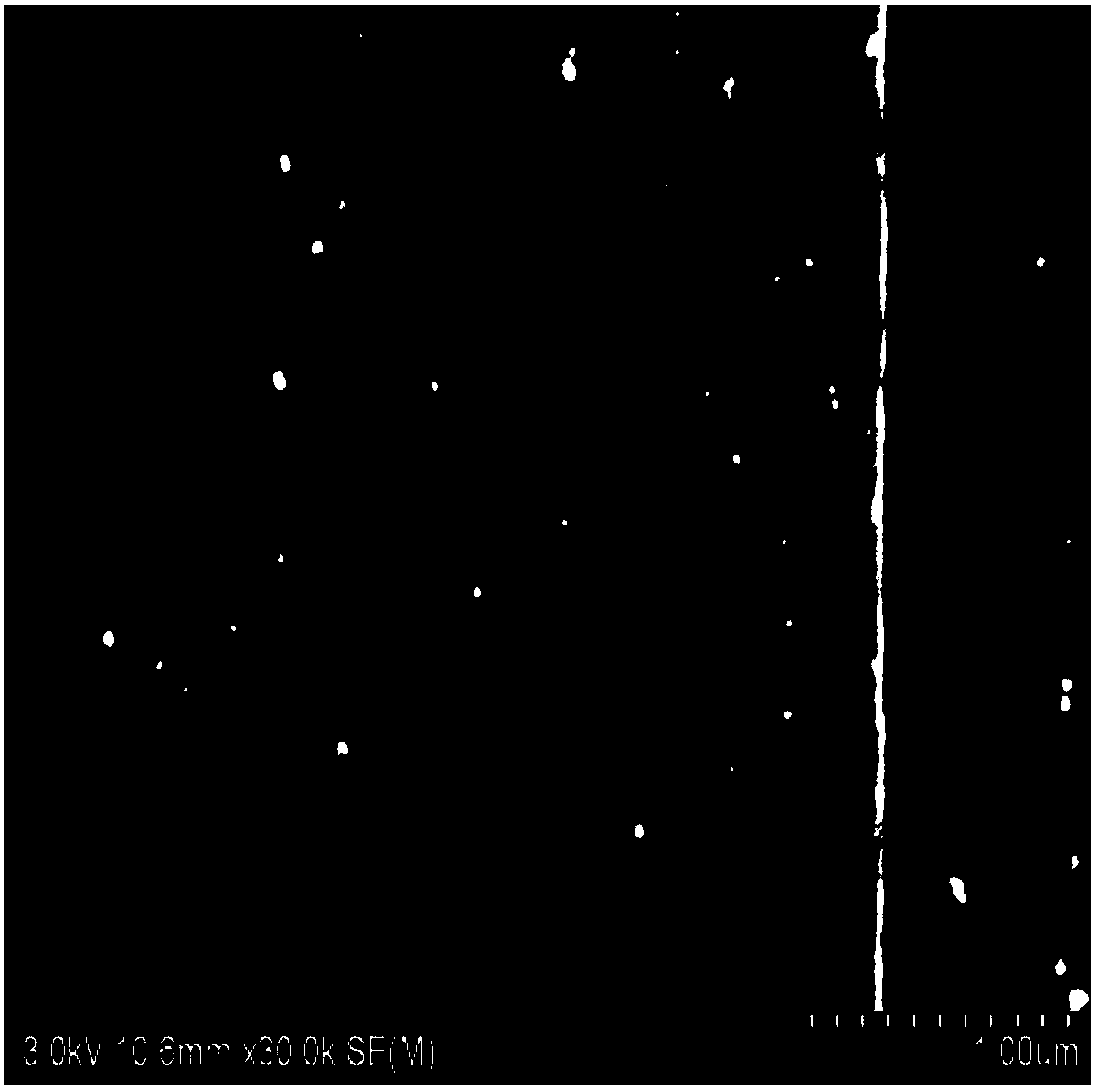

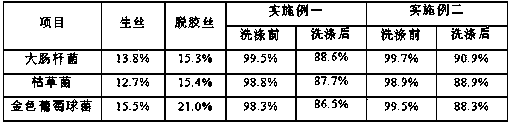

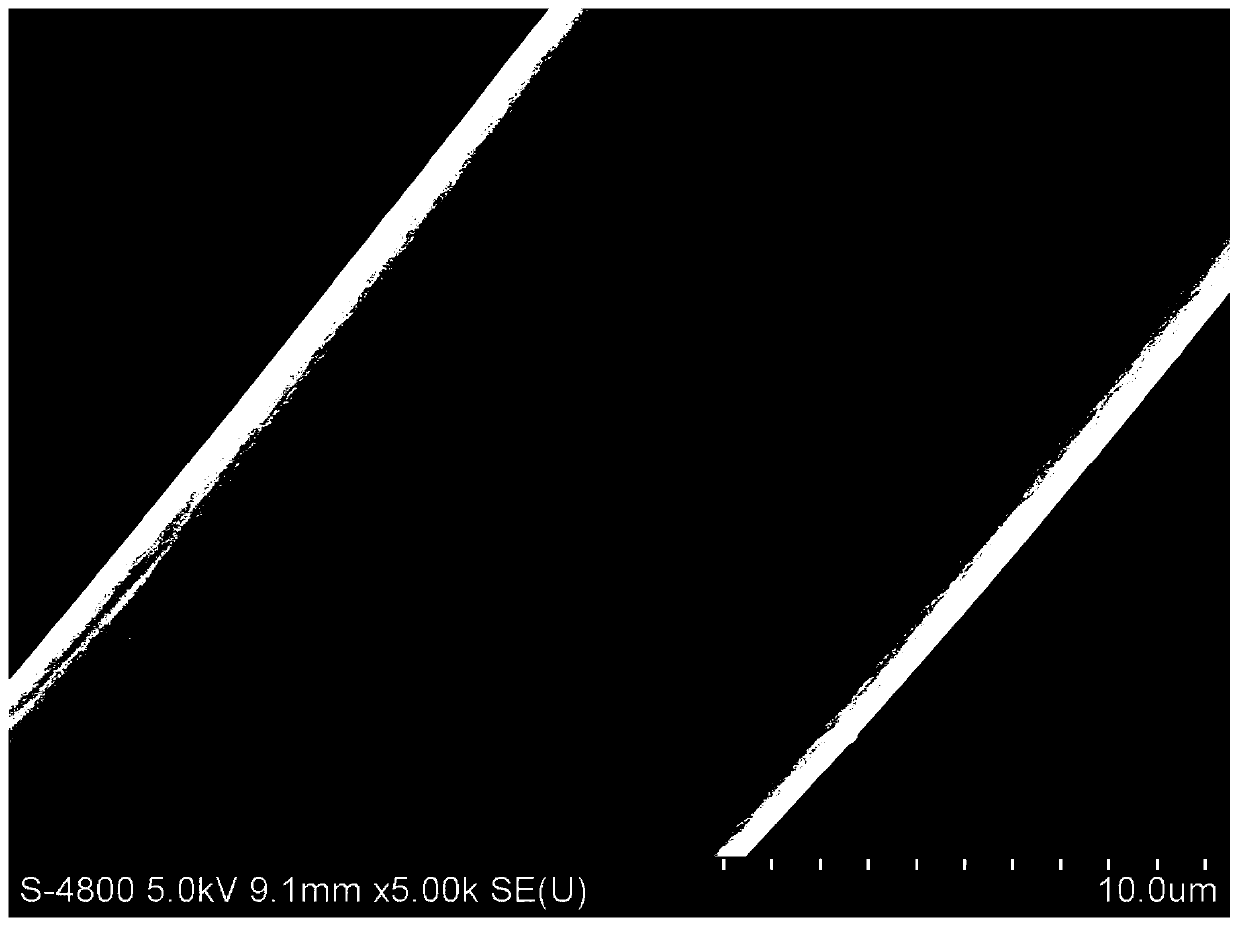

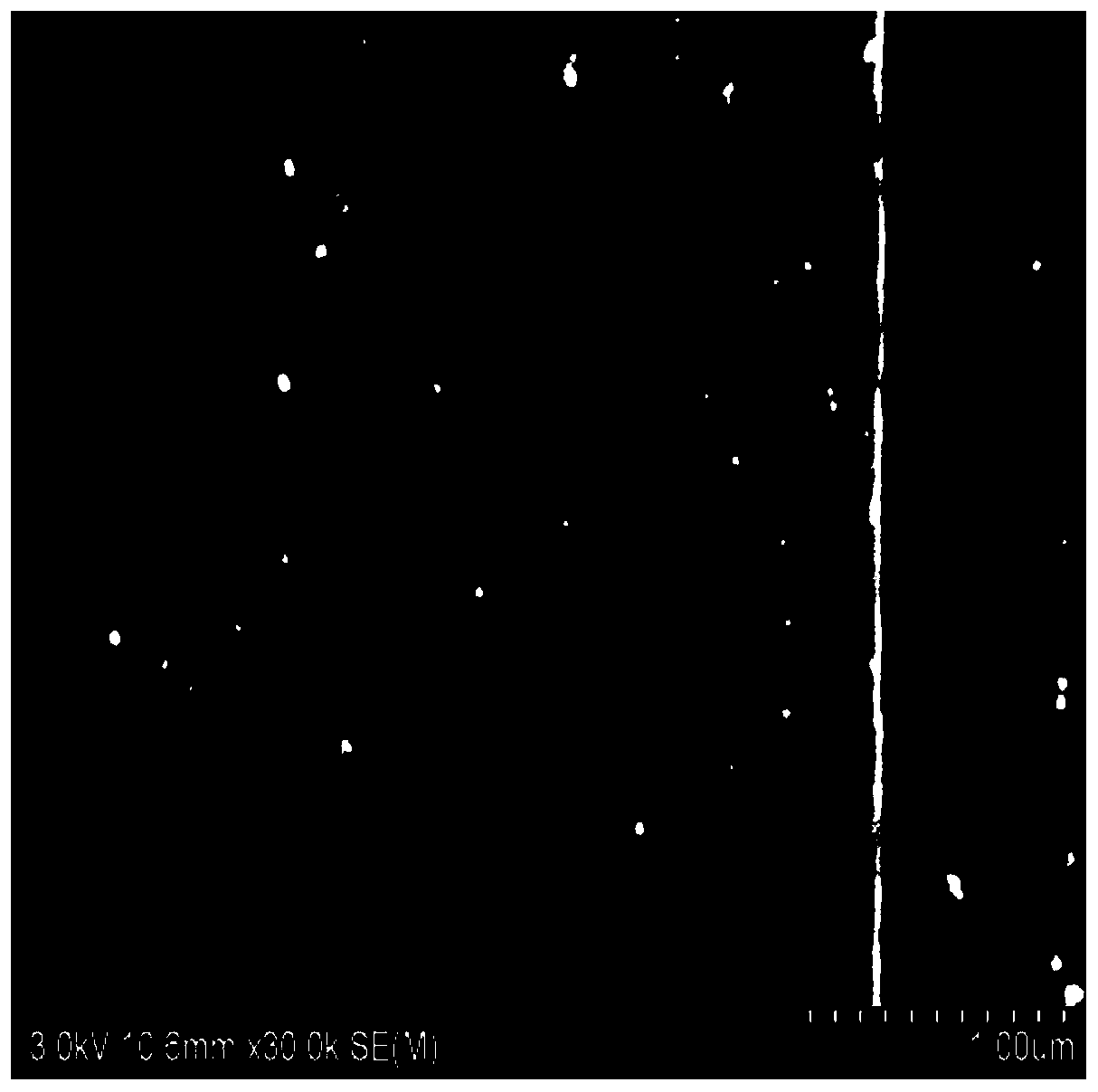

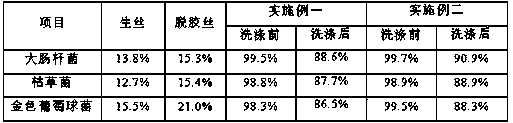

Antibacterial silk product with nano-copper and preparation method of antibacterial silk product with nano-copper

ActiveCN108004762AUniform penetrationUniform fixationBiochemical treatment with enzymes/microorganismsAnimal fibresReduction treatmentPollution

The invention discloses an antibacterial silk product with nano-copper and a preparation method of the antibacterial silk product with nano-copper. The preparation method comprises the following steps: immersing a silk product in a buffer solution containing monascus, then adding a copper hydrochloride solution for soaking the immersed silk product, then performing reduction treatment with a reducing agent, and finally, performing cleaning and drying to obtain the antibacterial silk product with nano-copper. The antibacterial silk product with nano-copper and the preparation method thereof have the advantages that the broad-spectrum antibacterial property of silk fibers and fabrics thereof can be improved, furthermore, harm to human bodies can be avoided, and pollution to the environment also can be avoided; the preparation method is simple and easy to realize batch production; and the prepared antibacterial silk fiber product has excellent and lasting antibacterial property.

