Patents

Literature

431results about How to "Shorten washing time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

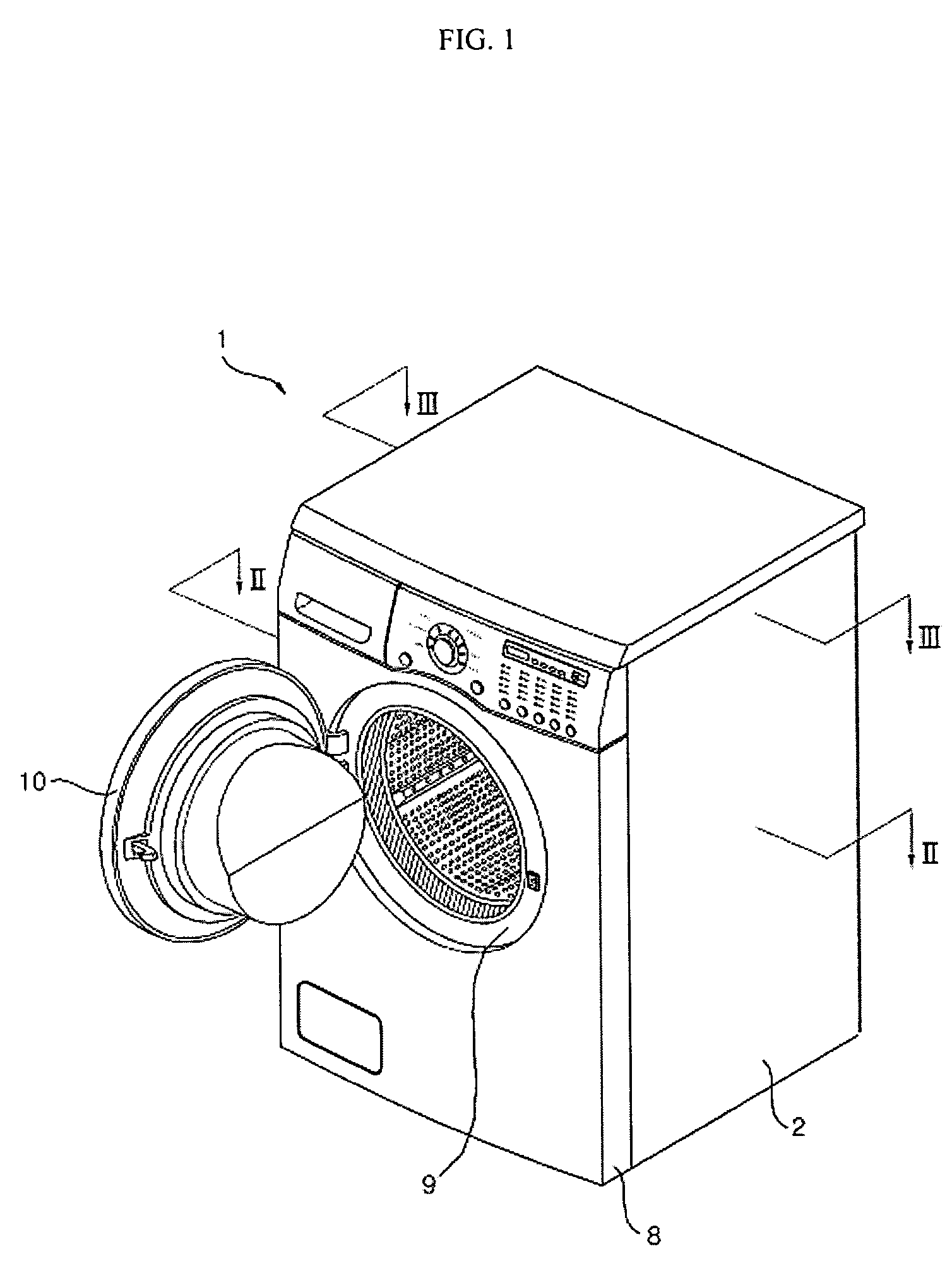

Washing machine and control method thereof

InactiveUS20050132503A1Grow fastShorten washing timeOther washing machinesControl devices for washing apparatusWash waterEngineering

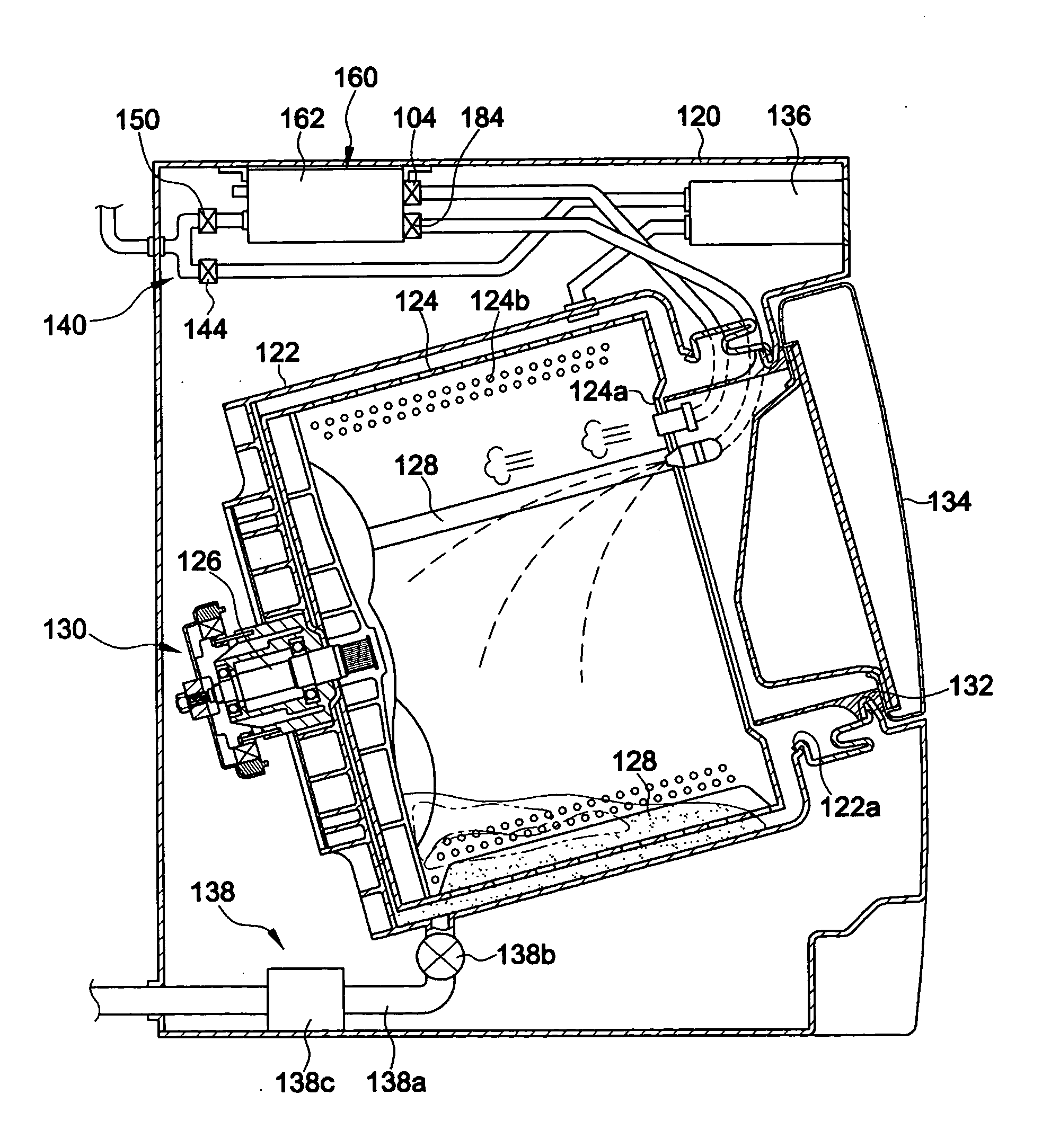

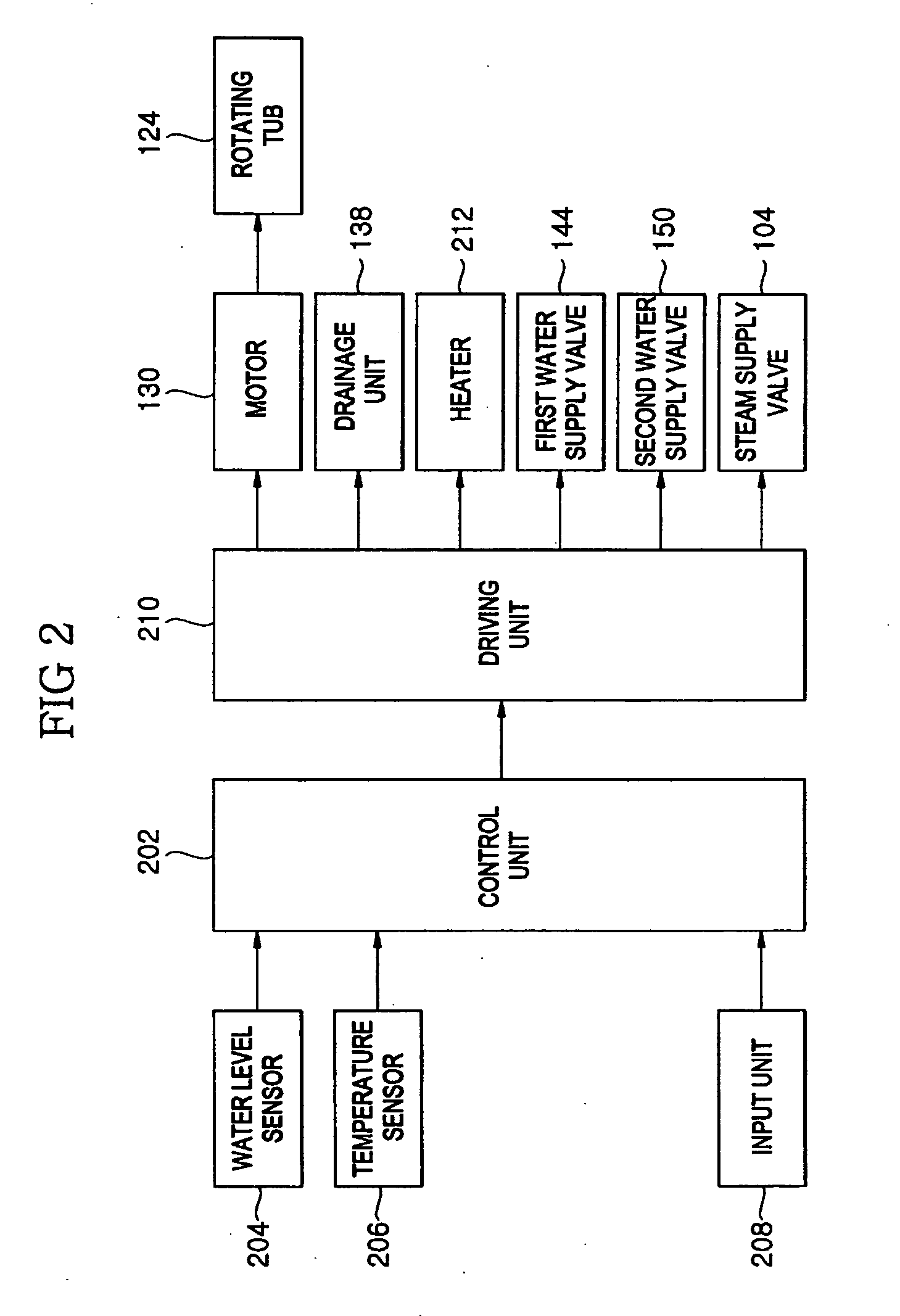

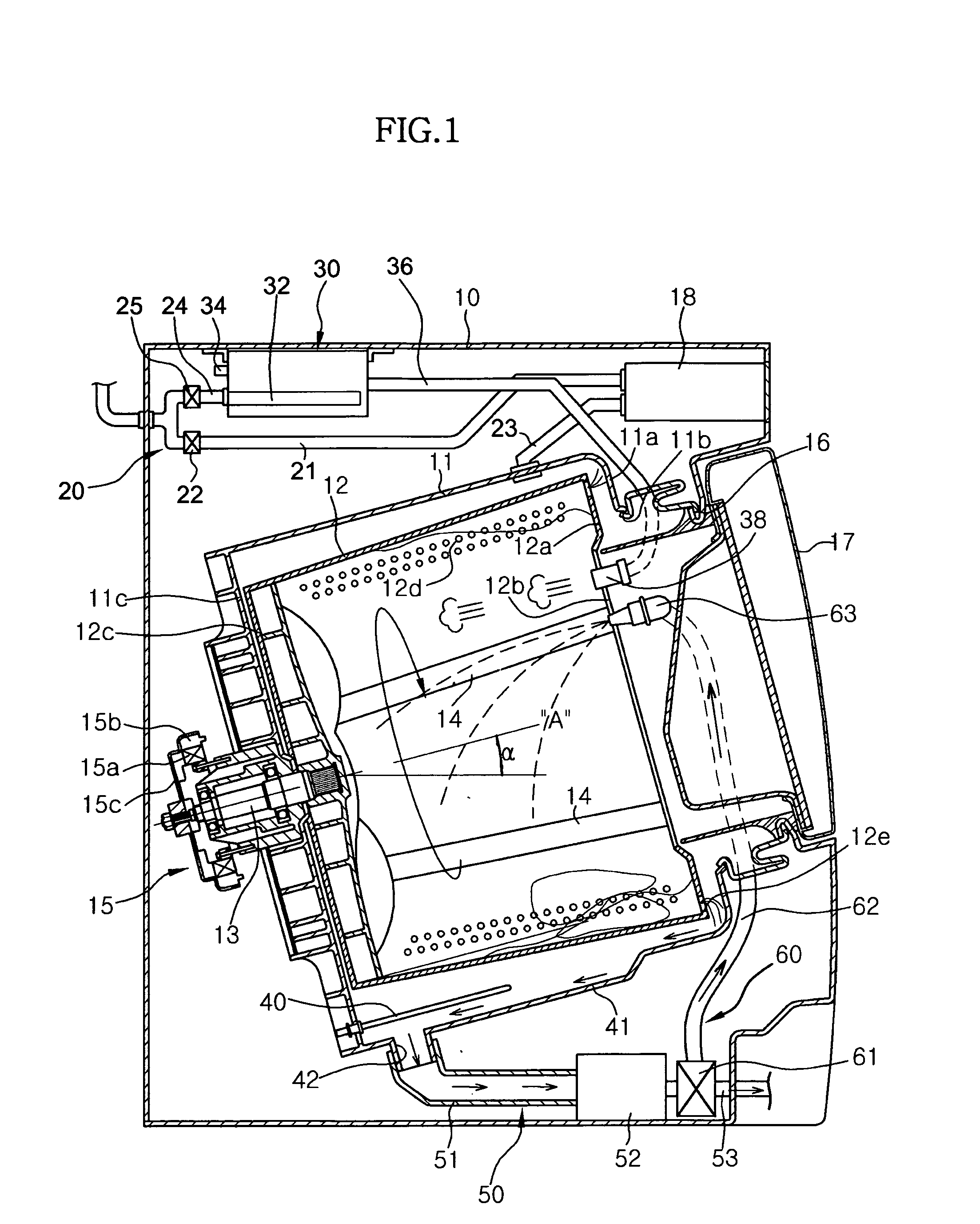

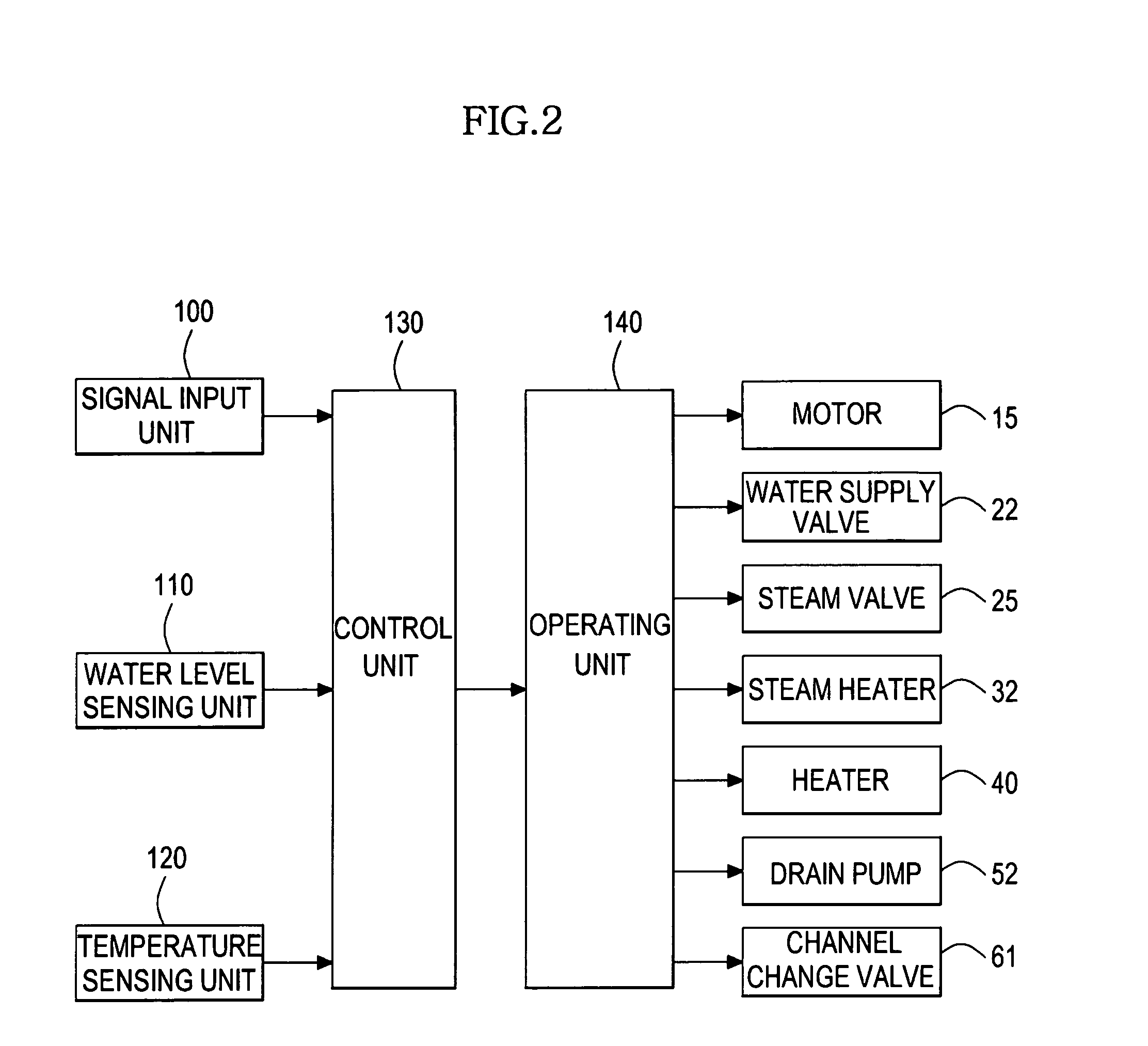

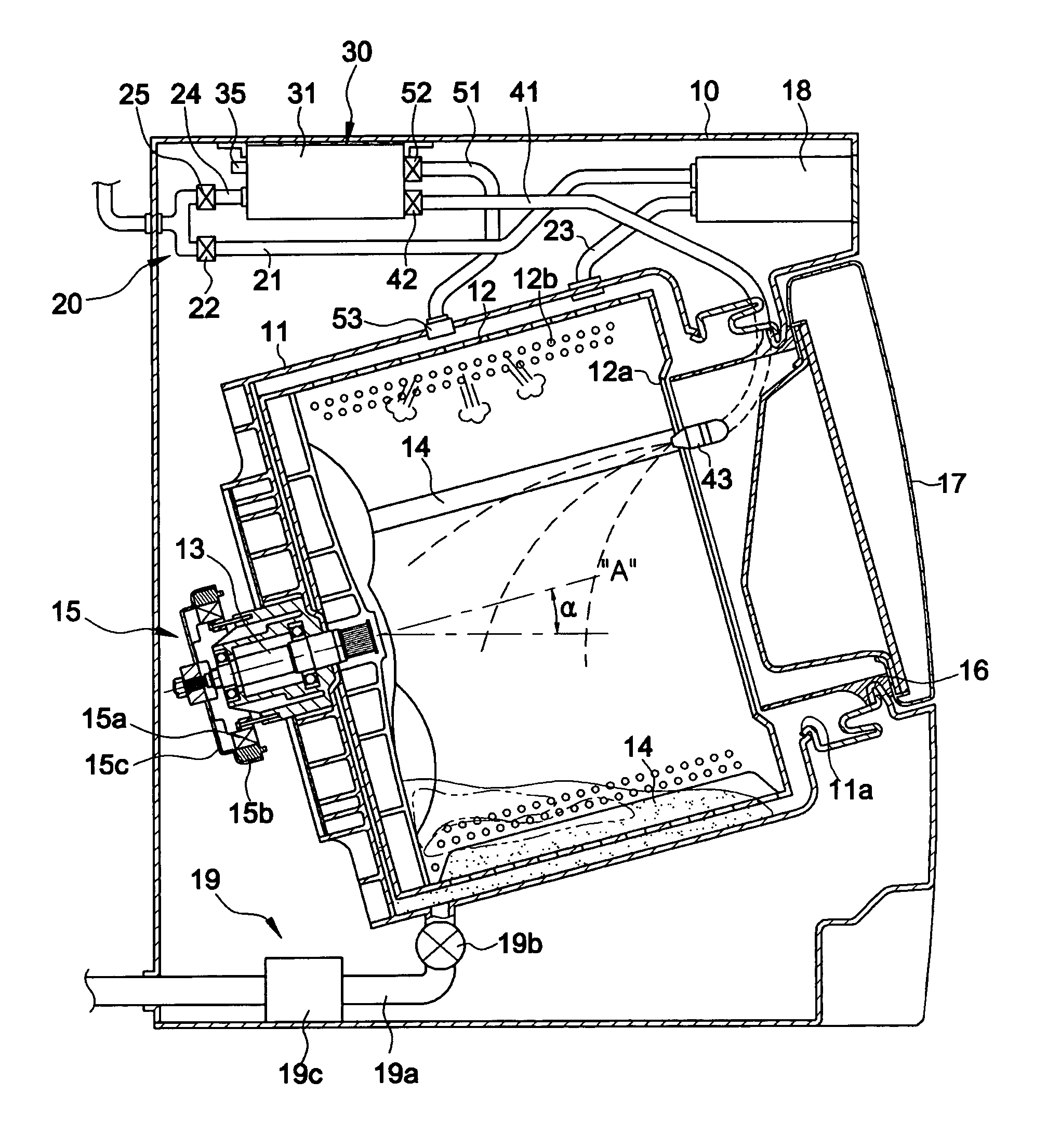

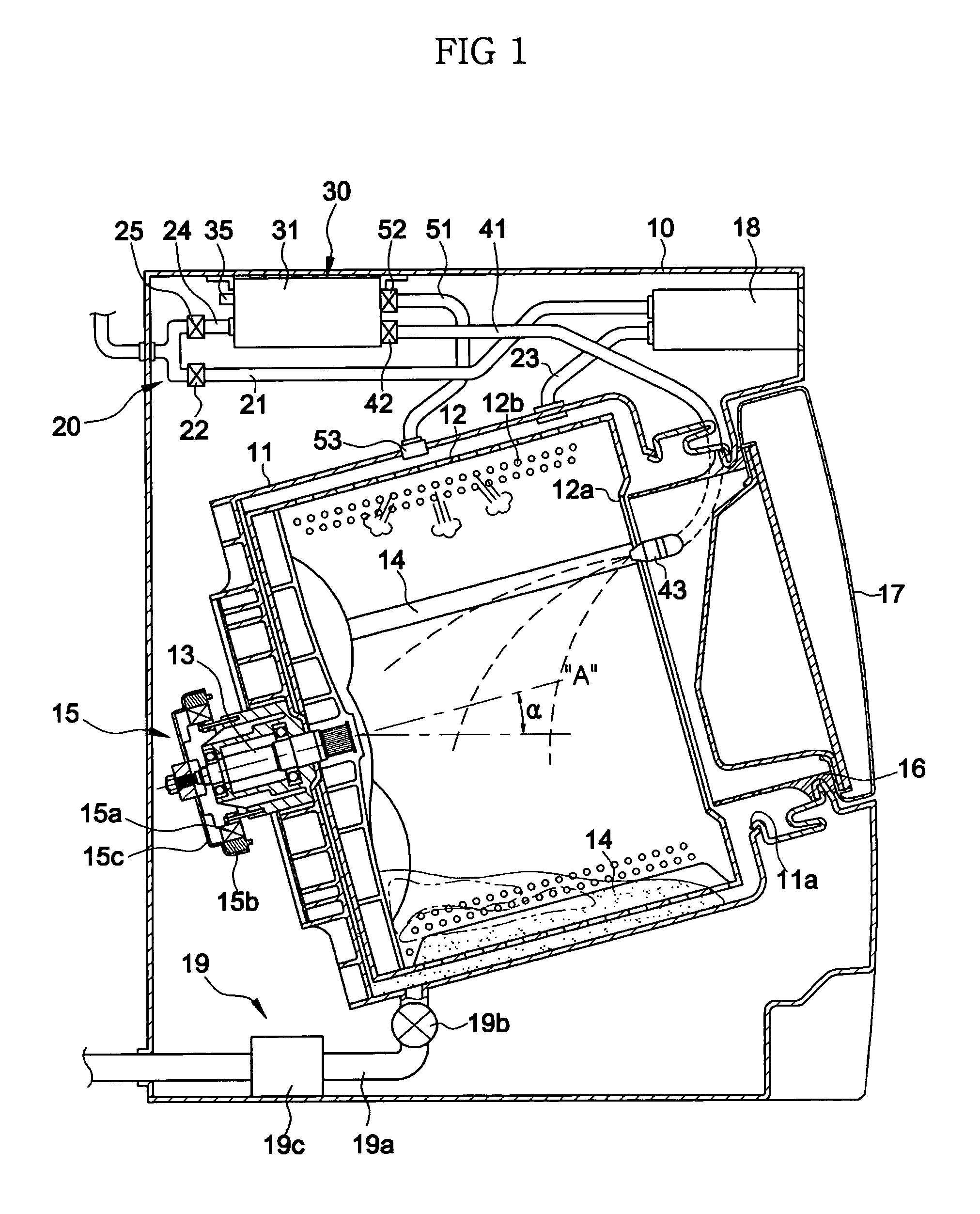

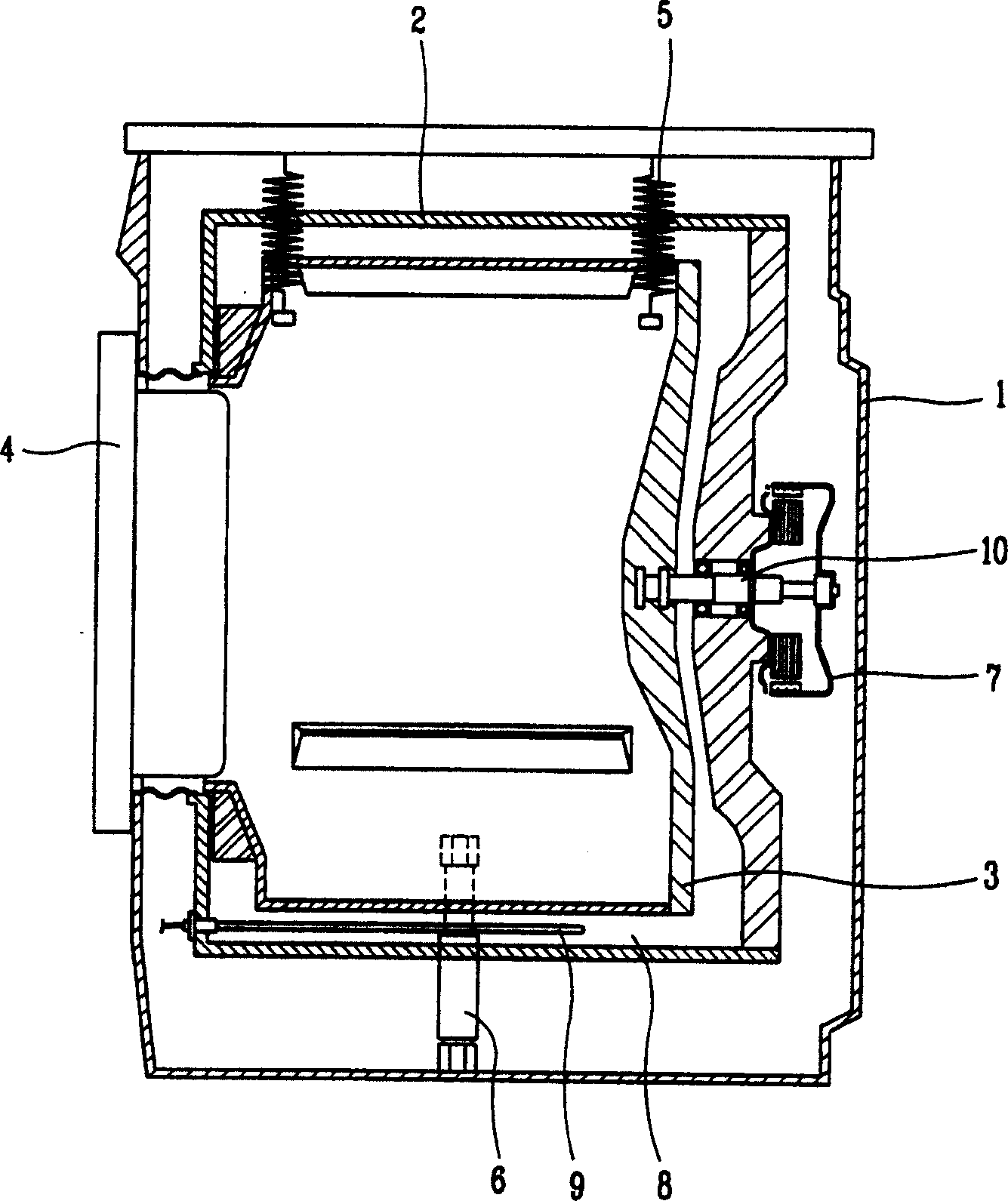

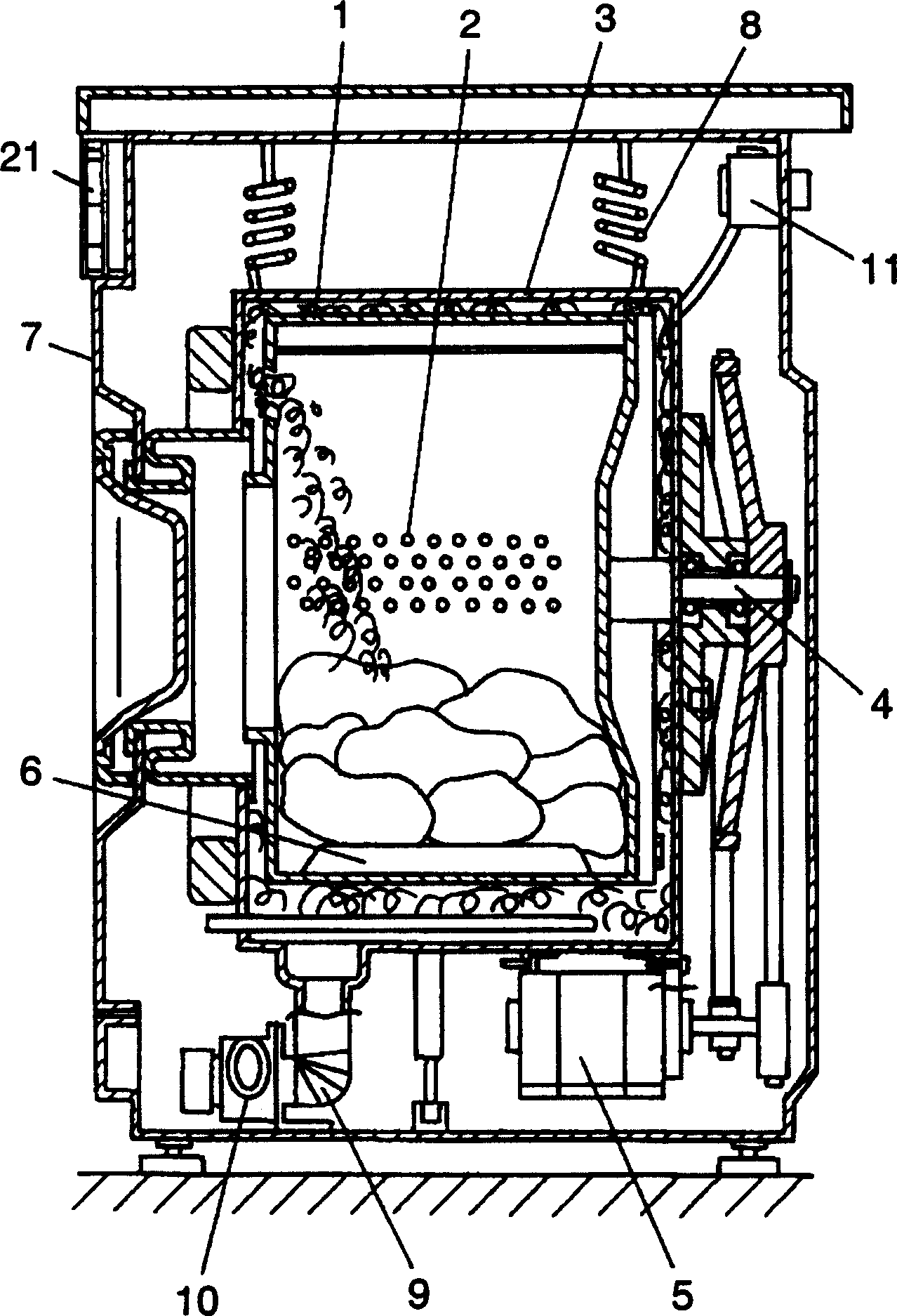

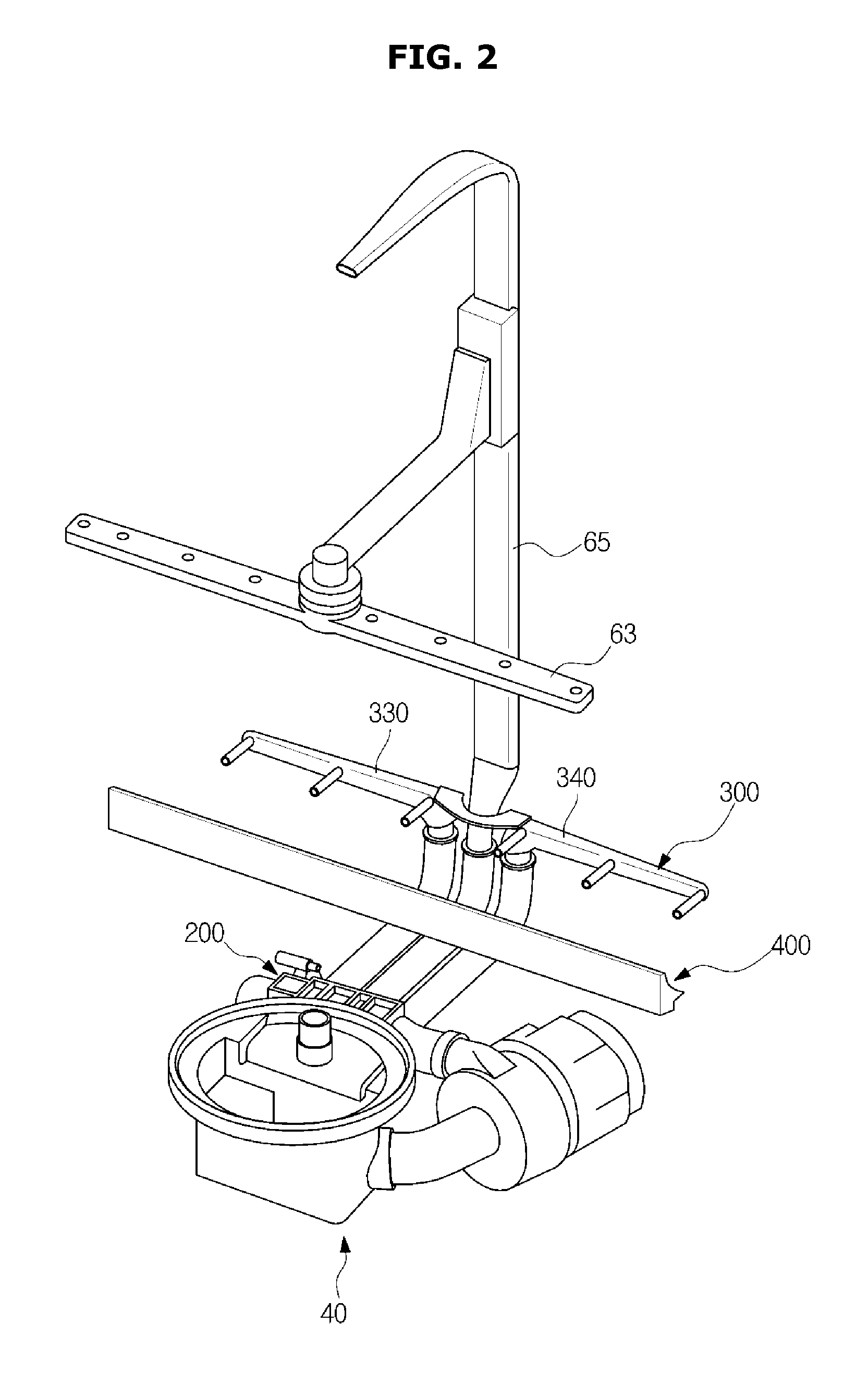

A drum type washing machine in which wash water and laundry contained in a rotating tub are heated by steam supplied into the rotating tub, so as to rapidly increase the temperature of the wash water and laundry, thereby being capable of reducing the total wash time while reducing the amount of wash water to be used, and reducing the consumption of energy caused by heating of the wash water. The washing machine includes a steam generating unit for heating water supplied thereto, thereby generating steam, and a control unit for rotating the rotating tub at a high speed to cause the laundry contained in the rotating tub to be in constant contact with an inner peripheral surface of the rotating tub without falling down, by virtue of a centrifugal force generated during the rotation of the rotating tub, the control unit supplying the steam from the steam generating unit into the rotating tub during the high-speed rotation of the rotating tub, to increase the internal temperature of the rotating tub and the temperature of the laundry.

