Patents

Literature

219results about How to "Evenly dehydrated" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

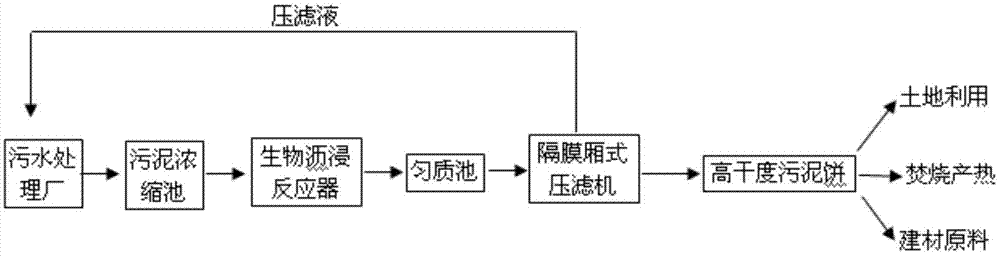

New method for deeply dewatering sludge through bio-leaching process rapid conditioning

ActiveCN103936246ASimple processLow running costSludge treatment by de-watering/drying/thickeningSludge processingSludge cakeResource utilization

The invention discloses a new method for deeply dewatering sludge through bio-leaching process rapid conditioning. The method comprises the steps of firstly performing bio-leaching conditioning on sludge, namely, directly pumping concentrated liquid sludge of a sewage treatment plant into a bio-leaching reactor which contains special composite microbial community, performing treatment for 1.5-2 days, changing bound water in the sludge into free water which can be removed relatively easily by virtue of the microbial substitution effect, biological oxidation effect and biological acidification effect, dissolving out heavy metals from the sludge at the same time, entering an aqueous phase, killing pathogens in the sludge, then collecting the sludge subjected to bio-leaching in a homogeneous pool, directly transporting to a common-pressure diaphragm chamber type filter press by virtue of a pump, and dewatering, wherein the moisture content of dewatered sludge cake is less than 60%, and no flocculant like PAM (polyacrylamide) is added during the preparation process. The method disclosed by the invention is performed under normal temperature and pressure, and has low cost; the dewatered sludge cake is low in moisture content, odorless, and yellowish-brown in color; and the organic matters, calorific values and nutrients of the dewatered sludge can not be reduced, thus facilitating the subsequent resource utilization.