Owner:湖州金裕丝绸科技有限公司

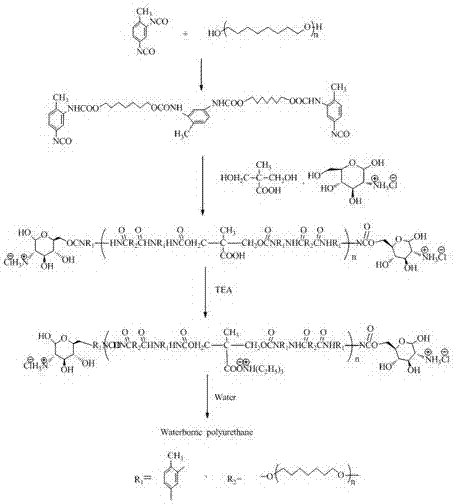

Antibacterial waterborne polyurethane and a synthetic method thereof

ActiveCN106947047AEffect on mechanical propertiesImprove antibacterial propertiesPolyesterPolymer science

The invention discloses an antibacterial waterborne polyurethane material and a synthetic method thereof and relates to an antibacterial waterborne polyurethane material and a preparing method thereof. Polyester polyol or polyether polyol, diisocyanate, 2,2-di(hydroxymethyl)butyric acid and D-glucosamine hydrochloride are adopted as basic raw materials. The raw materials are subjected to pre-polymerization, chain extension, neutralization and emulsification to obtain antibacterial waterborne polyurethane. The antibacterial waterborne polyurethane material and the method are characterized in that a certain amount of the D-glucosamine hydrochloride is added in the chain extending stage; and hydroxy in the D-glucosamine hydrochloride molecule reacts with isocyanate groups in a polyurethane prepolymer so as to introduce an antibacterial component into the molecule of the waterborne polyurethane through a chemical bonding manner. Influences of functional additives on mechanical performance of the waterborne polyurethane are avoided, and a good antibacterial effect can be achieved.

Owner:QUANGANG PETROCHEM RES INST OF FUJIAN NORMAL UNIV +1

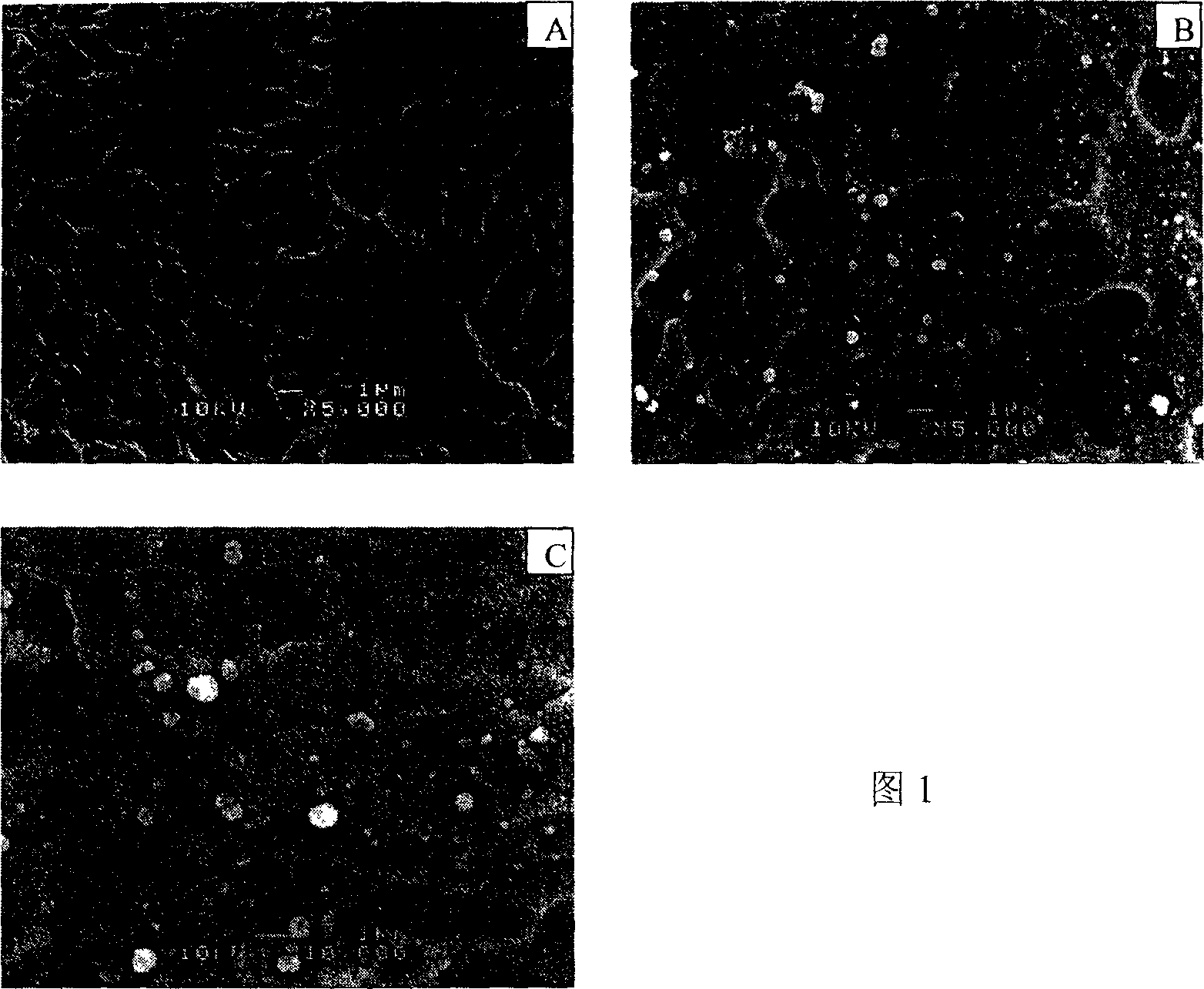

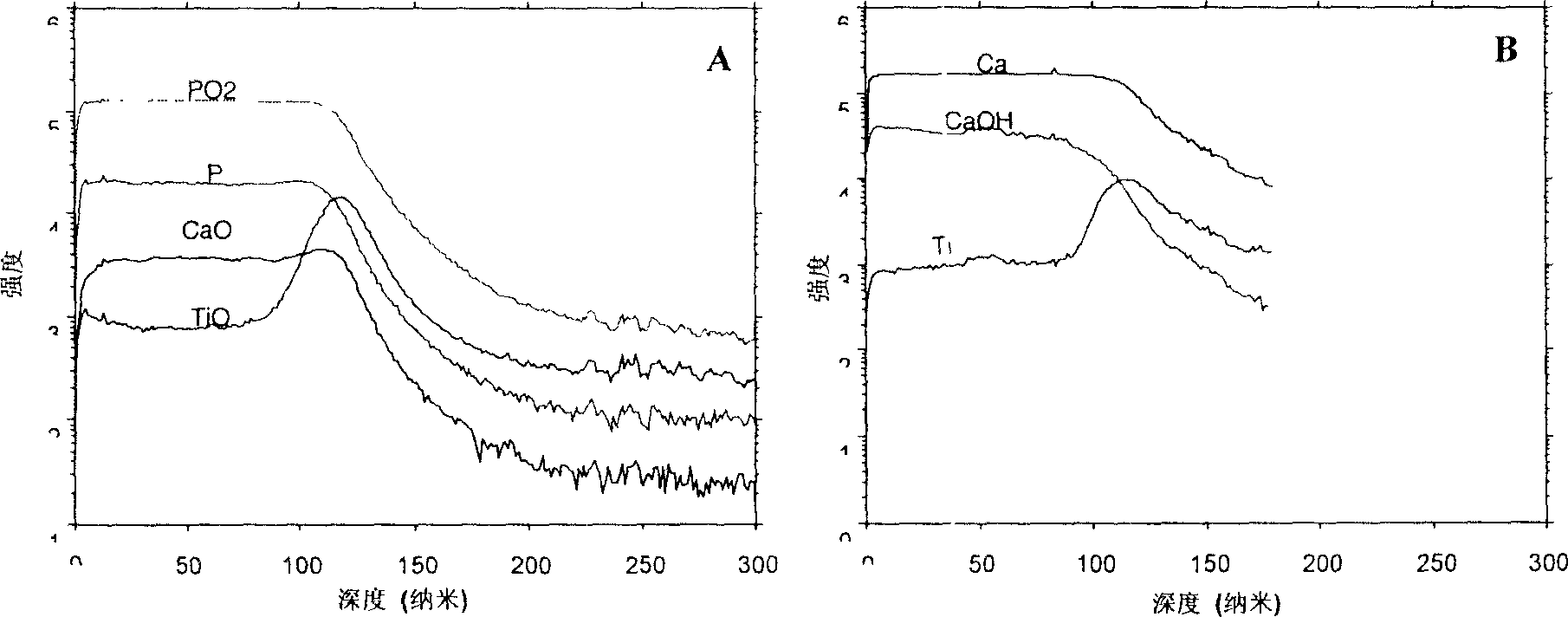

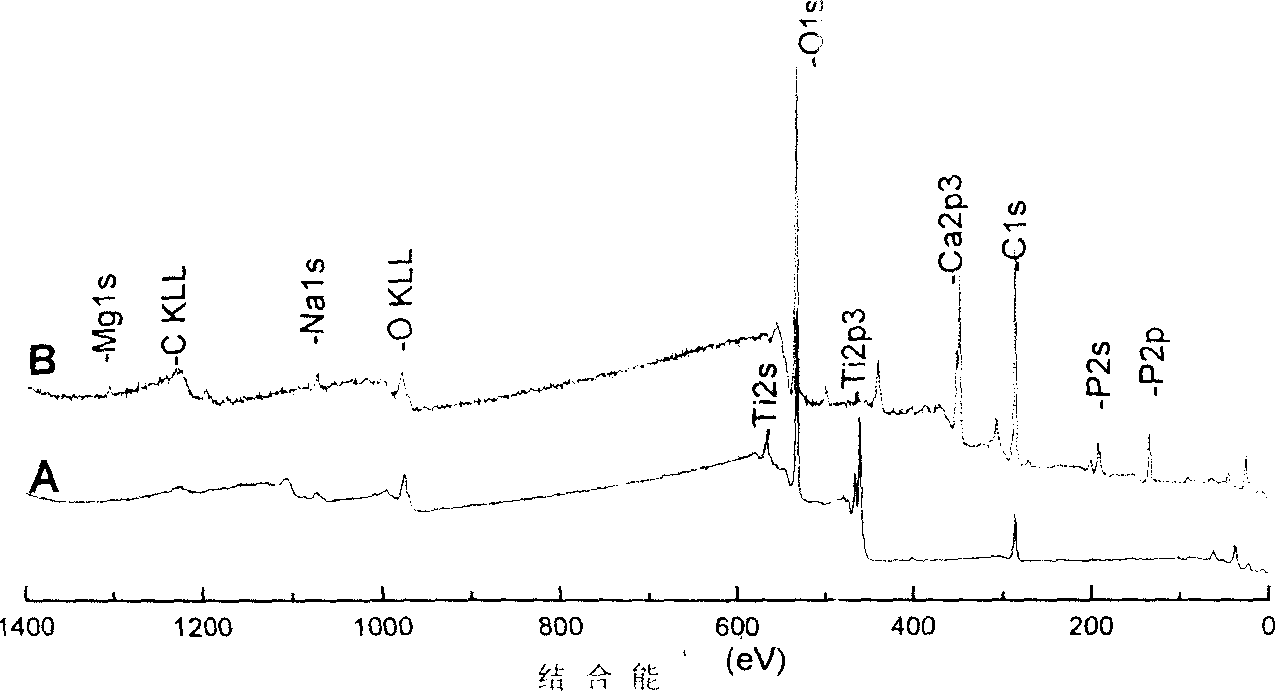

Surface activating method of medical metal material

InactiveCN1680632AAvoid impact on mechanical propertiesAvoid problems such as corrosionElectrolytic inorganic material coatingSupporting electrolytePhosphate

A surface-active method of metal material for medical use. It adopts three poles system. Negative pole is metal material. Positive pole is inert material. Fit them and reference electrode to electrolyte solution containing supported electrolyte solution. Soluble calcium salt and phosphate at pH2.5-6.5.Hold negative potential to be at -1 to -4V by way of constant potential or apply to electronic current 1-5Ma at constant value for 2 to 20min. Get sample of negative pole, wash and dry it.

