Patents

Literature

257results about How to "Save washing water" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

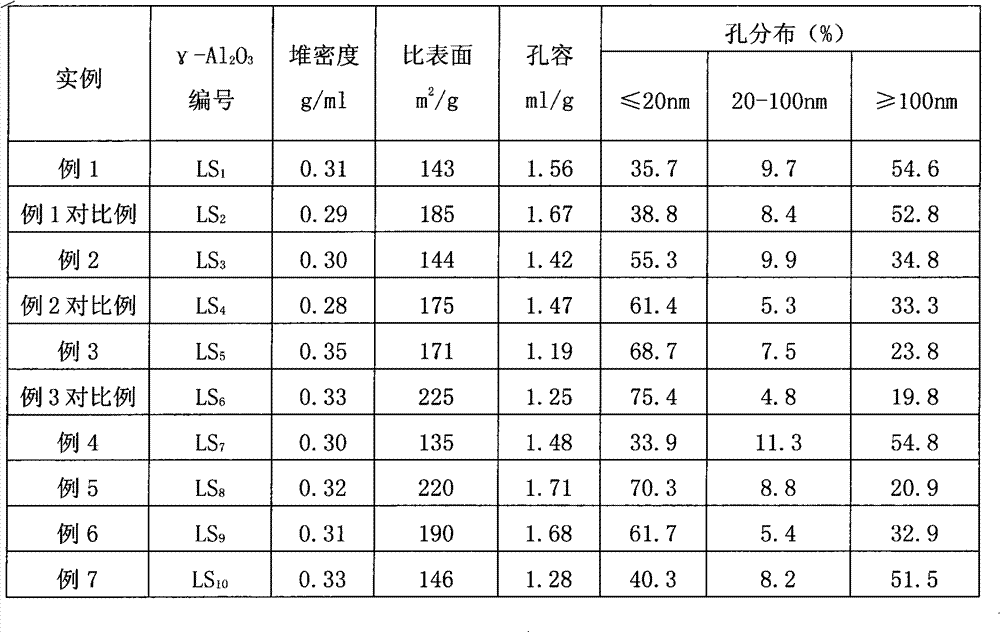

Preparation process for large pore volume and light bulk density activated alumina

InactiveCN102730724AChange the stacking methodFine grainAluminium oxides/hydroxidesWater vaporSodium aluminate

The invention relates to a preparation process for large pore volume and light bulk density activated alumina, and belongs to the technical field of activated alumina preparation. According to the process, an aluminum sulfate solution and a sodium aluminate solution form a glue in a stainless steel neutralization kettle through a continuous co-current flow method; then an aging treatment is performed for a certain time in a stainless steel aging washing tank; the resulting material is pressed to a plate and frame filter press with a material pressing pump to carry out continuous washing to prepare primary pseudo-boehmite particles with large grains; the removed filter cake is acidified, and proper amounts of a pore expanding agent and a surfactant are added during the acidification process to carry out forming; the formed wet balls are placed in a drying box to carry out drying; and the dried small balls are loaded into a calcination activation furnace to carry out high temperature calcination and pore expanding. The process of the present invention has characteristics of low cost and low equipment corrosion, can performs continuous washing cycle, and has advantages of low wastewater discharging, less pollution, and the like. With the process of the present invention, the production cycle can be reduced, the labor intensity can be reduced, and various performance indicators of the prepared gamma-Al2O3 can meet the international advanced level after pore expanding by water vapor.

Owner:JIANGSU JINGJING NEW MATERIALS

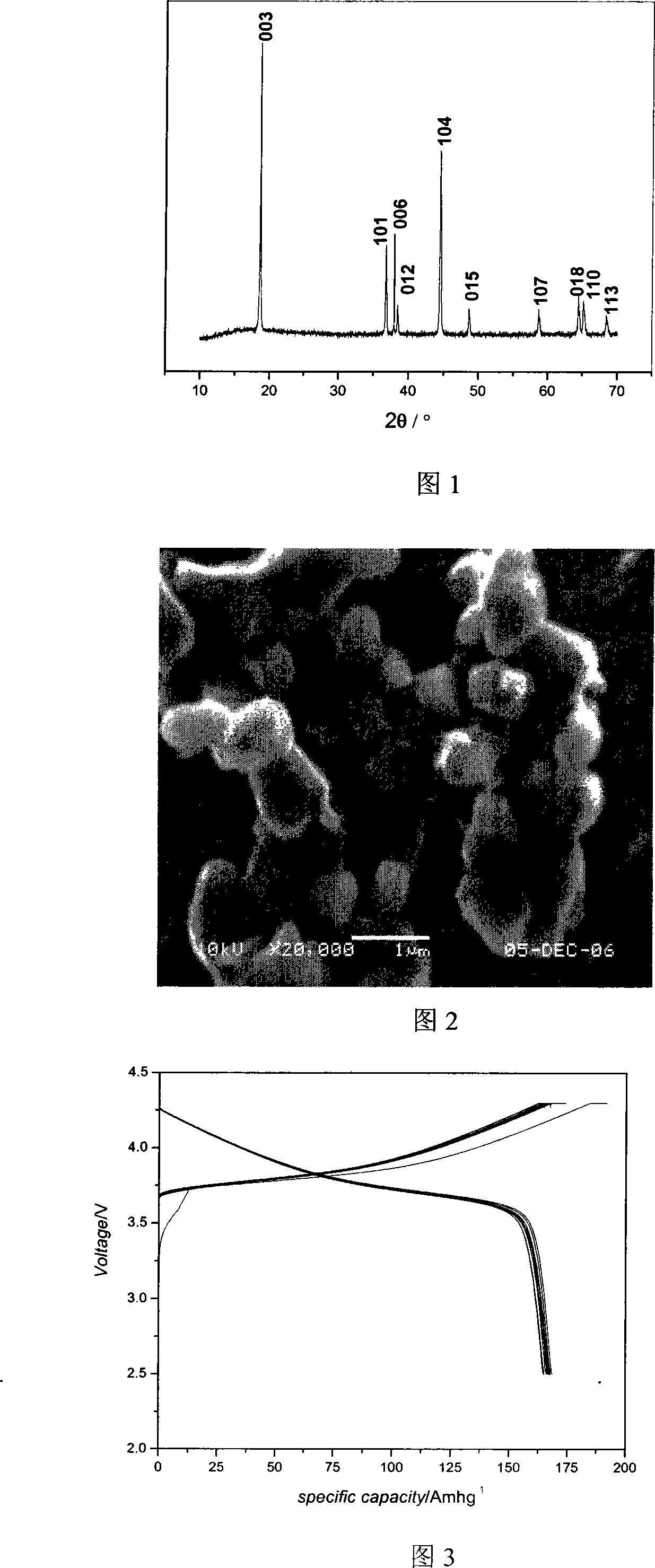

Coprecipitation-combustion synthesis method for lithium nickel cobalt manganate

InactiveCN101215011AGood chemical stabilityEliminate ingredient lossCell electrodesNickel compoundsSynthesis methodsManganate

The invention discloses a process of coprecipitation-combustion synthesis of nickel cobalt manganese lithium carbonate. (1) Utilizing acetate or nitrate of nickel, cobalt, and manganese as transition metal source and ammonia as complexing agent and utilizing H2C2O4, (NH4)3C2O4, (NH4)2CO3 or NH4HCO3 as precipitator, compound carbonate contained Ni-Co-Mn or oxalate precursors is synthesized by coprecipitation method. (2) Directly drying the compound carbonate containing Ni-Co-Mn or the suspension liquid of the oxalate and adding lithium nitrate or lithium acetate or a small quantity of water or ethanol to adjust into rheological phase. (3) Laying the materials in rheological phase in an electric stove to perform burning synthesis reaction, wherein the electric stove heats the materials in rheological phase at temperature of 400-600DEG C and then keeps constant temperature. (4) Temper drawing the reaction product with temperature of 600-1200DEG C, and anode active materials of lithium ion battery LiNixCoyMn1-x-yO2 is obtained. The invention has the advantages of simple technique, easy operation, saving water and energy and environment-friendliness, further, the synthetic material is provided with the shape of sphere or near-sphere, high specific capacity and fine cycle performance.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

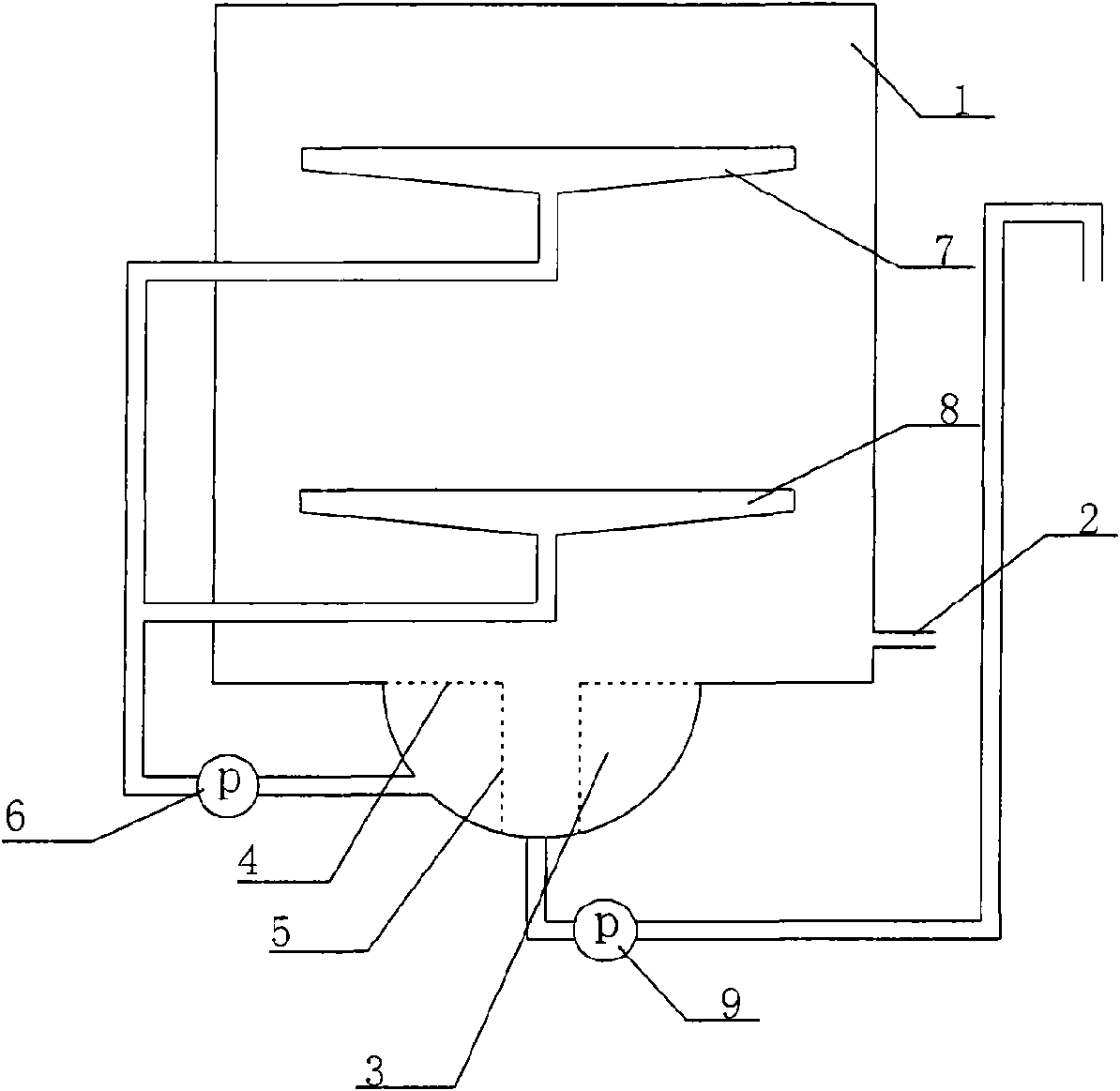

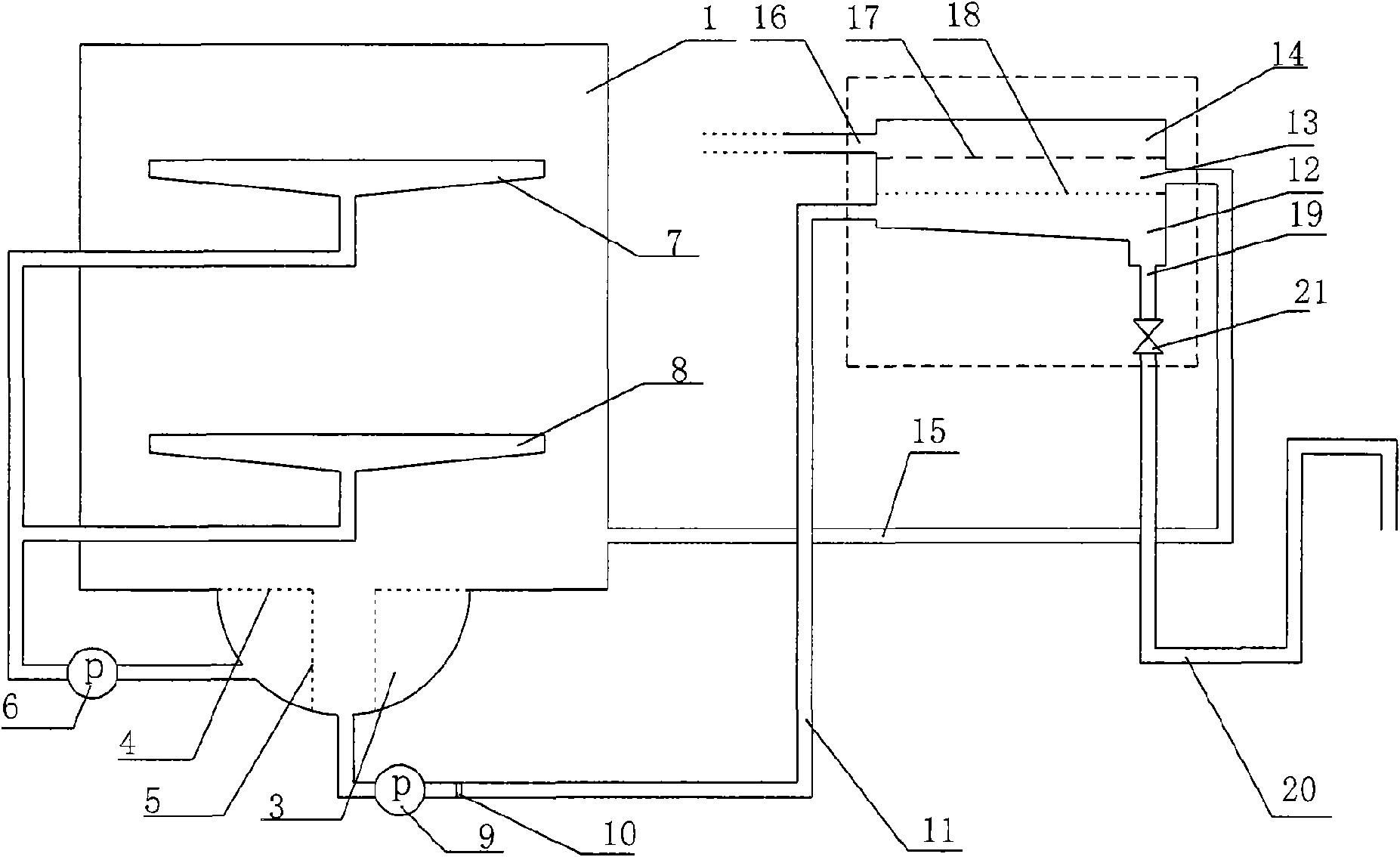

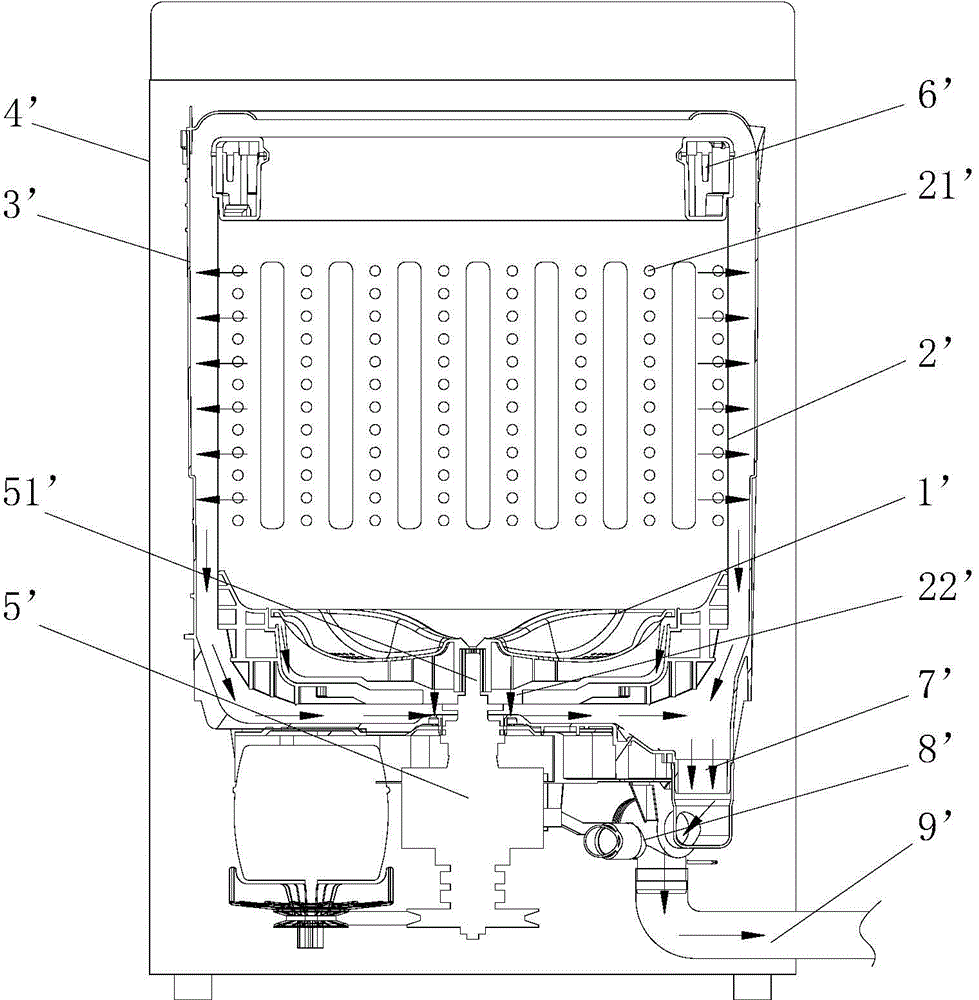

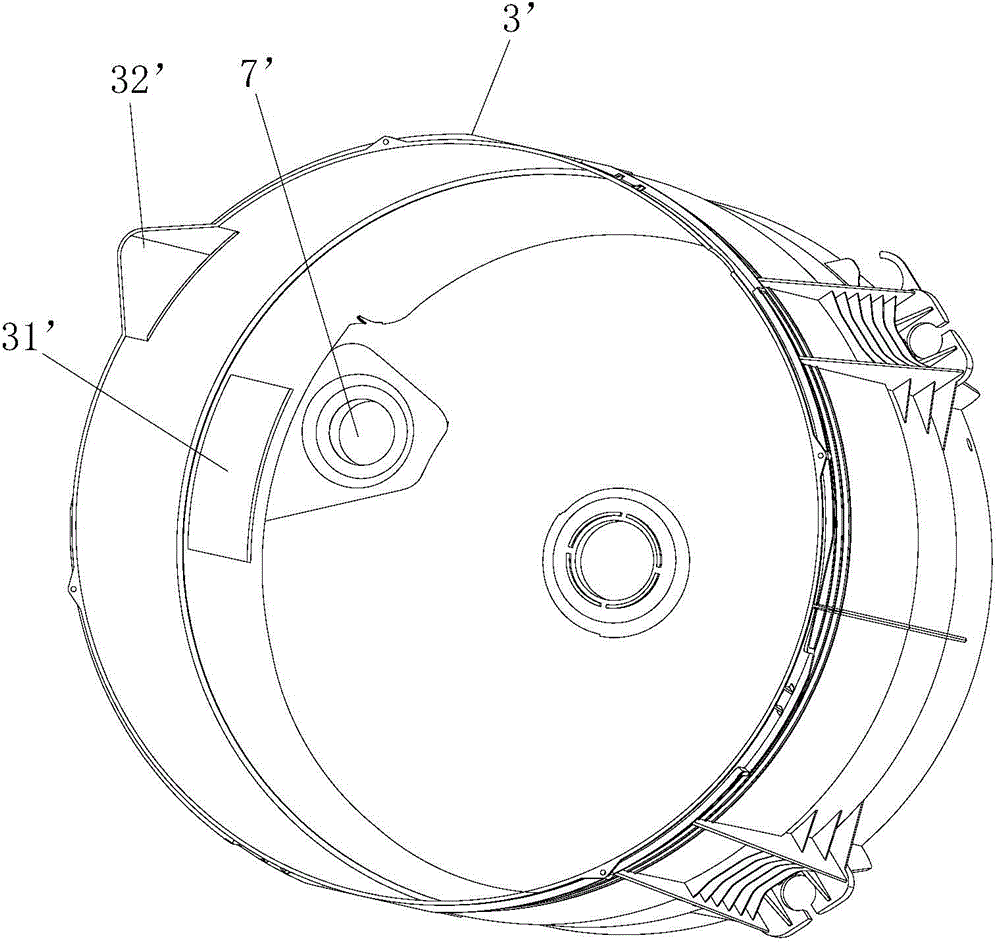

Filtering system for dishwasher

ActiveCN101642361AImprove cleaning efficiencyPlay the role of cleaning filterTableware washing/rinsing machine detailsFilter systemWaste management

The invention discloses a filtering system for a dishwasher, comprising an inner bag of a dishwasher, a water cup, a first channel connected with the water cup of the dishwasher and a drainage pump arranged on the first channel. A self-cleaning filtering residue removing device also comprises a filtering cavity; a filtering net is arranged in the filtering cavity; the filtering cavity is divided into a first cavity body and a second cavity body by the filtering net; the first cavity body is connected with the other end of the first channel; the second cavity body is connected with the inner bag of the dishwasher by the second channel; the first cavity body is also connected with a drainage pipe and the drainage pipe is provided with a drainage valve. The drainage pump is used for making washing water forcibly participate an individual filtering circulation system, thereby performing the cleaning and filtering function on the washing water; and simultaneously, food residues are collected and discharged, thereby enhancing the washing efficiency of the dishwasher, reducing the washing water and saving the washing time. The provided filtering residue removing device also has the function for automatically cleaning the filtering net.

