An improved device and method for removing phenol and desulfurization by ammonia washing method

A technology for washing and dephenolizing with ammonia water, which is applied in the preparation/separation of ammonia, etc. It can solve the problems of deterioration of washing effect, unstable liquid level, and fluctuation of washing liquid volume, so as to improve the treatment effect, reduce the overall energy consumption, and meet the quality requirements. required effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

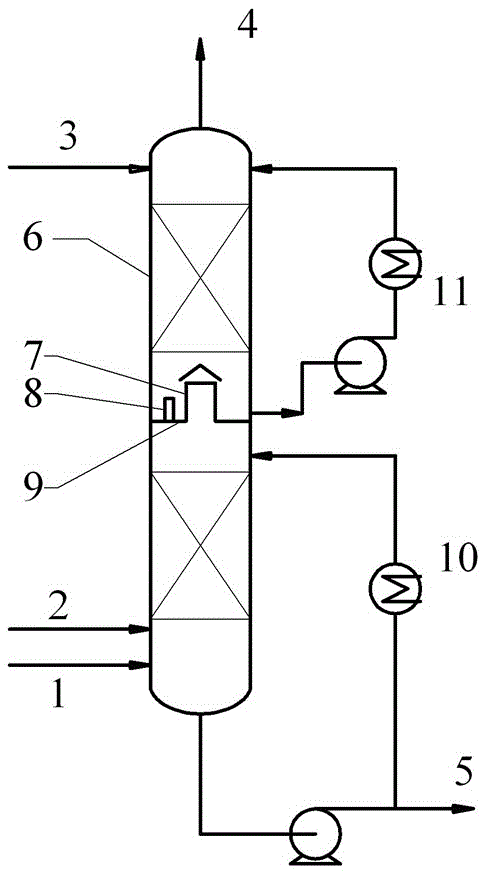

[0033] The flow rate is 1800kg / h and the phenol content is 4000mg / m 3 、H 2 Crude ammonia gas with 0.2% S content figure 1 The device shown is processed. The upper and lower sections of the ammonia gas purification tower are structured packing, the theoretical stages are both 10, the liquid-gas mass ratio of the upper section is 12, and the liquid-gas mass ratio of the lower section is 14. The cooling temperature of the circulating ammonia water is controlled to be 30°C, so that the top temperature of the ammonia purification tower is -2°C.

[0034] Treatment result: when the treated ammonia gas is diluted into dilute ammonia water, the phenol content is less than 48mg / L, H 2 The S content is less than 12mg / L, which can meet the desulfurization requirements.

Embodiment 2

[0036] The flow rate is 1500kg / h and the phenol content is 3000mg / m 3 、H 2 Crude ammonia gas with 0.2% S content figure 1 The device shown is processed. The upper and lower sections of the ammonia gas purification tower are structured packing, the theoretical stages are 18 and 16 respectively, the liquid-gas mass ratio of the upper section is 25, and the liquid-gas mass ratio of the lower section is 18. The cooling temperature of the circulating ammonia water is controlled to be 15° C., so that the temperature of the top of the ammonia purification tower is 0° C.

[0037]Treatment result: the treated ammonia gas is absorbed into dilute ammonia water, and the phenol content is less than 20mg / L, H 2 The S content is less than 10mg / L, which can meet the desulfurization requirements.

Embodiment 3

[0039] The flow rate is 3000kg / h and the phenol content is 3500mg / m 3 、H 2 Crude ammonia gas with 1% S content is attached figure 1 The device shown is processed.

[0040] The upper and lower sections of the ammonia gas purification tower are structured packing, the theoretical stages are 16 and 14 respectively, the liquid-gas mass ratio of the upper section is 20, and the liquid-gas mass ratio of the lower section is 15. The cooling temperature of the circulating ammonia water is controlled to be 35°C, and the top temperature of the ammonia gas purification tower is 40°C.

[0041] Treatment result: the treated ammonia gas is absorbed into dilute ammonia water, and the phenol content is less than 18mg / L, H 2 The S content is less than 13mg / L, which can meet the desulfurization requirements.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com