Owner:SICHUAN UNIV

Antibacterial silk product loaded with nano-copper and preparation method of same

ActiveCN107964785AAvoid chemical reagent residueEffective penetrationBiochemical fibre treatmentAnimal materialChemistryNanometre

The invention discloses an antibacterial silk product loaded with nano-copper and a preparation method of same. The method includes the steps of: soaking a silk product in a buffer solution containingmonascus bacteria, adding a copper salt acid solution to soak the silk product, and performing ultraviolet reduction treatment; finally cleaning and drying the product to prepare the antibacterial silk product loaded with nano-copper. The method can improve the broad-spectrum antibacterial effect of the silk fibers and a fabric thereof, can avoid damage on human body and pollution on environment.The preparation method is simple and is easy to carry out in large scale production. The antibacterial silk product has excellent and durable antibacterial function.

Owner:广东宸际内衣生物科技有限公司

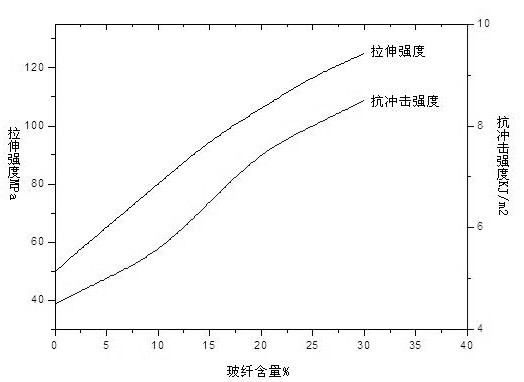

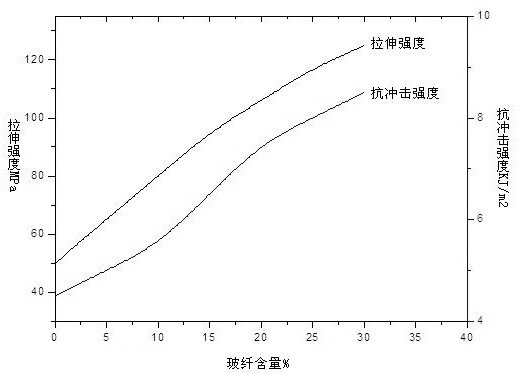

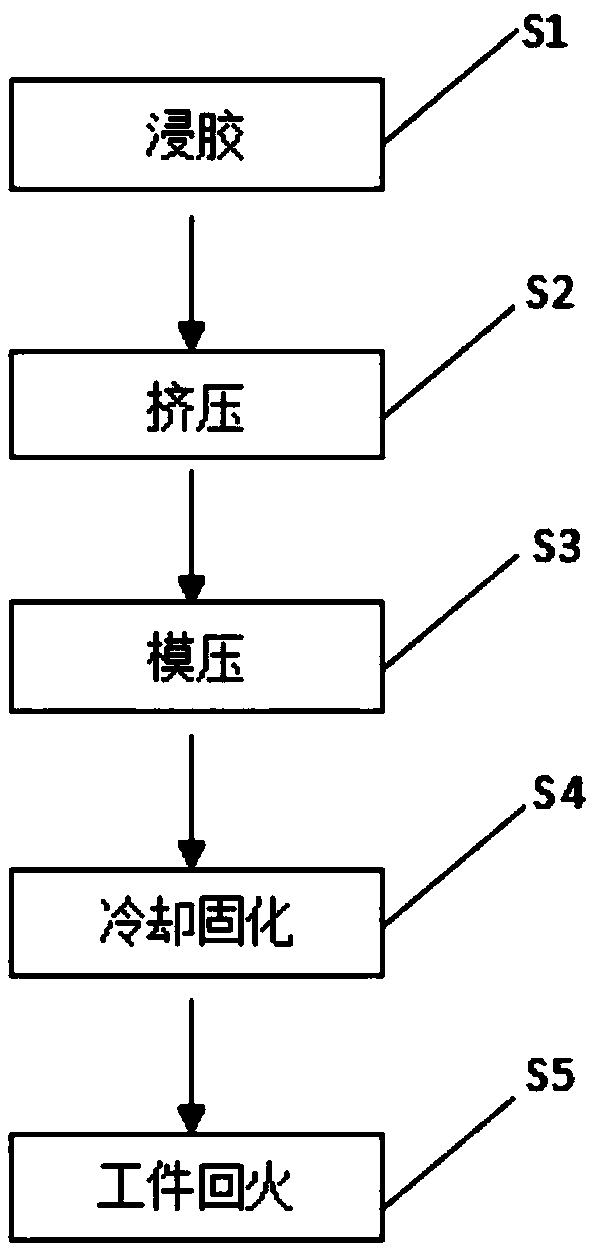

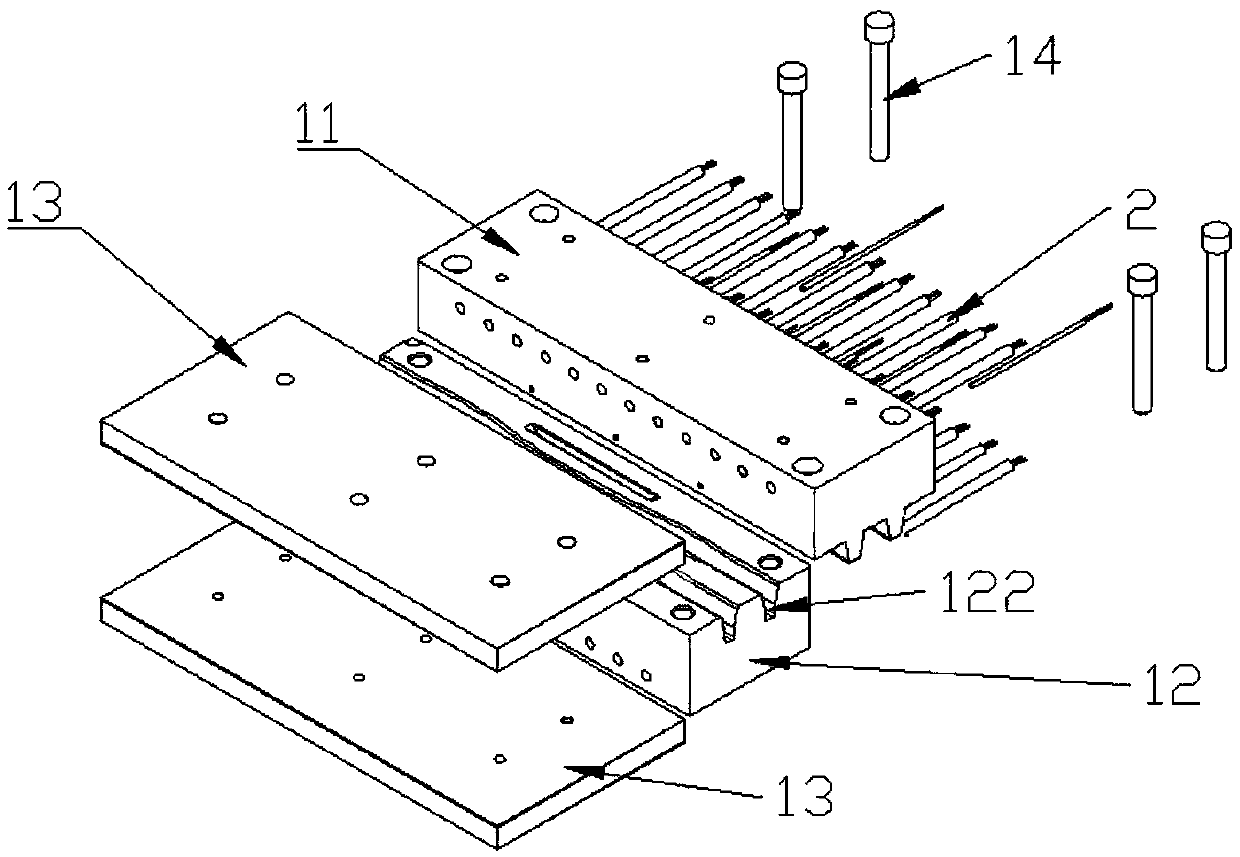

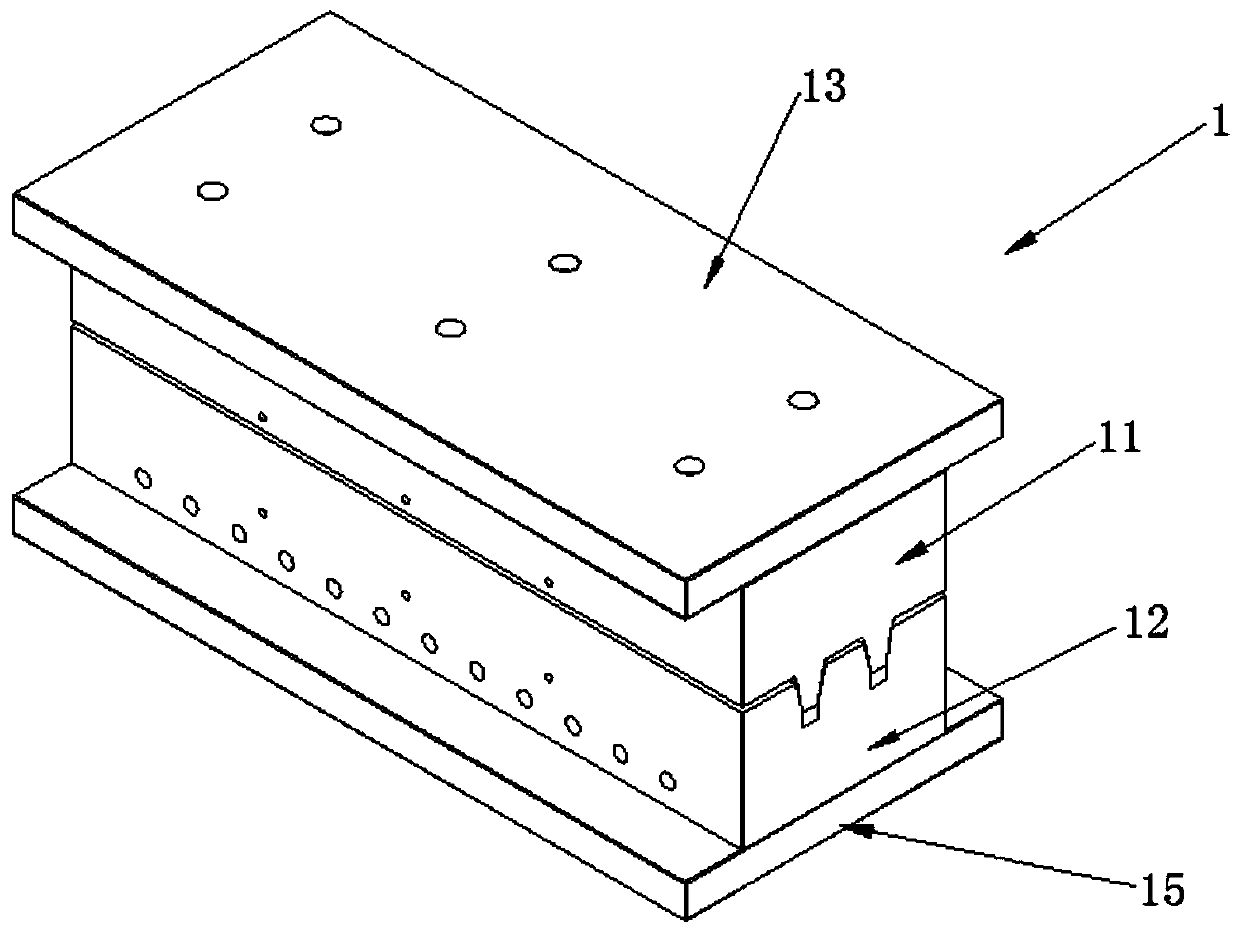

Mold pressing forming process of long glass fiber reinforced resin bow arm

InactiveCN108015946AImprove mechanical strengthIncrease the bendable arcCoatingsForming processesPolyresin

The invention discloses a mold pressing forming process of a long glass fiber reinforced resin bow arm. The mold pressing forming process sequentially comprises the procedures of gum dipping, extruding, mold pressing, cooling curing and workpiece tempering. In gum dipping, a long glass fiber bundle is drawn into resin to be pre-soaked. In extruding, residual resin is extruded out of the glass fiber bundle subjected to gum dipping treatment and resin pre-soaking by a drawing machine through an extrusion opening. In mold pressing, dipped glass fibers subjected to extruding treatment are formed by a mold pressing machine at the medium pressure of a mold cavity. In cooling, a glass steel product subjected to mold pressing forming is blown by a cold air gun, cooling is carried out for one minute, and demolding is facilitated. In workpiece tempering, a cooled workpiece is put in a drying box of 130+ / -5 DEG C for 120 min to 150 min to be tempered, and the resin in the bow arm is fully cured.The glass filter content of the bow arm obtained through the forming process reaches up to 75%, the mechanical strength of the bow arm can be effectively improved, the bendable radian of the bow arm is improved, surface cutting does not need to be carried out on the bow arm any more, and the situation that the glass fibers are cut off to influence the mechanical property of the bow arm is avoided.