Owner:SAMSUNG ELECTRONICS CO LTD

Washing machine and method for controlling the same

InactiveUS20060101586A1Shorten washing timeImprove washing effectOther washing machinesControl devices for washing apparatusProcess engineeringEnergy consumption

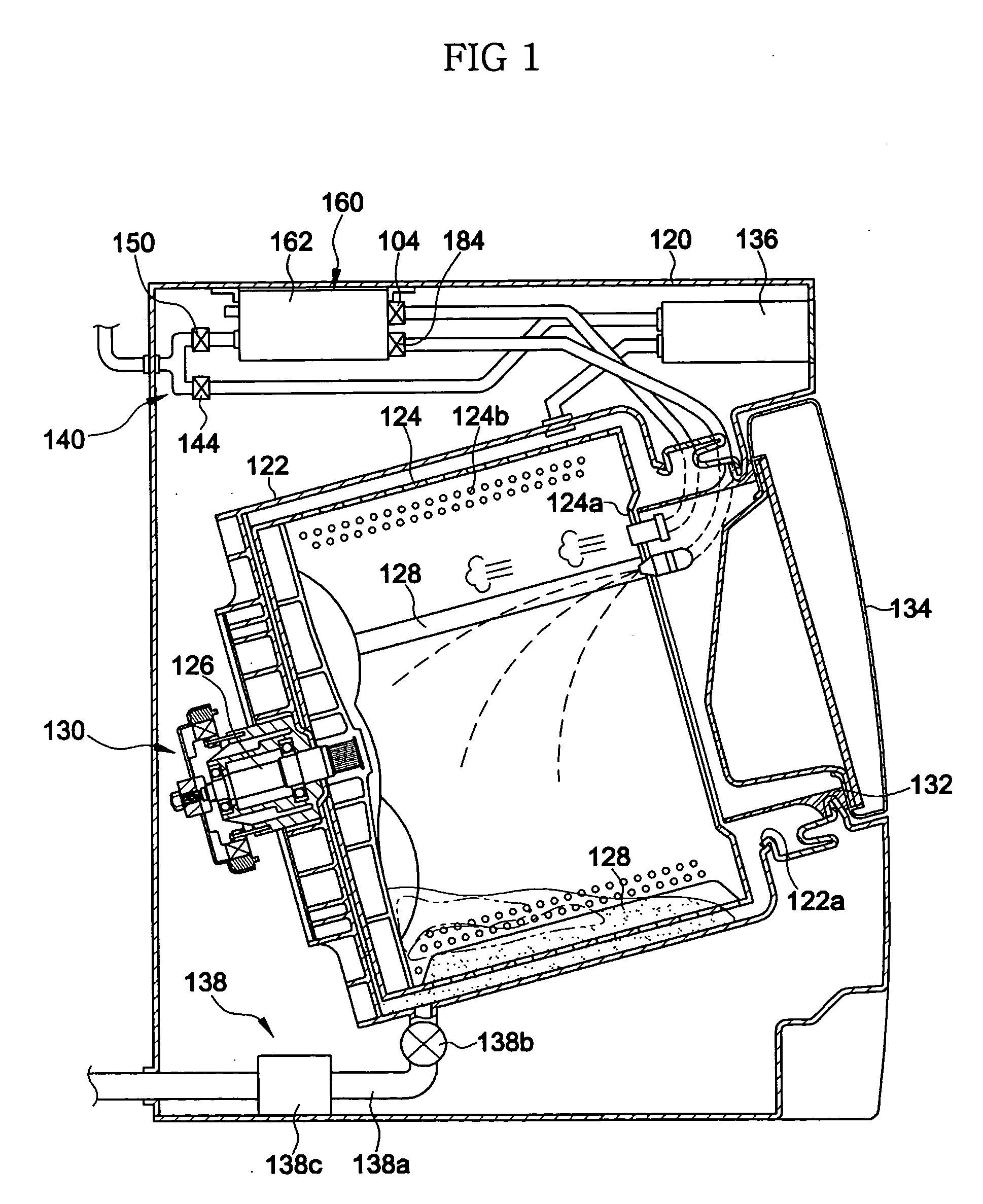

A washing machine having a steam generating device for directly heating wash water to generate optimum steam, and a method for controlling the same are provided. The method includes sensing a temperature of the steam generating device; controlling water supply means according to the temperature of the steam generating device such that wash water is supplied to the steam generating device; and controlling a quantity of wash water supplied from the water supply means. Further, the steam is supplied so as to rapidly soak laundry, thereby shortening overall washing time, and reducing energy consumption. Also, the steam is sprayed onto the laundry to provide sterilizing effects. Soaking effects of the laundry are improved, as well, so as to increase washing efficiency and eliminate wrinkling.

Owner:SAMSUNG ELECTRONICS CO LTD

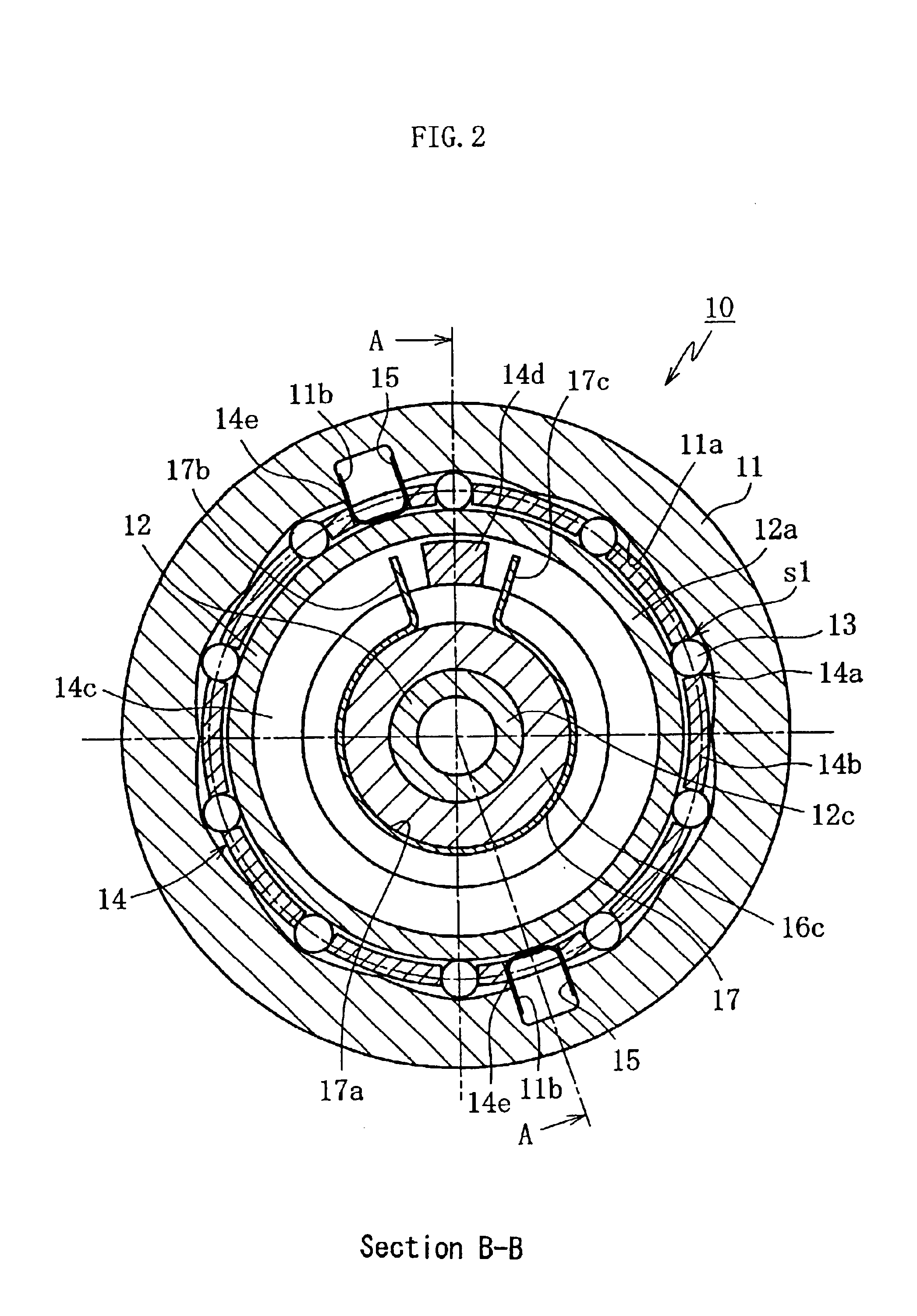

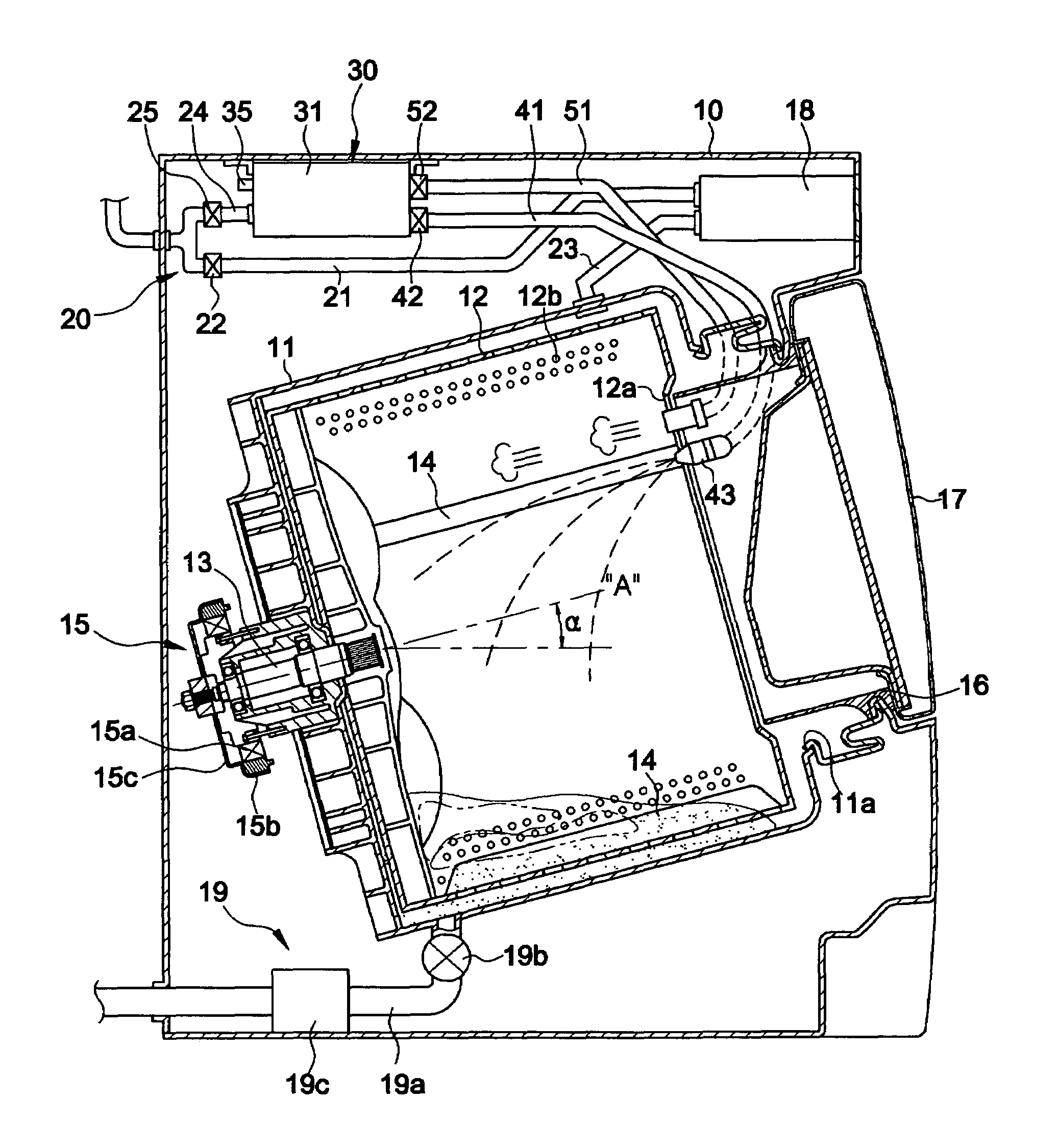

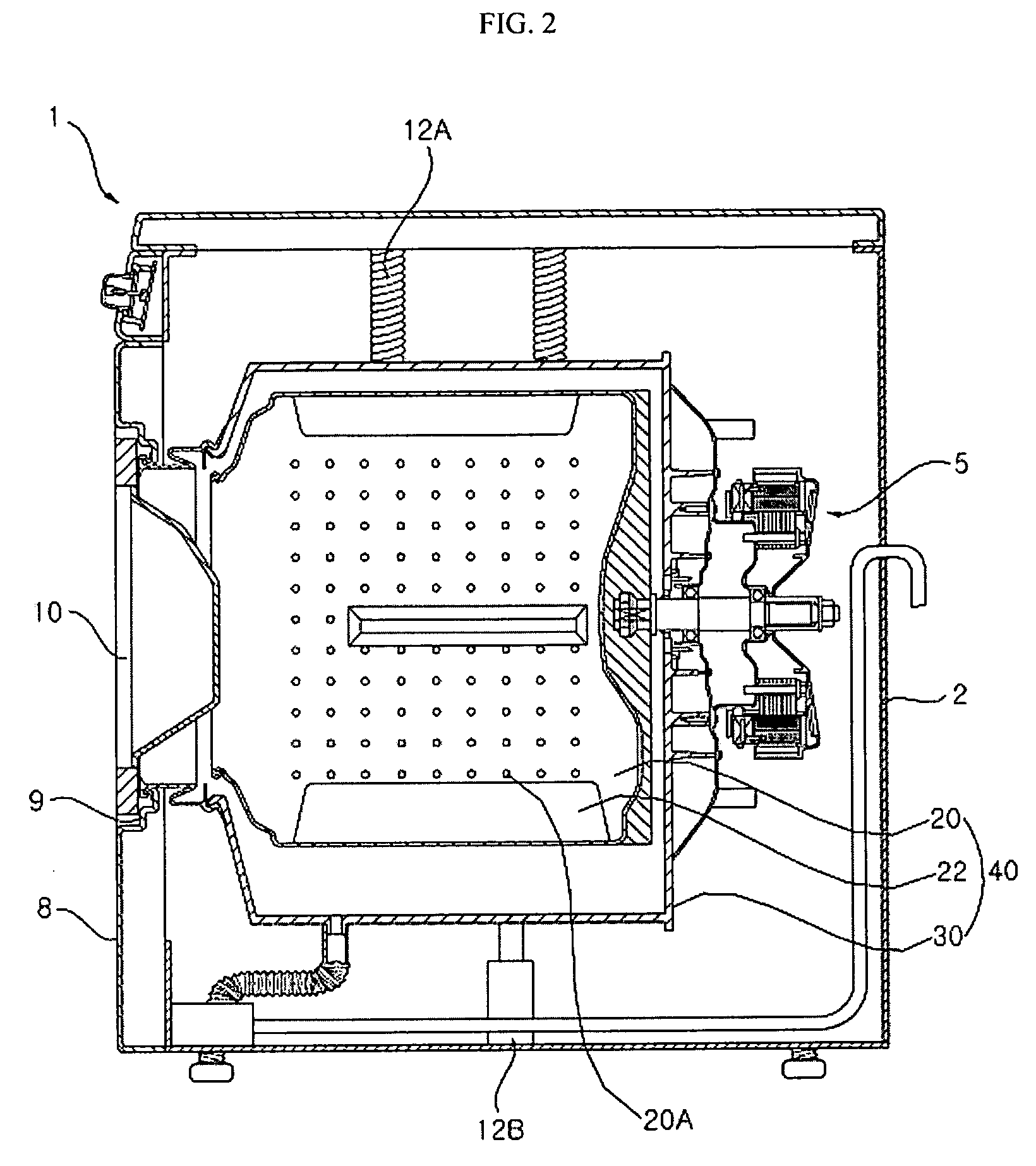

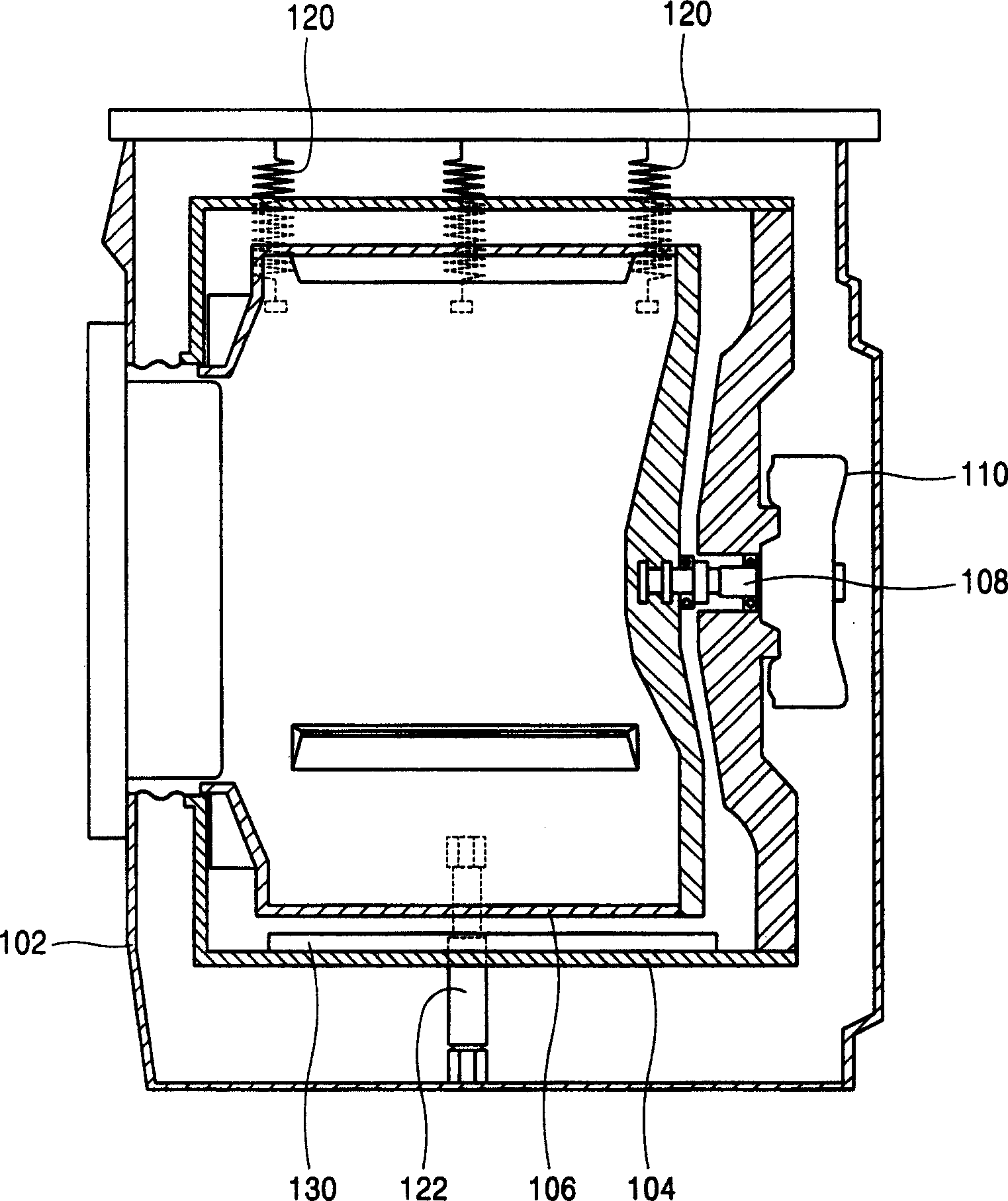

Washing machine

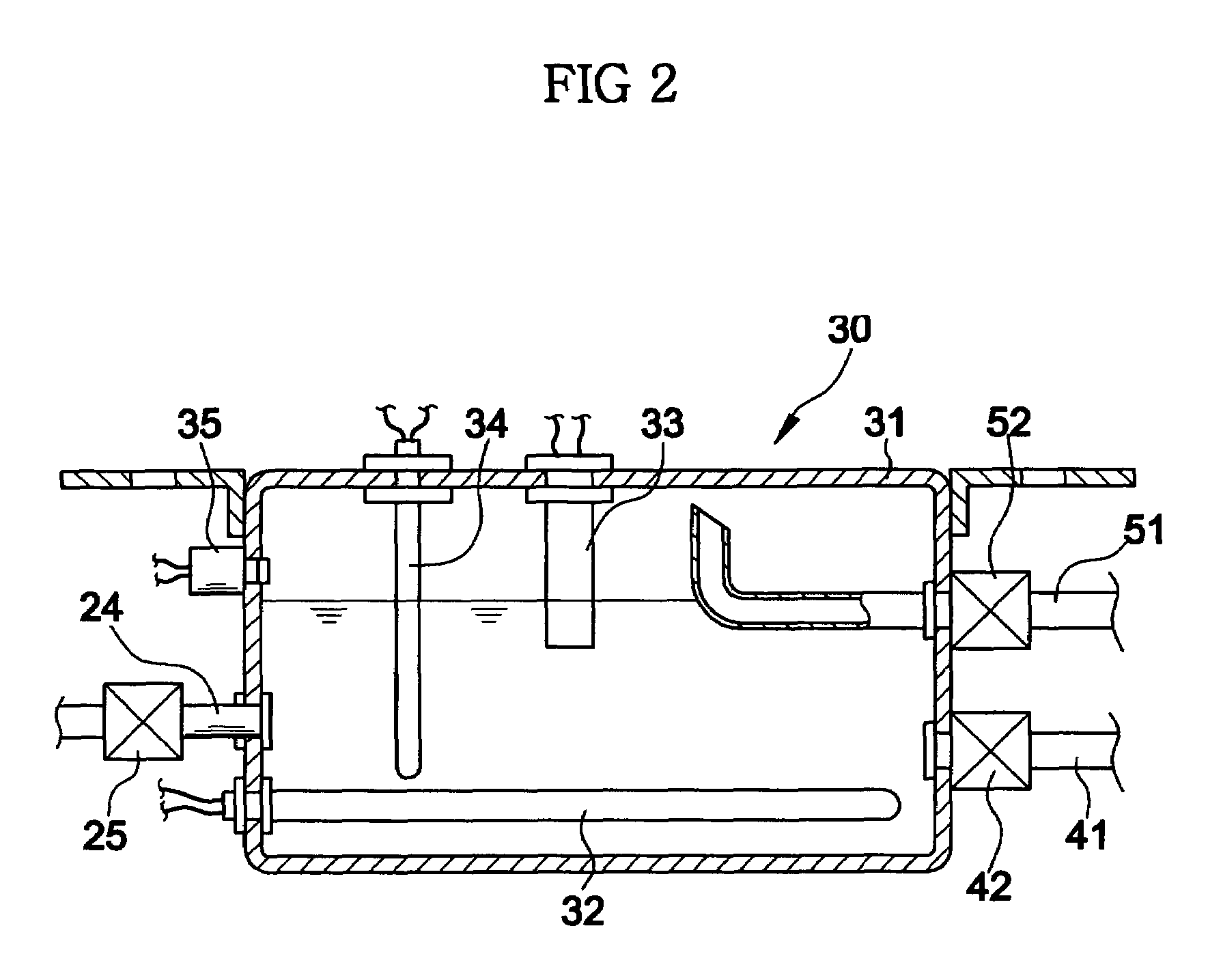

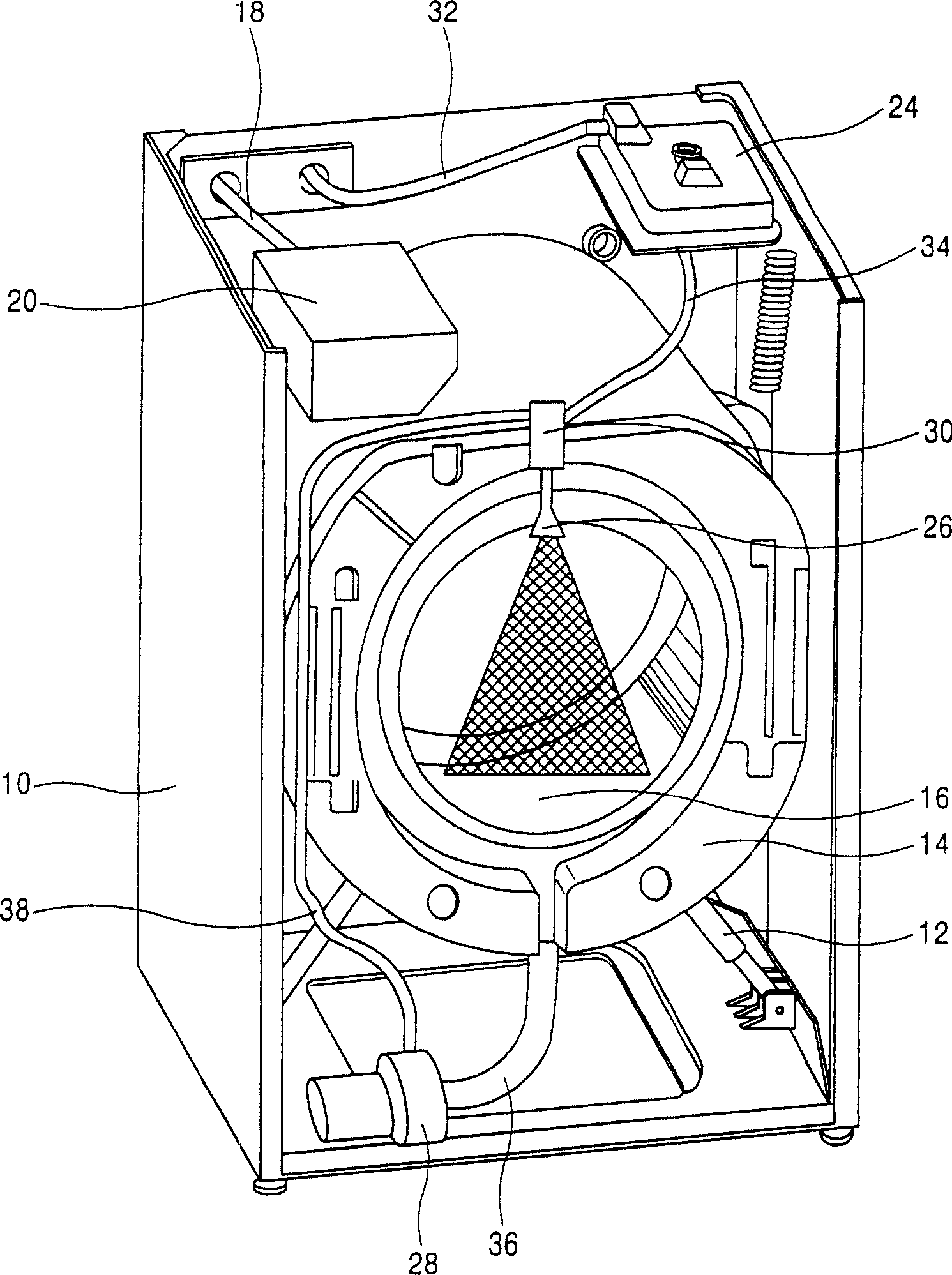

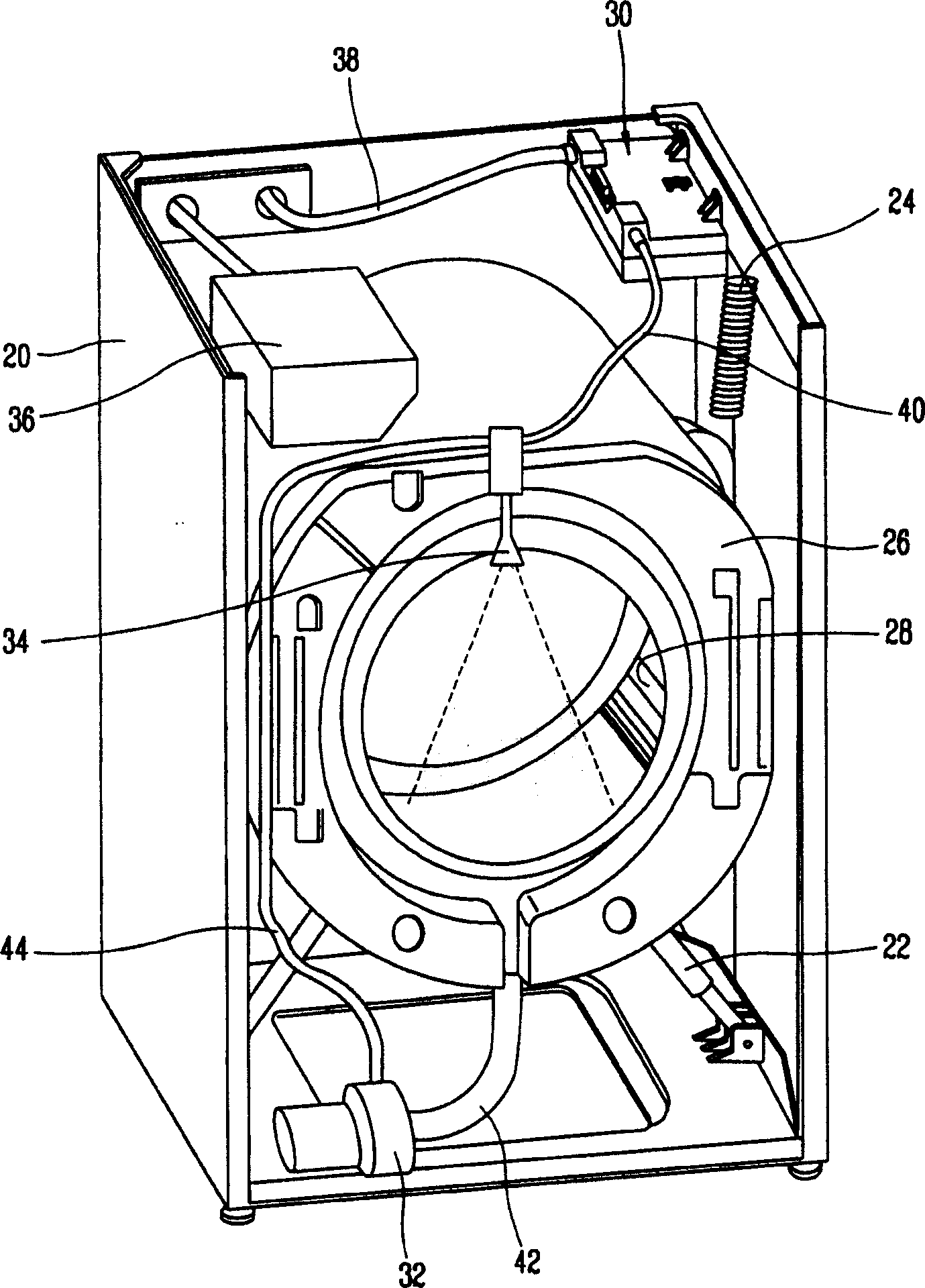

ActiveUS20050132756A1Raise temperatureWash time be reduceOther washing machinesControl devices for washing apparatusProcess engineeringGenerating unit

