Washing machine and control method thereof

A washing machine and flange technology, applied in the field of washing machine and its control, can solve the problems that affect the normal washing and experience of users, the ejector rod is easy to deflect, and the bottom of the inner barrel is stuck, so as to achieve stable opening mode, avoid accumulation of dirt, and save energy. The effect of washing water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

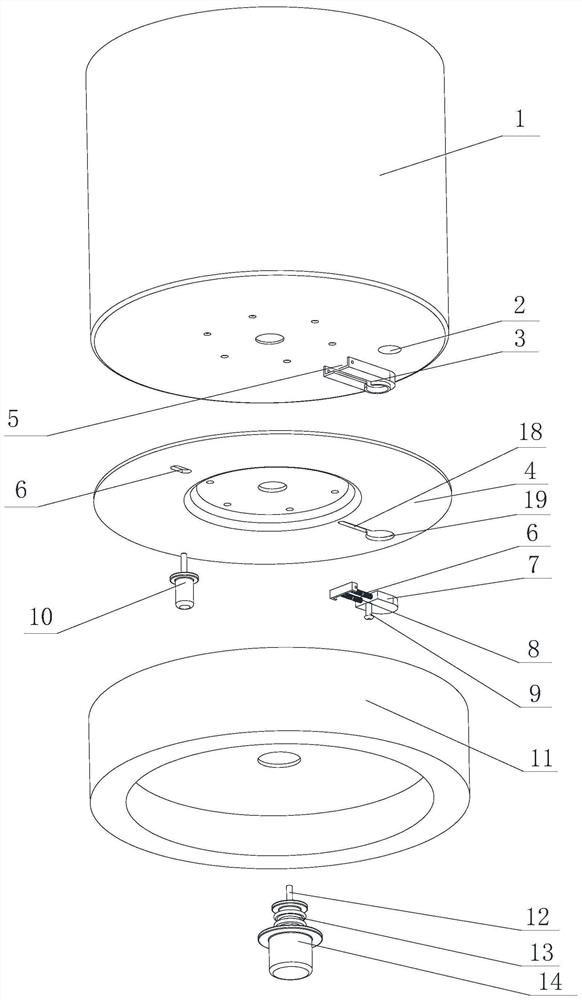

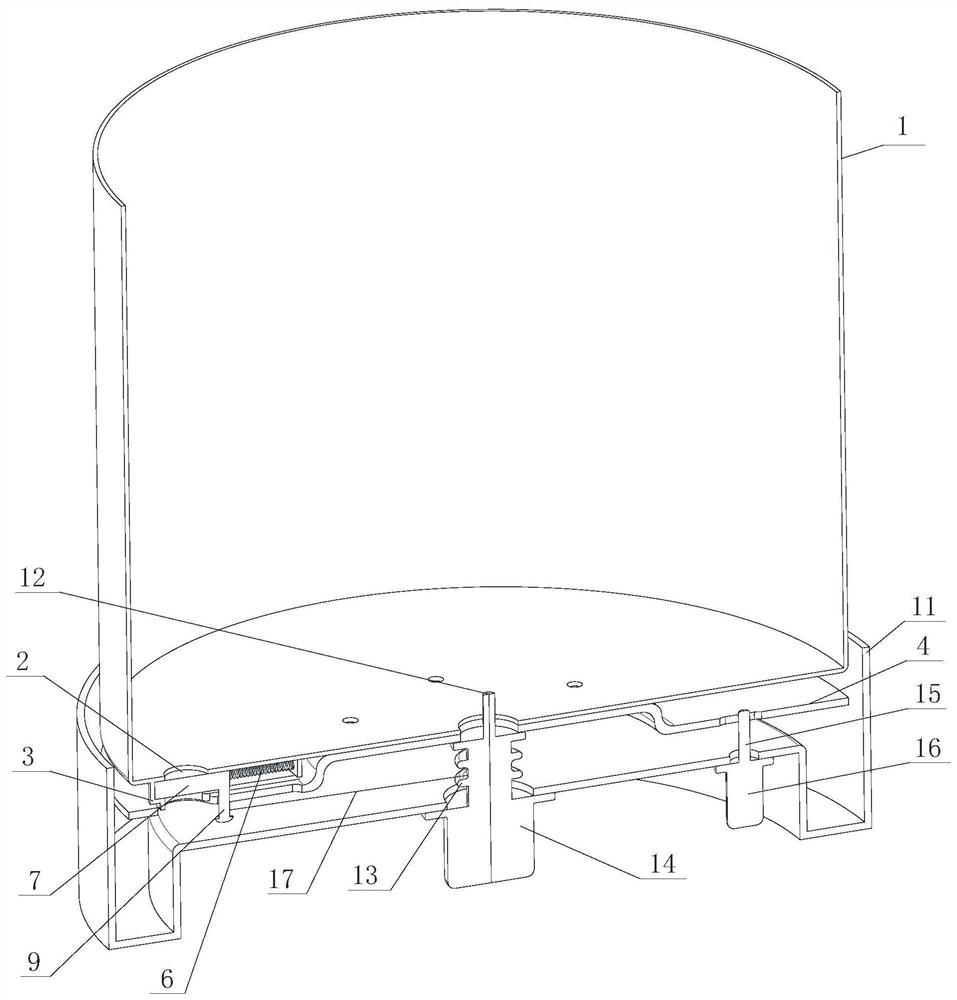

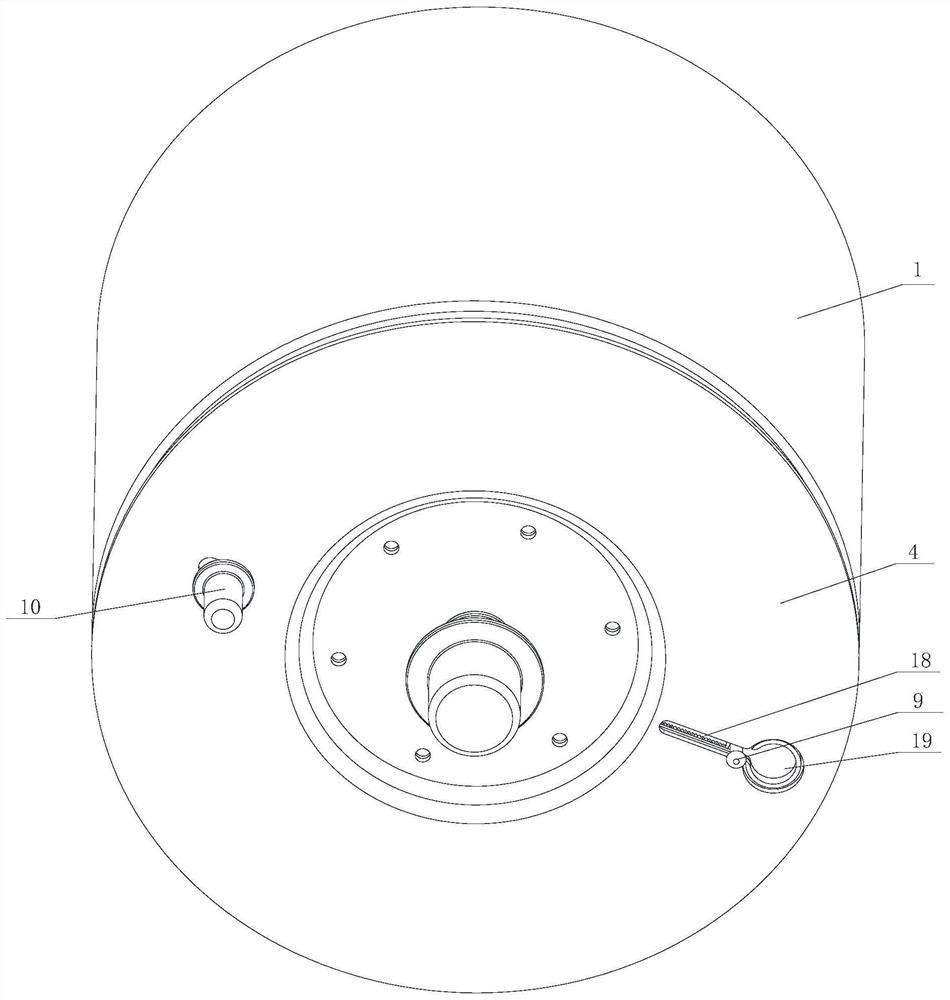

[0033] A washing machine and control method thereof and its control method thereof will be described in detail below with reference to the accompanying drawings:

[0034] Such as Figure 1-5 As shown, a washing machine of the present embodiment, including laundry, can be used independently in the inner bucket of washing water; the bottom of the inner tub 1 is provided with a drain opening 2 and a drainage, the drainage device including the bottom of the inner bucket. Transversely reciprocating the blocking assembly of the drainage opening and pulling the sealing assembly lateral motion.

[0035] When the washing machine of the present embodiment, the inner barrel 1 is separately placed in the laundry, and the washing water does not exist between the inner bucket and the outer tap relative to the traditional automatic washing machine, not only avoiding the outer wall of the inner bucket but outside. Dirty accumulation caused by the inner wall of the bucket affects the washing effect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com