Owner:ZENGCHENG HUACHANG PLASTIC HARDWARE MOLD

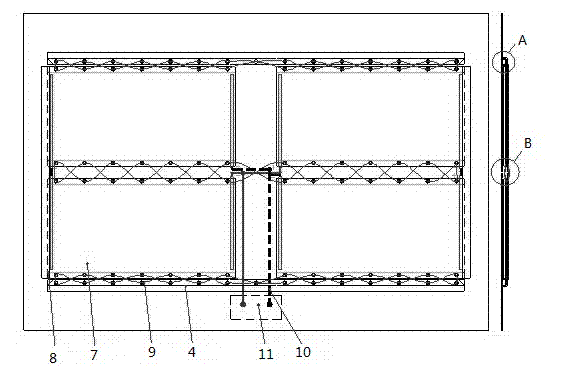

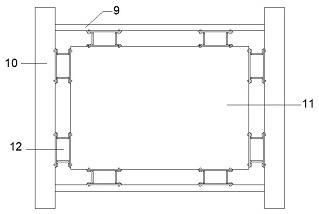

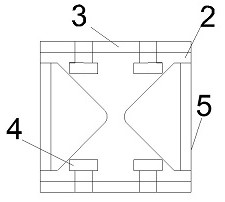

Bending and shearing mixed type square steel tube damper and manufacturing method

PendingCN112144690AEasy constructionLow costProtective buildings/sheltersShock proofingSteel tubeInfill wall

The invention provides a bending and shearing mixed type square steel tube damper. The bending and shearing mixed type square steel tube damper is mainly composed of a square steel tube, bending energy dissipation plates, flange restraining plates and connecting bolts. The side surface of the square steel tube is a rectangular energy dissipation face and can bear shearing load energy dissipation;the bending energy dissipation plates are welded to the two ends of the shearing energy dissipation face, are in an X shape and can bear bending load energy dissipation; and the flange restraining plates are welded to an upper square steel tube flange and a lower square steel tube flange, the flange restraining plates are arranged on the outer sides of the upper square steel tube flange and the lower square steel tube flange and are slightly longer than the upper square steel tube flange and the lower square steel tube flange, bolt holes are reserved in the two ends of the flange restraining plates, and the diameter and the distance of the bolt holes can be determined through calculation according to actual engineering requirements. The square steel tube is connected with frame beams, frame columns and infilled walls through the connecting bolts, and the upper square steel tube flange and the lower square steel tube flange are prevented from yielding and tilting.