Owner:MIDEA GRP CO LTD

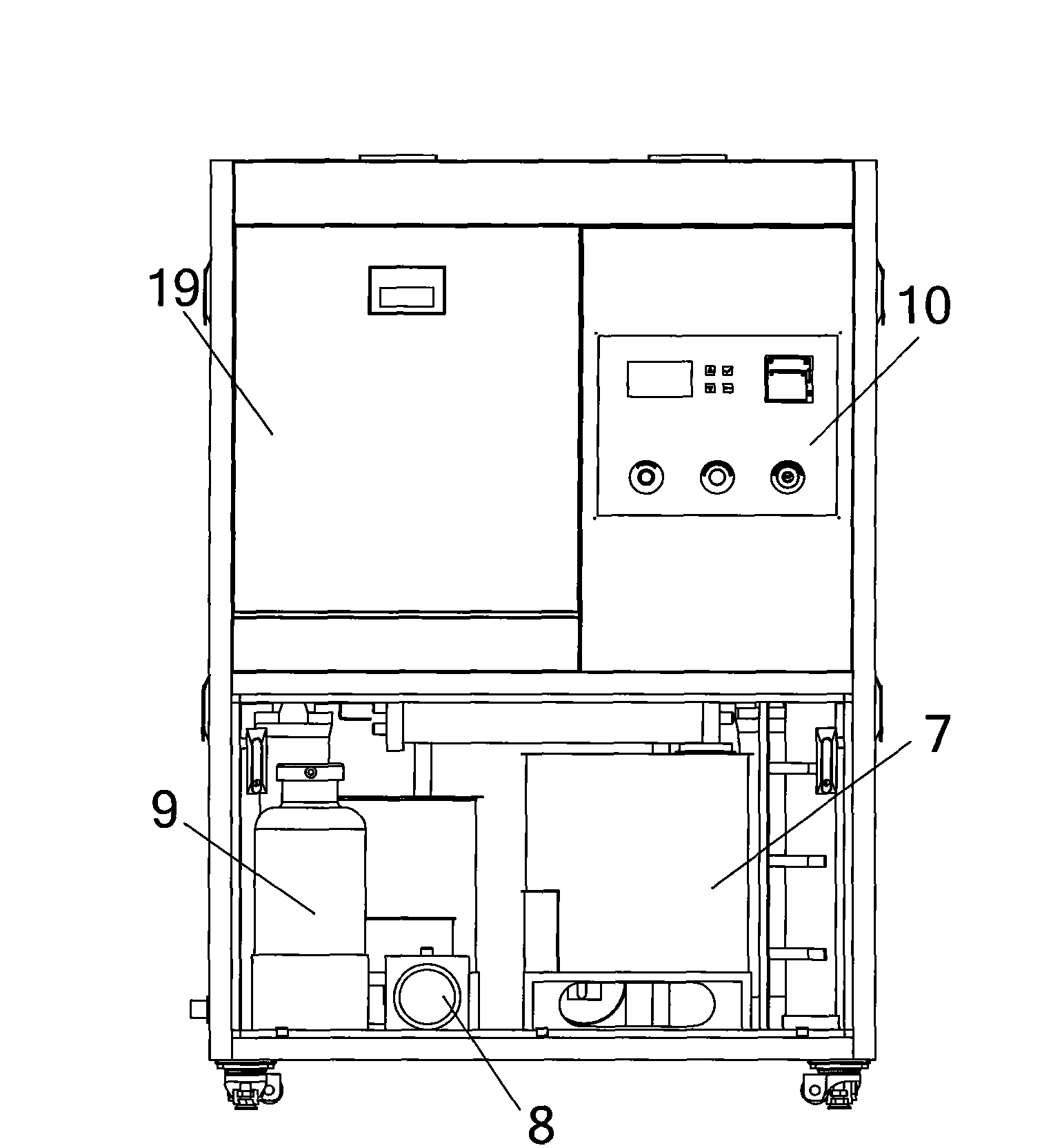

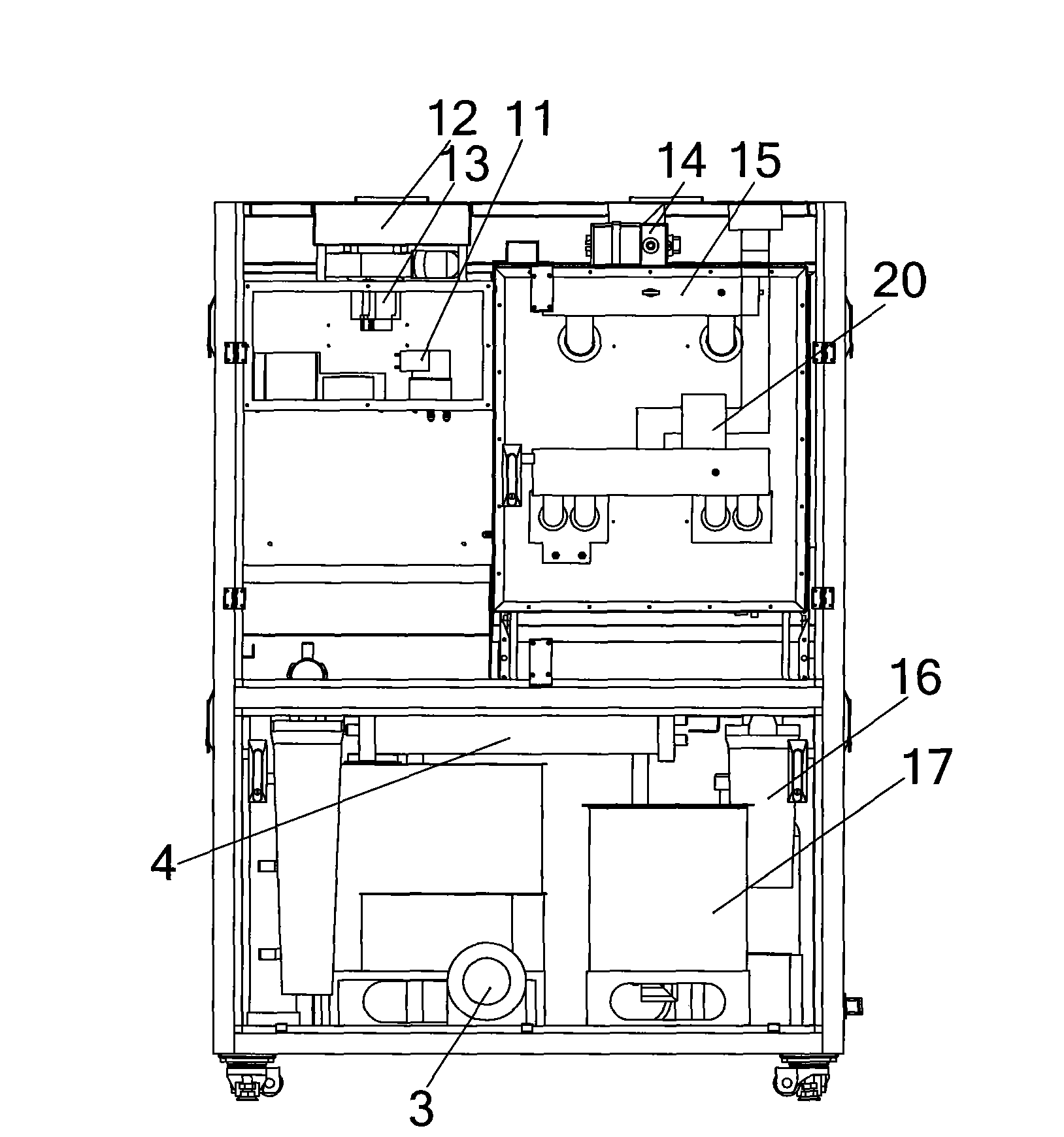

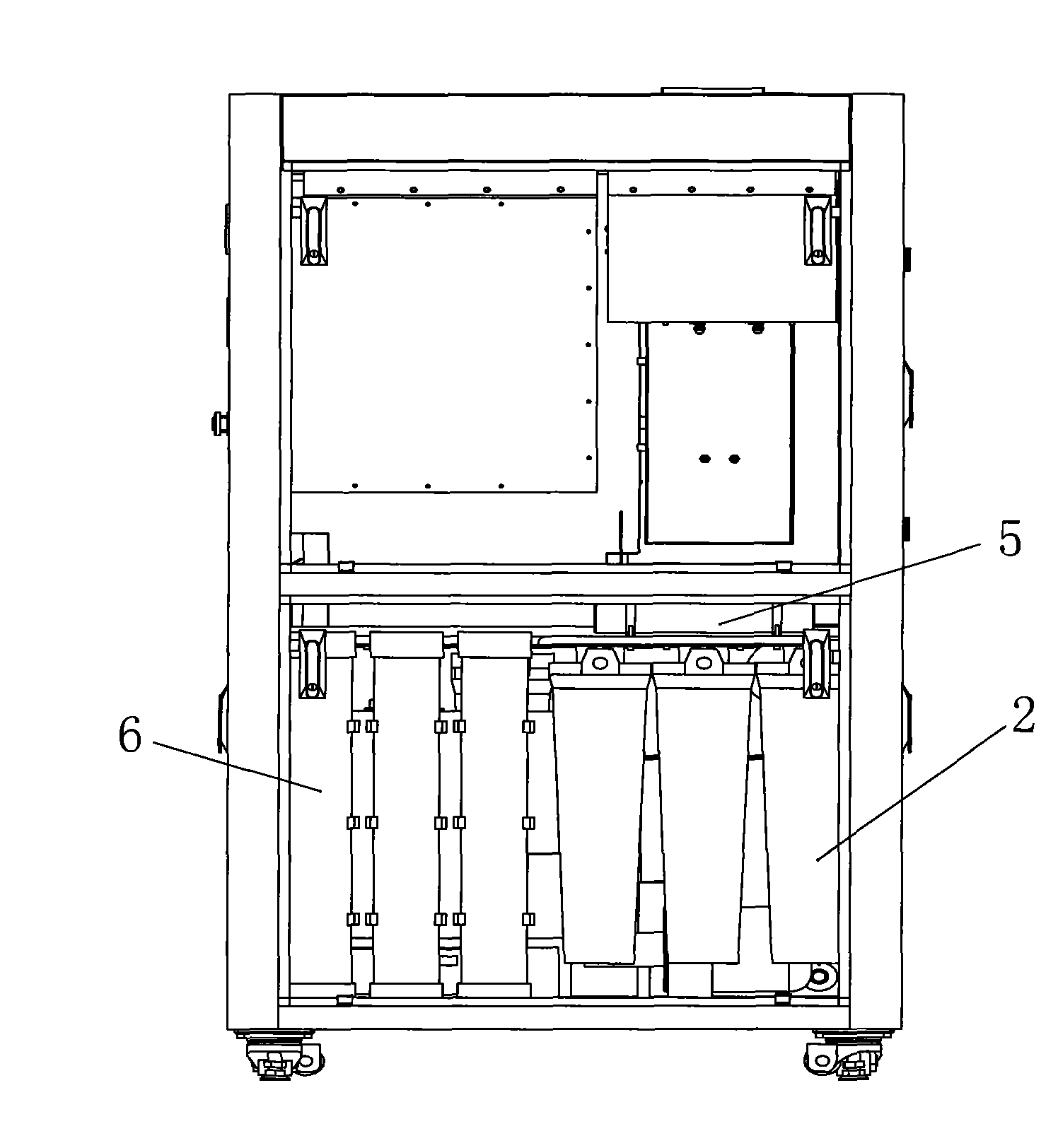

Printed circuit board cleaning machine

InactiveCN101583246AImprove washing efficiencyGood washing effectWater/sewage treatment by irradiationWater/sewage treatment bu osmosis/dialysisElectricityWater saving

The embodiment of the invention provides a printed circuit board cleaning machine, belonging to the technical field of printed circuit cleaning. The cleaning machine comprises a chassis, a master control system, a backing water treatment system, a cleaning system, a drying system, a waste water treatment system and a water detection system; the systems are all arranged in the chassis, the main control system is electrically connected with other systems and controls the operation of other systems; wherein, a water inlet and a water outlet are arranged on the backing water treatment system, the water outlet of the backing water treatment system is connected with the cleaning system, and the water outlet of the cleaning system is connected with the waste water treatment system; the drying system is connected with an air inlet of the cleaning system; the detection ends of the water detection system are respectively arranged on the water outlet ends of the backing water treatment system and the cleaning system, which are used for detecting the effluent water of the backing water treatment system and the cleaning system. The cleaning machine has the advantages of high cleaning efficiency, good cleaning effects, cleaning water saving and environmental protection.

Owner:常州至易环保科技有限公司

Iron and steel part surface oxidizing method

InactiveCN1422975AImprove corrosion resistanceReduce labor intensitySolid state diffusion coatingAtmospheric airNitrogen

There is an oxidation method of steel part surface, it belongs to the heat treatment technology and environmental protection field. The method is: the oxidition treatment is carried on in air stove, or adds in substance which isn't polluted, the color of the part mainly lies on the temperature, it acquires yellow, golden yellow, wine, blue, sandy beige, black oxidation film between 220 degree C -420 degree C. The craft in the ivnention tallies with clean production and green heat treatment.

Owner:SHANGHAI JIAO TONG UNIV

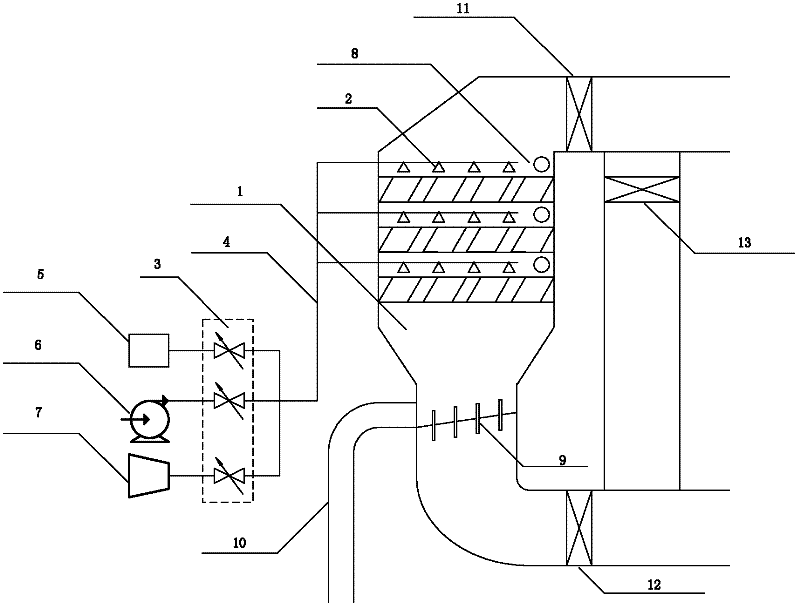

Device for on-line cleaning of selective catalyctic reduction (SCR) denitration catalyst and cleaning process thereof

ActiveCN102389838AShort cycleLow running costCatalyst regeneration/reactivationPtru catalystNitrogen oxides

The invention relates to a device for on-line cleaning of a selective catalyctic reduction (SCR) denitration catalyst and a cleaning process thereof. The device is formed through integrating a soot blower, a cleaning device, a waste liquid collecting device and a hot air drying device, in addition, the on-line cleaning on the catalyst is carried out in the early period of the catalyst invalidation, and catalyst surface sediments, pore blockage substances, alkali metal and other soluble toxic substances are removed. The technology has the advantages that the catalyst activity is improved, the service life of the catalyst is prolonged, the denitration efficiency is improved, the nitrogen oxide discharge is reduced, simultaneously, the cleaning process of the catalyst is simplified, the dismounting and handling work is not needed, the unnecessary loss caused by the dismounting and handling work is avoided, the catalyst cleaning period is shortened, and a large amount of operation cost issaved for enterprises using the SCR denitration catalyst.

Owner:XI AN JIAOTONG UNIV

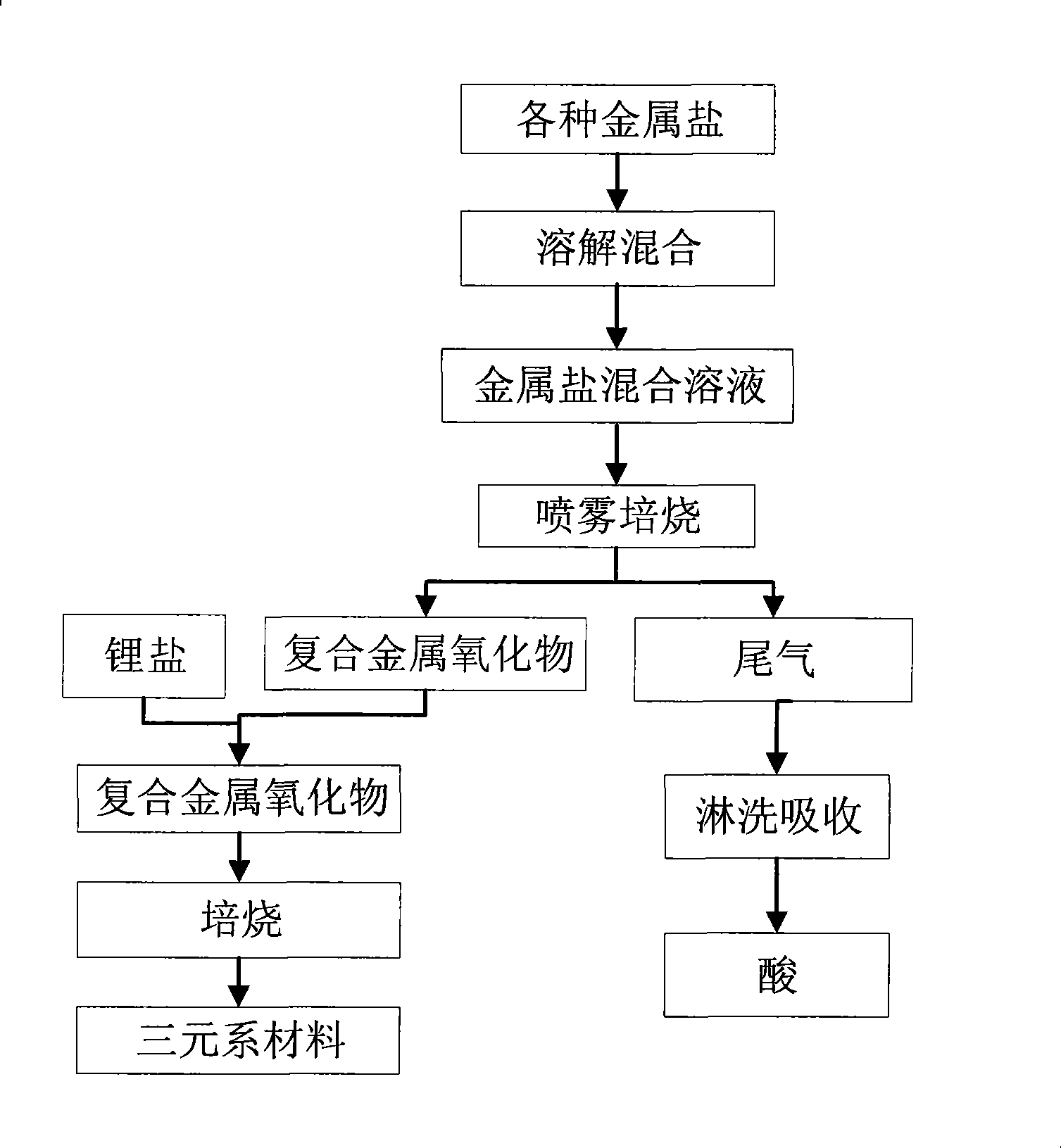

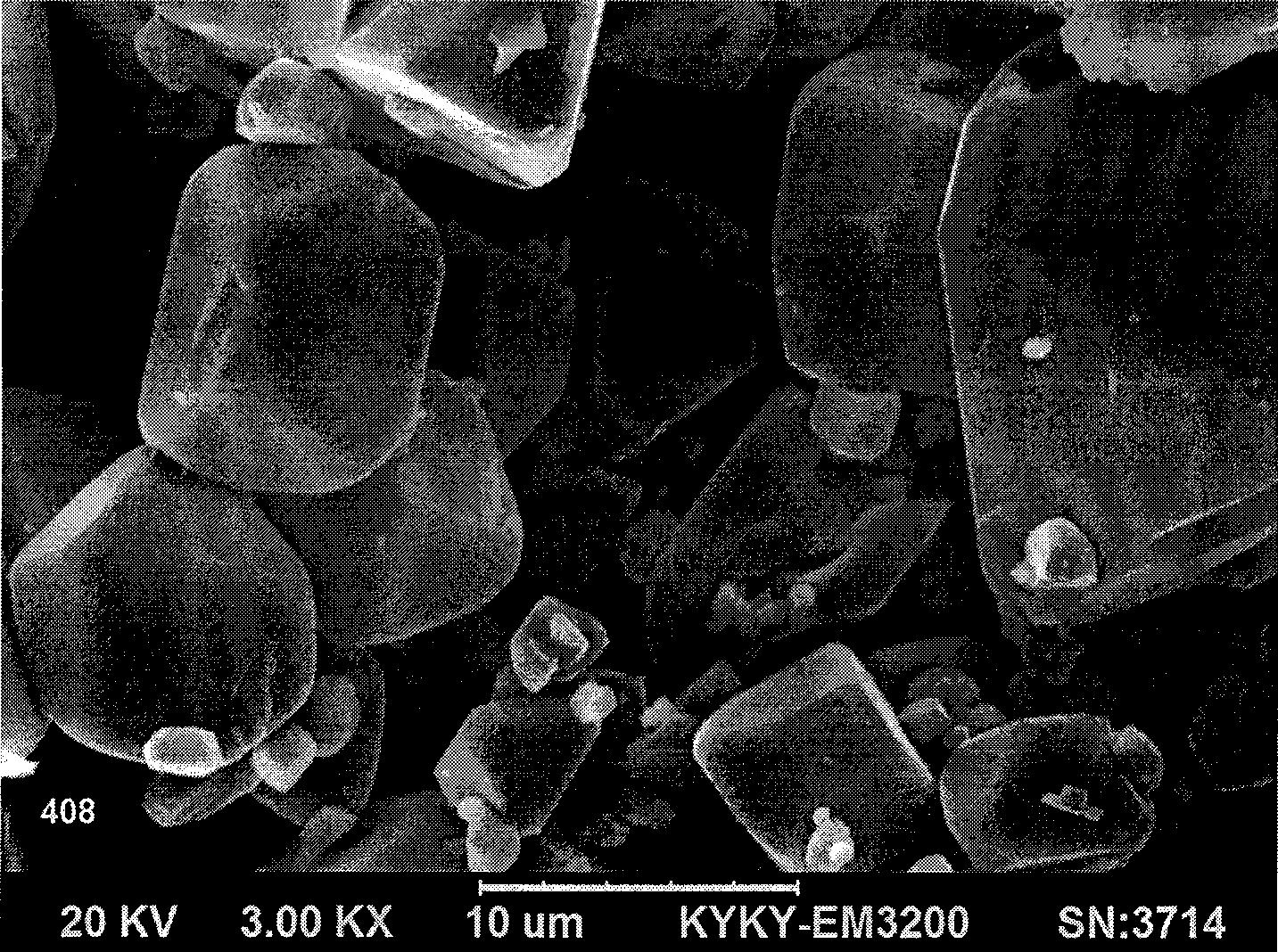

Novel method for preparing lithium ion battery anode ternary material LiCoxNiyMn2O2

InactiveCN101369651AGood fluidity of powderUniform particle sizeElectrode manufacturing processesCrystallinityManganese oxide

The invention relates to a preparation method of ternary system material, in particular to a preparation method of lithium cobalt nickel manganese oxide ternary system material for lithium ion batteries. The invention applies ensured ternary system material salt as raw material. After needed matching weight, by means of eve dissolving and mixing, a composite metal oxide prepared by a spray-roasting method is used as a fore body. The fore body is mixed with a lithium-source compound according to the substance amount of 1:1-1.5, and then roasting is carried out at the temperature of 700 to 1000 degrees centigrade to obtain the ternary system material. The tail gases, such as vapor, acidic gas, generated in the spray-roasting process are absorbed by a washing tower to obtain acid. The invention has the advantages of advanced technique, stable production, low cost, no waste water discharge, environmental protection, high product purity, even granularity, high crystallinity, etc.

Owner:ZHEJIANG HUAYOU COBALT

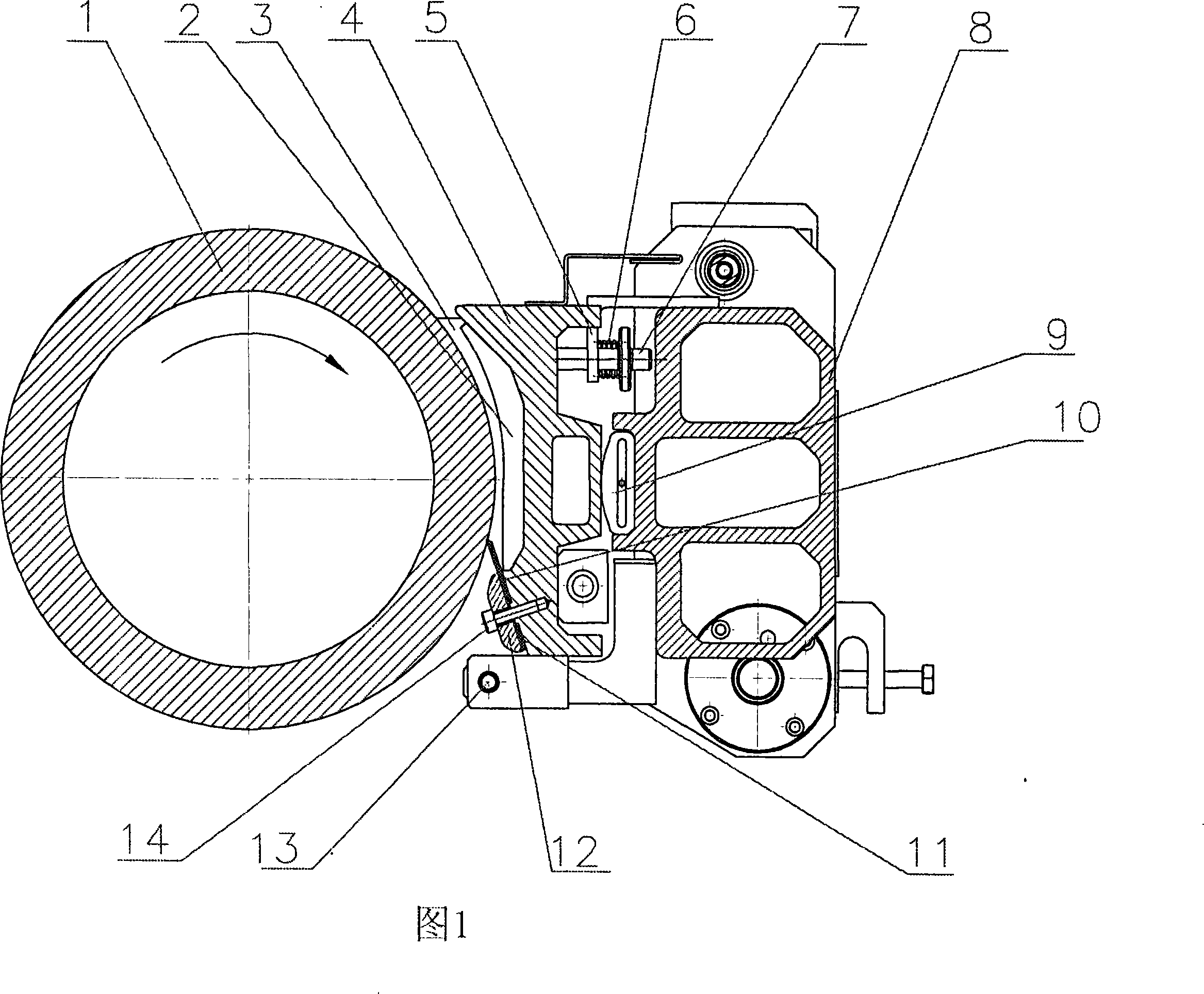

Cardboard box printing grooving machine printing unit single scraping cutter device

ActiveCN101214754ASave washing waterReduce pollutionRotary intaglio printing pressPaper-makingCartonEngineering

The invention particularly relates to a single scraper apparatus of a printing unit of a carton box print fluting machine, wherein an ink cavity of the single scraper is installed on a bracket by an articulated mechanism, and the scraper and a spacer are fixed on the ink cavity of the single scraper by a pressure plate and screws; a spring gauge is fixed on the bracket; one end of a spring rod is provided with threads, and the other end of the spring rod is a discoid fillet; the thread end of the spring rod is installed in the bolt hole of the ink cavity of the single scraper; a spring is installed between the spring gauge and the discoid fillet of the spring rod. A closing board at a nylon end and a closing board at an elastic end are respectively installed at both ends of the ink cavity of the single scraper; the ink cavity of the single scraper, the scraper, the closing board at the nylon end, the closing board at the elastic end and an air bag are installed between the ink cavity of the single scraper and the bracket. By adopting the technical scheme, an anilox roller can not be scratched, the ink can be recycled in the ink cavity, and the ink can be recovered and cleaned, which can save cleaning water, decrease pollutions of cleaning and decrease the cost of water treatment.