Owner:NANJING AGRICULTURAL UNIVERSITY

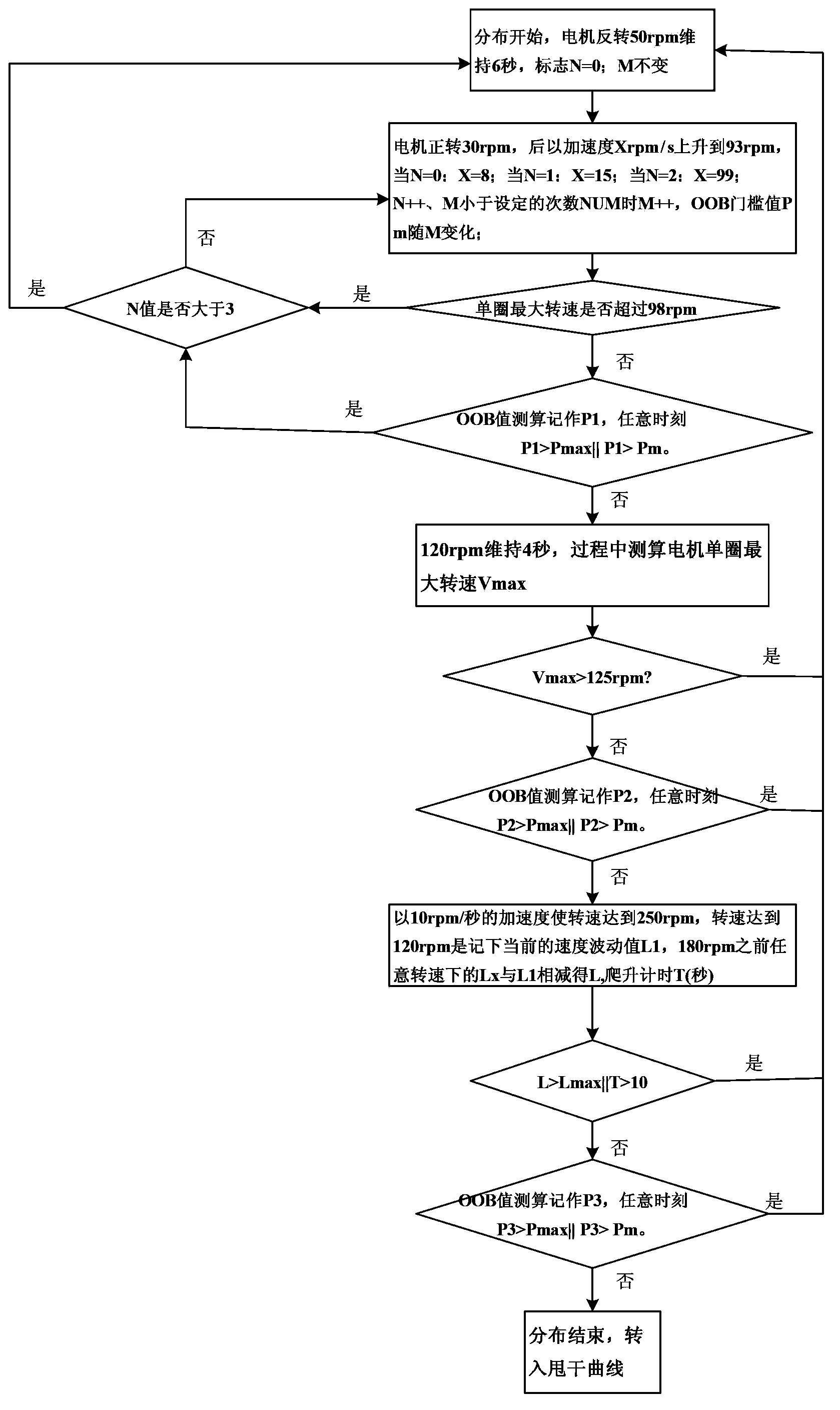

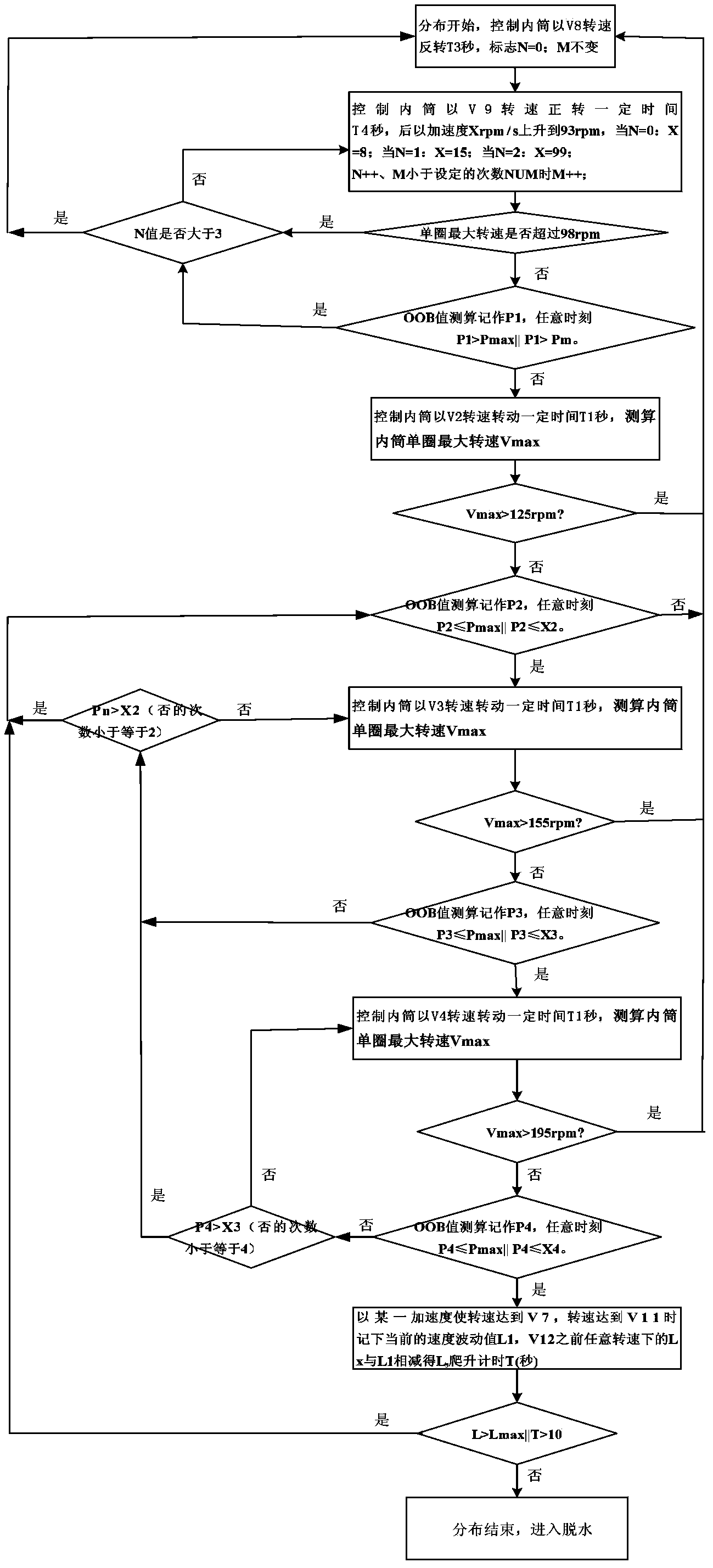

Dehydration distribution control method of washing machine

ActiveCN103911804AImprove stabilityEvenly dehydratedOther washing machinesControl devices for washing apparatusLow noiseDistribution control

The invention discloses a dehydration distribution control method of a washing machine. Before the washing machine is switched to a hydration function, the speed of an inner cylinder is controlled to be increased to a set rotating speed and stabilized at the set rotating speed, next, a process of repeatedly confirming an eccentric value of the load is added; the eccentric value of the load is repeatedly conformed before and after the rotating speed of the inner cylinder is controlled to be increased, and the eccentric value of the load is corrected after conforming that the eccentric value of the load satisfies a set condition; after hydration is began, the eccentric value is detected to determine the maximum dehydration rotating speed, the rotating speed is gradually increased to the hydration rotating speed and the hydration rotating speed is maintained for certain time for dehydration, next, the rotating speed is reduced to a certain rotating speed and maintained at the certain rotating speed for certain time, and then the rotating speed is increased to the hydration rotating speed again; by use of the method, the effects of steady dehydration, low vibration, low noise, low energy consumption and dehydration rate are achieved, and furthermore, the service life of a bearing, a speed reducer and the like of the washing machine is increased.

Owner:QINGDAO HAIER DRUM WASHING MACHINE

Animal chew

ActiveUS20050260306A1Increase nutritionGreat tasteFood processingAnimal feeding stuffAnimal scienceLarge Calorie

A nutritious, flavorful, digestible animal chew made from a dehydrated sweet potato is provided. The animal chew is non-allergenic and has a striated, deeply furrowed surface to improve the oral hygiene of an animal. The animal chew is low in calories, high in vitamins, minerals, and fiber and contains no animal-based or synthetic products.