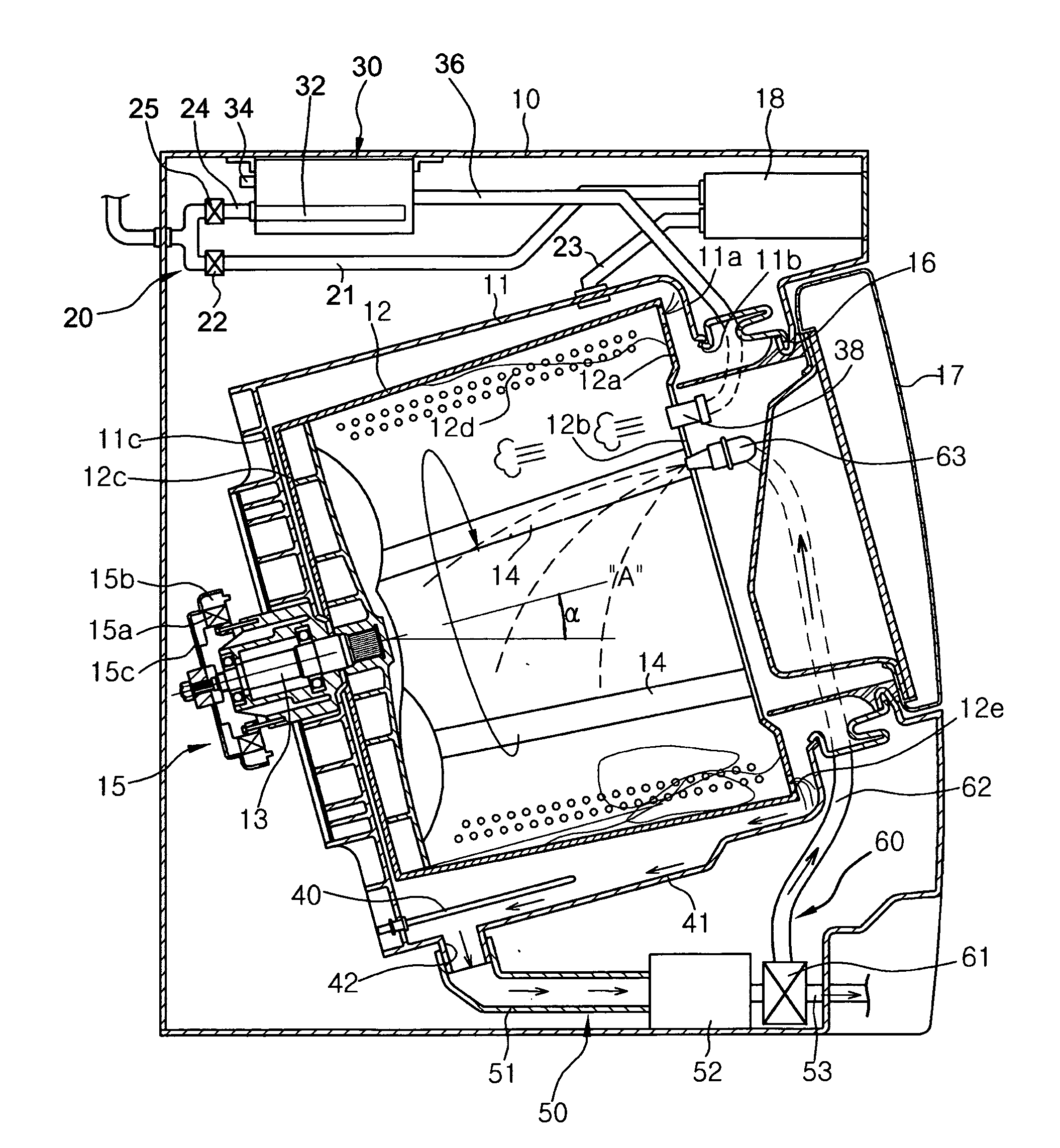

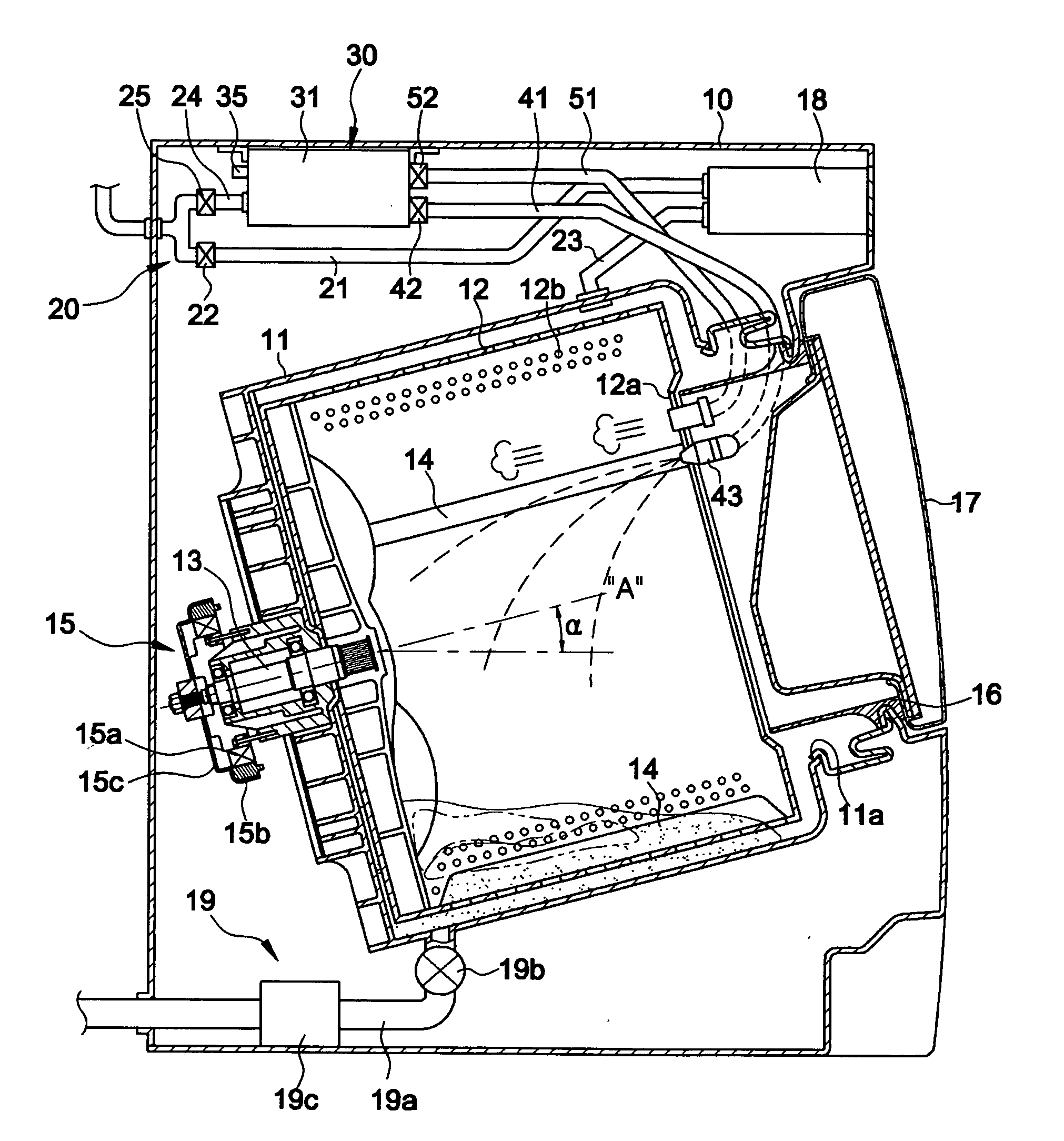

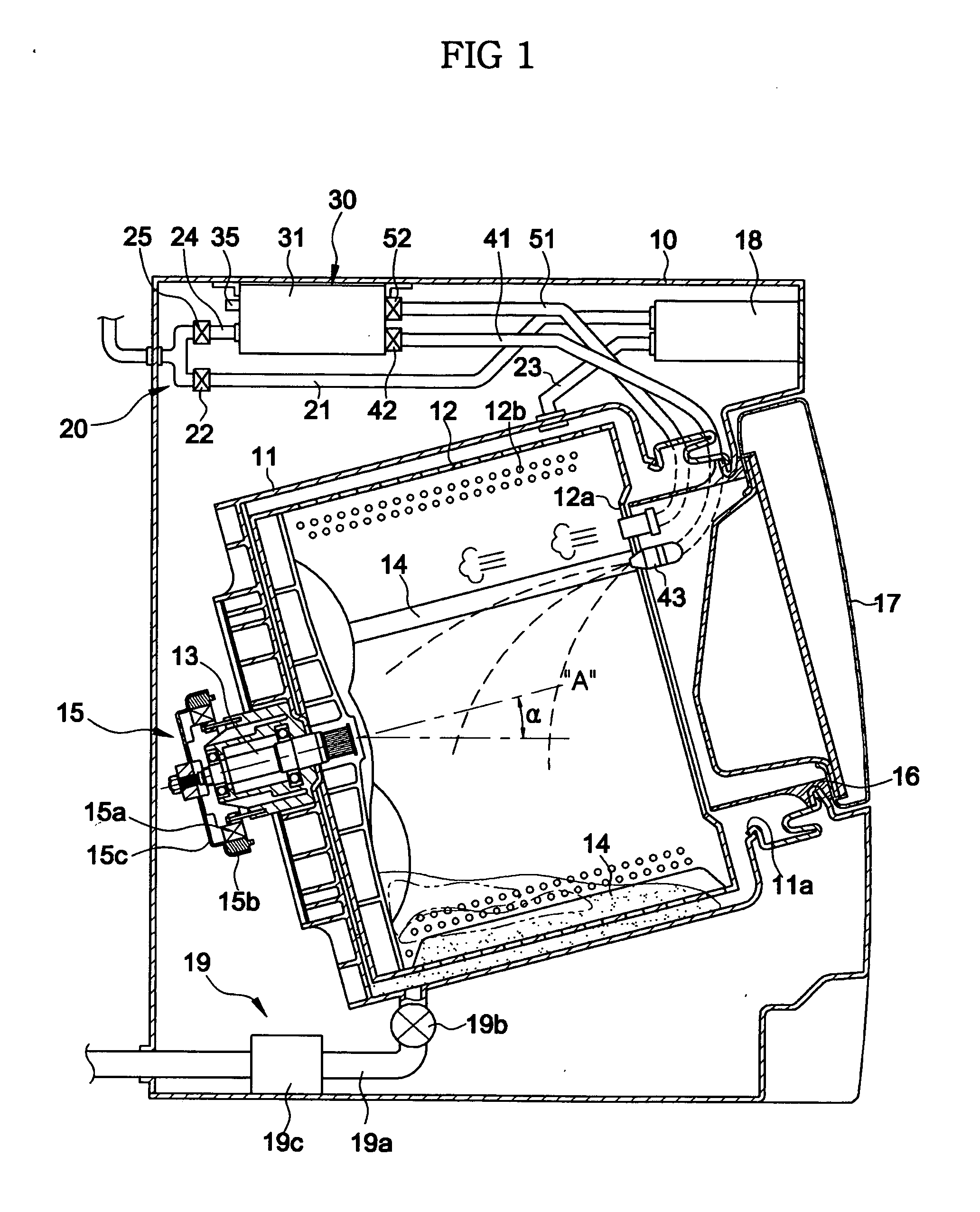

A washing machine in which steam and hot water are supplied to heat wash water. The washing machine includes a water tub for containing wash water, a steam generating unit for heating water supplied thereto, thereby generating steam, a water supply unit for supplying water into the water tub and the steam generating unit, a steam supply unit for supplying the steam generated from the steam generating unit into the water tub, and a hot water supply unit for supplying hot water from the steam generating unit into the water tub. In the washing machine, the temperature of wash water can be rapidly increased in accordance with steam and hot water supplied into the water tub. Accordingly, it is possible to reduce the overall wash time while reducing the amount of wash water to be used. The energy consumed to heat the wash water can also be reduced.