Owner:INST OF ENG MECHANICS CHINA EARTHQUAKE ADMINISTRATION

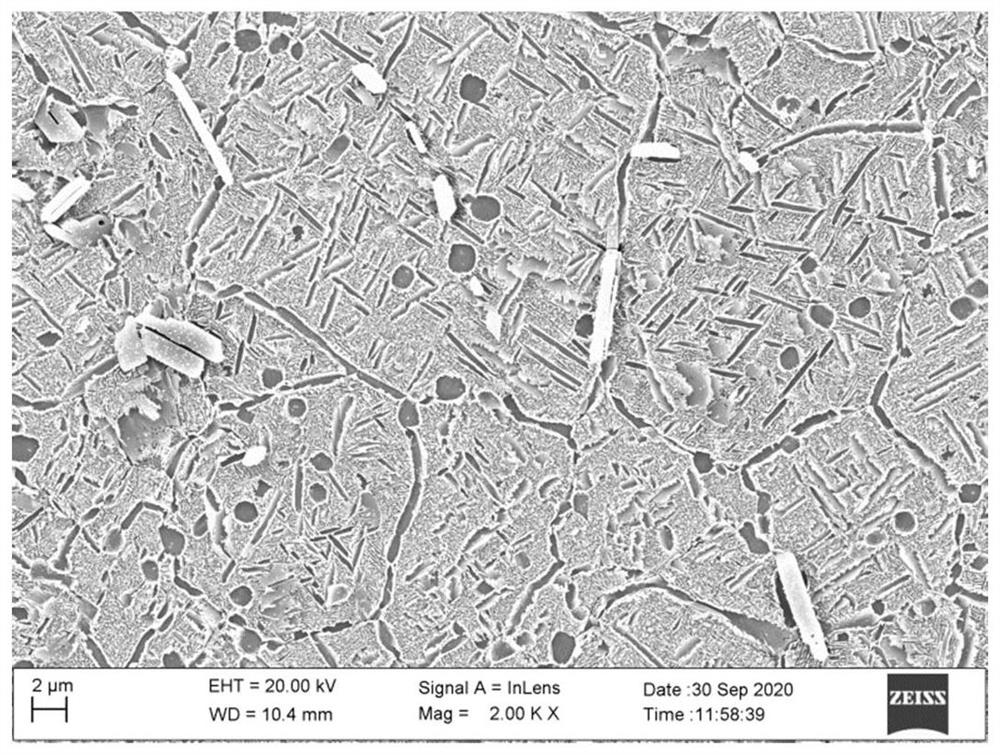

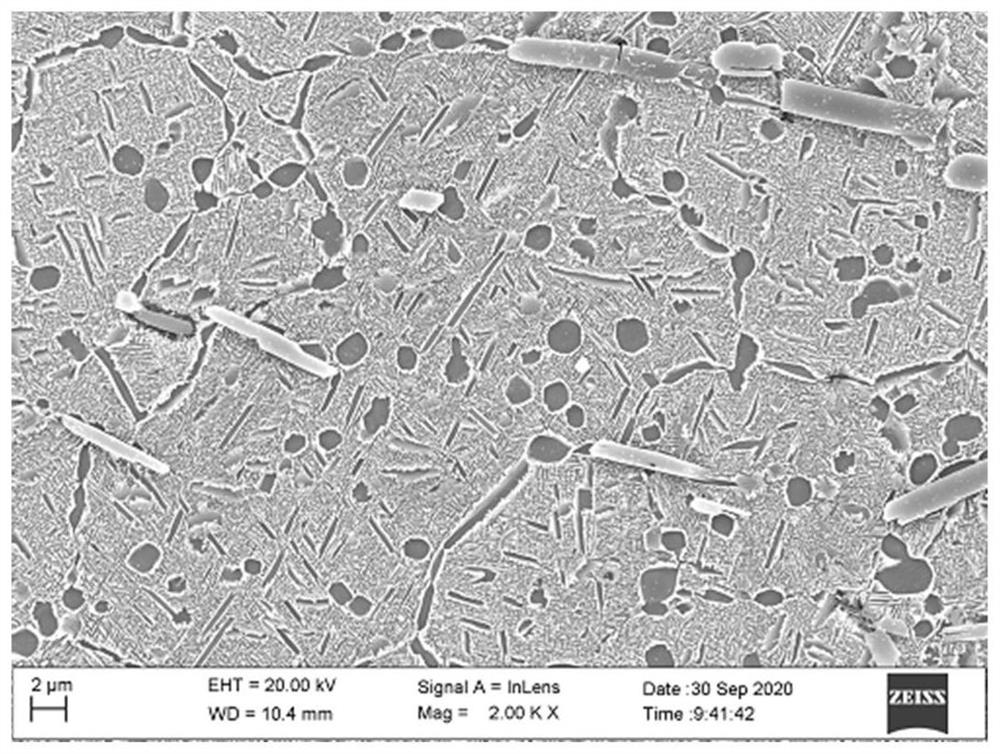

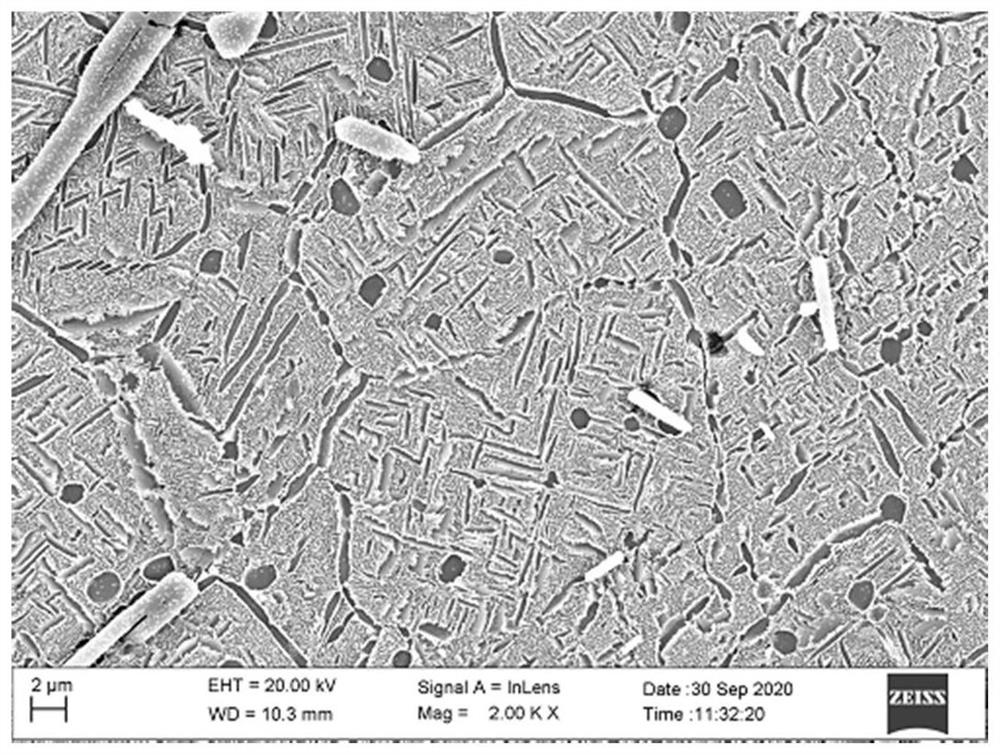

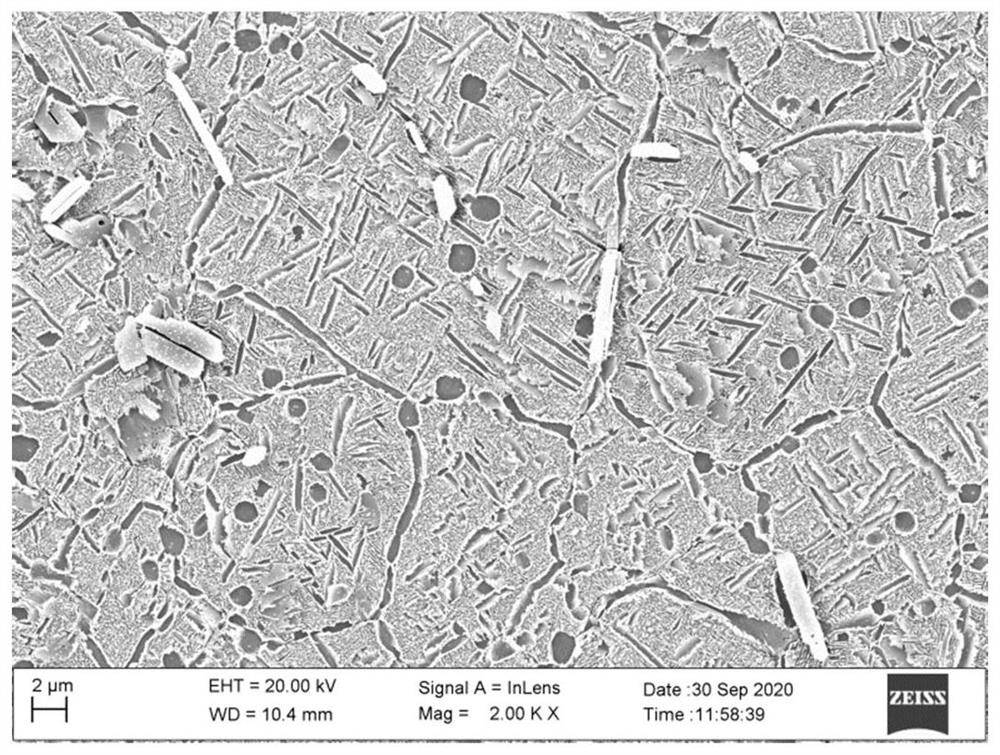

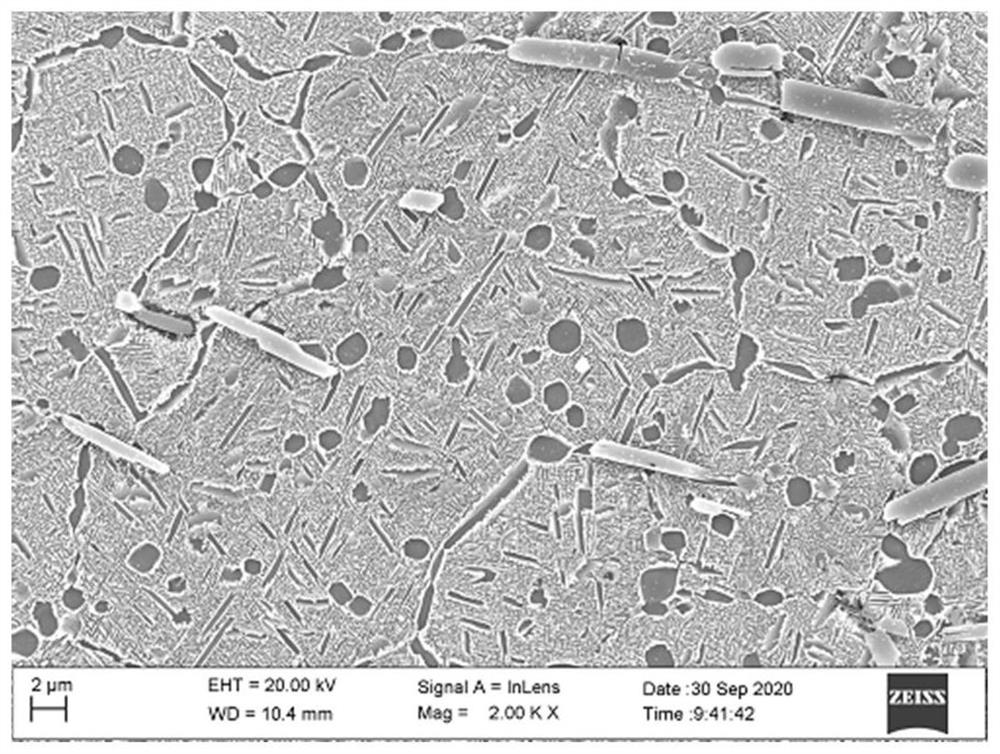

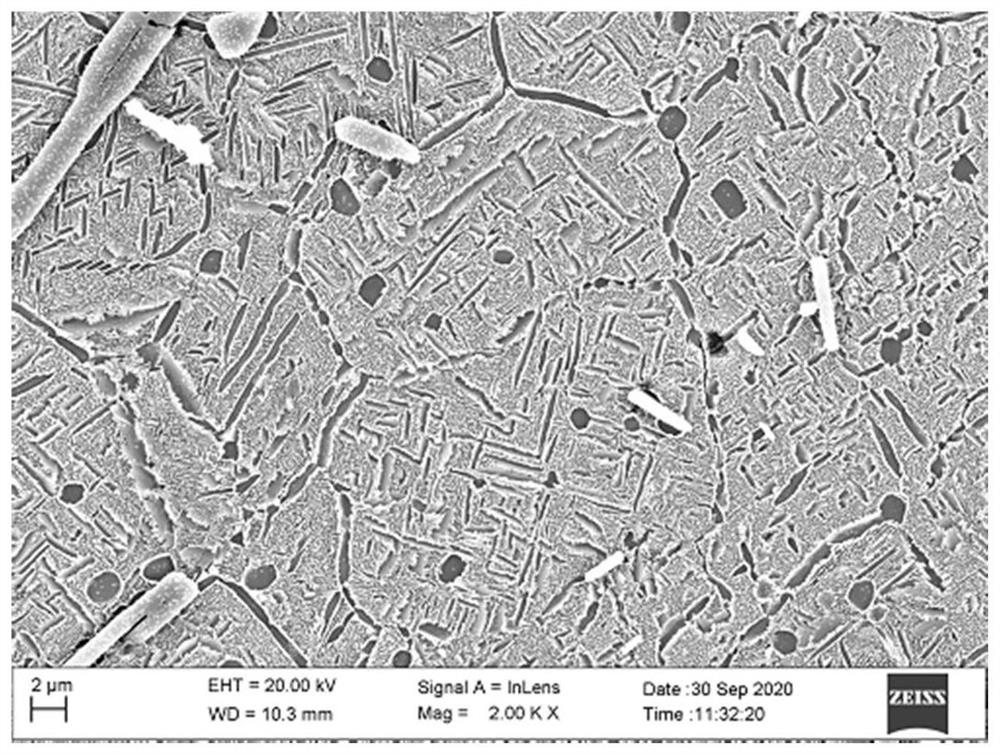

In-situ synthesized TiB reinforced beta titanium alloy composite, and preparation method thereof

ActiveCN113046591AEfficient refinement and uniform distributionReduced risk of crack initiationPlasticityContinuous rolling

The invention relates to an in-situ synthesized TiB reinforced beta titanium alloy composite which comprises TiB and beta titanium alloy, wherein the volume ratio of the TiB is 1%-2.5%, and the beta titanium alloy is Ti-5Al-5Mo-5V-3Cr-1Zr. The invention further relates to a preparation method for the in-situ synthesized TiB reinforced beta titanium alloy composite. The preparation method comprises the following steps of preparing an in-situ synthesized TiB reinforced beta titanium alloy Ti-55531 composite cast ingot by utilizing a vacuum consumable arc melting method; cogging the cast ingot through multi-pass upsetting and drawing near-isothermal thermal plastic deformation; re-forging the cogging forging blank through multi-pass upsetting and drawing near-isothermal thermal plastic deformation; carrying out multi-pass hot continuous rolling on the re-forged blank to obtain a titanium-based composite blank; and performing solid solution heat treatment to the titanium-based composite blank, performing aging heat treatment to the solid solution forging blank to obtain the TiB reinforced beta titanium alloy composite. According to the in-situ synthesized TiB reinforced beta titanium alloy composite and the preparation method thereof, the purpose of achieving good matching of ultrahigh strength, high rigidity and plasticity of beta titanium alloy is achieved.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

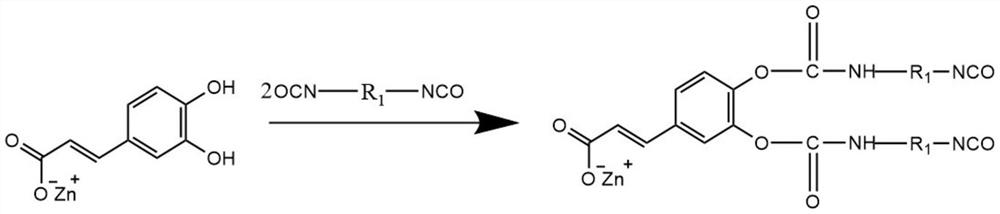

Water-based antibacterial and antiviral anionic polyurethane resin and preparation method thereof

InactiveCN112876636AAvoid impact on mechanical propertiesHigh mechanical strengthPolymer sciencePolyol

The invention discloses water-based antibacterial and antiviral anionic polyurethane resin and a preparation method thereof. The polyurethane resin is prepared from the following raw materials in parts by mass: 30-35 parts of macromolecular polyol, 5-10 parts of polyisocyanate, 2-6 parts of a hydrophilic chain extender, 1-2 parts of zinc hydroxide, 0.5-2 parts of a micromolecular alcohol chain extender, 1-2 parts of an amine chain extender, 0.01-0.5 parts of a catalyst, 5-12 parts of an organic solvent and 45-55 parts of deionized water, wherein the hydrophilic chain extender is caffeic acid. The caffeic acid is used as a hydrophilic chain extender, is easily dissolved in the organic solvent, can fully react with polyisocyanate, improves the polymerization reaction stability, has wide antibacterial and antiviral activity, can absorb ultraviolet rays, and can improve the coloring power of the waterborne polyurethane resin. Zn ions have long-acting antibacterial activity. The caffeic acid and zinc hydroxide are subjected to a neutralization reaction to obtain zinc caffeate solution modified waterborne polyurethane with Zn ions, so that the waterborne polyurethane can obtain excellent antibacterial and antiviral capacities without adding an antibacterial additive and shows better storage stability.