Owner:BACK PORCH HLDG LLC

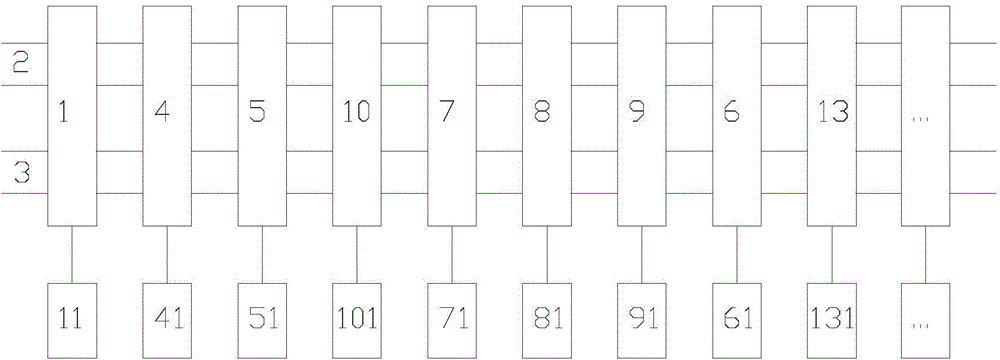

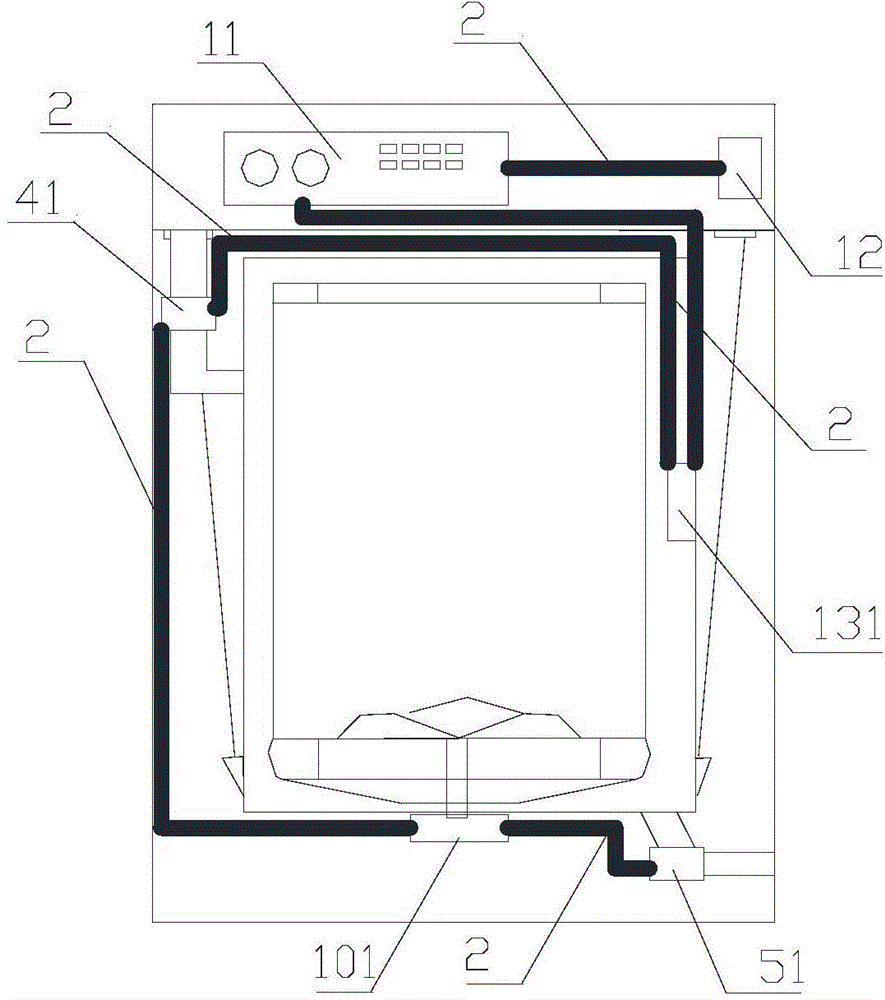

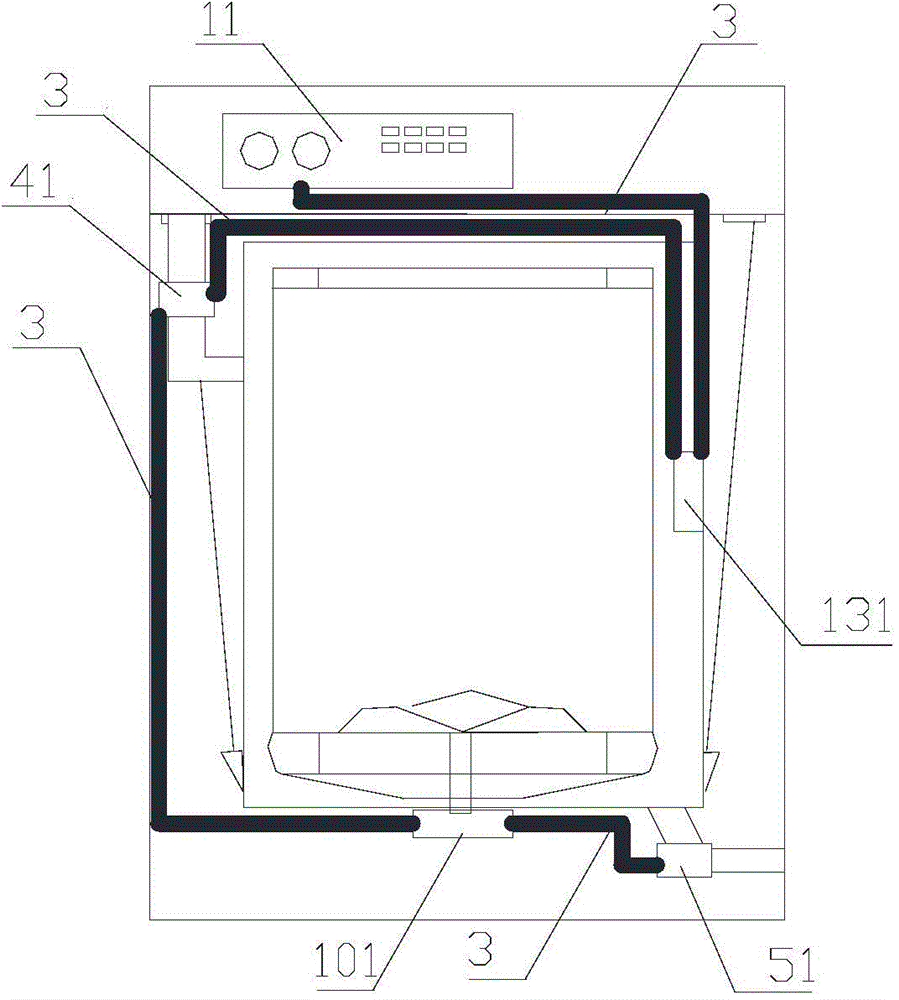

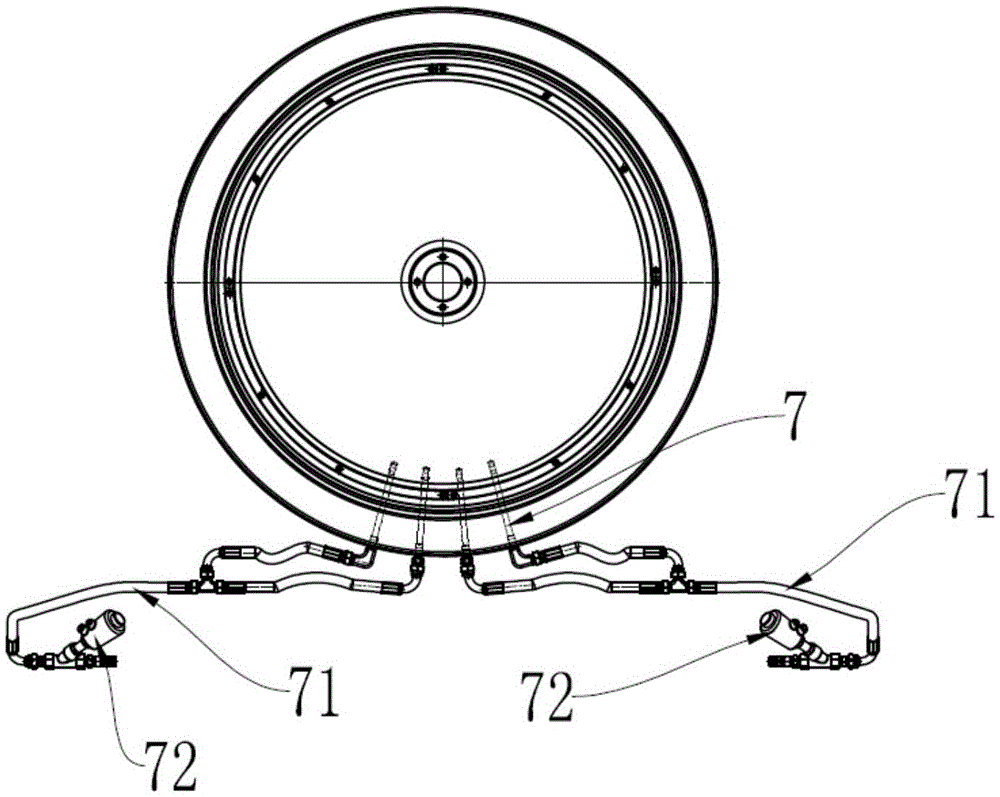

Imbalance detection washing machine and imbalance detection method

ActiveCN105274775AReduced chance of official dehydration eccentricityAvoid damageOther washing machinesStatic/dynamic balance measurementAccelerometerComputer module

The invention provides an imbalance detection washing machine comprising a main control module and function control modules respectively connected with corresponding loads; the function control modules comprise a sensor module (13); the sensor module (13) and the main control module are mutually independently arranged; the main control module and the sensor module (13) are respectively connected with a data bus and a power bus; the sensor module load corresponding to sensor module (11) is an accelerometer / six-axis sensor / nine axis sensor used for washing machine imbalance detection. The washing machine comprises independently arranged sensor modules, so modularization production and washing machine computer board insulation can be realized; the washing machine and method can real time actively detect and control imbalance of the washing machine.

