Patents

Literature

30results about How to "Avoid affecting the washing effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

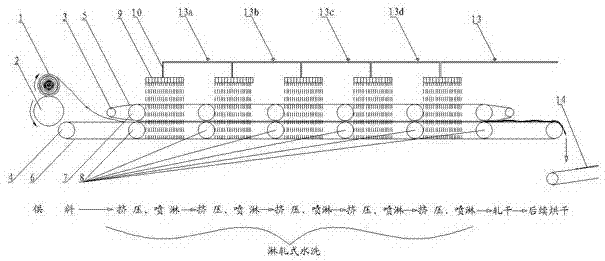

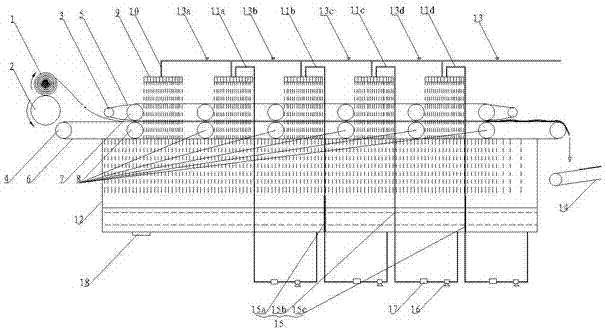

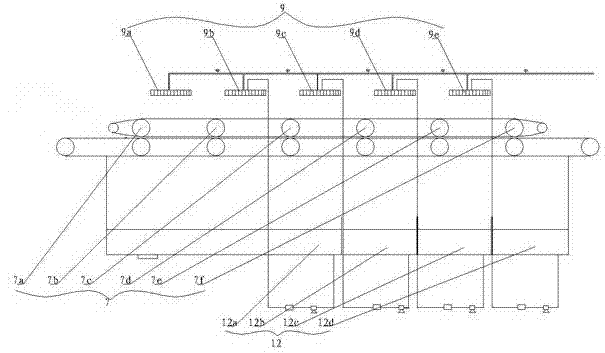

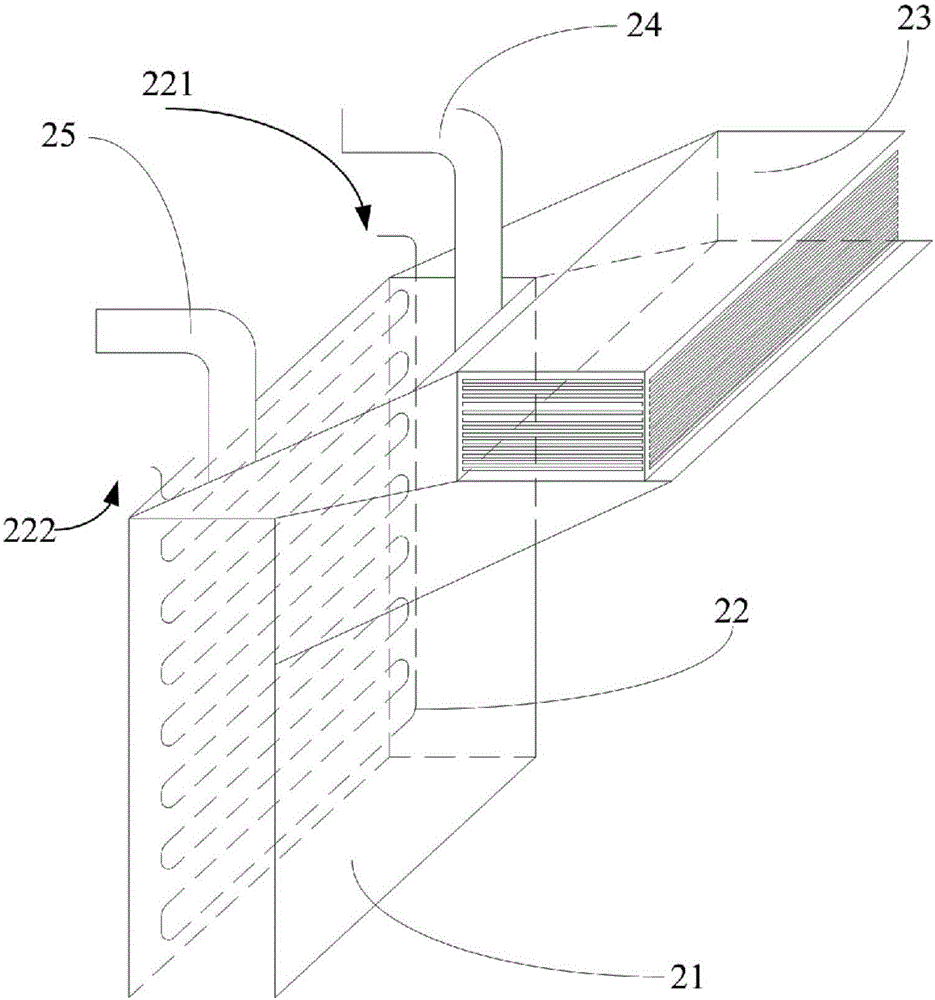

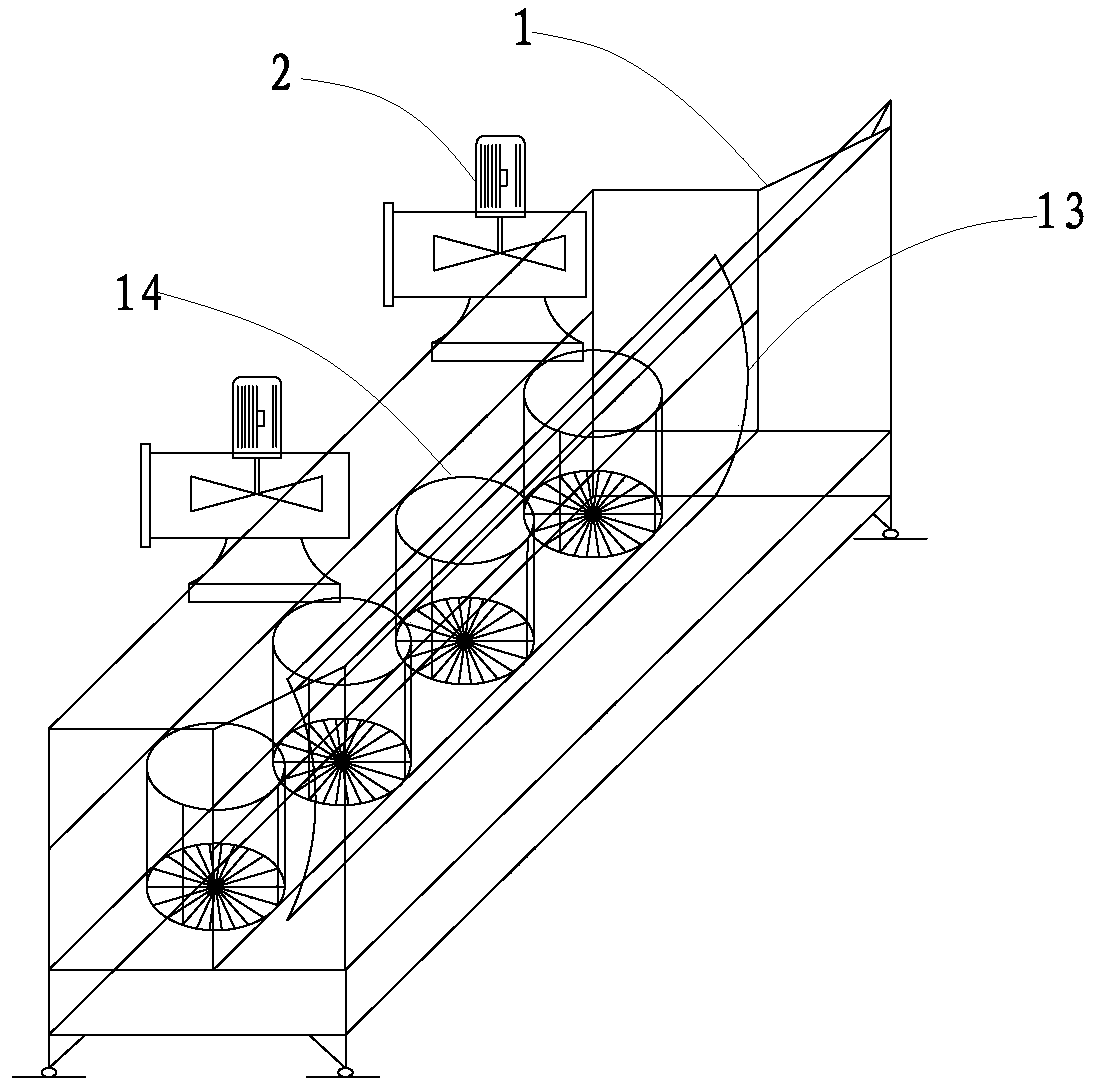

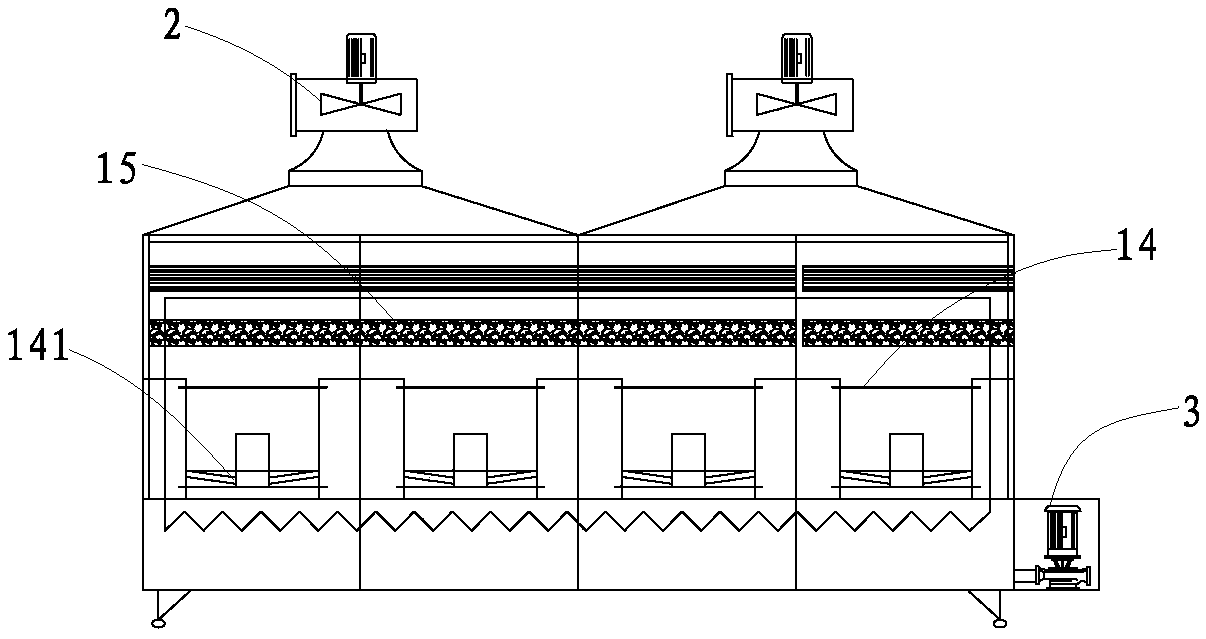

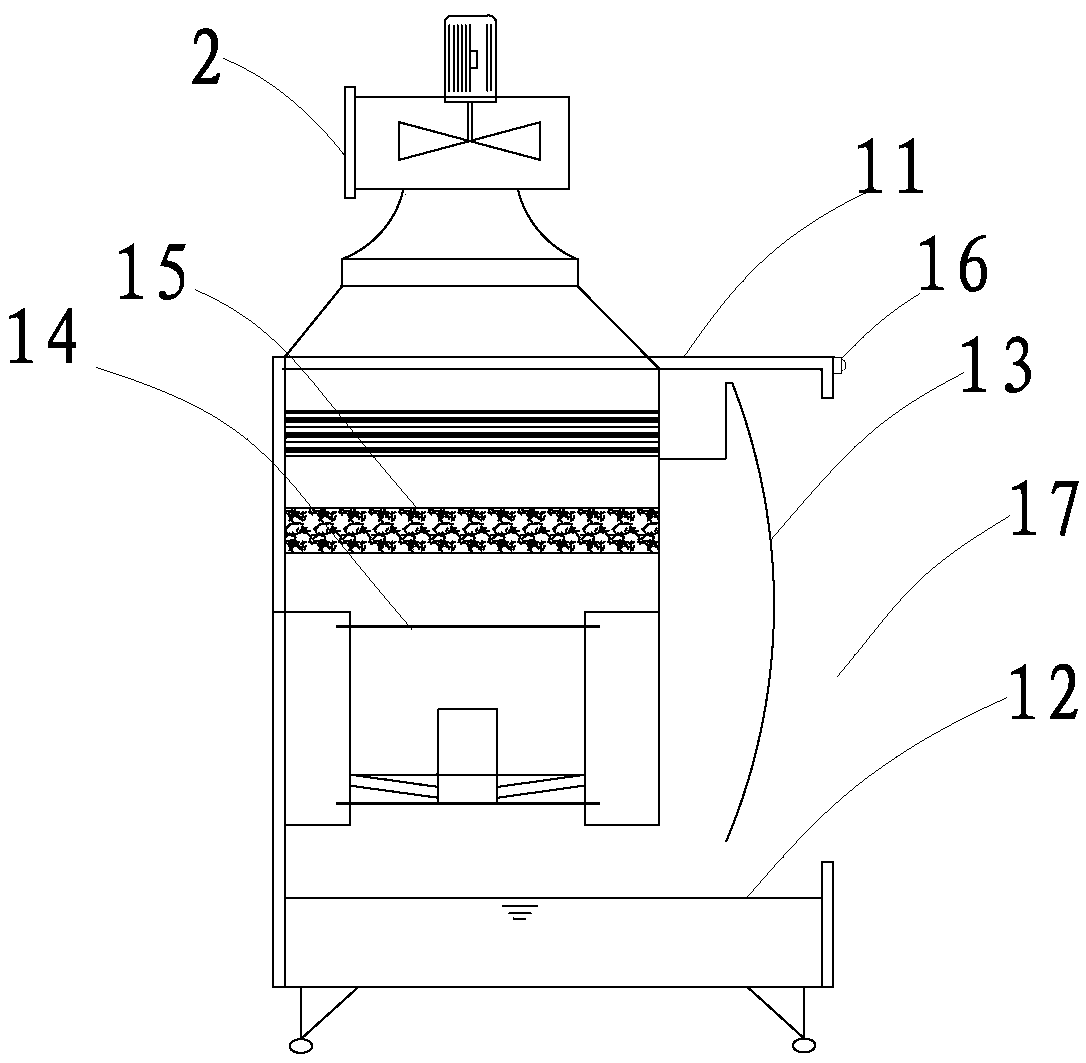

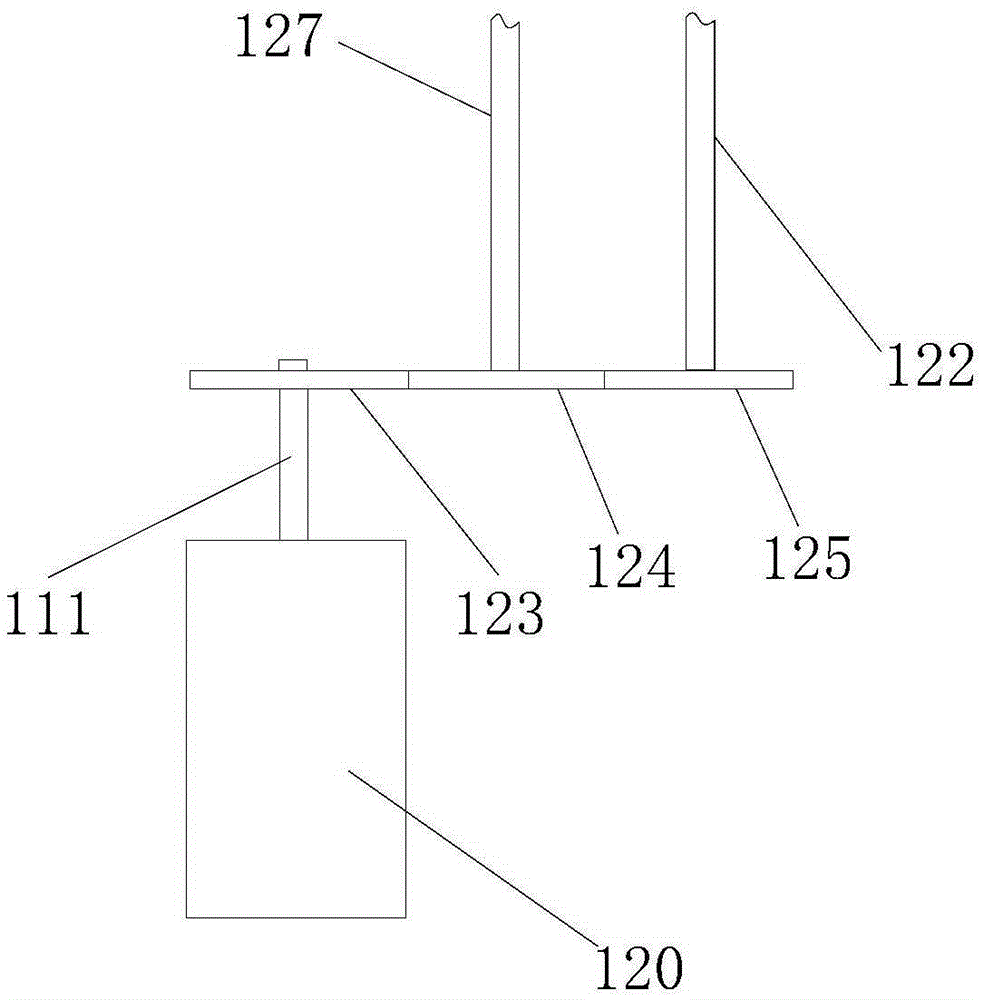

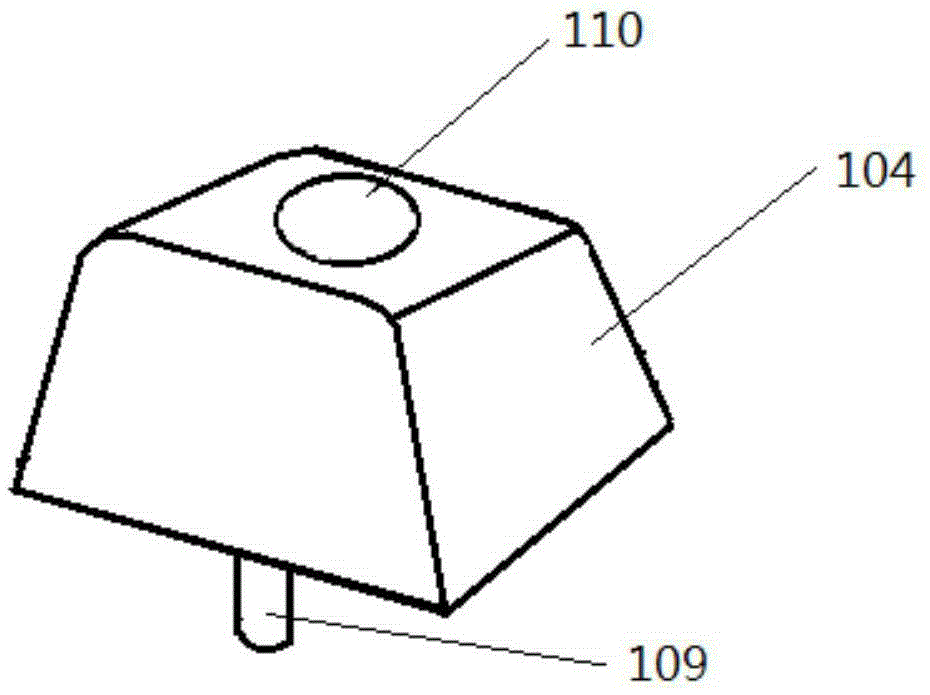

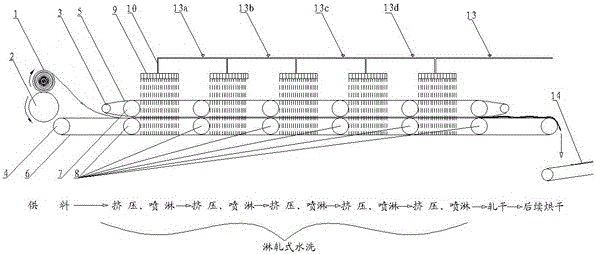

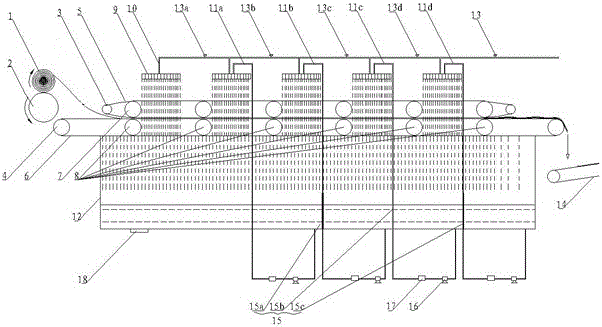

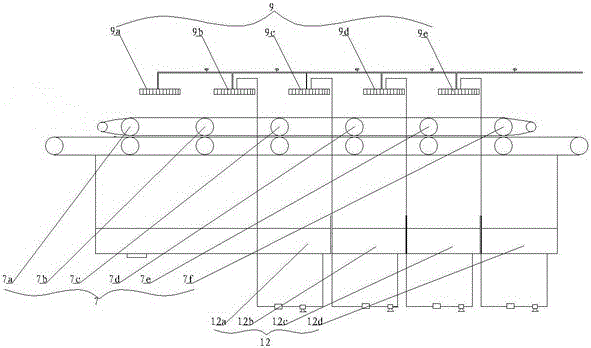

Spray-rolling type loose fiber washing process

ActiveCN103774362ALow water consumptionLow costLiquid/gas/vapor removal by squeezing rollersTextile treatment machine arrangementsDyeingFiber

The invention relates to a spray-rolling type loose fiber washing process, and belongs to the technical field of loose fiber dyeing. Dyed loose fibers are conveyed to a spray-rolling type washing device, while the loose fibers are horizontally clamped by a guide belt to be conveyed, a plurality of groups of spray-rolling type washing with alternative squeezing and spraying is carried out on the loose fibers, and the loose fibers are washed, rolled to be dry, and output. The spray-rolling type loose fiber washing process has the advantages that dyeing is even, water consumption is small, and the working procedure is simple.