Owner:江苏华缘高科股份有限公司 +1

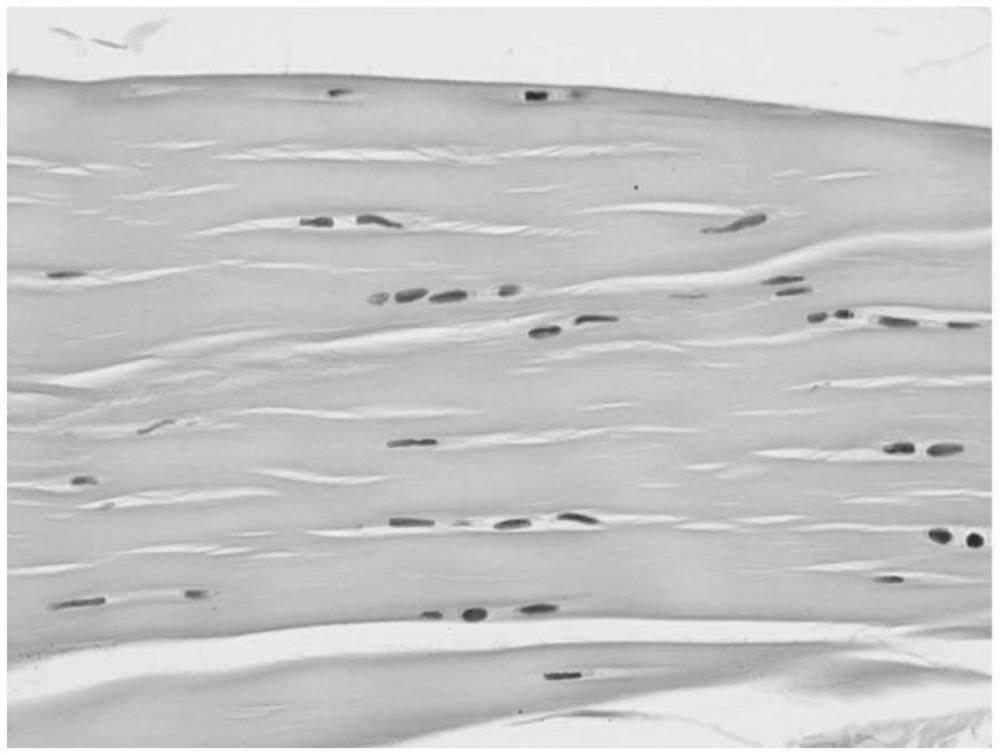

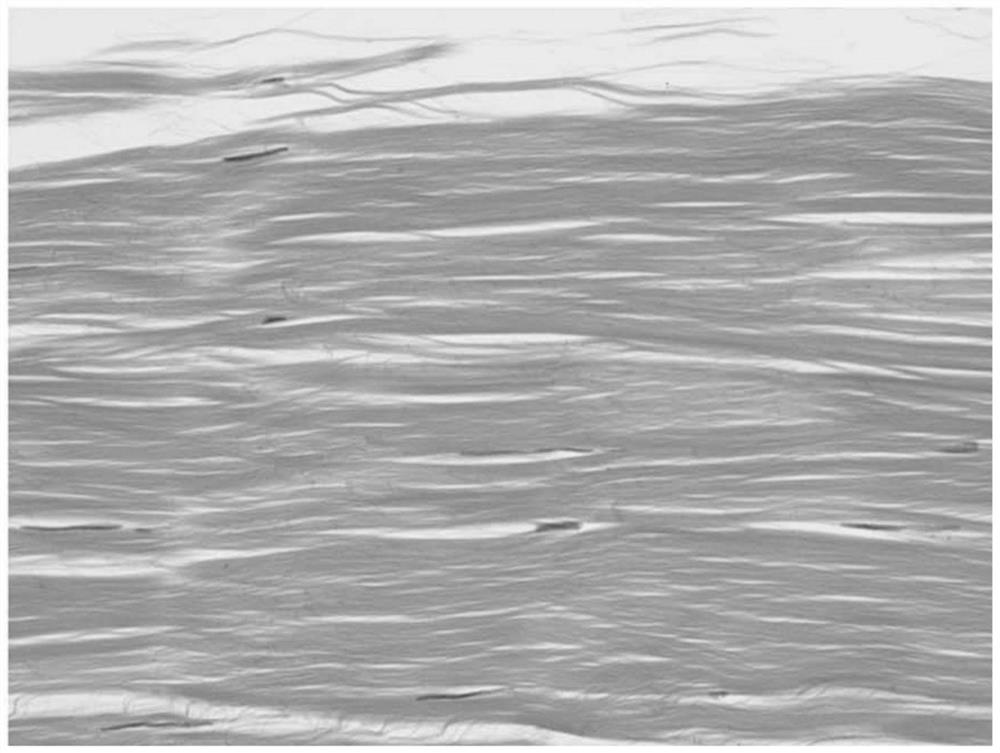

Preparation method of allogeneic or xenogeneic tendon and bone tendon complex

InactiveCN111686303AComplete structureIncrease lethalityTissue regenerationProsthesisBone tendon bonePlantaris tendon

The invention relates to a preparation method of an allogeneic or xenogeneic tendon and bone tendon complex. The preparation method comprises the following steps that: S1: an allogeneic or xenogeneictendon and bone tendon complex material is obtained, and bloodstains on the surfaces of the tendons are cleaned with purified water; S2, supercritical CO2 extraction equipment is started, and the cleaned tendons are put into the supercritical CO2 extraction equipment for extraction; S3, the extracted tendons are subjected to decellularization treatment and grease washing; S4, the purified water isadded into the tendons subjected to oscillation washing, and oscillation washing is carried out in a shaking table at room temperature; S5, the tendons subjected to oscillation washing are trimmed, water on the surfaces of the trimmed tendons is drained off, and vacuum packaging is carried out under aseptic conditions; and S6, the packaged tendons with cobalt-60 under the dosage of 10-30 kGy areirradiated, and sterilization again is carried out so as to obtain the tendons subjected to vacuum packaging. The preparation method has the advantages of convenient processing, high efficiency, environmental protection and safety.