Owner:QINGDAO HAIER WASHING MASCH CO LTD

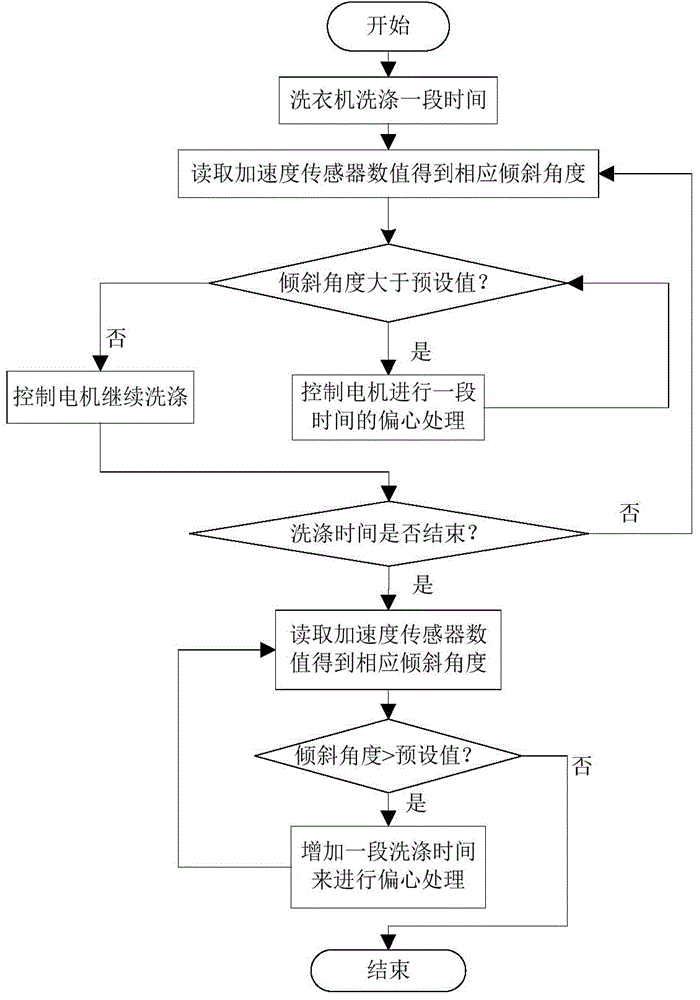

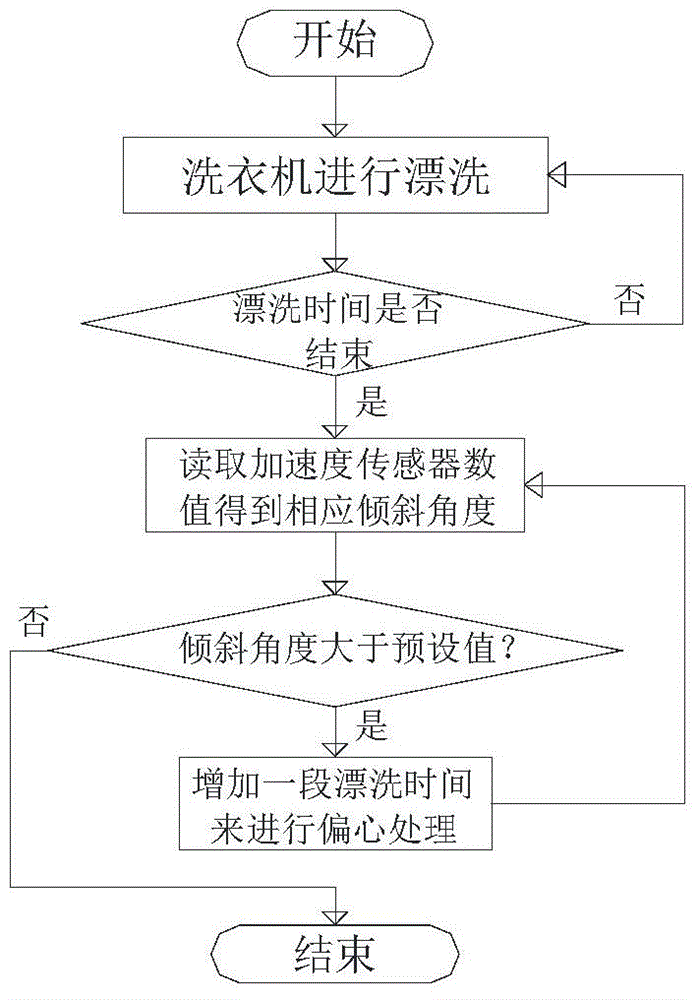

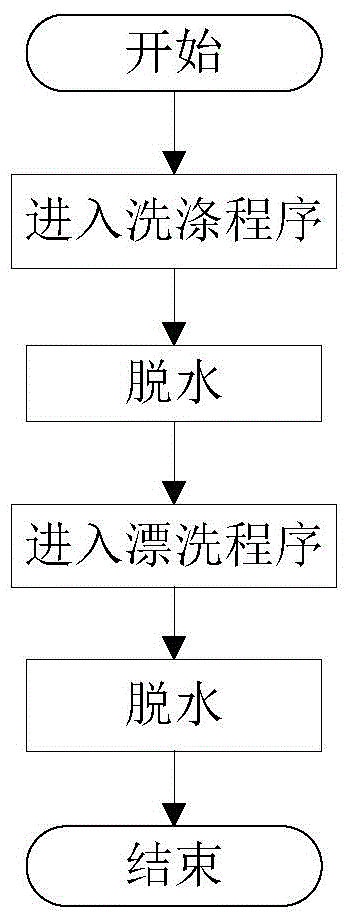

Eccentricity detection method for washing machine

ActiveCN105019191AShorten washing timeExtended service lifeOther washing machinesControl devices for washing apparatusProcess engineeringActive detection

The invention provides an eccentricity detection method for a washing machine. The method comprises the following steps: S1, entering a washing procedure; S2, reading the value of an acceleration sensor to obtain an inclination angle of a corresponding outer drum; S3, judging whether the inclination angle of the outer drum is greater than a preset value; S4, if the judgment result is yes, controlling a motor to perform a certain period of time of eccentric treatment, then returning to S3, and if the judgment result is no, entering next step; S5, judging whether the washing time is ended; and S6, if the judgment result is yes, detecting and correcting the inclination angle and then ending the washing procedure, and if the judgment result is no, returning to S2. The method provides an active detection mode, namely whether the washing machine is eccentric during washing and bleaching is detected by utilizing the acceleration sensor, and the corresponding eccentric treatment is performed if the washing machine is eccentric, so that a drum collision phenomenon caused by high eccentricity during dewatering in the washing machine is avoided, and the service life of the washing machine is prolonged.