Owner:SHAOXING JINYU TEXITLE NEW TECH CO LTD

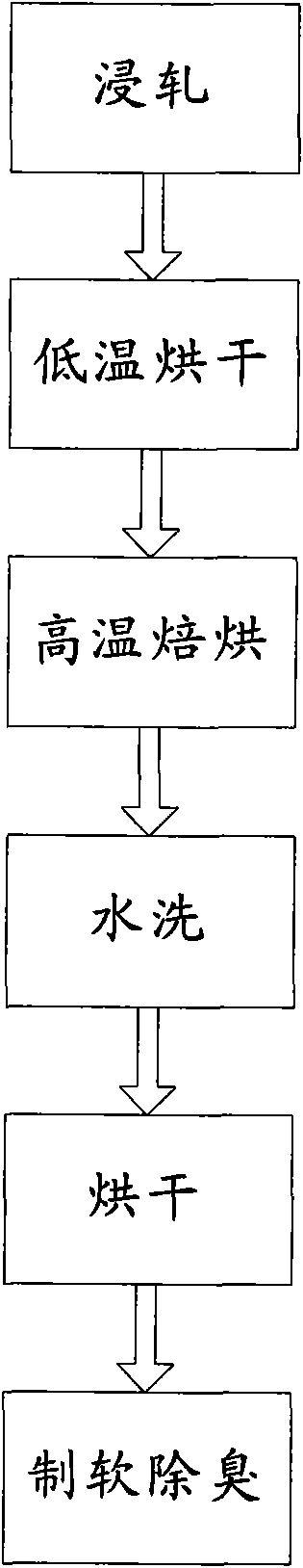

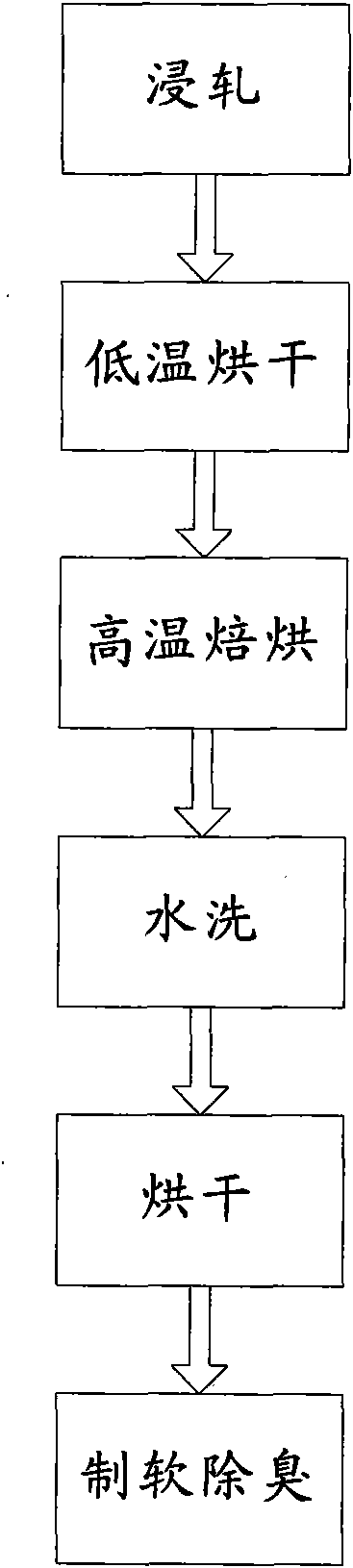

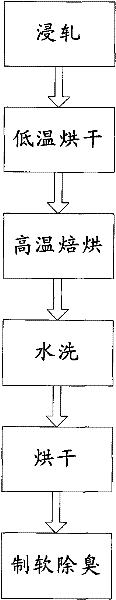

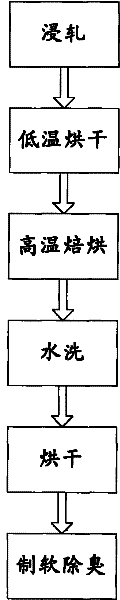

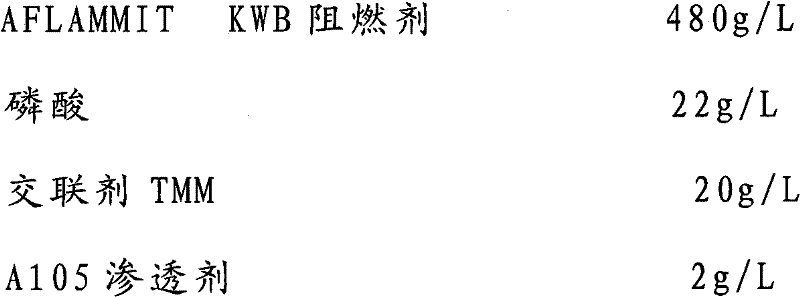

Environmentally-friendly and long-lasting fire-retarding treatment method for all-cotton knitted fabrics

The invention discloses an environmentally-friendly and long-lasting fire-retarding treatment method for all-cotton knitted fabrics, which adopts a processing flow comprising padding, low-temperature drying, high-temperature drying, washing with water, drying and softening and deodorizing. In the invention, an Aflammit KWB fire retardant is used, processing is performed on the conventional dyeing and finishing equipment, and the products have higher fire-retarding performance due to the combination of the fire retardant and cotton fibers by covalent bonds and offer a soft handfeel and are more in accordance with an environment protection requirement. The products produced by the process offer a soft handfeel, the fire-retarding effect after 50 times of washing with water reaches American CFR1615 standards, the formaldehyde content is lower than 20ppm, the products are more environmentally-friendly and have no irritating smell.

Owner:常熟新锦江印染有限公司

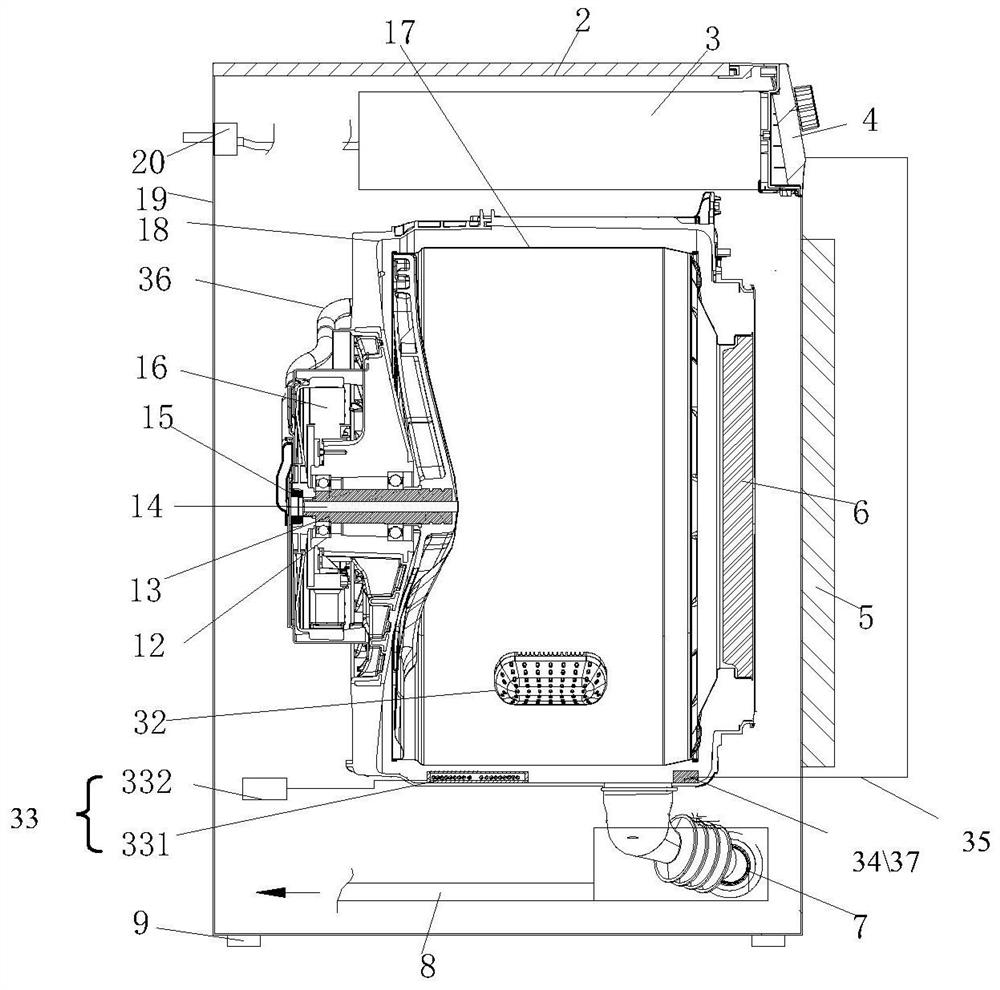

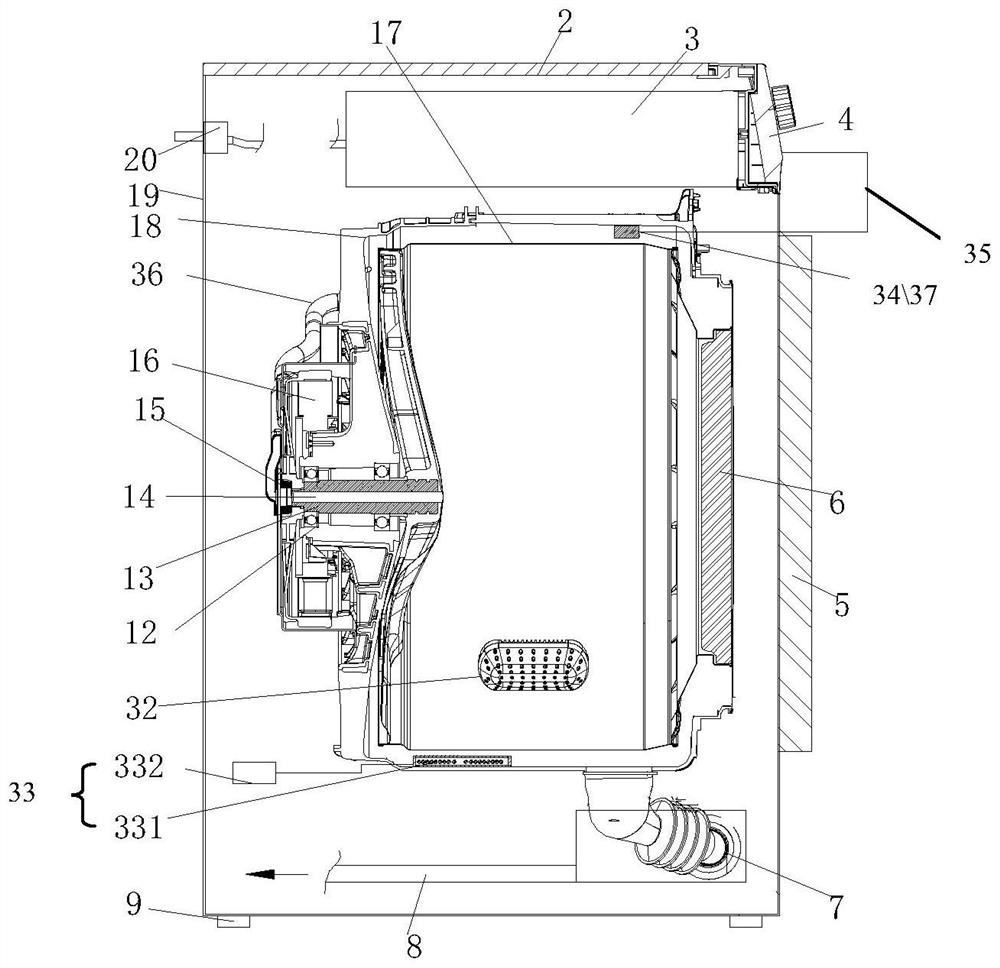

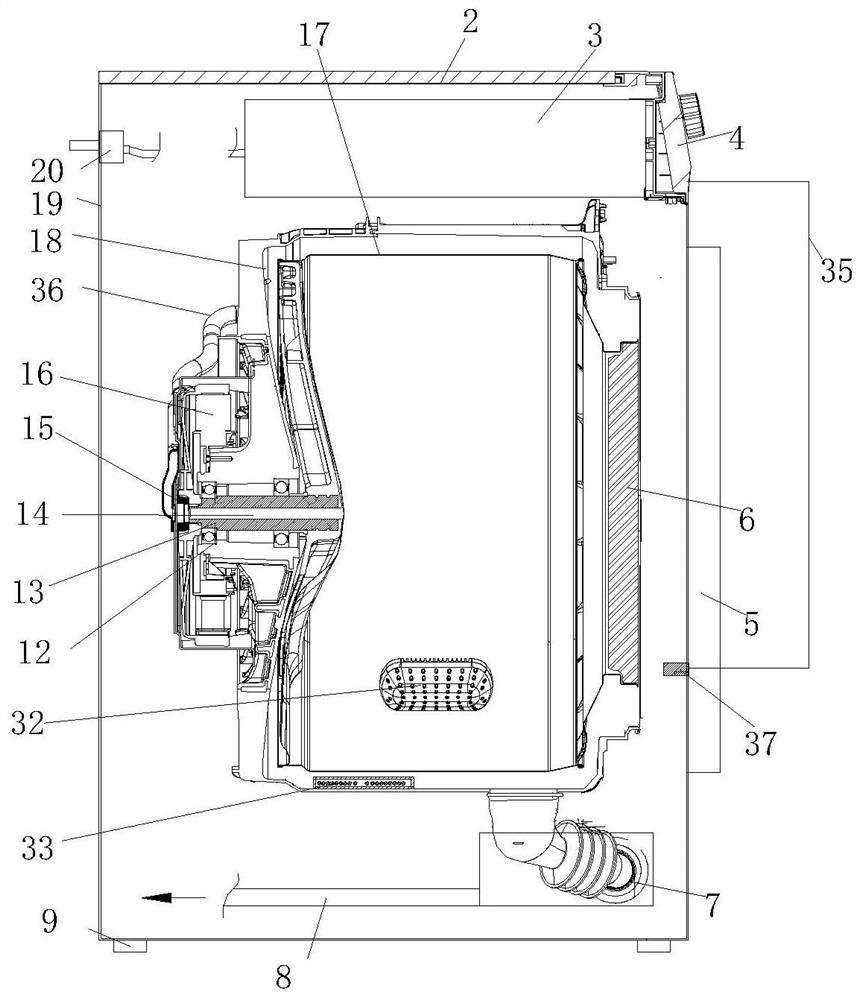

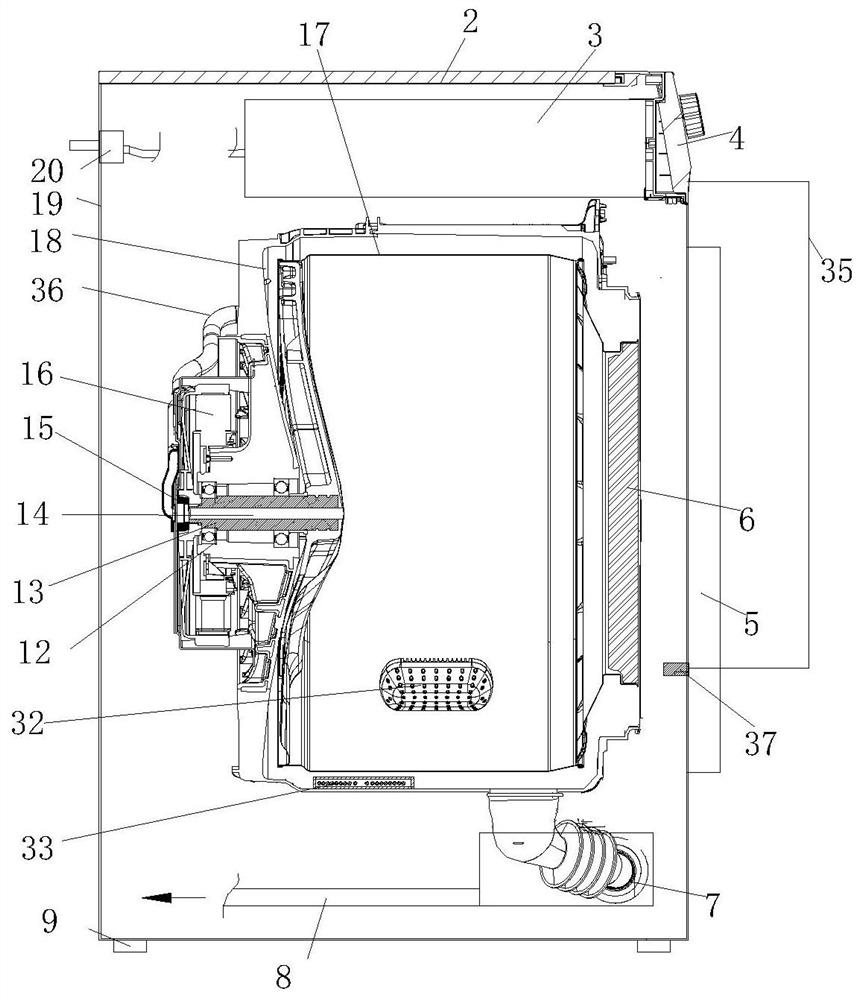

Steam washing machine and washing method

ActiveCN106906608ASimple structureLow costOther washing machinesControl devices for washing apparatusInlet valveEngineering

The invention discloses a steam washing machine. The steam washing machine comprises an outer cylinder, an inner cylinder contained in the outer cylinder, a water inlet valve, a heater and a control circuit. The heater is located at the bottom of the outer cylinder and between the inner cylinder and the outer cylinder, and a temperature detector is arranged at the bottom of the outer cylinder; a water level sensor is arranged on the inner wall of the outer cylinder; the heater is used for heating water to generate steam; the control circuit is used for controlling the heater to work to control the steam amount. Water inflows from the water inlet, the water inlet valve is turned off when the water level threshold is reached, and the heater starts to heat the water to generate the steam; when the water temperature is increased to a first water temperature threshold, the heater stops heating; the inner cylinder starts to rotate to conduct steam washing on clothes; when the water temperature is reduced to a second water temperature threshold, the inner cylinder stops rotating, and the steam washing procedure is completed; a lot of water inflows from the water inlet valve for later washing. The washing machine is simple in structure and easy to use, and the cost of the steam washing machine is reduced on the premise that the washing effect is not affected.

Owner:NANJING LG PANDA APPLIANCES

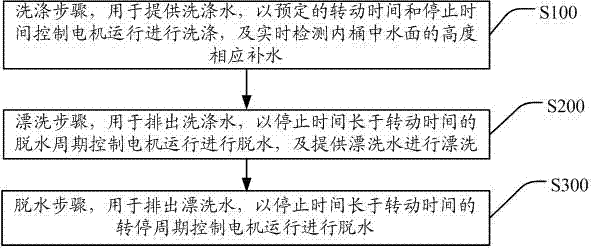

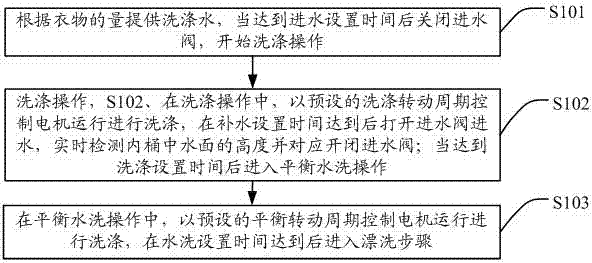

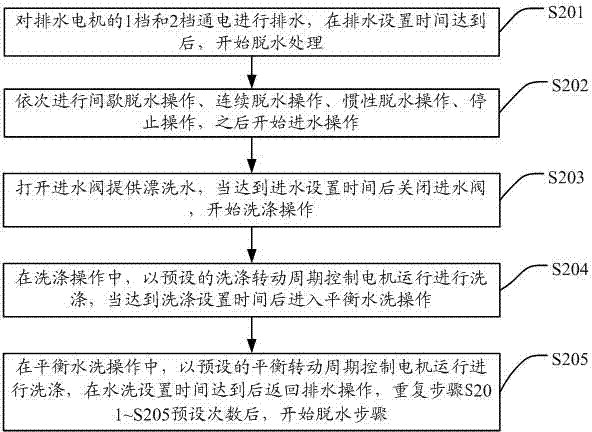

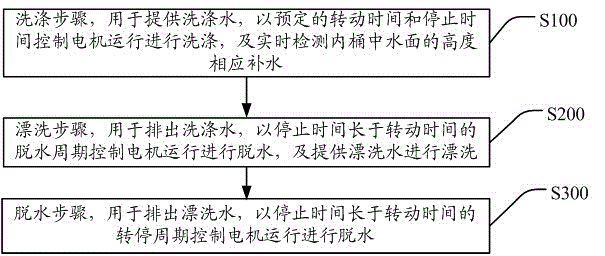

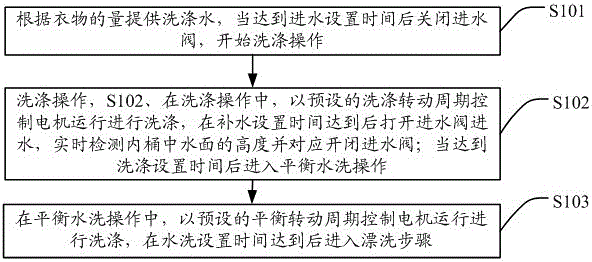

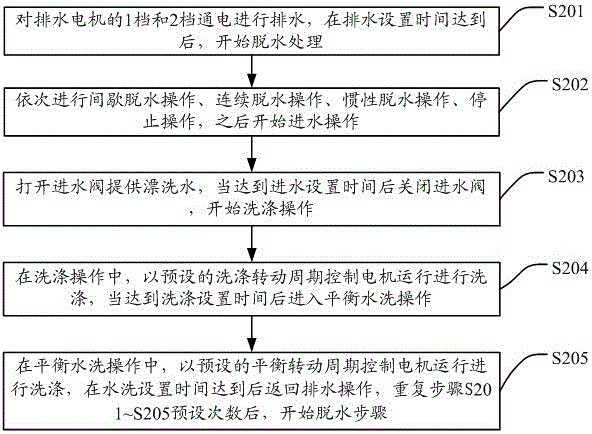

Washing control method and washing machine

InactiveCN104264416AAdequate heat dissipationReduce the temperatureOther washing machinesControl devices for washing apparatusRolloverRinse water

The invention discloses a washing control method and a washing machine. The washing control method comprises a washing step, a rinsing step and a dewatering step, wherein the washing steps is used for providing washing water to control a motor to operate at predetermined rotation time and stop time to wash and detecting the height of a water level in a bucket in real time to supplement water correspondingly; the rinsing step is used for discharging the washing water to control the motor to dewater at a dewatering period that the stop time is longer than the rotation time and providing rinsing water to rinse; the dewatering step is used for discharging the rinsing water to control the motor to operate to dewater at a rotation stop period that the stop time is longer than the rotation time. According to the method and the machine, the water is automatically supplemented during washing so as to prevent the influence of reduced water quantity on the washing effect; the rubbing time of clothes can be prolonged by controlling the motor to operate at the predetermined rotation time and stop time, so that the clothes have a better rollover effect; the motor is fully cooled through the dewatering period that the stop time is longer than the rotation time so as to reduce the temperature of the motor.

