Dedusting and cooling integrated device of solar photovoltaic panel

A solar photovoltaic panel and cooling panel technology, applied in the field of solar photovoltaic power generation, can solve problems such as inability to achieve optimization effects, affect power generation efficiency, and high panel temperature, and achieve labor cost savings, increase power generation efficiency, and low equipment investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings.

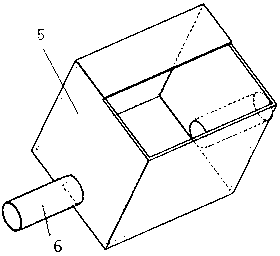

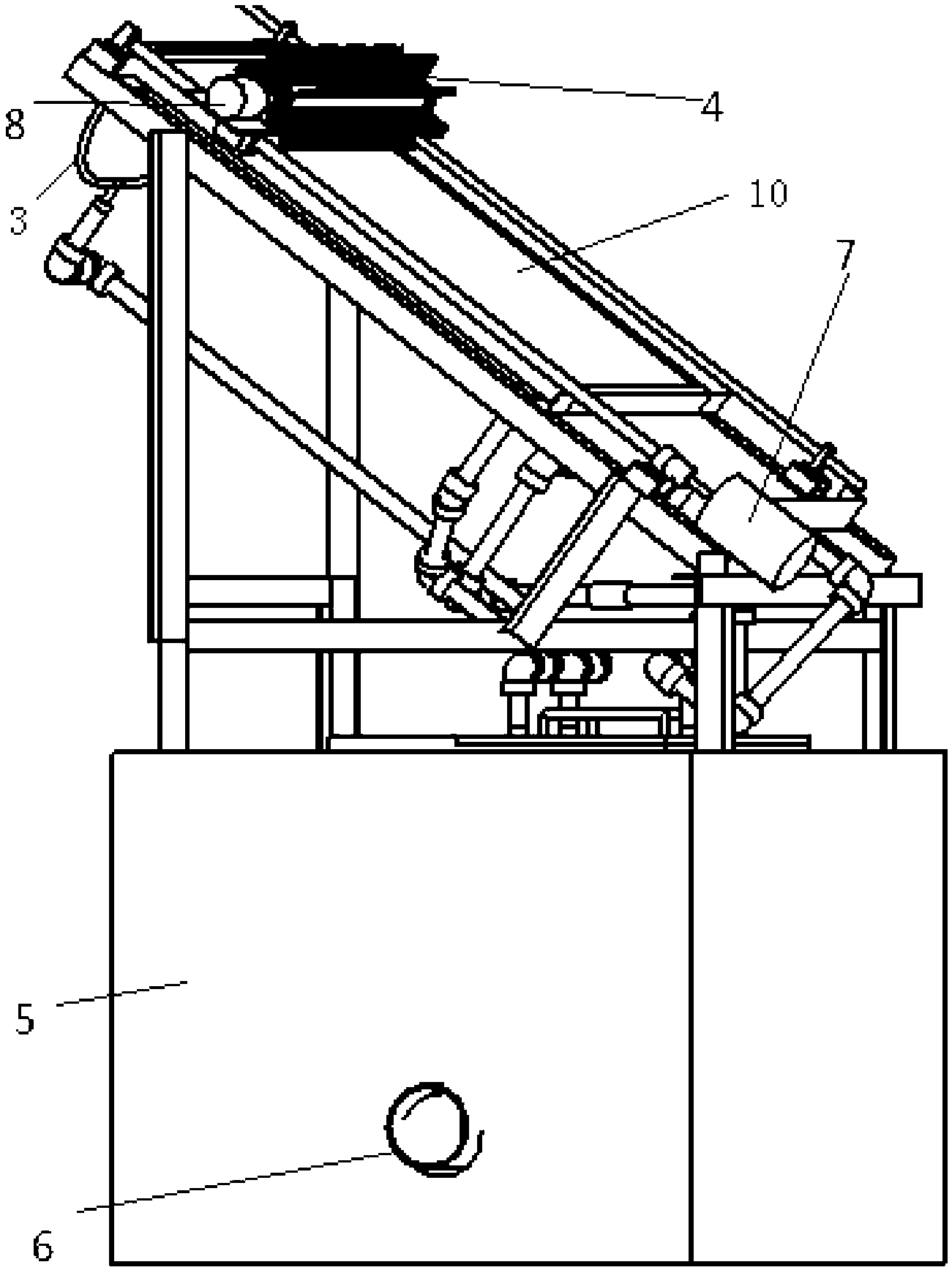

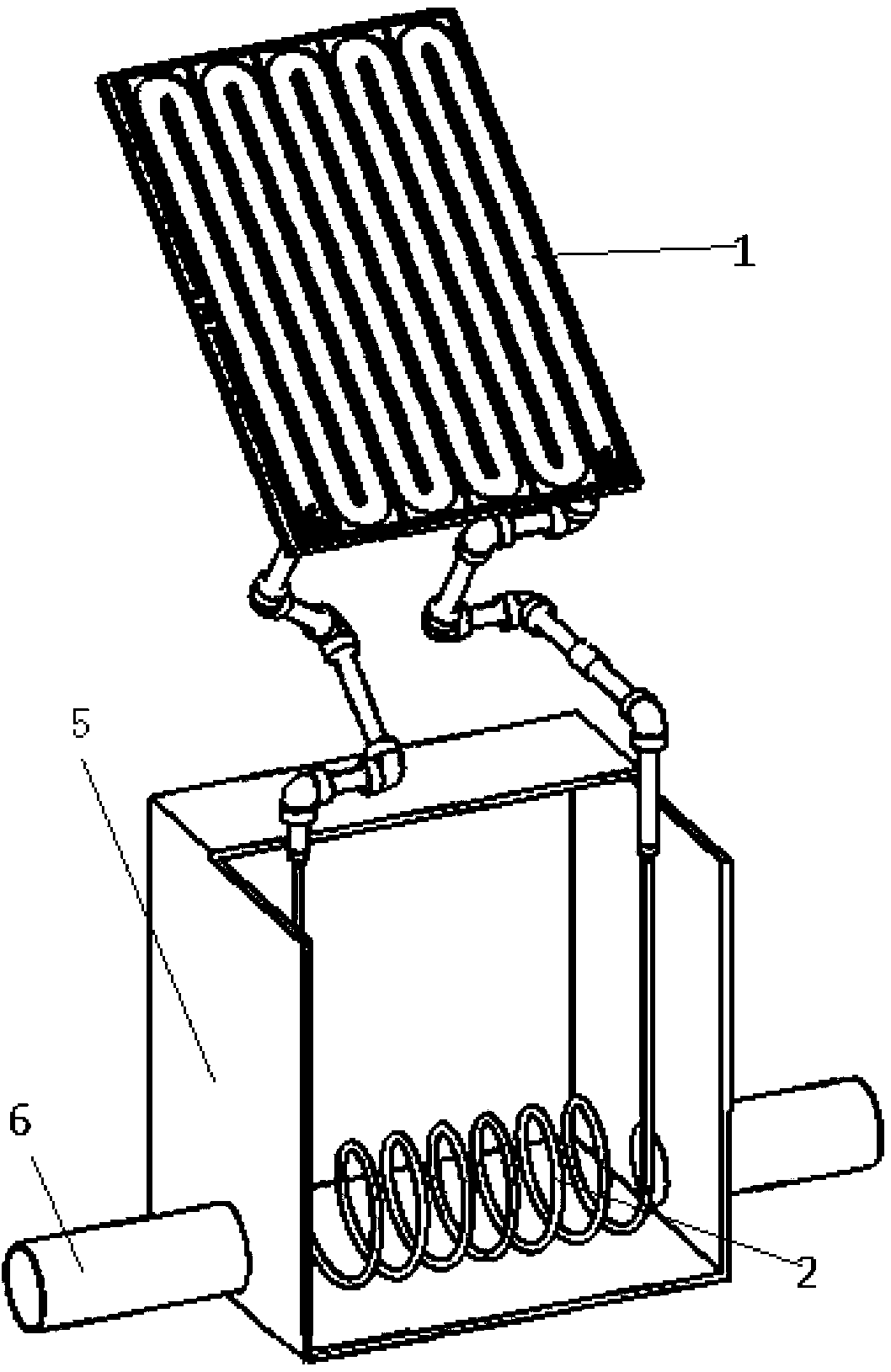

[0021] refer to figure 1 , 2 As shown, the present invention provides an integrated dust removal and cooling device for solar photovoltaic panels, including a dust removal system, a cooling pipeline system, a pool 5, and a solar photovoltaic panel 10 mounted on the pool 5 through a bracket, wherein the dust removal system includes The spray pipe 11 installed on the top of the solar photovoltaic panel 10, the spray pipe is connected with the Y-shaped hose 3 and the pool 5 through the water pump, and absorbs the water stored in the pool 5. The pool 5 is cement-fixed and the top is provided with a sealed cover. , and a square pool buried underground. A brush 4 for cleaning the solar photovoltaic panel 10 is installed on the front of the solar photovoltaic panel 10, and the bottom end of the solar photovoltaic panel 10 communicates with the pool 5 through a pipeline to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com