Owner:SAMSUNG ELECTRONICS CO LTD +1

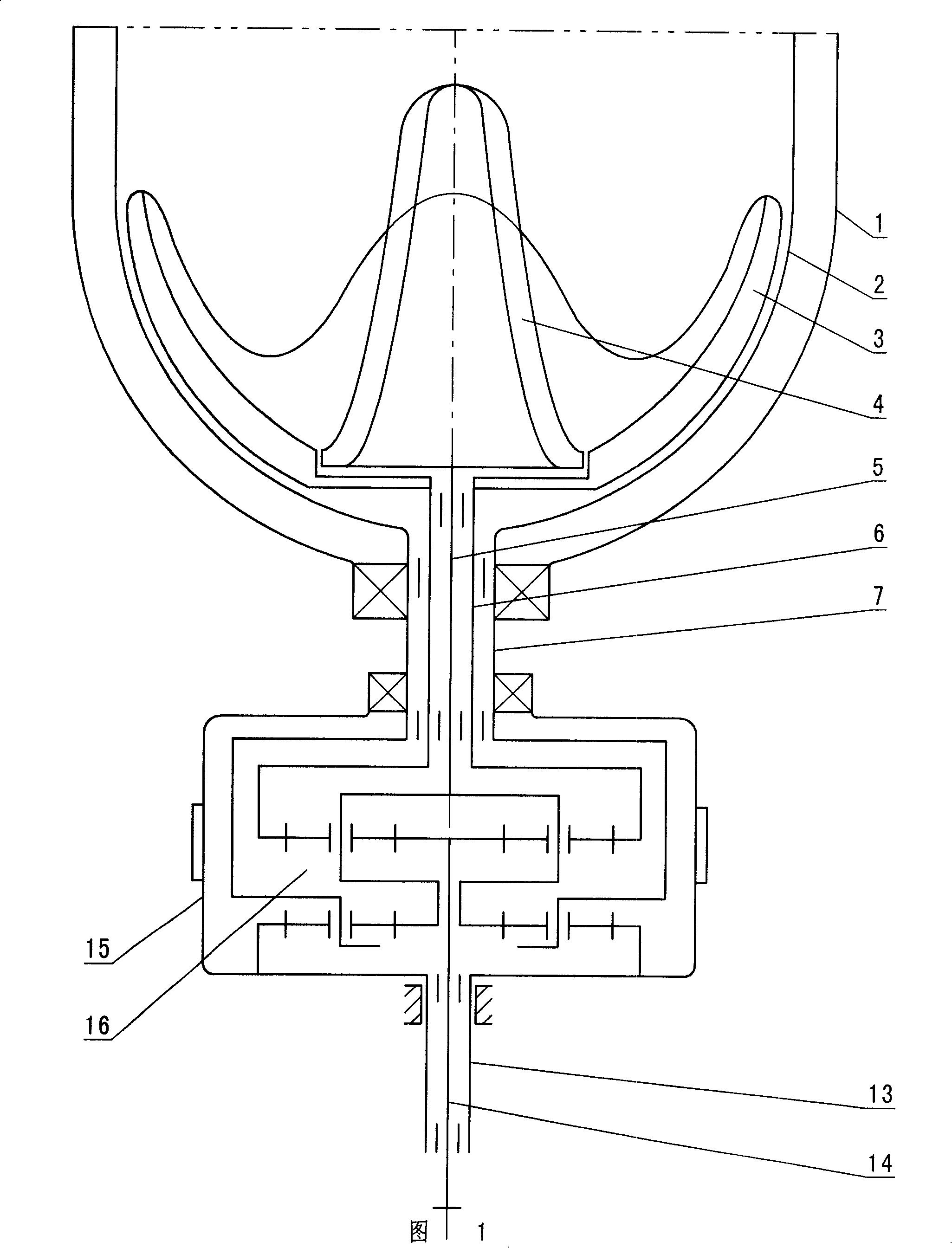

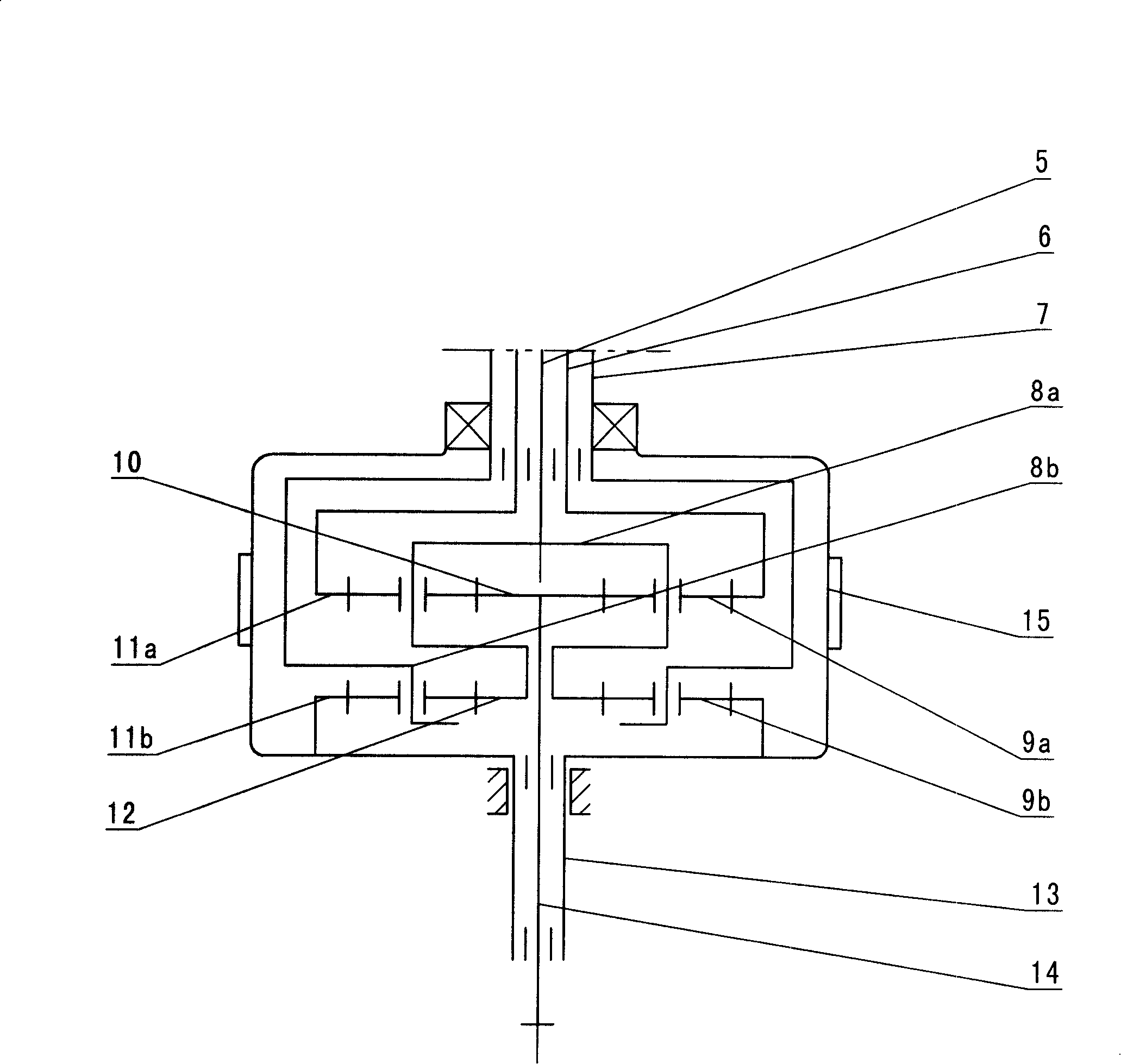

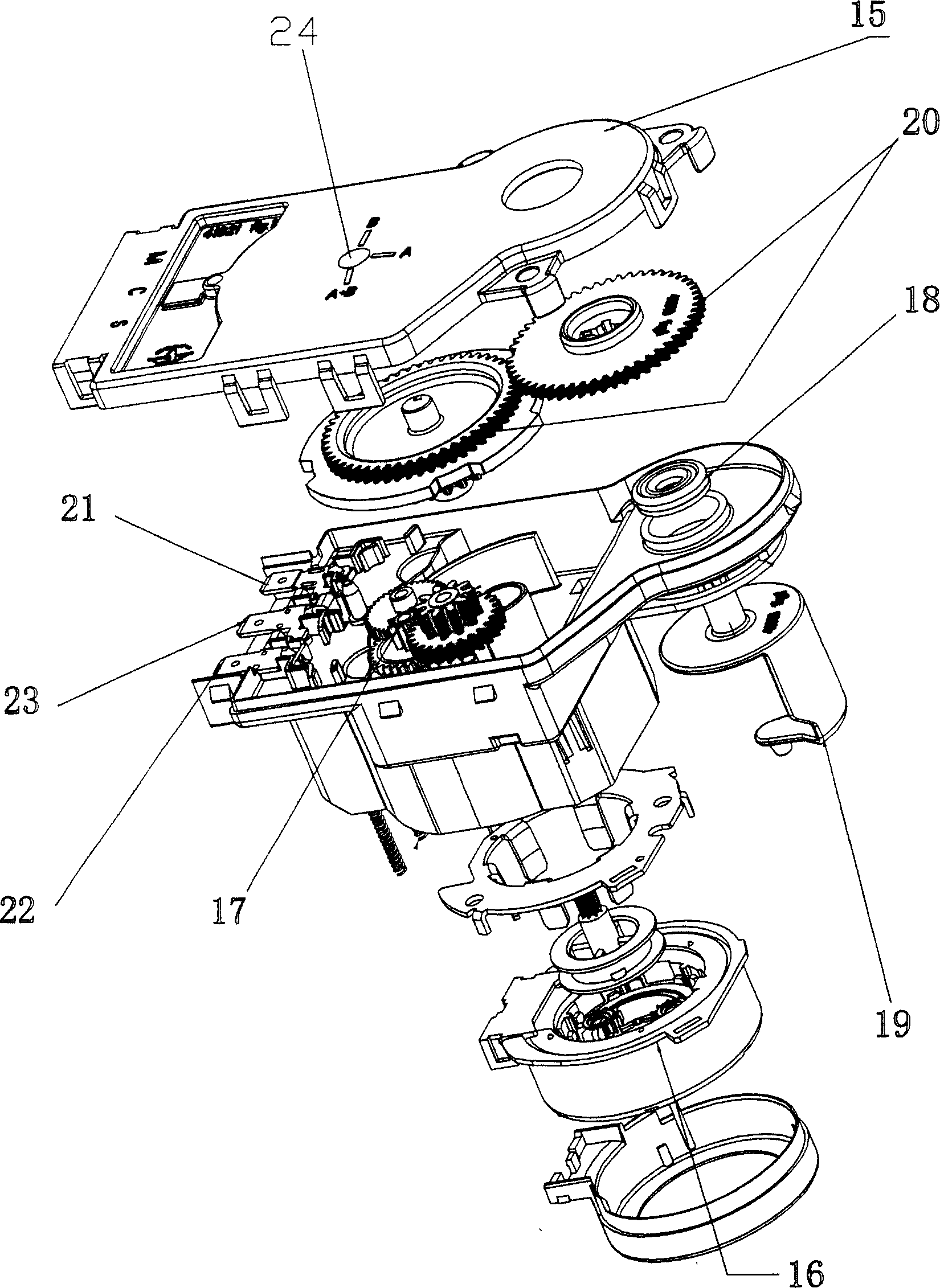

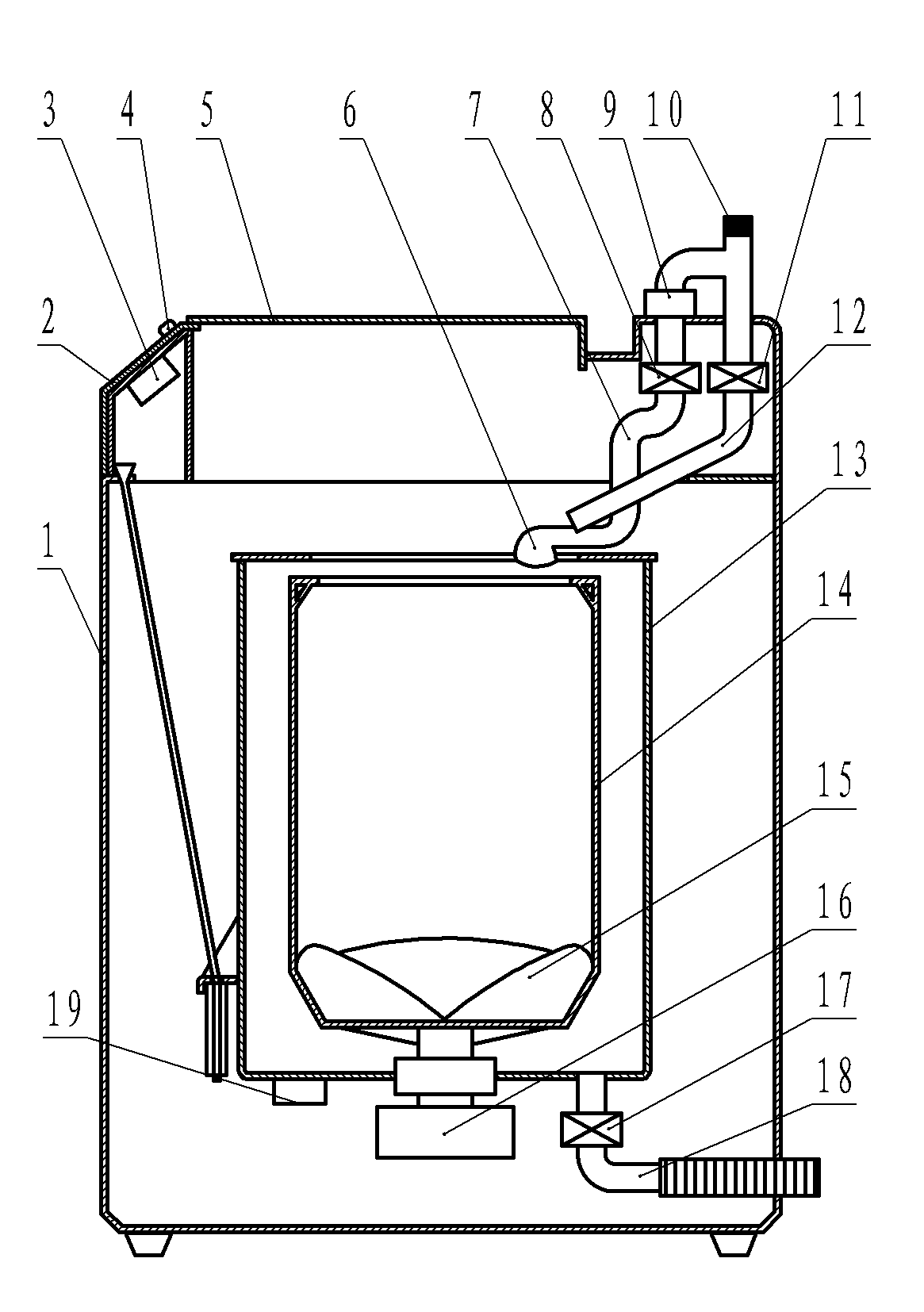

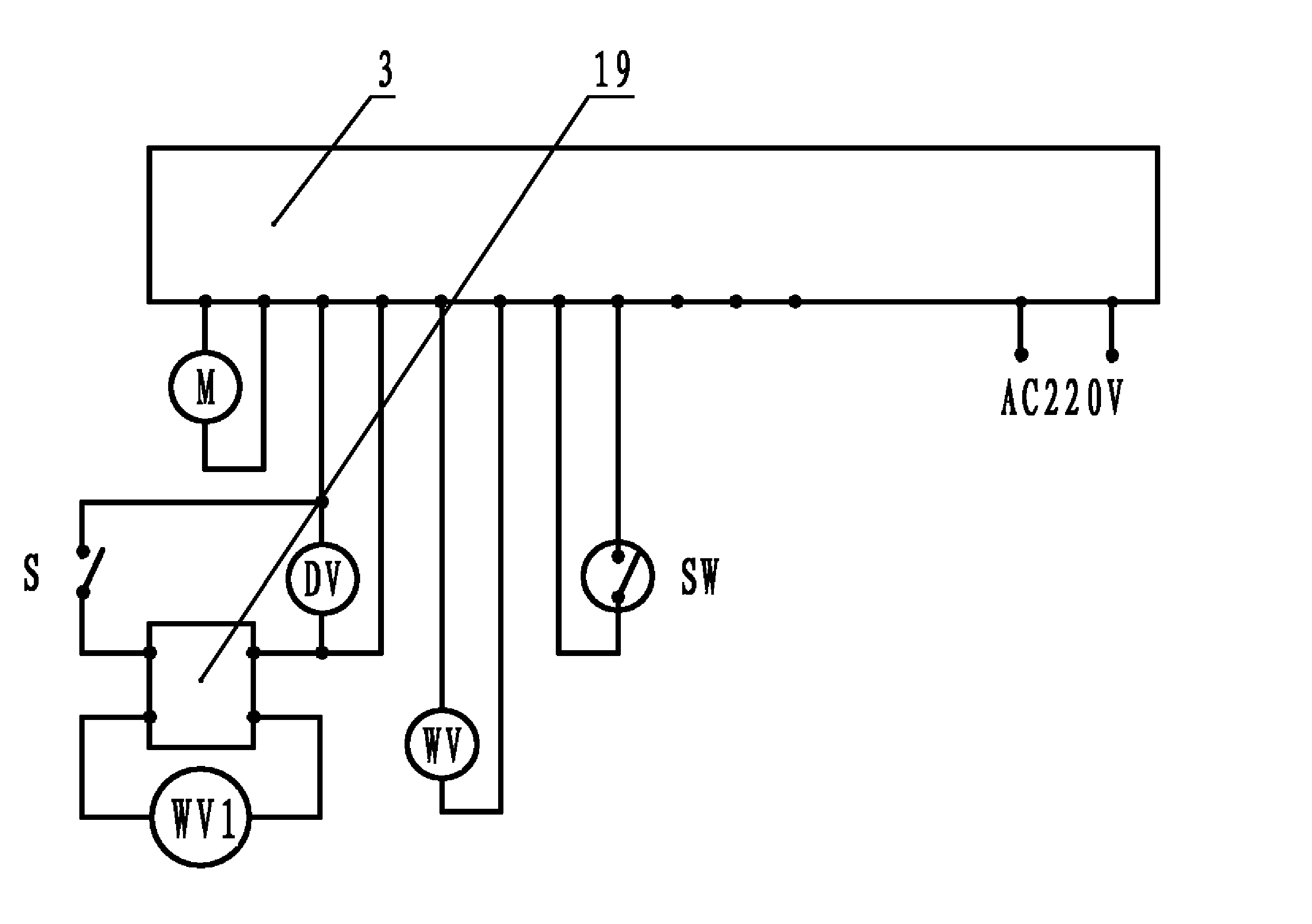

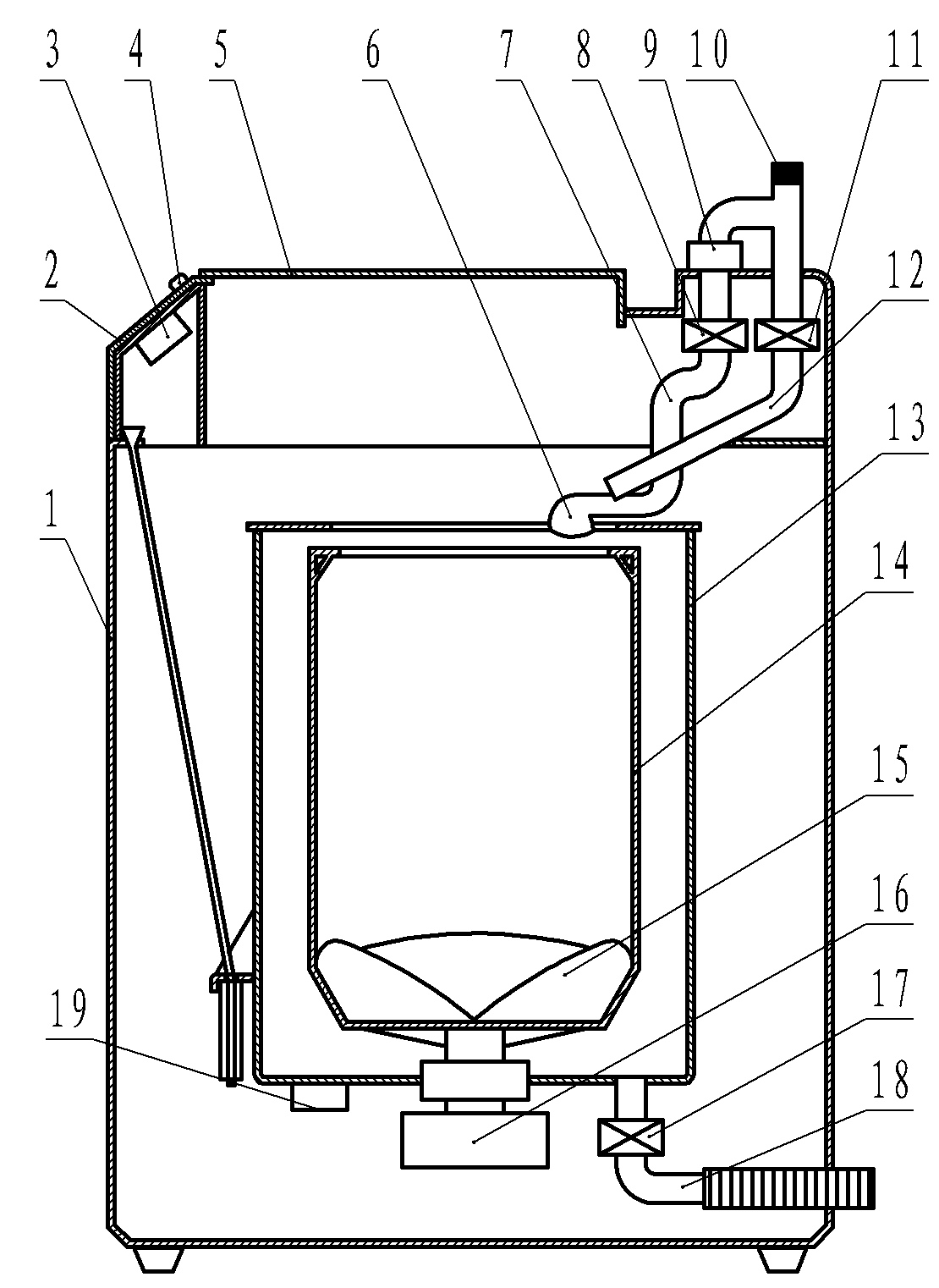

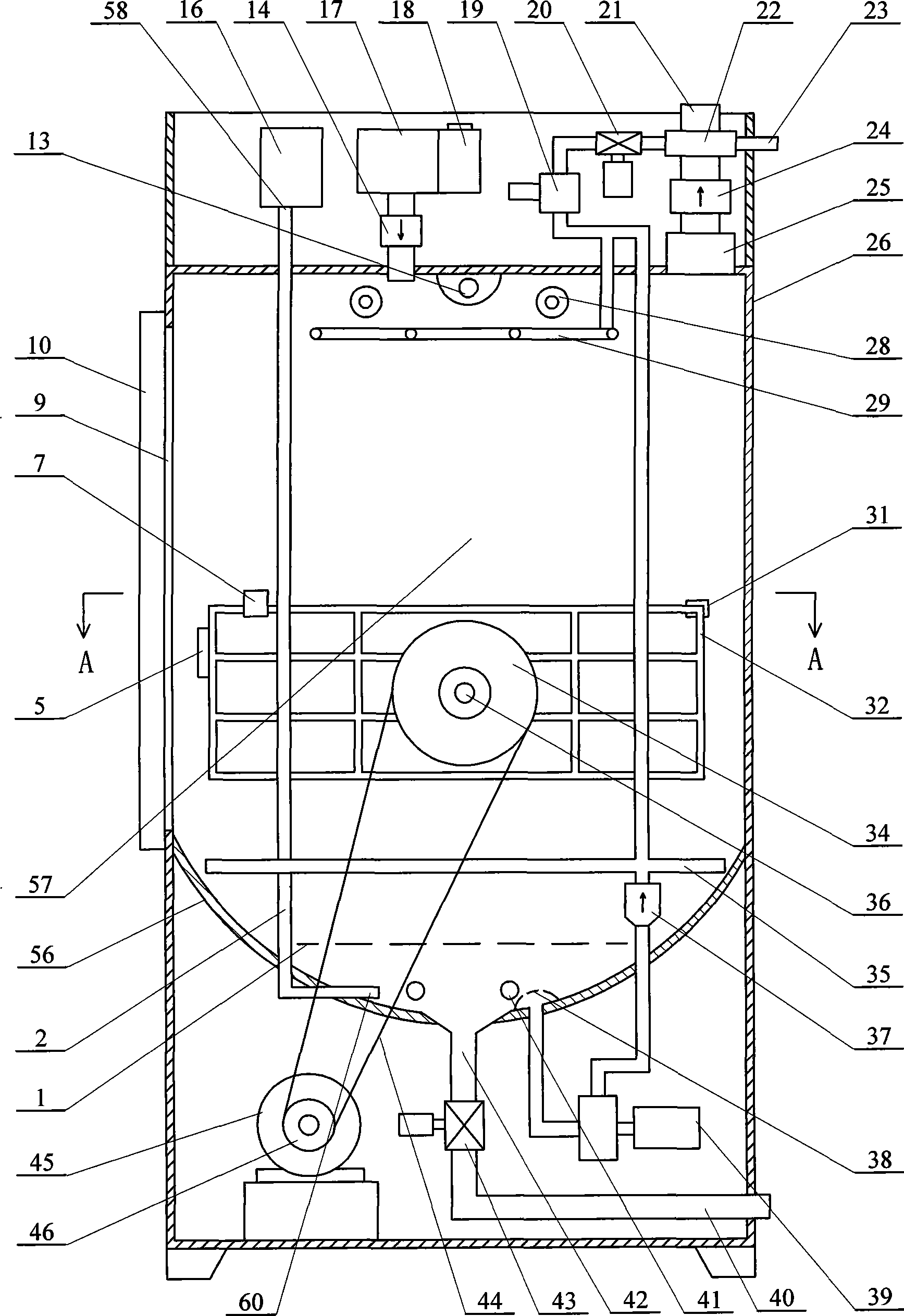

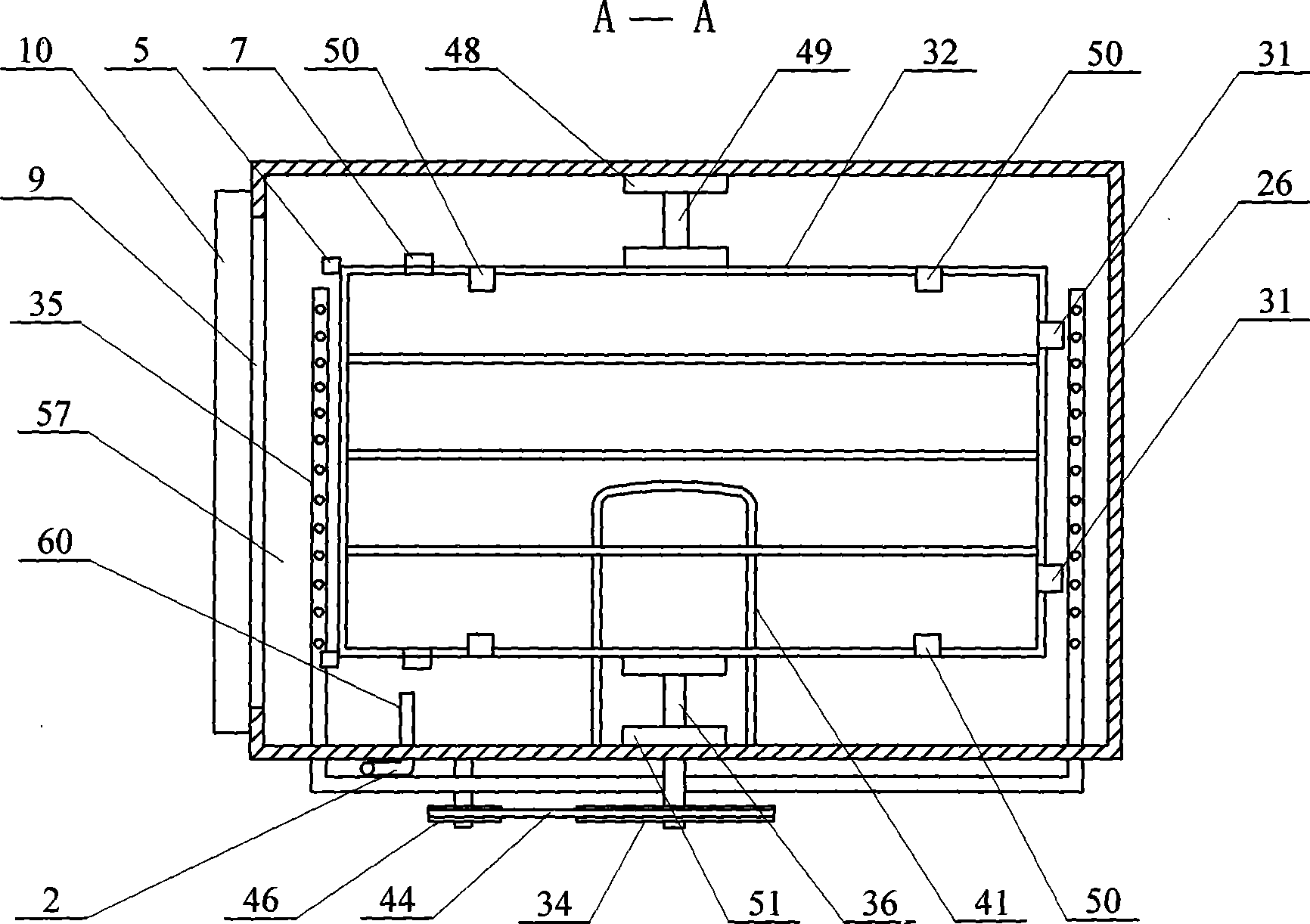

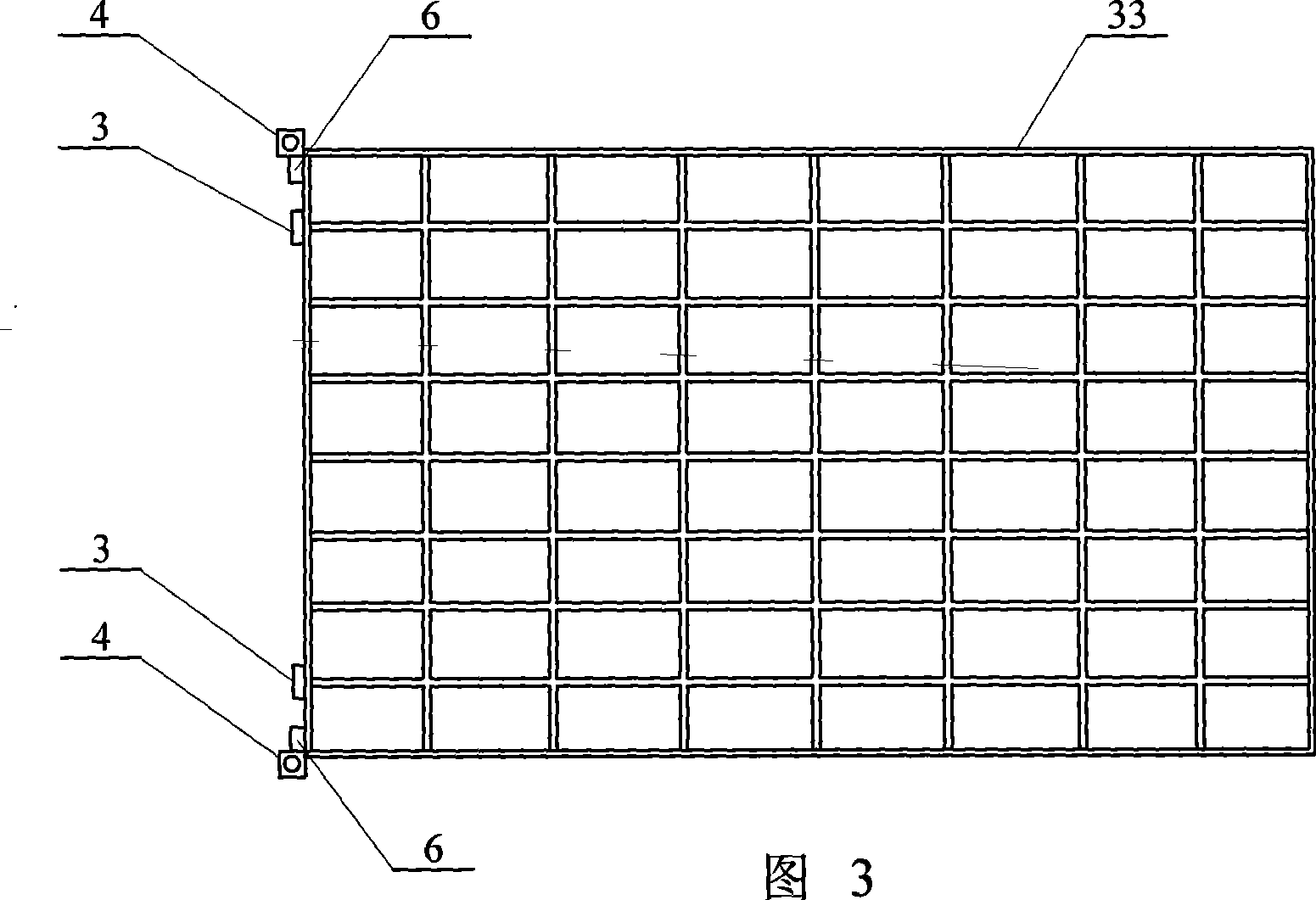

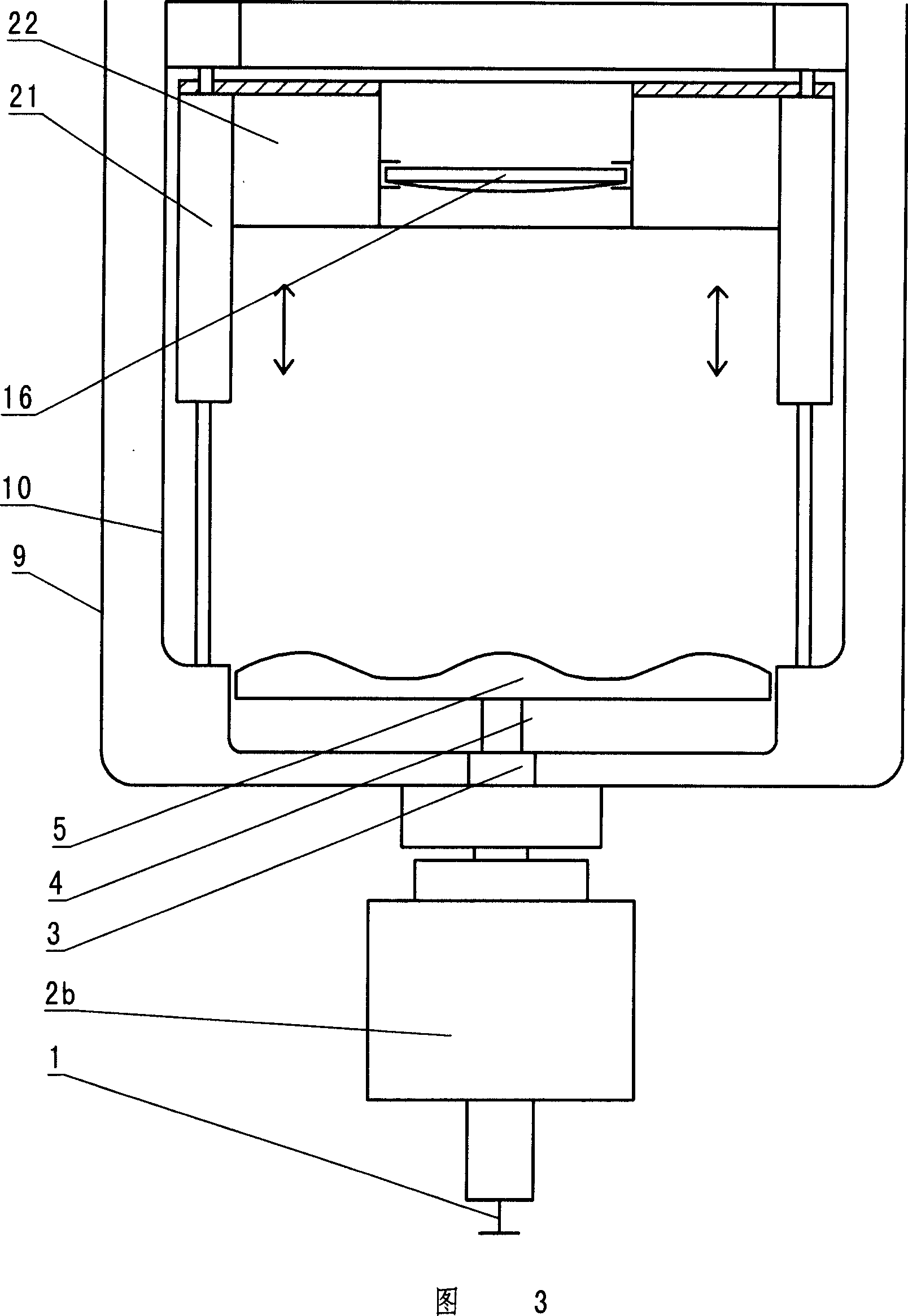

Washing machine deceleration clutch, washing machine and washing mode thereof

ActiveCN101210372ATumble fullImprove cleaning rateToothed gearingsOther washing machinesWater flowClutch

A decelerating clutch of a washer and the washer and a washing mode thereof relates to the technical field of washer. An output shaft of the decelerating clutch includes a small wave wheel shaft, a large wave wheel shaft and an inner barrel shaft, wherein the small wave wheel shaft is supported in the large wave wheel shaft, and the large wave wheel shaft is supported in the inner barrel shaft. By adopting the deceleration mechanism of the decelerating clutch, the invention can simultaneously drive a large wave wheel, a small wave wheel and an inner barrel to rotate. A washer manufactured by using the decelerating clutch comprises a small wave wheel and a large wave wheel, wherein the small wave wheel is fixedly arranged on the small wave wheel shaft and positioned at the middle portion of the large wave wheel; the large wave wheel is fixedly arranged on the large wave wheel shaft; and the inner barrel is fixedly arranged on the inner barrel shaft. The washer manufactured by using the decelerating clutch is operated in such a mode that the small wave wheel, the large wave wheel and the inner barrel make reciprocating rotation in mutually reverse directions at different speeds and different rotation angles by a ratio in two directions to produce complex and crossing shock water flow to scrub and clean the clothes, thus completely rotating the clothes, achieving strong scrubbing force and improving the cleaning rate.

Owner:NINGGUO JULONG IND

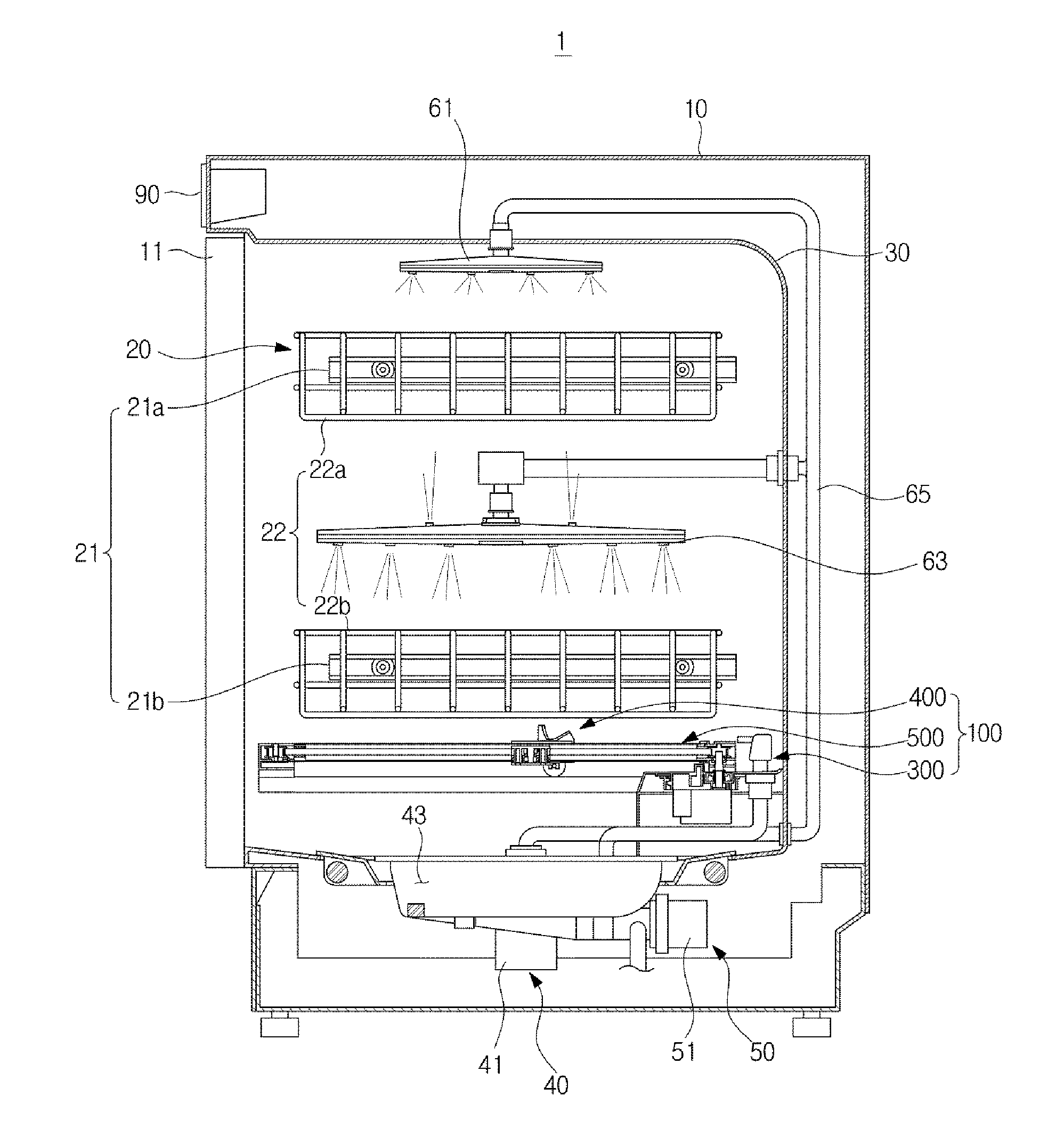

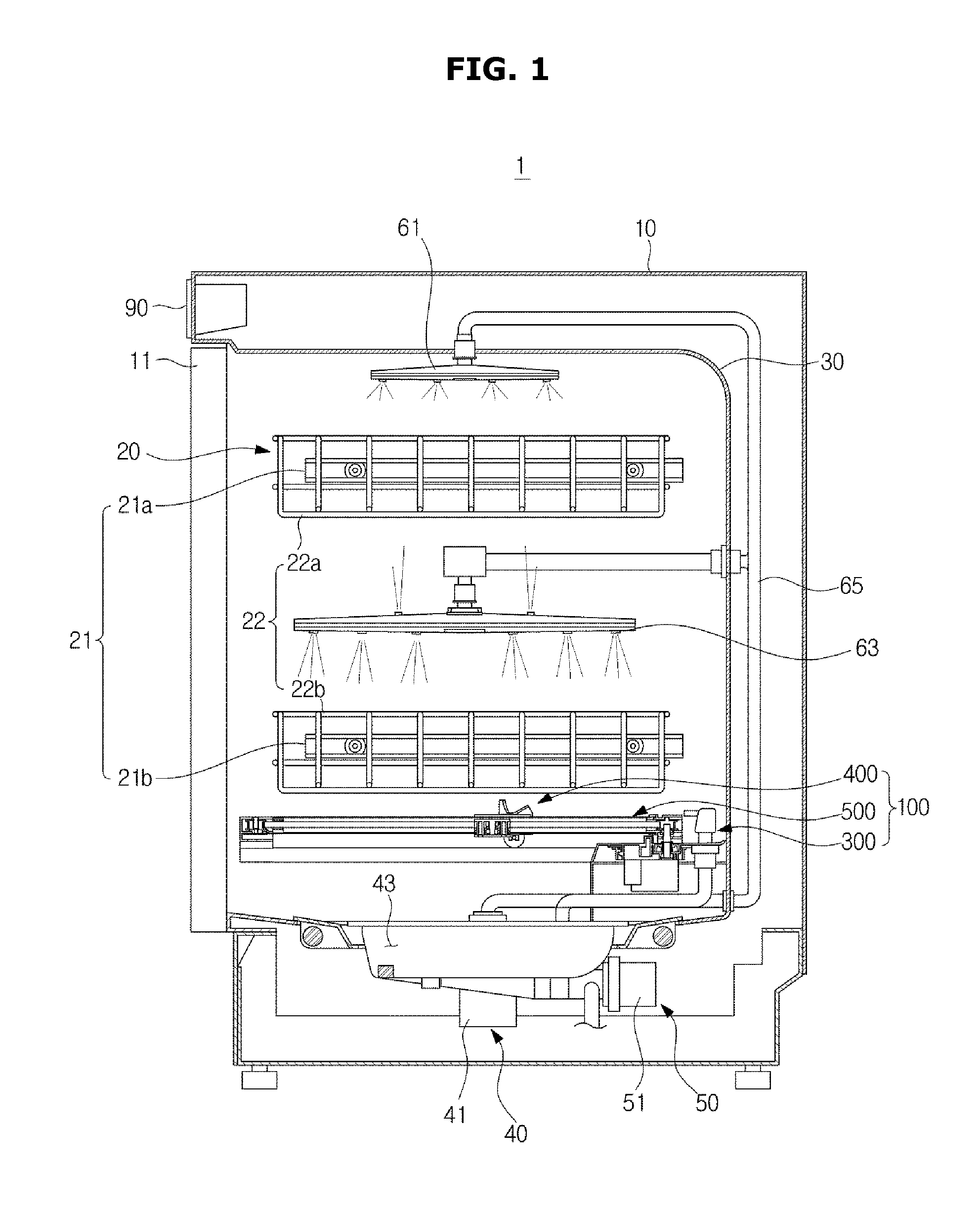

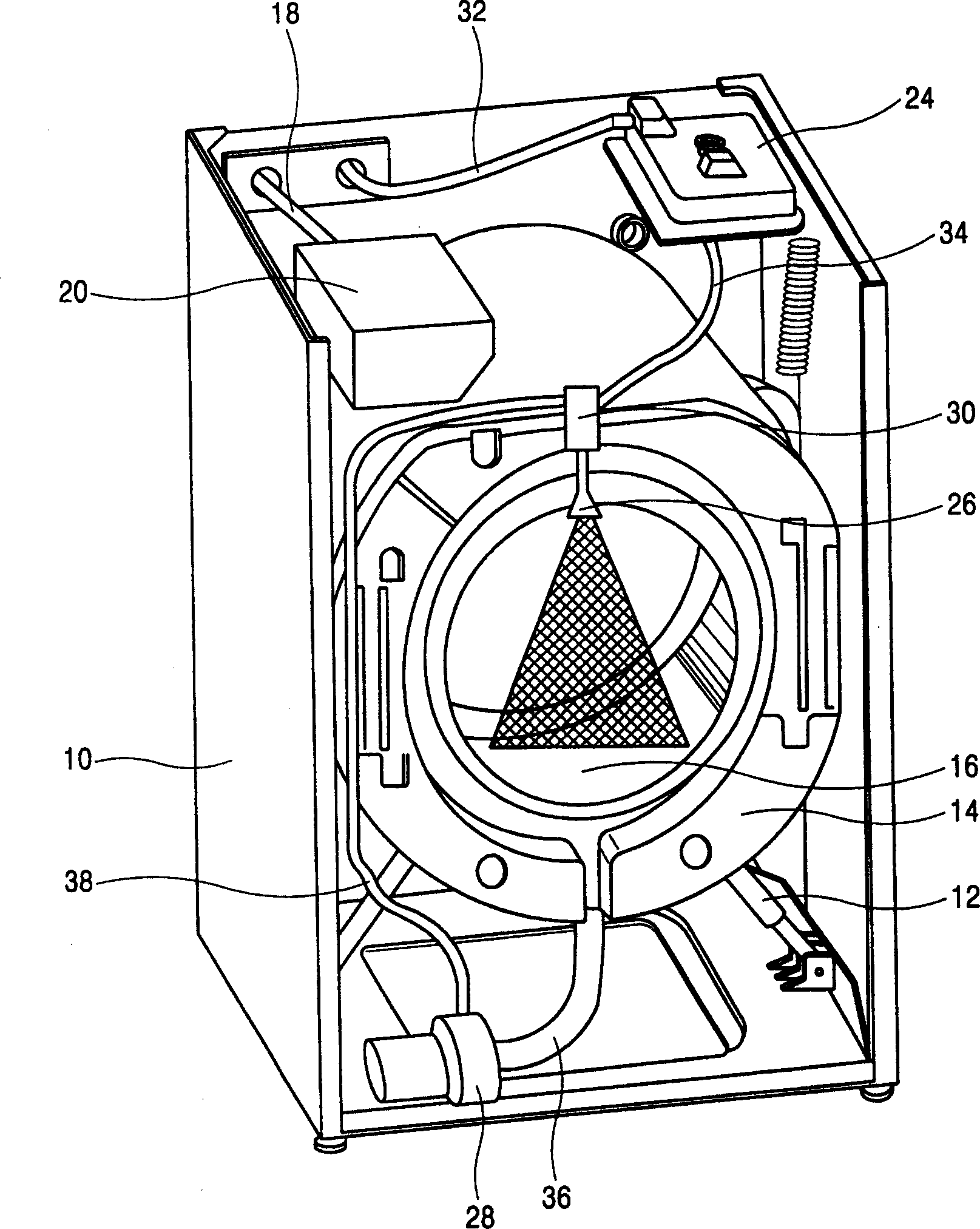

Washing machine

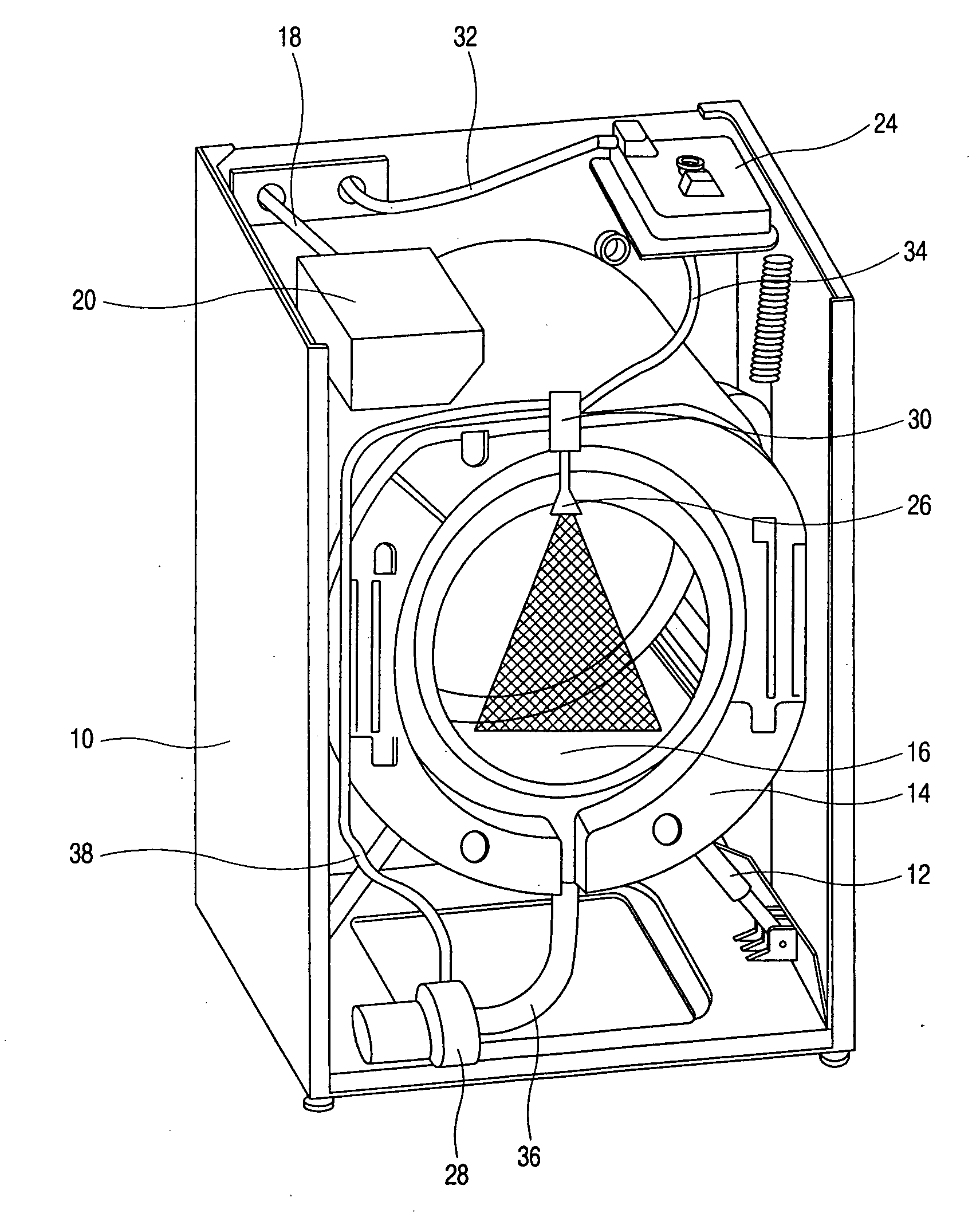

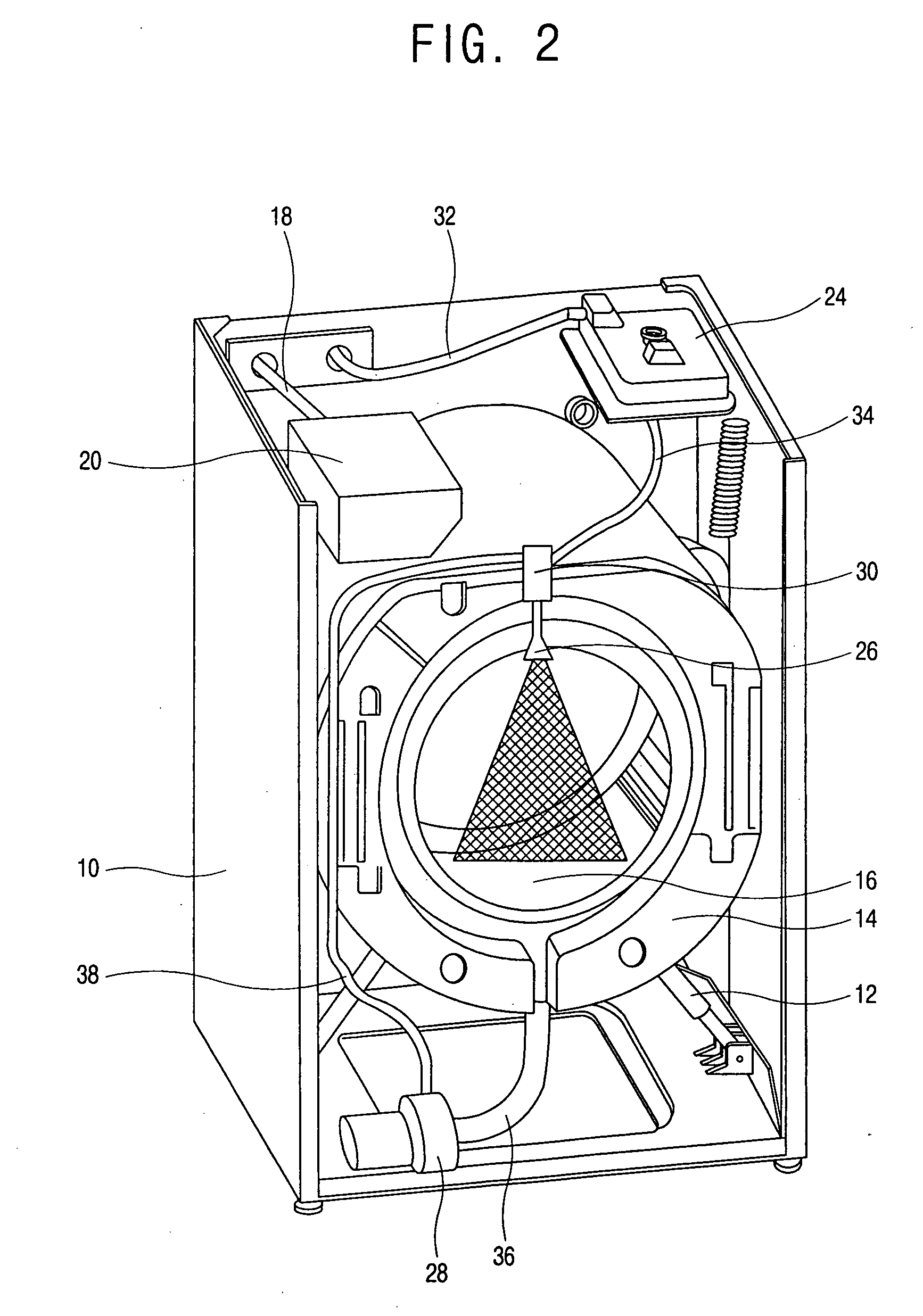

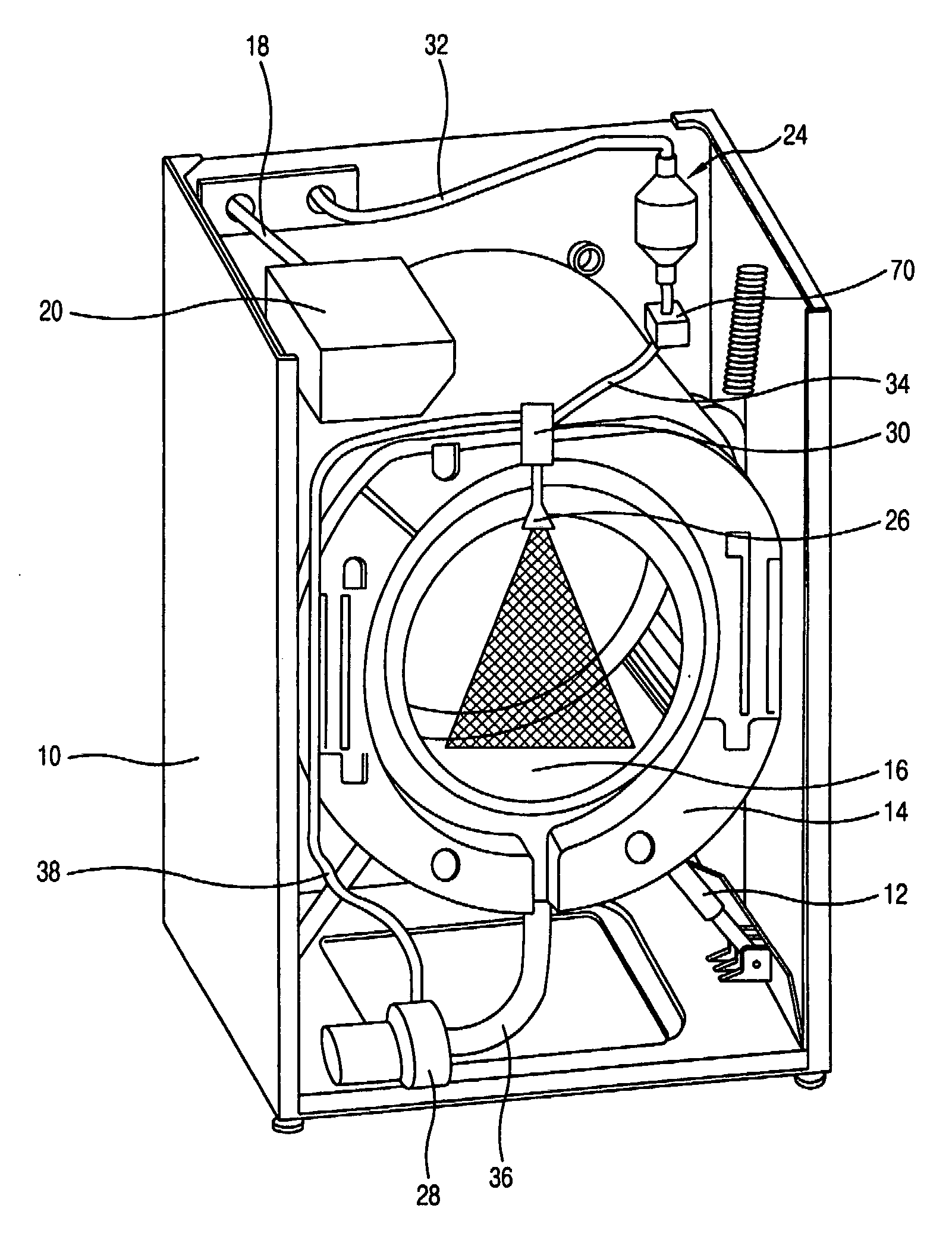

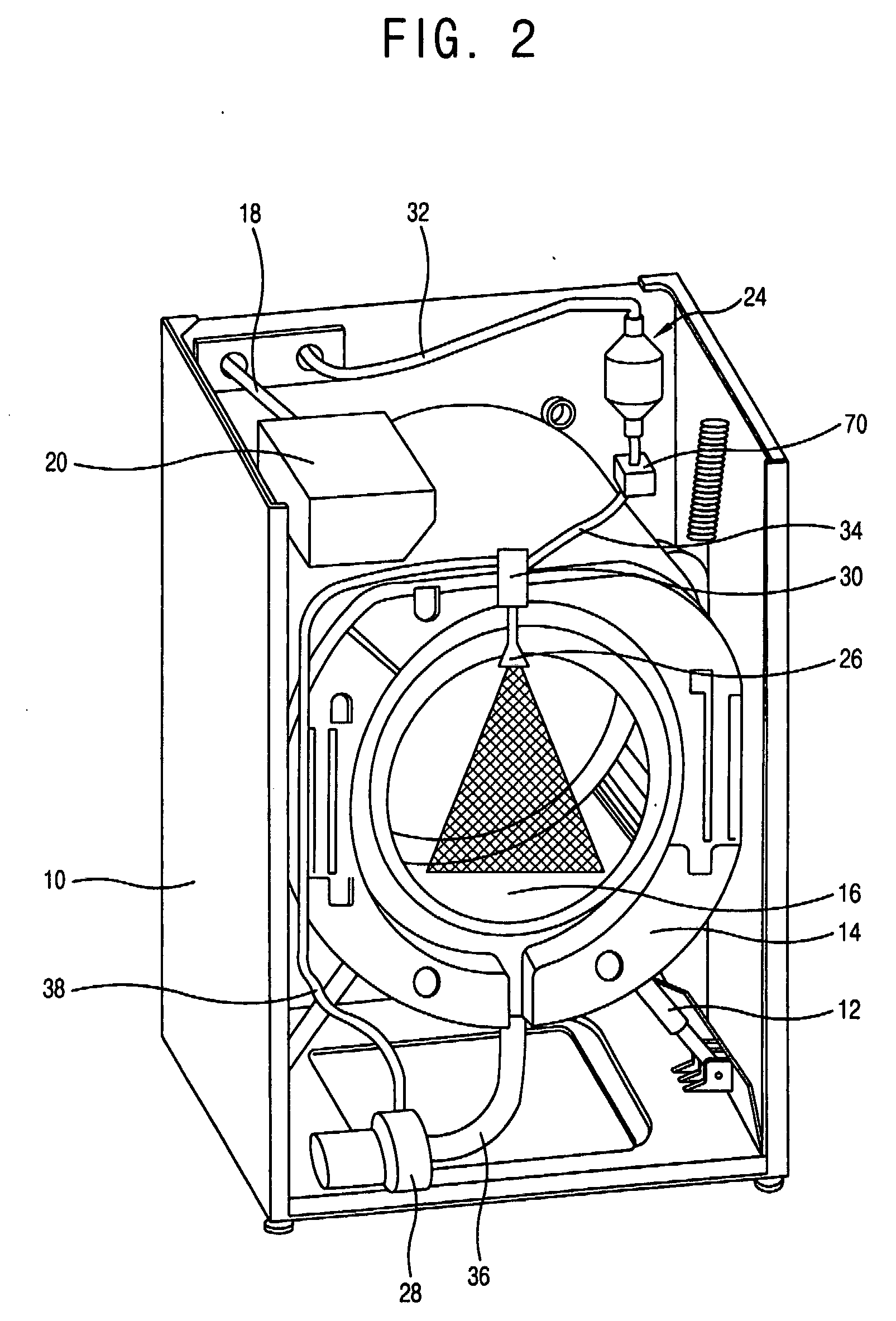

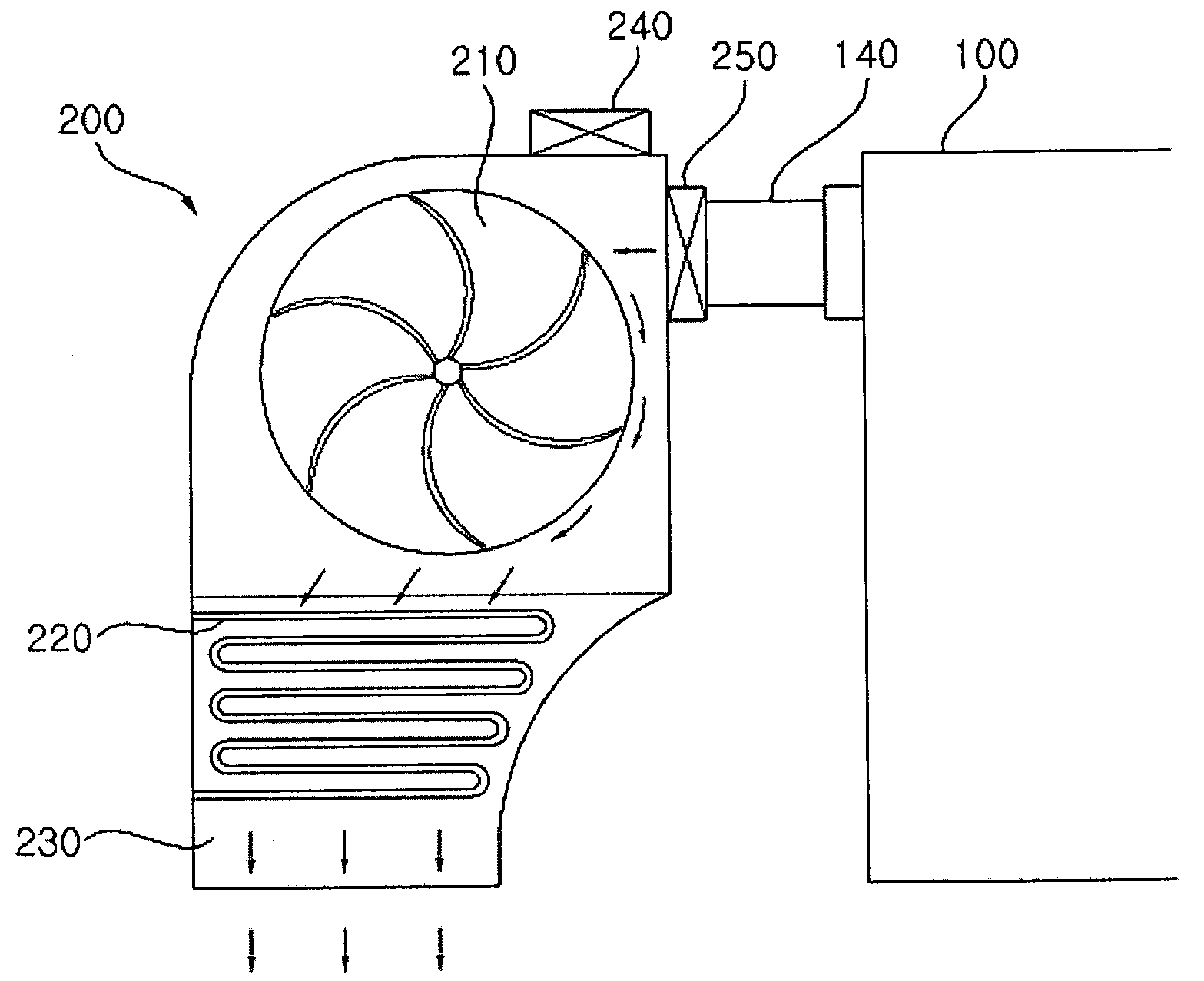

InactiveUS20080250824A1Reduce the amount requiredSmall sizeTextile treatment machine partsOther washing machinesManufacturing cost reductionWater discharge

A washing machine includes: a steam generator for generating steam; a circulation pump for pumping circulation water discharged from a tub and re-supplying it into a drum; a spray nozzle for spraying steam generated from the steam generator and the circulation water pumped from the circulation pump into the drum; and a back-current preventing branch unit connected to the steam generator by a steam supply line, connected to the circulation pump by a circulation line, and connected to the spray nozzle. With this structure, circulation water circulated by the circulation unit and steam generated from the steam generator are sprayed to the laundry through one spray nozzle, so that a system can be simplified and a fabrication cost can be reduced.