Owner:NANJING CHUANGWEI HOUSEHOLD ELECTRONICS APPLIANCES LTD

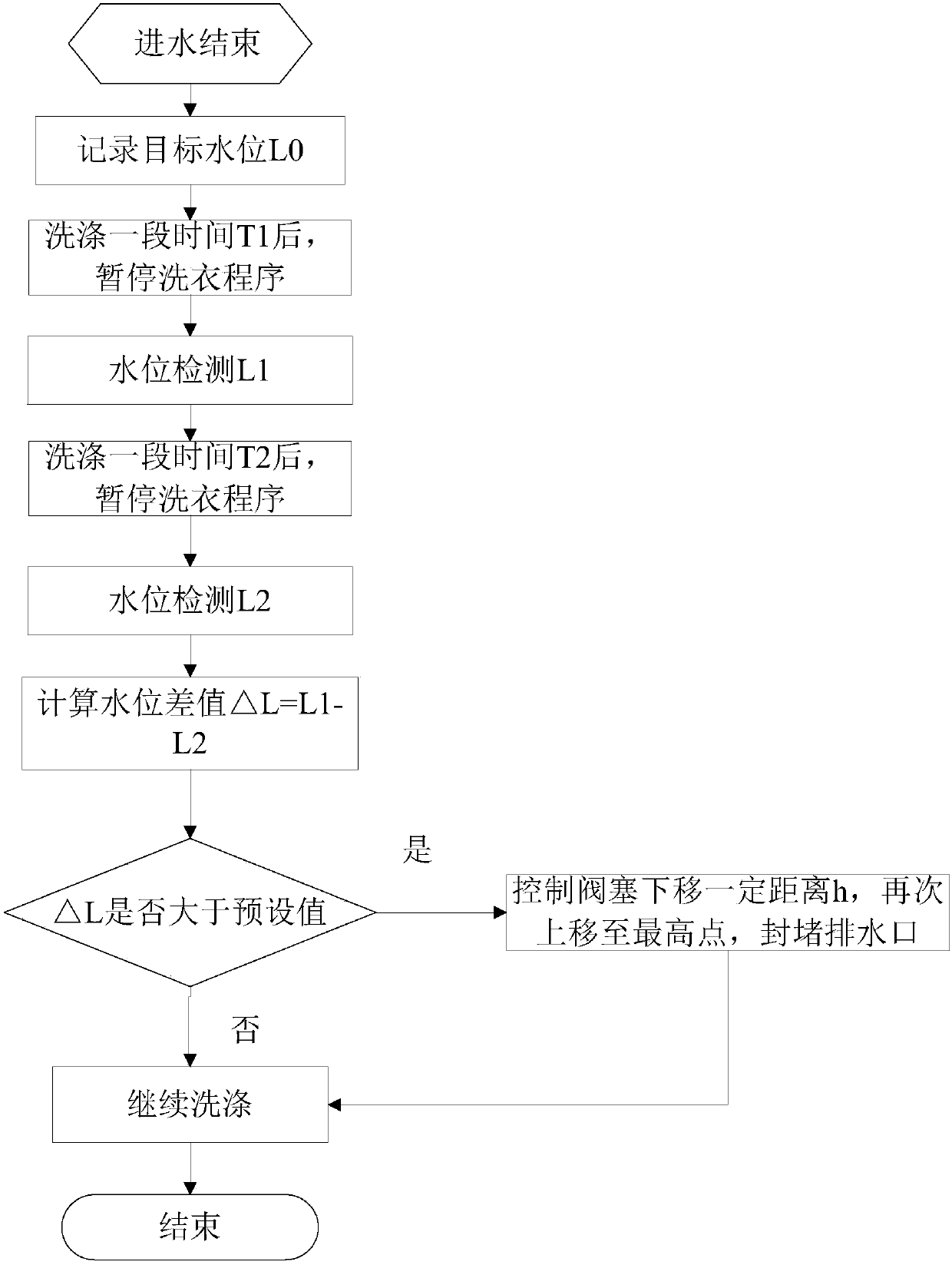

Control method of washing machine

ActiveCN110144698ALarge capacityAchieve expansion effectOther washing machinesControl devices for washing apparatusWater leakageProcess engineering

The invention provides a control method of a washing machine. The washing machine comprises a washing drum capable of containing water in the washing process and a washing water level detection devicecapable of detecting the water level in the washing drum. The control method comprises the following steps: in the washing process of the washing machine, the washing water level detection device detects the water level value in a certain time interval, and whether the washing drum leaks is judged according to the change trend of the water level value. According to the control method, in the washing process, whether the washing drum leaks is judged according to the change trend of the water level value in a certain time interval, and the washing effect is prevented from being influenced by water leakage of the washing drum.

Owner:QINGDAO HAIER WASHING MASCH CO LTD +1

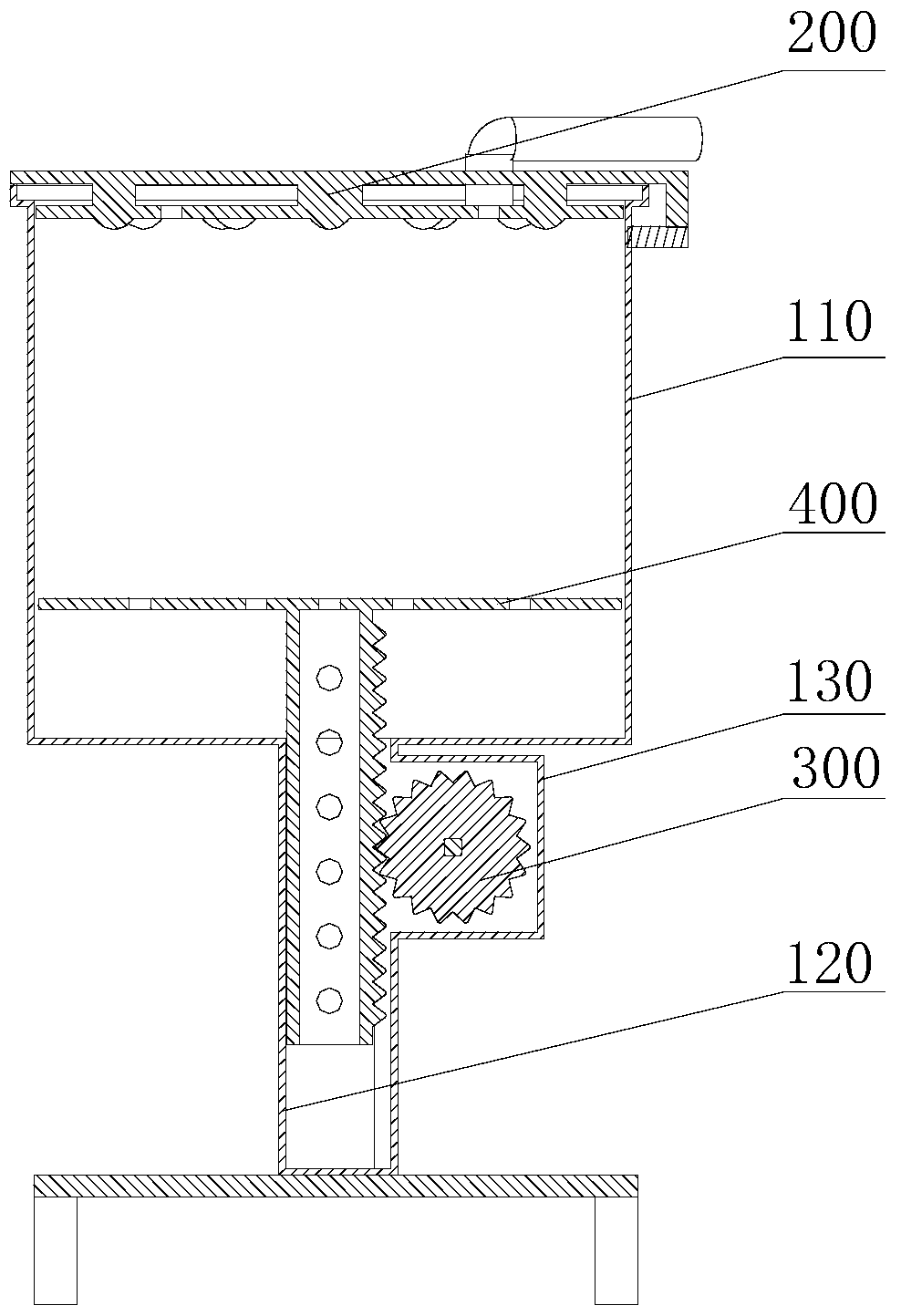

Reciprocating type washing machine

ActiveCN104975458AOvercome the disadvantages of large wear and large water consumptionImprove washing effectOther washing machinesTextiles and paperImpellerReciprocating motion

The invention provides a reciprocating type washing machine. The reciprocating type washing machine comprises a washing bucket, an upper cover, a transmission mechanism, a piston and a driving device, wherein the upper cover is movably connected to an opening of the washing bucket, the washing bucket comprises an upper portion and a lower portion, the upper portion of the washing bucket is used as a washing cavity for containing / washing clothes, the piston is arranged in the washing cavity, the lower portion of the washing bucket is used as a control cavity, the transmission mechanism is arranged in the control cavity, the input end of the transmission mechanism is connected with the driving device, the transmission mechanism and the piston are in screw transmission, and the driving device drives the piston to perform up-down reciprocating motion in the washing bucket through the transmission mechanism. According to the reciprocating type washing machine, washing is performed through reciprocating extrusion on the clothes by the piston, the defects that an existing impeller type washing machine and a tumbling-box washing machine are serious in wear of the clothes and large in water consumption are overcome, and the better washing effect is achieved.

Owner:QINGDAO HAIER WASHING MASCH CO LTD

Polishing bath of aluminium material and production technology of aluminium material

InactiveCN105780007AReduce oxidation reactionAvoid affecting the washing effectPhosphoric acidFresh water

The invention discloses a polishing bath of an aluminium material. The polishing bath of the aluminium material comprises a two-acid main bath and a rinsing bath, and further comprises a two-acid sub bath, wherein the two-acid sub bath accommodates a bath solution, and is equipped with a cooling device used for dissipating heat of the bath solution. The invention further discloses an aluminium material polishing production technology utilizing the polishing bath of the aluminium material. During aluminium material polishing production, after polishing of the two-acid main bath, the two-acid sub bath is newly added for temperature decreasing treatment, the temperature of the bath solution is controlled between 10 DEG C and 40 DEG C through temperature decreasing of the cooling device, the high-temperature aluminium material is quickly cooled, and the bath solution is enabled to drip for a long time till the bath solution is empty, so that the bath solution in the two-acid main bath is recycled during aluminium material polishing, and the unnecessary waste of raw materials such as phosphoric acid and sulfuric acid, and the fresh water resource is avoided.

Owner:FOSHAN HAIHUA SURFACE TREATMENT TECH CO LTD

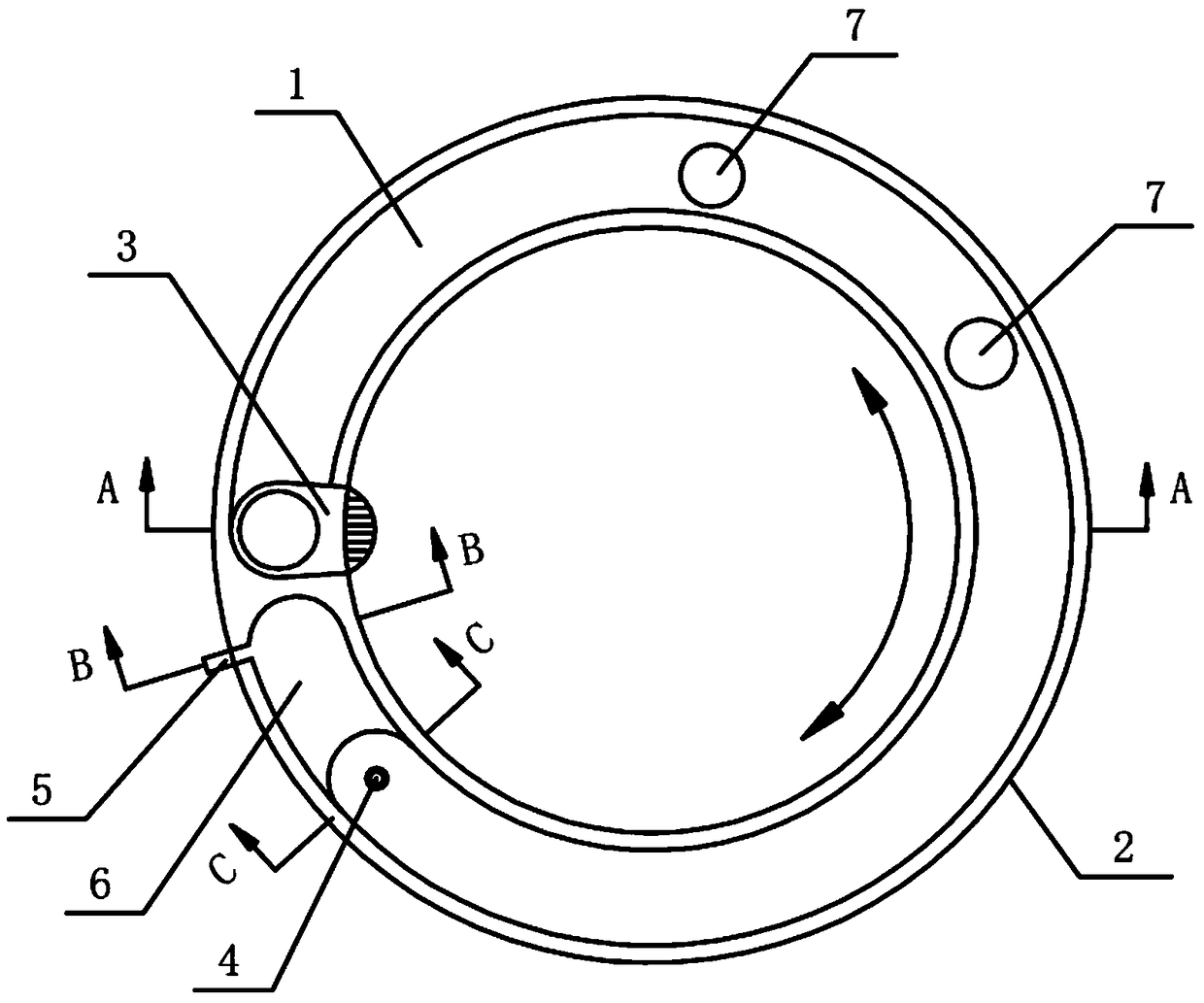

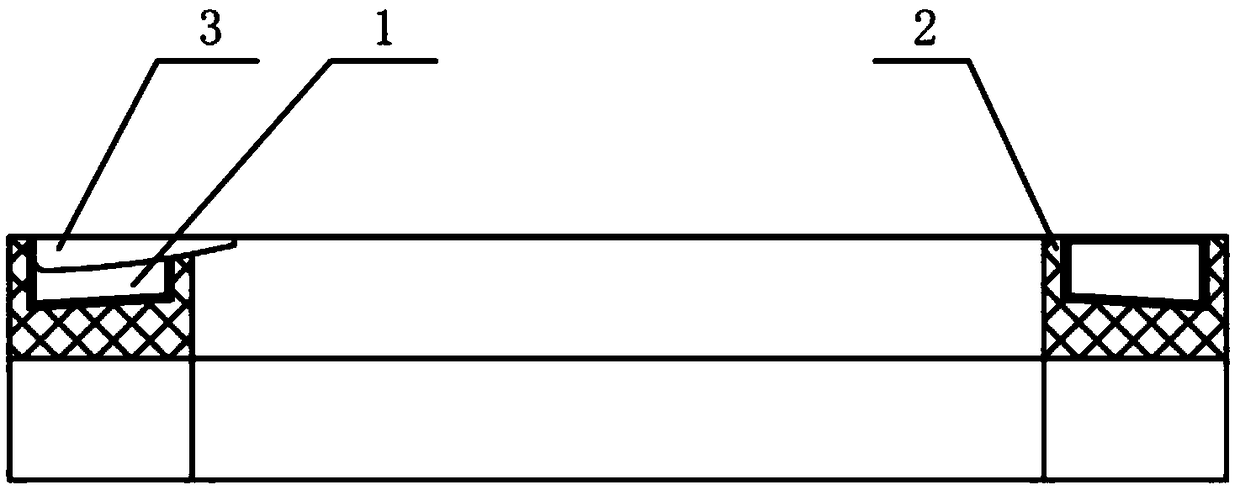

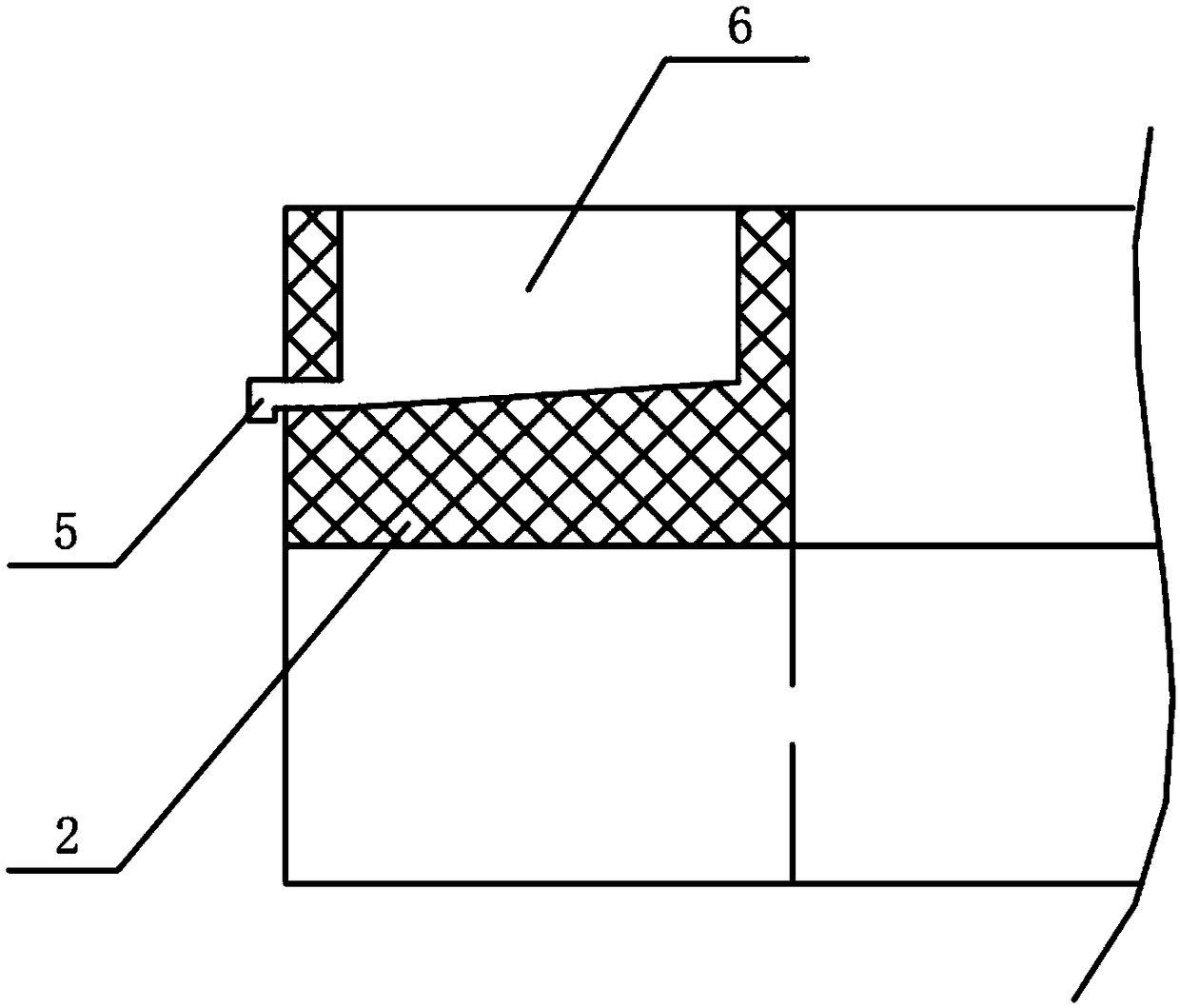

Detergent powder dissolving structure and washing machine

ActiveCN108691153AImprove solubilityEvenly distributedOther washing machinesTextiles and paperSiphonPulp and paper industry

The invention belongs to the technical field of washing machines, and discloses a detergent powder dissolving structure. The detergent powder dissolving structure includes a balancing ring in which acavity is formed / with a cavity formed, an input opening is formed in one end of the cavity, and the other end of the cavity is provided with a siphon structure of which the outlet is communicated withan inner bucket of a washing machine. The invention further discloses the washing machine containing the detergent powder dissolving structure. Through the detergent powder dissolving structure, after detergent powder is put into the cavity through the input opening, the balancing ring can do reciprocating rotation along with the inner bucket, so that the detergent powder is uniformly distributedinside the cavity; then, washing water is poured into the cavity through the input opening and can fully dissolve the detergent powder in the reciprocating rotation process of the balancing ring, then, washing water continues to be poured into the cavity, and the washing water in which the detergent powder is dissolved can be siphoned into the inner bucket of the washing machine through the siphon effect of the siphon structure. Through the detergent powder dissolving structure, the detergent powder can be fully dissolved, waste of the detergent powder is avoided, and the washing capability rate of the washing machine can be increased, so that clothes are fully washed.

Owner:FOSHAN SHUNDE HAIER ELECTRIC APPLIANCES CO LTD +1

Special efficient softener composition for laundry powder

InactiveCN101348752ASoft function is obviousEasy to operateInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsSodium phosphatesLaundry

The invention relates to an addition agent for washing powder, in particular to a high-efficiency softening agent composition special for the washing powder and a manufacturing technique thereof. The high-efficiency softening agent composition special for the washing powder and the manufacturing technique thereof solve the problem of the manufacture of the softening agent added into the washing powder in the prior art. The high efficiency softening agent composition special for the washing powder comprises the compositions in weight portion: 2 to 60 portions of surface active agent for positive ions, 5 to 50 portions of swell soil, 10 to 35 portions of calcined soda, 1 to 20 portions of trimeric sodium phosphate, and 0.1 to 20 portions of anhydrous sodium sulphate. All raw materials are mixed, pelletized and dried. The product has the advantages: 1. the product can be combined and used together with various surface active agents; 2. the softening function is evident; and 3. the operation is simple. The manufacturing technique has the advantages of saving energy, reducing consumption, lowering the fee of the device, protecting the environment, and having high efficiency.

