Circulating washing tower

A technology of circulating washing and circulating pump, which is used in the separation of dispersed particles, chemical instruments and methods, and the use of liquid separators, etc., and can solve problems such as inability to remove pollutants.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

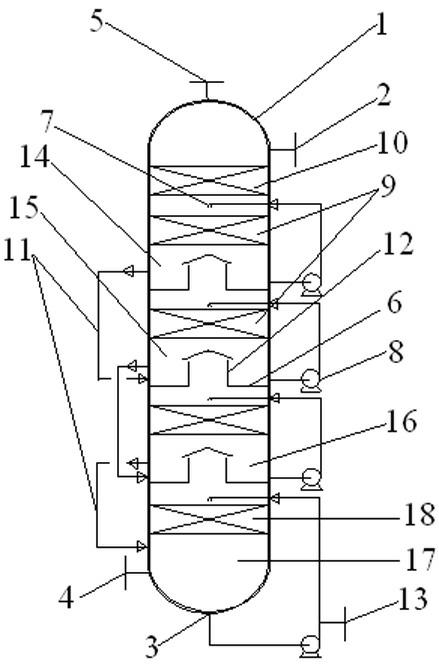

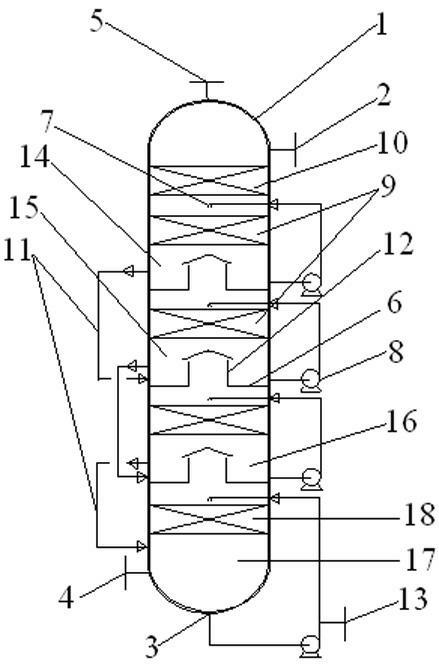

[0033] The structure of the circulation washing tower of the present invention is as figure 1 As shown, it includes a tower body 1, the lower part of the tower body 1 is provided with a gas inlet 4, the top of the tower body 1 is provided with a gas outlet 5, the upper part of the tower body 1 is provided with a liquid inlet 2, and the bottom of the tower body 1 A liquid outlet 3 is provided; N-level trays 6, N greater than or equal to 2, the trays 6 are connected to the inner wall of the tower body 1 to separate the tower body 1 into different gas-liquid exchange spaces in the axial direction, And the tray 6 of each stage and the gas-liquid exchange space to which it belongs constitute a gas-liquid exchange unit, so that the first stage, the second stage, ..., the Nth stage are sequentially formed from the upper end to the lower end of the tower body 1 Level gas-liquid exchange unit; in each of the gas-liquid exchange units, and located above the tray 6, a liquid spray head 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com