Owner:LG ELECTRONICS INC

Filtering system for dishwasher

ActiveCN101642361AImprove cleaning efficiencyPlay the role of cleaning filterTableware washing/rinsing machine detailsFilter systemWaste management

The invention discloses a filtering system for a dishwasher, comprising an inner bag of a dishwasher, a water cup, a first channel connected with the water cup of the dishwasher and a drainage pump arranged on the first channel. A self-cleaning filtering residue removing device also comprises a filtering cavity; a filtering net is arranged in the filtering cavity; the filtering cavity is divided into a first cavity body and a second cavity body by the filtering net; the first cavity body is connected with the other end of the first channel; the second cavity body is connected with the inner bag of the dishwasher by the second channel; the first cavity body is also connected with a drainage pipe and the drainage pipe is provided with a drainage valve. The drainage pump is used for making washing water forcibly participate an individual filtering circulation system, thereby performing the cleaning and filtering function on the washing water; and simultaneously, food residues are collected and discharged, thereby enhancing the washing efficiency of the dishwasher, reducing the washing water and saving the washing time. The provided filtering residue removing device also has the function for automatically cleaning the filtering net.

Owner:MIDEA GRP CO LTD

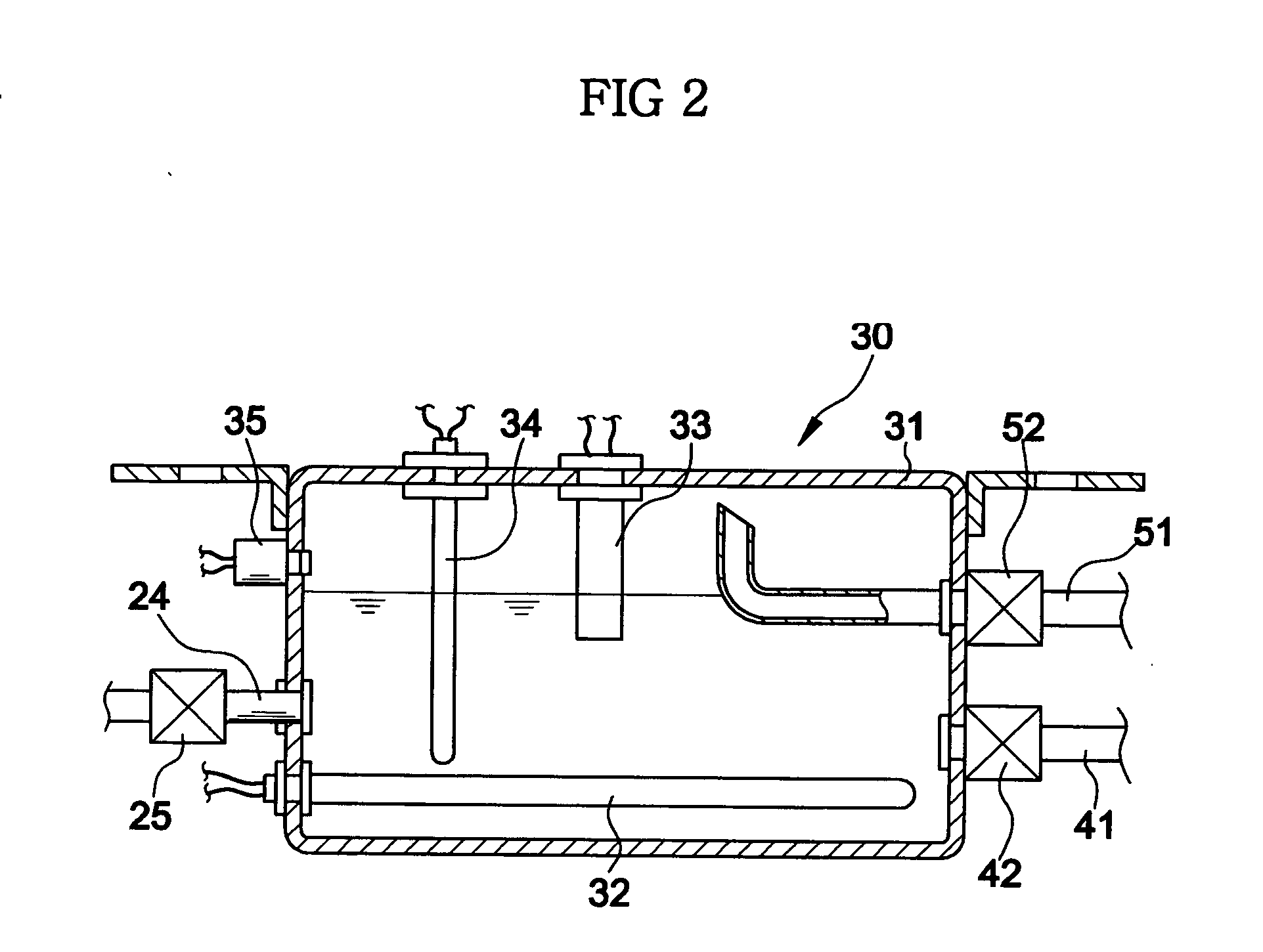

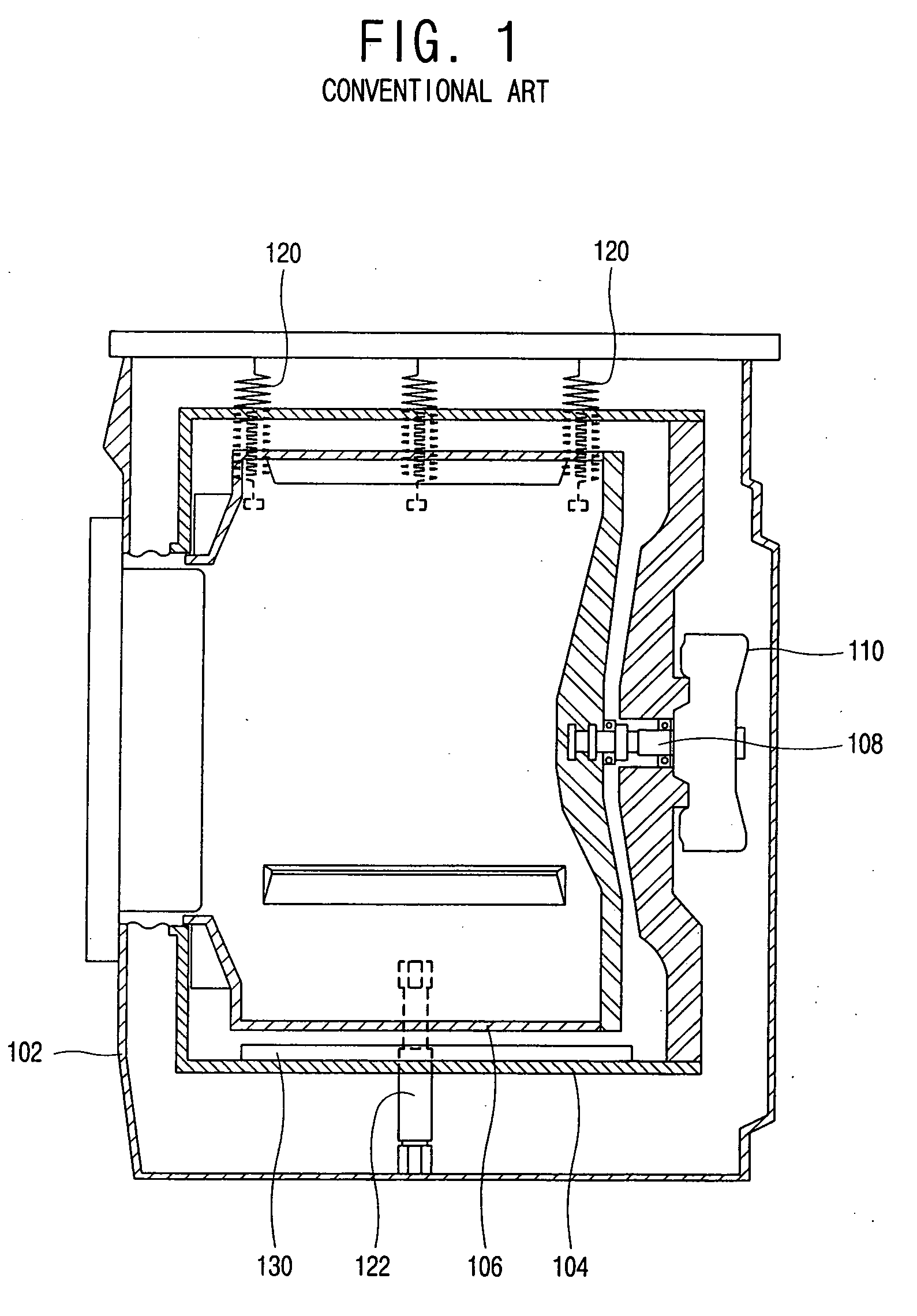

Drum type washing machine with heater using steam and hot water

InactiveUS7404304B2Increase temperatureShorten washing timeTextile treatment machine partsOther washing machinesWash waterEngineering

Owner:SAMSUNG ELECTRONICS CO LTD

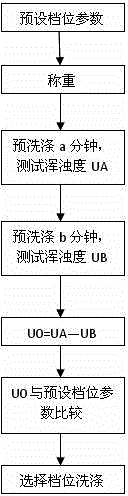

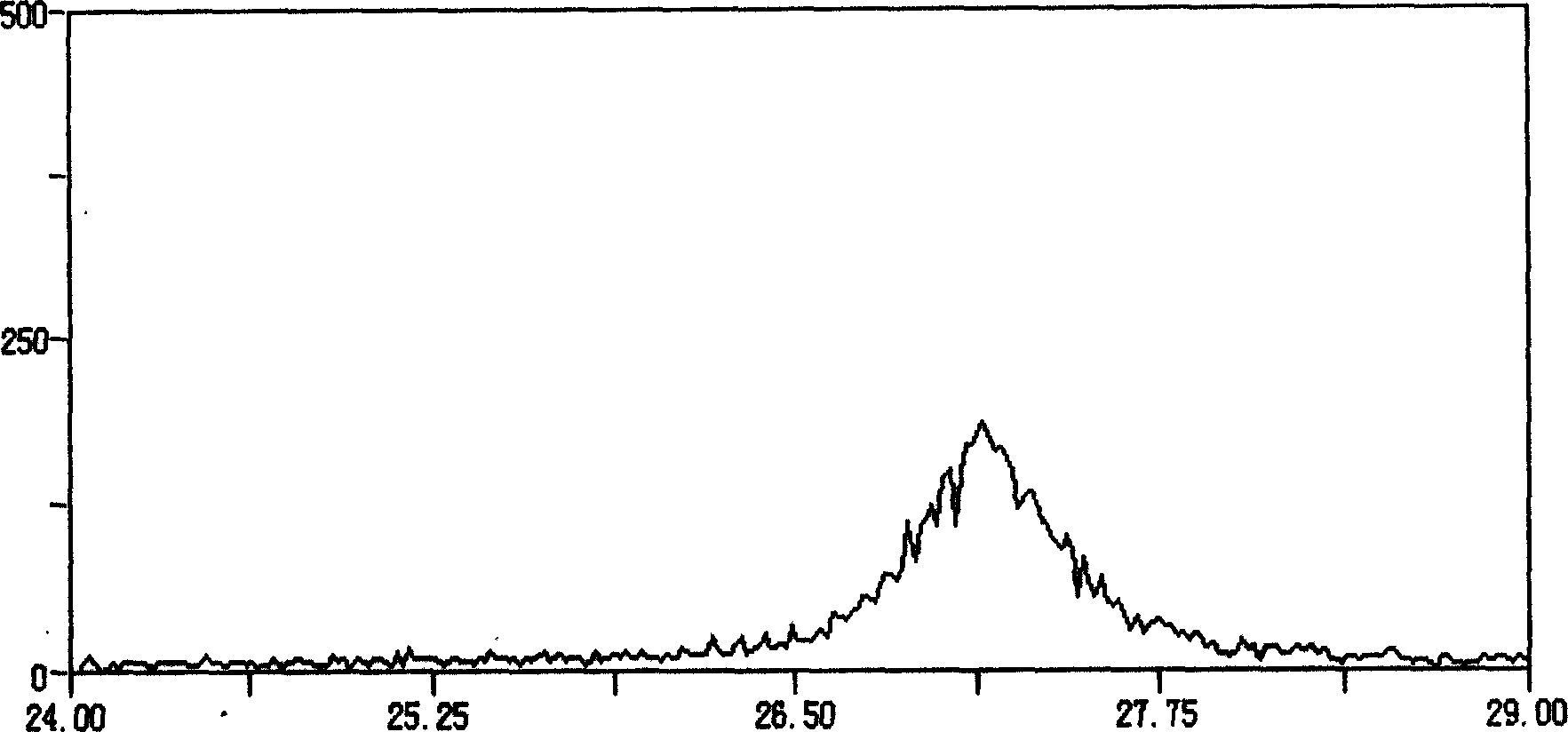

Method for distinguishing smudgy degree of clothes

ActiveCN102720033AShorten washing timeIncrease washing timeOther washing machinesControl devices for washing apparatusMachine controlStart time

The invention relates to a washing machine control method, which is particularly characterized in that the corresponding clothes washing control method is selected after the smudgy degree of clothes is judged. According to the method, firstly, the turbidity degree of water in the starting time period of the clothes washing is compared, the smudgy degree of clothes to be washed is distinguished, and then, the washing time, the washing intensity, the detergent addition quantity, the rinsing time and the like are regulated according to the smudgy degree of the clothes. The corresponding clothes washing procedure is selected according to the smudgy degree of the clothes, the clothes washing time of cleaner clothes can be reduced, the washing time of dirtier clothes is increased, and the clothes washing efficiency is improved.

Owner:WUXI LITTLE SWAN ELECTRIC CO LTD

Washing machine

ActiveUS20070125133A1Reduce the amount requiredSmall sizeSteam generation heating methodsTextile treatment machine partsEngineeringLaundry

A washing machine includes a tub disposed inside a cabinet, for storing water; a drum rotatably disposed inside the tub, for washing laundry; and a steam generating apparatus disposed at the cabinet, for generating steam supplied to the inside of the drum, by using high-frequency induction heating. Accordingly, by generating steam using high-frequency induction heating, a structure of the steam generating apparatus can be simplified, and performance of generating steam can be improved.

Owner:LG ELECTRONICS INC

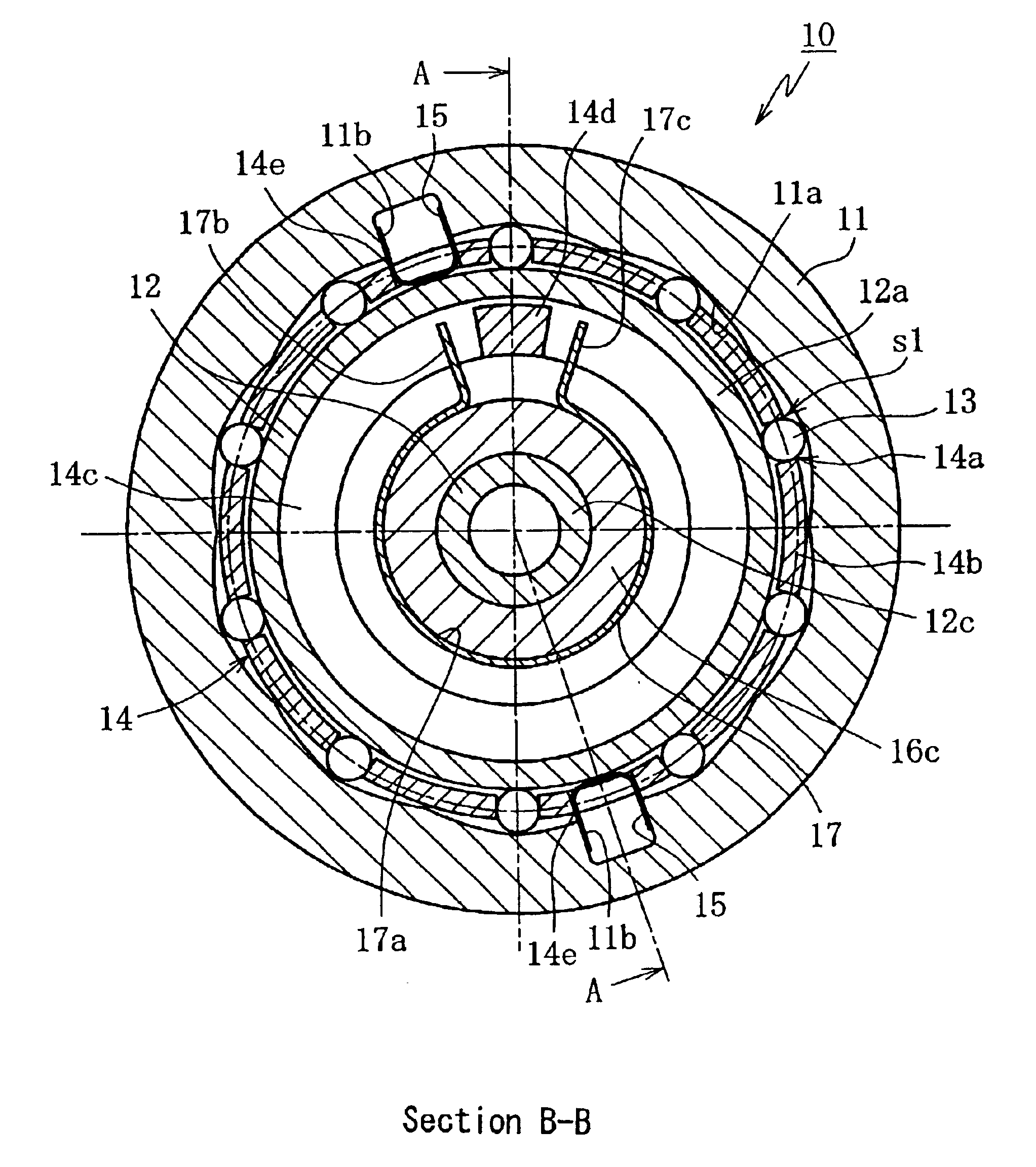

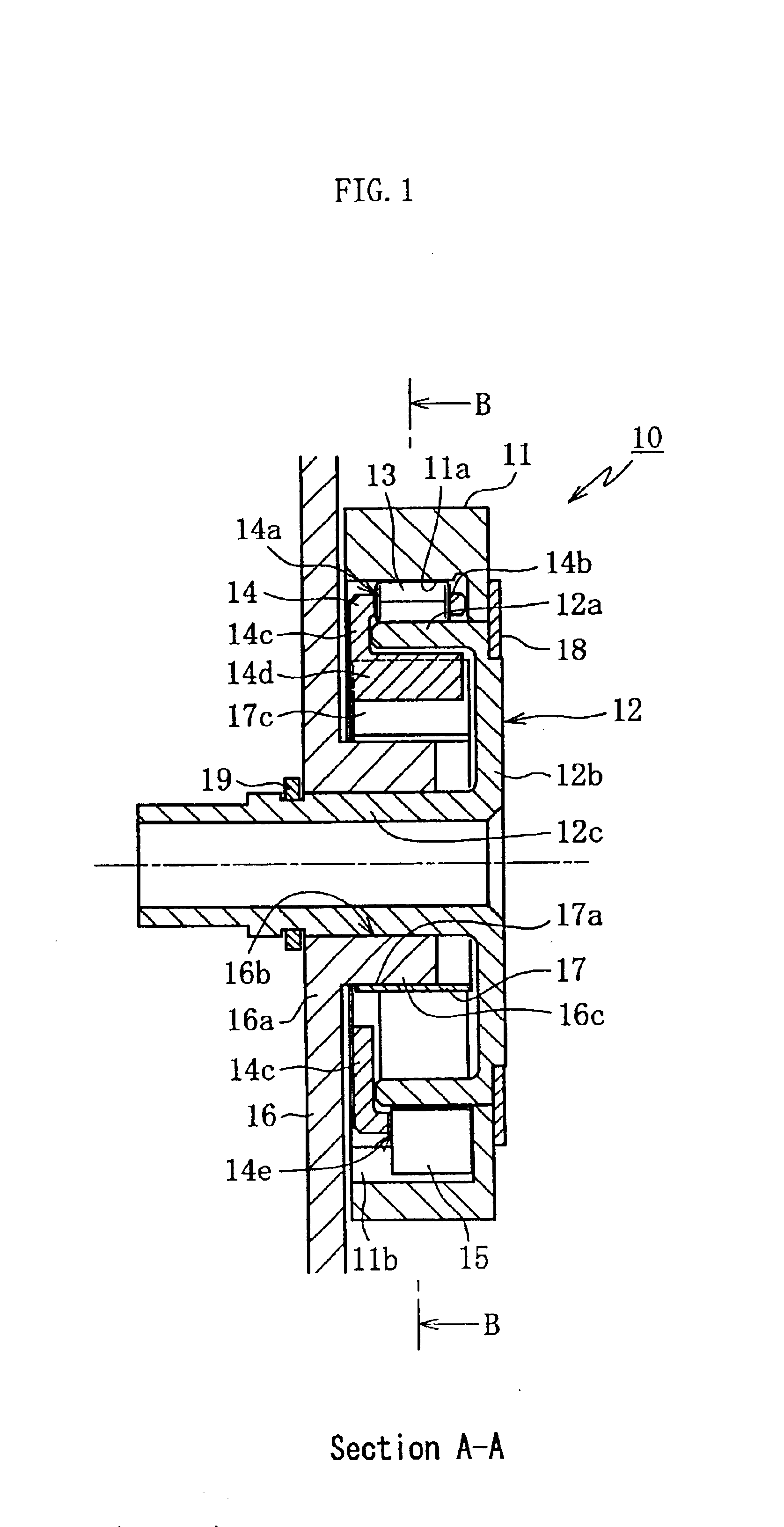

Reverse-input shutoff clutch and rotation drive device

InactiveUS6871735B2Excellent in start-up responseImprove responseYielding couplingMan-operated mechanismTorque transmissionEngineering

A reverse-input shutoff clutch according to the invention includes an outer ring as an input-side rotation member, an inner ring as an output-side rotation member, rollers as torque transmission means, a cage for retaining the roller, a centering spring as an elastic member for positioning the cage, a housing as a stationary-side member, and a sliding spring coupled to and co-rotate with the cage while sliding against the housing. With the constitution described above, the clutch applies rotational resistance induced by friction resistance to the cage.

Owner:NTN CORP

Washing machine

ActiveUS7290412B2Grow fastShorten washing timeTextile treatment machine partsOther washing machinesWash waterProcess engineering

A washing machine in which steam and hot water are supplied to heat wash water. The washing machine includes a water tub for containing wash water, a steam generating unit for heating water supplied thereto, thereby generating steam, a water supply unit for supplying water into the water tub and the steam generating unit, a steam supply unit for supplying the steam generated from the steam generating unit into the water tub, and a hot water supply unit for supplying hot water from the steam generating unit into the water tub. In the washing machine, the temperature of wash water can be rapidly increased in accordance with steam and hot water supplied into the water tub. Accordingly, it is possible to reduce the overall wash time while reducing the amount of wash water to be used. The energy consumed to heat the wash water can also be reduced.

Owner:SAMSUNG ELECTRONICS CO LTD +1

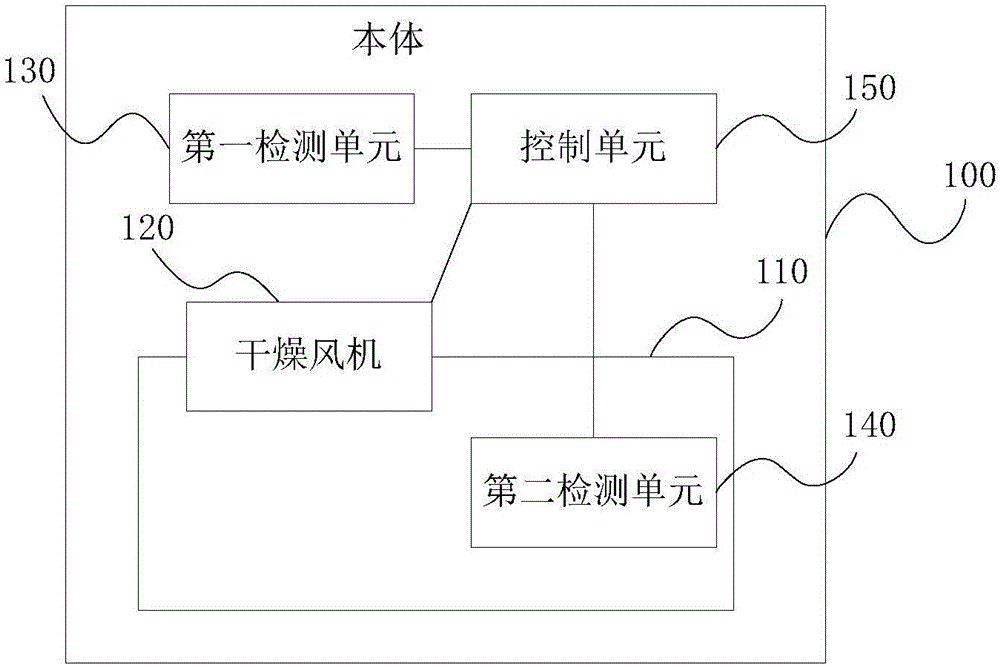

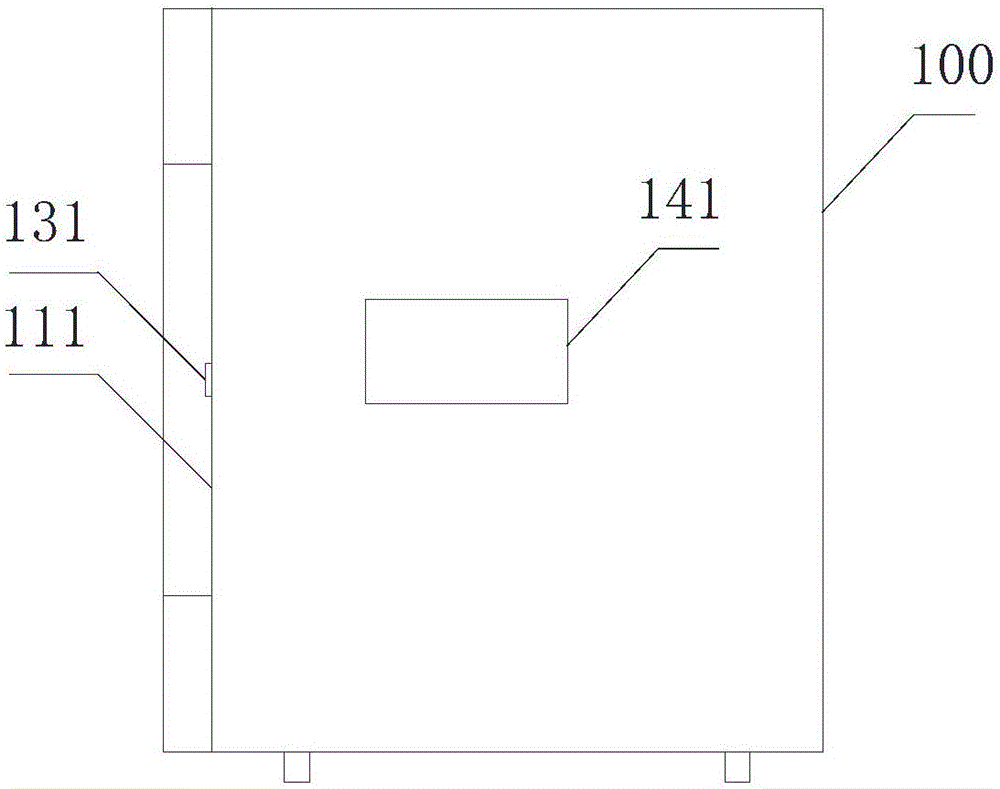

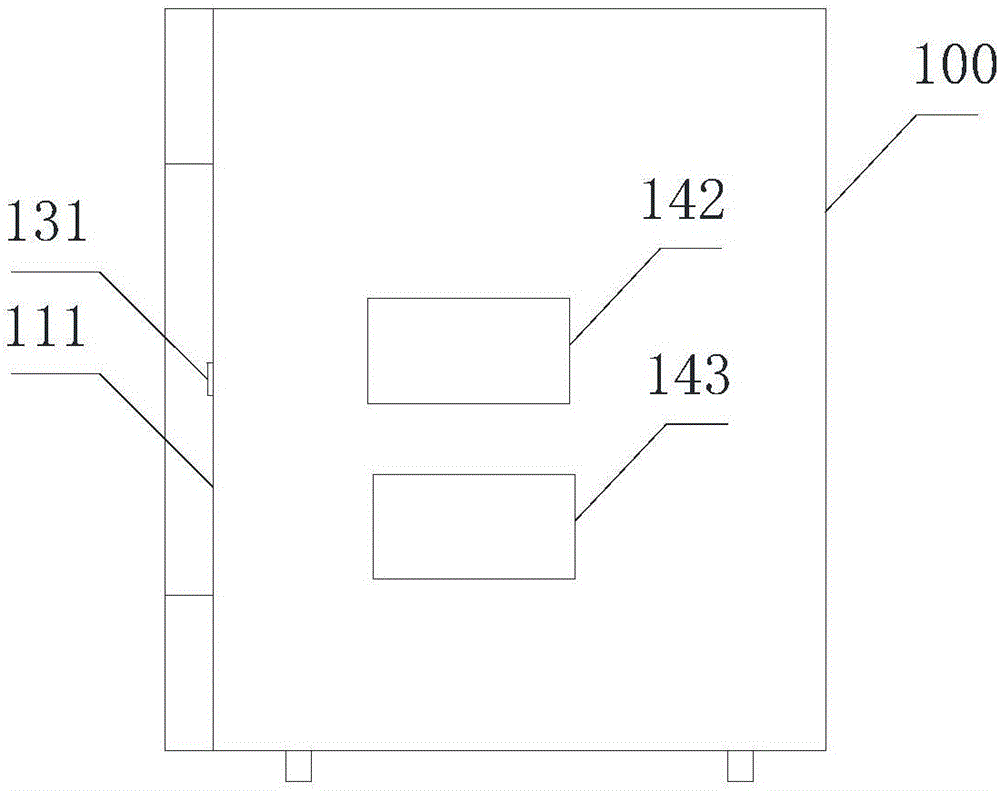

Dish washing machine and control method thereof

ActiveCN106725184ASolve the problem of re-contaminationShorten washing timeTableware washing/rinsing machine detailsProcess engineeringContamination

The invention discloses a dish washing machine and a control method thereof. The dish washing machine comprises a body, an inner container arranged in the body, a drying fan arranged in the body, a first detection unit used for detecting the environment temperature outside the inner container, a second detection unit for detecting the temperature and humidity of space of the inner container, and a control unit used for calculating the dew point temperature of the space of the inner container according to the temperature and humidity of the space of the inner container and controlling the drying fan according to the dew point temperature and the environment temperature outside the inner container when the dish washing machine gets into a dish drying storage stage. Thus, after washing is completed, the drying fan is controlled according to the environment temperature outside the inner container and the dew point temperature of the space of the inner container to carry out drying storage on dishes. The problem of re-contamination caused by the fact that the dishes are not taken out in time is effectively solved, and meanwhile the whole washing time of the dishes can be effectively shortened.