Owner:NAFINE CHEMICAL INDUSTRY GROUP CO LTD

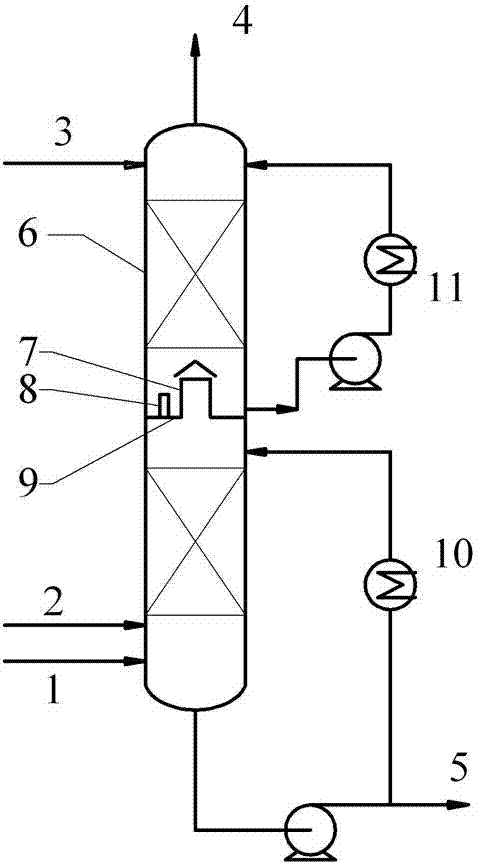

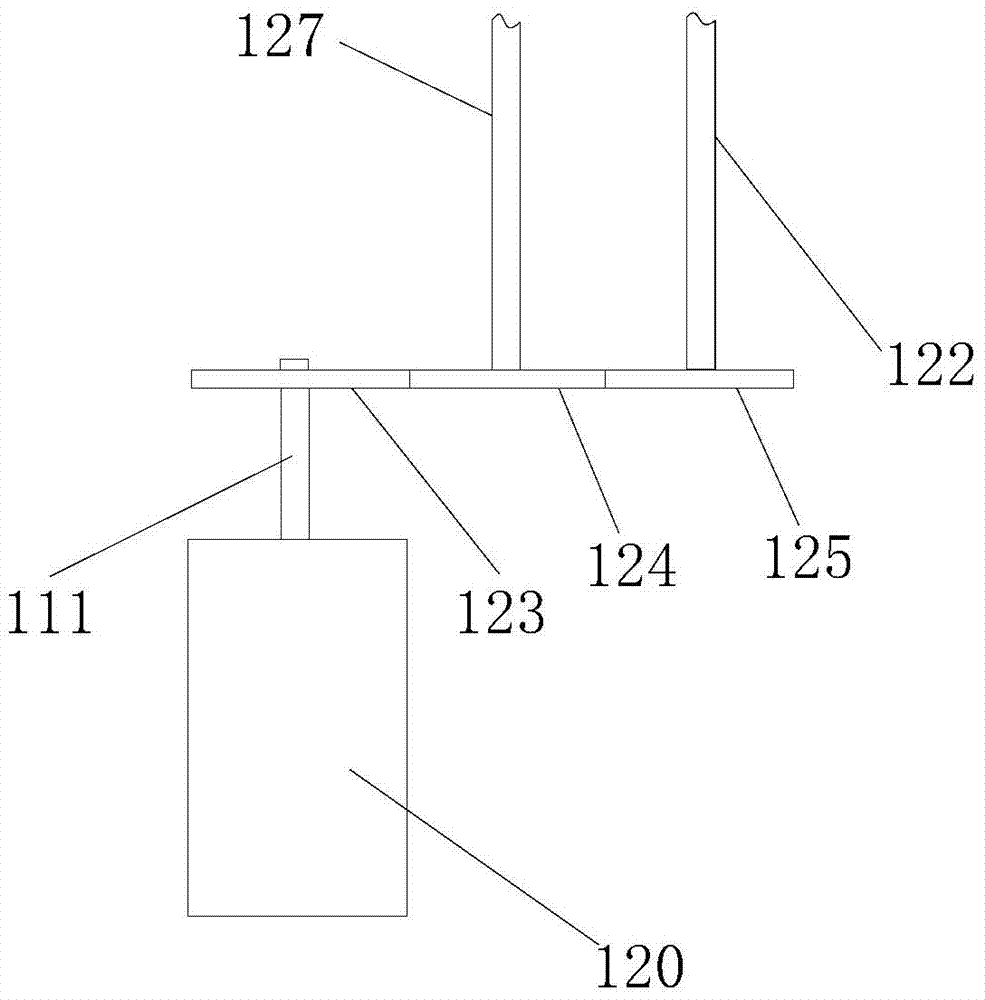

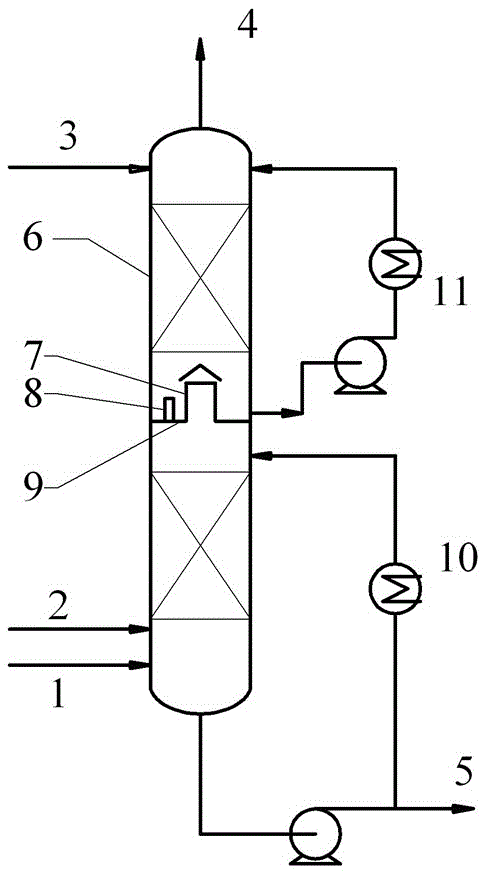

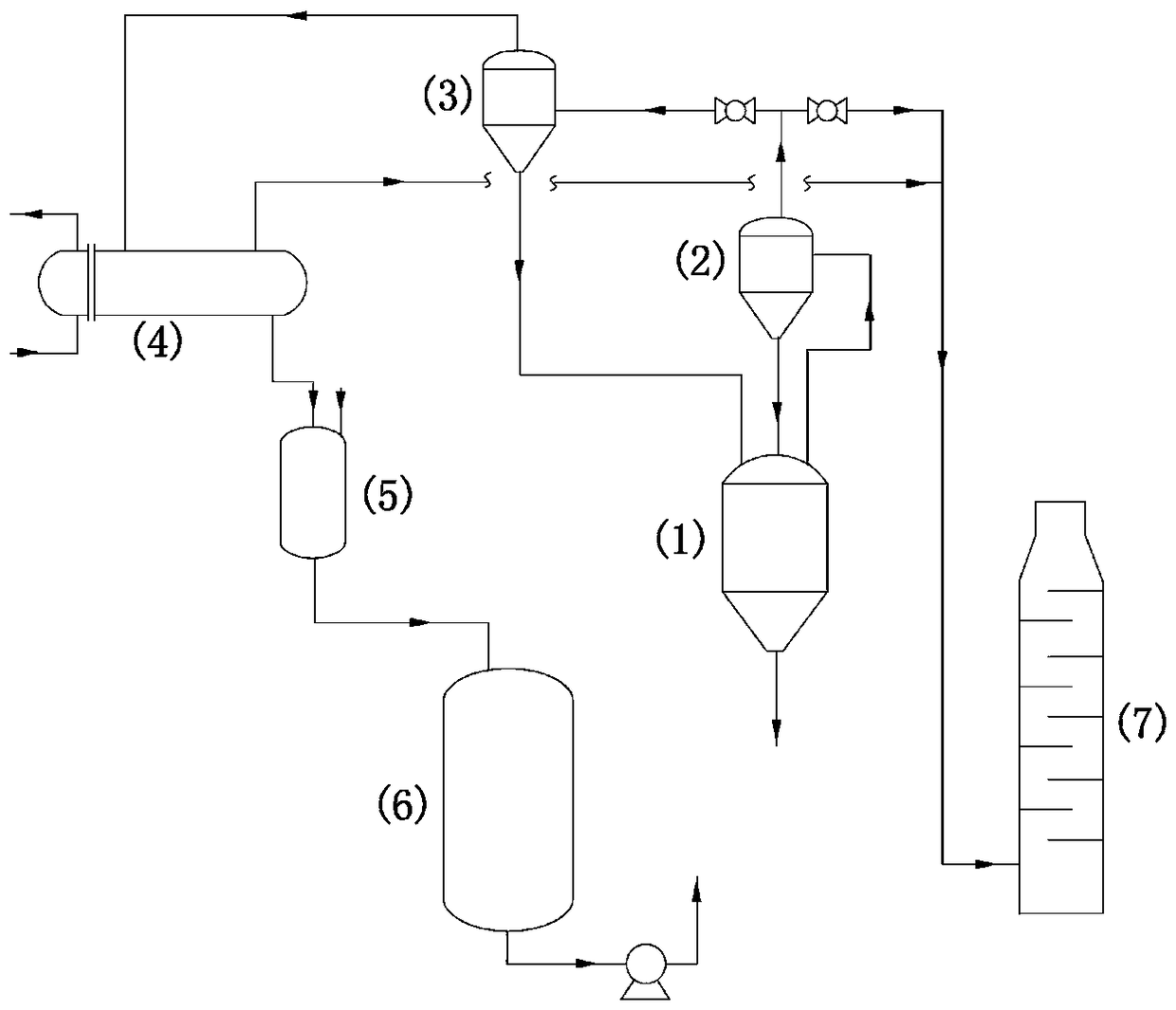

Improved device and method for dephenolization and desulfuration according to ammonium hydroxide washing method

ActiveCN103523798AIncrease the liquid to gas ratioWash smoothlyAmmonia preparation/separationPhysical chemistryAmmonia gas

The invention discloses an improved device for dephenolization and desulfuration according to the ammonium hydroxide washing method. The improved device for dephenolization and desulfuration according to the ammonium hydroxide washing method comprises an ammonia gas purification tower, a heat exchanger and a pump. A rough ammonia gas feeding pipeline is connected to the bottom of the ammonia gas purification tower. A fresh dilute aqueous ammonia feeding pipeline is connected to the top of the ammonia gas purification tower. A liquid ammonia feeding pipeline is connected to the middle or the lower portion of the ammonia gas purification tower. The top of the ammonia gas purification tower is connected with a following-up device. The bottom of the ammonia gas purification tower is connected with a lower circulation return opening of the ammonia gas purification tower and a pipeline connected with a raw material water tank through a pump. The middle side line of the ammonia gas purification tower is connected with an upper circulation return opening of the ammonia gas purification tower through a pump. A liquid collecting disk is arranged in the middle of the ammonia gas purification tower. A gas rising cap and an overflowing pipe are arranged on the liquid collecting disk. An overflowing opening of the overflowing pipe is connected with the upper portion of a lower-section packing. The invention further discloses a method for dephenolization and desulfuration according to the ammonium hydroxide washing method through the device. According to the improved device and method for dephenolization and desulfuration according to the ammonium hydroxide washing method, a stable liquid level of an ammonium hydroxide collecting area arranged in the middle of the mmonia gas purification tower can be effectively guaranteed, impurities such as phenols, H2S and organic sulfur of recycled ammonia can be effectively removed, and the purity of the ammonia is greatly improved.

Owner:QINGDAO UNIV OF SCI & TECH

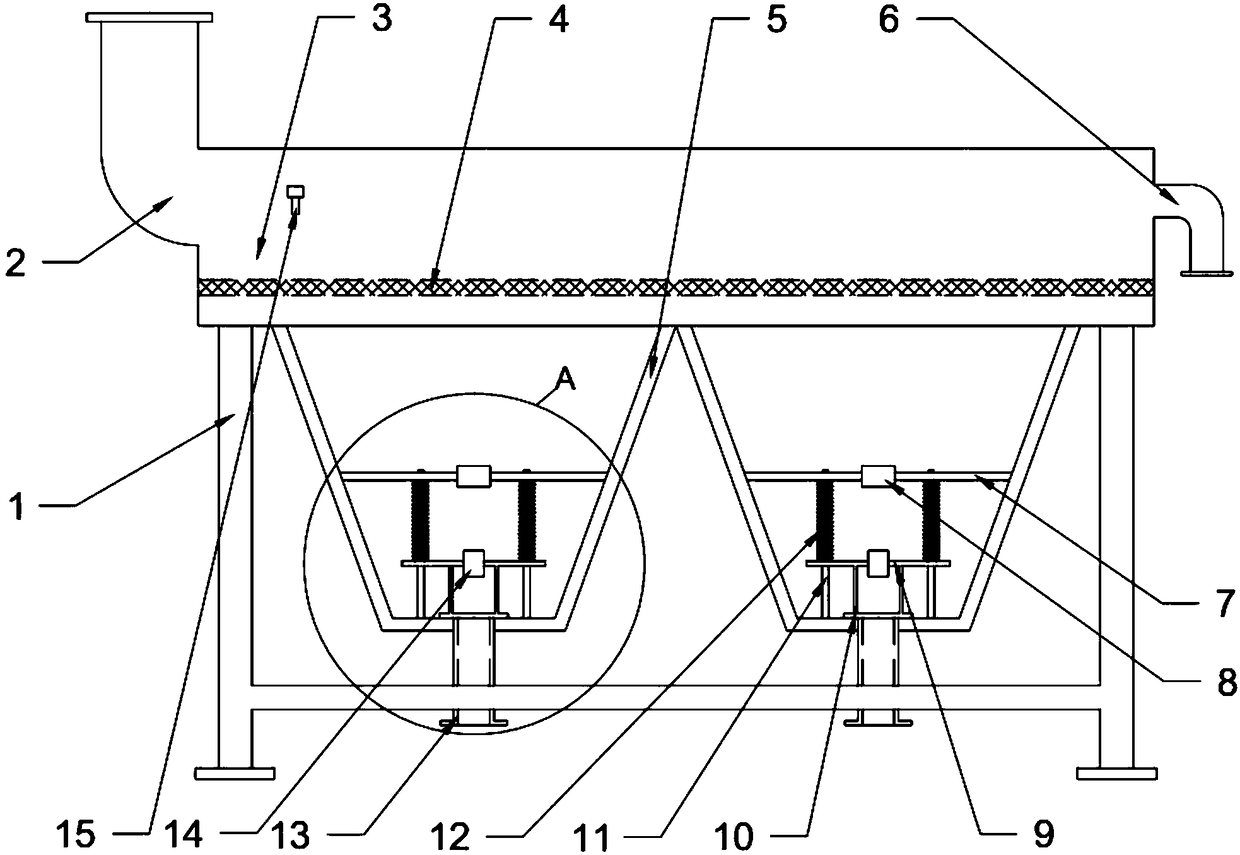

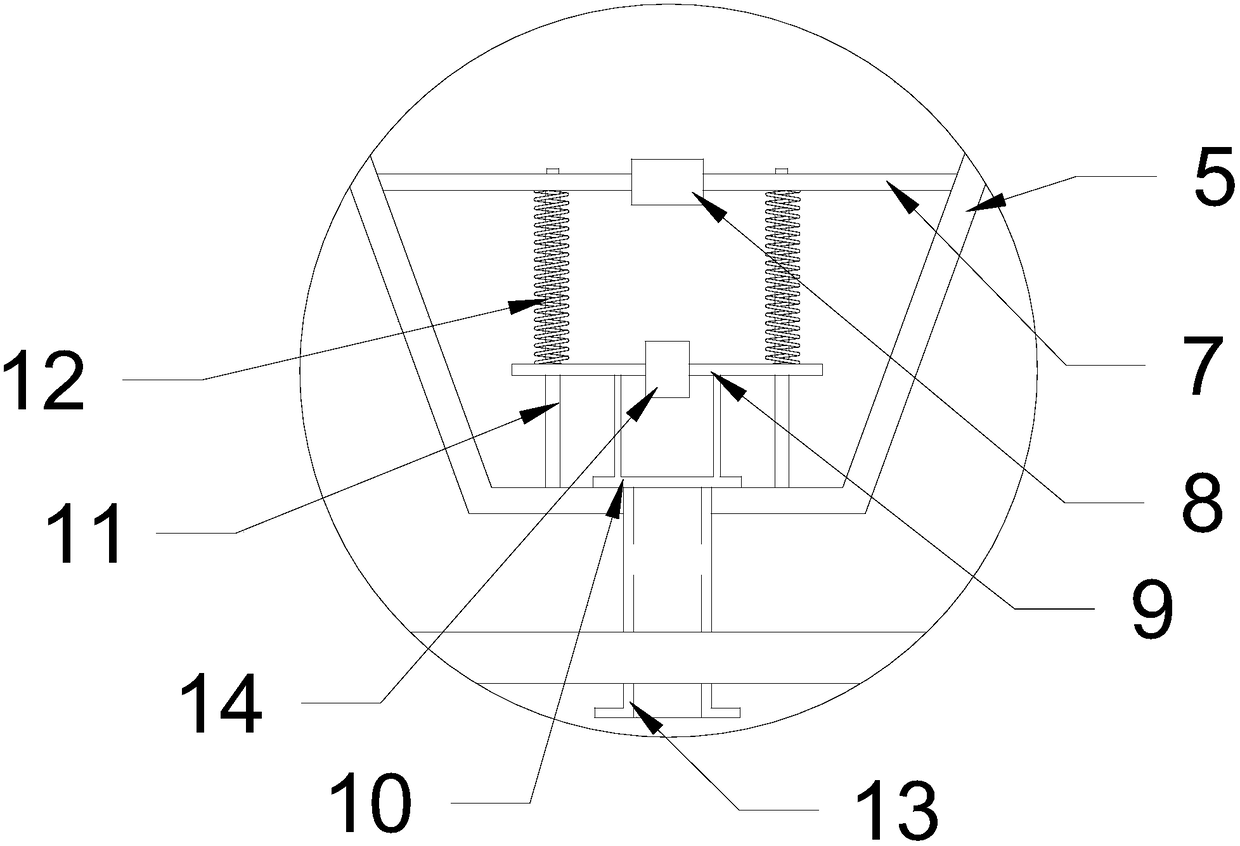

Electromagnetic type jigging machine

The invention relates to the field of coal mining equipment, in particular to an electromagnetic type jigging machine. The electromagnetic type jigging machine comprises a machine frame, a passing tank is installed above the machine frame, an ore supply pipe is installed at one end of the passing tank, and a discharge outlet is formed in the other end of the passing tank; the bottom of the passingtank communicates with two taper hoppers; and supports are installed inside the taper hoppers and provided with electromagnets, the supports are downwards connected with the bottoms of the taper hoppers through sliding rods, a vibrating plate is arranged below each support and provided with positioning holes allowing the corresponding sliding rods to penetrate through, the inner walls of the positioning holes are attached to the outer walls of the sliding rods, and magnets are installed on the vibrating plates. According to the electromagnetic type jigging machine, vibration is carried out inside the taper hoppers by effectively adopting an electromagnetic vibrating mode, and washing is conducted on coal mine through vertical alternating medium fluid; and compared with the traditional mode that the taper hoppers vibrate by adopting a cam to achieve the vertical alternating medium fluid, vibration is small, the machine is not prone to being damaged, the service life of the machine is prolonged, noise generated in the production process is low, and harm to the auditory system of field personnel is reduced.