Owner:GUANGDONG DONGFANG PRECISION SCI & TECH CO LTD

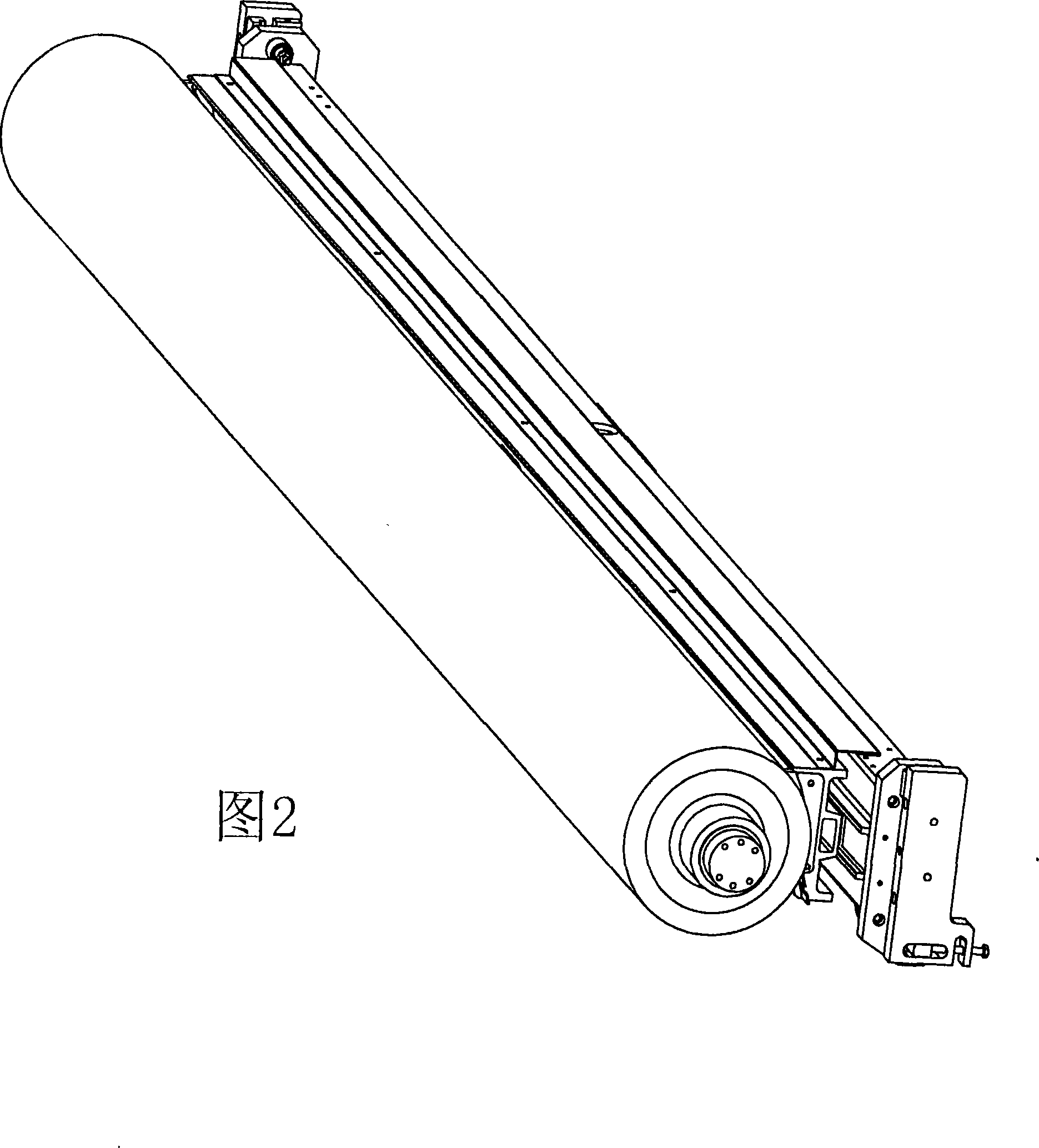

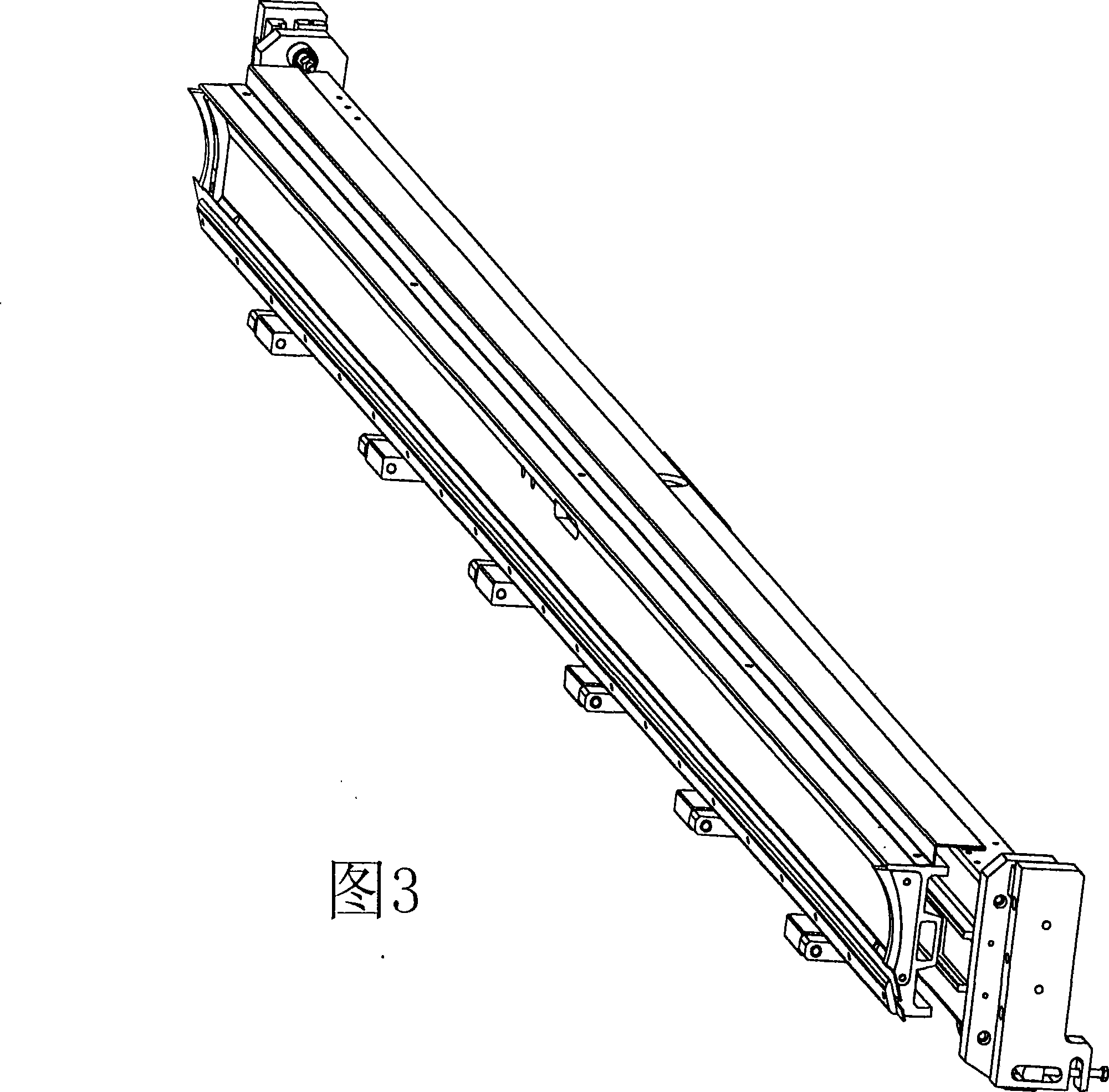

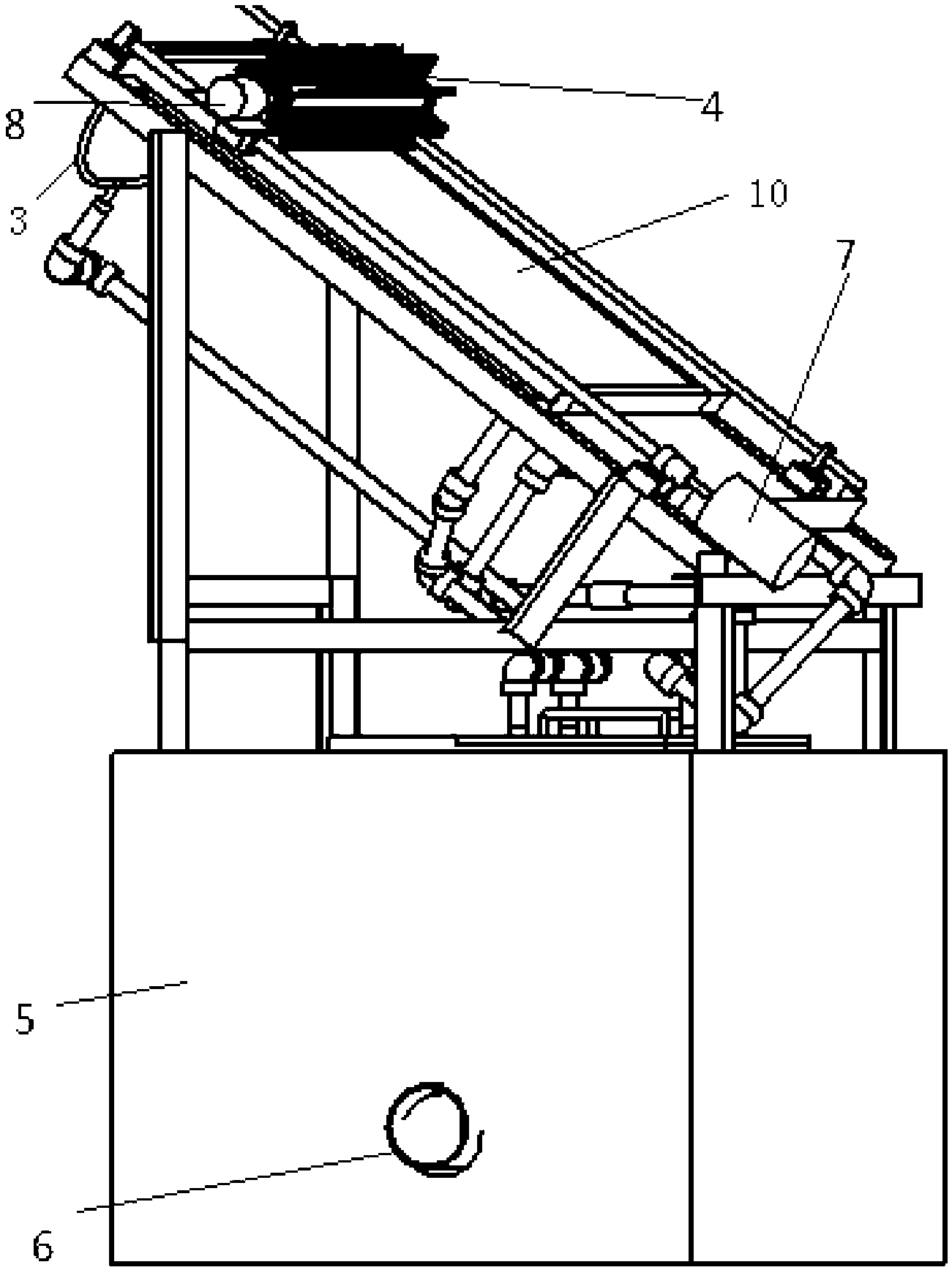

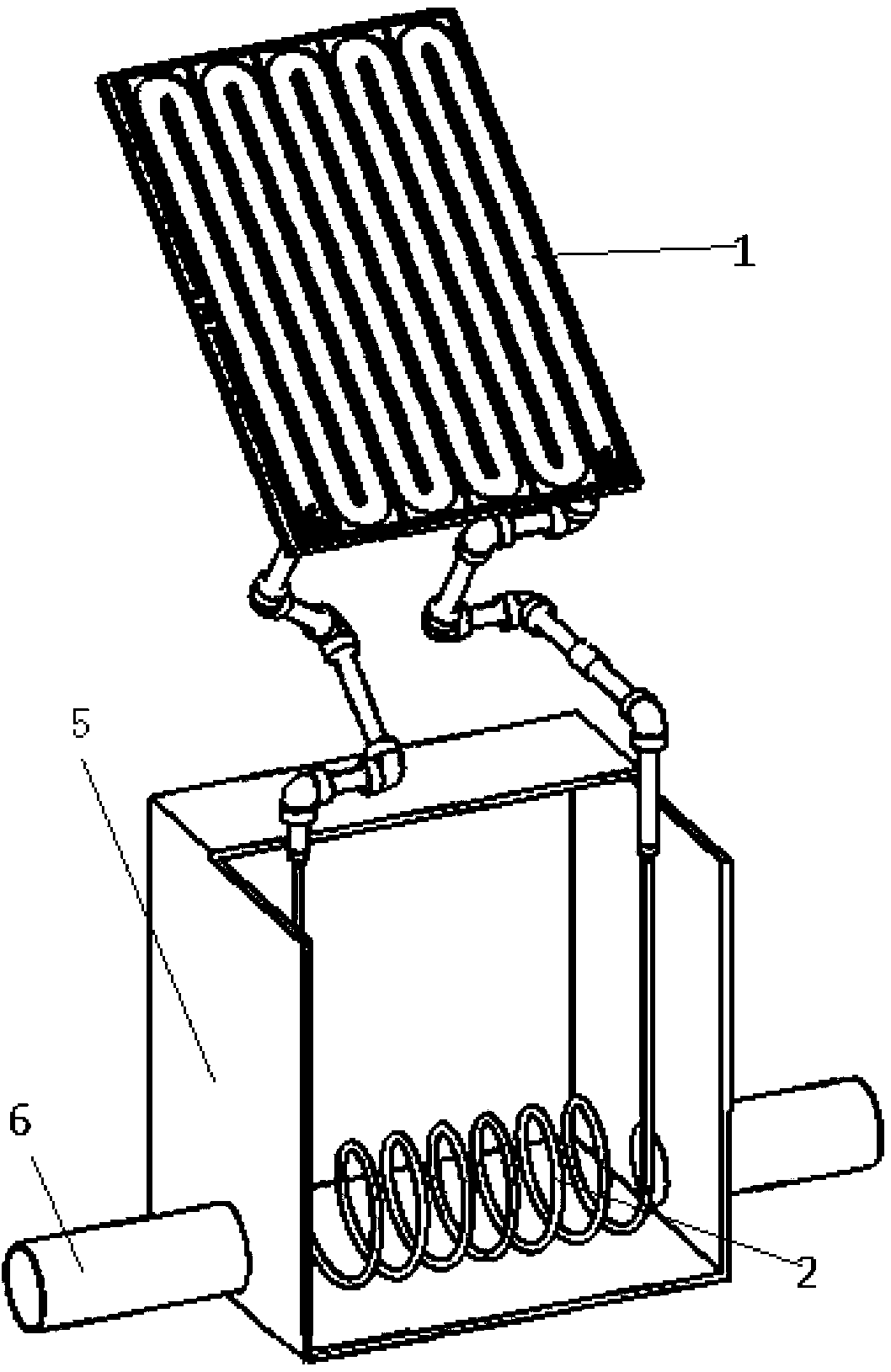

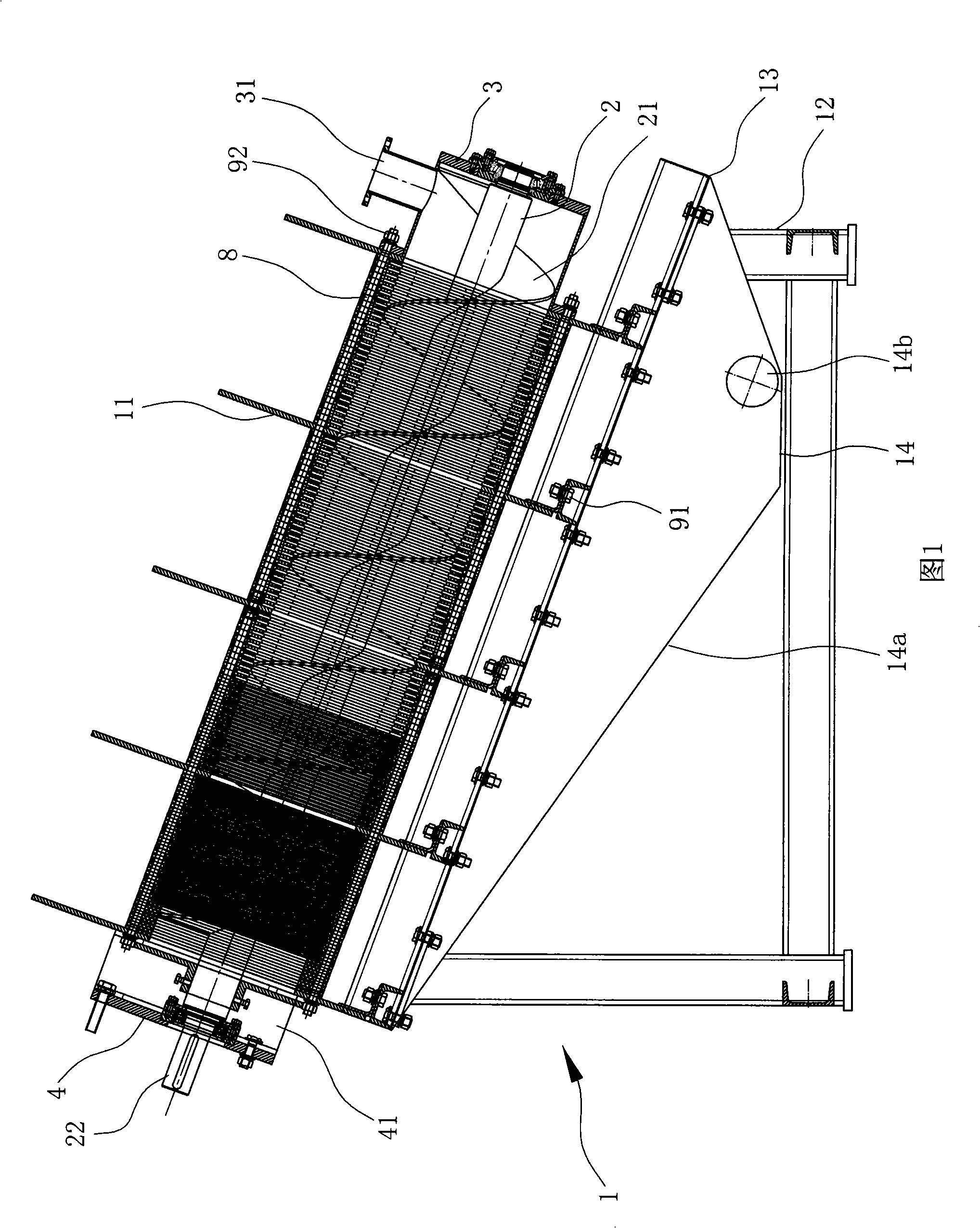

Dedusting and cooling integrated device of solar photovoltaic panel

ActiveCN103268896AReduce labor costsSave washing waterPhotovoltaicsPhotovoltaic energy generationEngineeringIntegrated devices

The invention discloses a dedusting and cooling integrated device of a solar photovoltaic panel. The dedusting and cooling integrated device of the solar photovoltaic panel comprises a dedusting system, a cooling pipeline system, a water pool and the solar photovoltaic panel installed on the water pool, wherein the dedusting system comprises a showering pipe installed at the top end of the solar photovoltaic panel, the showering pipe is communicated with the water pool through a water pump, the solar photovoltaic panel is provided with a hair brush used for cleaning the solar photovoltaic panel, and the bottom end of the solar photovoltaic panel is communicated with the water pool through pipelines; the cooling pipeline system comprises a cooling plate provided with a cooling pipeline, and the outlet and the inlet of the cooling plate are communicated with a horizontal spiral pipe which is placed in the water pool. According to the dedusting and cooling integrated device of the solar photovoltaic panel, manpower cost and used water of washing are greatly saved, dedusting operation can be carried out timely, and power generating efficiency of the solar photovoltaic panel can be effectively improved. Compared with an independent dedusting device and a cooling device, the dedusting and cooling integrated device of the solar photovoltaic panel achieves dedusting and cooling integration, comprehensive energy consumption of the device is low, and investment of equipment is low while same production capacity is achieved.

Owner:XI AN JIAOTONG UNIV

Impeller full-automatic washing machine

PendingCN105463790AReduce deliveryAvoid cross infectionOther washing machinesTextiles and paperImpellerWater discharge

The invention discloses an impeller full-automatic washing machine comprising an external barrel, an internal barrel disposed in the external barrel and an impeller disposed in the internal barrel. A drainage port is arranged on the bottom of the external barrel; the washing machine does not have a draining valve; the drainage port of the external barrel is directly communicated with a drain pipe; during washing and rinsing, washing water is only accommodated in the internal barrel and the external barrel contains no washing water; during dehydration, the washing water passes through the external barrel, the external barrel drainage port and the drain pipe from the upper part of the internal barrel and then is directly discharged; during water inlet, water is only charged into the internal barrel; after washing is finished, the internal barrel is driven to rotate at high speed to produce centrifugal force; water in the internal barrel and water in the clothes spirally rise and are discharged out of the external barrel via water discharging holes of the internal barrel; and the water can be directly discharged via the drain pipe. Without the draining valve, assembling technology of the external barrel components can be reduced, installation space of a barrel bottom driving device can be increased and cost can be reduced.

