Eccentricity detection method for washing machine

An eccentric detection and washing machine technology, applied in the field of washing machines, can solve the problems of washing machine box displacement, low accuracy, washing machine outer tub hitting the box, etc., to achieve the effect of shortening the washing time, improving the service life and shortening the washing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] A kind of washing machine eccentric detection method of the present invention is described in detail below in conjunction with accompanying drawing:

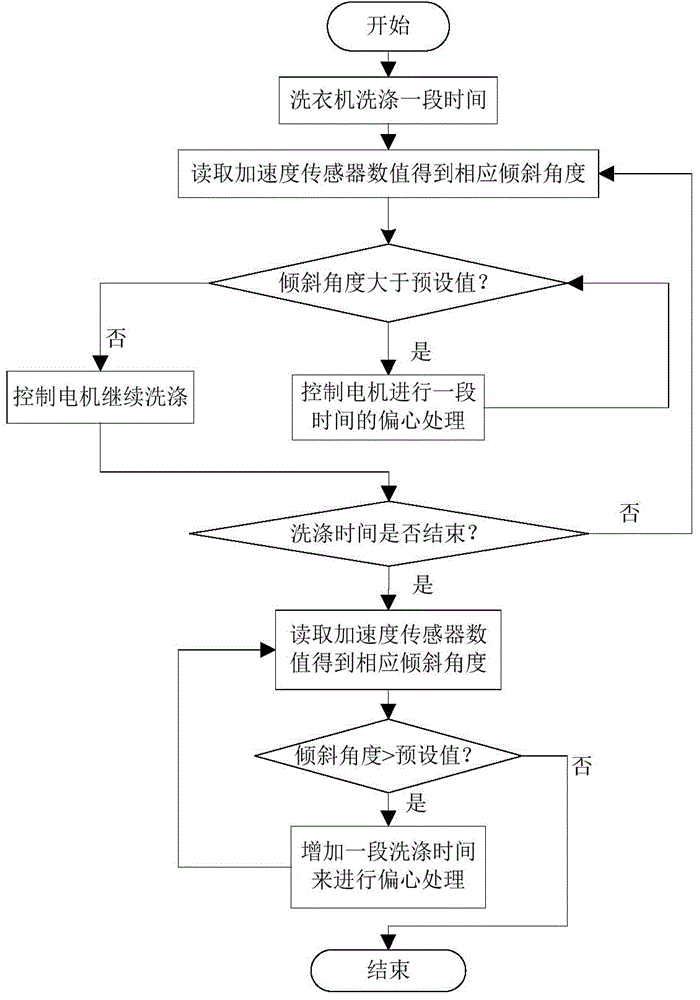

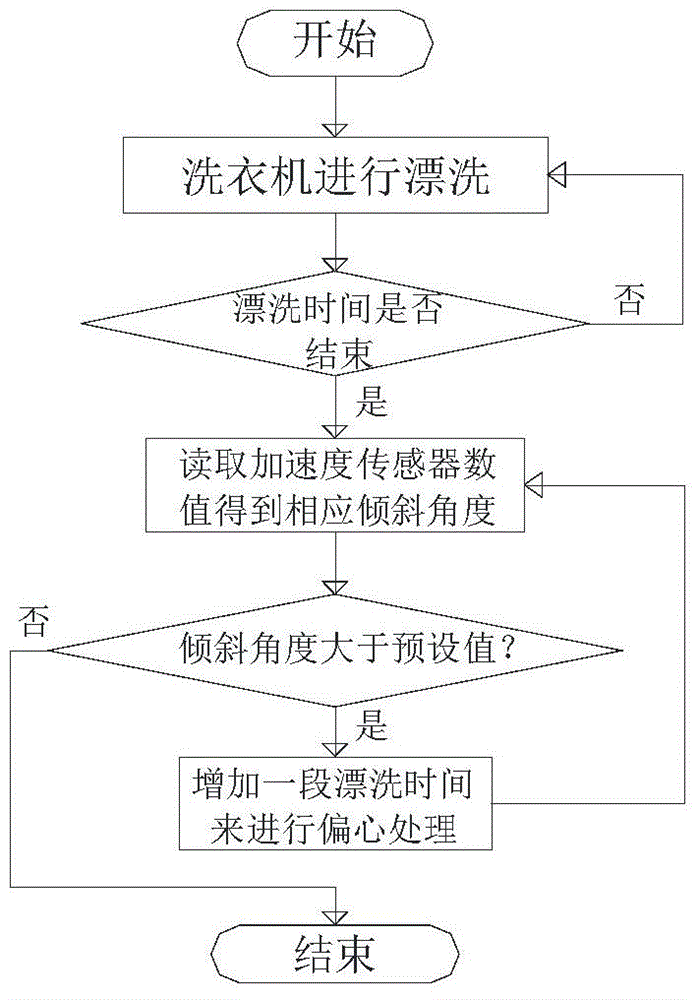

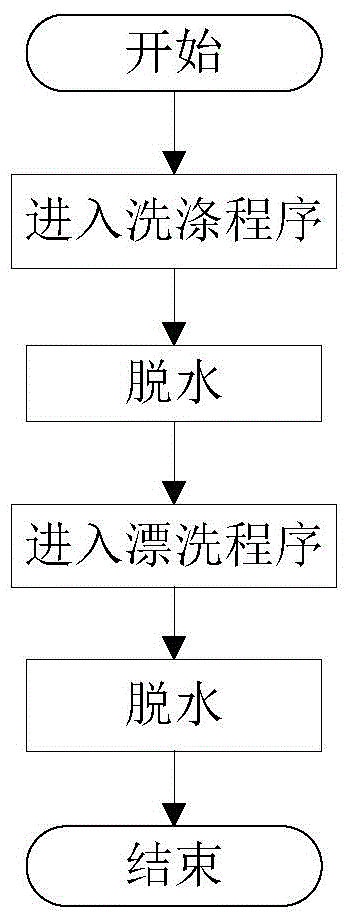

[0048] A washing machine eccentric detection method of the present invention is mainly applicable to the washing program and the rinsing program of the washing machine, such as figure 1 Shown, is the washing program control flowchart of the present invention, comprises the following steps:

[0049] Step S1, enter the washing procedure;

[0050] Step S2, read the value of the acceleration sensor to obtain the corresponding tilt angle of the outer barrel;

[0051] Step S3, judging whether the inclination angle of the outer barrel is greater than a preset value;

[0052] Step S4, if the judgment result is yes, control the motor to perform eccentric processing for a period of time, and then return to step S3, if the judgment result is no, enter the next step;

[0053] Step S5, judging whether the washing time is over;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com