Owner:SICHUAN DONGLIN MINE TRANSPORT MACHINERY

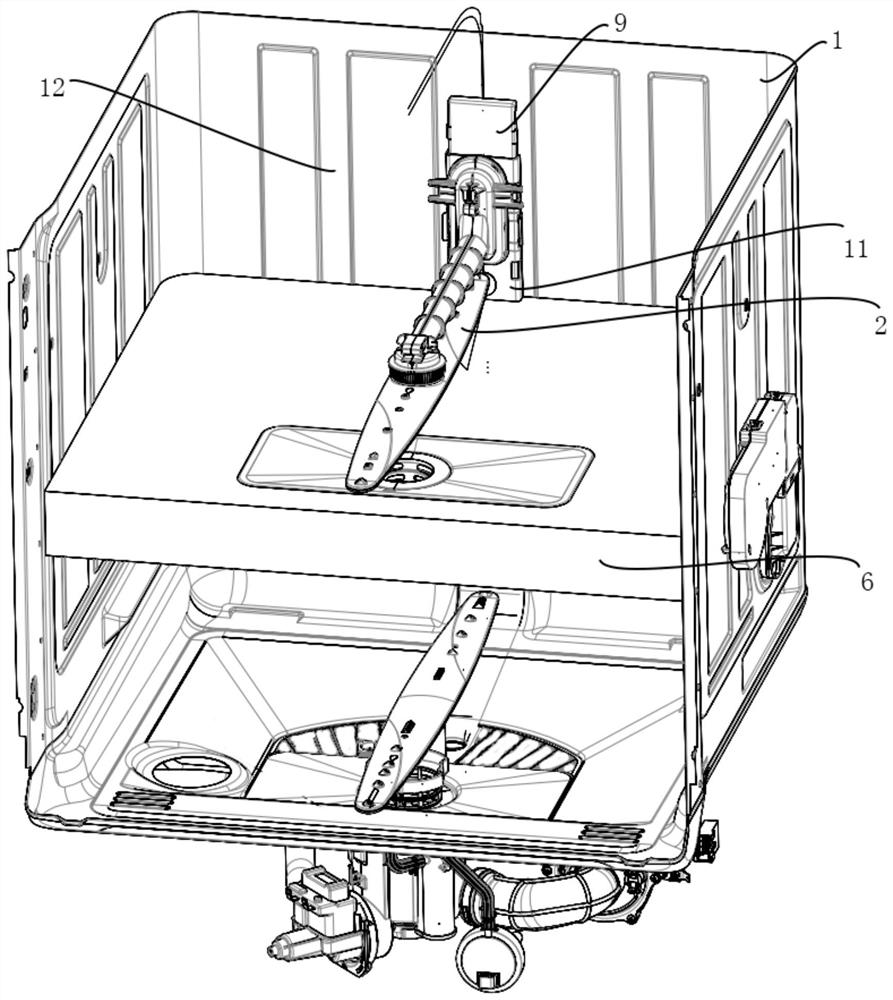

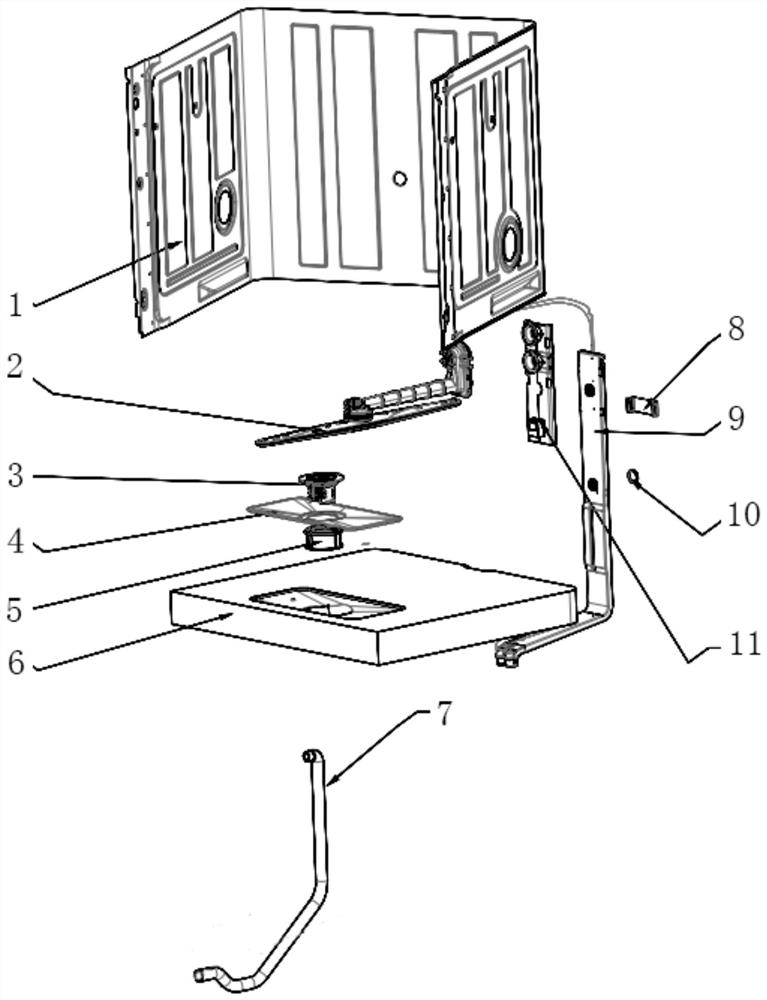

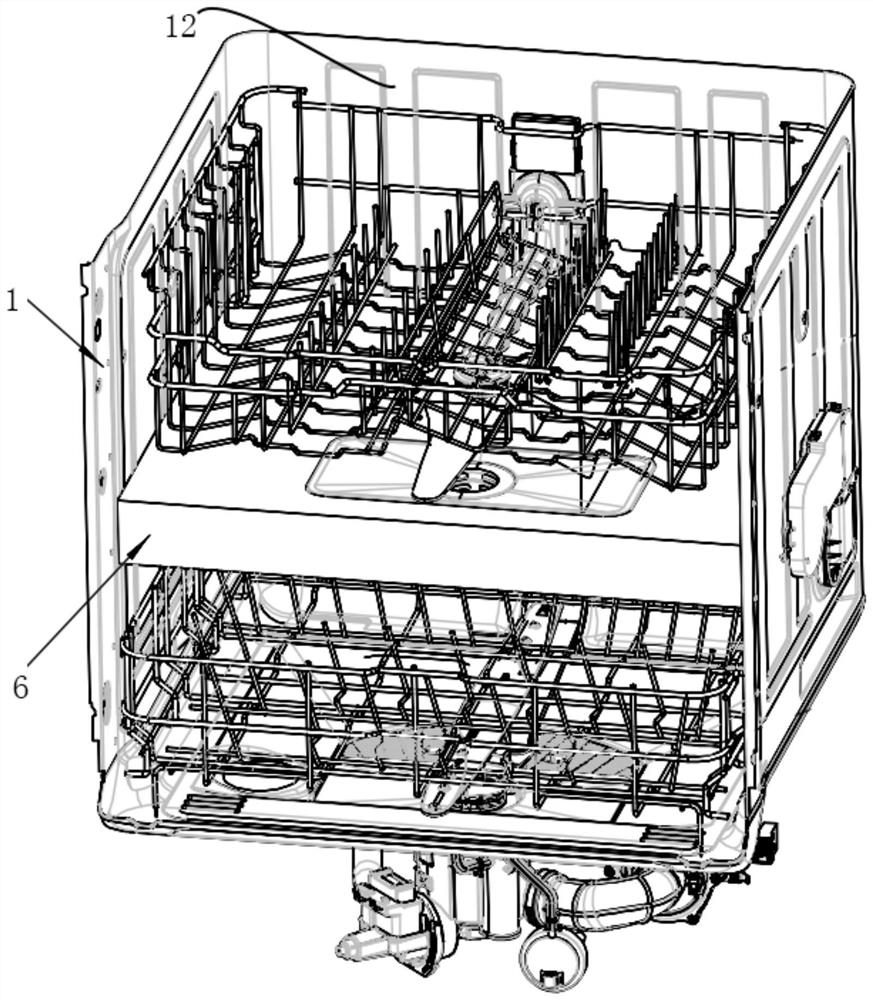

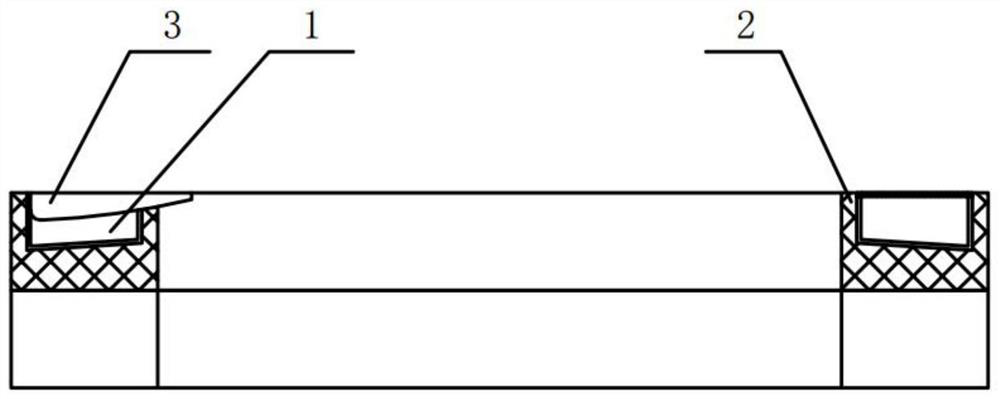

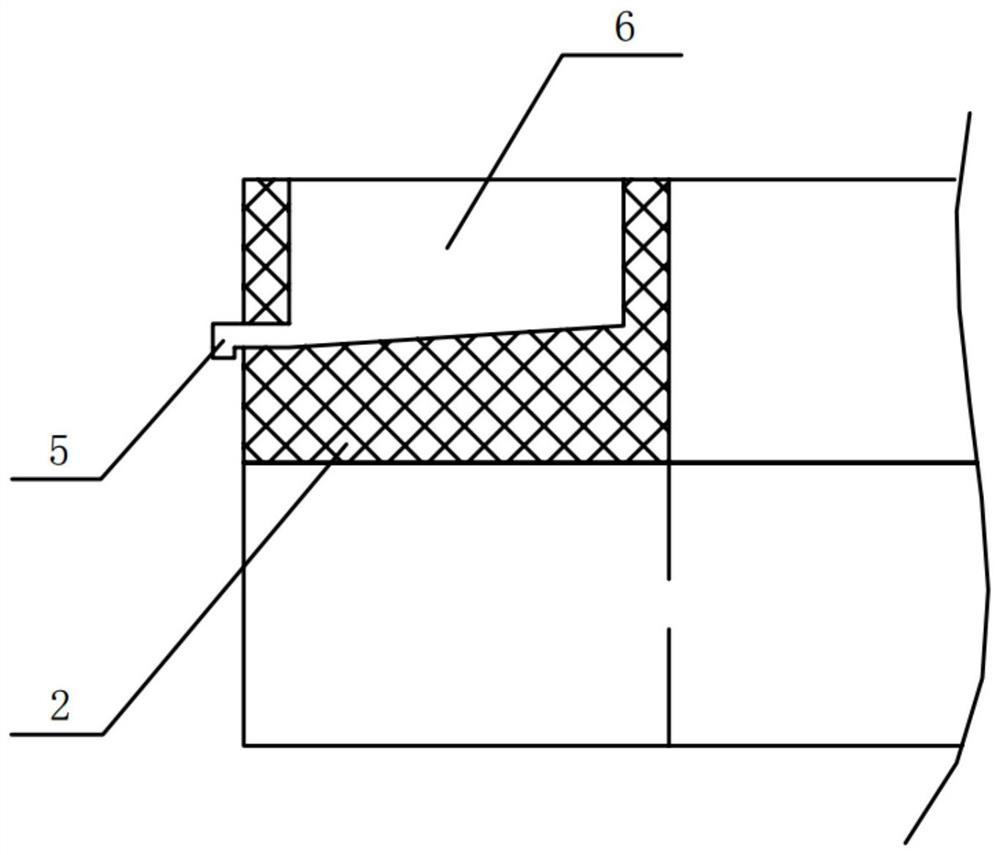

Dish washing machine

PendingCN112842212AImprove space utilizationReduce volumeTableware washing/rinsing machine detailsProcess engineeringMechanical engineering

The invention discloses a dish washing machine which comprises an inner container arranged in a shell and at least one separation structure. The at least one separation structure is arranged in the inner container, the separation structure divides the inner container into a plurality of washing areas, and each washing area is provided with a washing assembly; and the separation structure is further provided with a water inlet, a drainage cavity and a water outlet, the water inlet, the drainage cavity and the water outlet are sequentially communicated, the water inlet is formed in the top face of the separation structure, and the water outlet is communicated with a drainage system of the dish washing machine. According to the arrangement, the dish washing machine inner container is divided into the multiple washing areas through the separation structures, each washing area is provided with the washing assembly, washing can be directly carried out in each washing area, a dish washing cavity does not need to be independently formed in each washing area, and therefore the space utilization rate of the dish washing machine can be increased.

Owner:GREE ELECTRIC APPLIANCES INC

Washing control method and washing machine

InactiveCN104264416BAdequate heat dissipationReduce the temperatureOther washing machinesControl devices for washing apparatusLaundry washing machineCycle control

The invention discloses a washing control method and a washing machine. The washing control method comprises a washing step, a rinsing step and a dewatering step, wherein the washing steps is used for providing washing water to control a motor to operate at predetermined rotation time and stop time to wash and detecting the height of a water level in a bucket in real time to supplement water correspondingly; the rinsing step is used for discharging the washing water to control the motor to dewater at a dewatering period that the stop time is longer than the rotation time and providing rinsing water to rinse; the dewatering step is used for discharging the rinsing water to control the motor to operate to dewater at a rotation stop period that the stop time is longer than the rotation time. According to the method and the machine, the water is automatically supplemented during washing so as to prevent the influence of reduced water quantity on the washing effect; the rubbing time of clothes can be prolonged by controlling the motor to operate at the predetermined rotation time and stop time, so that the clothes have a better rollover effect; the motor is fully cooled through the dewatering period that the stop time is longer than the rotation time so as to reduce the temperature of the motor.