Owner:QINGDAO HAIER WASHING MASCH CO LTD

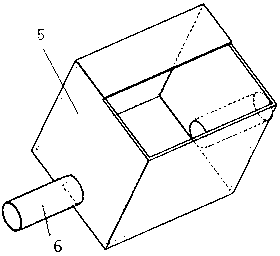

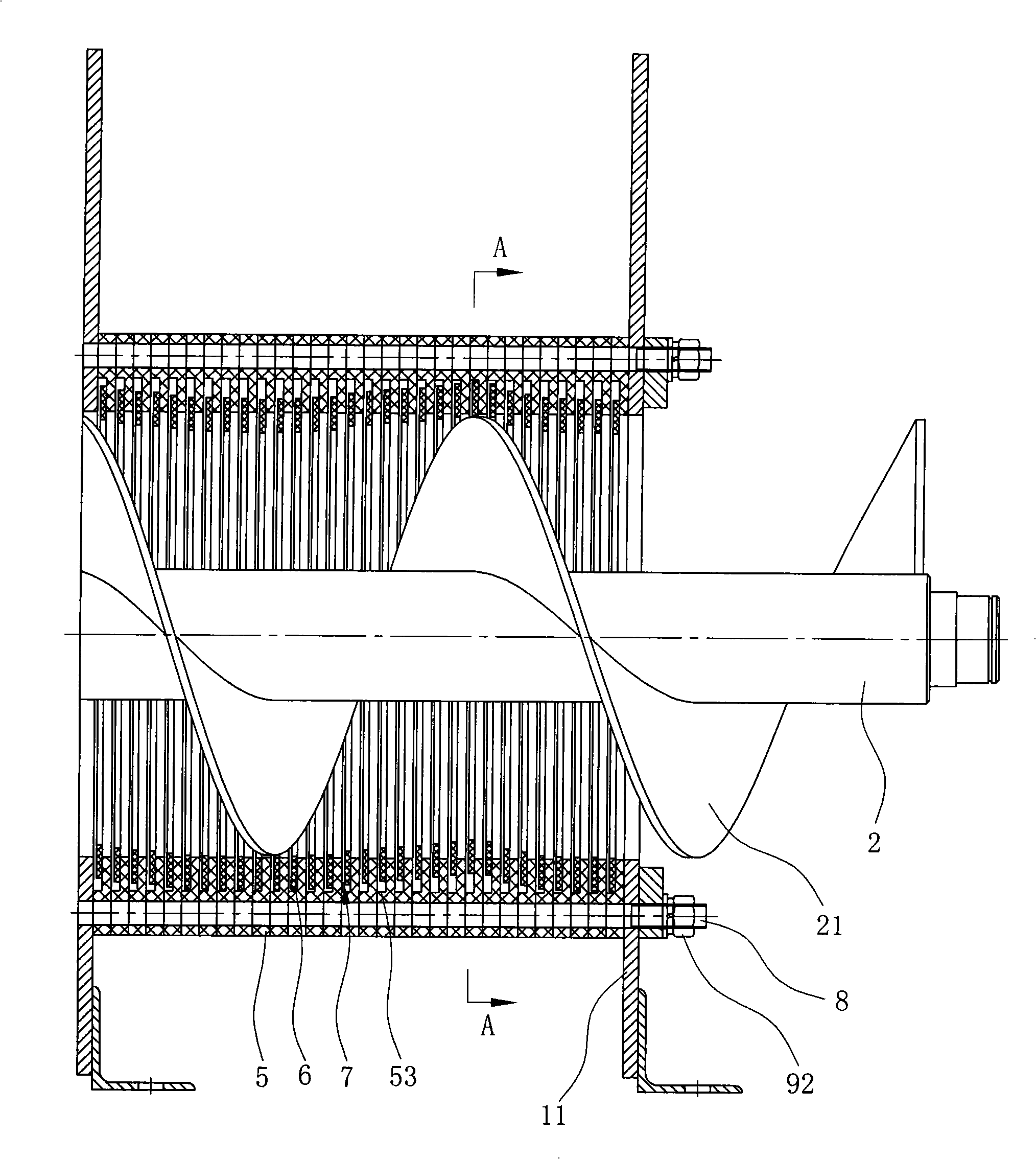

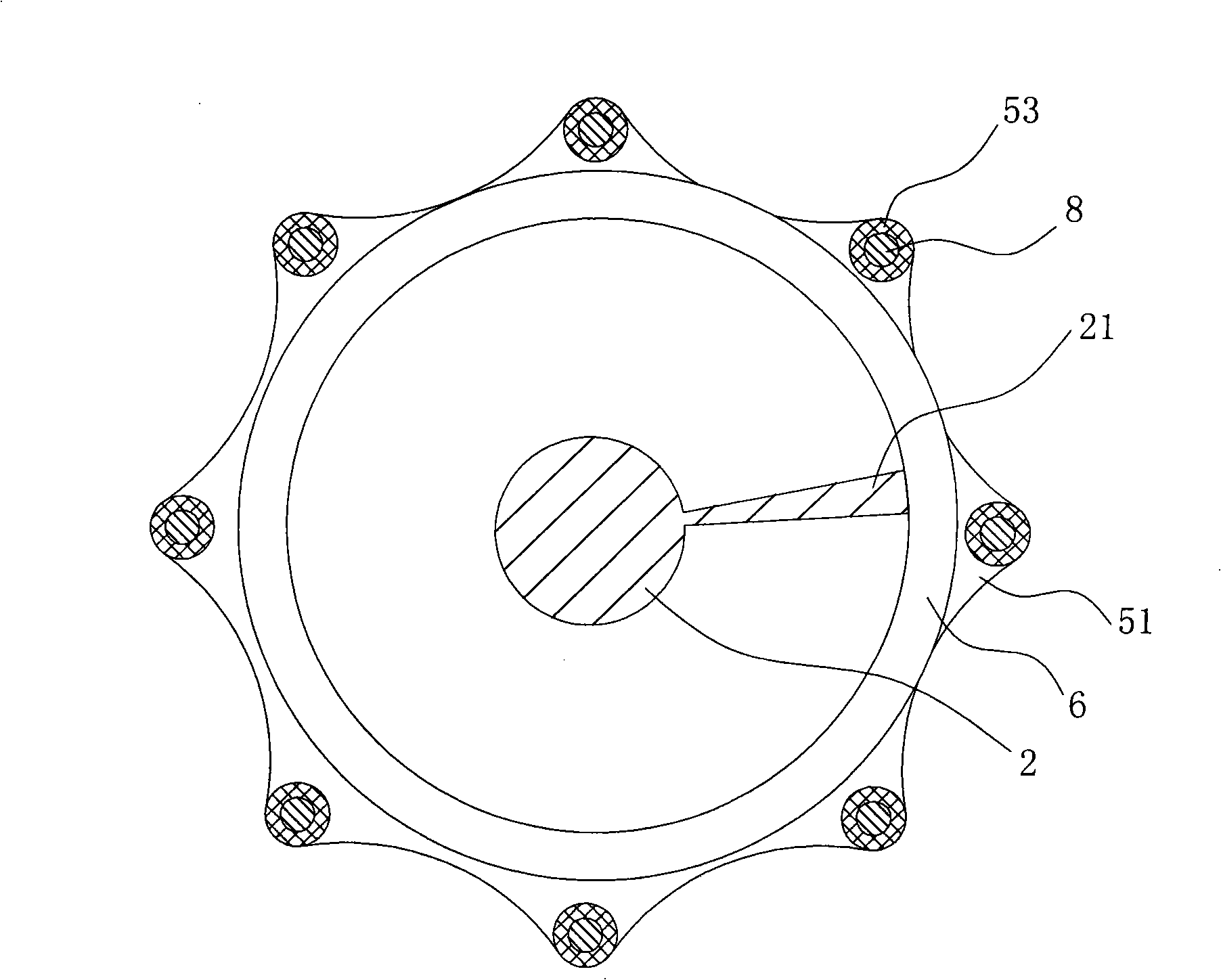

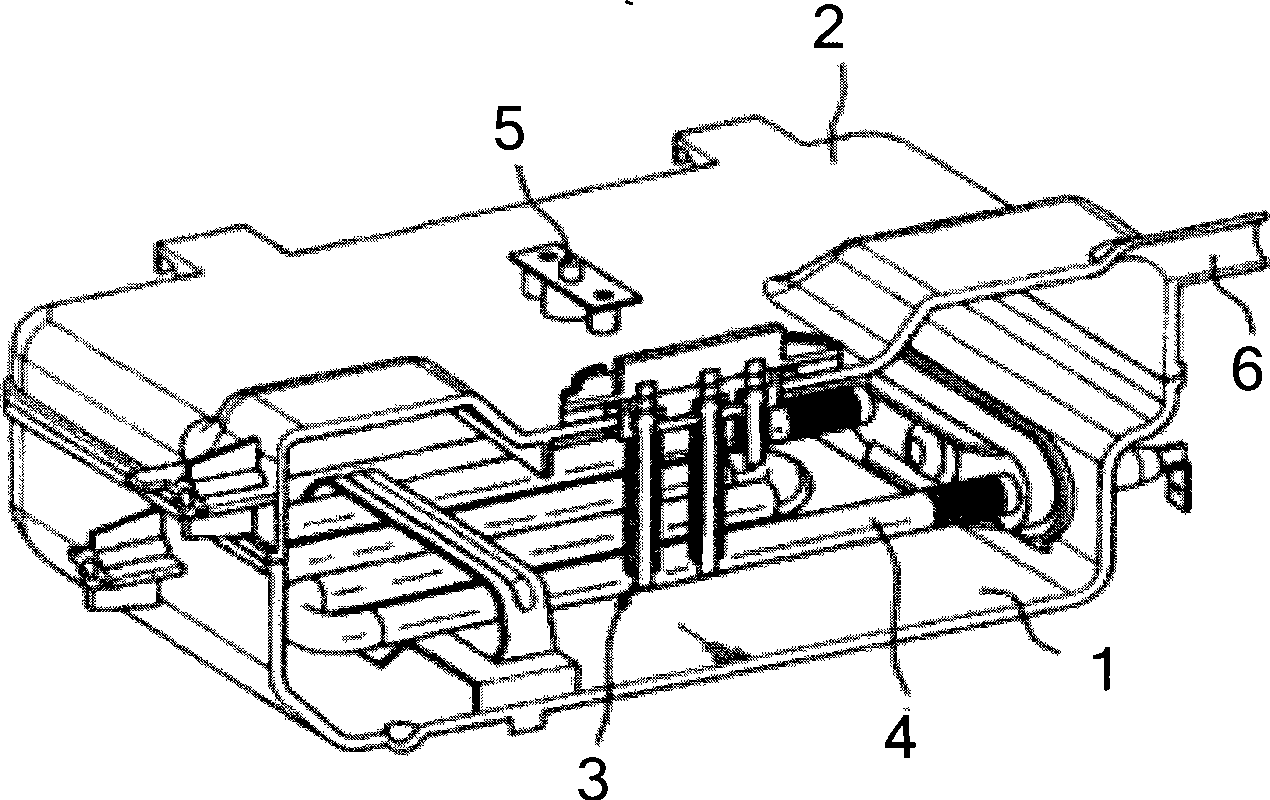

Spiral squeezing type sludge dewatering equipment

InactiveCN101333060AAvoid wear and tearExtended service lifeSludge treatment by de-watering/drying/thickeningEngineeringEnergy consumption

The invention discloses a screw extrusion type sludge dewatering machine, comprising a machine base (1), a water inlet part, a sludge exit part (41), a water outlet part, a screw shaft (2) with a spiral blade (21), as well as a filter disc assembly composed of a plurality of annular static filter discs (5) and annular dynamic filter discs (6) in a cross-interval arrangement; wherein, each static filter disc (5) is fixed relatively to the machine base (1); the internal diameter of each dynamic filter disc (6) coincides with the external diameter of the blade (21) and has line contact with the blade (21); moreover, the space between two adjacent static filter discs (5) is slightly greater than the thickness of the dynamic filter disc (6) between the two adjacent static filter discs (5) so as to form a gap (7) between the static filter discs (5) and the dynamic filter disc (5); water can flow through the gap (7). Compared with the prior art, the invention enables water to directly flow out through the gaps of the filter disc assembly so as to avoid the abrasion to the static filter discs and the dynamic filter discs caused by sludge; the device has a longer service lifer and adopts only one power source to realize solid-liquid separation, so that the energy consumption is lower; besides, the components of the device are easy to install and simple in structure to facilitate actual implementation.

Owner:浙江德安新技术发展有限公司

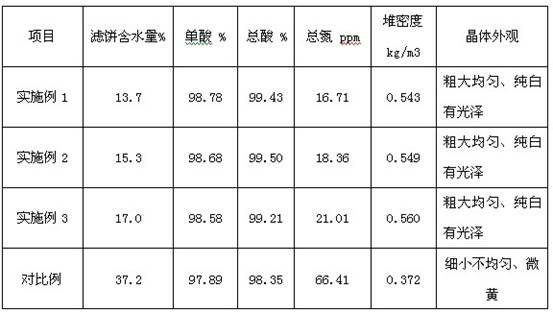

Refining method for long-chain binary acid

ActiveCN102329212AAchieve reuseAvoid hidingCarboxylic compound separation/purificationSingle crystalPre treatment

The invention discloses a refining method for long-chain binary acid. The refining method comprises the steps of: performing pretreatments including demulsifying, filtering and decoloring on fermentation liquor, then, reacting the pretreated fermentation liquor with dilute sulphuric acid through a microchannel reactor, heating an obtained mixture by using a sleeve to remove fine crystals, introducing crystal mush into a crystallization kettle for curing, controlling the growing speed and the size of crystals by means of gradient temperature to form crystals with uniform particle size, filtering, washing and drying to obtain long-chain binary acid crystals. The long-chain binary acid crystals have the advantages of uniform particles, low content of protein and impurities, high product purity, good color, and capability of meeting requirements on quality of polymerization-level products.

Owner:CHINA PETROLEUM & CHEM CORP +1

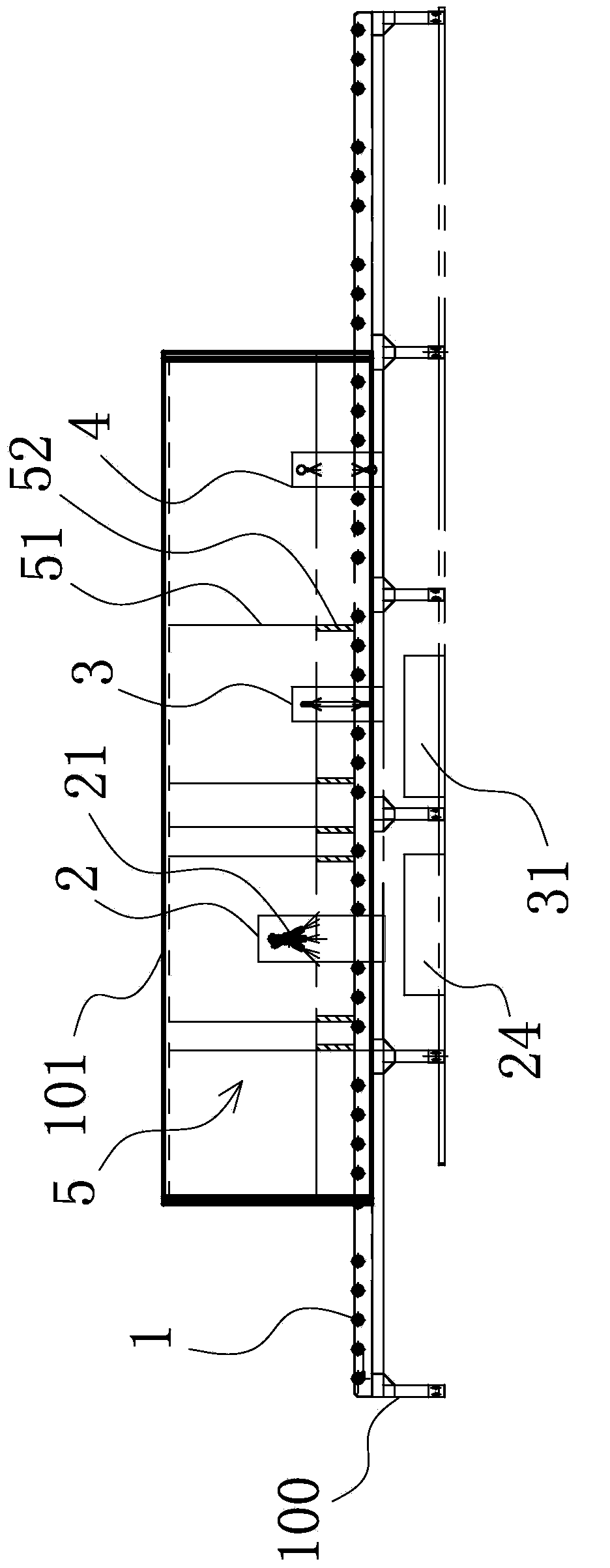

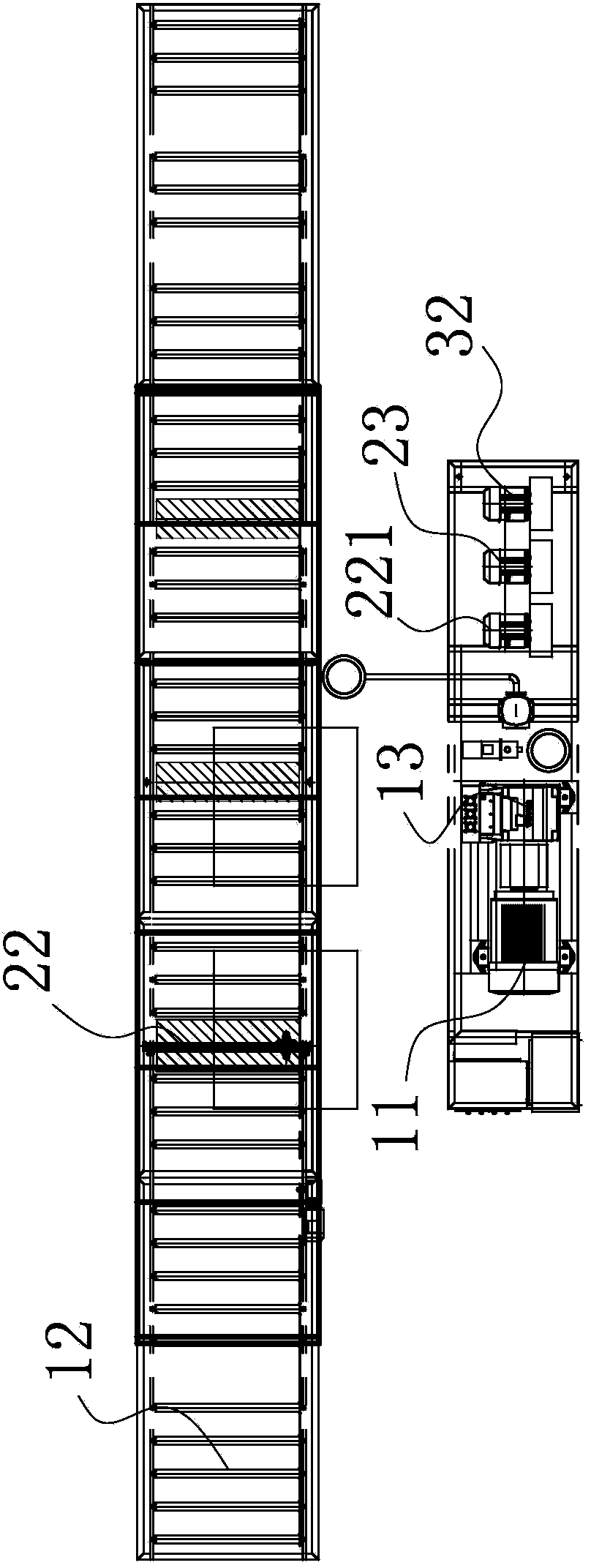

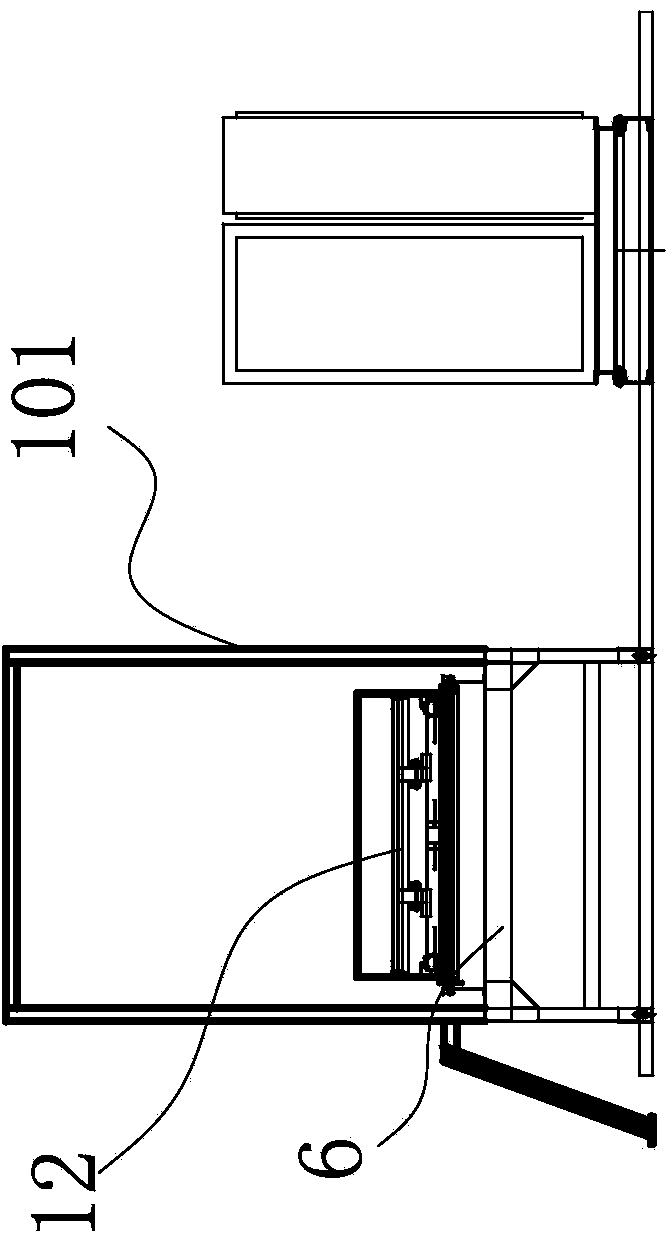

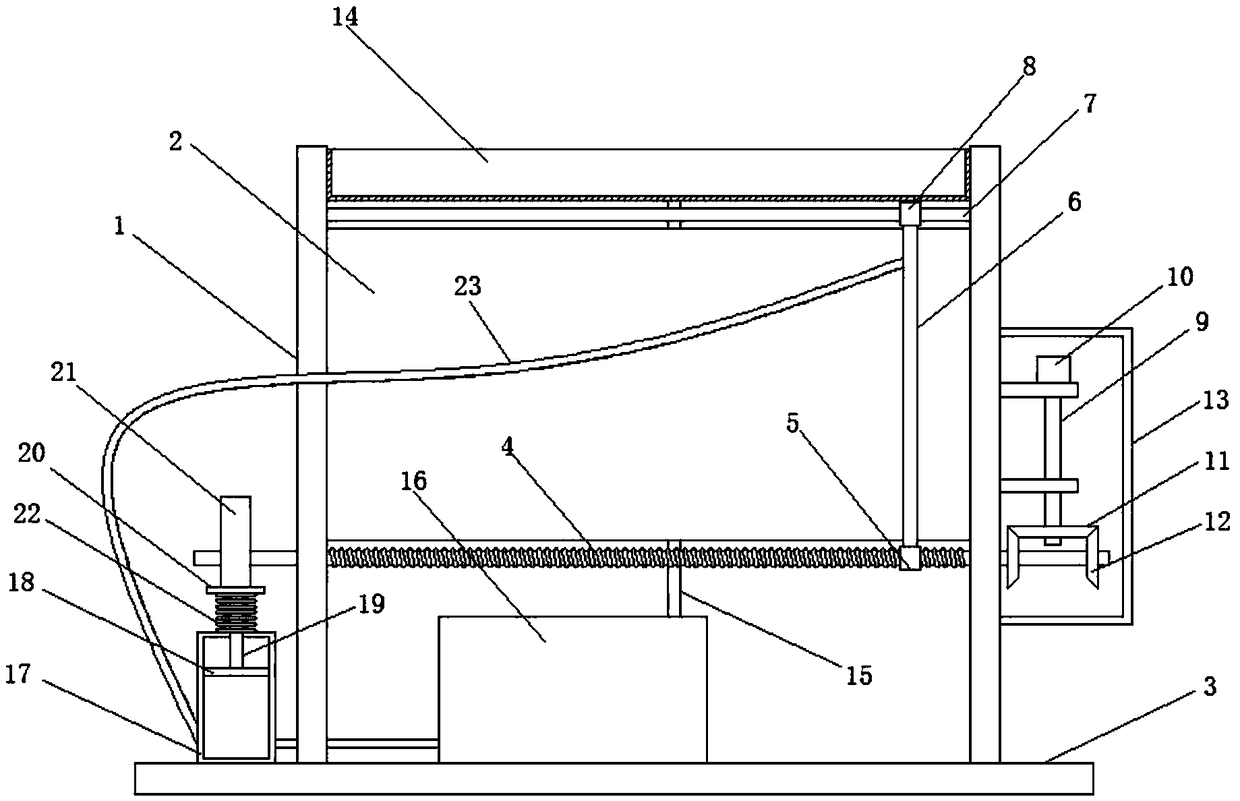

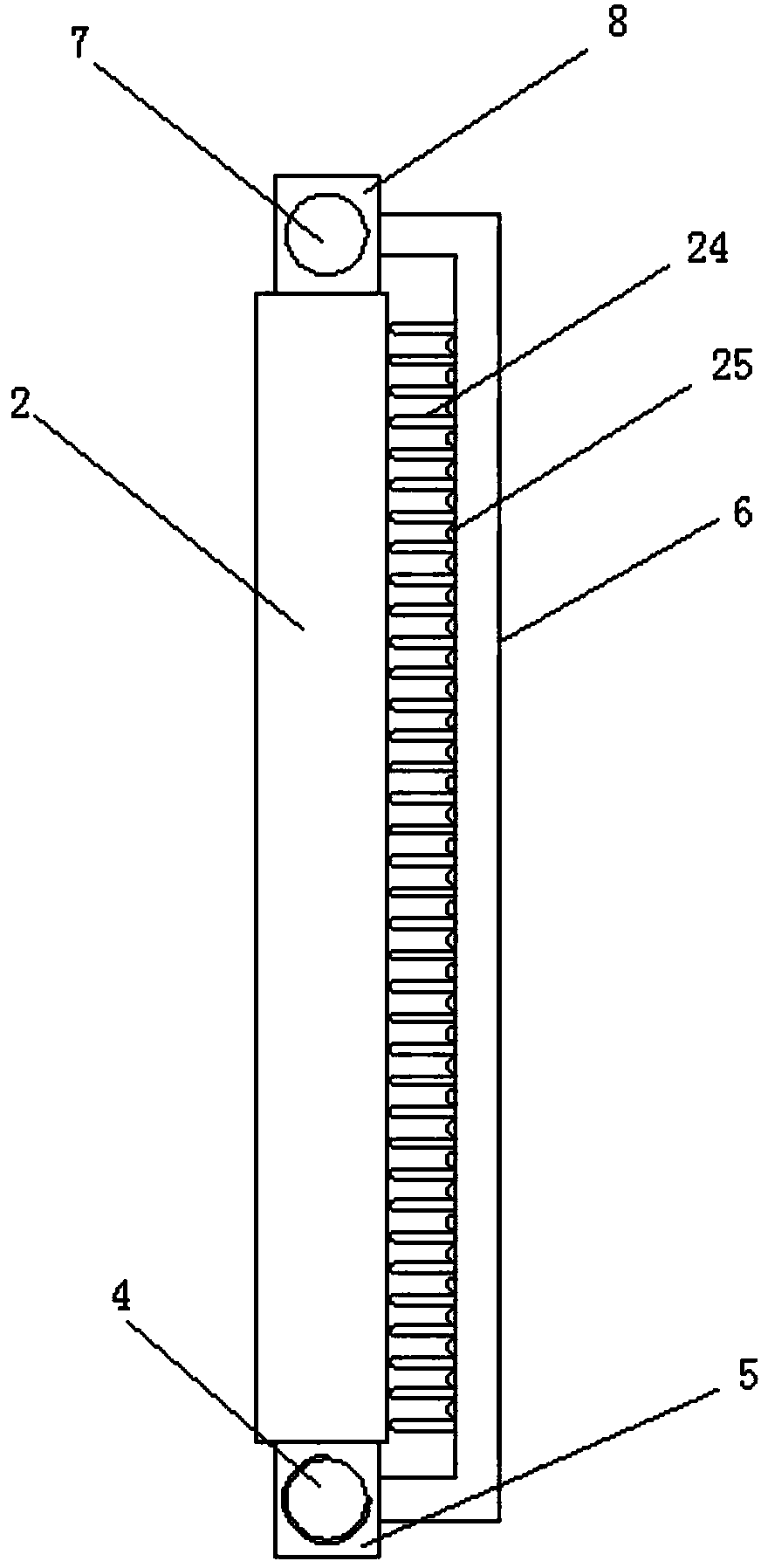

Water-saving high pressure water workpiece washing line

InactiveCN103949428AGood cleaning effectSave washing waterCleaning using liquidsEngineeringHigh pressure

The invention belongs to the technical field of the washing of mechanical workpieces, and relates to a water-saving high pressure water workpiece washing line. The washing line comprises a base, wherein a case is arranged on the base; a belt wheel conveying mechanism is arranged on the base and positioned in the case, and a high pressure water spraying mechanism is also arranged in the case; the high pressure water spraying mechanism comprises a high pressure water spray head which can spray high pressure water and a spray head driving mechanism which can drive the high pressure water spray head to move in a reciprocal manner; the high pressure water spray head is positioned above the belt wheel conveying mechanism and is fixedly connected with the spray head driving mechanism. The washing line has the advantage of good washing effect and the like, can save washing water, and can realize washing, rinsing and drying in one step.

