Detergent powder dissolving structure and washing machine

A technology for washing powder and washing machine, applied in the field of washing machines, can solve the problem that the washing powder cannot be fully dissolved, and achieve the effect of avoiding waste and improving the washing ratio.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

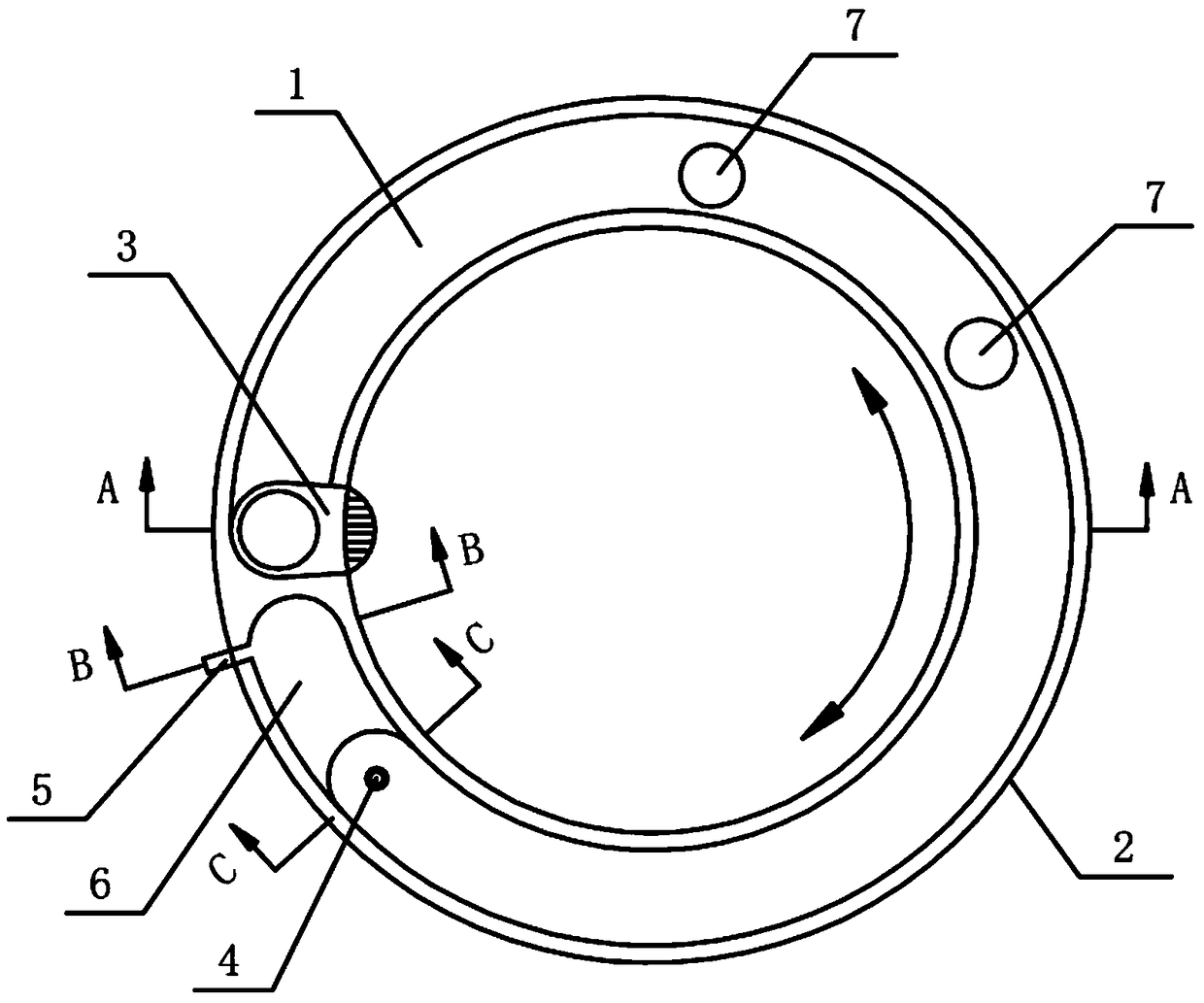

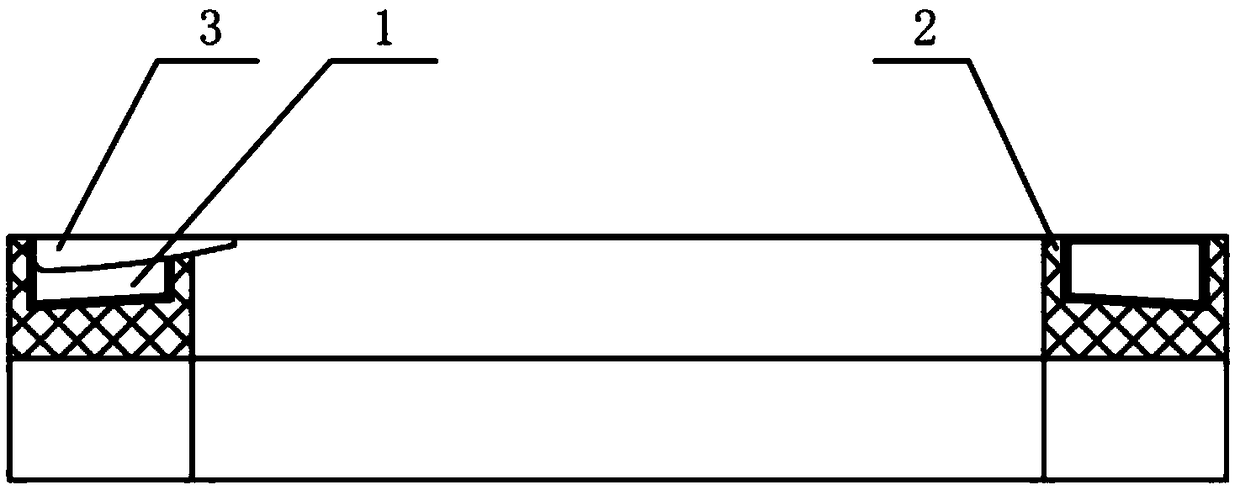

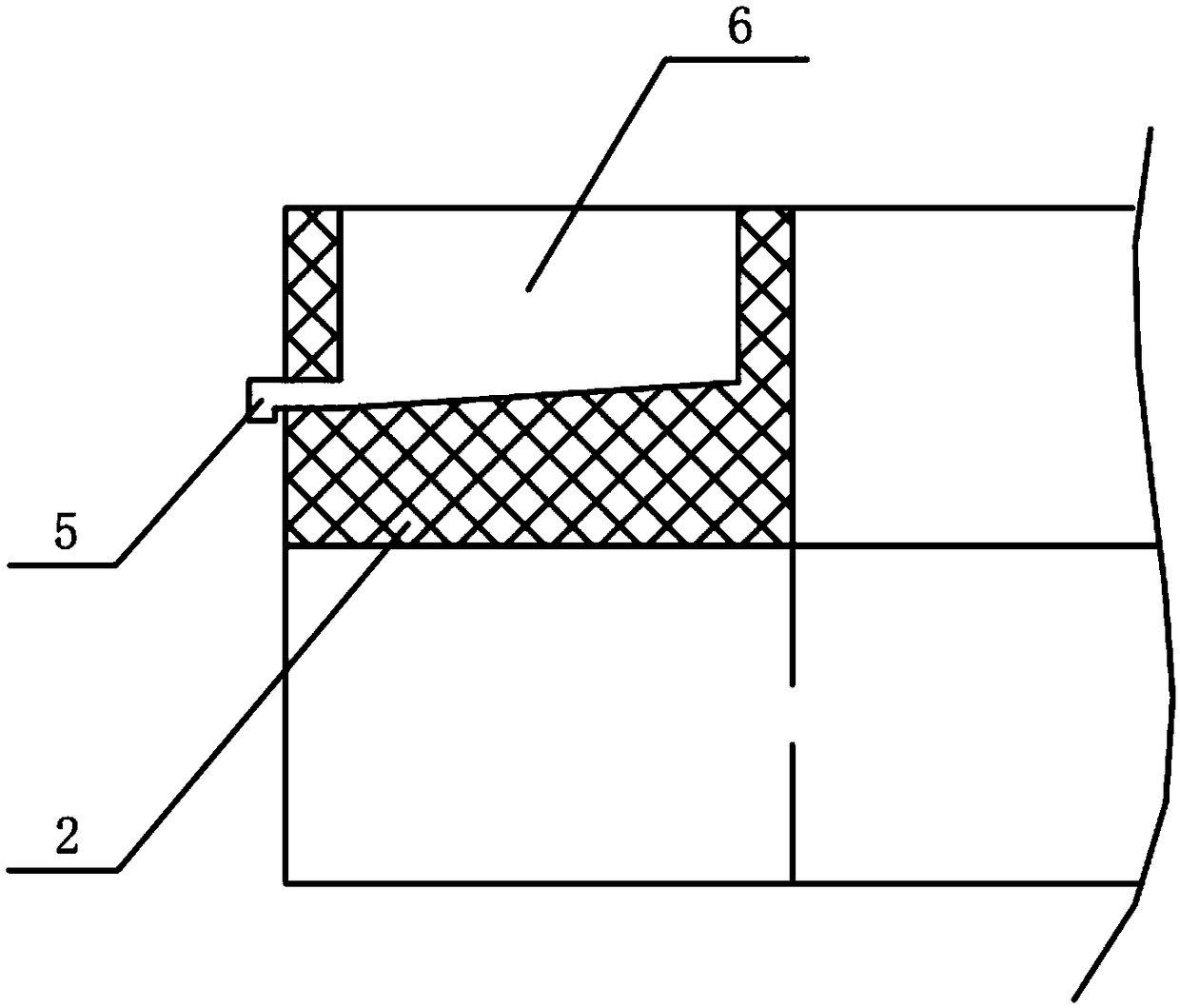

[0027] This embodiment provides a washing powder dissolving structure, such as figure 1 As shown, the washing powder dissolving structure includes a balance ring 2 with a cavity 1 inside. Specifically, the cavity 1 is arranged along the inner circumference of the balance ring 2 . An input port 3 is provided at one end of the cavity 1, and the input port 3 is