Owner:NANJING CHUANGWEI HOUSEHOLD ELECTRONICS APPLIANCES LTD

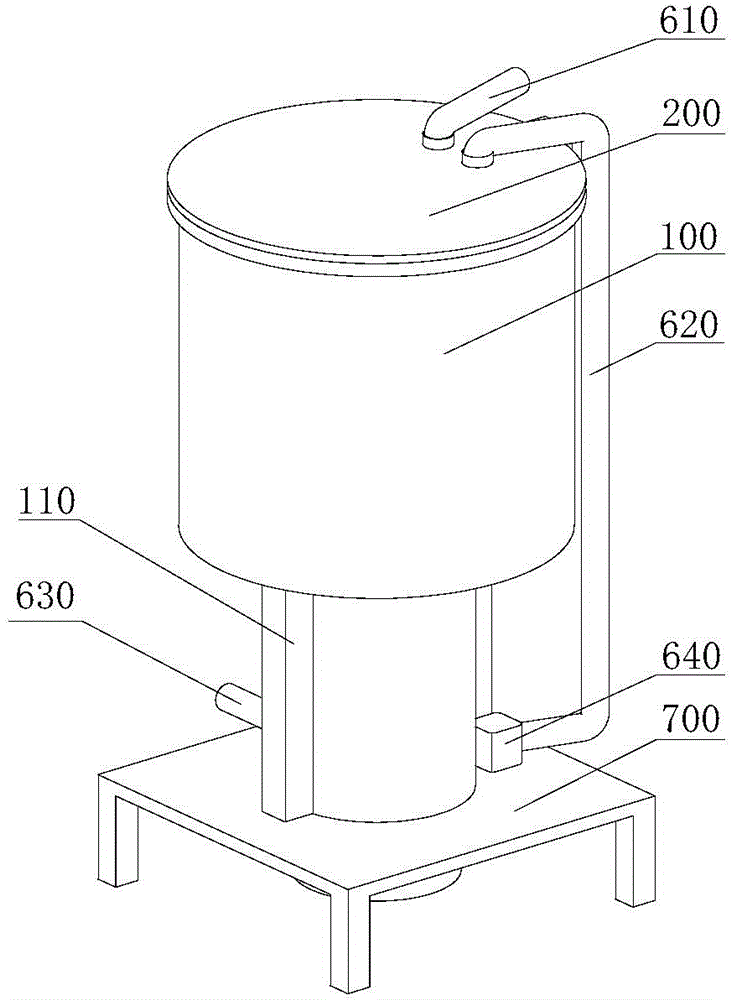

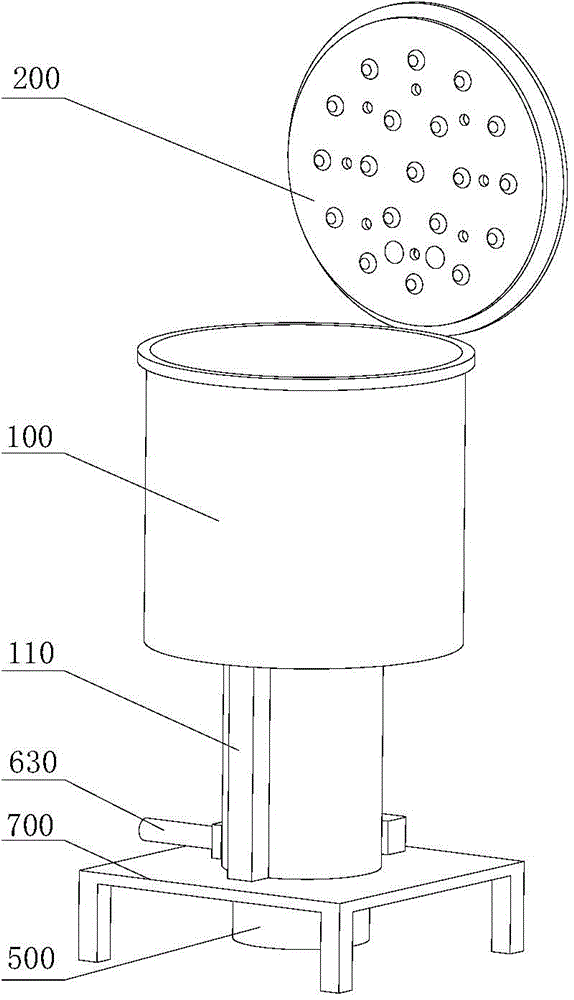

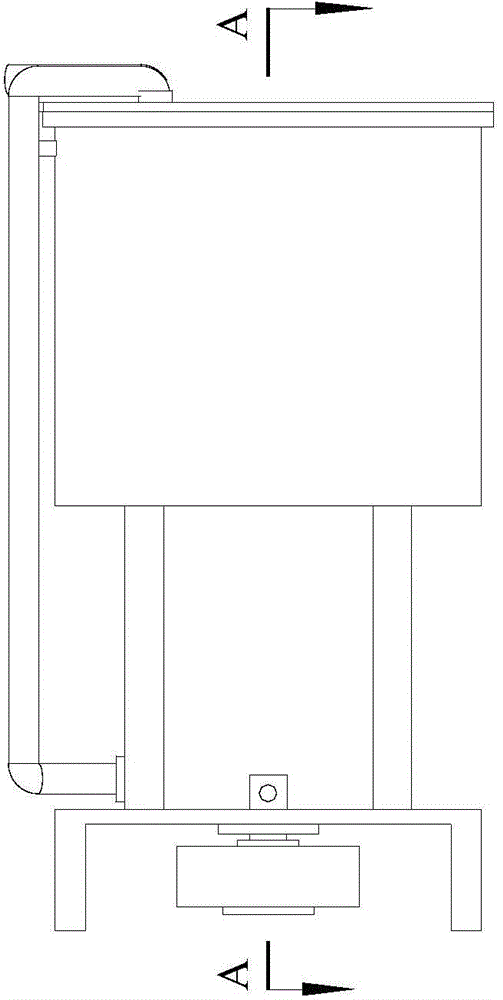

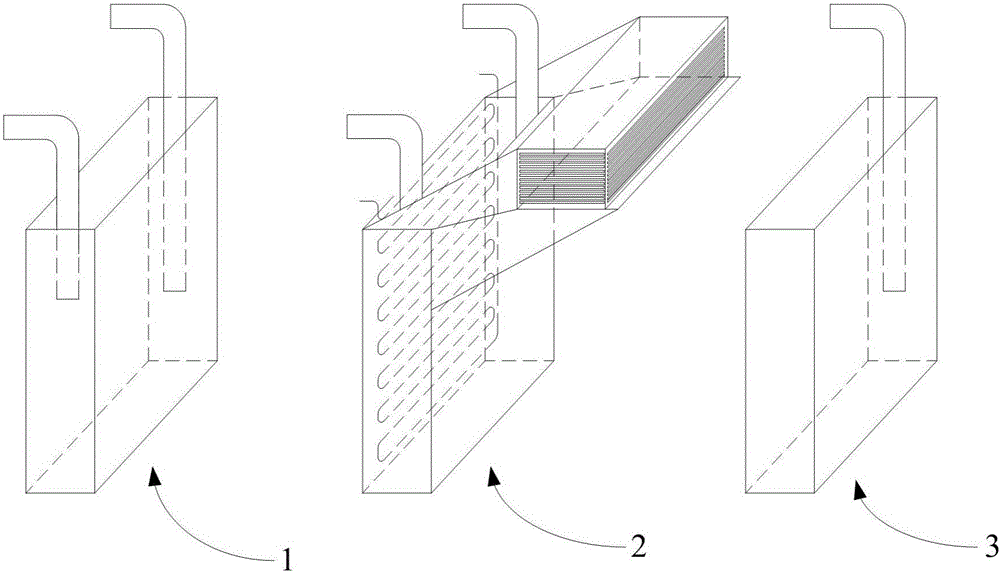

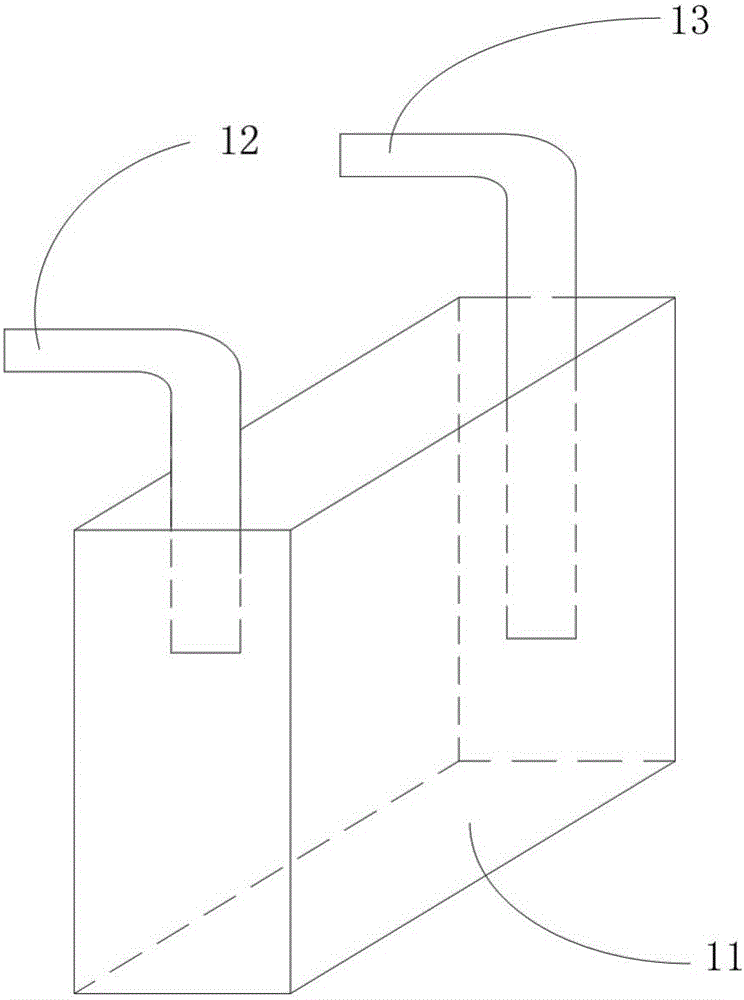

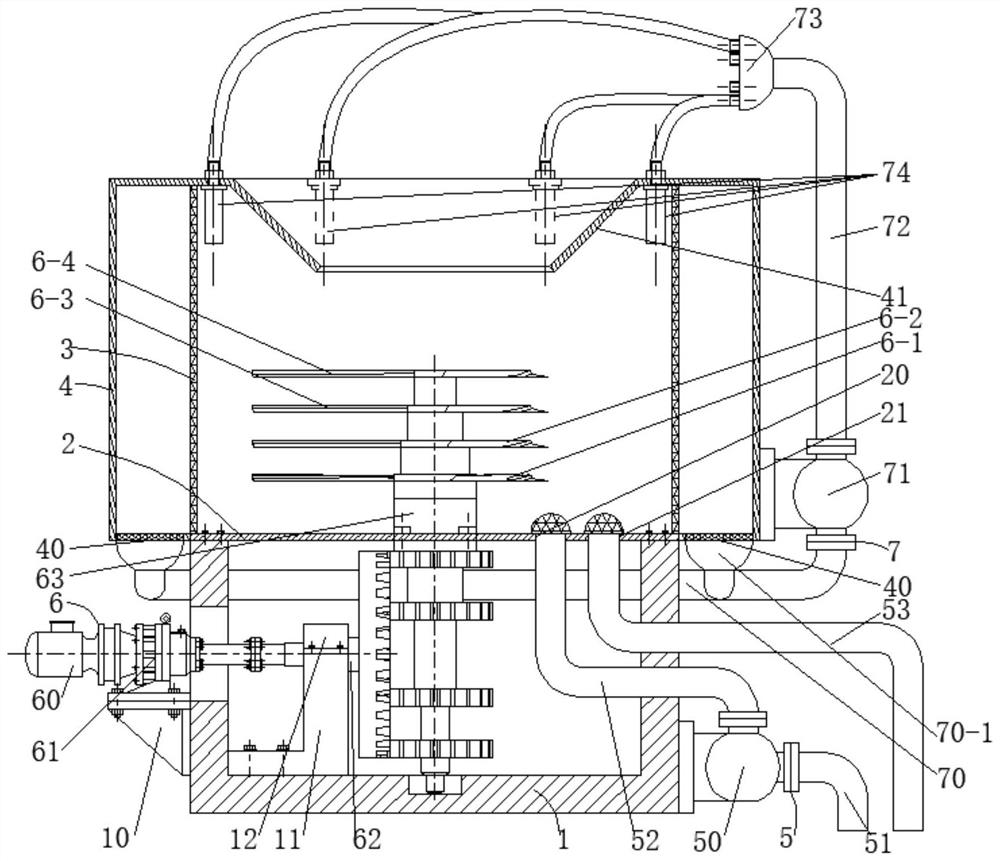

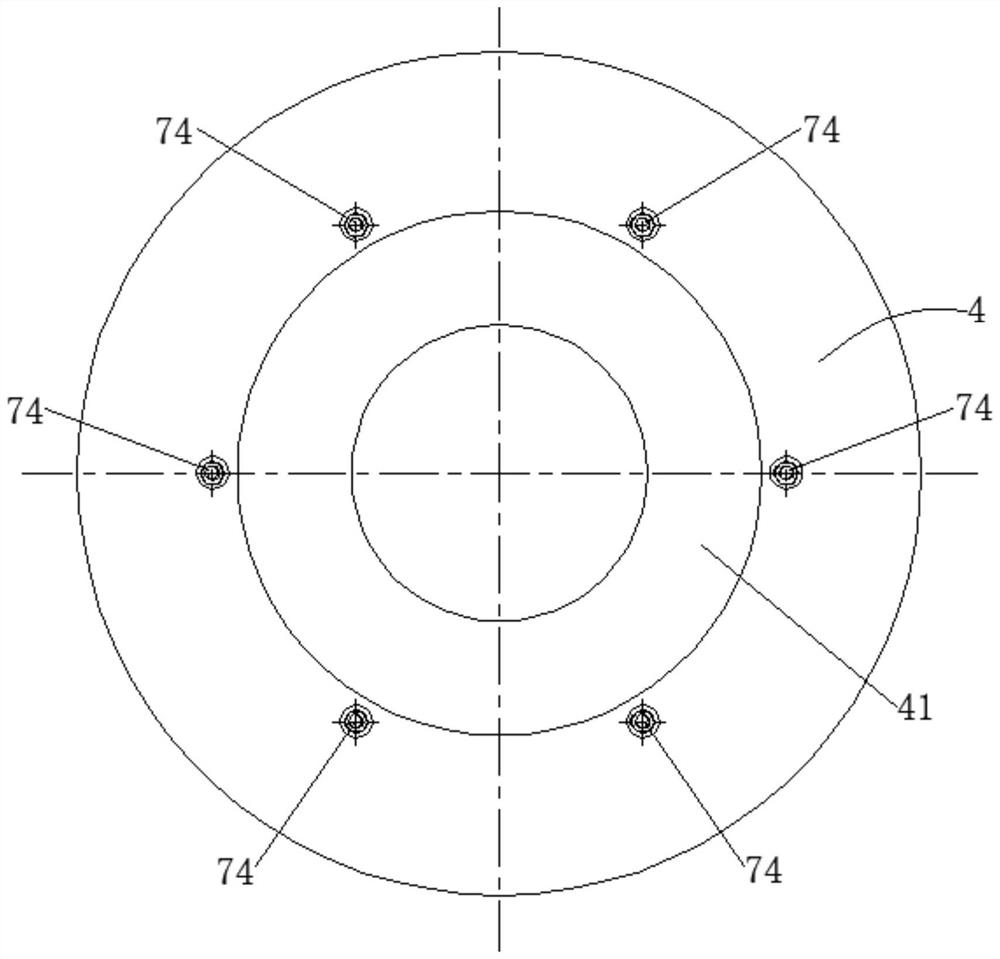

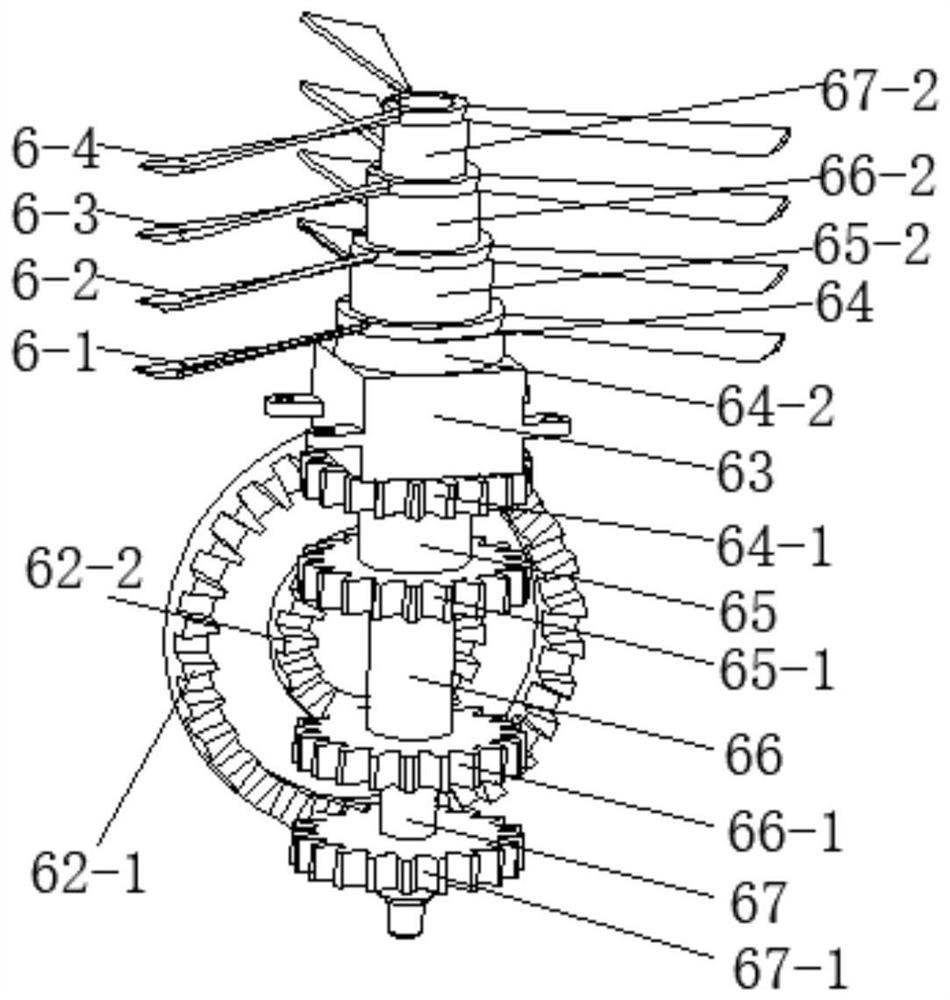

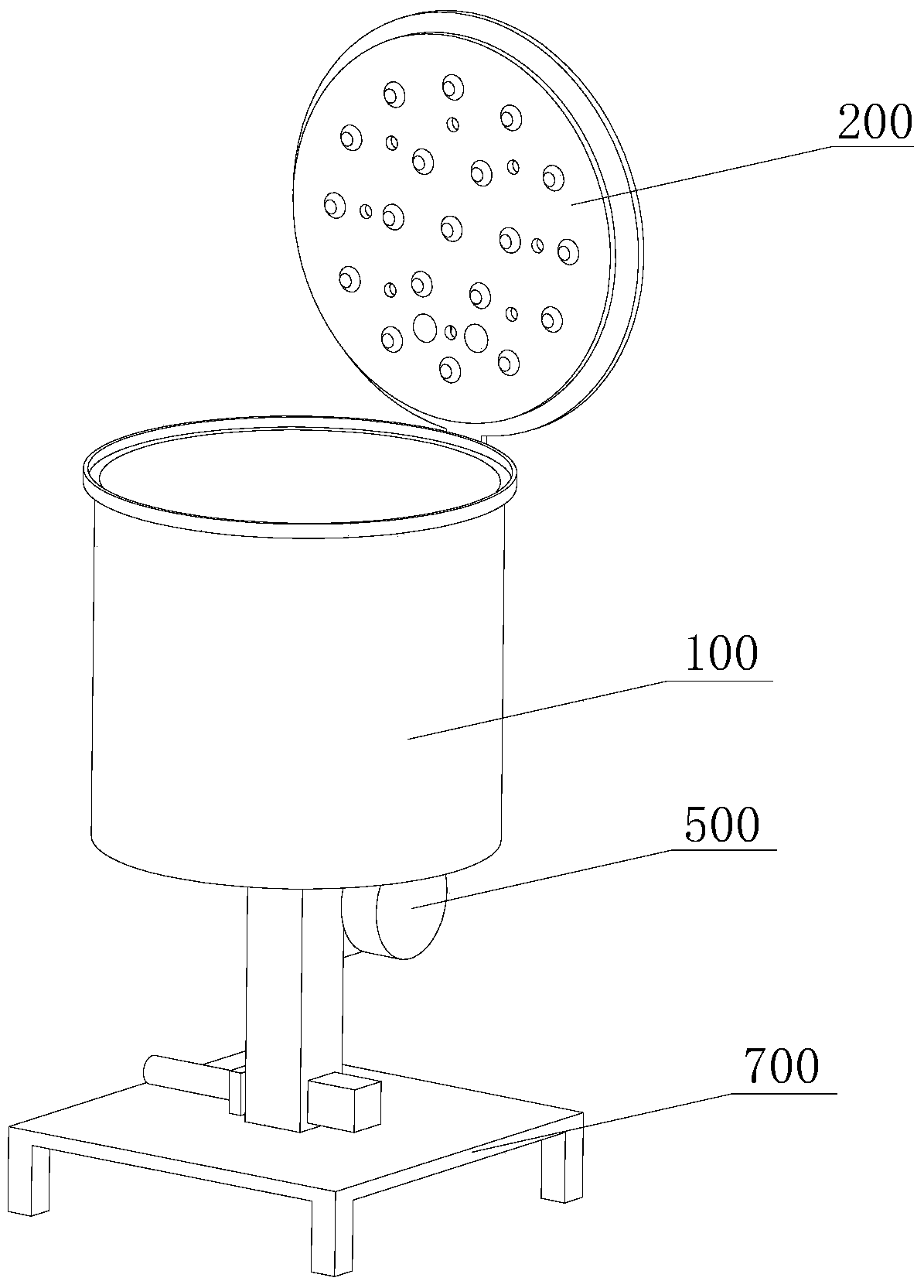

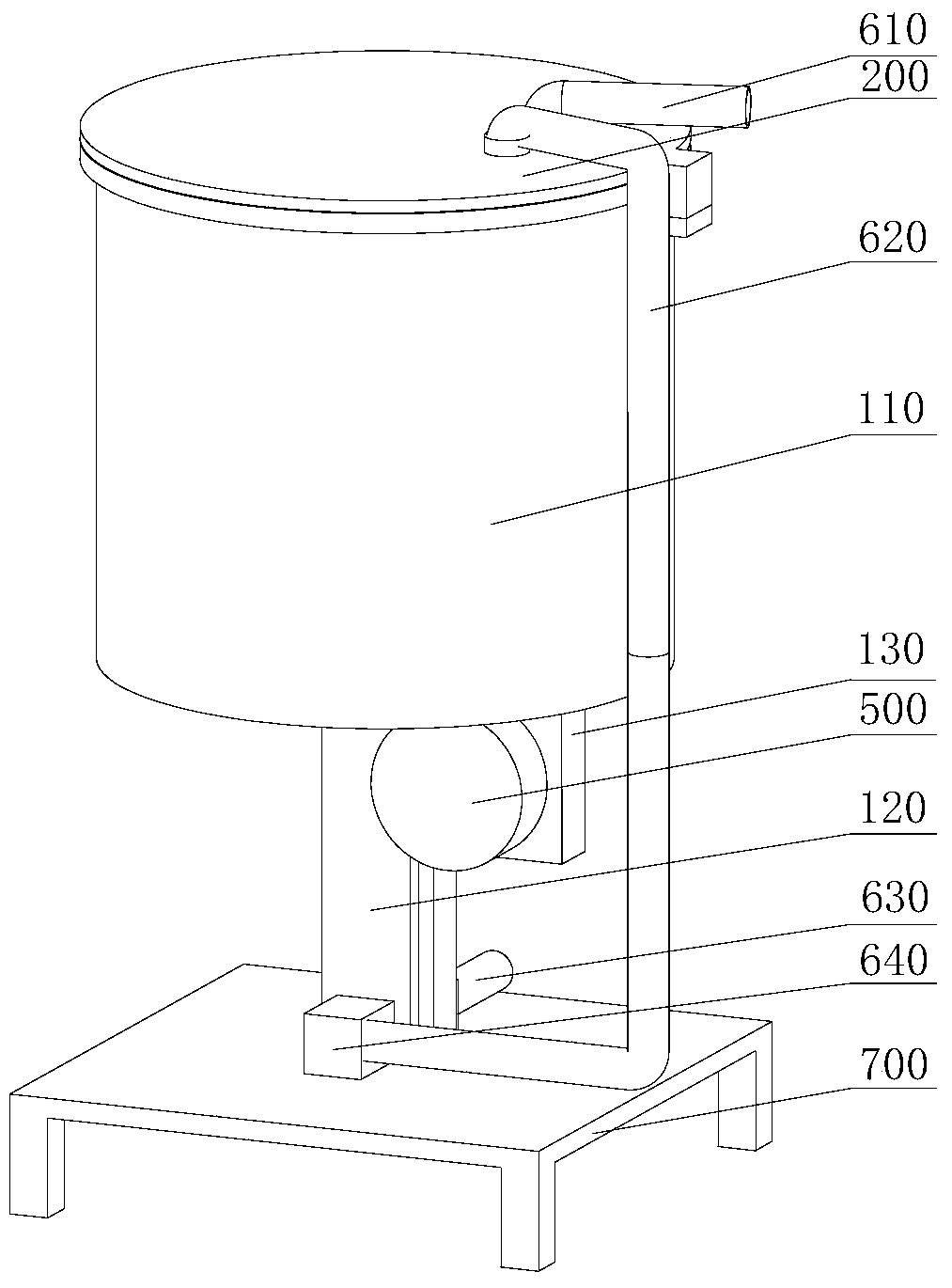

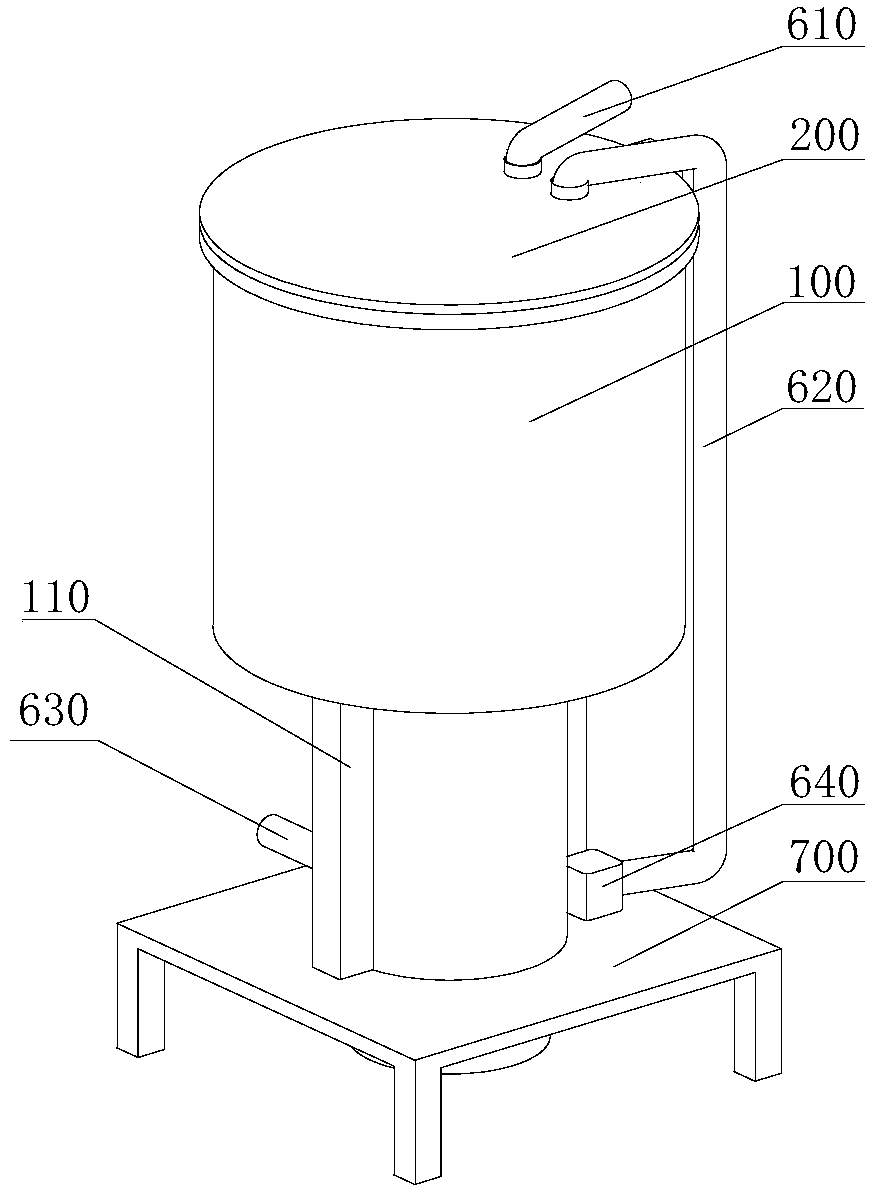

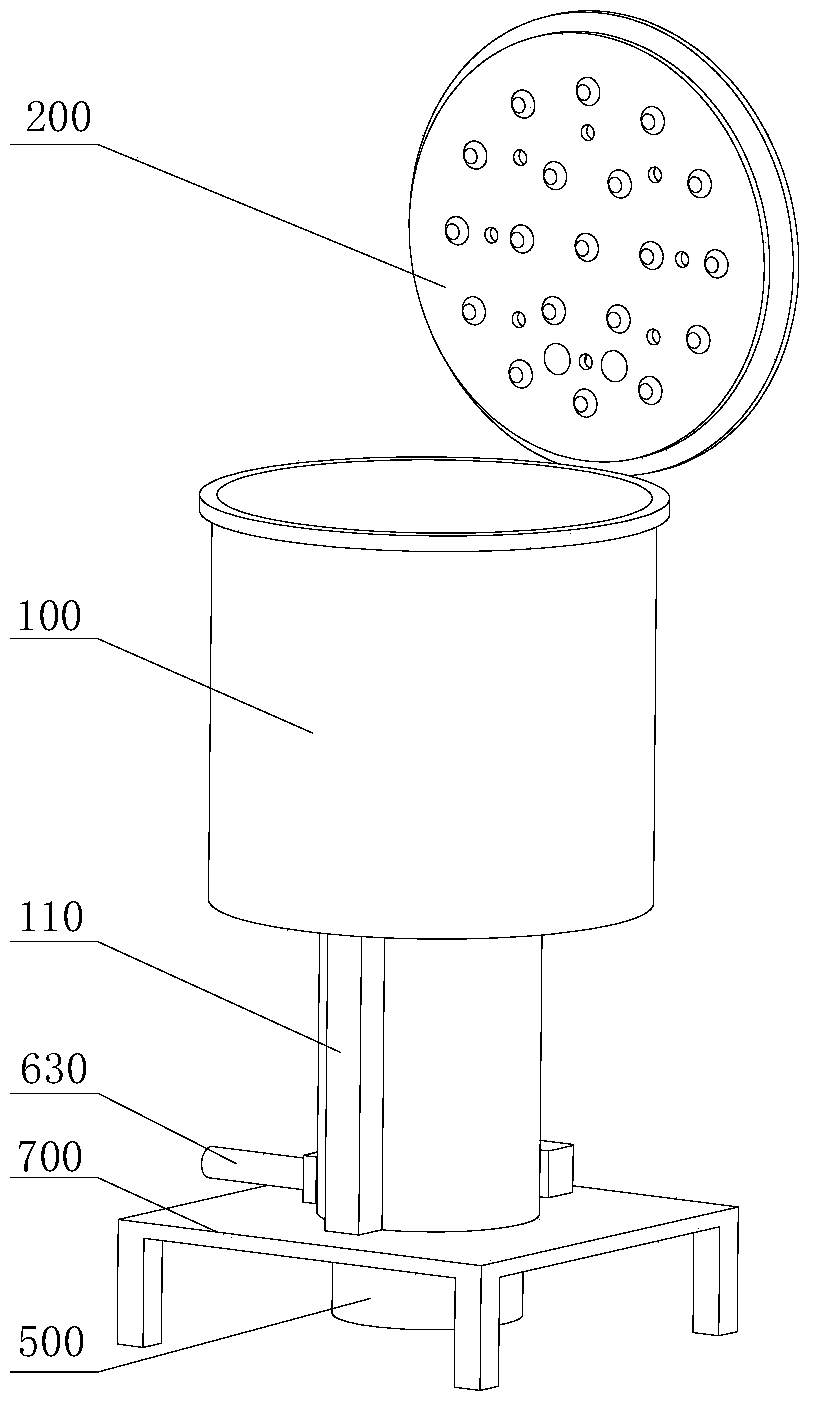

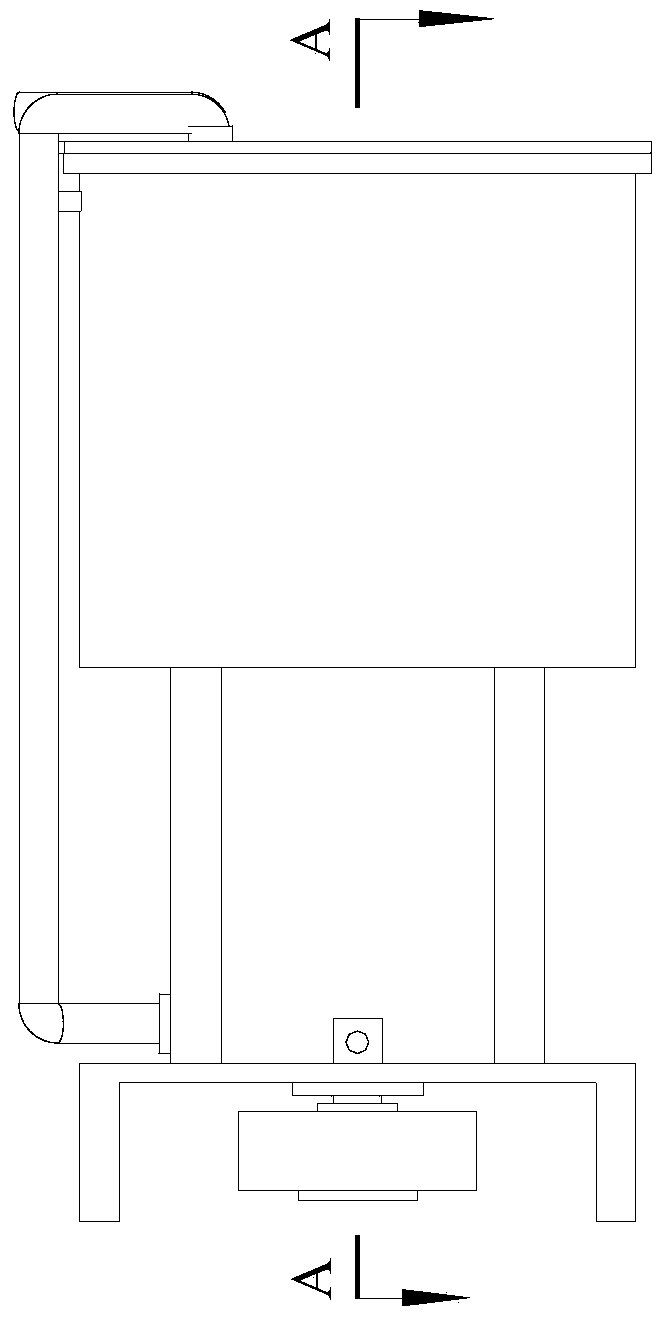

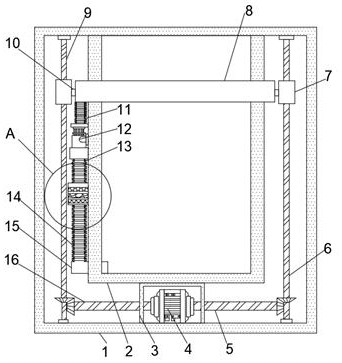

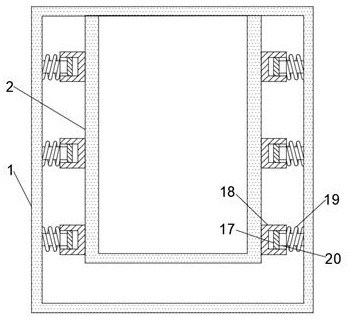

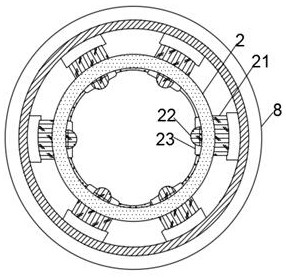

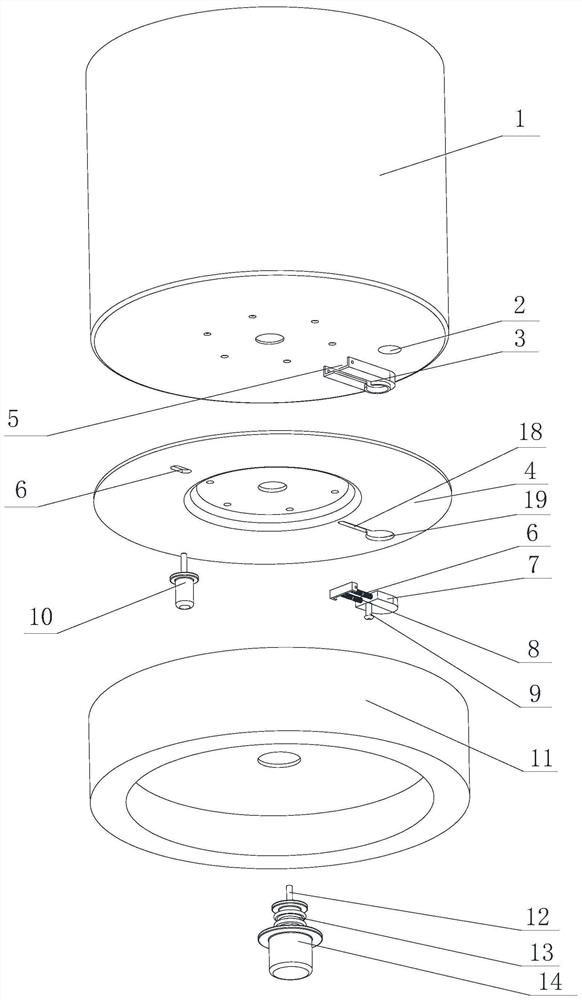

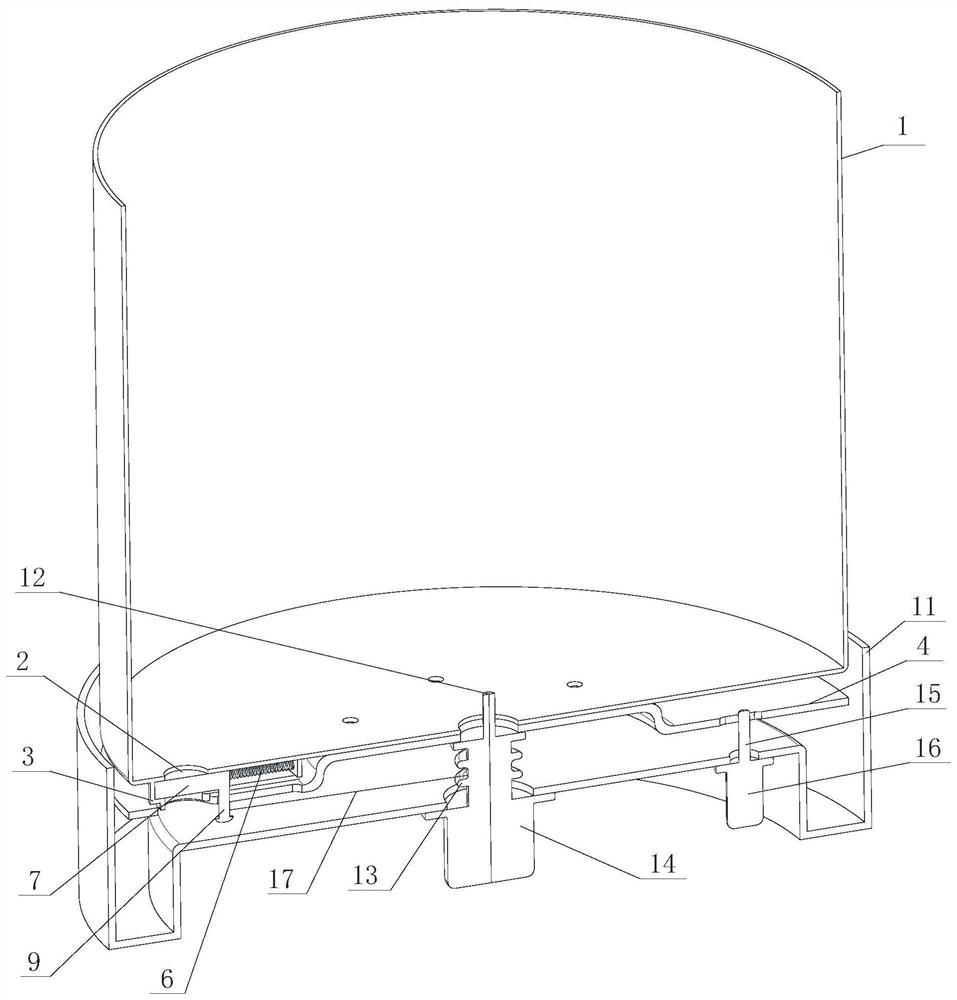

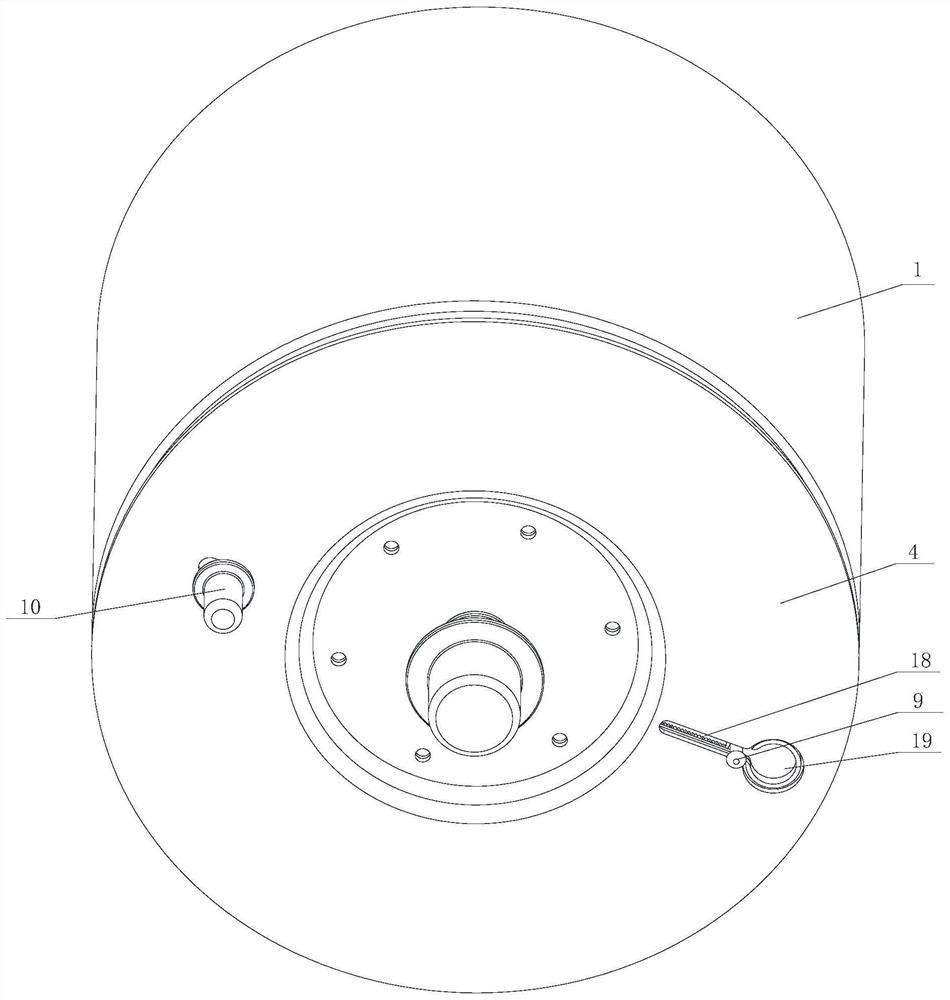

Immersive sprinkling-type feather and down feather washing device with low bath ratio and washing method

ActiveCN111733460AAchieve decontaminationRealize scrubbing functionClimate change adaptationWool fibre washing/scouringMechanical engineeringDown feather

The invention discloses an immersive sprinkling-type feather and down feather washing device with a low bath ratio. The immersive sprinkling-type feather and down feather washing device with the low bath ratio comprises a lower box base, a base plate, a washing cylinder, an outer cylinder, a water supply and drain system, a stirring system and a high-pressure sprinkling system, wherein the base plate is connected with the upper end of the lower box base in a fastened mode, the lower end of the washing cylinder is connected with the upper end face of the base plate in a fastened mode, the lowerend of the outer cylinder is connected with the side wall of the base plate in a fastened mode, the outer cylinder is connected with the washing cylinder in a fastened mode, the water supply and drain system is communicated and connected with the interior of the washing cylinder, the stirring system is connected with the lower box base and the base plate, and the high-pressure sprinkling system is connected with the outer cylinder, so that cyclic sprinkling of a washing solution is realized, the functions of automatic turning and repeated scrubbing of down feather are also realized, the cleaning efficiency is higher, and the cleaning effect is better.

Owner:GUQI FEATHER & DOWN PLC

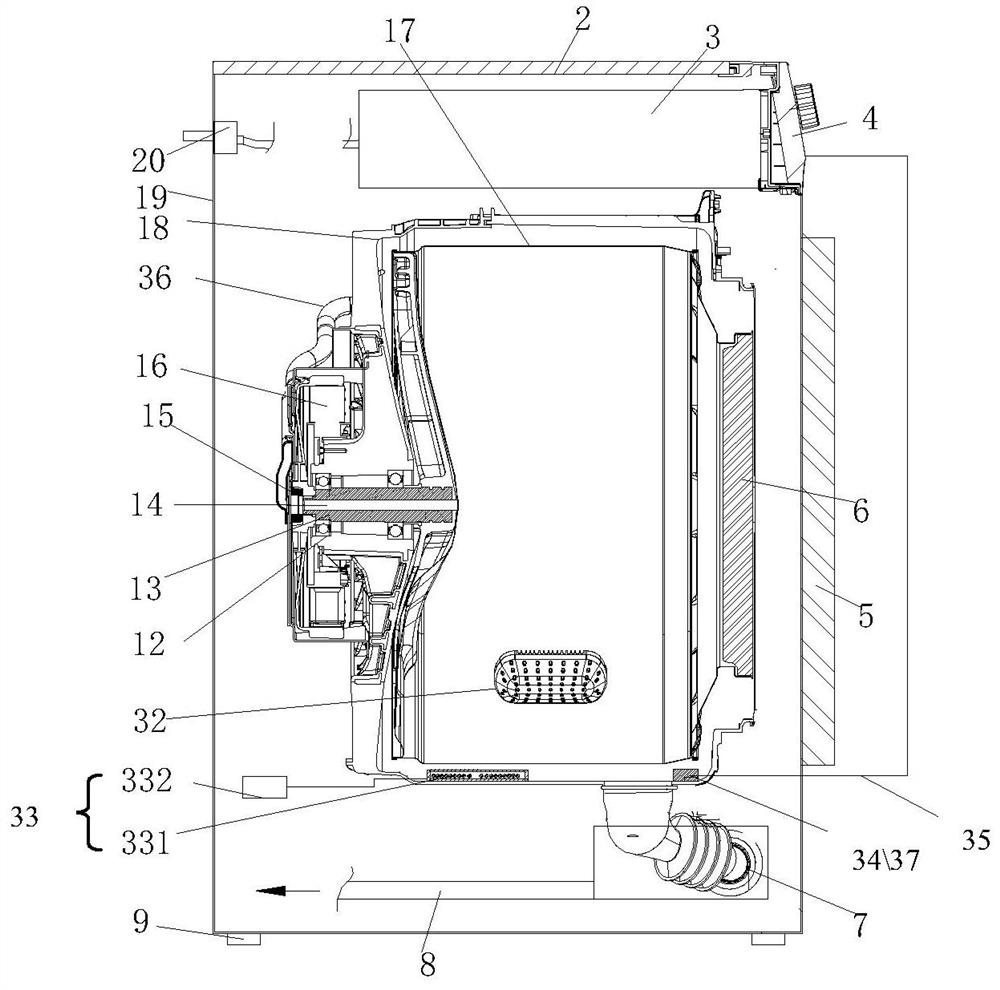

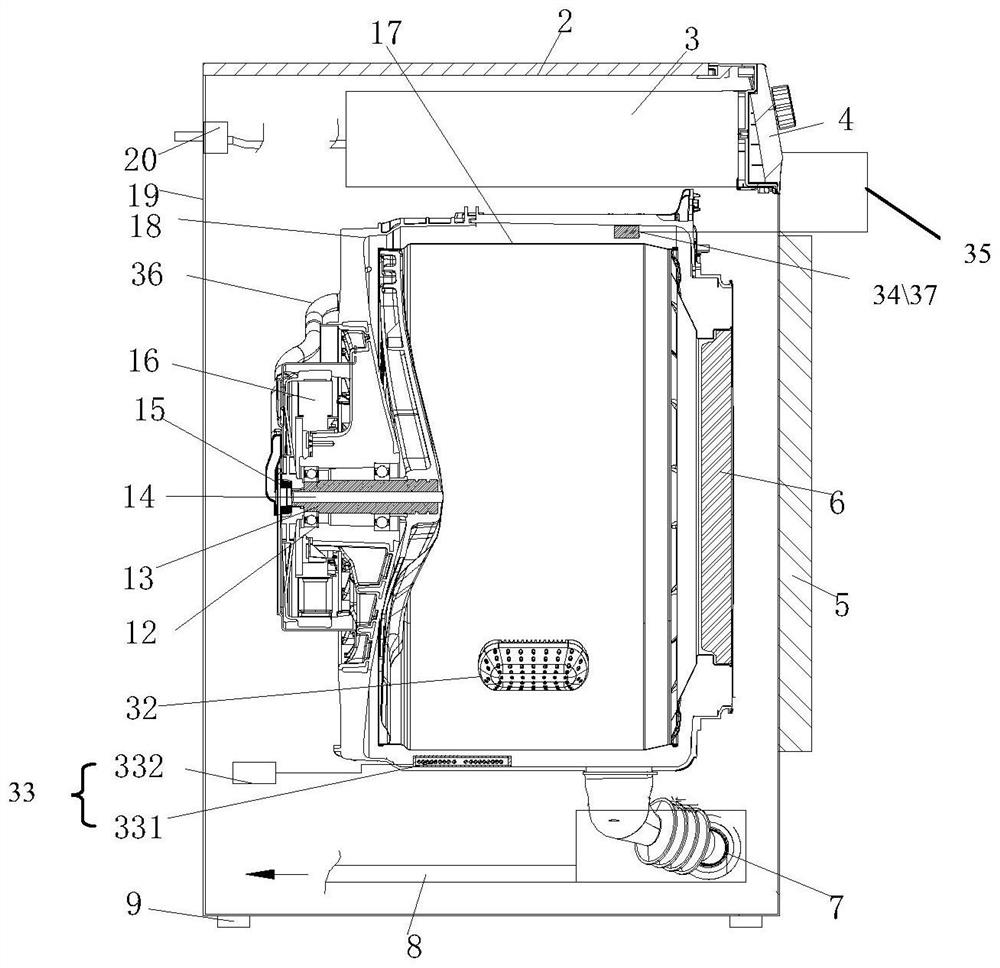

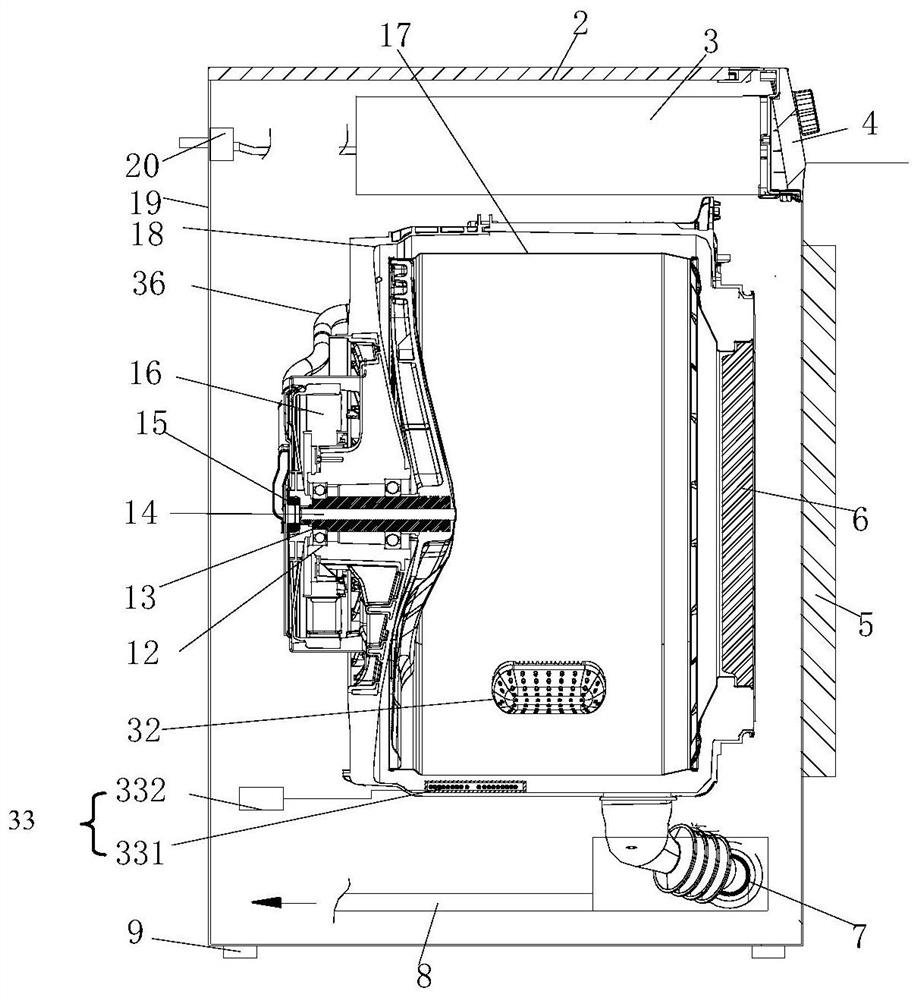

Washing machine and control method thereof

PendingCN112064288AControl heating timeImpact damageOther washing machinesControl devices for washing apparatusThermodynamicsLaundry washing machine

The invention discloses a washing machine and a control method thereof. The washing machine comprises an inner barrel used for containing washing water independently when clothes are washed, a water inlet system which communicates with the inner barrel, a heating device used for heating the water in the inner barrel, and a temperature detection device arranged in the water inlet system to detect the water inlet temperature; and when the washing machine executes a water inlet program, a control unit of the washing machine controls the heating time of the heating device according to a result detected by the temperature detection device. According to the washing machine, the heating device and the temperature detection device are combined, so that the heating time of washing water in the non-porous inner barrel is controlled, and the situation that the normal work of the washing machine is affected due to the fact that the water temperature is too low or too high due to the fact that theheating time of the heating device is short or too long is effectively avoided.

Owner:QINGDAO HAIER DRUM WASHING MACHINE +1

Environmentally-friendly and long-lasting fire-retarding treatment method for all-cotton knitted fabrics

Owner:常熟新锦江印染有限公司

A kind of steam washing machine and washing method

ActiveCN106906608BSimple structureLow costOther washing machinesControl devices for washing apparatusInlet valveEngineering

Owner:NANJING LG PANDA APPLIANCES

A reciprocating extrusion washing machine

ActiveCN104975455BReduce wearReduce water consumptionOther washing machinesTextiles and paperImpellerLaundry washing machine

Owner:QINGDAO HAIER WASHING MASCH CO LTD

A reciprocating washing machine

ActiveCN104975458BReduce wearReduce water consumptionOther washing machinesTextiles and paperImpellerReciprocating motion