Owner:CHONGQING HAIER WASHING MASCH CO LTD

Loose fiber dyeing process

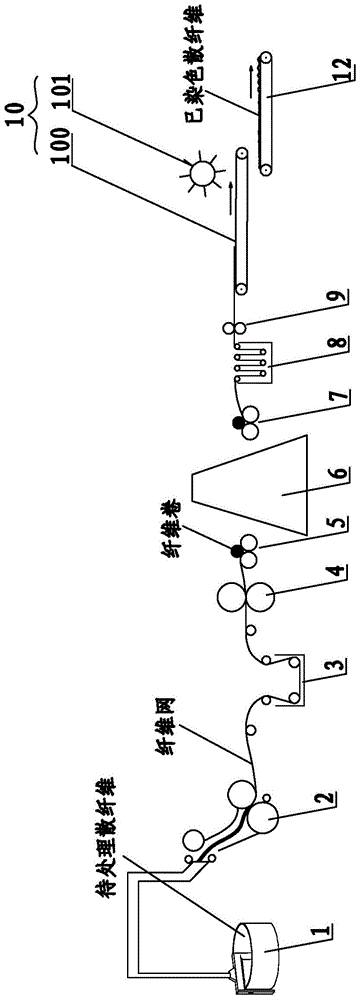

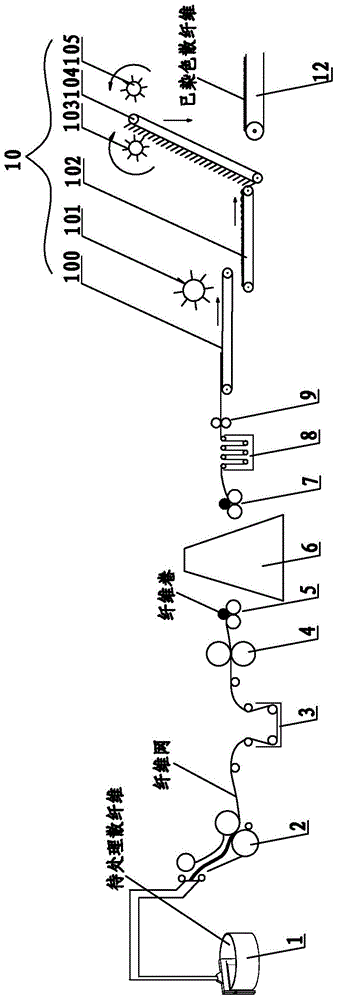

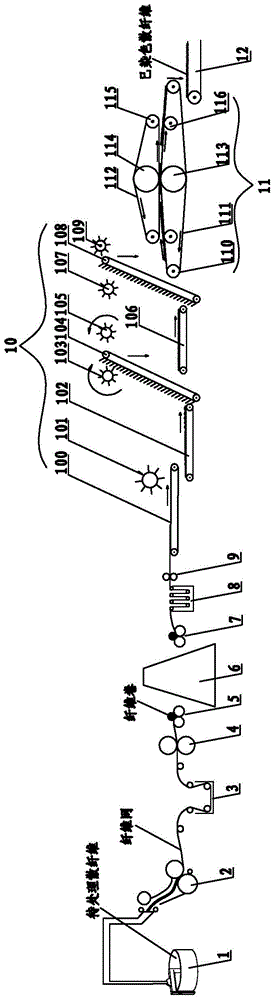

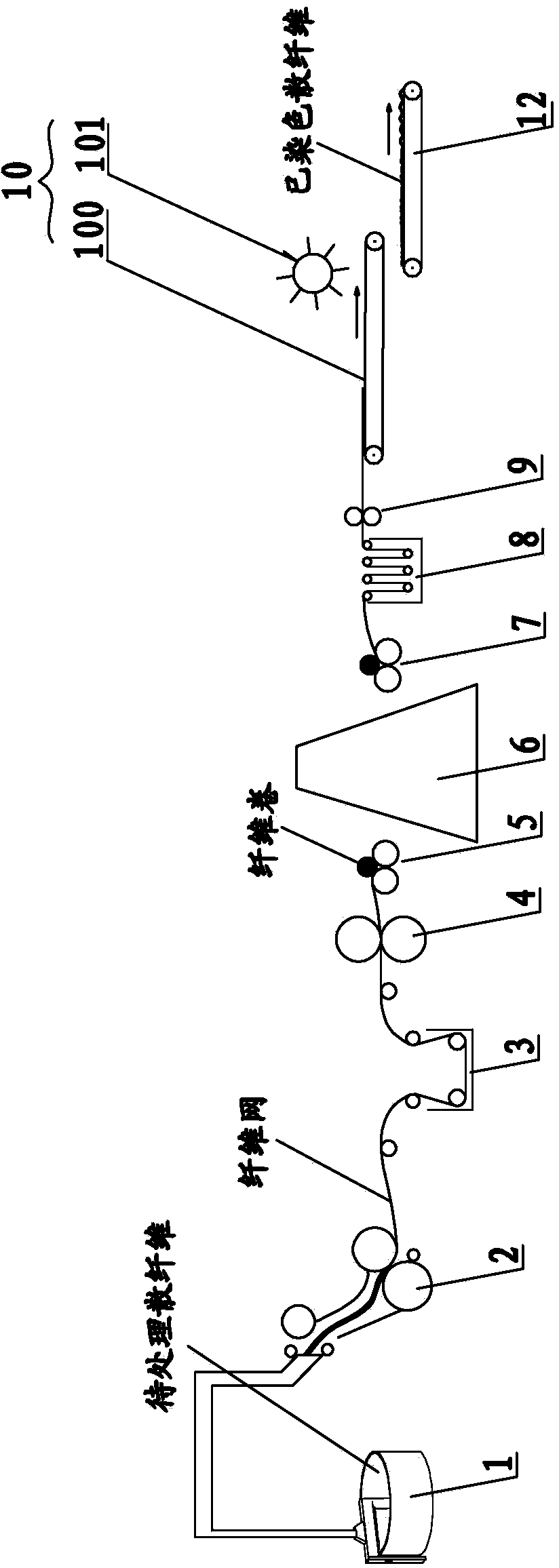

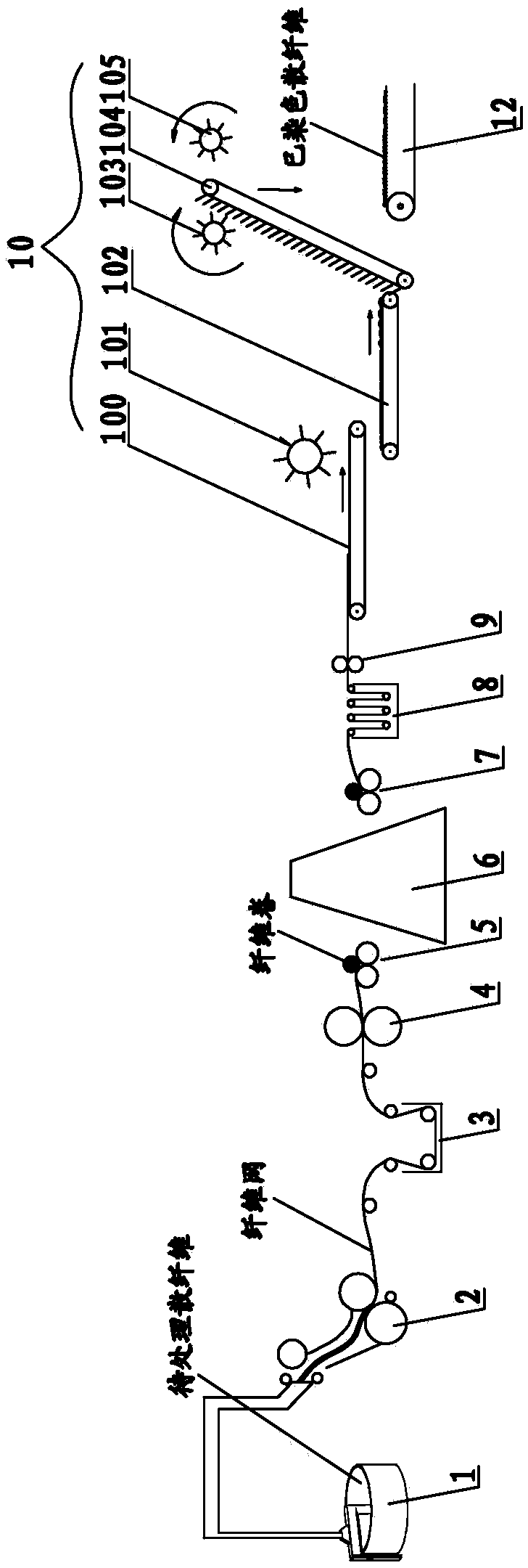

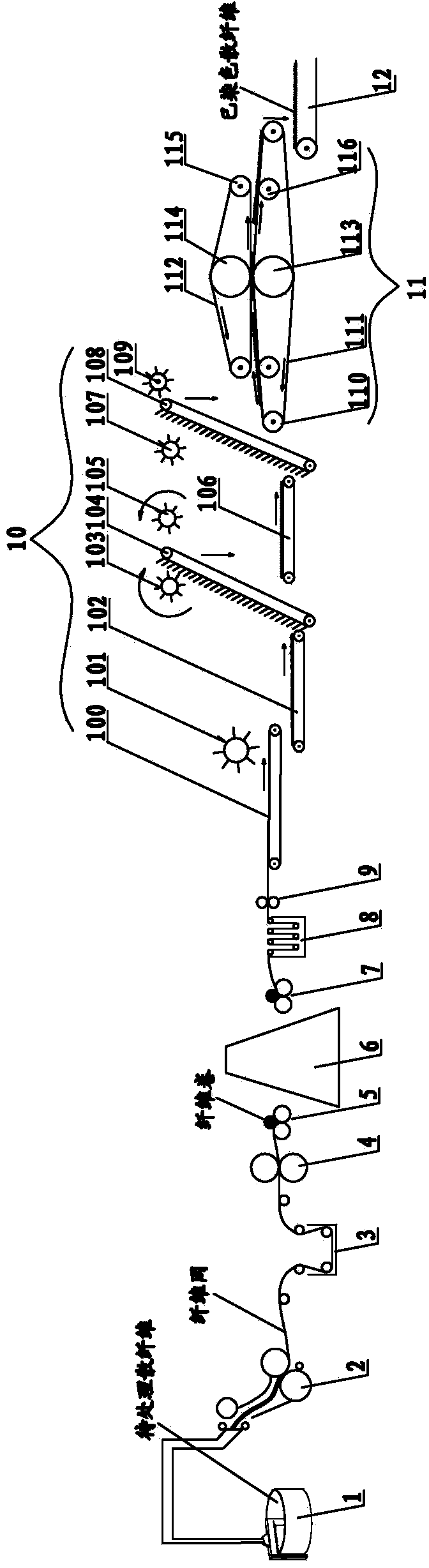

ActiveCN103911782AEvenly dyedConvey evenlyTextile treatment machine partsLiquid/gas/vapor fibres/slivers/rovings treatmentFiberPolymer science

The invention relates to a loose fiber dyeing process and belongs to technical field of fiber dyeing. The process sequentially includes: grabbing cotton, forming nets, soaking, mangling, forming rolls, cold piling, unrolling, washing, squeezing, splitting, spreading and drying. Squeezed loose fibers are fed to the spreading procedure after splitting, the loose fibers are squeezed at the squeezing force of 3-15kg / cm<2> under the premise of not damaging the fibers, the squeezed dyed fibers are directly fed through a lower conveying belt to an eight-cage dryer or a loose fiber high-frequency dryer for drying. By the process, the defects that continuous production cannot be performed and machining efficiency is low in conventional technologies are overcome, the defects that of uneven dyeing, low drying efficiency, large energy consumption and the like when the loose fibers are dried in a net structure are overcome, fiber damage is low during processing, and the quality of the finished fibers is guaranteed.

