A kind of absorbent for recovering toluene in industrial waste gas and its application

A technology of industrial waste gas and absorbent, applied in gas treatment, separation method, separation of dispersed particles, etc., can solve the problems of easy volatilization, low solubility, increased loss of NMP, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

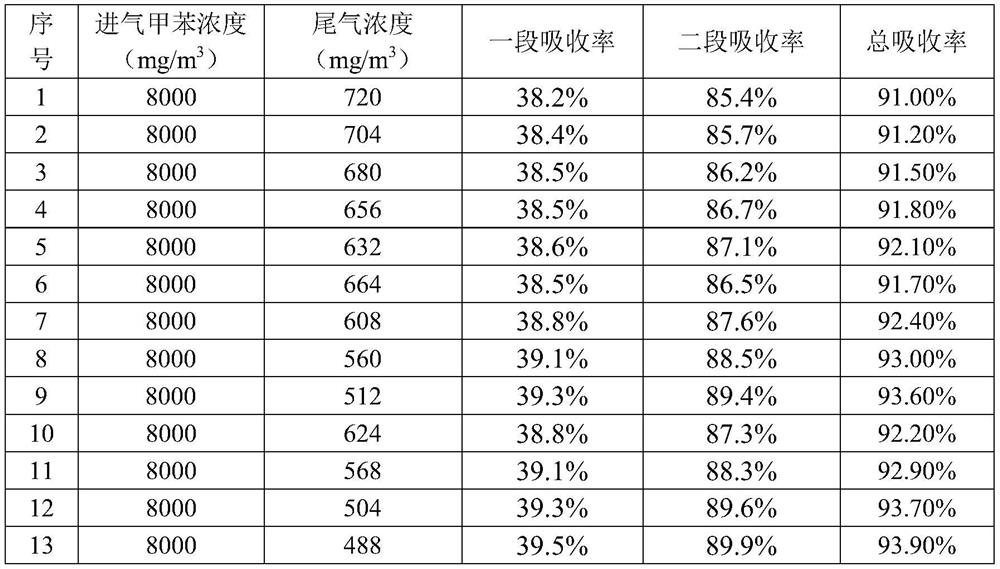

[0031] The waste gas to be treated in the present invention comes from the tail gas of aromatics production, containing 6-10g / m 3 Toluene and some water vapour. Since the toluene exhaust gas with the same composition as the actual factory cannot be obtained under the existing experimental conditions, it is necessary to simulate the toluene exhaust gas used in the experiment, and the toluene content in the simulated exhaust gas is about 8000mg / m 3 , the water vapor content is about 2.0%.

[0032] The moisture content is measured with a Karl Fischer method trace moisture analyzer, and the GC9800 gas chromatograph is used to detect the concentration of toluene in the intake air and exhaust gas. The measured peak area reflects the measured toluene content through the toluene standard curve, and then calculates the toluene content. Absorption rate, and the content of toluene in the solution before and after desorption by gas chromatography.

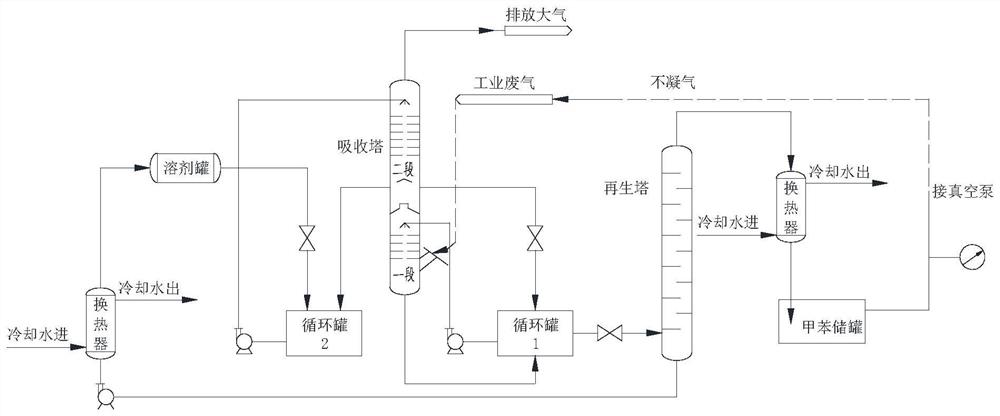

[0033] Process equipment: such as F...

Embodiment 2

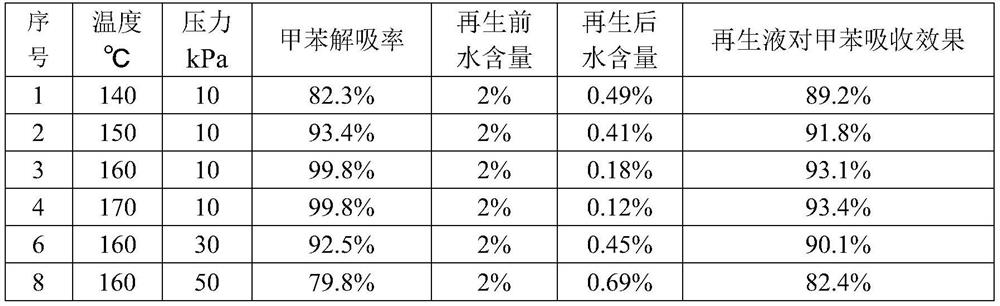

[0042] 80wt% NHD and 20wt% sulfolane are used to make absorbent to absorb toluene in waste gas. The produced rich absorption liquid containing toluene flows out from the outlet of the lower section of the absorption tower, enters the circulation tank 1, and then flows into the regeneration tower from the feed inlet of the lower section of the regeneration tower by the circulation tank 1 (the operating temperature of the regeneration tower is 140-170°C, The operating pressure is 10-50kPa) for vacuum distillation, and the regenerated lean liquid (toluene content is less than 0.5‰, and water content is less than 0.5%) flows out from the outlet of the lower section of the regeneration tower, and passes through the condenser (the cooling medium is cooling water ) is cooled to 18-20°C, stored in the solvent tank, and regularly flows into the circulation tank 2. The results are shown in Table 3

[0043] Table 3 Repeated absorption effect

[0044]

[0045] It can be seen from Tab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com