Owner:ZHEJIANG DEQING BAOFEN JETTING SYST ENG CO LTD

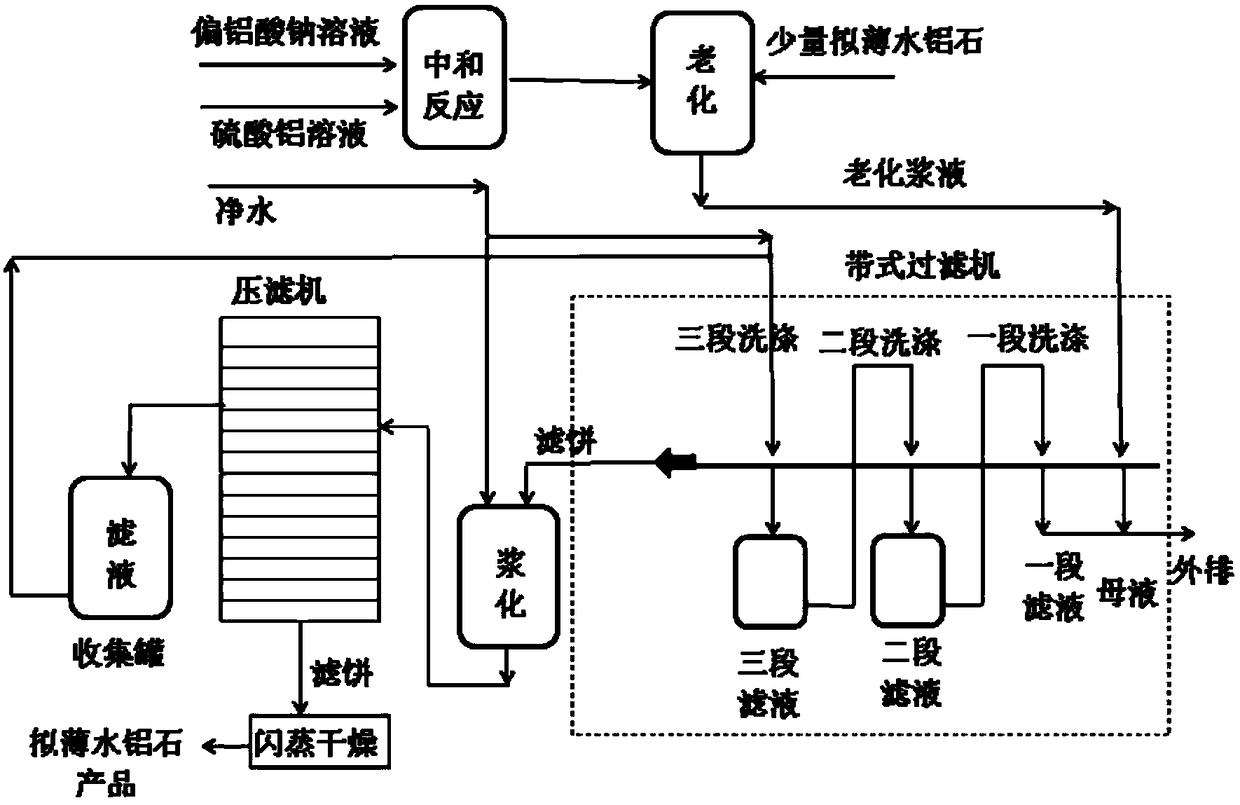

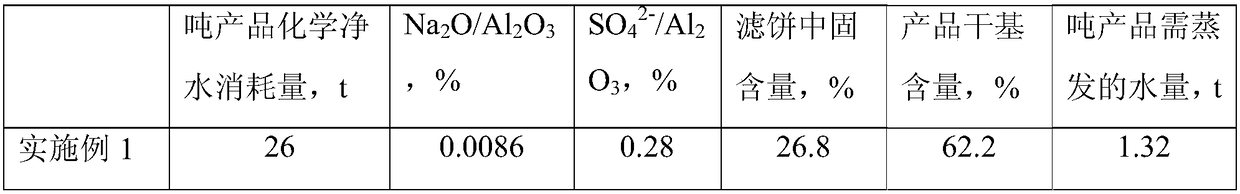

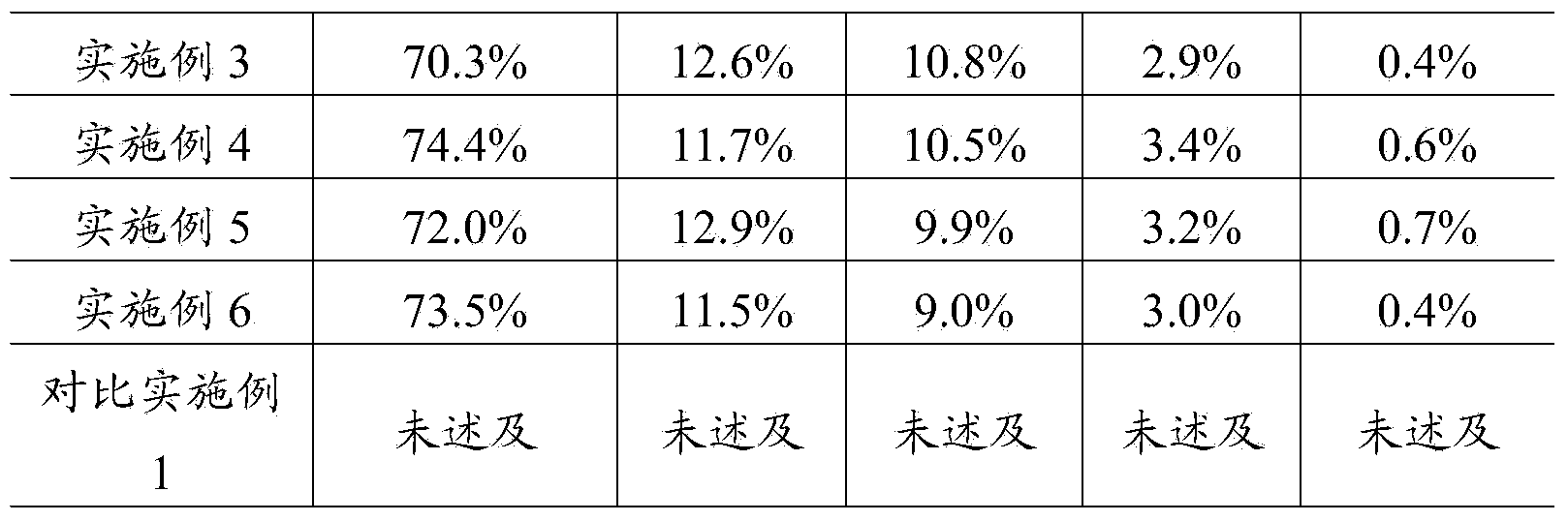

Preparation method of pseudoboehmite

ActiveCN108910925AGood water permeabilityReduce dosageAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationPseudoboehmiteEvaporation

The invention discloses a preparation method of pseudoboehmite. The whole process consists of neutralization, aging, washing and drying steps. The process is characterized in that: 0.5%-5% of dried pseudoboehmite is added at the end of aging, the washing process adopts a continuous belt filter and intermittent filter press two-stage combination process, the washing water amount is 10-30 times thatof the pseudoboehmite product, the solid content of a pseudoboehmite filter cake is in the range of 26.0%-35.0%, the washing water amount is reduced by 50% or more, the amount of water needing evaporation for unit product is reduced by 40% or more, and the energy consumption for drying is reduced by 40% or more. The process saves the washing water amount, reduces the energy consumption for dryingand makes the product quality more stable.

Owner:ZIBO QIMAO CATALYST

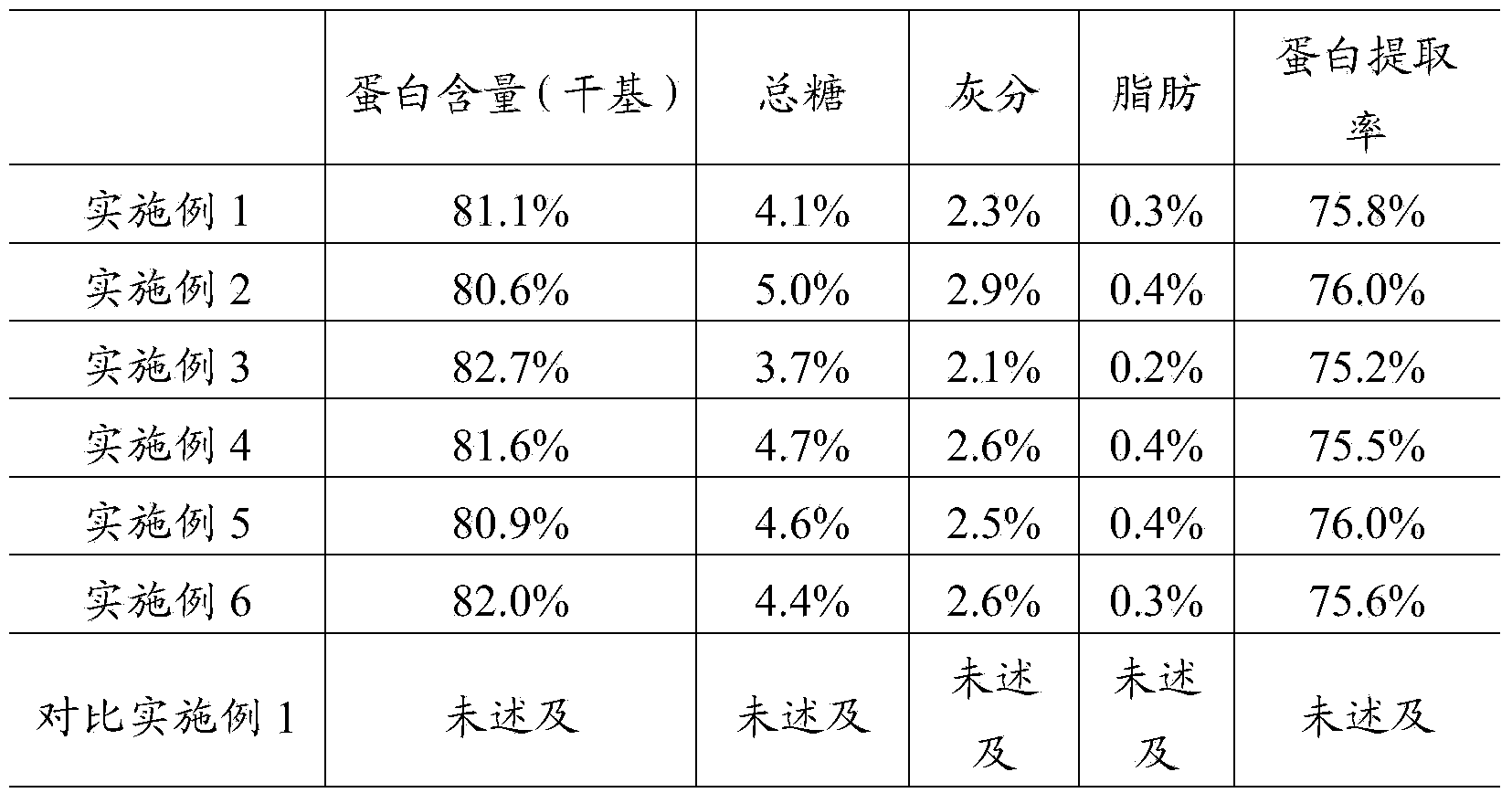

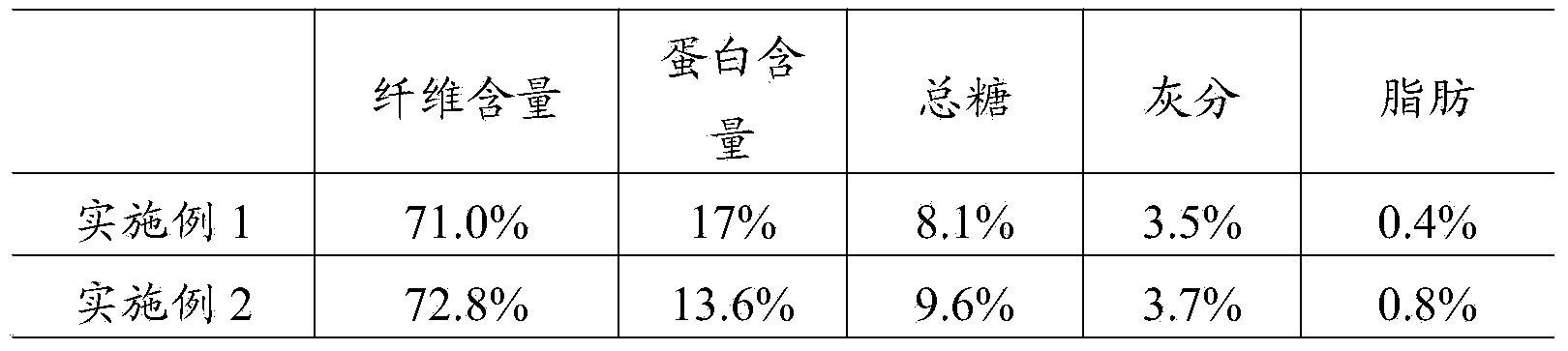

High-purity rice bran protein and rice bran fibers and preparation method thereof

The invention relates to high-purity rice bran protein and rice bran fibers, and further relates to a preparation method of the high-purity rice bran protein and the rice bran fibers. The preparation method includes the steps of raw material pretreatment, first size mixing and enzyme reaction, second size mixing and enzyme reaction, separate washing, drying and the like. According to the method, through superfine grinding and amylase and cellulose hydrolyzing, components of defatted rice bran are effectively separated, a whirlcone is utilized to conduct the washing treatment, and therefore separate washing efficiency is greatly improved. Compared with spray drying, flash drying equipment is utilized, investment is saved by about 40%, operating cost is saved by about 35%, in rice bran protein products, the protein content is over 80%, the ash content is below 3%, the fat content is below 0.5%, the protein extraction ratio is over 75%, and in rice bran fiber products, the fiber content is over 70%, the ash content is below 4%, and the fat content is below 1%. The high-purity rice bran protein and the rice bran fibers all can be widely applied to the field of health food, nutritious food and the like, and additional value of rice deep processing is greatly improved.

Owner:格乐瑞(无锡)营养科技有限公司

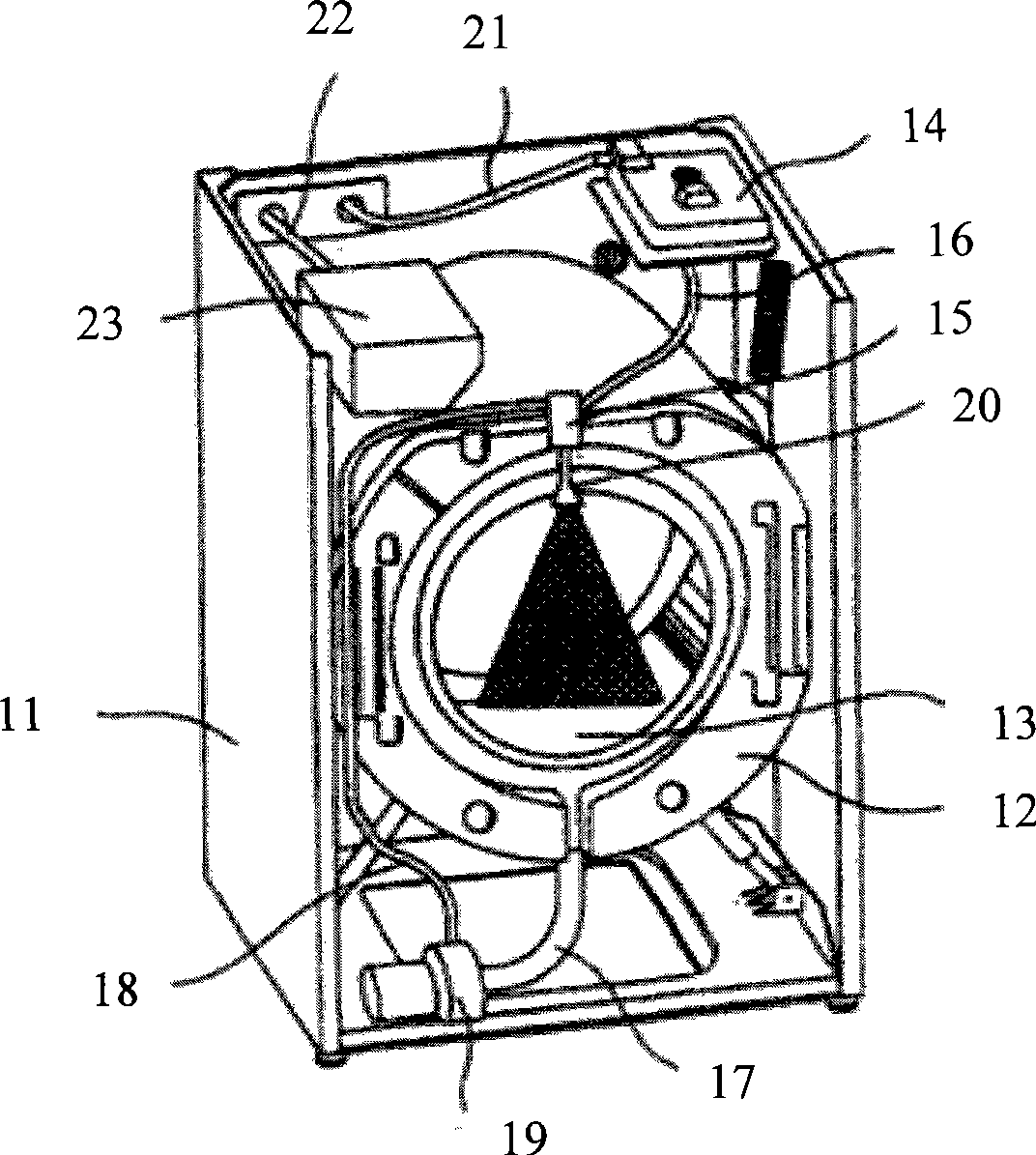

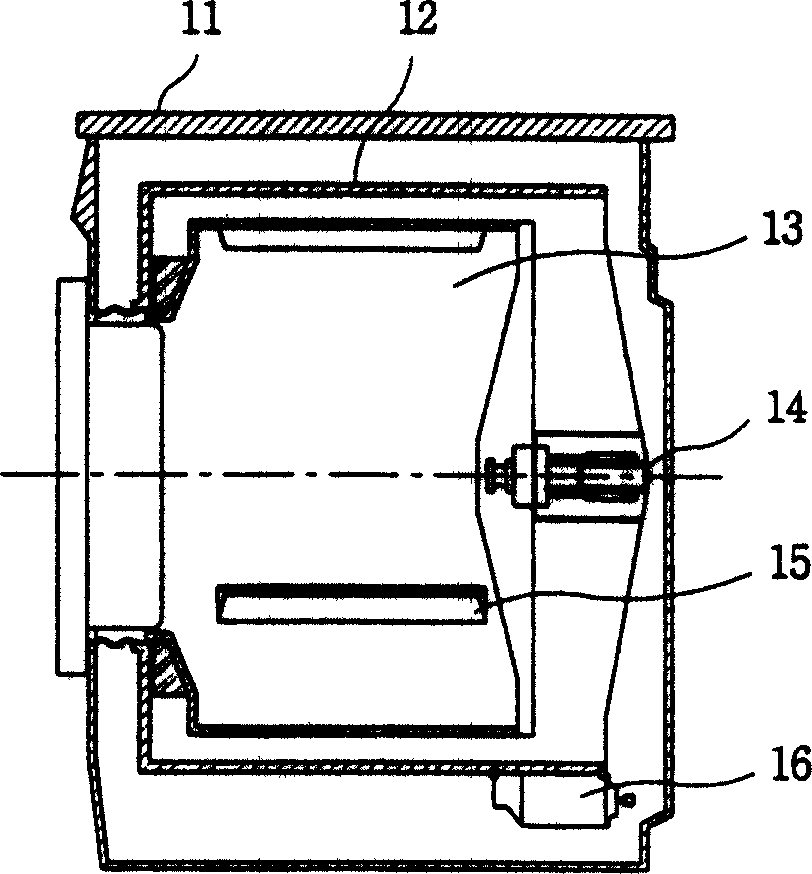

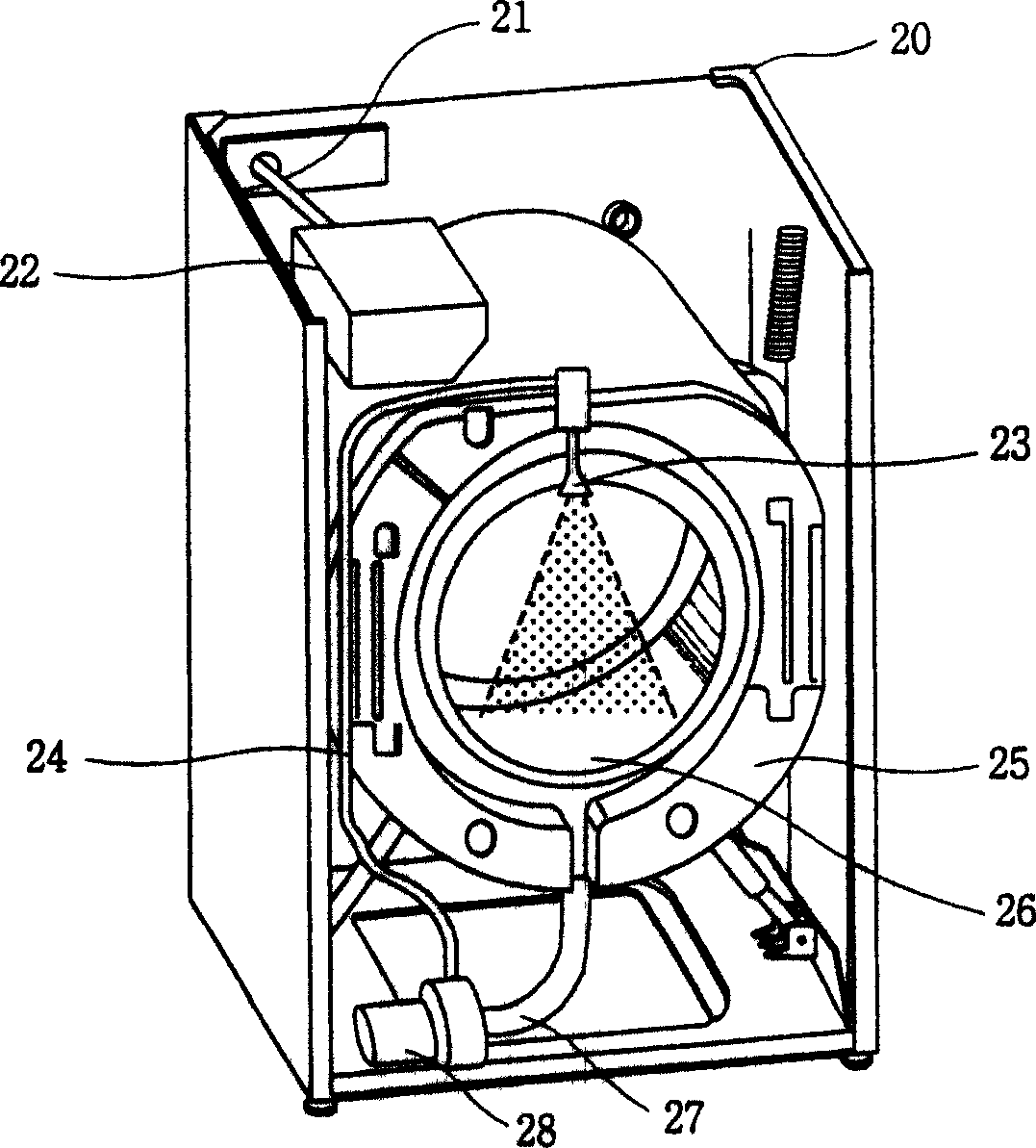

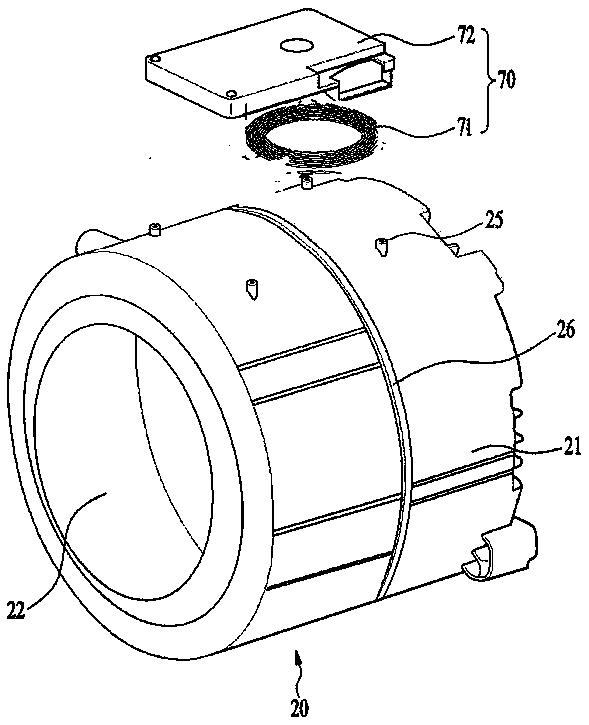

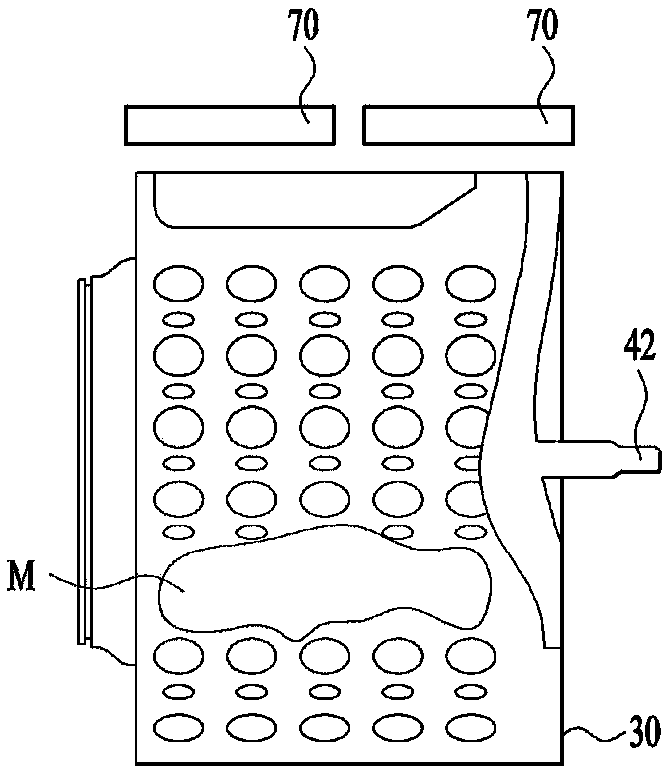

Steam generator of washing machine and wave wheel washing machine equipped with the same

ActiveCN101498092ALow costReduce thicknessOther washing machinesSteam generation plantsThermodynamicsLaundry washing machine

The invention discloses a steam generator of a washing machine and a rotary drum washing machine with the steam generator. The steam generator is of a long column drum structure, a water space capable of storing water is arranged at the lower part of the long column drum structure, and a steam space capable of storing steam is arranged at the upper part of the long column drum structure and is communicated with the water space. The steam generator of the long column drum structure is mounted between the side wall of a casing and the side wall of an outer drum of the rotary drum washing machine. The steam generator structure effectively utilizes the space of the rotary drum washing machine, can mount the steam generator under the condition that an original structure of the rotary drum washing machine is not changed so as to add the steam generation function for the rotary drum washing, and has simple structure and low cost.

