Washing machine

A washing machine and washing water technology, which is applied in other washing machines, washing devices, textiles and papermaking, etc., can solve the problems of detection, inability to install the heating temperature of washing water, etc., to simplify the structure, simplify the structure and control procedures, and improve the washing efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

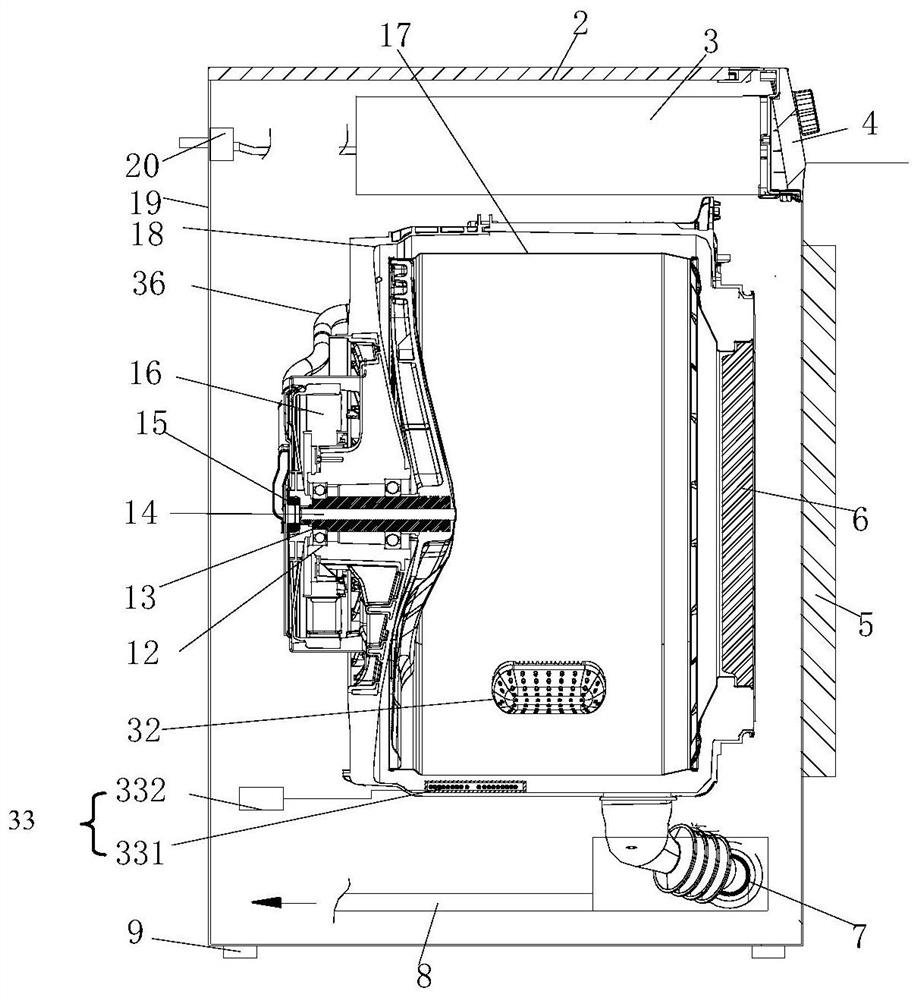

[0064] Such as Figure 1 to Figure 5 As shown, this embodiment provides a washing machine in which the heating temperature of the washing water can be obtained through calculation without detection by a temperature detection device during the heating program of the washing machine.