The invention provides a reciprocating type washing machine. The reciprocating type washing machine comprises a washing bucket, an upper cover, a transmission mechanism, a piston and a driving device, wherein the upper cover is movably connected to an opening of the washing bucket, the washing bucket comprises an upper portion and a lower portion, the upper portion of the washing bucket is used as a washing cavity for containing / washing clothes, the piston is arranged in the washing cavity, the lower portion of the washing bucket is used as a control cavity, the transmission mechanism is arranged in the control cavity, the input end of the transmission mechanism is connected with the driving device, the transmission mechanism and the piston are in screw transmission, and the driving device drives the piston to perform up-down reciprocating motion in the washing bucket through the transmission mechanism. According to the reciprocating type washing machine, washing is performed through reciprocating extrusion on the clothes by the piston, the defects that an existing impeller type washing machine and a tumbling-box washing machine are serious in wear of the clothes and large in water consumption are overcome, and the better washing effect is achieved.

Owner:QINGDAO HAIER WASHING MASCH CO LTD

Washing machine convenient for cleaning internal dirt

InactiveCN114134687AEasy to cleanEasy to operateOther washing machinesTextiles and paperLaundry washing machineThreaded pipe

The washing machine comprises a machine body and a rotating drum, a double-shaft motor is installed on the inner wall of the bottom of the machine body through screws, a first rotating shaft is welded to the output end of the left side of the double-shaft motor, and the left end of the first rotating shaft is rotationally connected with a second rotating shaft through a bevel gear; a third rotating shaft is welded to the output end of the right side of the double-shaft motor, a fourth rotating shaft is rotatably connected to the right end of the third rotating shaft through a bevel gear, the outer wall of the rotating cylinder is sleeved with a flow guide pipe, connecting rods are welded to the outer wall of the left side and the outer wall of the right side of the flow guide pipe correspondingly, and threaded pipes are welded to the ends, away from each other, of the connecting rods correspondingly; the device is simple in structure, novel in design, convenient to clean dirt in the washing machine, convenient to use, capable of preventing the dirt from remaining in the rotary drum and affecting the washing effect, capable of reducing the shaking amplitude of the rotary drum and improving the practicability of the washing machine, and suitable for wide popularization.

Owner:余平桂

Dissolving structure of washing powder and washing machine

ActiveCN108691153BImprove solubilityEvenly distributedOther washing machinesTextiles and paperLaundry washing machineProcess engineering

The invention belongs to the technical field of washing machines, and discloses a washing powder dissolving structure, comprising a balance ring with a cavity inside, one end of the cavity is provided with an input port, and the other end is provided with a siphon structure whose outlet is connected to the inner tub of the washing machine. The invention also discloses a washing machine comprising the above washing powder dissolving structure. Through the above washing powder dissolving structure, after the washing powder is put into the cavity through the input port, the balance ring will reciprocate with the inner tub, so that the washing powder is evenly distributed in the cavity, and then the washing water is injected through the input port, and the balance ring can be placed in the cavity. In the process of reciprocating rotation, the washing powder is fully dissolved, and then the washing water is continued to be injected. Through the above structure, the washing powder can be fully dissolved, the waste of the washing powder can be avoided, and the washing ratio of the washing machine can be improved, so that the clothes can be washed sufficiently.

Owner:FOSHAN SHUNDE HAIER ELECTRIC APPLIANCES CO LTD +1

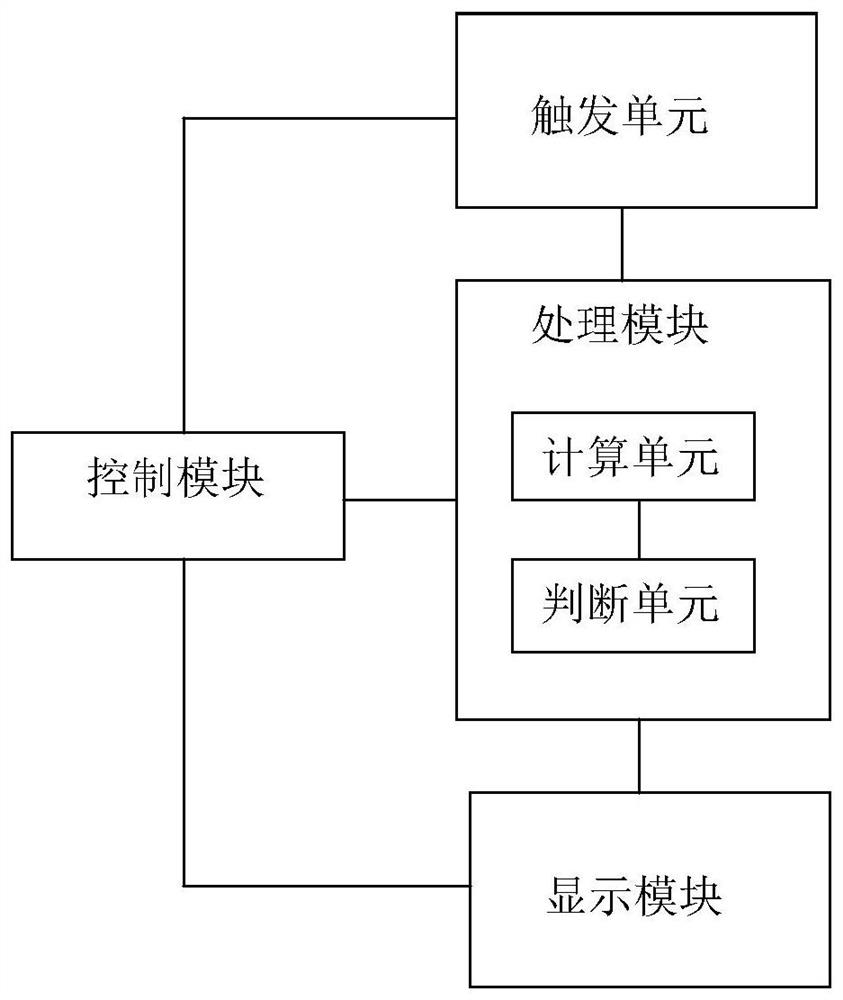

Washing machine and control method thereof

ActiveCN112144219AImpact damageAvoid affecting the washing effectOther washing machinesControl devices for washing apparatusLaundry washing machineControl cell

The invention discloses a washing machine and a control method thereof. The washing machine comprises an inner barrel, an electromagnetic heating device and a temperature detection device, wherein theinner barrel is used for independently containing washing water during clothes washing; the electromagnetic heating device heats water in the inner barrel; and the temperature detection device detects the water temperature in the inner barrel, or detects the temperature of the inner barrel, or detects the temperature at a certain distance outside the inner barrel. A control unit of the washing machine judges the current water temperature in the inner barrel according to a result fed back by the temperature detection device and controls the on-off of the electromagnetic heating device. By combining the electromagnetic heating device and the temperature detection device, the water temperature of the hole-free inner barrel washing machine is controlled, and the situation that normal work ofthe washing machine is affected due to the fact that the heating water temperature is too low or too high is effectively avoided.