Owner:HAIER GRP CORP +1

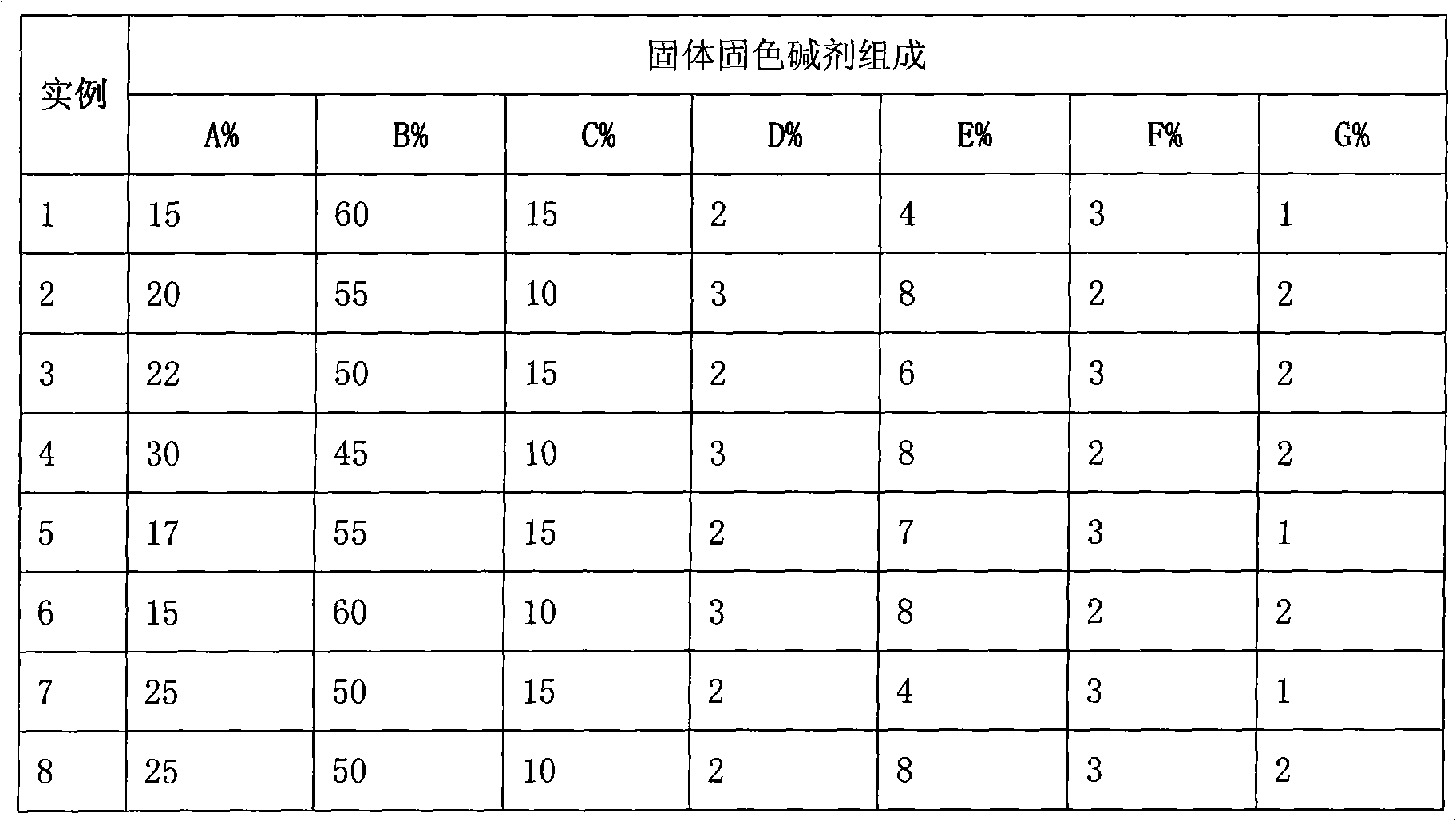

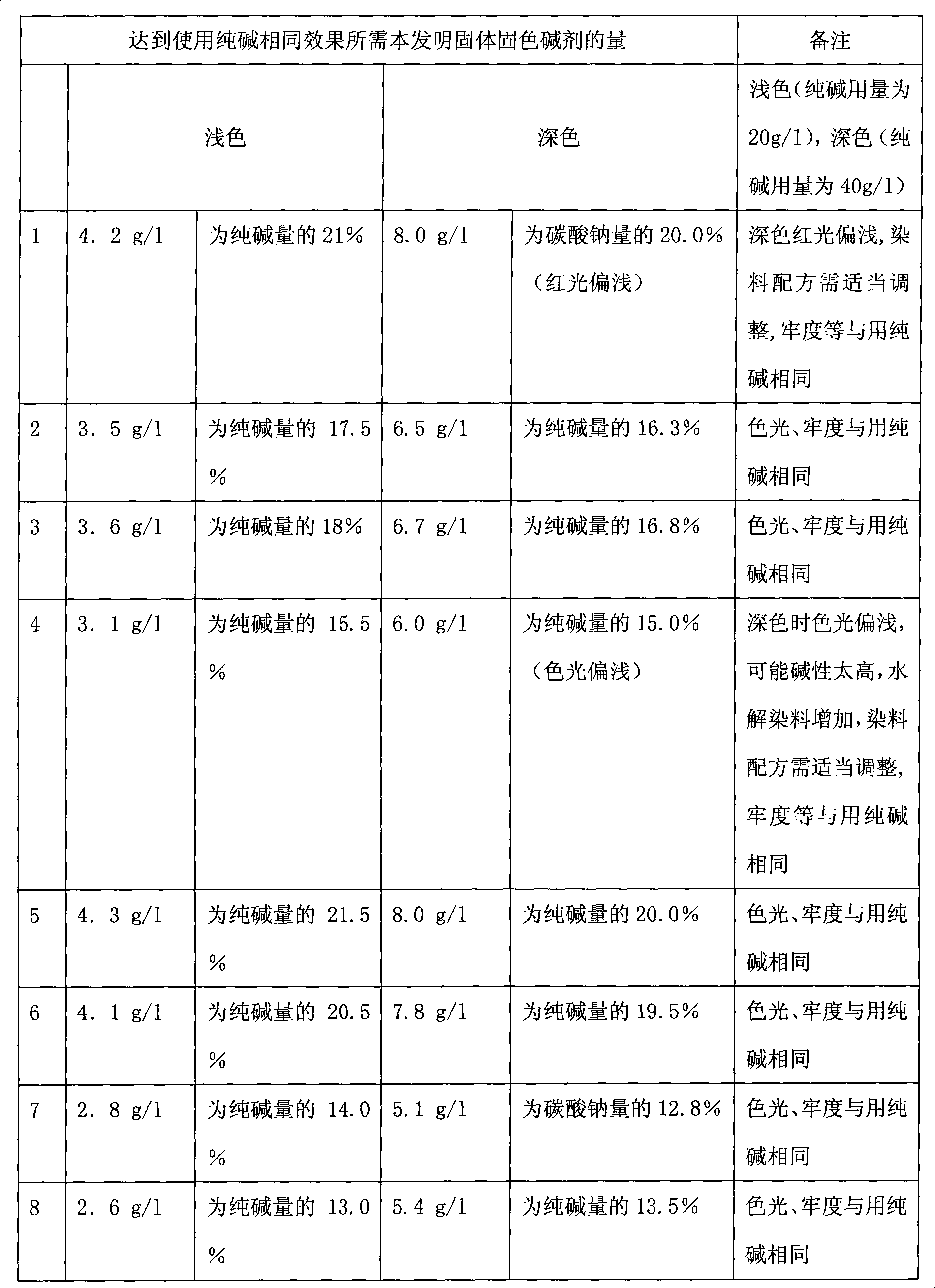

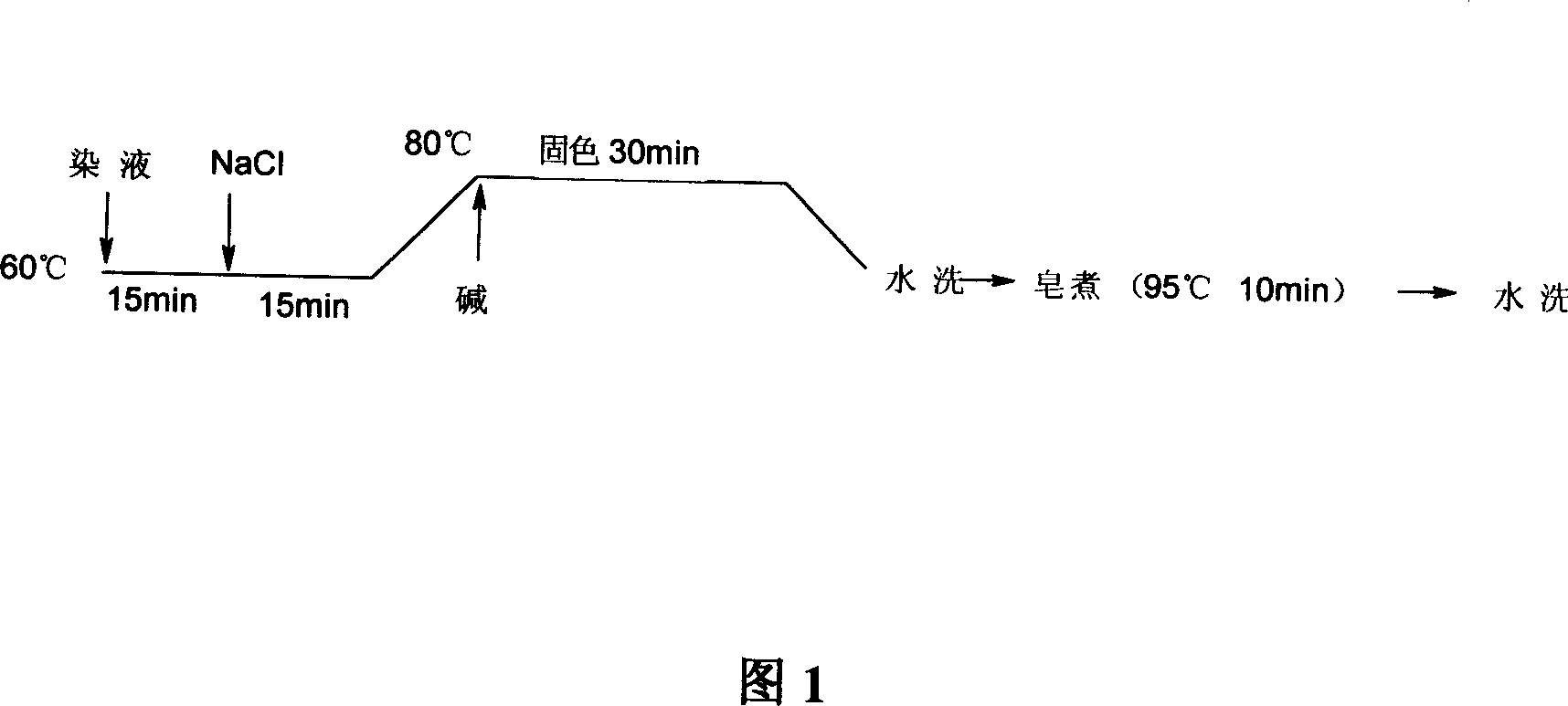

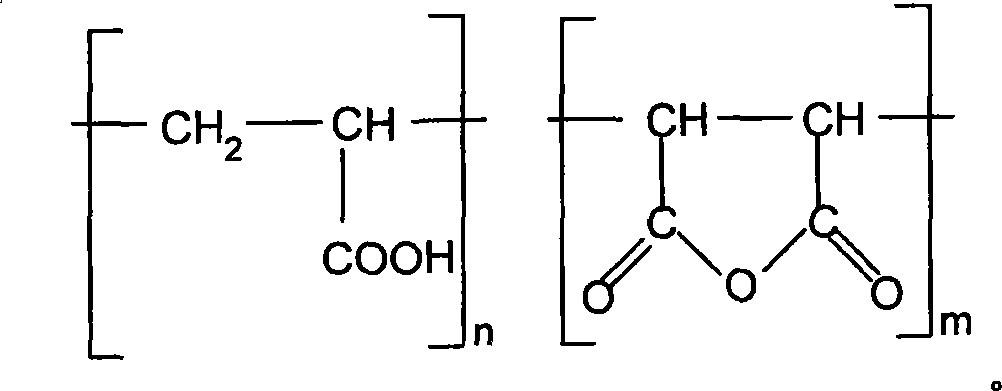

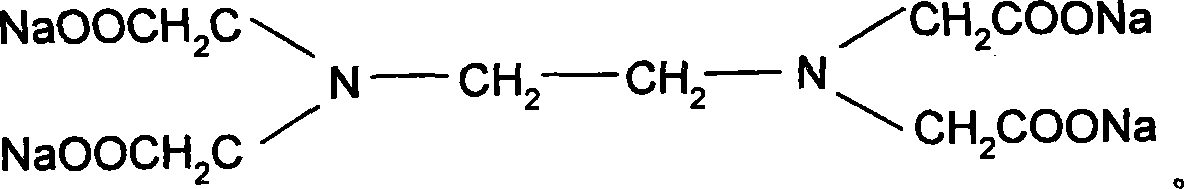

Solid fixation alkaline agent used for reactive dye rolling braizing method dyeing

The invention discloses a solid fixation alkaline agent for pad steaming process dyeing through reactive dyes, comprising the following components in percentage by weight: 15-30 percent of alkali metal hydroxide, 60-45 percent of alkali metal carbonate, 16-10 percent of alkali metal phosphate, 1-2 percent of chelator, 2-3 percent of alkali-resistant penetrating agent, 4-8 percent of cosolvent and 1-2 percent of color light protective agent. The alkaline agent is characterized in little dosage, convenient manufacturing and transportation, etc., and has the advantages that production cost can be reduced and environmental pollution is reduced. The alkaline agent meets the requirements on efficiency increase, emission reduction and clean production, and is sufficient to replace the prior fixation soda ash for pad steaming process dyeing through reactive dyes.