used for inputting washing powder and washing water. The other end of above-mentioned cavity 1 is provided with siphon structure 4 ( Figure 4 shown), the outlet of the siphon structure 4 is communicated with the inner tub of the washing machine.

[0028] Through the above structure, when doing laundry, first put washing powder into the cavity 1 through the input port 3, since the balance ring 2 will reciprocate with the inner tub, so that the washing powder is evenly distributed in the cavity during the reciprocating rotation of the balance ring 2 1, and then inject washing water through the input port 3. During the rec...

Embodiment 2

[0040] The difference between this embodiment and Embodiment 1 is that there are multiple cavities 1 in this embodiment, and correspondingly, there are multiple input ports 3 , siphon structures 4 , output ports 5 and grooves 6 . Specifically, such as Figure 5 As shown, the washing powder dissolving structure of this embodiment includes a plurality of cavities 1 , an inlet 3 , a siphon structure 4 , an outlet 5 and a groove 6 , and the cavities 1 are circumferentially distributed in the balance ring 2 . The structures and installation positions of the input port 3, the siphon structure 4, the input port 5, and the slot 6 are the same as those described in the first embodiment, and will not be repeated here.

[0041] In this embodiment, by setting a plurality of cavities 1, when washing powder is put in, one or more cavities 1 can be selectively dropped, on the one hand, the dissolving of the required amount of washing powder can be accelerated through multiple cavities 1, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com