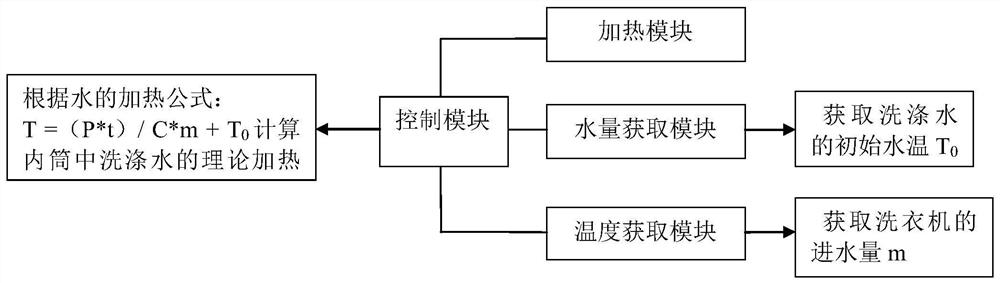

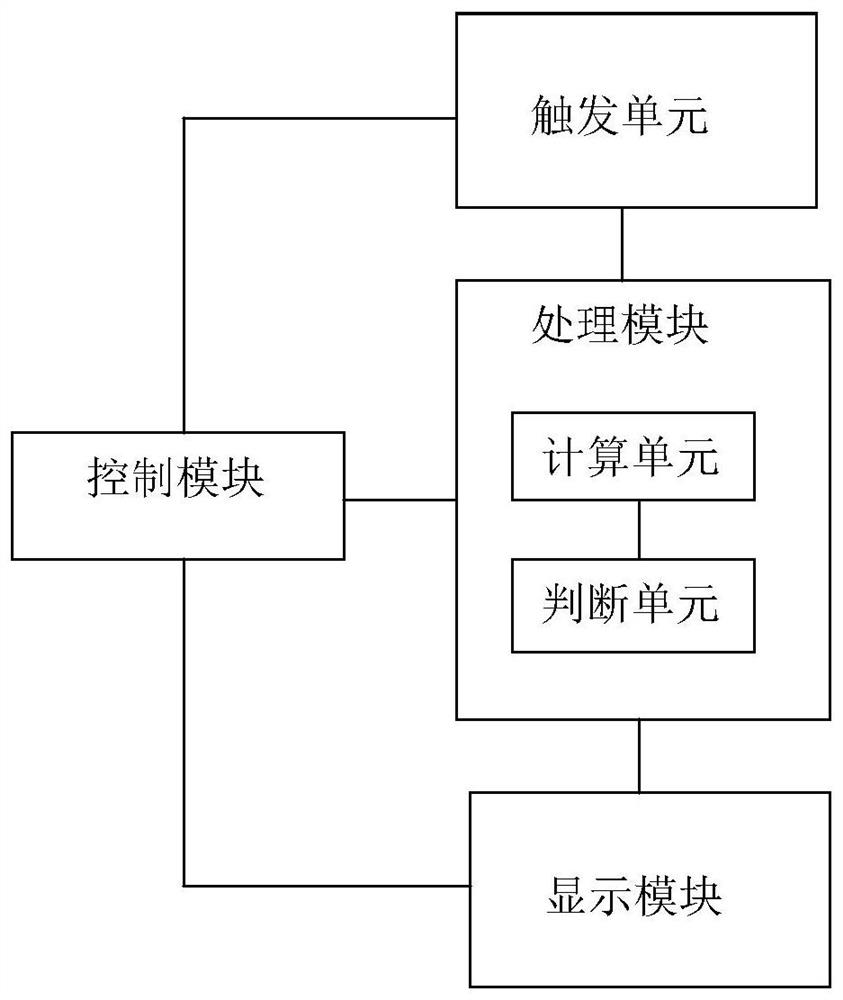

[0065] Specifically, such as Figure 1-Figure 4 As shown, the washing machine includes: an inner cylinder 17, which holds washing water independently when washing clothes, avoiding the accumulation of dirt outside the inner cylinder 17 and the problems of excessive washing water and bacterial growth; a non-contact heating module, Non-contact heating of the washing water in the inner cylinder; the water quantity acquisition module, which acquires the water intake of the washing machine; the temperature acquisition module, which acquires the initial water temperature of the washing water; the control module, which is based on the power of the non-contact heating module and the acquired initial water...

Embodiment 2

[0121] This embodiment is mainly about how to obtain the initial water temperature T through the detection of the temperature detection device in the first embodiment. 0 Describe in detail.

[0122] see image 3As shown, the present embodiment provides a washing machine, comprising: an inner cylinder 17, which independently holds washing water when washing clothes; a water inlet system, which communicates with the inner cylinder 17; a temperature detection device (in the figure not shown), set in the water inlet system to detect the inlet water temperature. The temperature of the water inlet can be detected in real time by the temperature detection device provided in the water inlet system, so as to ensure that the control system of the washing machine controls the water temperature in the inner tub 17 to achieve a better washing effect.

[0123] In the above solution, the washing machine also includes a flow detection device (not shown in the figure) installed in the water ...

Embodiment 3

[0131] This embodiment introduces the structure and working principle of the electromagnetic heating device 33 in the first embodiment in detail.

[0132] combine image 3 , Figure 4 The washing machine includes an outer cylinder 18 coaxially sleeved outside the inner cylinder 17, and the electromagnetic heating device 33 is arranged on the outer cylinder 18 to heat the inside of the outer cylinder 18 and transfer the heating heat To the washing water contained in the inner cylinder 17.

[0133] By arranging the above-mentioned electromagnetic heating device 33 on the outer cylinder 18, the inner cylinder 17 inside the outer cylinder 18 and the washing water inside the inner cylinder 17 are heated by electromagnetic force, so as to achieve the purpose of adjusting the temperature of the washing water in the inner cylinder 17 of the washing machine. .

[0134] In this embodiment, at least a part of the inner cylinder 17 is made of metal material, so as to generate heat due ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com