Owner:夏建明 +1

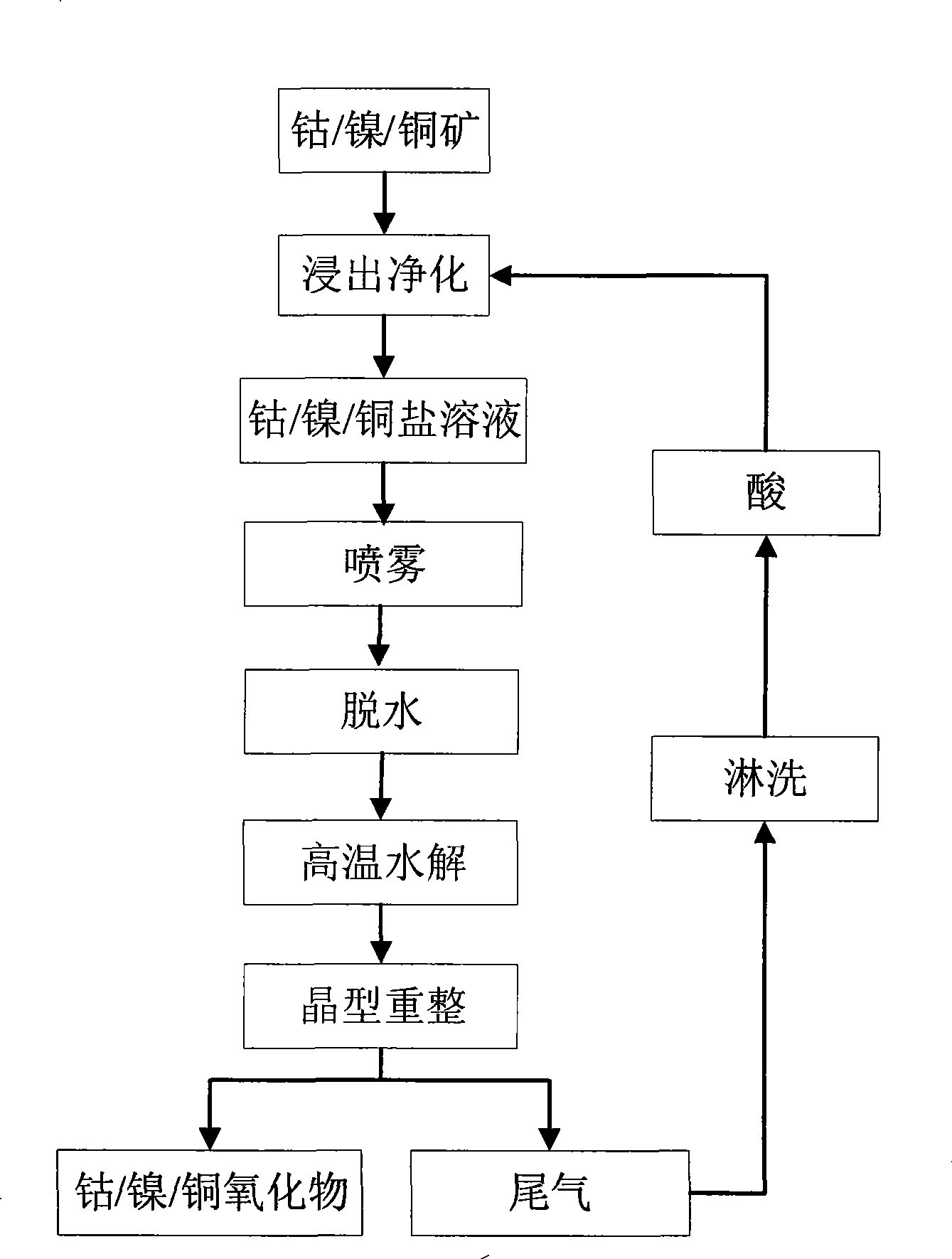

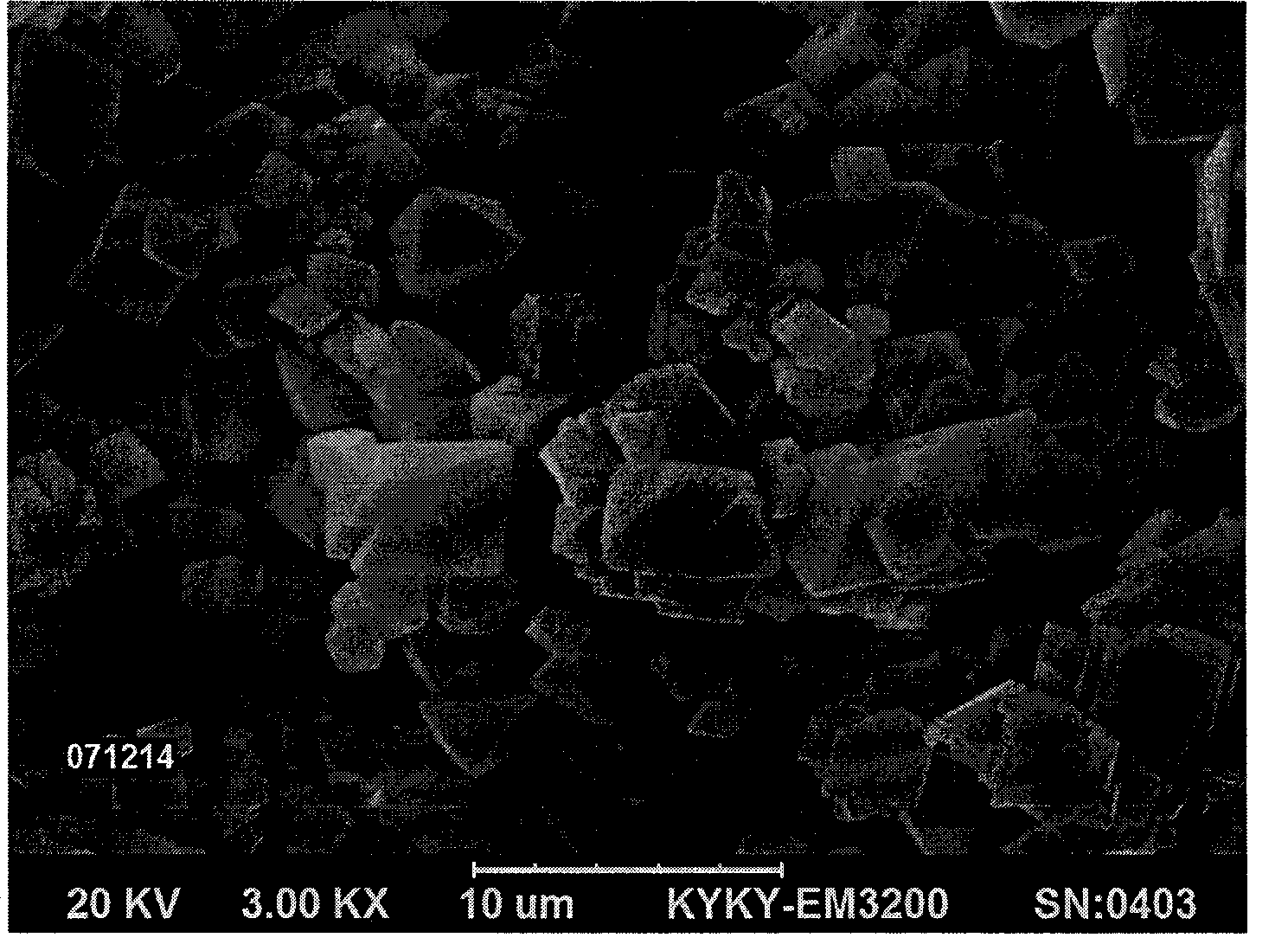

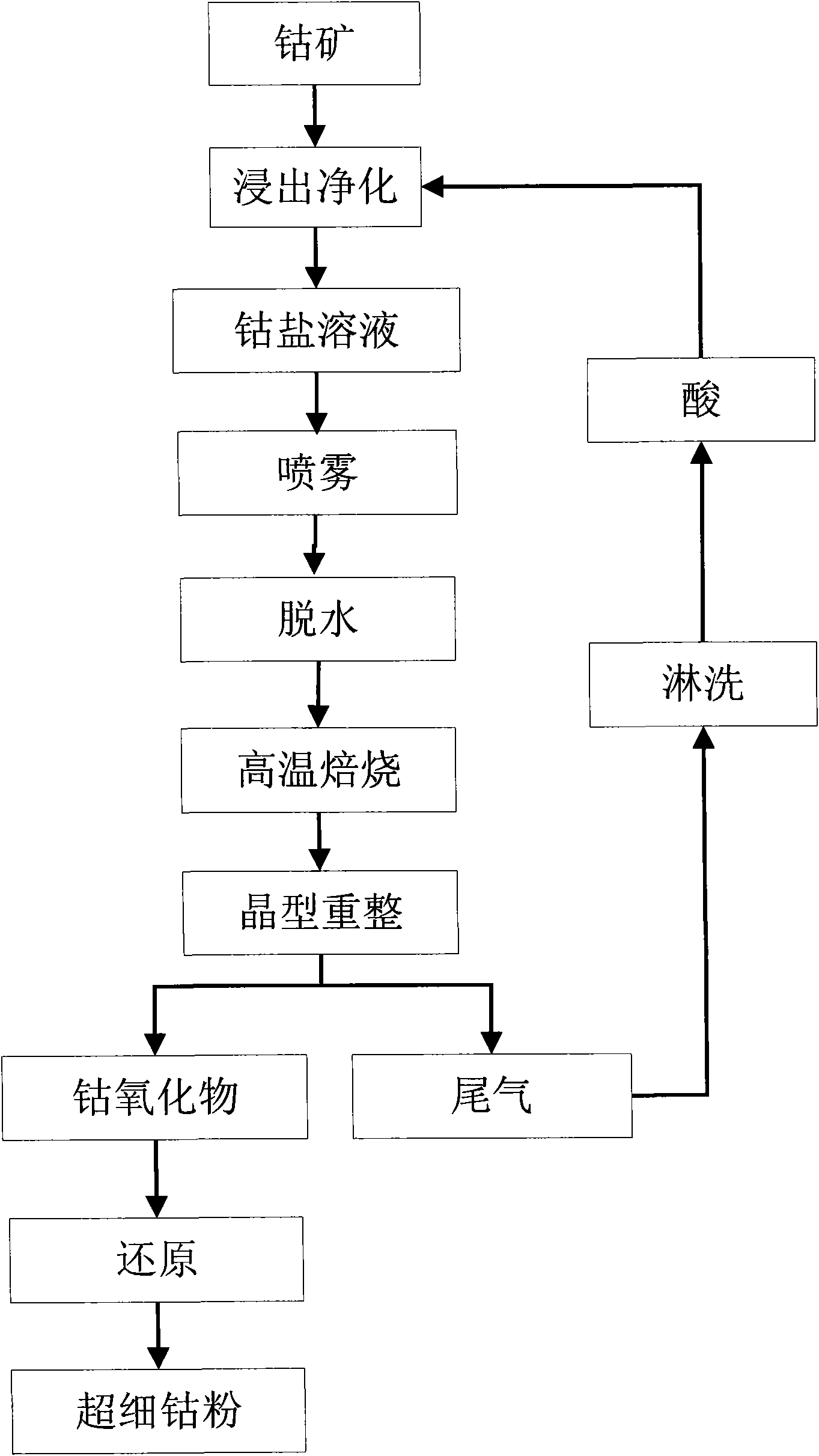

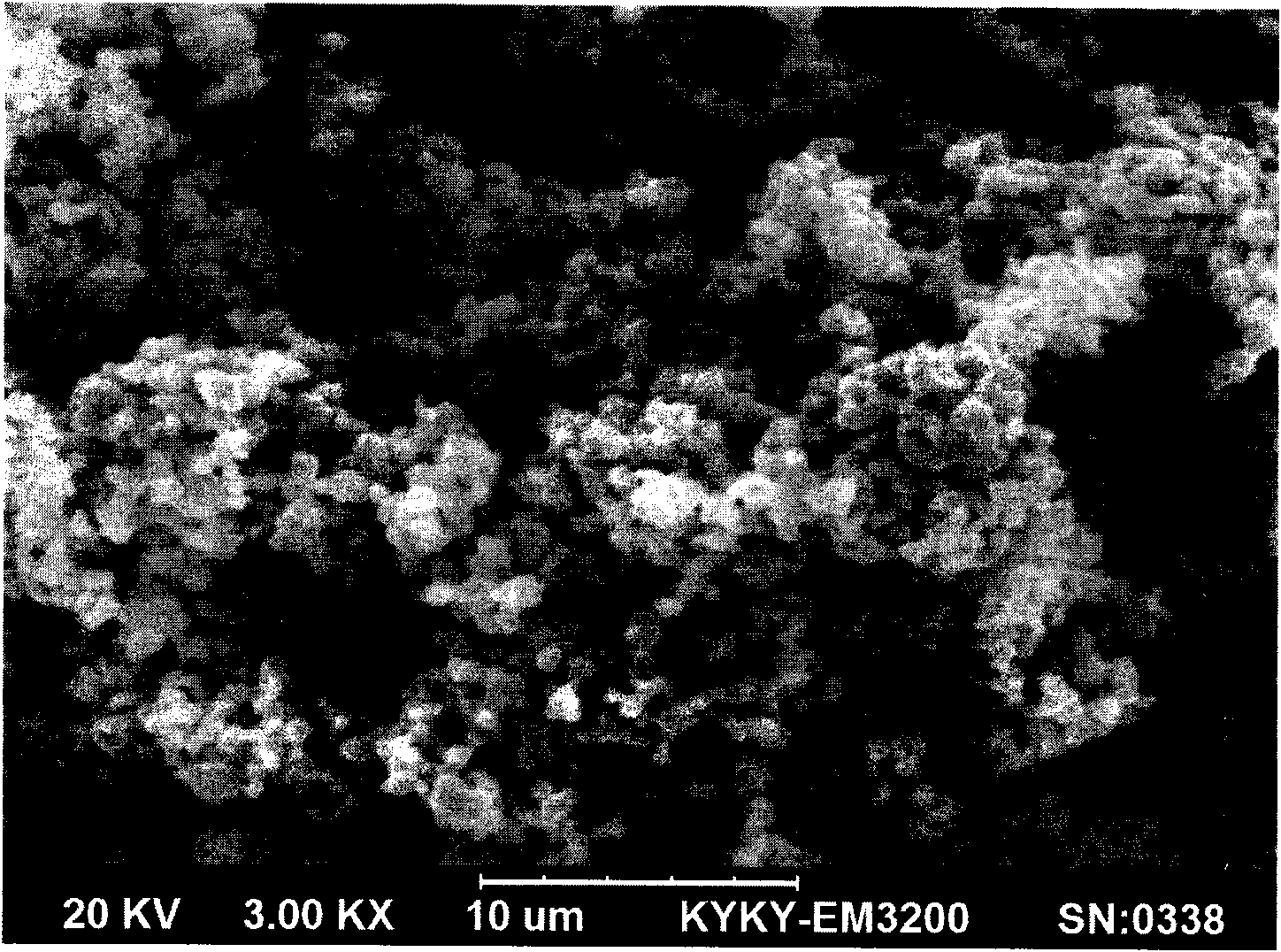

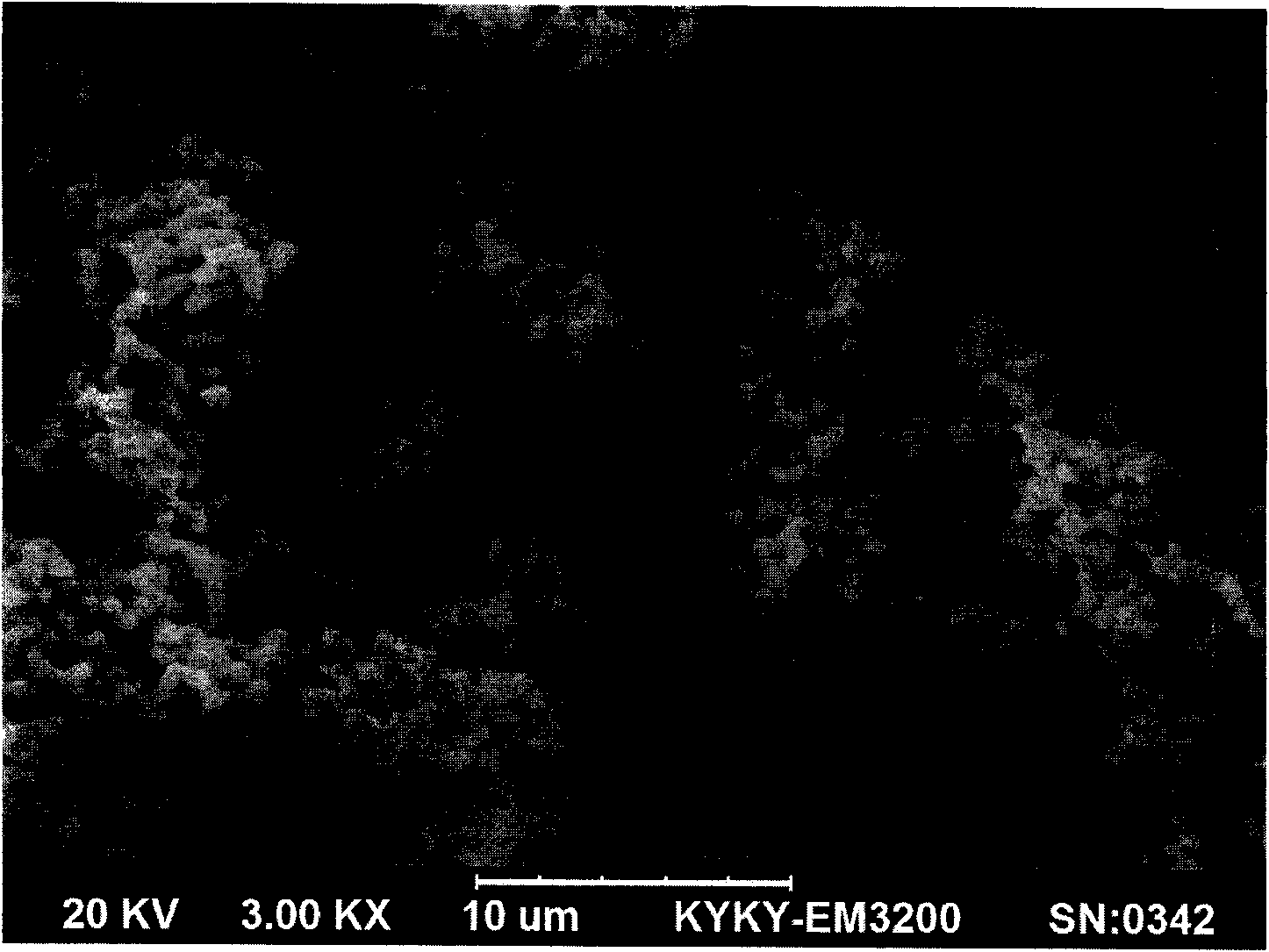

Novel methods for preparing cobalt oxide, nickel oxide and copper oxide

ActiveCN101367555AImprove liquidityUniform particle sizeCopper oxides/halidesNickel oxides/hydroxidesCopper oxideHydrolysis

The invention relates to a method for preparing cobalt oxide, nickel oxide and copper oxide, in particular relates to a method for preparing the oxide of the cobalt (Co3O4, Co2O3), the oxide of the nickel (NiO), the oxide of the copper (CuO), and the like. The minerals containing the cobalt, the nickel or the copper are adopted as the raw material; after the minerals is dipped and purified to get high-purity cobalt salt, nickel salt or copper salt solution; the salt solution is made into the mist-shaped liquid drop in the mist spraying way; the cobalt oxide, the nickel oxide or the copper oxide can be prepared through the dehydration, high-temperature hydrolysis and the crystal-shape re-shaping; the tail gases such as the vapor and the acid gases that are generated in the hydrolysis process are absorbed by a leaching tower to get the acid, and the acid is returned to be used for the dipping and purification process of the minerals, thereby realizing the comprehensive cycling application in the preparation process. The method can also be used for processing the waste material containing the cobalt, the nickel or the copper. The invention has the advantages of advanced process, stable production, low cost, no waste water discharging, environmental protection, high purity of the product, uniform granularity, high crystallization, and the like.

Owner:ZHEJIANG HUAYOU COBALT

Environment protection type reactive dye color fixing liquid alkali

The invention discloses an environmental protective reactive dye fixation liquid alkali which can replace dying powder fixation alkali of prior reactive dying. The fixation liquid alkali has the characteristics of little dosage, convenient operation and environmental protection, and can reduce production cost, reduce environmental pollution and fulfill the requirement of automation batching. The formula of the reactive dye fixation liquid alkali of the invention according to weight percentage consists of: alkali metal hydroxide NaOH 5-12.5 percent; KOH 5-12.5 percent; alkali carbonate Na2CO3 7.5-15 percent; K2CO37.5-15 percent; stabilizer 4.9-5.1 percent; chelating agent 0.09-0.11 percent; and the rest is water.

Owner:ZHEJIANG SCI-TECH UNIV +1

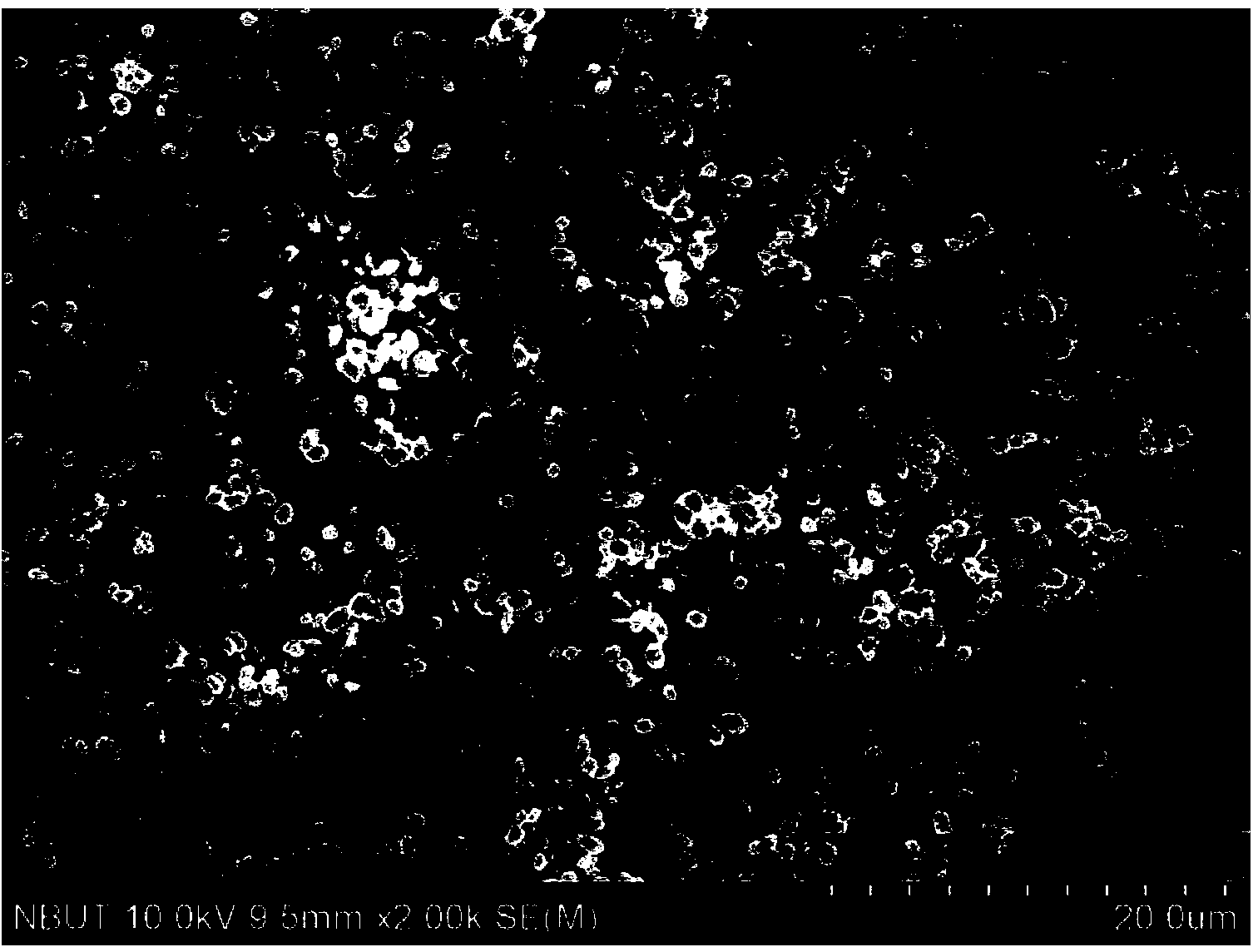

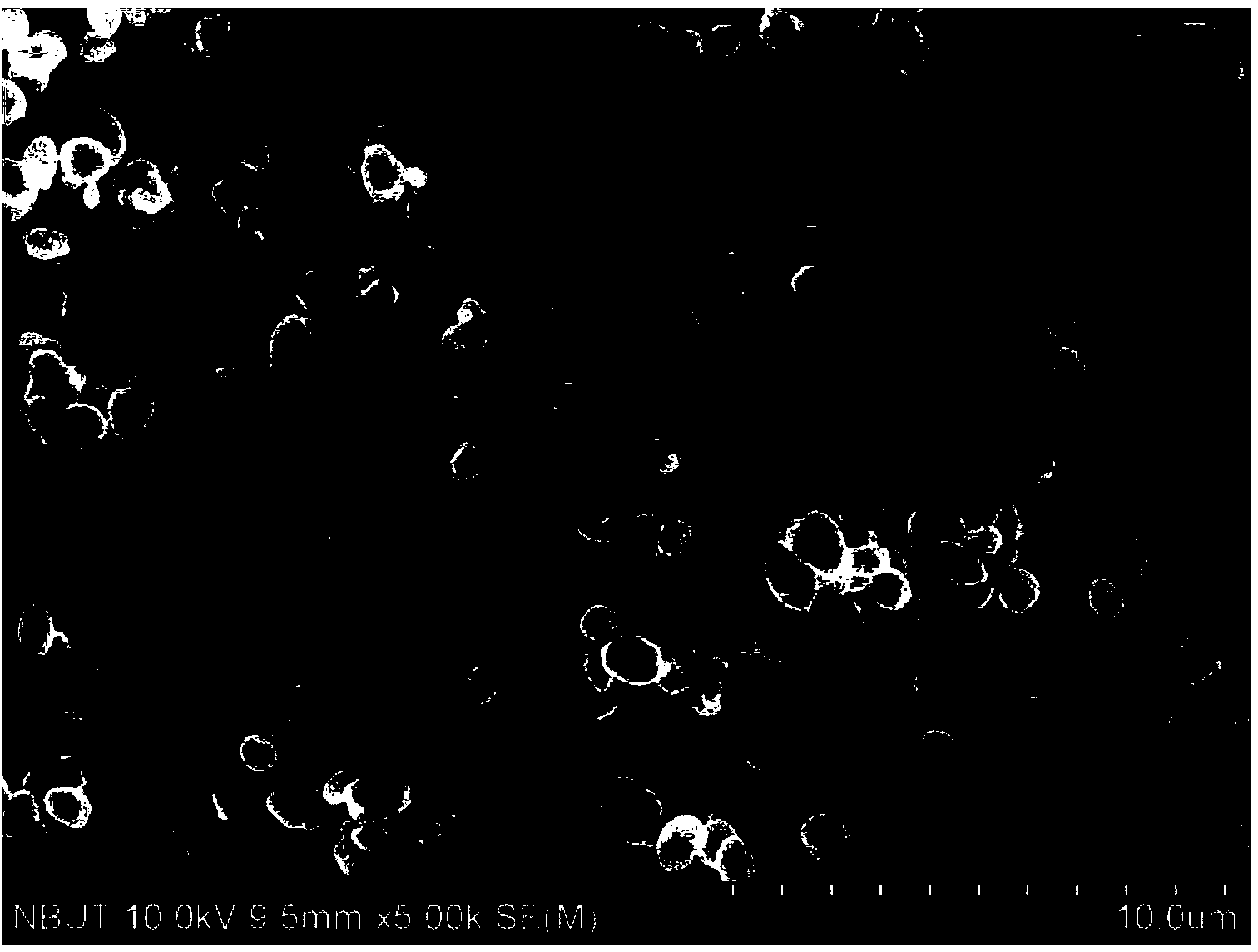

Battery-grade ferric phosphate and preparation method

Owner:NINGBO UNIVERSITY OF TECHNOLOGY +1

Nano self cleaning silk broadcloth and products

ActiveCN1277019CWith self-cleaning functionIncreased durabilityFibre treatmentChlorideSolid particle

This is a self-clean real silk cloth and its productive method. It features are: To treat the real silk cloth with the organic fluorine regulator it is nano-grade inorganic solid grain, use to soak, to coat or to spray on them, to make their surface have water-distant and oil-distant function. The organic fluorine regulator contains: the organic fluorine resin 10-70g / L, nano-grade inorganic solid grain water 5-30g / L. In the advanced organic fluorine regulator also contain the silicon alkanet, magnesium chloride, or isopropyl alcohol at least one of above compositions.

Owner:韦钧千

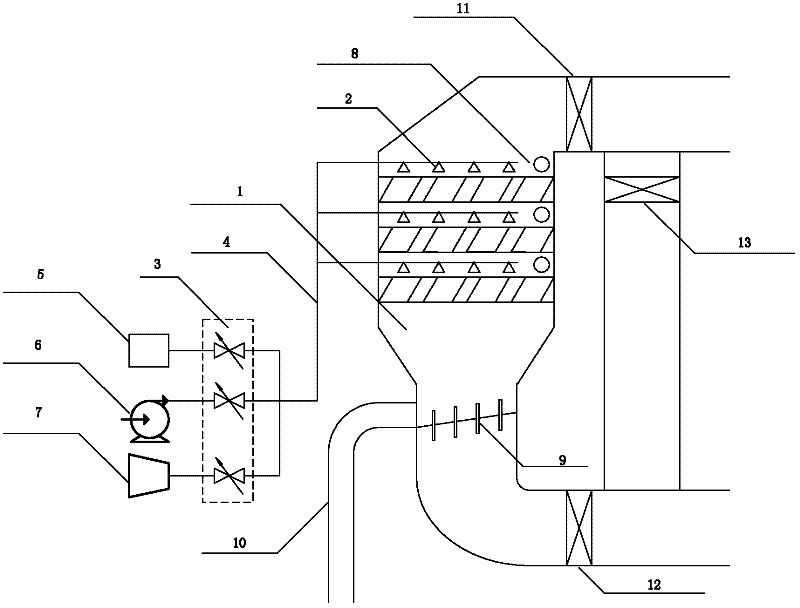

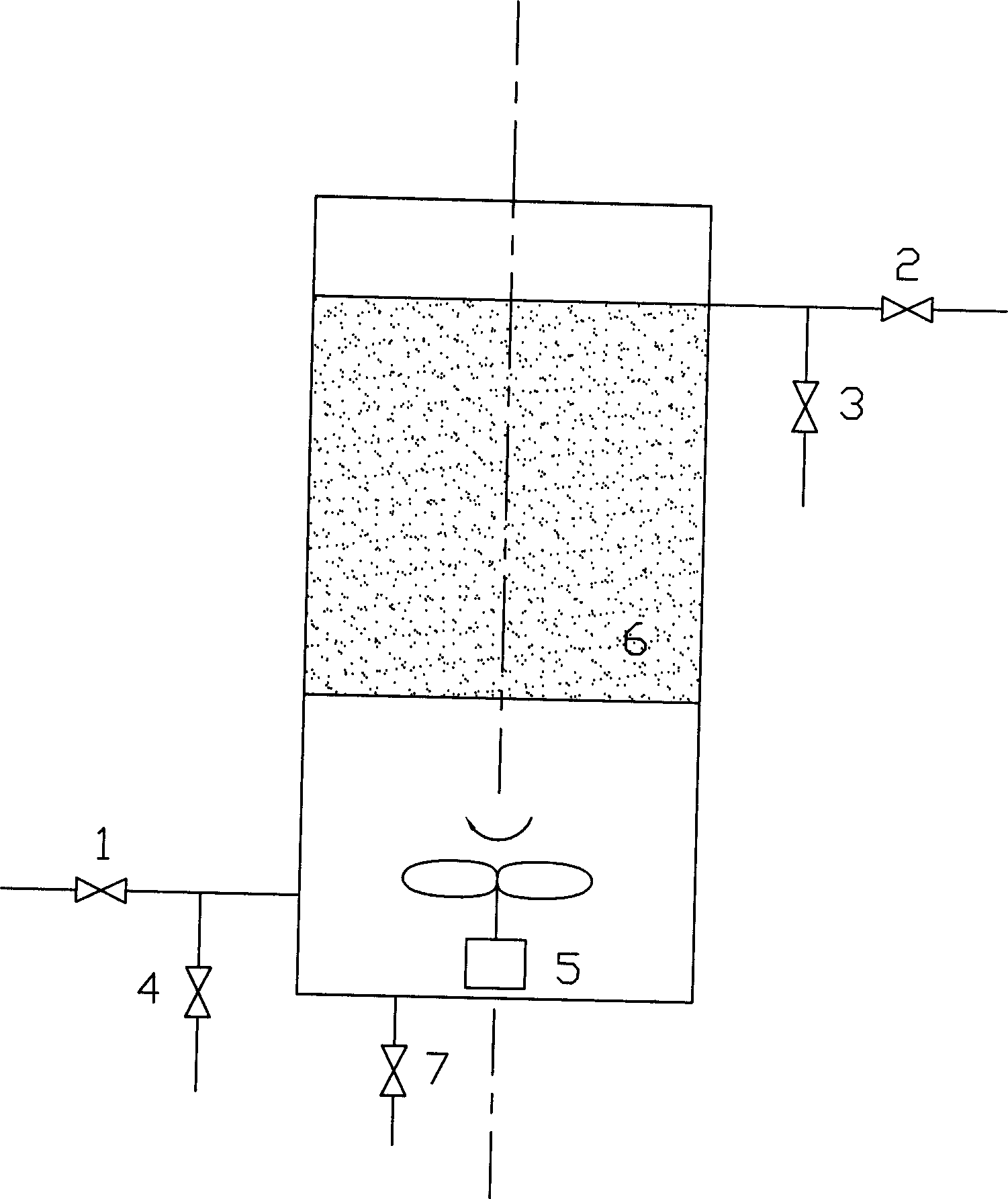

Rotary flow aeration biological filter

InactiveCN1640825AWash evenlySave washing waterTreatment using aerobic processesSustainable biological treatmentWater flowBiological filter

The rotary flow aerating and biologically filtering tank is circular or squared, adopts light suspended stuffing and has mechanical stirrer installed to make water and the stuffing rotate around the center of the tank. The aerating and biologically filtering tank runs in upstream mode. During processing sewage, the stirrer rotates slowly to rotate the bottom water flow for the homogeneous mixing and distribution of inflowing water. During washing the aerating and biologically filtering tank, the stirrer rotates quickly to rotate water and filtering material, the collision among filtering grains and the shearing force of water flow make the biological film on the stuffing fall down, and clear water is led in for rinsing to complete the washing process.

Owner:向连城

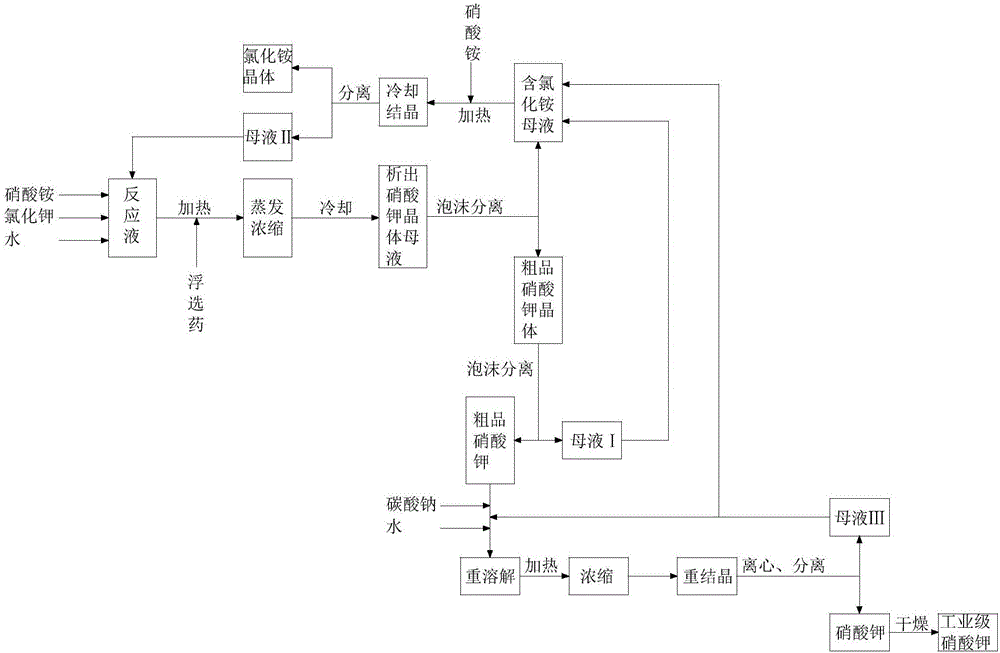

Potassium chloride and ammonium nitrate double decomposition and circulation method for producing high quality potassium nitrate

ActiveCN105060317AHigh quality contentSimple separation processAlkali metal nitrate preparationWater useSeparation technology

The invention discloses a potassium chloride and ammonium nitrate double decomposition and circulation method for producing high quality potassium nitrate. According to the method, potassium chloride and ammonium nitrate are taken as the raw materials, and the method comprises steps of raw material preparation, potassium nitrate crystallization, foam floatation and separation, potassium nitrate refinement, and ammonium chloride crystallization. The method is developed on the basis of conventional potassium nitrate production technology by improving part of the technology; wherein in the foam flotation and separation technology, in the presence of a floatation reagent (C12-C20 higher straight-chain aliphatic amine) and in a certain pH value range, the ammonium chloride and coarse potassium nitrate can be separated through foam entrainment; in the potassium nitrate refinement, the refined potassium mother liquid in the previous circulation is used to wash the coarse potassium nitrate, and then potassium nitrate is purified by sodium carbonate. In one aspect, the conventional potassium nitrate production technology is optimized, the potassium nitrate quality is improved, and the impurity content of the potassium nitrate product is greatly reduced. In the other aspect, the water using amount is reduced, the labor intensity is also reduced, and the production cost is saved. The industrial grade KNO3 mass content is not less than 99.7%, the content of Cl<-> is not more than 0.01%, and the content of NH4<+> is not more than 0.03%. the method has a wide application value and can generate prominent social benefit and economic benefit.