Owner:上海亚朋生物技术有限公司

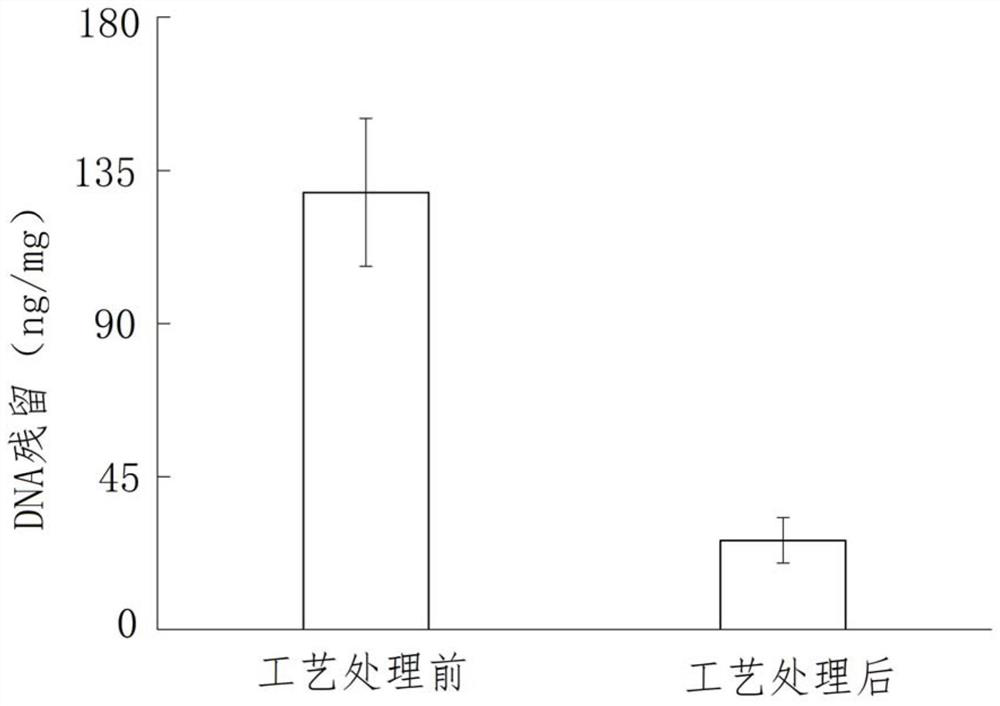

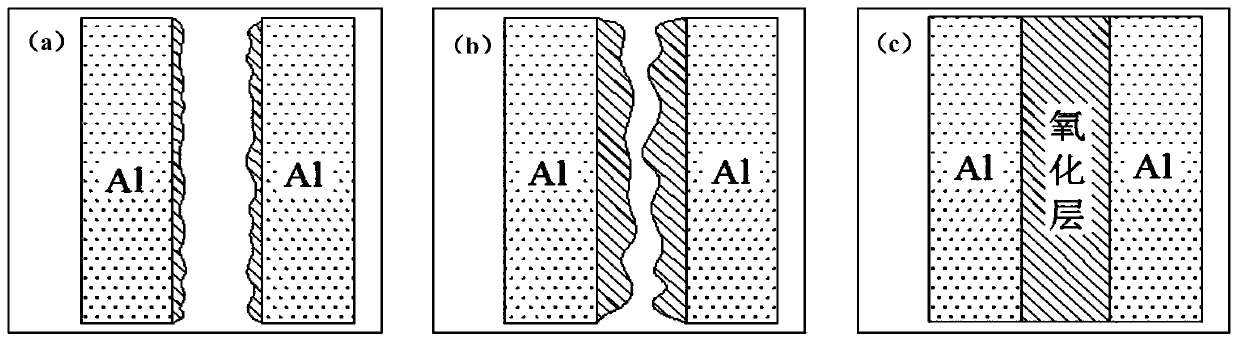

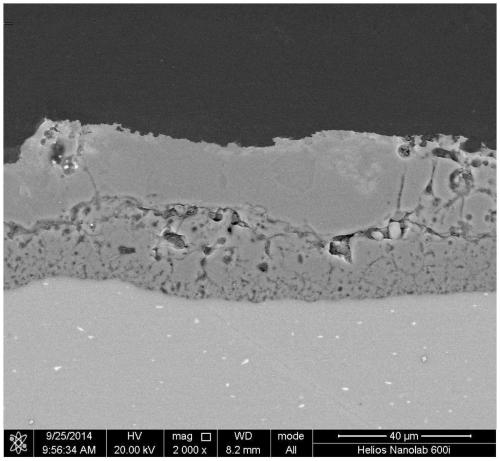

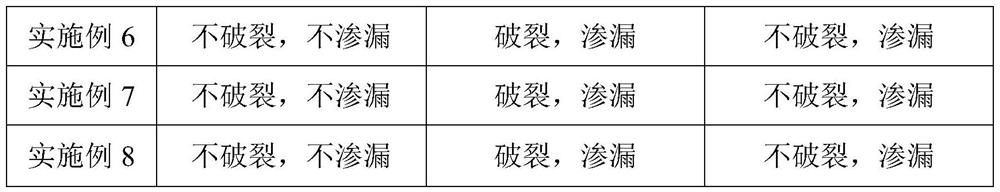

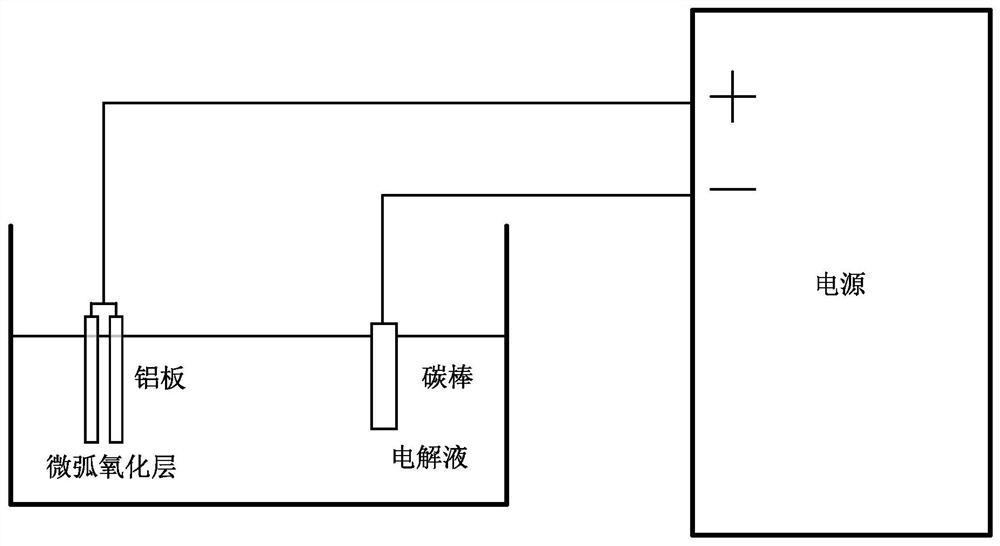

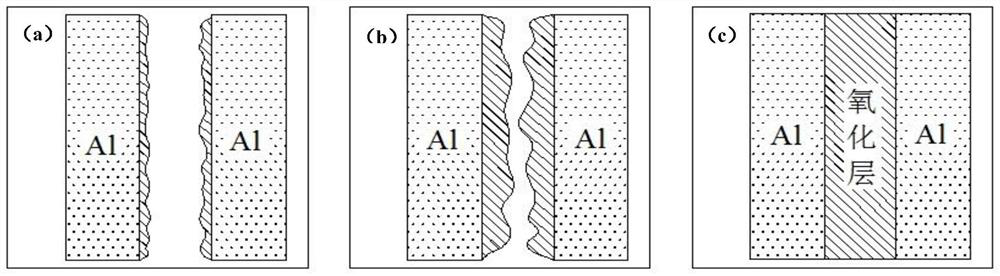

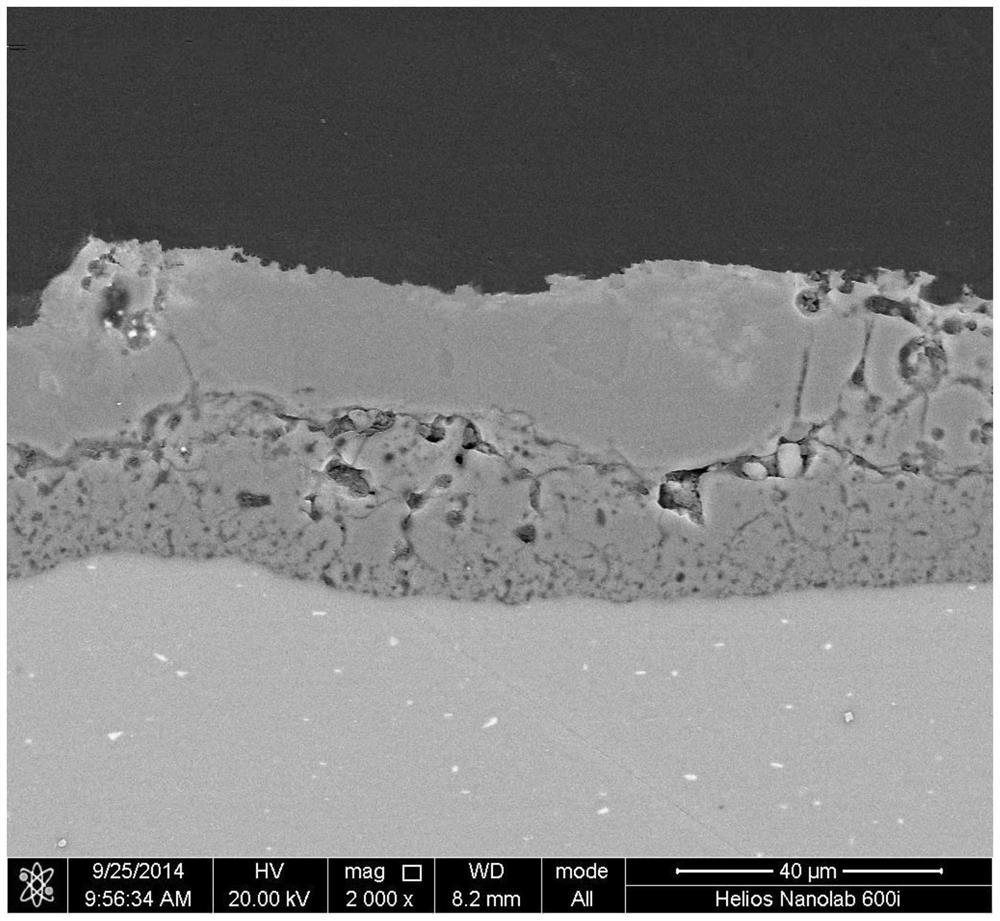

Alloy room temperature connection method based on micro-arc oxidation

The invention provides an alloy room temperature connection method based on micro-arc oxidation. The alloy room temperature connection method comprises the following steps of polishing to-be-welded surfaces of two alloys, and assembling to form a to-be-welded connector, wherein the gap between the two to-be-welded surfaces is 30-100 [mu]m; then immersing the assembled connector in electrolyte, connecting the two alloys with a cathode, and connecting a carbon rod with an anode, wherein the interval between the cathode and the anode is 10-50 mm; and performing micro-arc oxidation to enable oxidefilms to begin to grow to the centers of the two to-be-welded surfaces separately until the oxide films on two sides grow to meet to form a connector. Various aluminum alloys can be connected at roomtemperature, so that the problem that a parent material is softened due to welding thermal cycle can be solved, and the defect of low strength of low-temperature brazed joints is overcome.

Owner:HEBEI UNIV OF TECH

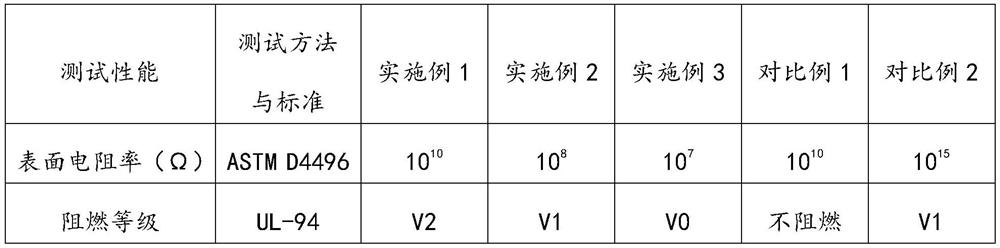

A kind of flame-retardant antistatic thermoplastic polyurethane elastomer and its preparation method and application

ActiveCN109796748BAvoid impact on mechanical propertiesSimple manufacturing methodPolyurethane elastomerPolymer science

The invention belongs to the technical field of polymer materials, and in particular relates to a flame-retardant and antistatic thermoplastic polyurethane elastomer and its preparation method and application. The flame-retardant and antistatic thermoplastic polyurethane elastomer is composed of the following raw materials in parts by weight: 100 parts of thermoplastic polyurethane elastomer , 1-20 parts of flame retardant, 1-10 parts of antistatic agent, 1-20 parts of plasticizer and 0.05-0.2 part of antioxidant; the polyurethane elastomer prepared by the present invention has excellent flame retardant and antistatic properties , and its preparation method is simple and feasible.

Owner:MIRACLL CHEM

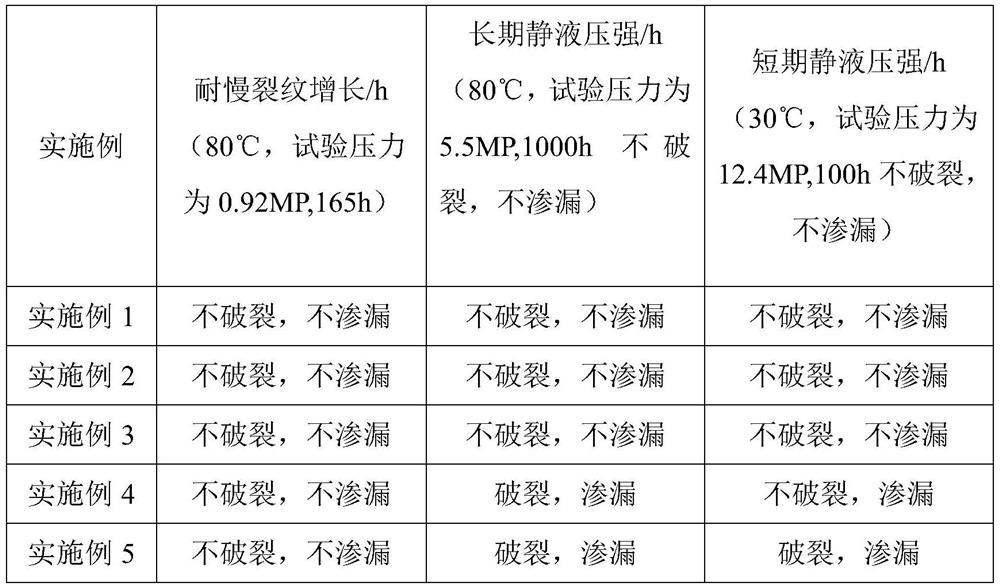

Polyolefin gas pipe and performance detection device thereof

ActiveCN111675842AObvious beneficial effectImprove scratch resistanceDetection of fluid at leakage pointChemical analysis using combustionSilane compoundsWax

The invention relates to the technical field of polyolefin gas pipes, and provides a polyolefin gas pipe. The polyolefin gas pipe at least comprises, by weight, 85-135 parts of polyolefin, 1-5 parts of polymer wax powder, 0.5-3.5 parts of a vinyl silane compound, 0.1-1.5 parts of a composite flame retardant and 0.05-0.5 part of an antioxidant. The prepared polyolefin gas pipe has the advantages ofvery excellent scratch resistance and stress cracking resistance, can be conveniently transported and assembled, and still has very excellent flame retardant property under the condition that the influence on the mechanical property of the pipe is avoided.

Owner:SHANGHAI ZHONGSU PIPE

A kind of ti-al-mo-n multi-component hard gradient film and its preparation method and application

ActiveCN106119784BImprove wear and corrosion resistanceImprove bindingVacuum evaporation coatingSputtering coatingMaterials preparationPapermaking

Owner:长沙科辉炉业科技有限公司

A Room Temperature Joining Method of Alloys Based on Micro-arc Oxidation

InactiveCN110014271BAvoid softeningSolve the problem of low strengthAnodisationElectrolytic agentMicro arc oxidation

The invention provides an alloy room temperature connection method based on micro-arc oxidation. The alloy room temperature connection method comprises the following steps of polishing to-be-welded surfaces of two alloys, and assembling to form a to-be-welded connector, wherein the gap between the two to-be-welded surfaces is 30-100 [mu]m; then immersing the assembled connector in electrolyte, connecting the two alloys with a cathode, and connecting a carbon rod with an anode, wherein the interval between the cathode and the anode is 10-50 mm; and performing micro-arc oxidation to enable oxidefilms to begin to grow to the centers of the two to-be-welded surfaces separately until the oxide films on two sides grow to meet to form a connector. Various aluminum alloys can be connected at roomtemperature, so that the problem that a parent material is softened due to welding thermal cycle can be solved, and the defect of low strength of low-temperature brazed joints is overcome.

Owner:HEBEI UNIV OF TECH

A kind of 3004 aluminum foil and its preparation method and application

ActiveCN111074107BLow costImprove efficiencyCasting cleaning apparatusEconomic benefitsAluminum foil

The invention discloses a 3004 aluminum foil, a preparation method and application thereof. The aluminum foil contains the following chemical elements in mass percentage: Si 0.15-0.25%, Fe≤0.55%, Cu 0.14-0.2%, Mn 1.02-1.15%, Mg 0.95-1.1%, Cr≤0.05%, Zn≤0.15 %, Ti 0.015~0.025%, other <0.1%, and the rest is Al. Through smelting, refining, standing still, on-line degassing and slag removal, casting, milling, soaking treatment, hot rolling, cold rolling, intermediate annealing, cold foil rolling and finished product annealing, 3004 is obtained after the finished product annealing Aluminum foil; through the combination of various elements and the preparation process, the aluminum foil prepared has high strength and good toughness. When used as a container, the thinness is greatly reduced, it is convenient to use, and the amount of raw materials is reduced; Using discarded cans as raw materials reduces raw material consumption, realizes resource reuse, broadens the source of raw materials for preparing aluminum foil, avoids the burden on the environment, reduces production costs, and has good social and economic benefits.

Owner:河南明泰科技发展有限公司

Method for reliably connecting flexible thin-film solar cell and airship envelop

ActiveCN102897330BAvoid thermal couplingRealize the assemblyCosmonautic power supply systemsPhotovoltaic energy generationThermal insulationSolar power

Owner:湖南航天远望科技有限公司 +1

A kind of rolling type loose fiber washing machine

ActiveCN103774359BAffect the washing effectAvoid disconnectionLiquid/gas/vapor removal by squeezing rollersTextile treatment machine arrangementsFiberEngineering

The invention relates to a spray-rolling type loose fiber washing machine, and belongs to the technical field of loose fiber dyeing. The spray-rolling type loose fiber washing machine comprises a cotton conveying roller, a transmission component and a spraying component. The cotton conveying roller is arranged in front of the transmission component, the transmission component is composed of a guide belt, a roller and a drive roller, the guide belt is horizontally arranged, and the drive roller drives the guide belt to move synchronously with the cotton conveying roller. The spraying component is located above the guide belt and used for washing the loose fibers below the spraying component, and the roller is matched with the guide belt to be mounted and used for squeezing the loose fibers which are conveyed to the guide belt through the cotton conveying roller. The spray-rolling type loose fiber washing machine is used for a loose fiber washing process, and has the advantages of being even in dyeing, small in water consumption, simple in process, and the like.

