Electromagnetic type jigging machine

A jigger and electromagnetic technology, which is applied in solid separation, wet separation, chemical instruments and methods, etc., can solve the problems of field workers' auditory system damage, jig vibration, short service life, etc., and achieve noise reduction. Small, small vibration, and the effect of reducing the damage of the auditory system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

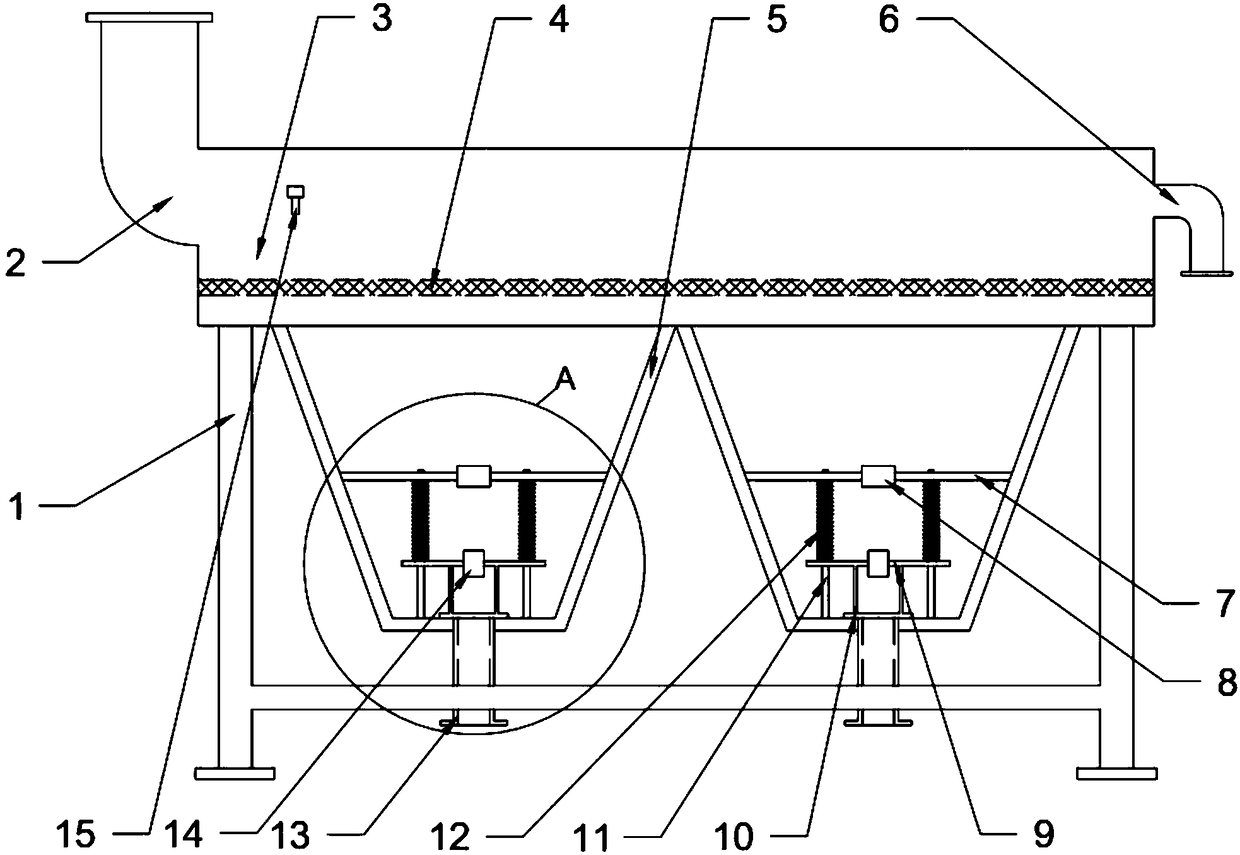

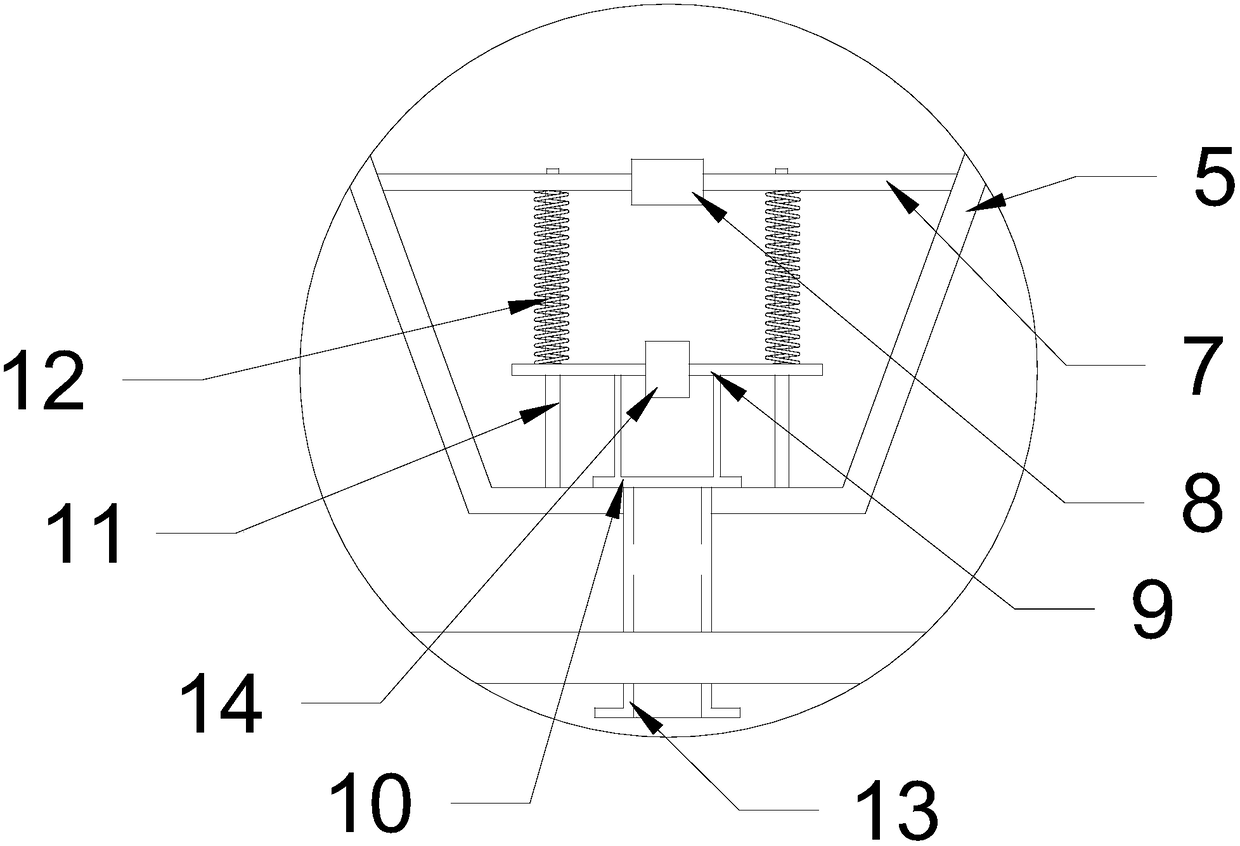

[0028] see figure 1 , an electromagnetic jig, comprising a frame 1, a slot 3 is installed above the frame 1, a feeding pipe 2 is installed at one end of the slot 3, and a discharge port 6 is installed at the other end, the bottom of the slot 3 is connected to the two A cone bucket 5 is connected, and a bracket 7 is installed inside the cone bucket 5, an electromagnet 8 is installed on the bracket 7, a slide bar 11 is connected with the bottom of the cone bucket 5 downward on the bracket 7, and a shock plate 9 is arranged below the bracket 7, and the shock plate 9 is provided with a positioning hole through which the slide bar 11 passes, and the inner wall surface of the positioning hole is attached to the outer wall surface of the slide bar 11 , and a magnet 14 is installed on the shock plate 9 .

[0029] In this example, the raw coal is crushed and sieved and mixed with water, and flows into the passage 3 on the frame 1 through the feed pipe 2, and the electromagnet 8 in the ...

Embodiment 2