Owner:FOSHAN SHUNDE MIDEA WASHING APPLIANCES MFG CO LTD +1

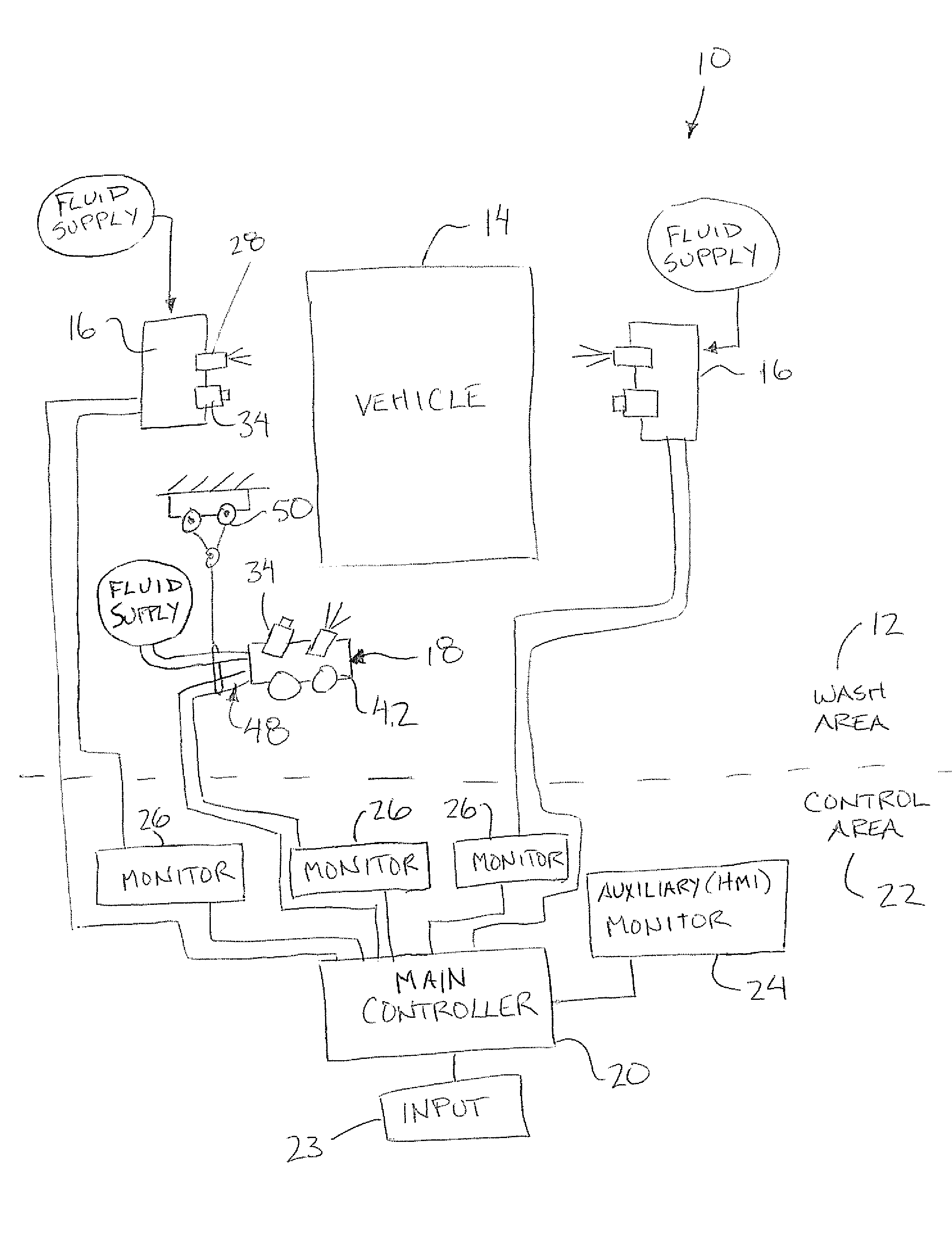

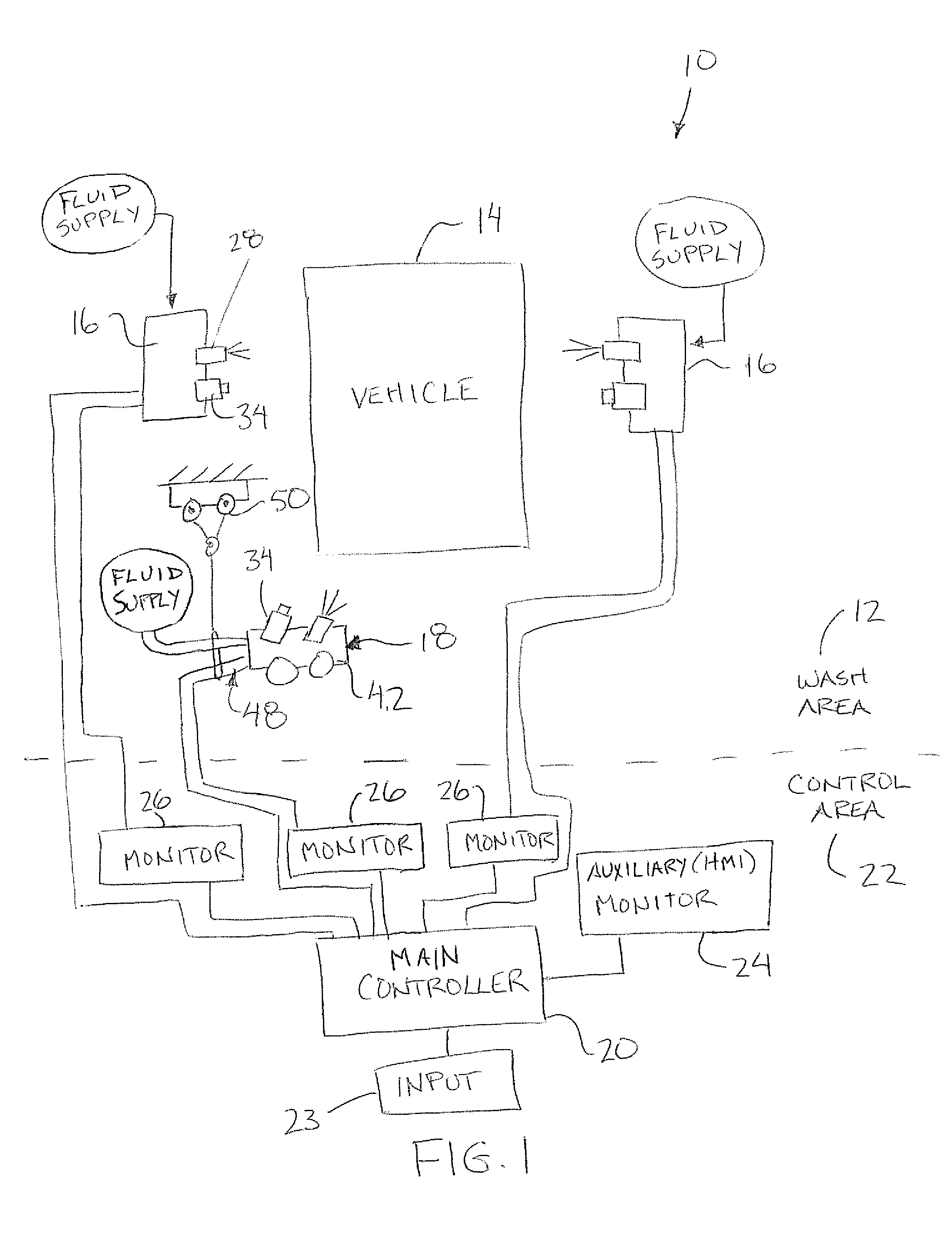

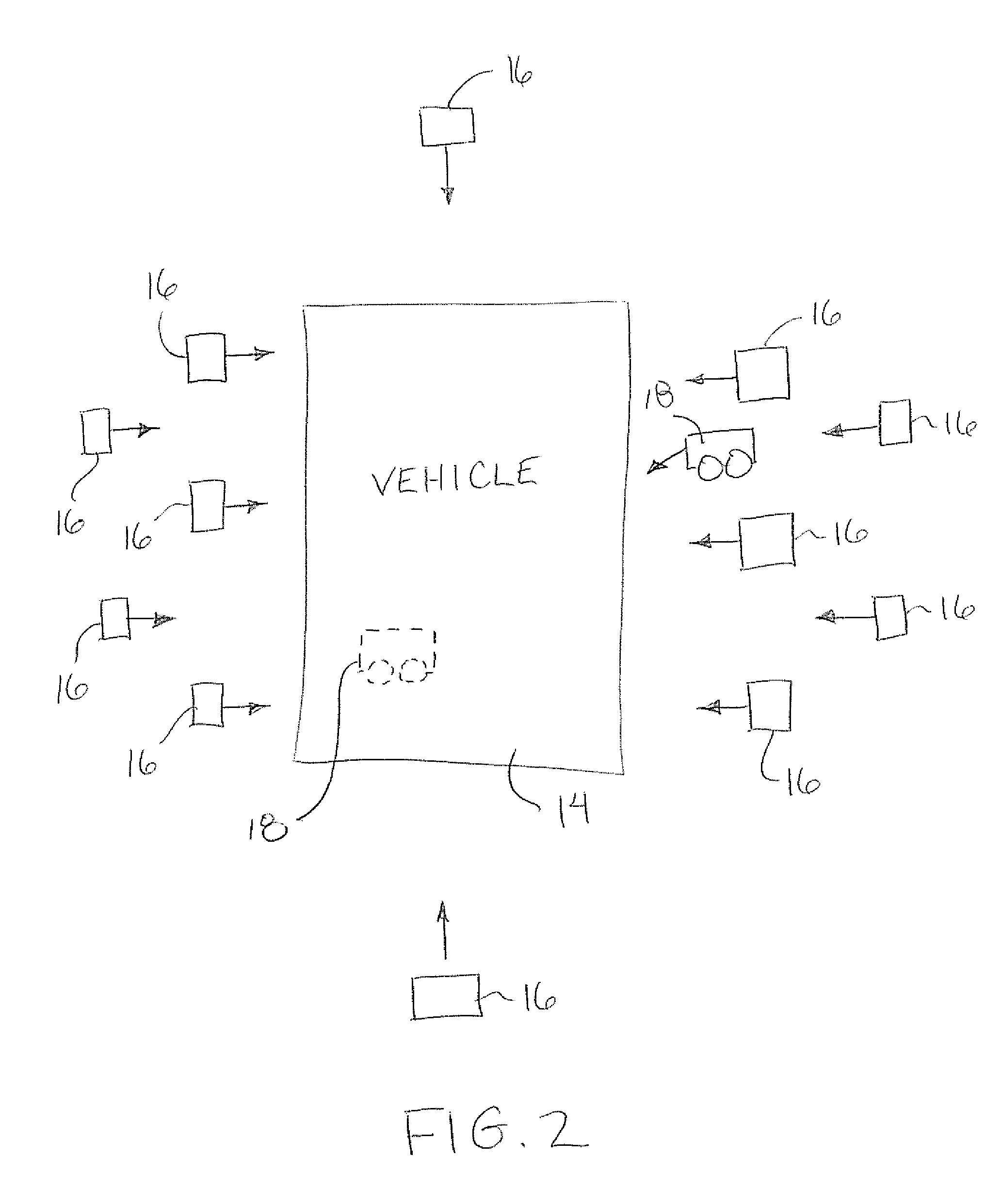

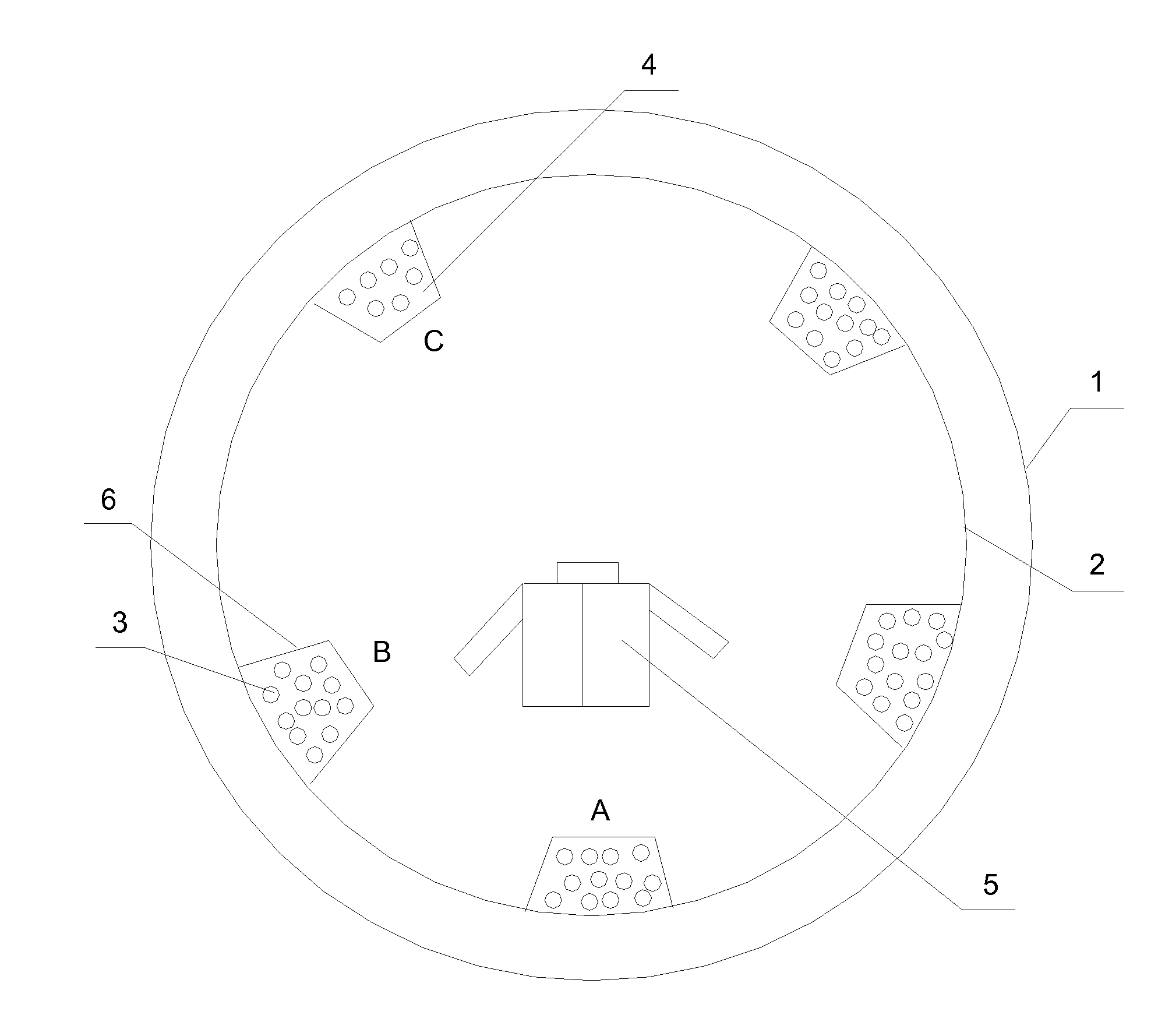

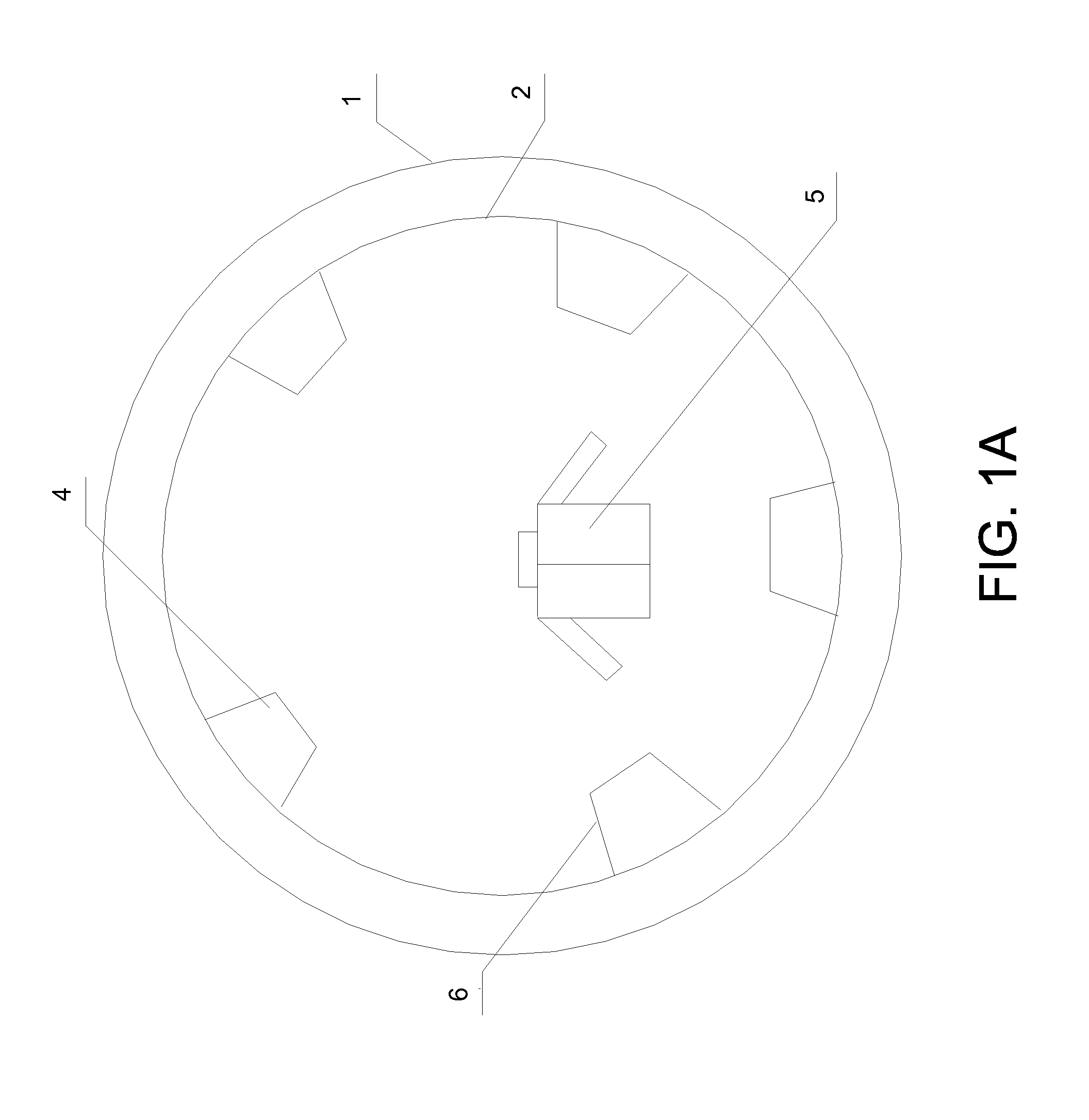

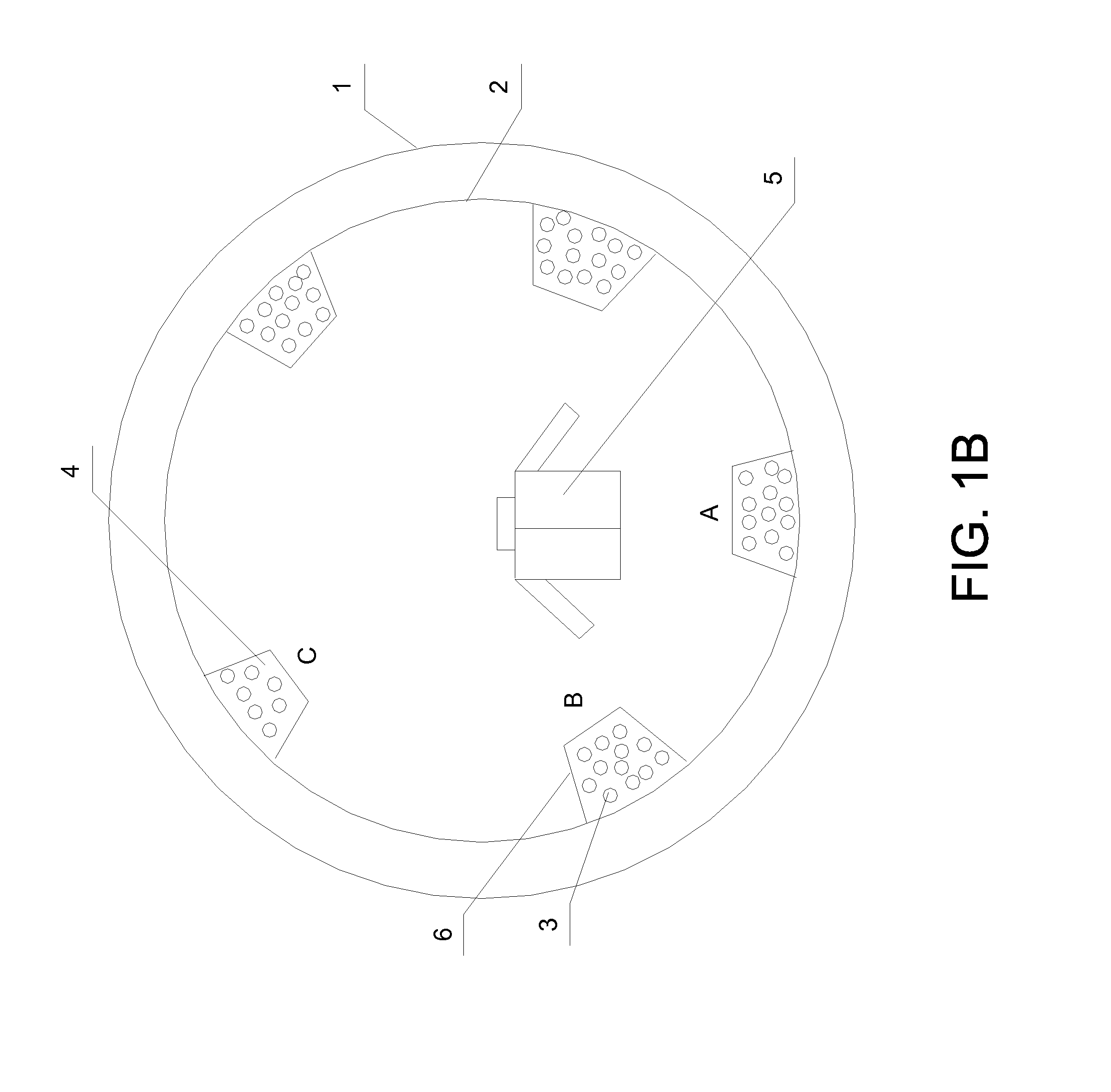

Automated Wash System for Industrial Vehicles

InactiveUS20100186778A1Shorten washing timeMinimizing wasted wash waterCleaning apparatus for vehicle exteriorsCleaning using liquidsComputer moduleControl area

An industrial vehicle wash system comprises a wash area receiving the vehicle and a separate control area receiving an operator. A plurality of wash modules are supported in the wash are to direct respective jets of wash fluid onto the vehicle. A controller varies orientation of the wash modules according to respective wash patterns. Cameras associated with the wash modules provide a visual display of the vehicle being washed to the operator in the control area. Using an operator input in the control area, the operator can interrupt the wash pattern of one wash module to provide additional washing to one area of the vehicle under manual operator control while the other wash modules continue to wash the vehicle according to the respective wash patterns thereof. The interrupted wash pattern can be resumed upon completion of the additional washing.

Owner:MARTIN GREGG

Washing machine drum baffle and washing machine therewith

InactiveUS20150027173A1Simple processShorten laundry washing cycleWashing receptaclesOther washing machinesInterior spaceSolid particle

The invention relates to a drum baffle and a washing machine having the same. The drum baffle includes a sheath and a bottom plate. The sheath and the bottom plate form a cavity having a hollow structure. The drum baffle is made by injection molding using one or more polymer adsorption materials, which may be used as a washing medium. The cavity of the drum baffle is internally filled with solid particles. The drum baffle includes a plurality of holes defined for communicating with the cavity of the drum baffle and an inner space of the inner drum of the washing machine to allow washing water to flow through. The drum baffle assists laundry to be rolled inside the inner drum, where the drum baffle and the solid particles inside adsorb and absorb soil in the laundry so as to achieve better washing results.

Owner:XEROS LTD

Washing method of dish-washing machine, and said machine

ActiveCN1903115AImprove cleanlinessReduce running timeTableware washing/rinsing machine detailsWater channelWater flow

A dish washer has a two-layer dish shelf, two water channels, a pulse device for pulse washing, a control microprocessor, and a water dividing plate controlled by control microprocessor to turn off one of two water channels. Its washing method features that said two water channels are alternatively turned off for increasing the spray force of water steam and in turn the clean level.

Owner:HAIER GRP CORP +1

Washing machine and washing control method thereof

InactiveCN102140749AShorten washing timeOther washing machinesControl devices for washing apparatusElectricityTime delays

The invention discloses a washing machine and a washing control method thereof. The water inlet of the washing machine is communicated with a spray nozzle provided with a plurality of water outlets by a spraying inlet tube; the spraying inlet tube is connected with a flow regulating valve and a spraying water inlet electronic control valve in series; a time delay controller is connected on the output end of a water outlet electronic control valve by the program controller of the washing machine; and the output end of the time delay controller is connected with the spraying water inlet electronic control valve. The dehydration control method of the washing machine comprises: in the steps of washing dehydration and rinsing dehydration, spraying clean water to the inner wall and the bottom of the dehydration bucket of the washing machine. Compared with the fully automatic washing machine in the prior art, the washing machine and the washing control method thereof can be used for solving the problems that the fully automatic washing machine wastes more water, electricity and time when clothes are washed.

Owner:蒋全林

Integrated machine of washing vegetables, washing bowl, and disinfecting

InactiveCN101427891ASave electricityShorten washing timeKitchen equipmentTableware washing/rinsing machinesWater flowKitchen utensils

An integrative machine with functions of vegetable washing, dish washing and disinfection solves the problems of repeated expenditure and large occupied area of the prior separated vegetable washing machine and dish washing machine. The integrative machine is characterized in that two buckles are arranged on the left side of the upper end of a moving basket bracket; two pins are respectively arranged on the front and the rear sides of the left end of the moving basket bracket; an exhaust fan is fixed on the upper part of a housing and is communicated with a sealed chamber; the air inlet of a one-way air discharge door is fixed on the air outlet of the exhaust fan; and the air outlet of the one-way air discharge door is connected with an exhaust pipe. The fruits and vegetables can be washed by swaying and rotating the basket for the first time and then by swaying and sprinkling the basket for the second time. Water droplets on the washed dishes can be blown off by the fan, and the dished can be dried by a FIR drying device. No dead corners are present for the UV rays and the ejected water flow due to the swaying of the dish washing basket.

Owner:宋大伟

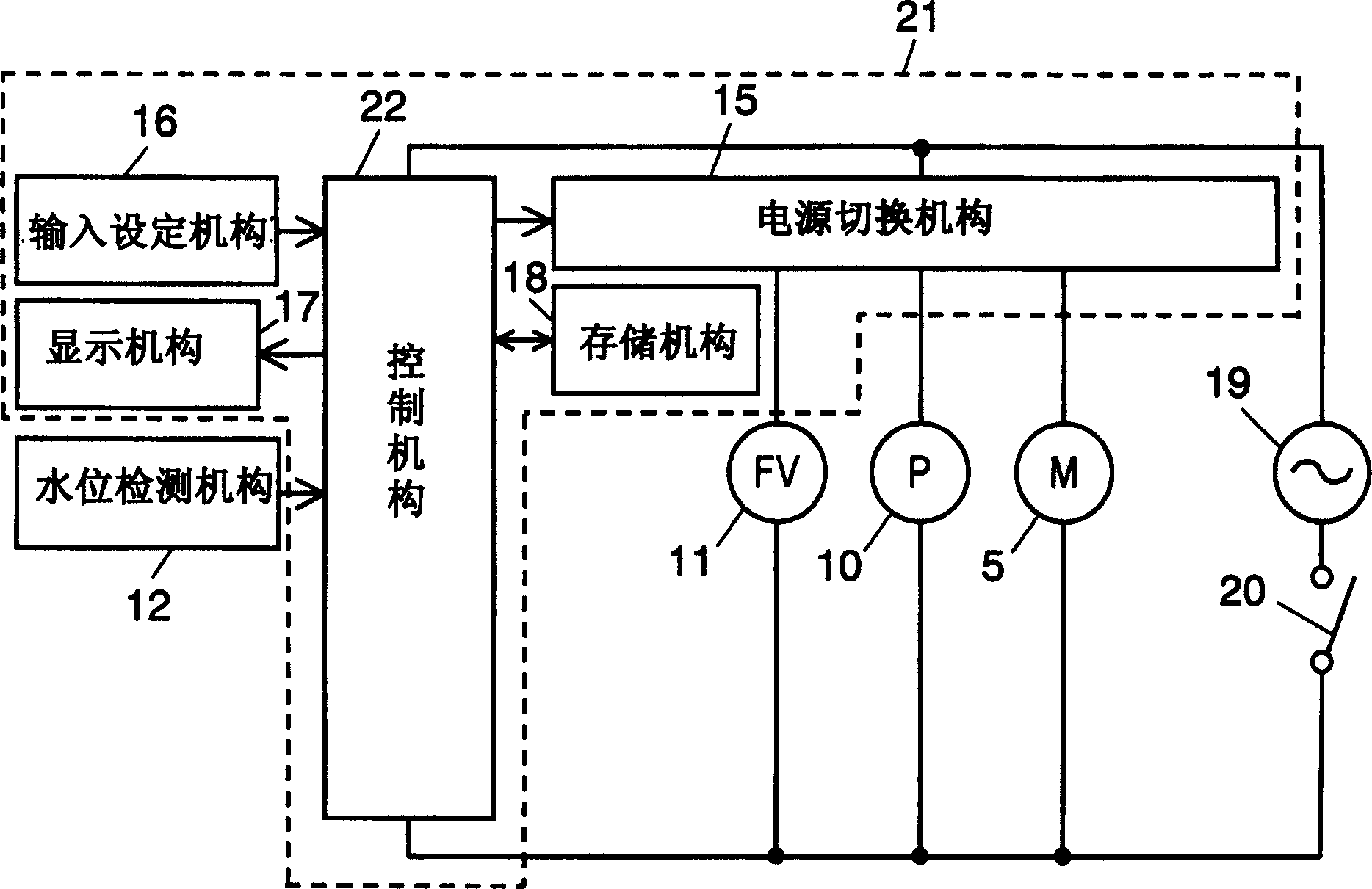

Heating apparatus of washing machine and control method thereof

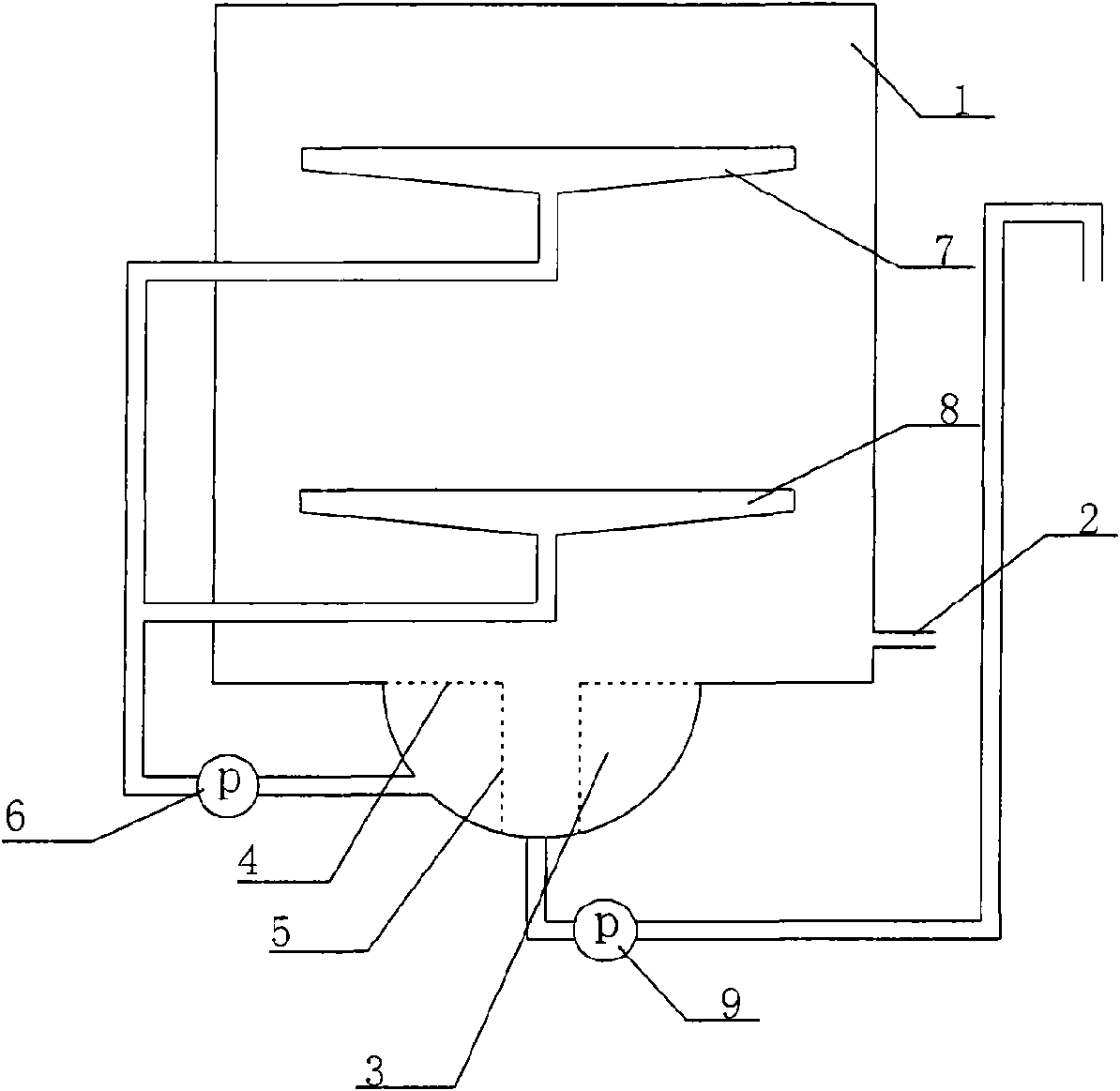

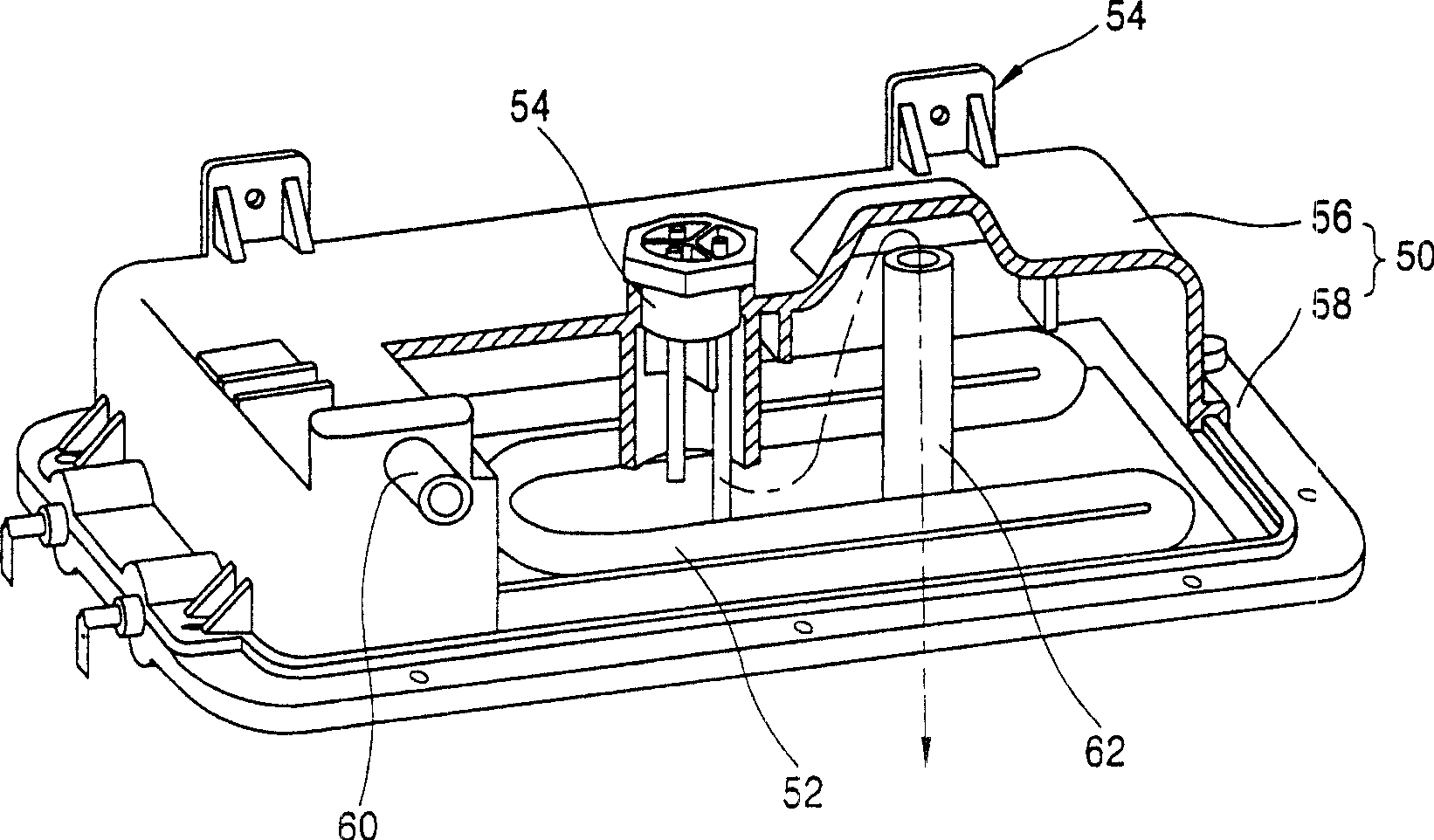

ActiveCN1580369ASmall sizeReduce washing water consumptionOther washing machinesControl devices for washing apparatusProcess engineeringWater supply

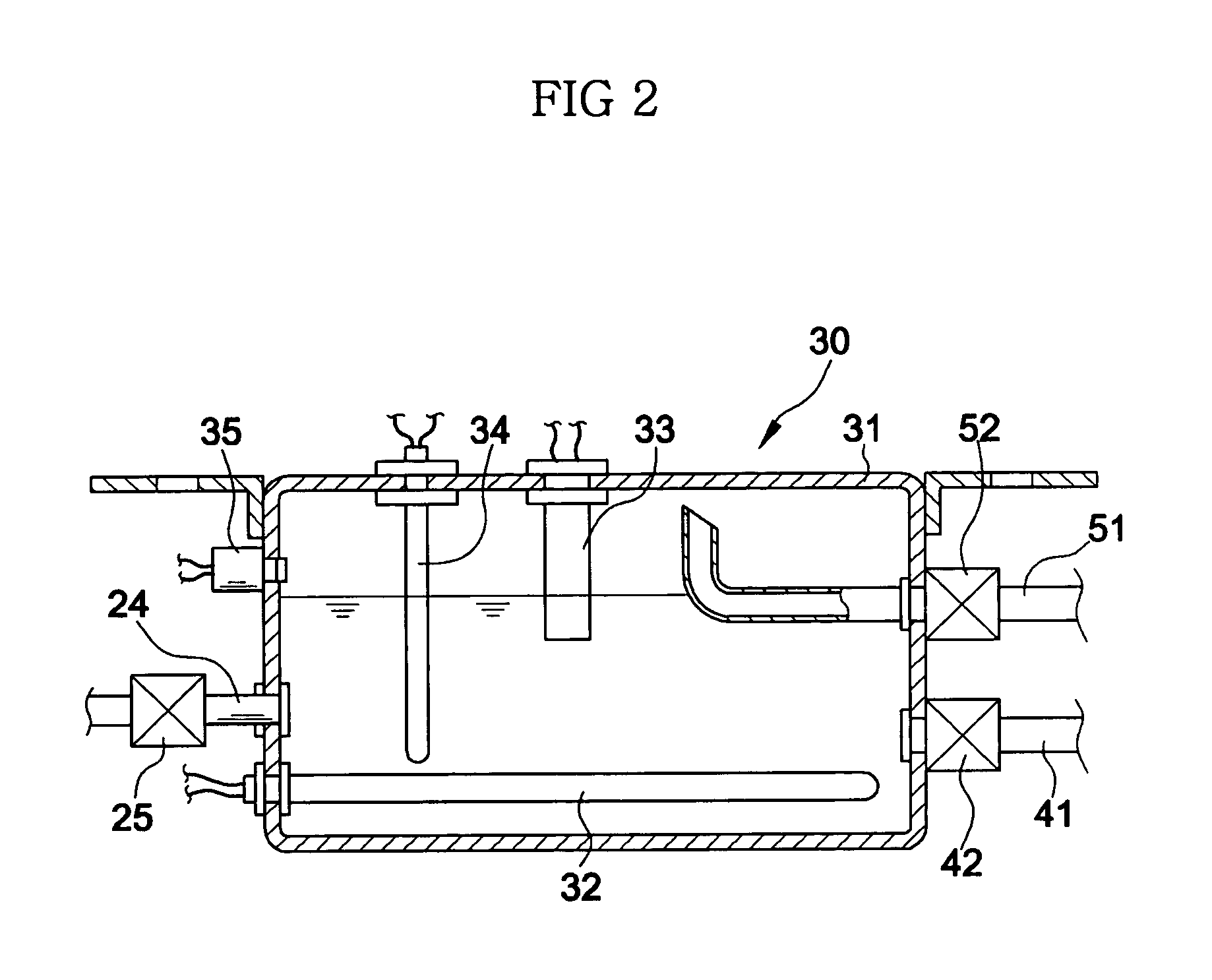

A heating apparatus of a washing machine comprises: a steam generator for generating steam; and a spray nozzle for spraying steam generated from the steam generator into a tub, in which a water level sensor for detecting a level of water supplied for steam generation step by step is mounted at the steam generator. According to this, an entire size of the washing machine is reduced, an amount of washing water is reduced, and a water level inside the steam generator is detected more accurately, thereby enhancing a performance of the heating apparatus.