Owner:SHAOXING JINYU TEXITLE NEW TECH CO LTD

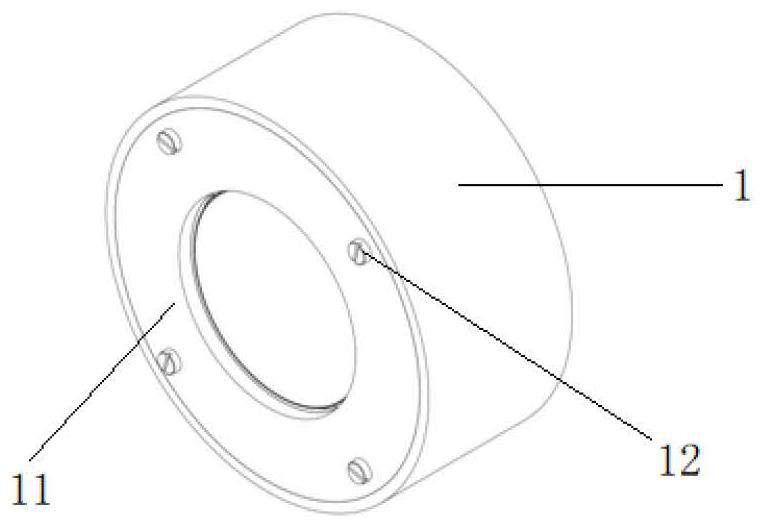

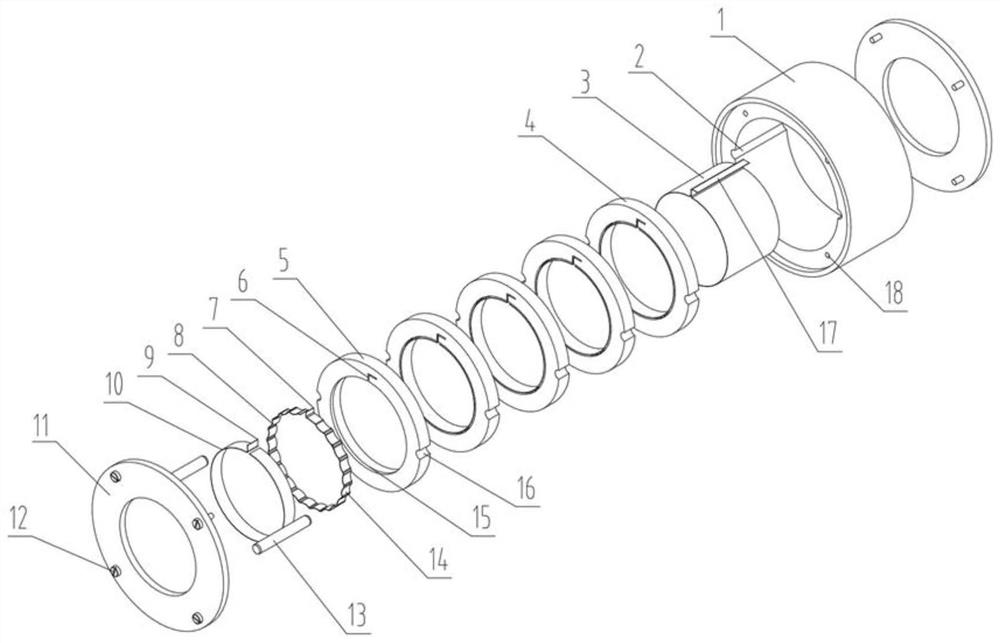

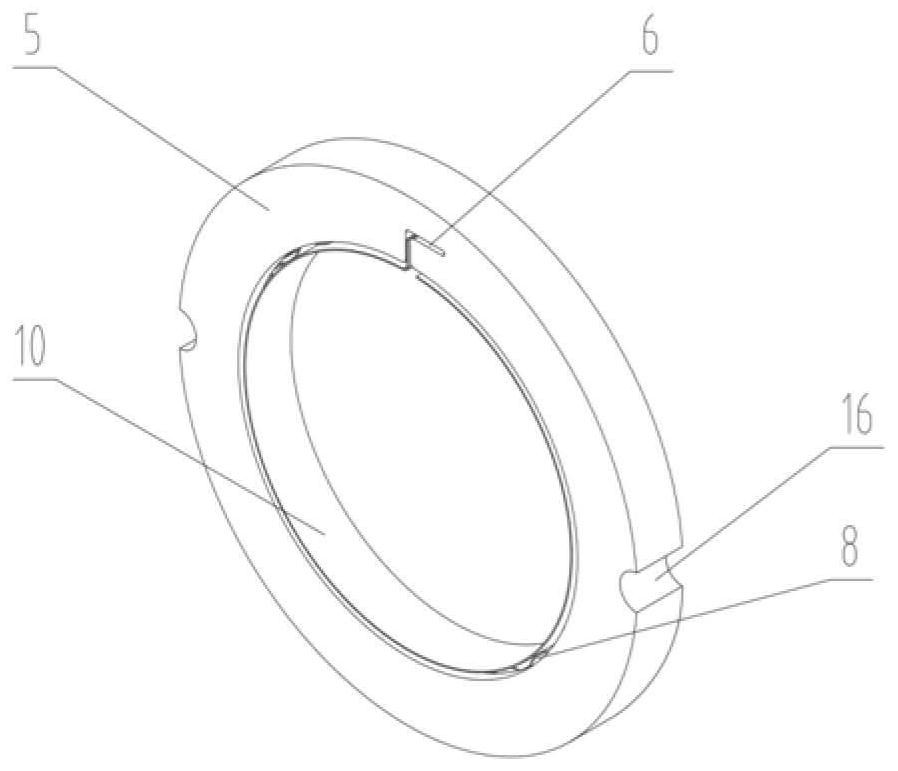

Unit ring combined bump foil type radial air bearing

ActiveCN113494529AEasy to processThe process is easy to implementShaftsBearing componentsAir bearingEngineering

The invention provides a unit ring combined bump foil type radial air bearing. The unit ring combined bump foil type radial air bearing comprises an outer bearing sleeve and end covers located at the two ends of the outer bearing sleeve, wherein a plurality of unit rings are arranged in the bearing sleeve, a top foil is connected in the unit rings in a clamped and closed mode, and the top foil axially extends into all the unit rings. According to the unit ring combined bump foil type radial air bearing, free combination of the unit rings with different waveforms and widths enables the bearing to realize targeted optimization adjustment of the bearing rigidity and the bearing width so as to meet the requirements of specific working conditions; the unit rings are easy to machine, the process is easy to realize, and installation is convenient; and in addition, the unit rings with the small axial widths are combined, the foil structure inclination rigidity can be reduced, compensation for shaft neck deflection is realized, and the impact resistance of a bearing-rotor system is improved.

Owner:SUZHOU CHANGHENG PRECISION METAL DIE CASTING

A kind of in-situ self-generated tib reinforced β titanium alloy composite material and preparation method thereof

ActiveCN113046591BSolve crackingEfficient refinement and uniform distributionThermoplasticAlloy composite

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

Flame-retardant polyester material with high glow wire ignition temperature and preparation method thereof

ActiveCN102250450BGWIT performance improvementsAvoid impact on mechanical propertiesPolyester resinUltimate tensile strength

The invention discloses a fame-retardant polyester material with a high glow wire ignition temperature and a preparation method thereof. The flame-retardant polyester material with a high glow wire ignition temperature is composed of the following components in parts by weight: 100 parts of polyester resins, 15-50 parts of bromine-series flame retardant, 5-20 parts of synergistic flame retardant, 0-20 parts of toughening agent, 0-80 parts of carbon forming agent, 5-40 parts of hot oxygen barrier agent, 0-120 parts of fibrous reinforcing agent and 0-10 parts of processing aid. The preparation method of the flame-retardant polyester material with a high glow wire ignition temperature comprises: drying the polyester resins, mixing with other components to obtain a premixed material, then feeding the premixed material into a twin-screw extruder, melting and plasticizing, kneading and mixing, extruding, drawing, cooling, pelletizing, drying and finally packaging. The flame-retardant polyester material with a high glow wire ignition temperature has the advantages of low cost, high glow wire ignition temperature, similar mechanical strength to ordinary flame-retardant polyester and wide application range.

Owner:KINGFA SCI & TECH CO LTD +1

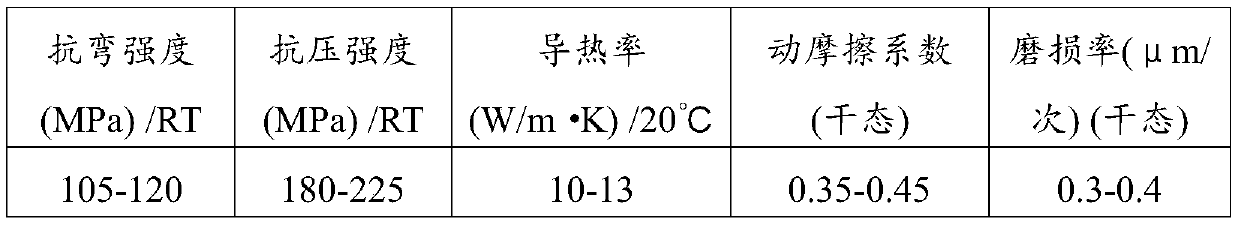

A preparation method of ceramic reinforced carbon/carbon composite brake disc

ActiveCN109372916BImprove fracture toughnessAvoid catastrophic consequencesBraking discsActuatorsCarbon compositesCarbon fibers

The invention discloses a preparation method of a ceramic reinforced carbon / carbon composite material brake disc. The preparation method comprises the following steps that a carbon fiber prefabricatedbody is put into a deposition furnace, firstly, a chemical vapor-phase permeation process is adopted, then liquid-phase resin or liquid-phase asphalt is used for carrying out a dipping-carbonizationprocess, and a carbon / carbon composite material brake disc blank body is obtained; a liquid-phase siliconizing treatment is carried out on the blank body so as to obtain a disc body with the density of 2-2.2 g / cm<3>; and machining is carried out according to the shape and the size of the required brake disc so as to obtain the ceramic reinforced carbon / carbon composite material brake disc. According to the preparation method, the reasonable composition proportion and the preparation process are adopted, so that the high-quality ceramic reinforced carbon / carbon composite material brake disc with excellent mechanical property, oxidation resistance, friction resistance and wear resistance is prepared; the bake disc is light in weight, good in braking performance, short in production period and capable of realizing industrial production, the brake performance of a brake system of a transport vehicle can be improved, the weight of the brake system can be reduced, the service life of the brake disc is prolonged, and a good market prospect is achieved.

Owner:HUNAN JINTIAN ALUMINUM HI TECH CO LTD

Antibacterial silk product loaded with nanometer copper and preparation method thereof

ActiveCN107964785BEffective penetrationEvenly dispersedBiochemical fibre treatmentAnimal materialReduction treatmentNano copper

The invention discloses an antibacterial silk product loaded with nano-copper and a preparation method of same. The method includes the steps of: soaking a silk product in a buffer solution containingmonascus bacteria, adding a copper salt acid solution to soak the silk product, and performing ultraviolet reduction treatment; finally cleaning and drying the product to prepare the antibacterial silk product loaded with nano-copper. The method can improve the broad-spectrum antibacterial effect of the silk fibers and a fabric thereof, can avoid damage on human body and pollution on environment.The preparation method is simple and is easy to carry out in large scale production. The antibacterial silk product has excellent and durable antibacterial function.

Owner:广东宸际内衣生物科技有限公司

A kind of preparation method of highly flame-retardant cross-linked polyphosphazene elastomer

ActiveCN111303434BHigh limiting oxygen indexEasy to crosslinkFireproof paintsElastomerPolymer science

The invention discloses a preparation method of a high-flame-retardant cross-linked polyphosphazene elastomer. The technical scheme specifically comprises the following steps: performing a substitution reaction process on ethylene glycol monosodium, sodium phenolate and hexachlorocyclotriphosphazene under an ice bath condition and nitrogen protection to prepare hydroxyethyl phenoxy cyclotriphosphazene, and performing a substitution reaction process on ethoxy phenoxy cyclotriphosphazene sodium, sodium phenolate and polydichlorophosphazene to prepare the ethoxy phenoxy cyclotriphosphazene phenoxy polyphosphazene elastomer. The ethoxyphenoxy cyclotriphosphazene substituent synthesized in the scheme is large in volume, strong in steric effect and high in phosphorus and nitrogen element content, the polyphosphazene elastomer can be used as the cross-linking point of phosphazene chain segment entanglement, such that the product has advantages of excellent flame retardancy, excellent thermalstability and excellent mechanical property while the room temperature cross-linking is achieved, the synthesis process of the high-flame-retardant high-performance polyphosphazene elastomer is effectively optimized, and the important significance is provided for the low-cost and large-scale industrial production of the high-performance cross-linked polyphosphazene elastomer.

Owner:BEIJING UNIV OF CHEM TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com