[0031] see figure 1 , an electromagnetic jig, comprising a frame 1, a slot 3 is installed above the frame 1, a feeding pipe 2 is installed at one end of the slot 3, and a discharge port 6 is installed at the other end, the bottom of the slot 3 is connected to the two A cone bucket 5 is connected, and a bracket 7 is installed inside the cone bucket 5, an electromagnet 8 is installed on the bracket 7, a slide bar 11 is connected with the bottom of the cone bucket 5 downward on the bracket 7, and a shock plate 9 is arranged below the bracket 7, and the shock plate 9 is provided with a positioning hole through which the slide bar 11 passes, and the inner wall surface of the positioning hole is attached to the outer wall surface of the slide bar 11 , and a magnet 14 is installed on the shock plate 9 .

[0032] There is a row of ore openings at the bottom of the cone bucket 5, and an ore discharge pipe 13 is connected to the bottom of the ore discharge opening. The denser mineral pa...

Embodiment 3

[0034] see figure 1 , an electromagnetic jig, comprising a frame 1, a slot 3 is installed above the frame 1, a feeding pipe 2 is installed at one end of the slot 3, and a discharge port 6 is installed at the other end, the bottom of the slot 3 is connected to the two A cone bucket 5 is connected, and a bracket 7 is installed inside the cone bucket 5, an electromagnet 8 is installed on the bracket 7, a slide bar 11 is connected with the bottom of the cone bucket 5 downward on the bracket 7, and a shock plate 9 is arranged below the bracket 7, and the shock plate 9 is provided with a positioning hole through which the slide bar 11 passes, and the inner wall surface of the positioning hole is attached to the outer wall surface of the slide bar 11 , and a magnet 14 is installed on the shock plate 9 .

[0035] Oscillating plate 9 is downwardly connected with ore discharge baffle 10, and ore discharge baffle 10 can block the ore discharge outlet, reduce the amount of replenishing wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com