A process and equipment for recovering organic silicon monomer and dust in exhaust gas

A technology of organosilicon and tail gas, applied in the direction of silicon compounds, inorganic chemistry, separation methods, etc., can solve the problems of increasing consumption of silicon powder, not conducive to saving production costs, waste of raw materials, etc., achieve significant economic and social benefits, and improve raw materials Utilization rate, effect of avoiding environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

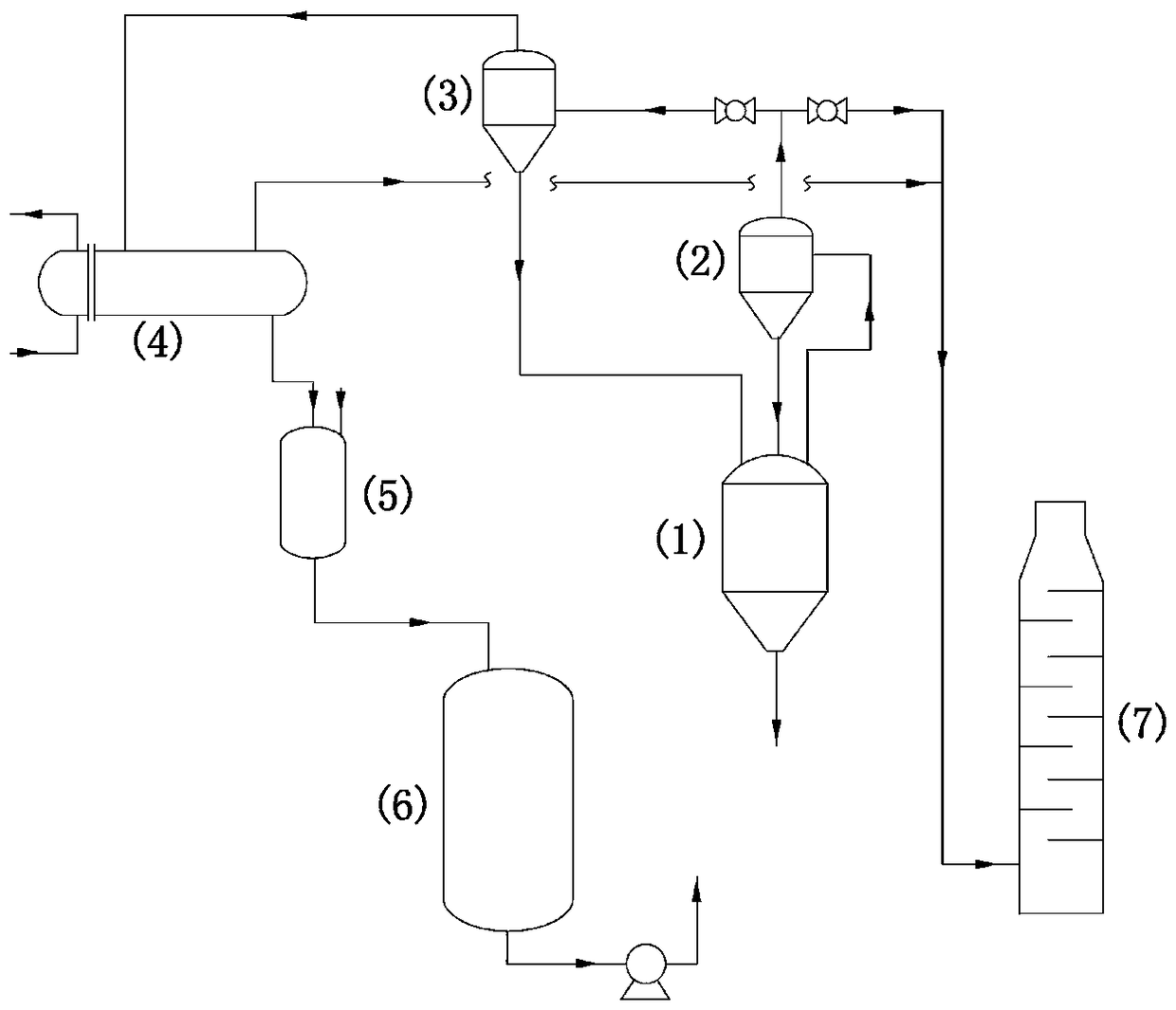

[0023] A process and equipment for efficiently recovering the dust and monomers in the exhaust gas of organosilicon monomers, including fine powder storage tanks, bag filters, special filters, tail gas condensers, condensate recovery tanks, and intermediate tanks for coarse monomers , water washing tower, bag filter 2, special filter 3 cone outlet is connected to the top inlet of fine powder storage tank 1, the exhaust gas outlet on the top of bag filter 2 is connected to the special filter 3 inlet, and the exhaust gas outlet on the top of special filter 3 It is connected with the inlet of tail gas condenser 4, the condensate outlet of tail gas condenser 4 is connected with the inlet of condensate recovery tank 5, the condensate outlet of the top of tail gas condenser 4 is connected with the inlet of water washing tower 7, and the bottom outlet of condensate recovery tank 5 is connected with the crude monomer The top inlet of the intermediate tank 6 is connected, the powder in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| separation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com