Owner:湖南丹化农资有限公司

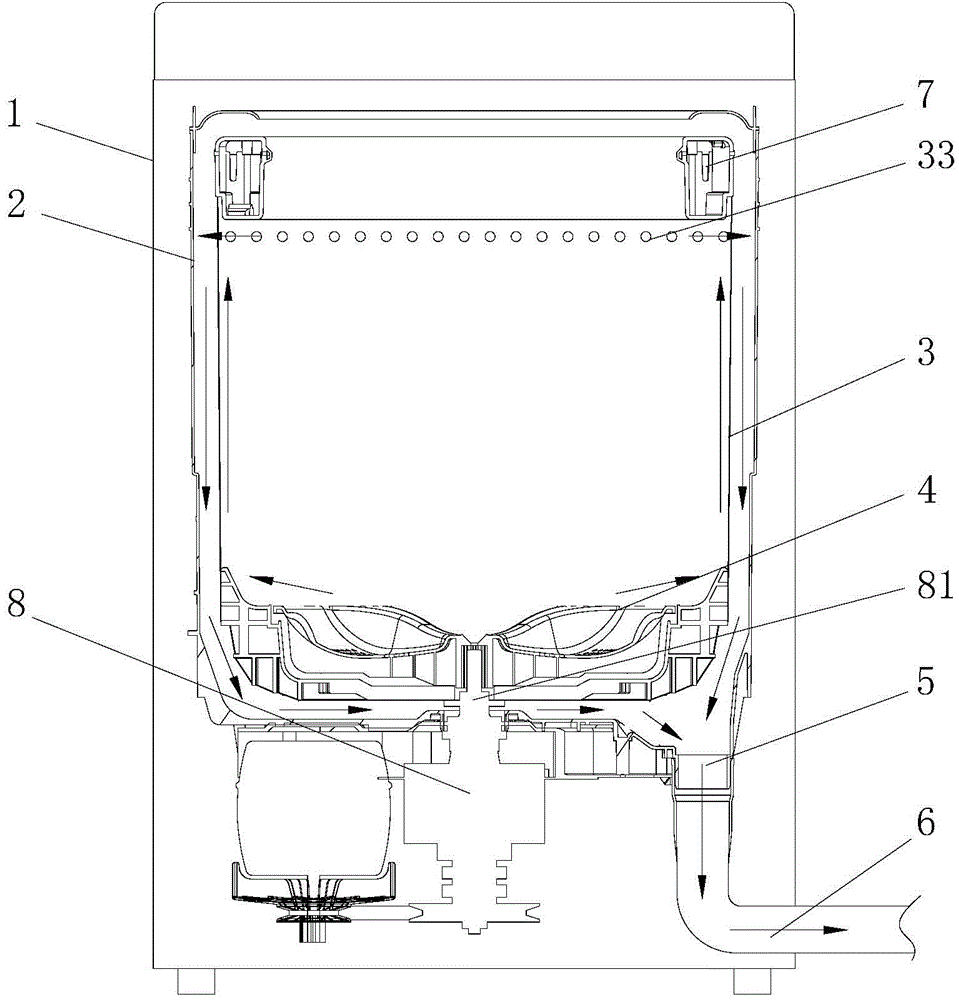

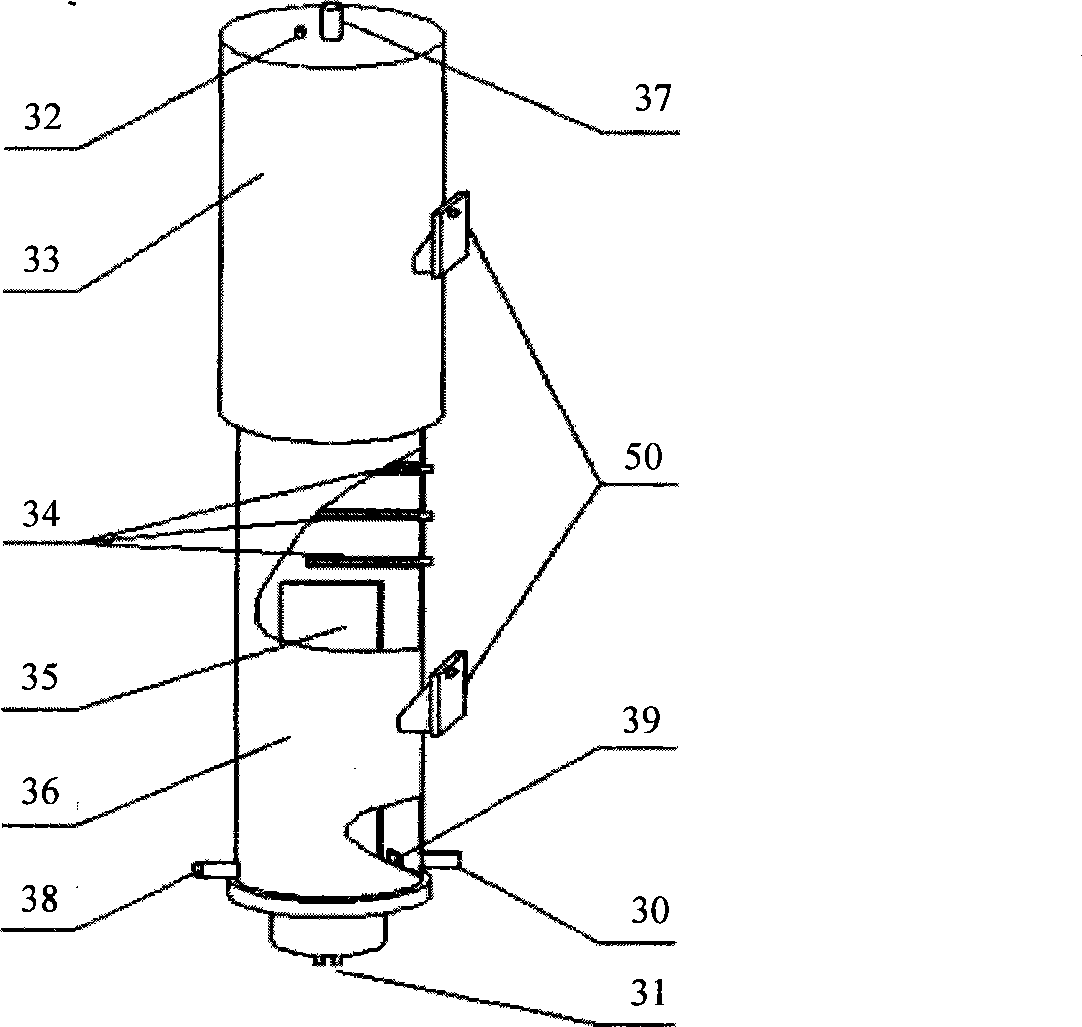

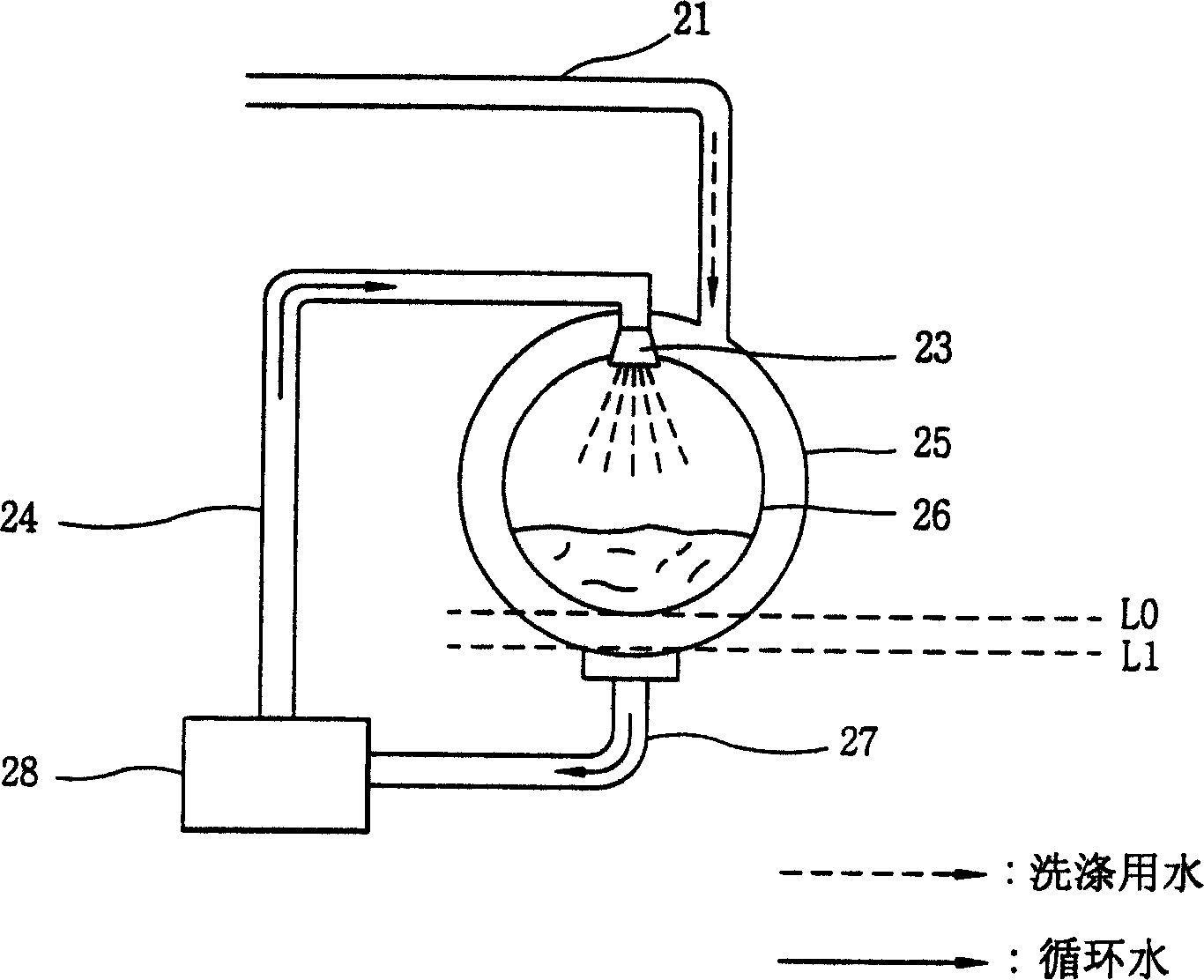

Water supplying device of drum washing machine and method thereof

InactiveCN1580373ASave washing waterReduce consumptionOther washing machinesControl devices for washing apparatusSpray nozzleCirculator pump

An water supply apparatus and its method of a drum-type washing machine includes a rotation pump for rotating washing water supplied into a tub, and a spray nozzle for spraying washing water supplied from the rotation pump into the drum.

Owner:LG ELECTRONICS INC

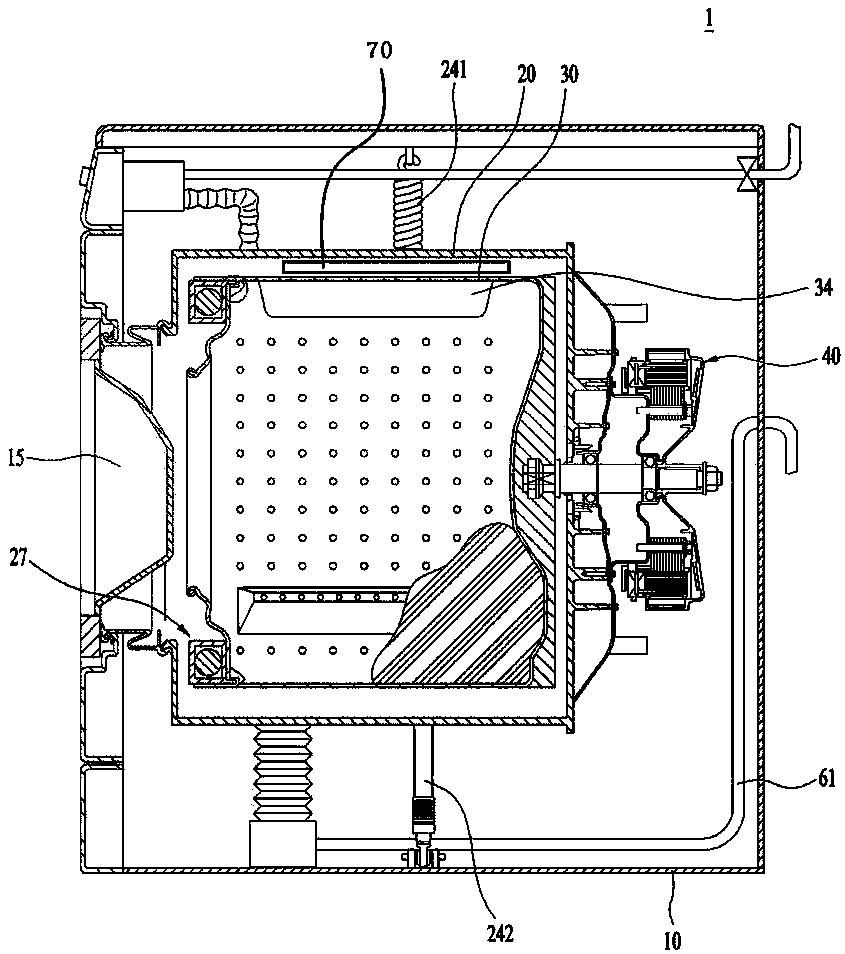

Clothes treatment apparatus

ActiveCN107780163AIncrease temperatureDry evenlyCoil arrangementsOther washing machinesPower flowElectrical conductor

The present invention relates to a clothes treatment apparatus comprising: a cabinet; a tub provided in the cabinet and defining a receiving space, with an opening portion formed in a front; a drum made of a conductor and rotatably provided in the receiving space for receiving clothes; and an induction unit provided in an outer circumferential surface of the tub and heating the drum by generatingan electromagnetic field, wherein the induction unit comprises a coil generating an eddy current in the drum by generating a magnetic field, using an electric current supplied thereto; and a coil arranging portion provided in the outer circumferential surface of the tub and guiding the coil to be wound around front and rear portions of the tub at least one time, spaced a preset distance apart fromeach other.

Owner:LG ELECTRONICS INC

Method for preparing barium sulfate

InactiveCN101332998AGood responseSave washing waterCalcium/strontium/barium sulfatesChemical combinationChemistry

The invention discloses a preparation method of precipitated barium sulfate; a piece of nano-filter cloth is added in the traditional preparation method for filtering to obtain refined solution; chemical combination, separation, acid adjustment, drying and evaporation are carried out; barium sulfate, the main component of the product, is raised from 98% to 98.6-99%, the grain diameter of the finished product reaches 900-1,000 meshes, the Na2S, the iron content of which drops below 30ppm, can meet the standard of the first-class product of low-iron sodium sulphide, the coal consumption per ton product is reduced from 3t coal per t sodium sulphide to 1.2t coal per t sodium sulphide; furthermore, the preparation method can save scouring water by 34% and electricity by 11%, improve the quality of the product and lower cost and is beneficial for energy saving and environment protection.

Owner:ZHUSHAN COUNTY QINBA BARIUMSALT CO LTD

Process for preparing ammonia synthesis catalyst

InactiveCN1385238AThe preparation device is simpleEasy to obtain preparation equipmentMetal/metal-oxides/metal-hydroxide catalystsActivated carbonActive carbon

The preparation method of catalyst for synthesizing ammonia includes the following steps: firstly, using ruthenium trifluoride solution with a certain concentration and adopting conventional wte impregnation method or coating method to impregnate the dried commercial active carbon carrier; drying at 30-120 deg.c; using dilute reducing agent solution to make reduction; using dilute alkaline solution to wash and using pure water to wash, drying at 30-120 deg.c; using conventional wet impregnation method or coating method to impregnate alkaline soil, rare earth or alkali metal solution as adjuvant; finally drying at 30-120 deg.c. As compared with catalyst prepared by hydrogen reduction process the activity of said invented catalyst can be raised by 5-30%.

Owner:FUZHOU UNIVERSITY

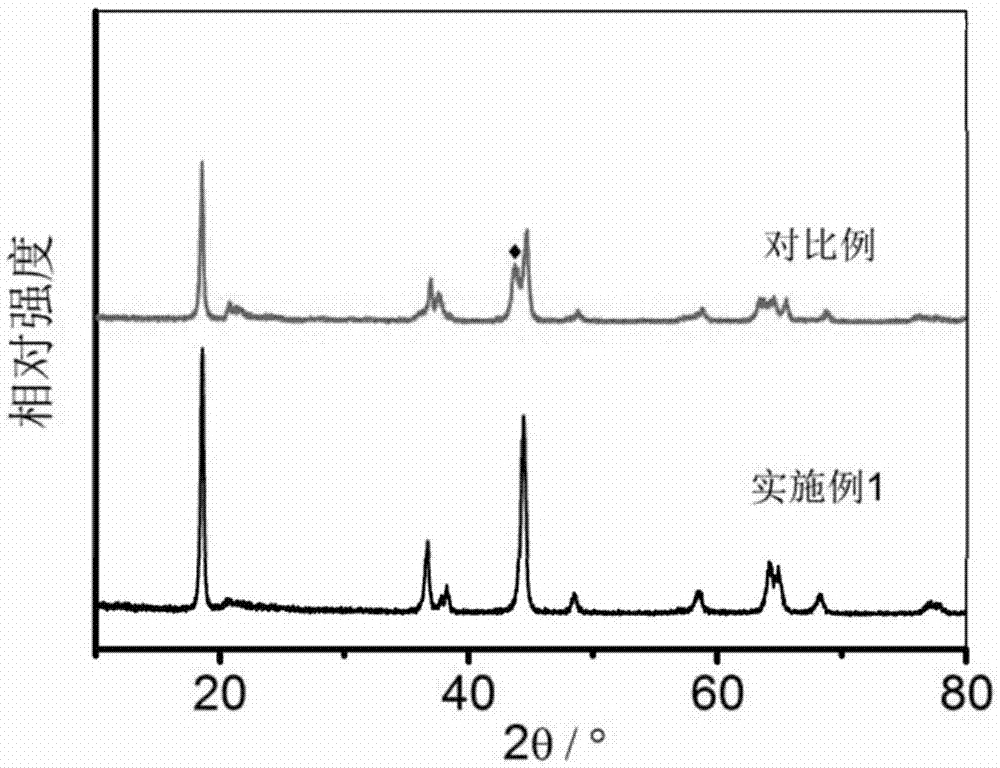

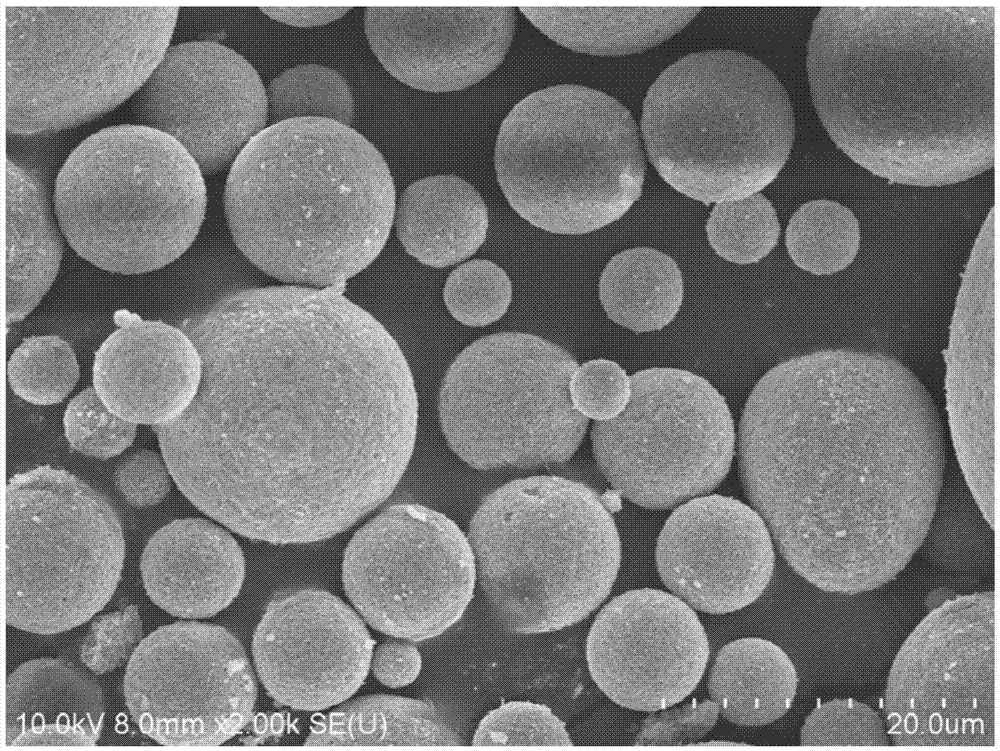

Lithium-rich manganese-based anode material, preparation method thereof and lithium ion battery containing anode material

ActiveCN106910887AThe problem of achieving compactionAchieve spherificationCell electrodesSecondary cellsManganeseLithium-ion battery

The invention discloses a lithium-rich manganese-based anode material, a preparation method thereof and a lithium ion battery containing the anode material. A chemical formula of the lithium-enrichment manganese-based anode material is Li1+xMnyMzAwOr, wherein the M is at least one of Ni, Co, Al, Mg, Ti, Fe, Cu, Cr, Mo, Zr, Ru and Sn; the A is at least one of S, P, B and F; the x is larger than 0 and smaller than or equal to 1, the y is larger than 0 and smaller than or equal to 1, the z is larger than or equal to 0 and smaller than 1, the w is larger than or equal to 0 and smaller than or equal to 0.2, and the r is larger than or equal to 1.8 and smaller than or equal to 3. The lithium-enrichment manganese-based anode material is prepared by methods of oxalate coprecipitation, spray drying and high-temperature roasting. The lithium-enrichment manganese-based anode material disclosed by the invention overcomes agglomeration of a material prepared through an oxalate coprecipitation method; a prepared material is controllable in particle size, meets requirements of engineering indexes and can achieve the purpose that transition metal ions are evenly mixed at an atom level; the particle size of the prepared lithium-enrichment manganese-based anode material is 3 to 25mu m, and the lithium-rich manganese-based anode material has good rate capability and circulation performance at the same time; furthermore, the lithium-enrichment manganese-based anode material has the advantages of simple preparation technology, low cost and wide application prospect.

Owner:CHINA AUTOMOTIVE BATTERY RES INST CO LTD +1

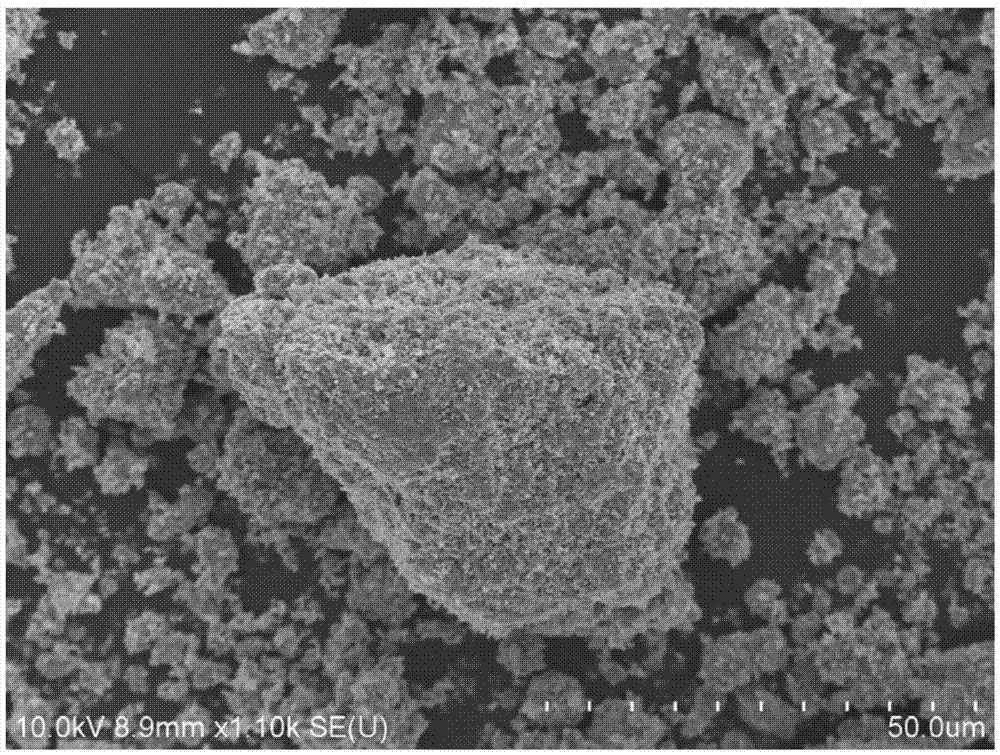

Preparation method of ultrafine cobalt powder

The invention discloses a preparation method of ultrafine cobalt powder. Some prior methods have the disadvantages of higher cost, or existence of discharge problems of ammonia-nitrogen waste water, or coarser cobalt powder particles or difficult acquisition of high-purity products, and the like; and the prior methods are not suitable for large-scale industrialized production. In the invention, the cobalt ore is used as raw material, a spraying and roasting-reducing method is used for preparing ultrafine spherical cobalt powder, and meanwhile, the tail gas generated in the spraying and roasting processes is absorbed, treated and returns to a production system for recycling, thereby shortening the technological processes, reducing the discharge of the waste water and achieving the purposesof environmental protection and large-scale industrialized production of ultrafine spherical cobalt powder.

Owner:ZHEJIANG HUAYOU COBALT

Indication board, capable of collecting rainwater for cleaning, for municipal construction

InactiveCN108176622ASimple structureImprove wiping efficiencyCleaning using toolsCleaning using liquidsPulp and paper industryWater collection

The invention discloses an indication board, capable of collecting rainwater for cleaning, for municipal construction. The indication board comprises an indication board body and two supporting upright columns; a cleaning screw rod and a guide rod are arranged between the two supporting upright columns; the cleaning screw rod is provided with a drive block which is matched with the cleaning screwrod; the guide rod is provided with a guide sleeve; the guide sleeve is fixedly connected with the drive block through a wiping vertical rod; the wiping vertical rod is hollowly arranged; a water collection groove is fixedly connected between the top ends of the two supporting upright columns and is communicated with a water collection tank which is arranged on the upper end surface of a fixed bottom plate through a water inlet pipe; a base plate is provided with a drainage cylinder body; the bottom end of the drainage cylinder body is communicated with the interior of the wiping vertical rodand the interior of the water collection groove through a water guide pipe; and a plurality of water spraying holes are formed in the side of the wiping vertical rod. The indication board is simple instructure, relatively high in wiping efficiency, relatively small in labor, relatively good in cleaning effect and relatively strong in practicability, is convenient and rapid and can save water forcleaning.

Owner:ZHENGZHOU GUOZHI NETWORK TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com