Filtering system for dishwasher

A filtration system and dishwasher technology, applied in the direction of washing machine/rinsing machine parts of tableware, etc., can solve the problems of secondary pollution, time-consuming and time-consuming of tableware, reduce washing water, improve washing efficiency, save money Effect of washing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

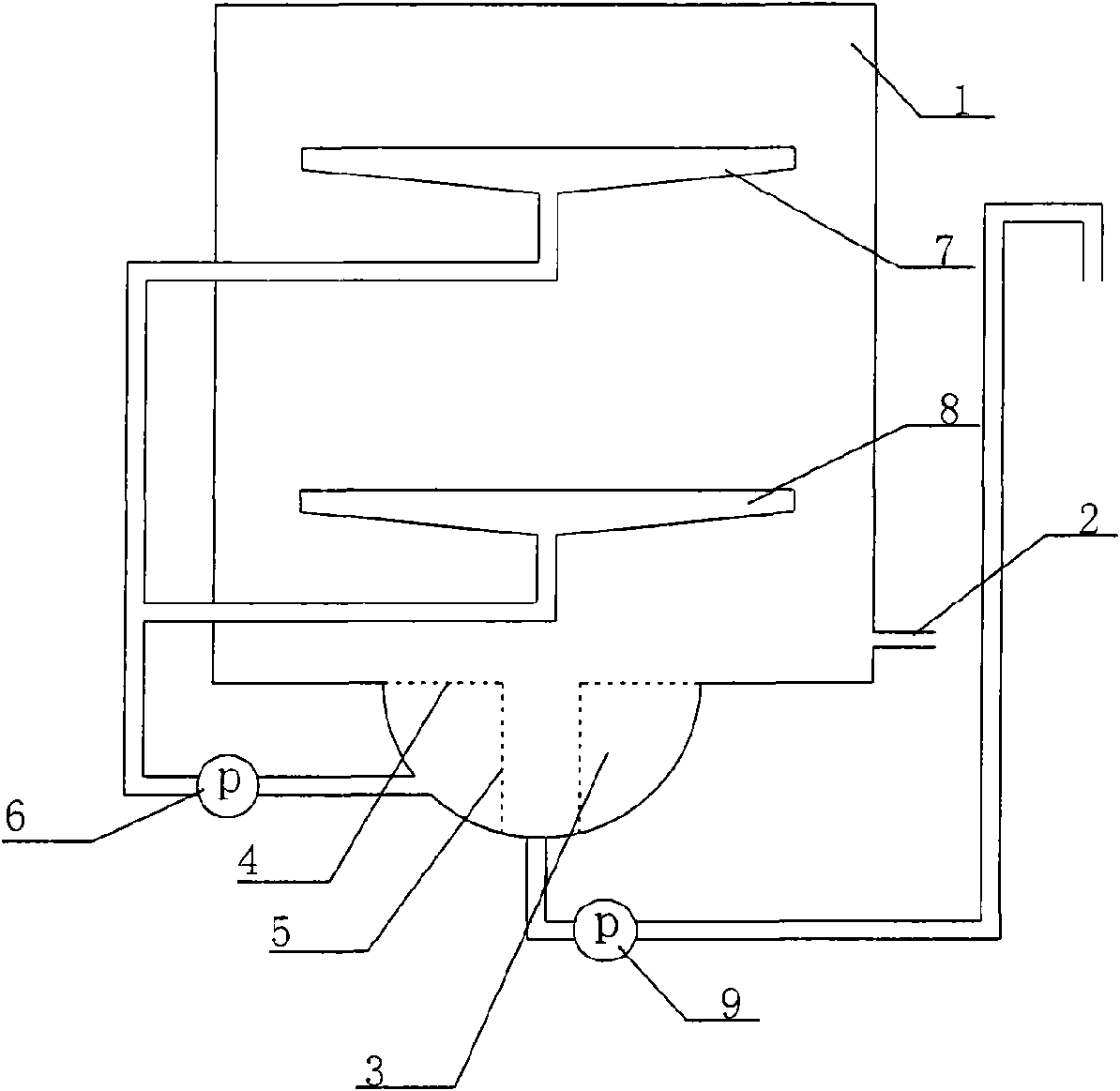

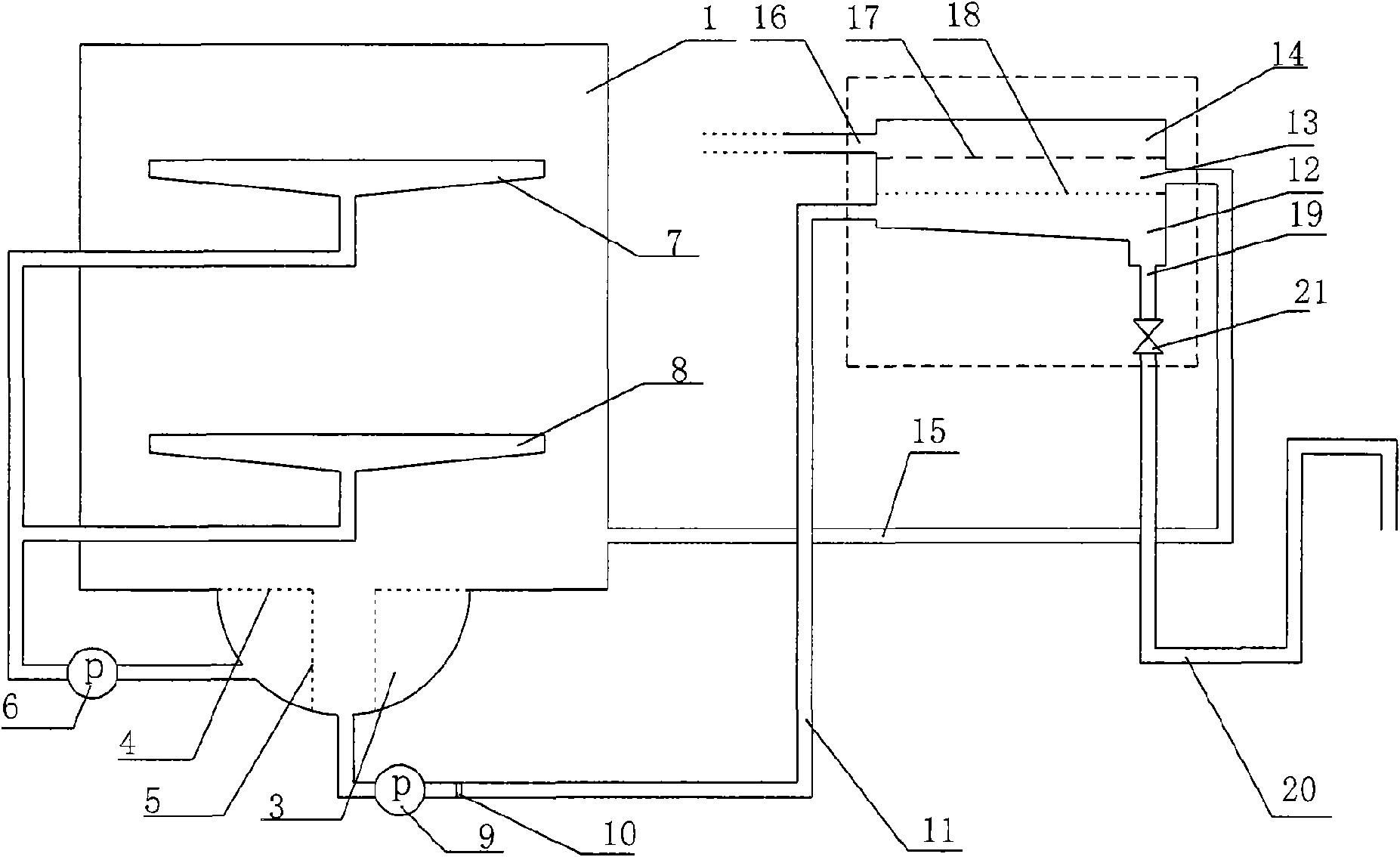

[0013] Such as figure 2 As shown, it is a structural schematic diagram of a dishwasher connected with the self-cleaning filter system of the present invention. The bottom of the water cup 3 of the dishwasher is provided with a first passage 11, and the other end of the first passage 11 communicates with the filter cavity. A drain pump 9 and a non-return piece 10 are arranged on the first channel 11, and the non-return piece 10 only allows the washing water to flow into the filter cavity through the drain pump 9. The filter chamber is divided into an upper chamber 14, a lower chamber 13 and a first chamber body 12 by a water spray plate 17 and a filter screen 18 in turn, and the upper chamber 14 is connected with the water inlet pipe 16, and the water inlet pipe 16 is provided with a water inlet valve; the lower chamber 13 It is connected with the second passage 15, and the other end of the second pipe 15 is connected with the inner tank 1 of the dishwasher; the first cavity ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com