Owner:QINGDAO HAIER WASHING ELECTRIC APPLIANCES CO LTD +1

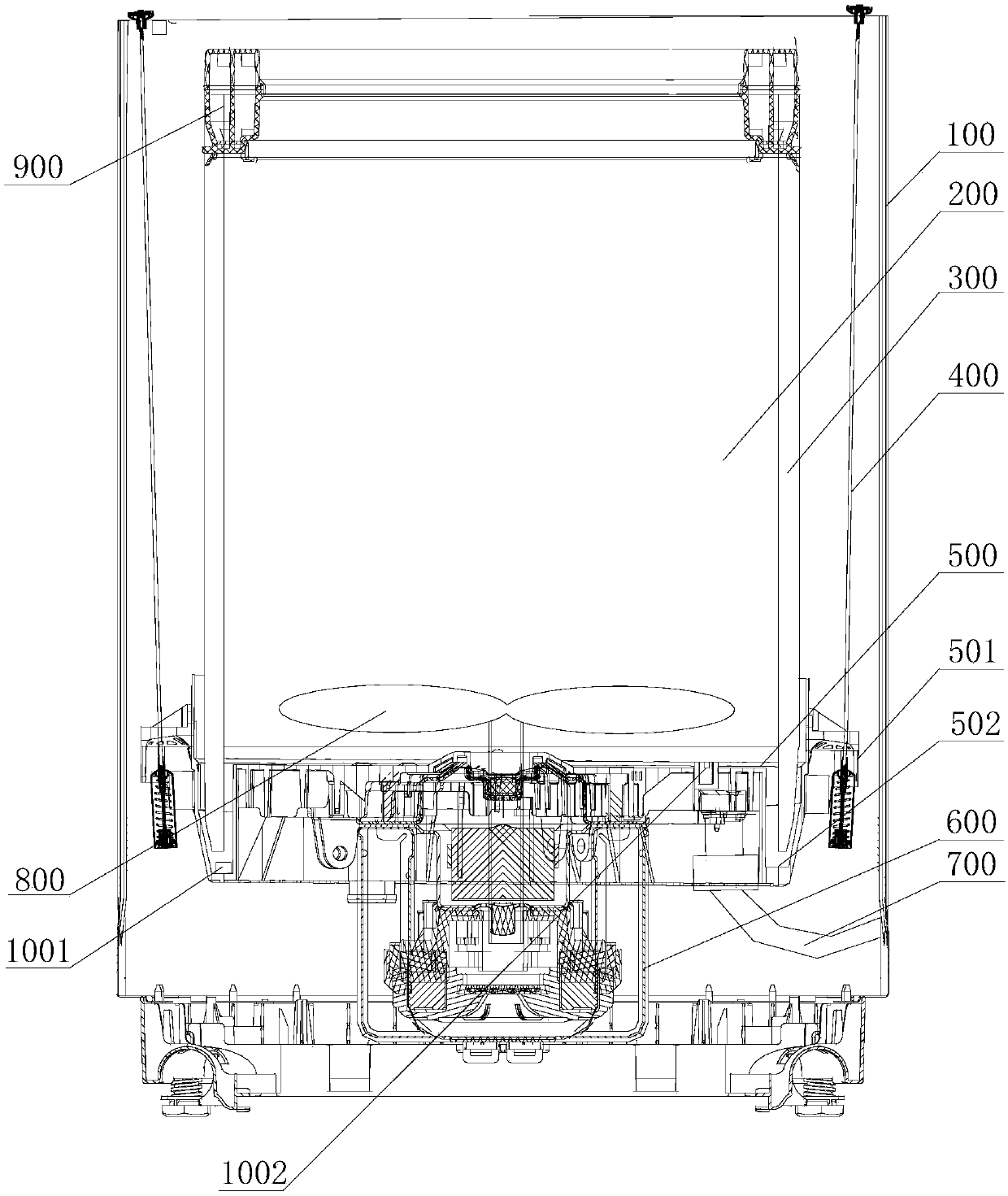

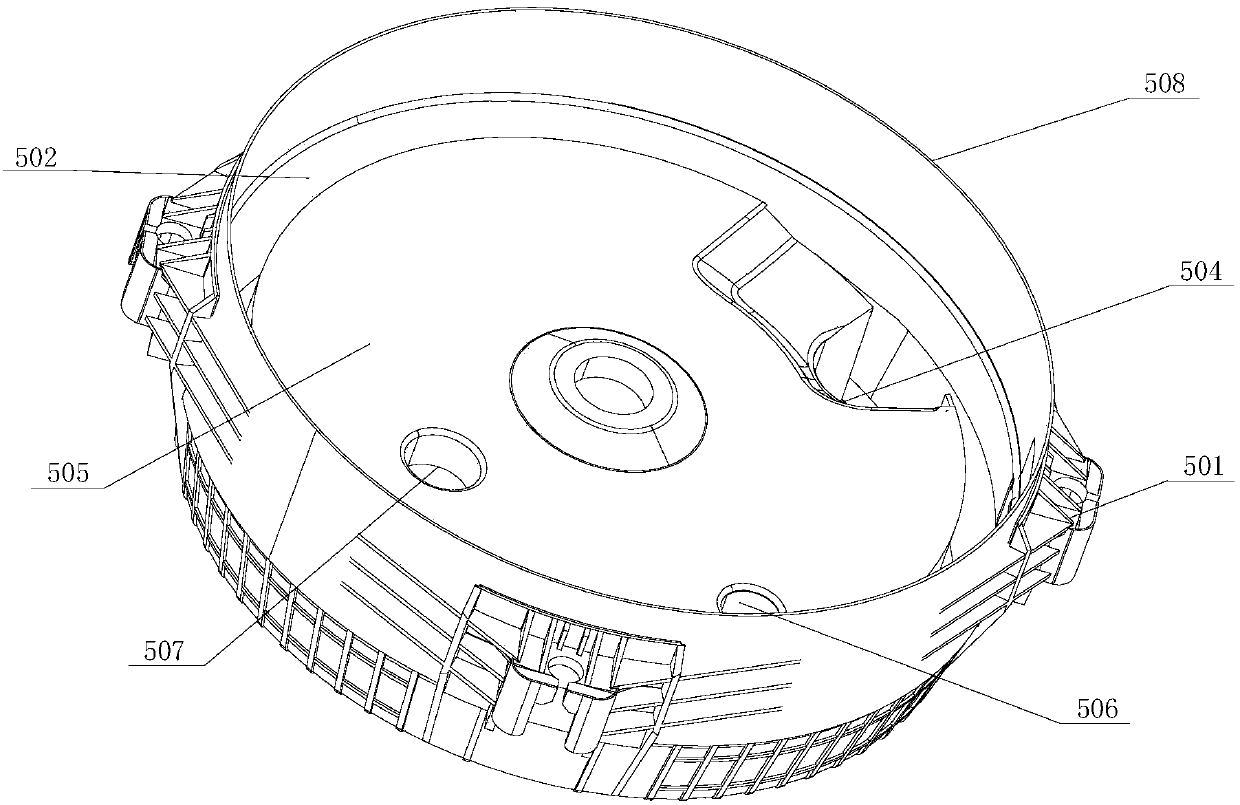

Washing machine and control method thereof

PendingCN113136676AAvoid affecting the washing effectSave washing waterOther washing machinesControl devices for washing apparatusLaundry washing machineReciprocating motion

The invention provides a washing machine and a control method thereof. The washing machine comprises an inner barrel capable of independently containing washing water during washing; a water outlet and a water drainage device are arranged in / at the bottom of the inner barrel; and the water drainage device comprises a plugging assembly which is mounted at the bottom of the inner barrel and can transversely reciprocate to open / close the water outlet and a driving assembly for pulling the plugging assembly to transversely move. The driving assembly of the water drainage device pulls the plugging assembly to transversely move to open the water outlet; compared with a mode that an ejector rod moves up and down to eject a sealing valve plug on the water outlet, the opening mode of the water outlet is more stable, and the problem that the ejector rod deflects in ejection or is jammed at the bottom of the inner barrel is solved; and the washing machine works more stably, and the user experience is better.

Owner:QINGDAO HAIER WASHING MASCH CO LTD +1

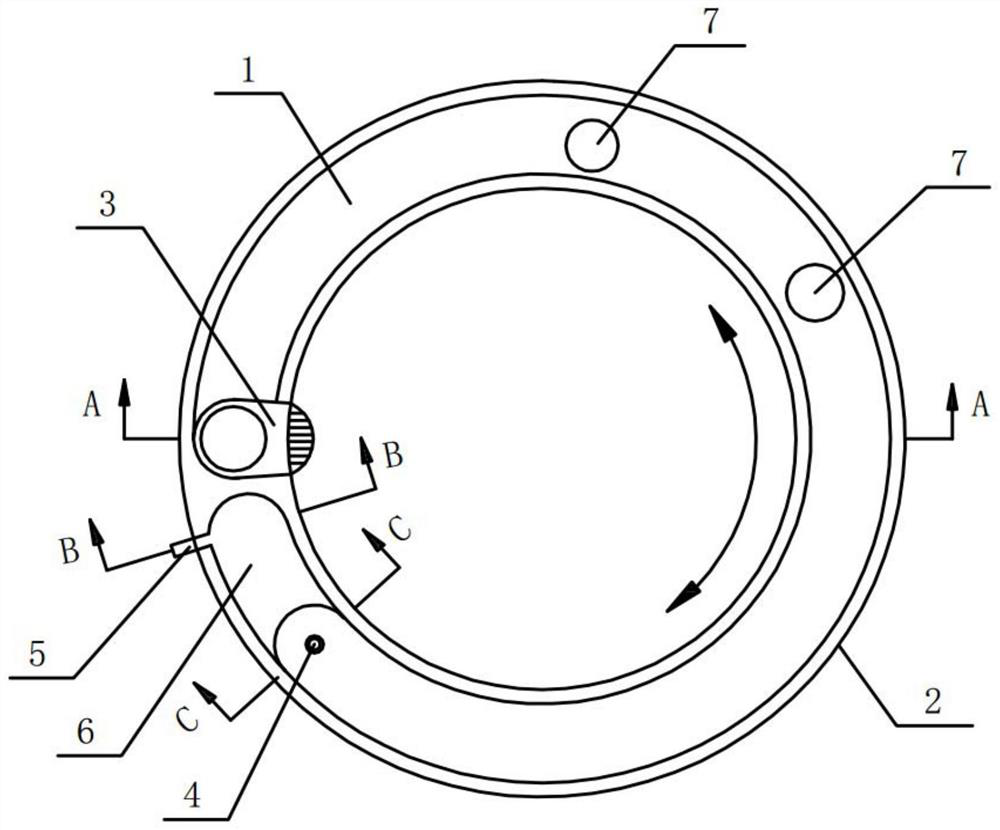

A method and water curtain cabinet for treating spraying exhaust gas

ActiveCN105413362BPrevent affecting the effect of swirling water washingAvoid affecting the washing effectUsing liquid separation agentSeparation devicesInfraredAutomatic control

The invention relates to the paint spraying coating technology field, and especially relates to a method for processing spray exhaust gas and a water curtain cabinet. The method comprises the following steps: exhaust gas suction, water curtain absorption, rotational flow washing, demisting absorption and exhaust gas pumping-out. A paint mist decomposition medicament and a paint mist trapping medicament are added circulating water. Starting and finishing of the water curtain absorption, rotational flow washing, exhaust gas suction and exhaust gas pumping-out steps are controlled through an infrared ray sensing device. The water curtain cabinet employs a water curtain baffle plate and a rotational flow device, paint mist removal effects of a spray cabinet is raised. The water curtain cabinet cooperates with addition of the paint mist decomposition medicament and the paint mist trapping medicament in circulating water, the situation can be prevented effectively that pain mist adheres to the inner walls of the rotational flow device and the water curtain cabinet, and the paint mist in the circulating water flocculates and floats, which facilitates cleaning of paint mist scum. Starting and finishing of the spray exhaust gas treatment operation can be controlled automatically through infrared ray sensing, usage is convenient and the energy saving effects are raised.

Owner:吴永光 +1

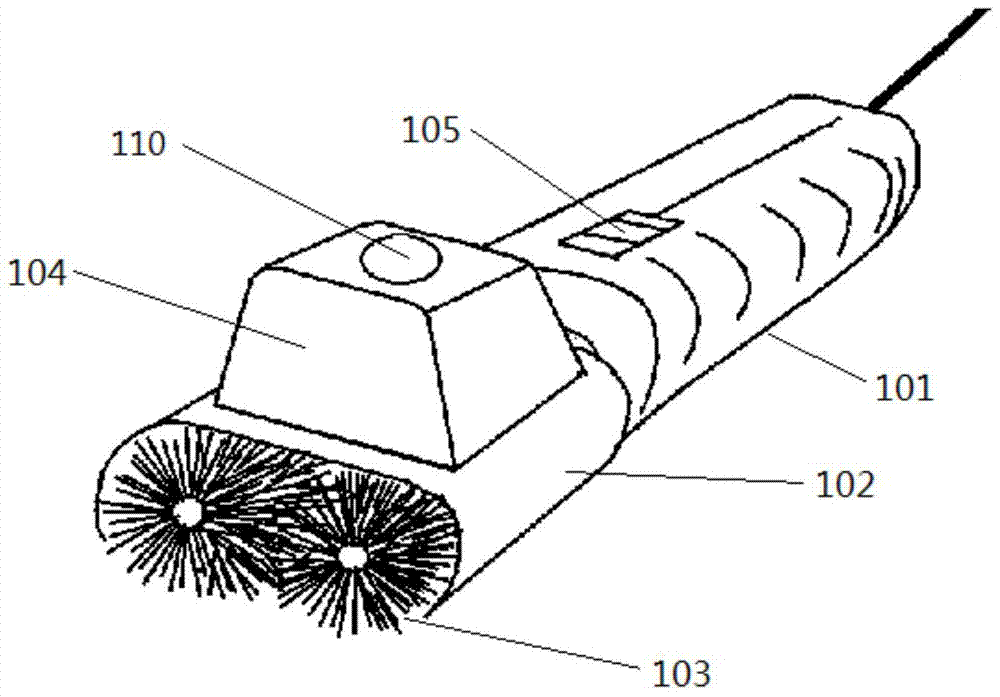

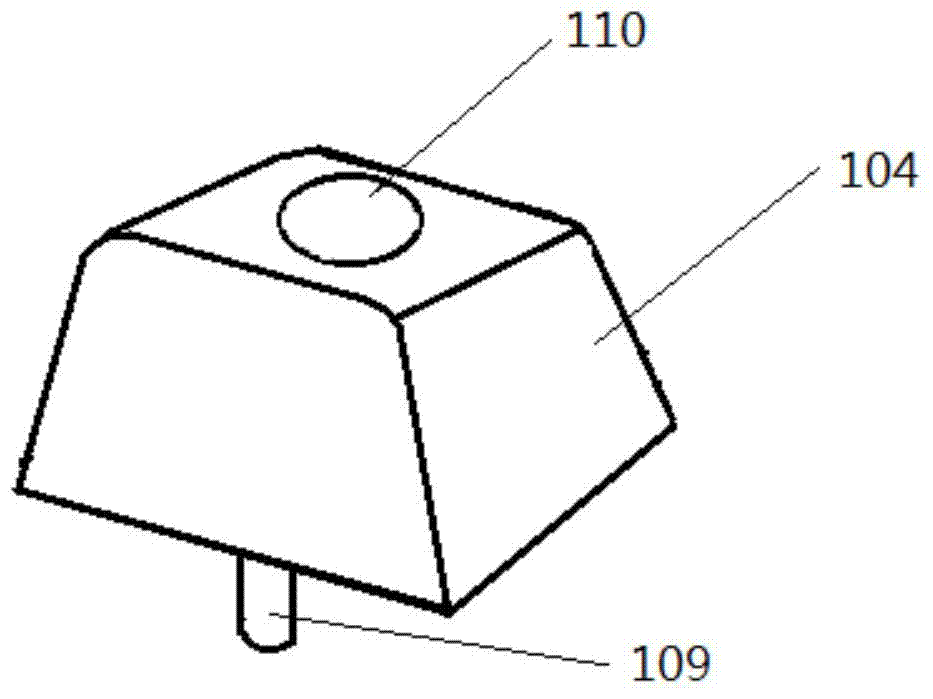

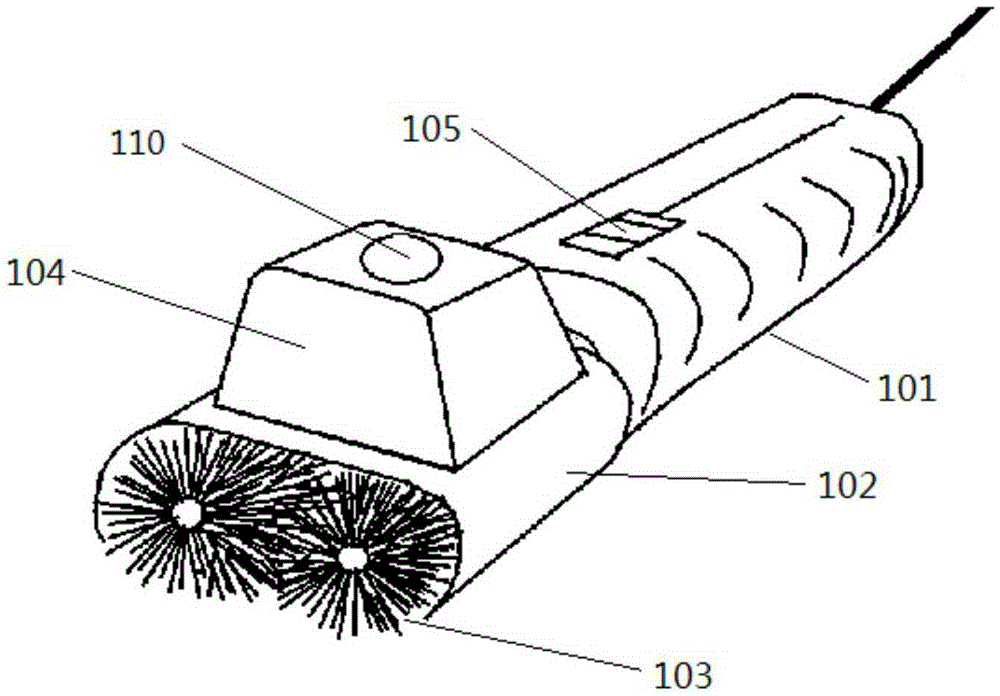

Self-balancing electric brush

ActiveCN105394926BAvoid affecting the washing effectEasy to operateBrush bodiesEngineeringPower apparatus

Owner:梁大君 +1

An improved device and method for removing phenol and desulfurization by ammonia washing method

ActiveCN103523798BIncrease the liquid to gas ratioWash smoothlyAmmonia preparation/separationProcess engineeringEnvironmental engineering

The invention discloses an improved device for removing phenol and desulfurization by washing with ammonia water, which comprises an ammonia gas purification tower, a heat exchanger and a pump. At the top of the ammonia gas purification tower, the liquid ammonia feed pipe is connected to the middle or lower part of the ammonia gas purification tower, the top of the ammonia gas purification tower is connected to the follow-up device, and the bottom of the tower is connected to the lower circulation return port of the ammonia gas purification tower and the raw material through the pump. The pipeline connected to the water tank, the side line in the middle of the ammonia purification tower passes through the pump and connects to the upper circulation return port of the ammonia purification tower; The overflow port of the flow pipe is connected to the upper part of the lower packing. It also discloses a method for using the device to remove phenol and desulfurize by washing with ammonia water. The invention can effectively ensure the stability of the liquid level in the ammonia water collection area in the middle of the tower, and effectively remove impurities such as phenols, H2S, and organic sulfur in the recovered ammonia, so that the purity of the ammonia is greatly improved.

Owner:QINGDAO UNIV OF SCI & TECH

Self-balancing electric brush

ActiveCN105394926AAvoid affecting the washing effectEasy to operateBrush bodiesMechanical engineering

The invention provides a self-balancing electric brush. The self-balancing electric brush comprises a handle, a power device and at least one brush head group, wherein the power device is arranged in the handle, an output shaft of the power device is connected with the at least one brush head group, and the at least one brush head group comprises a first brush head and second brush head with different rotation directions during work. When the electric brush with the structure is used, the at least one brush head group contacts the objects needing to be brushed and washed, such as clothes, shoes and cars, and generates two drawing forces having different directions on the surfaces of the objects; if the self-balancing electric brush is used for washing clothes, the phenomenon that the clothes shrink to form a ball due to sliding so that the washing effect is affected is effectively avoided. When the self-balancing electric brush is used for washing objects, the handle is subjected to two counter-acting forces from the objects, and the two counter-acting forces counteract mutually due to different directions, so that the brush heads are kept balanced, and are easy to operate and control.

Owner:梁大君 +1

A water-washing process of drenching and rolling loose fibers

ActiveCN103774362BAchieve cleaningNo overlappingLiquid/gas/vapor removal by squeezing rollersTextile treatment machine arrangementsFiberMaterials science

The invention relates to a spray-rolling type loose fiber washing process, and belongs to the technical field of loose fiber dyeing. Dyed loose fibers are conveyed to a spray-rolling type washing device, while the loose fibers are horizontally clamped by a guide belt to be conveyed, a plurality of groups of spray-rolling type washing with alternative squeezing and spraying is carried out on the loose fibers, and the loose fibers are washed, rolled to be dry, and output. The spray-rolling type loose fiber washing process has the advantages that dyeing is even, water consumption is small, and the working procedure is simple.

Owner:SHAOXING JINYU TEXITLE NEW TECH CO LTD

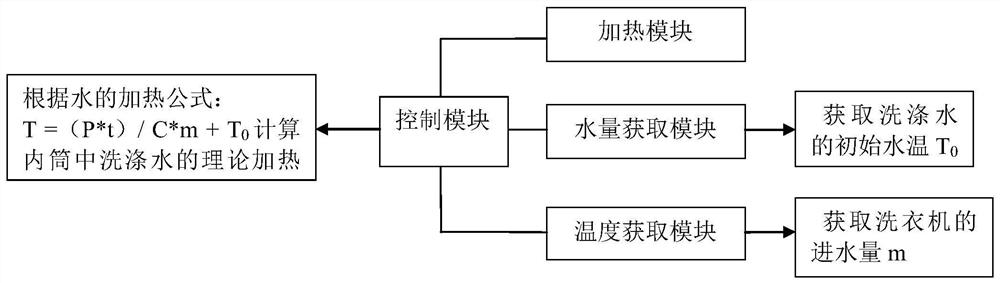

Washing machine

PendingCN114164615AGuaranteed washing effectSimple structureOther washing machinesTextiles and paperProcess engineeringMechanical engineering

The present invention discloses a washing machine, comprising: an inner tub independently containing washing water when washing clothes; the non-contact heating module is used for heating the washing water in the inner drum in a non-contact manner; the water volume acquisition module acquires the water inflow of the washing machine; the temperature acquisition module is used for acquiring the initial water temperature of the washing water; and the control module is used for calculating the heating temperature of the washing water in the inner barrel according to the power of the non-contact heating module and the obtained initial water temperature, water inflow and heating time. According to the washing machine, the problem that a temperature detection device cannot be installed in the inner barrel of the washing machine with the hole-free inner barrel to detect the temperature in the washing water heating process is solved, and in the heating process, the real-time heating temperature of the washing water in the inner barrel is calculated through a water heating formula; therefore, the heating process of the washing water is controlled to reach the set target heating temperature, the washing effect is guaranteed, and the structure of the washing machine is simplified.

Owner:QINGDAO HAIER DRUM WASHING MACHINE +1

A process and equipment for recovering organic silicon monomer and dust in exhaust gas

ActiveCN105999891BReduce consumptionAvoid cloggingDispersed particle filtrationSilicon compoundsEngineeringCopper

The invention relates to a process and equipment for recycling organic silicone monomers and dust in vented tail gas. A filter top tail gas outlet in the equipment is connected with a special filter inlet, a special filter top tail gas outlet is connected with a tail gas condenser inlet, a tail gas condenser condensate outlet is connected with a condensate recycling groove inlet, and a condensate recycling groove bottom outlet is connected with a crude monomer middle groove top inlet. The equipment is adopted for recycling organic silicone monomers and dust in vented tail gas, solid phases (silica powder, copper powder and the like) and vapor phases (monomers) in tail gas generated in the organic silicon monomer production process are recycled in a classified mode, the phenomenon that remaining dust blocks a condenser is avoided, the phenomenon that monomers enter a water scrubber to form acid mist, the fine powder recycling rate is increased from about 80% in the existing process to 99.9% or above, the organic silicon monomers in tail gas is recycled by 99% or above instead of total evacuation in the prior art, and environmental pollution is avoided while the raw material utilization rate is improved.

Owner:HUBEI XINGFA CHEM GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com