Owner:LG ELECTRONICS INC

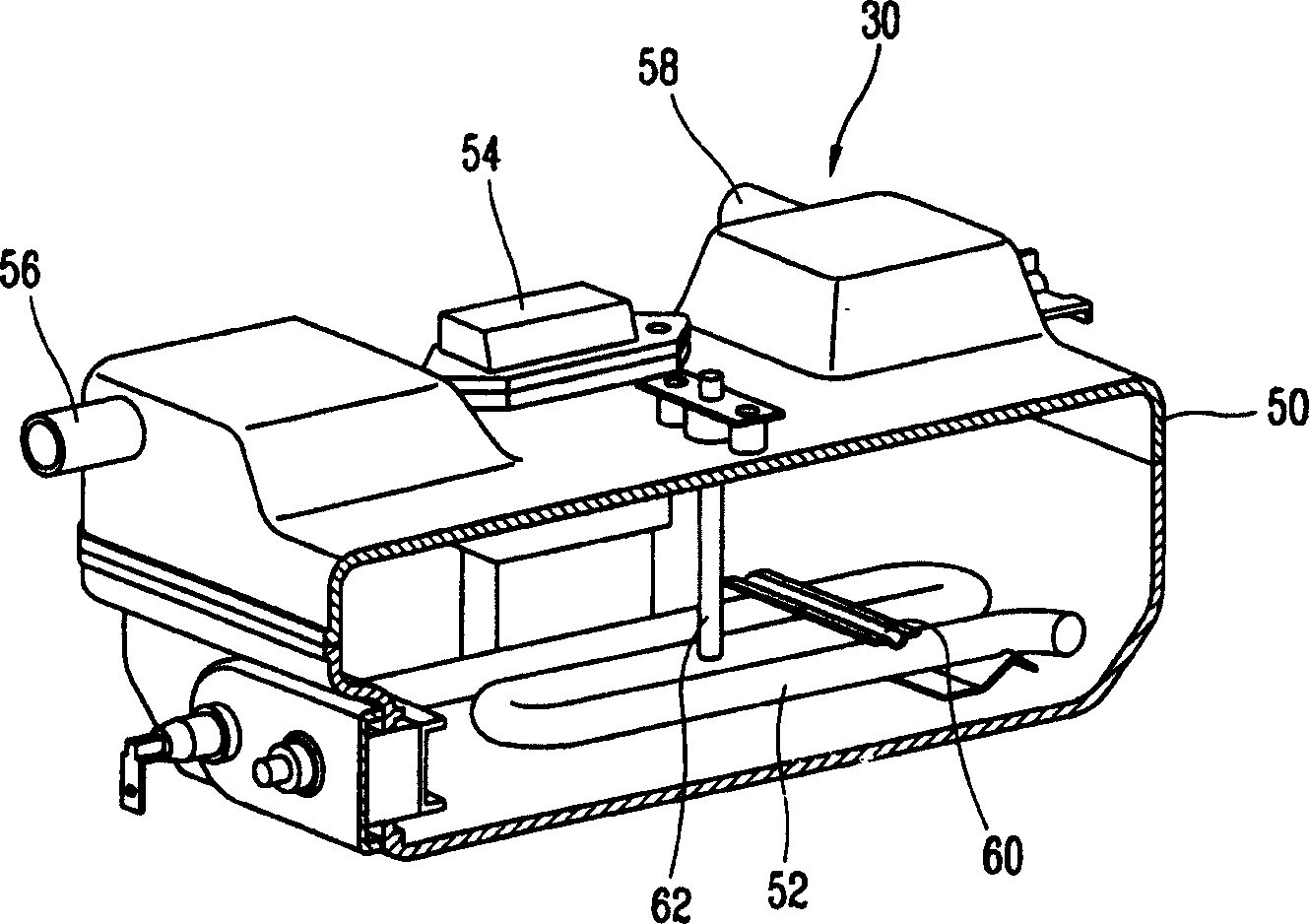

Steam generation apparatus for washing machine

ActiveCN1721616ASmall sizeReduce the amount of washing waterOther washing machinesTextiles and paperEngineeringWater level

A steam generation apparatus for a washing machine includes: a case having an accommodating space for storing water; a heater disposed inside the case to heat the water stored in the case; and a heater overheating prevention unit for cutting off power of the heater when the heater is overheated above the set temperature, so that a fire and deflection of a case can be prevented by preventing overheating of the heater by cutting off power being supplied to the heater when the heater is overheated due to malfunctions of a water level sensor or a clogged spray nozzle or a clogged flow passage.

Owner:LG ELECTRONICS INC

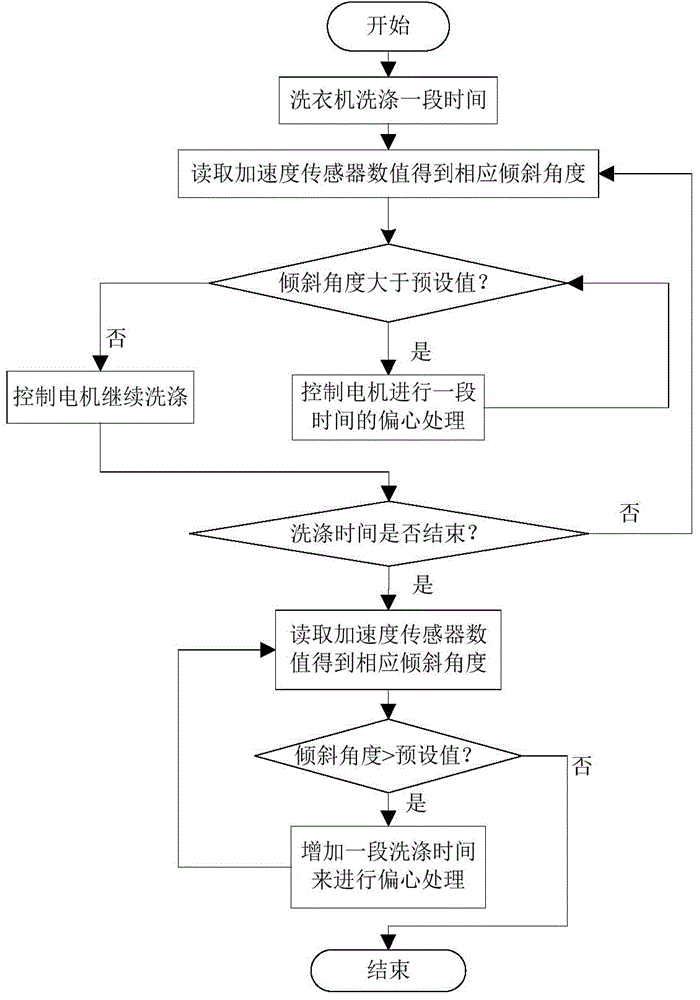

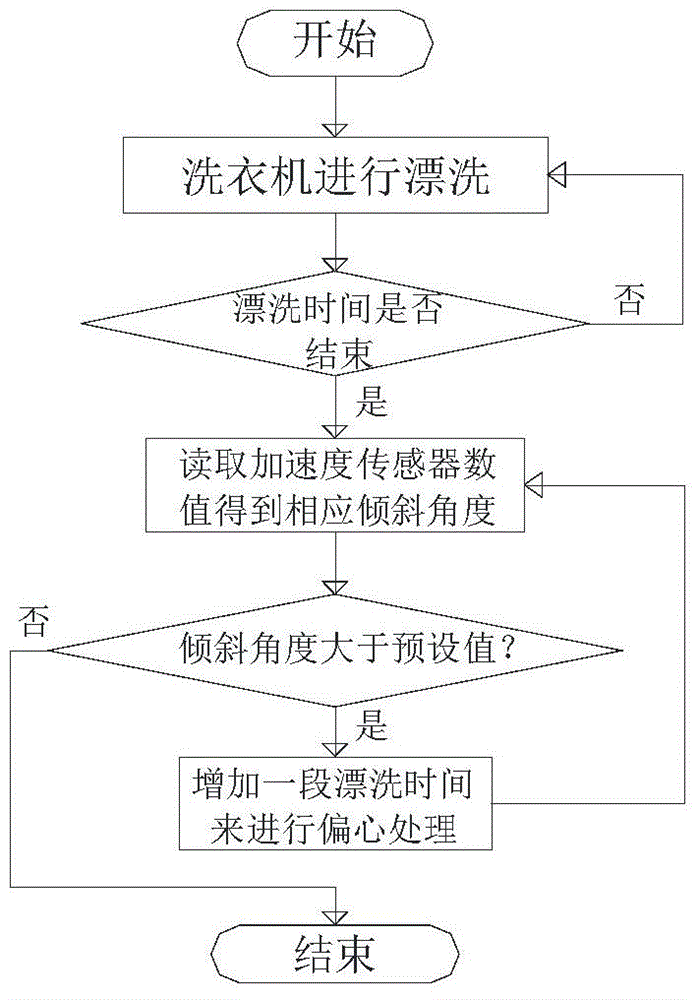

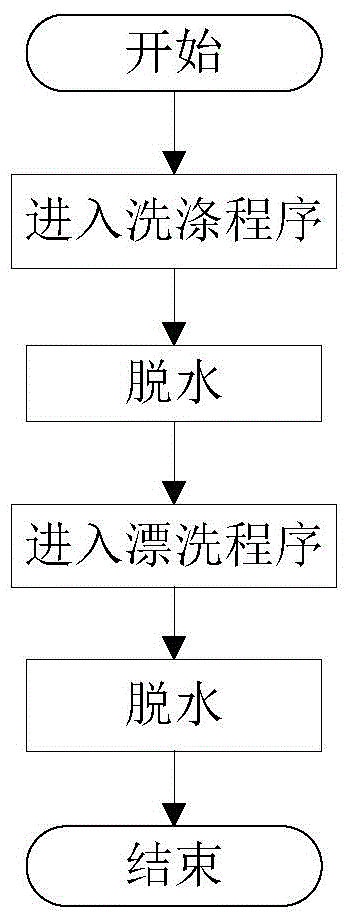

Eccentricity detection method for washing machine

ActiveCN105019191AShorten washing timeExtended service lifeOther washing machinesControl devices for washing apparatusProcess engineeringActive detection

The invention provides an eccentricity detection method for a washing machine. The method comprises the following steps: S1, entering a washing procedure; S2, reading the value of an acceleration sensor to obtain an inclination angle of a corresponding outer drum; S3, judging whether the inclination angle of the outer drum is greater than a preset value; S4, if the judgment result is yes, controlling a motor to perform a certain period of time of eccentric treatment, then returning to S3, and if the judgment result is no, entering next step; S5, judging whether the washing time is ended; and S6, if the judgment result is yes, detecting and correcting the inclination angle and then ending the washing procedure, and if the judgment result is no, returning to S2. The method provides an active detection mode, namely whether the washing machine is eccentric during washing and bleaching is detected by utilizing the acceleration sensor, and the corresponding eccentric treatment is performed if the washing machine is eccentric, so that a drum collision phenomenon caused by high eccentricity during dewatering in the washing machine is avoided, and the service life of the washing machine is prolonged.

Owner:CHONGQING HAIER WASHING MASCH CO LTD

Cylindrical washer

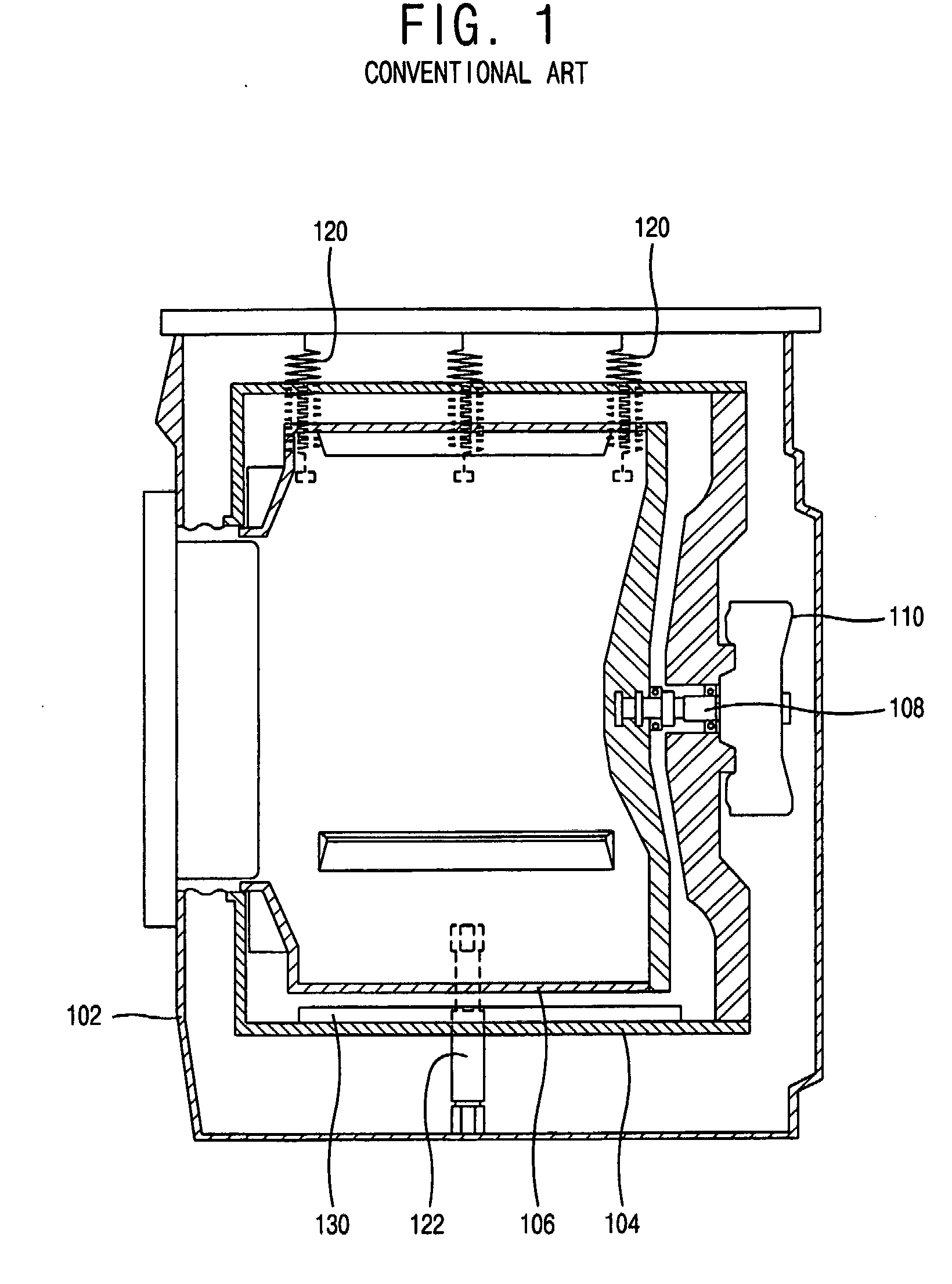

InactiveCN1478943AReduce unevennessImprove cleanlinessOther washing machinesControl devices for washing apparatusRotating drumElectric motor

A drum type washing machine includes rotating drum having a rotating axis in a substantially horizontal direction and sustained rotatably in a tub. The washing machine further includes a motor for driving the rotating drum, a water supplying means for supplying water into the tub, and a controlling means for washing, rinsing and liquid-extracting by controlling workings of the motor. The controlling means of the washing machine washes a laundry by pouring detergent bubbles in the washing process.

Owner:PANASONIC CORP

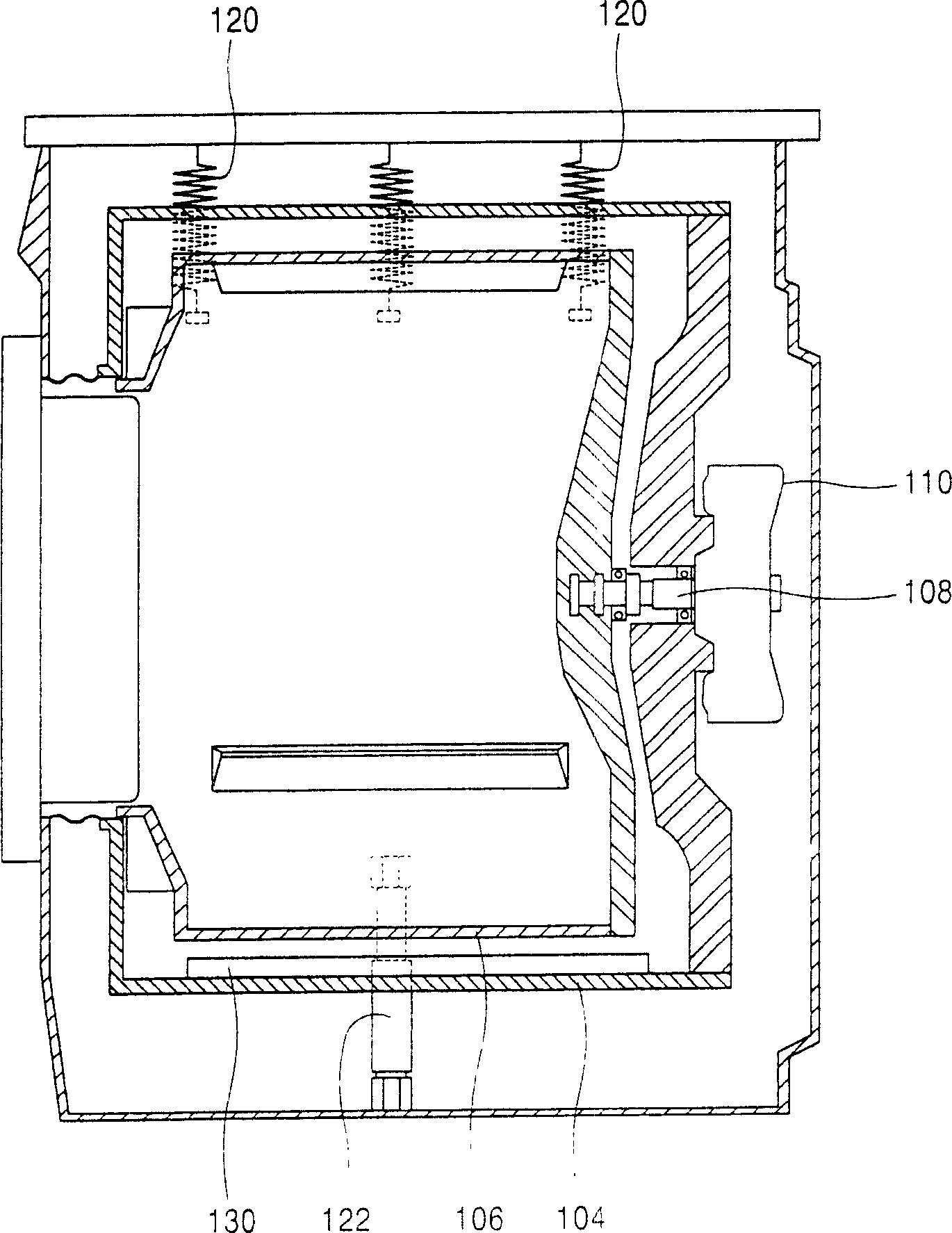

Laundry treatment apparatus

InactiveUS20090095032A1Reduce manufacturing costReduce componentsTextile treatment machine partsOther washing machinesProcess engineeringLaundry

A laundry treatment apparatus is provided to improve energy efficiency by generating steam by a steam generating means using ultrasonic waves and reduce production costs and improve working efficiency by reduction of the number of heat suppliers by heating the generated steam by a heat supplier provided at a dryer. The laundry treatment apparatus includes a cabinet; a washing tub disposed inside the cabinet to treat laundry put therein; and an ultrasonic steam generating means for generating steam to be supplied into the washing tub by using ultrasonic waves.

Owner:LG ELECTRONICS INC

Dishwasher and controlling method thereof

ActiveUS20150128999A1Shorten washing timeWeaken energyTableware washing/rinsing machine detailsAutomatic washing/rinsing machine detectionReciprocating motionEngineering

A dishwasher includes a tub that accommodates dishes; a nozzle assembly that sprays washing water; a vane assembly that is moved between a first position and a second position of an inside of the tub and changes a progression path of the washing water so that the sprayed washing water can be directed toward the dishes; and a controller that moves the vane assembly to the second position if the vane assembly is disposed at the first position. When a linear washing portion washes a small quantity of dishes by spraying washing water while making a reciprocal motion in part of an inside of a washing chamber, a washing time can be reduced, and concentrated washing can also be performed.

Owner:SAMSUNG ELECTRONICS CO LTD

Cell culture support and manufacture thereof

ActiveUS20080227203A1Shorten washing timeCell adhesion cell facilitatedBioreactor/fermenter combinationsBiological substance pretreatmentsRadiation exposureCell sheet

An object of the present invention is to provide a cell culture support making the detachment of a cell sheet easy as well as enabling the formation of a uniform cell sheet. The present invention relates to a method for manufacturing a cell culture support having a temperature responsive polymer immobilized onto the surface thereof via covalent bonding, the method including a coating step in which a composition including a monomer that can form the polymer by polymerization by radiation irradiation, an organic solvent and, in some cases, a prepolymer formed by polymerization of the monomer is coated onto the substrate having a surface containing a material which can be covalently bonded to the temperature responsive polymer by radiation irradiation to form a film on the surface of the substrate, a radiation irradiation step in which a polymerization reaction and a binding reaction between the substrate surface and the temperature responsive polymer are allowed to proceed by irradiating radiation to the film, and a drying step to dry the film.

Owner:CELLSEED +2

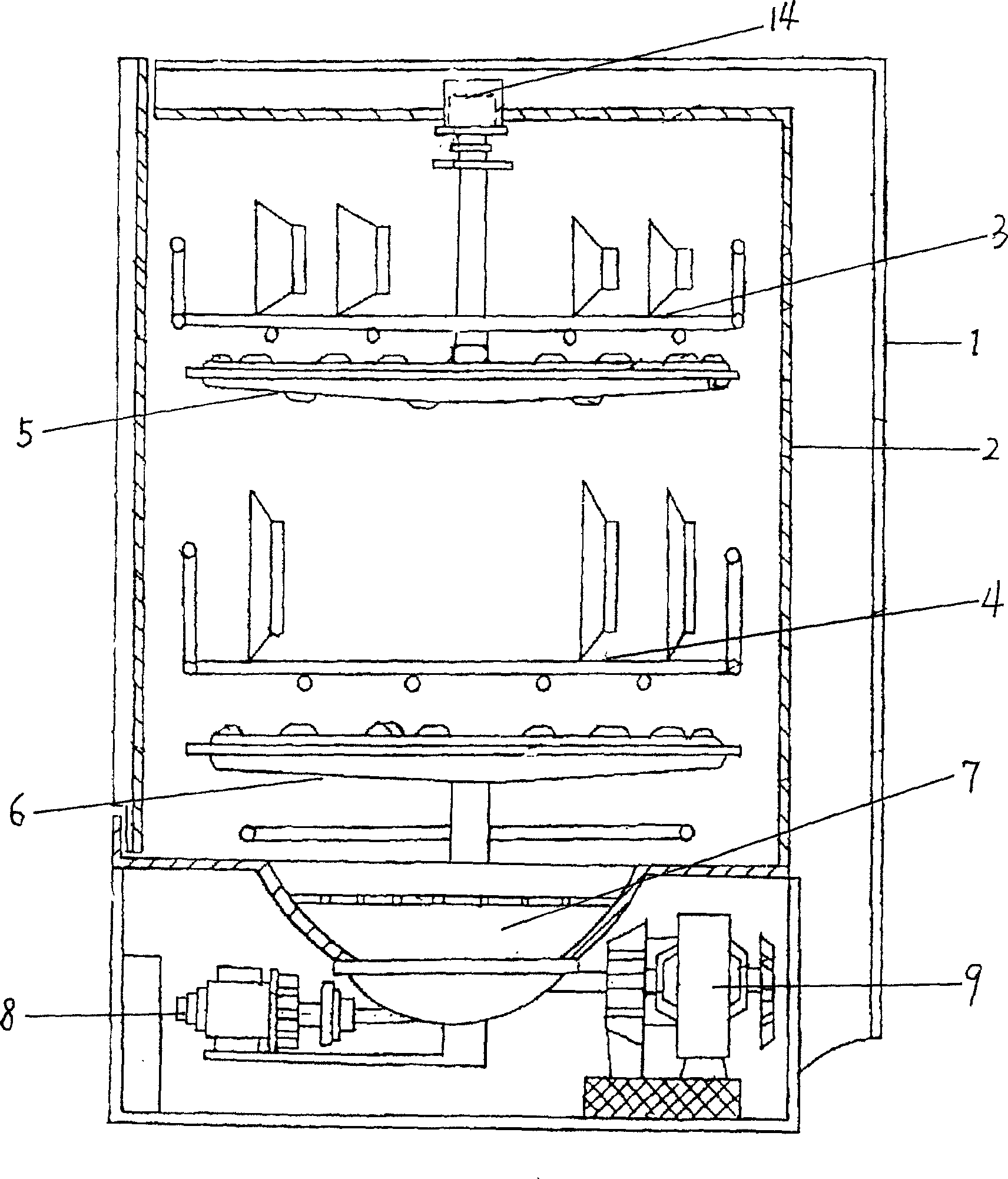

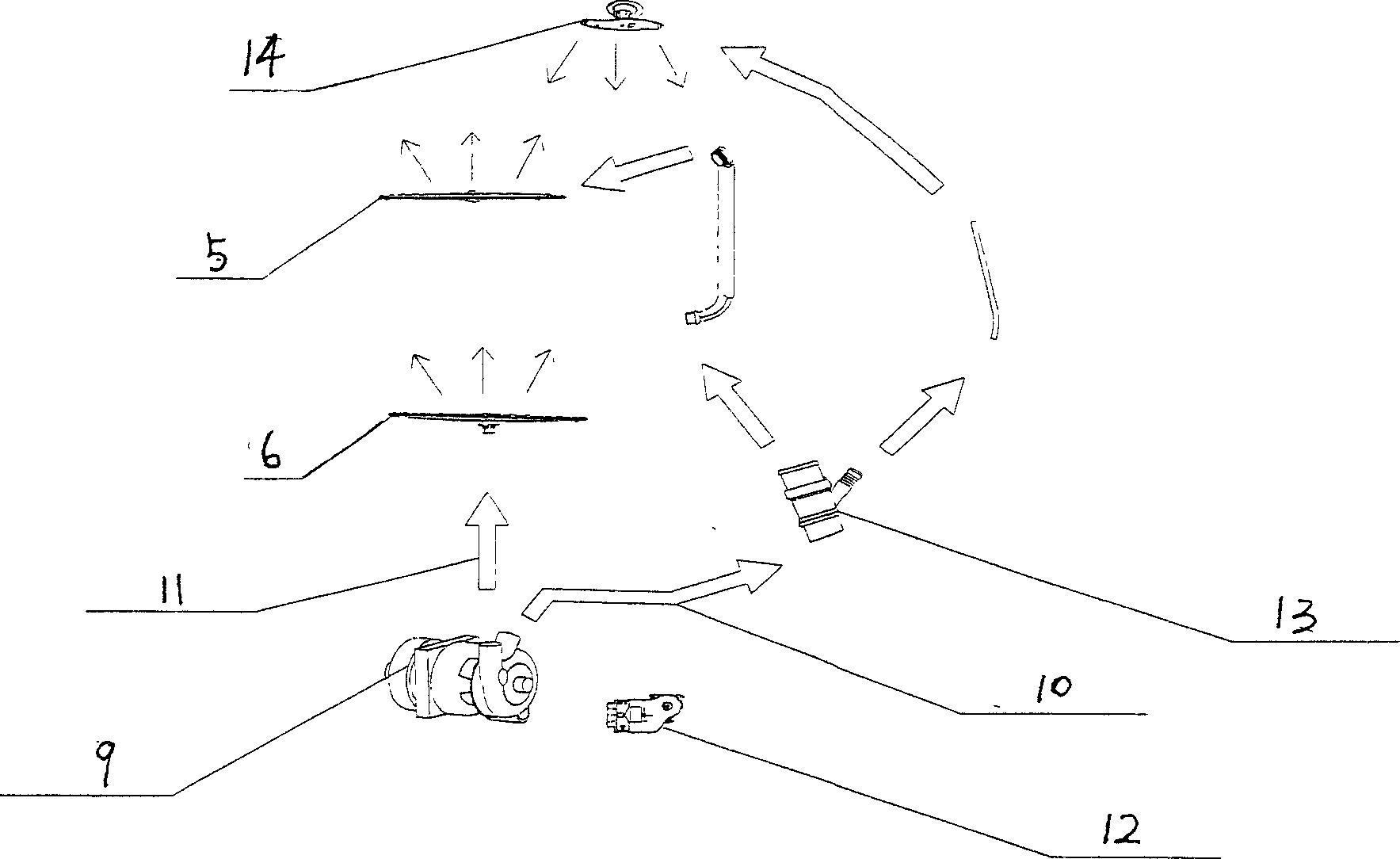

Washing mode of washing machine and fully automatic washing machine

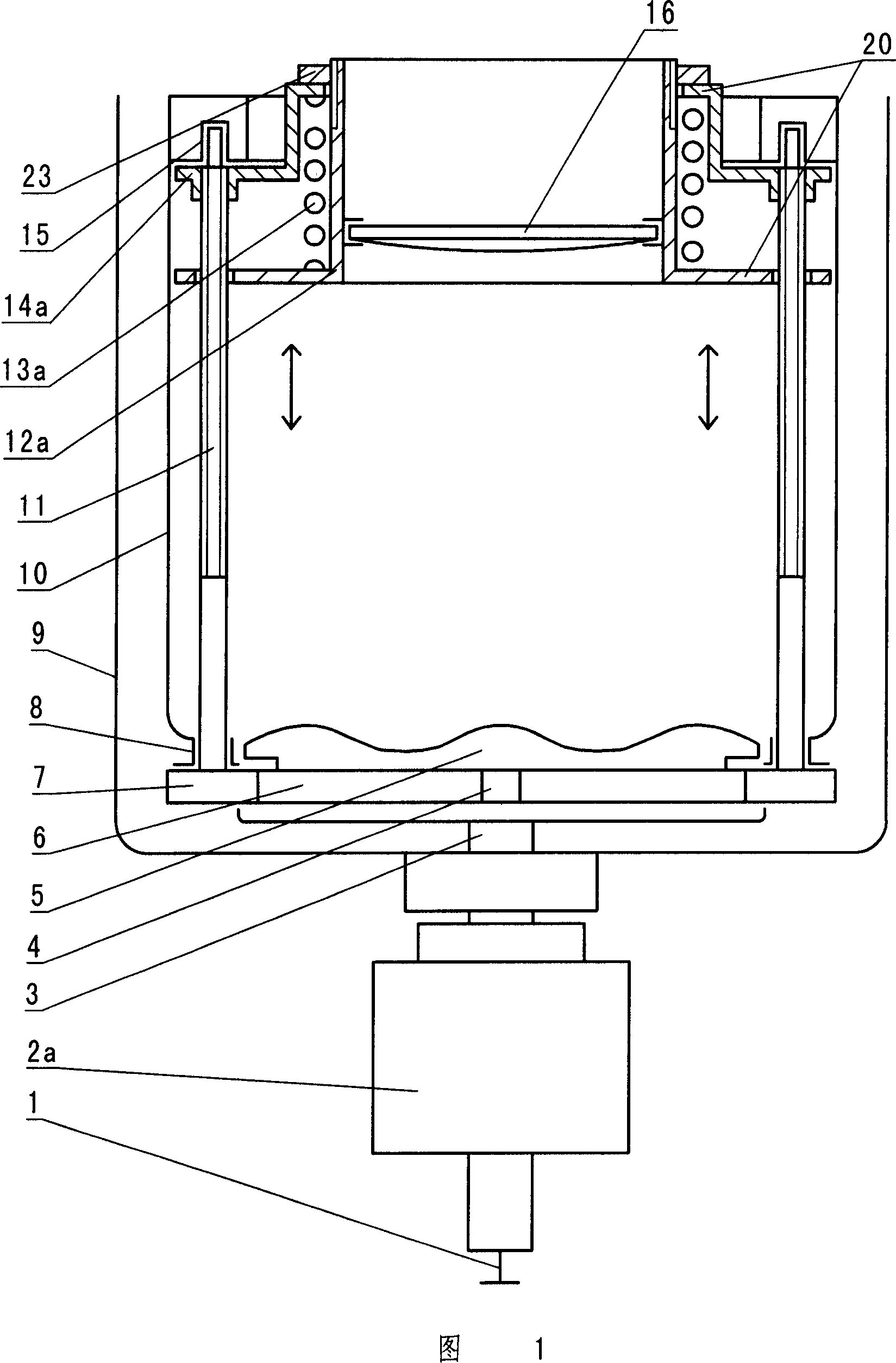

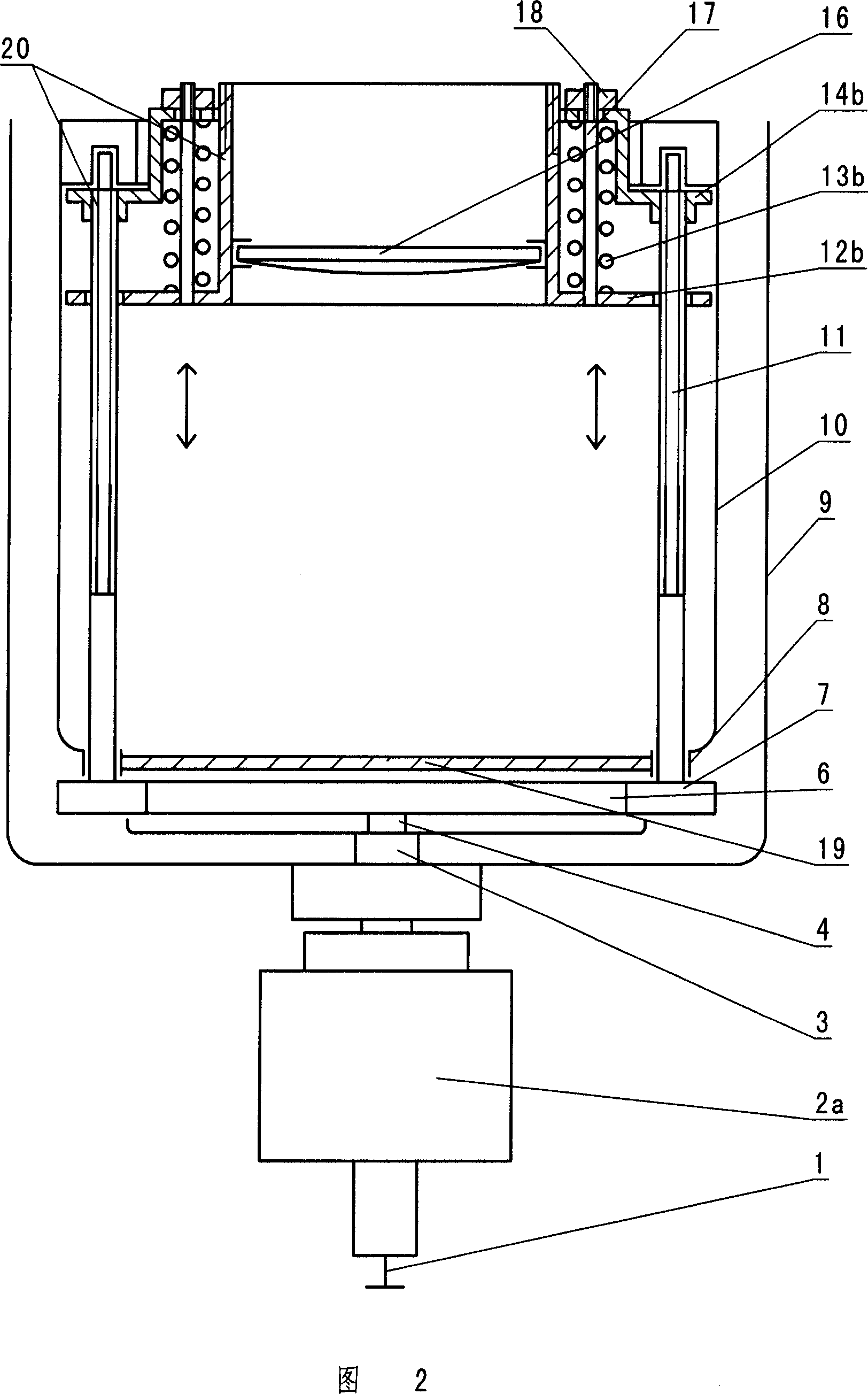

InactiveCN1986942ASignificant comprehensive benefitsImprove washing qualityWashing machine with receptaclesTextiles and paperReduction driveReciprocating motion

A washing mode of washer is characterized by that an axially reciprocating pressure disc is arranged in a washing drum for generating both bidirectionally rotary water stream and axially reciprocating pressure water stream to flush, beat and press the object to be washed. A full-automatic washer with said washing mode is composed of an external drum, an internal drum, a speed reducer or speed-reducing clutch with output axle and axle sleeve, a waving wheel or bottom plate, and an axially reciprocating pressure disc unit in said internal drum.

Owner:ANHUI JULONG TRANSMISSION TECH

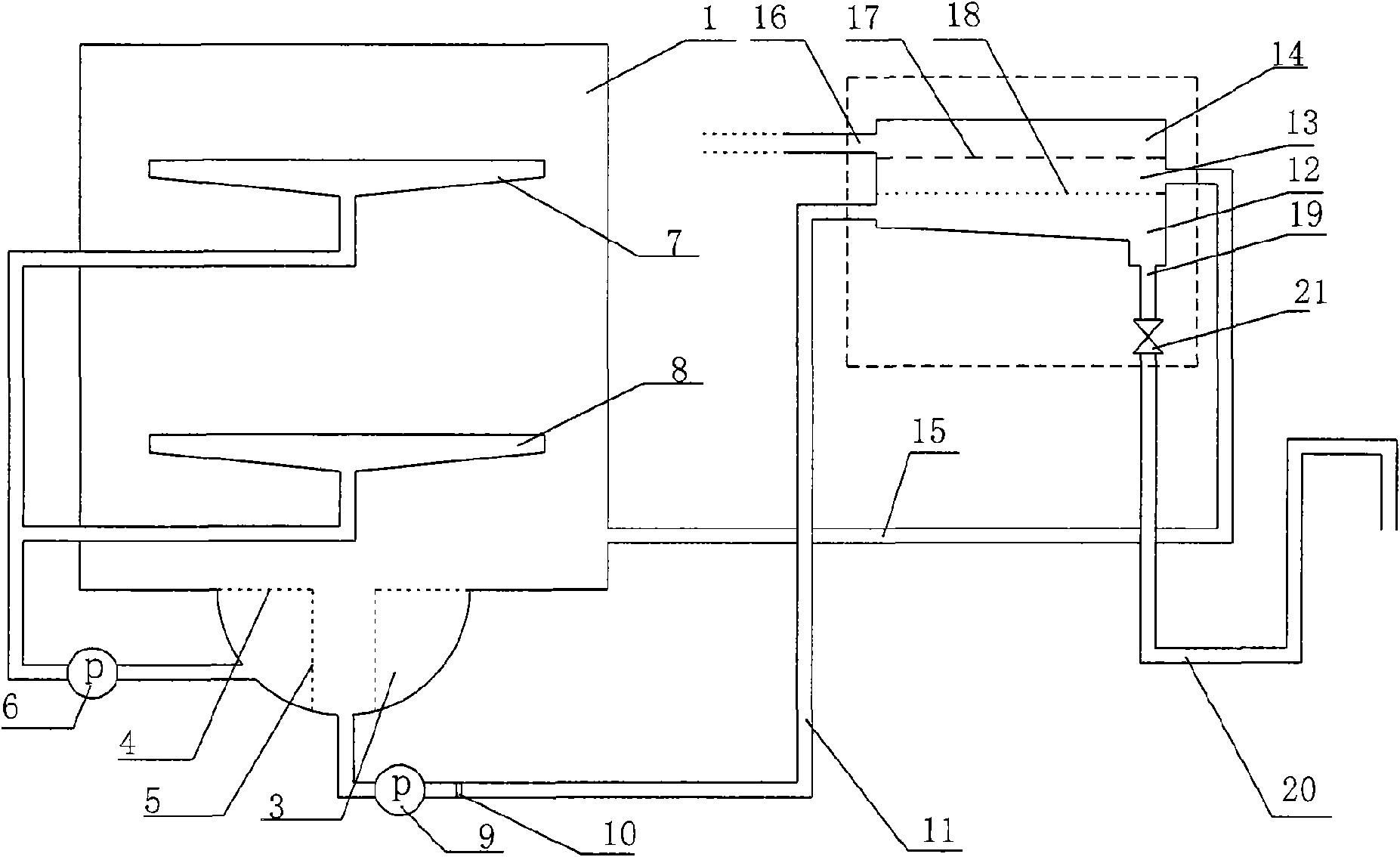

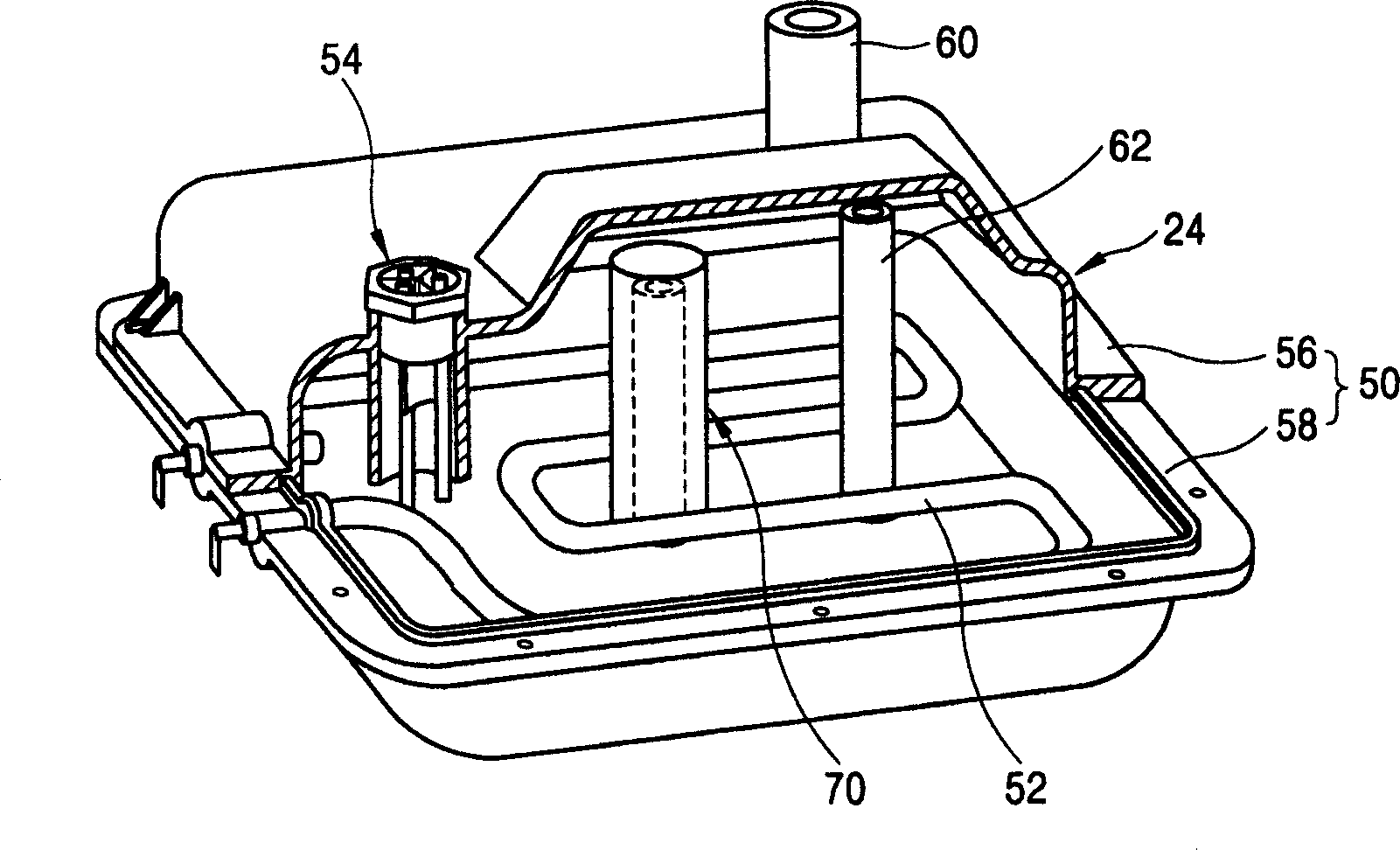

Steam generator for washing machine

InactiveCN1580371AReduce volumeReduce washing water consumptionSteam generation heating methodsOther washing machinesProcess engineeringWater supply

A steam generator for a washing machine comprises: a hermetic container provided with a water supply port for supplying water and a steam exhaustion port for exhausting steam; a heater arranged in the hermetic container for heating water supplied into the hermetic container; and a drain unit for draining residual water inside of the hermetic container outwardly. According to this, residual water inside of the steam generator is outwardly exhausted thus to maintain cleanness of the steam generator. Also, the drain unit using a siphon principle is installed thus to naturally exhaust residual water inside of the steam generator without an additional valve device, thereby reducing a fabrication cost.

Owner:LG ELECTRONICS INC

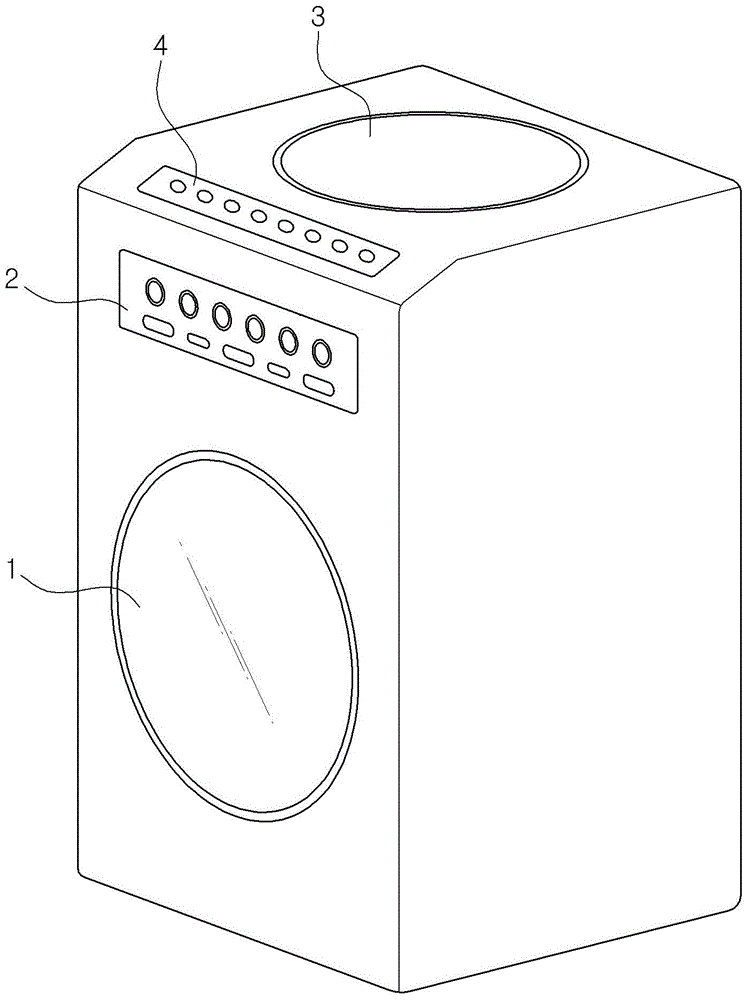

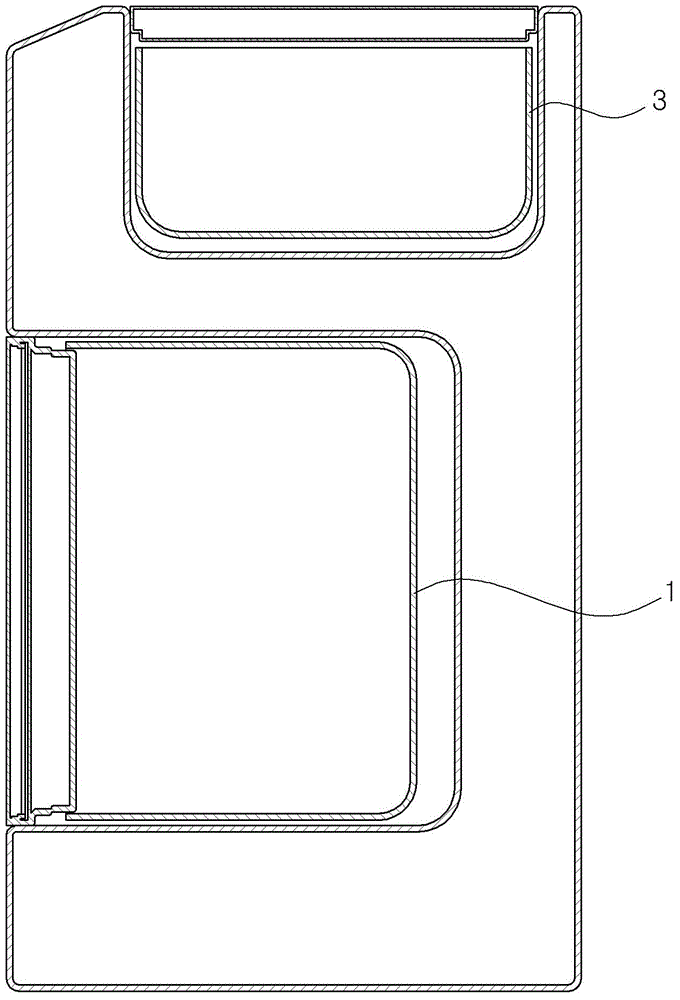

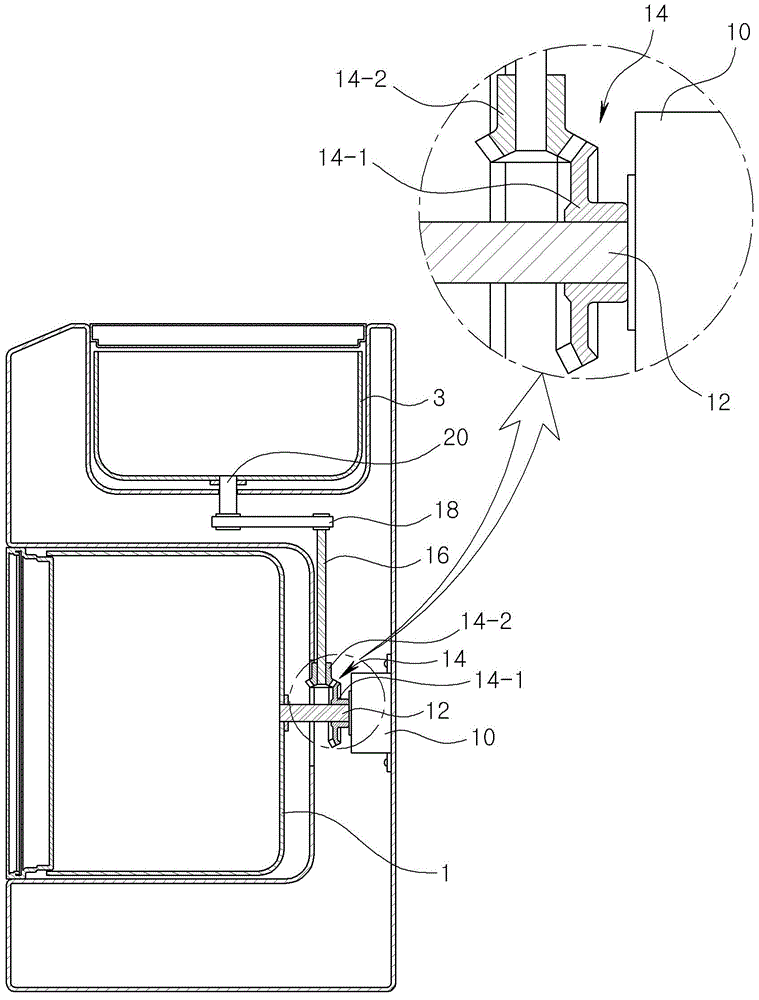

Washing machine with double drums

InactiveCN104652080AMaximize wash productivityShorten washing timeOther washing machinesWashing machine with receptaclesEngineeringMechanical engineering

A dual washing machine includes a general type tub and a drum type tub in a main body and / or case. The drum type tubis at or in a lower portion of the main body and / or case, and the general type is at or in an upper portion of the main body and / or case.

Owner:DONGBU DAEWOO ELECTRONCIS CORP

Process for preparing crystal seed used for rutile type titanium dioxide production

InactiveCN1594103AShorten washing timeImprove the effect of impurity removalTitanium dioxideChemistryDecomposition

The invention discloses a process for preparing crystal seed used for rutile type titanium dioxide production which comprises the steps of alkali boiling reaction, dilution and hydrolytic decomposition, scouring edulcoration, neutralization with acids, acid solution, and cooling down, wherein the alkali-titanium ratio in the alkali boiling reaction is 1.7:1-1.9:1, and the scouring edulcoration is conducted with a press filtration mode.

Owner:湖南永利化工股份有限公司

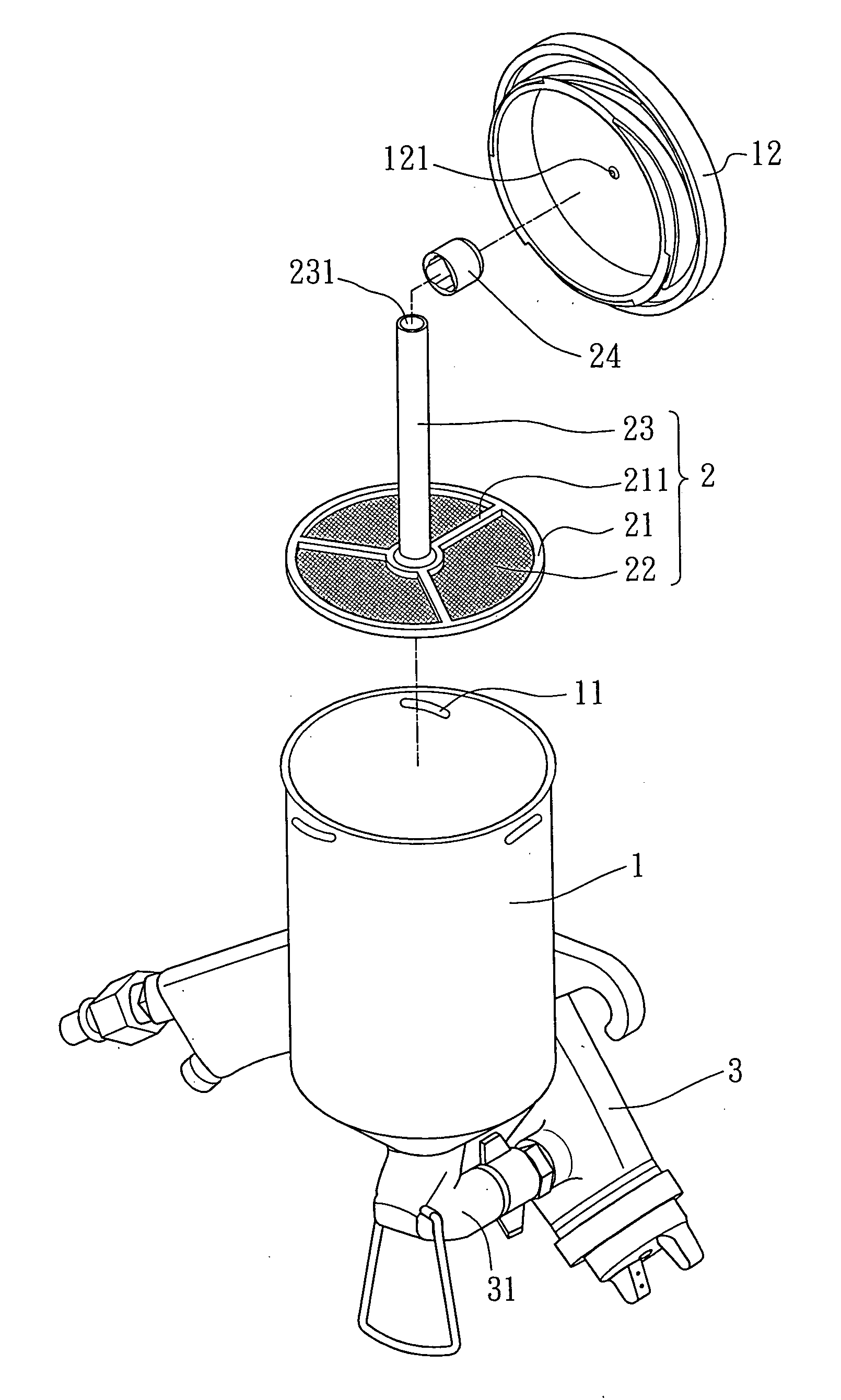

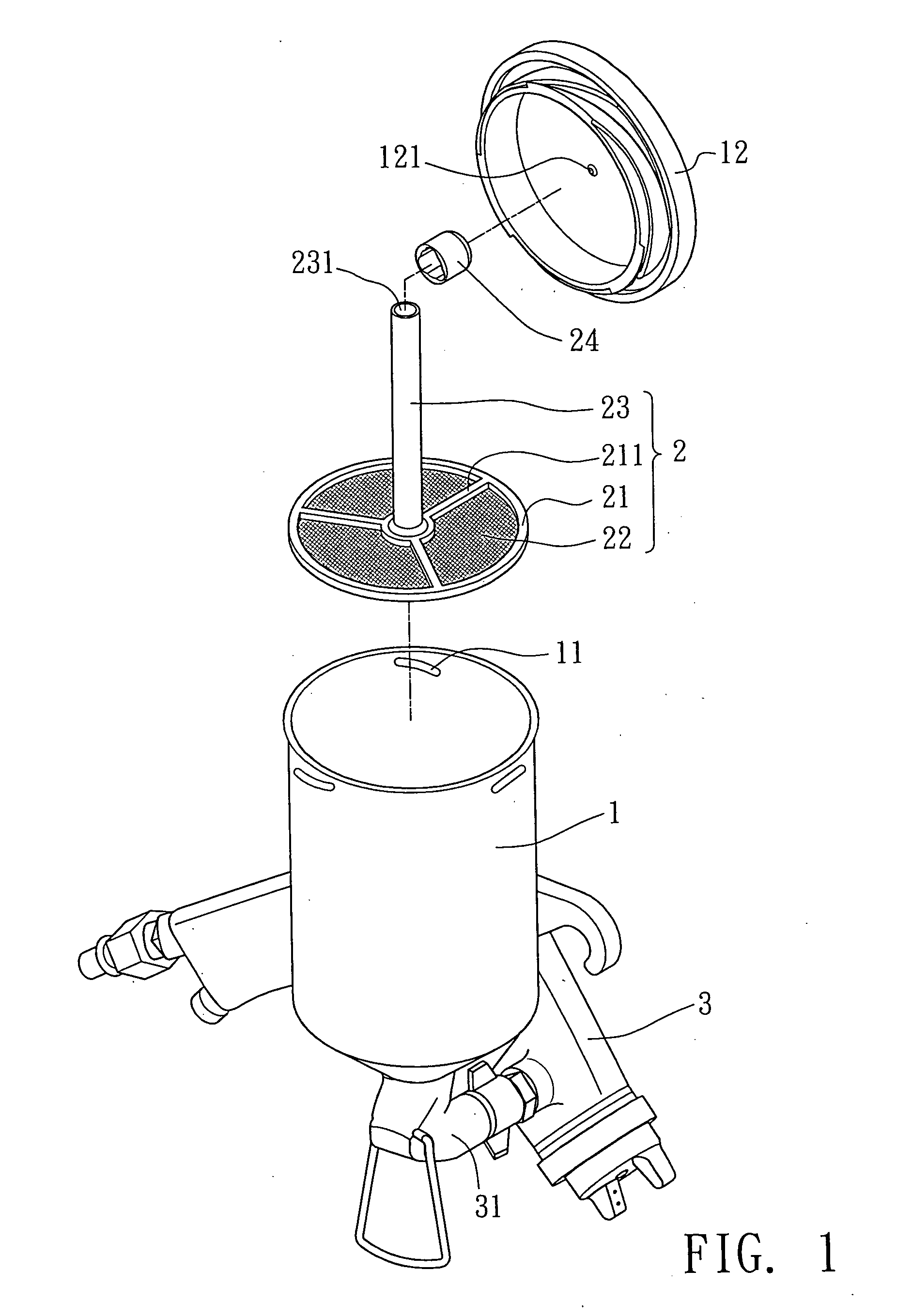

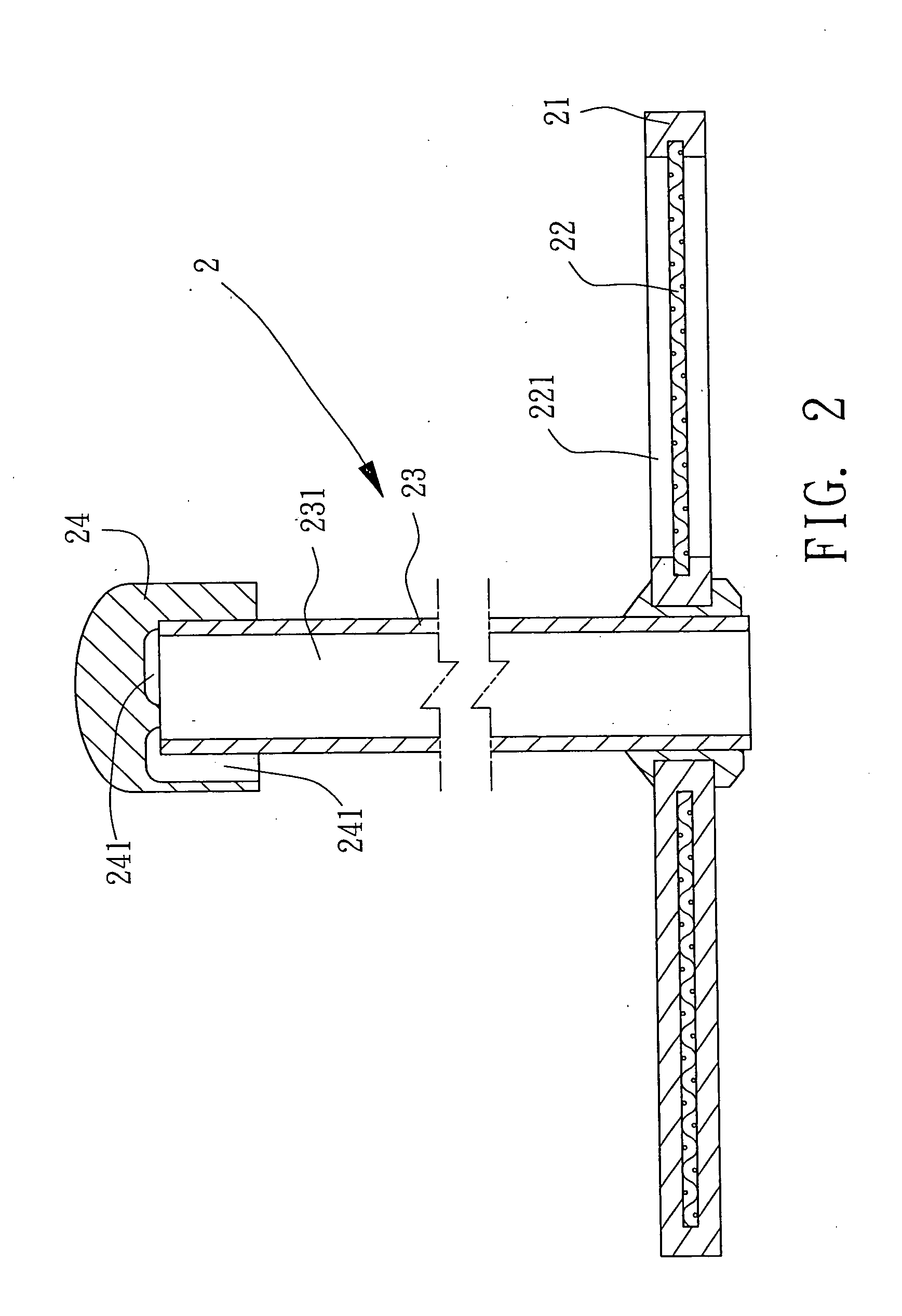

Filter device used in a paint cup of a spraying gun

InactiveUS20060049099A1Large filter areaSimple structureLoose filtering material filtersCartridge filtersVentilation tubeLacquer

Owner:CHANG JEN CHIH

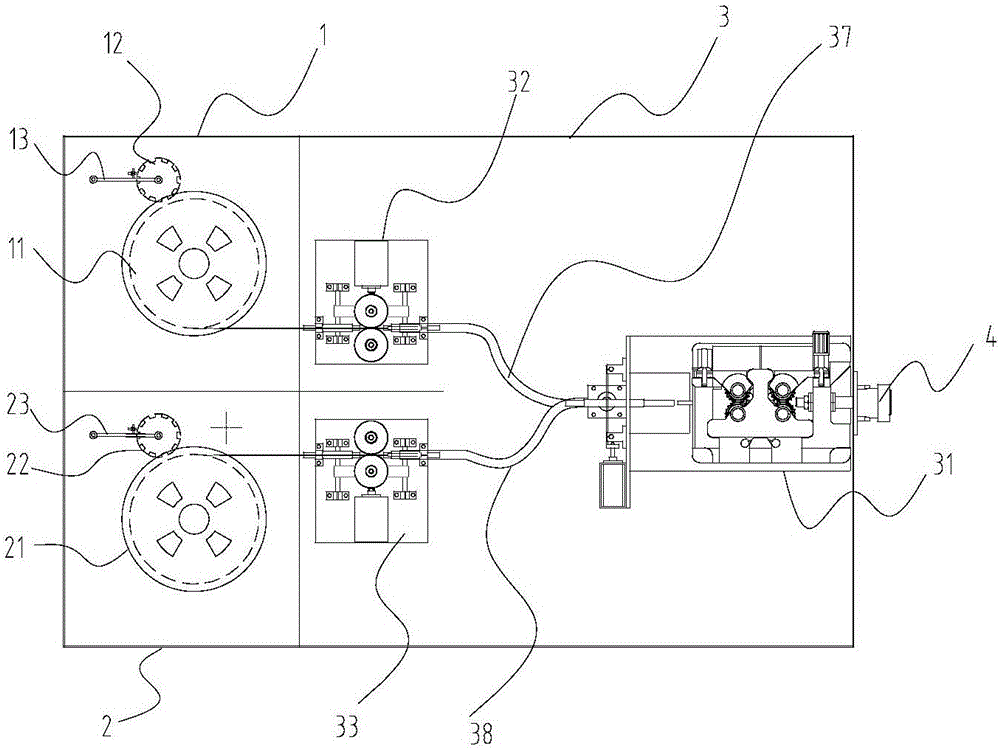

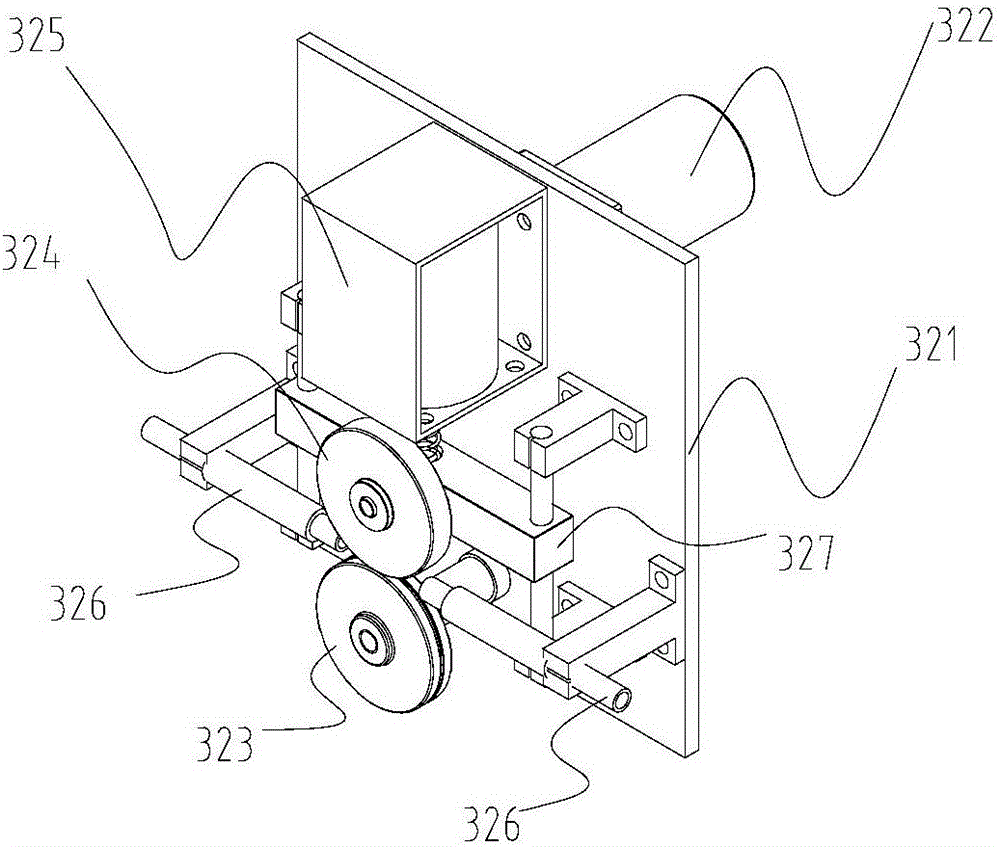

Two-cabin automatic wire supplementing system and method

ActiveCN106735751AUninterrupted automatic wire changeIncrease productivityArc welding apparatusMechanical engineeringAdditive layer manufacturing

The invention provides a two-cabin automatic wire supplementing system and method. The two-cabin automatic wire supplementing system is used for electric arc, laser and plasma arc fuse additive manufacturing and comprises a wire feeding cabin and a wire disc cabin which can provide metal wires for the wire feeding cabin. The wire disc cabin comprises a first wire disc cabin body and a second wire disc cabin body which are arranged in parallel. The first wire disc cabin body and the second wire disc cabin body are connected to the wire feeding cabin. A replaceable first wire disc is installed in the first wire disc cabin body. A metal wire is coiled on the first wire disc. A replaceable second wire disc is installed in the second wire disc cabin body. A metal wire is coiled on the second wire disc. The wire feeding cabin is internally provided with a wire feeding machine externally connected with a welding gun connector. A wire feeding selecting device is arranged between the wire feeding machine and the wire disc cabin and selects to feed wire for the wire feeding machine in the first wire disc and the second wire disc so that automatic wire replacing between the first wire disc cabin body and the second wire disc cabin body can be achieved. The method uses the system. According to the two-cabin automatic wire supplementing system and method, materials can be uninterruptedly supplied under the condition that the working atmosphere of a sealed cabin is not damaged.

Owner:青岛卓思三维智造技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com