Owner:SHAOXING GUOZHOU TEXTILE NEW MATERIAL

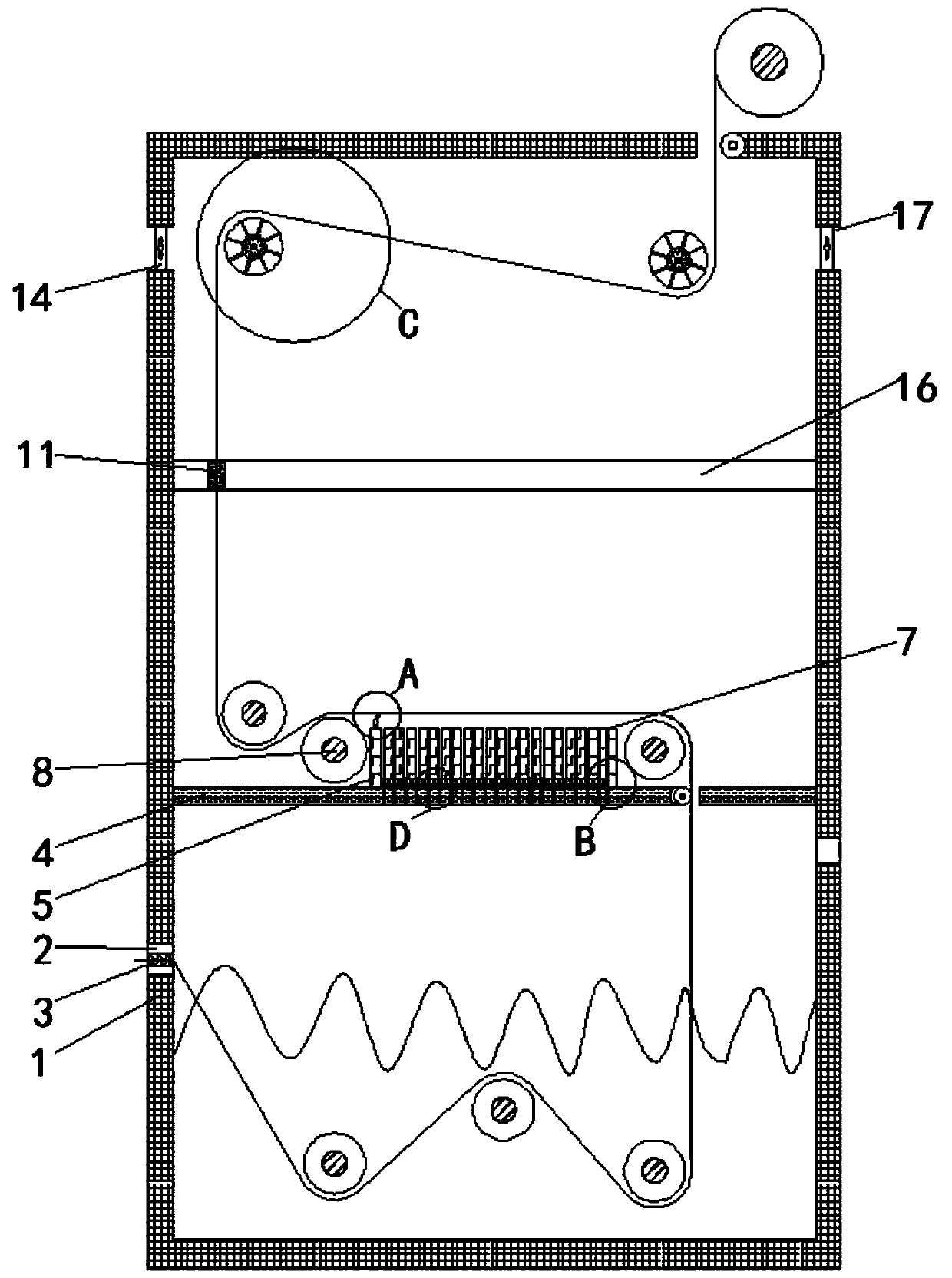

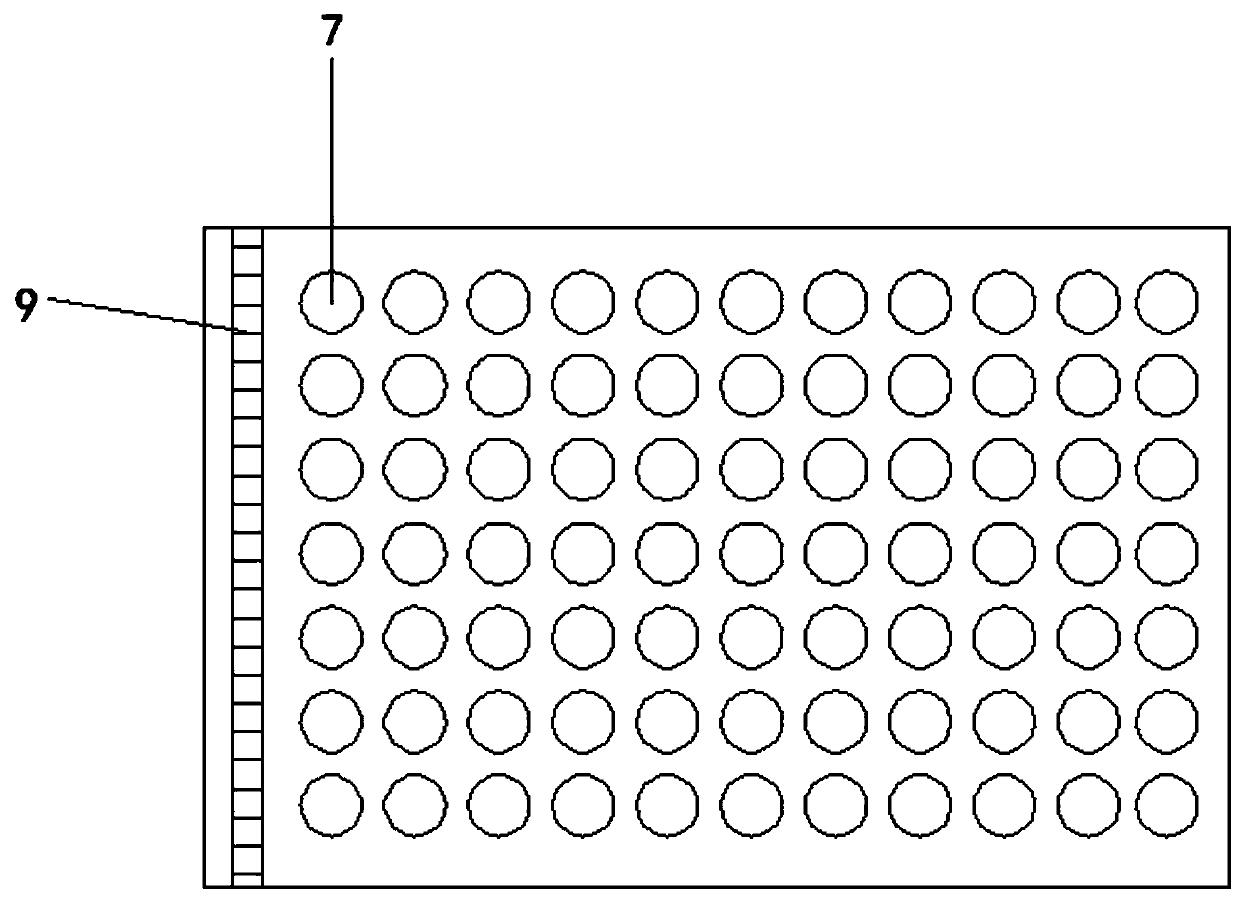

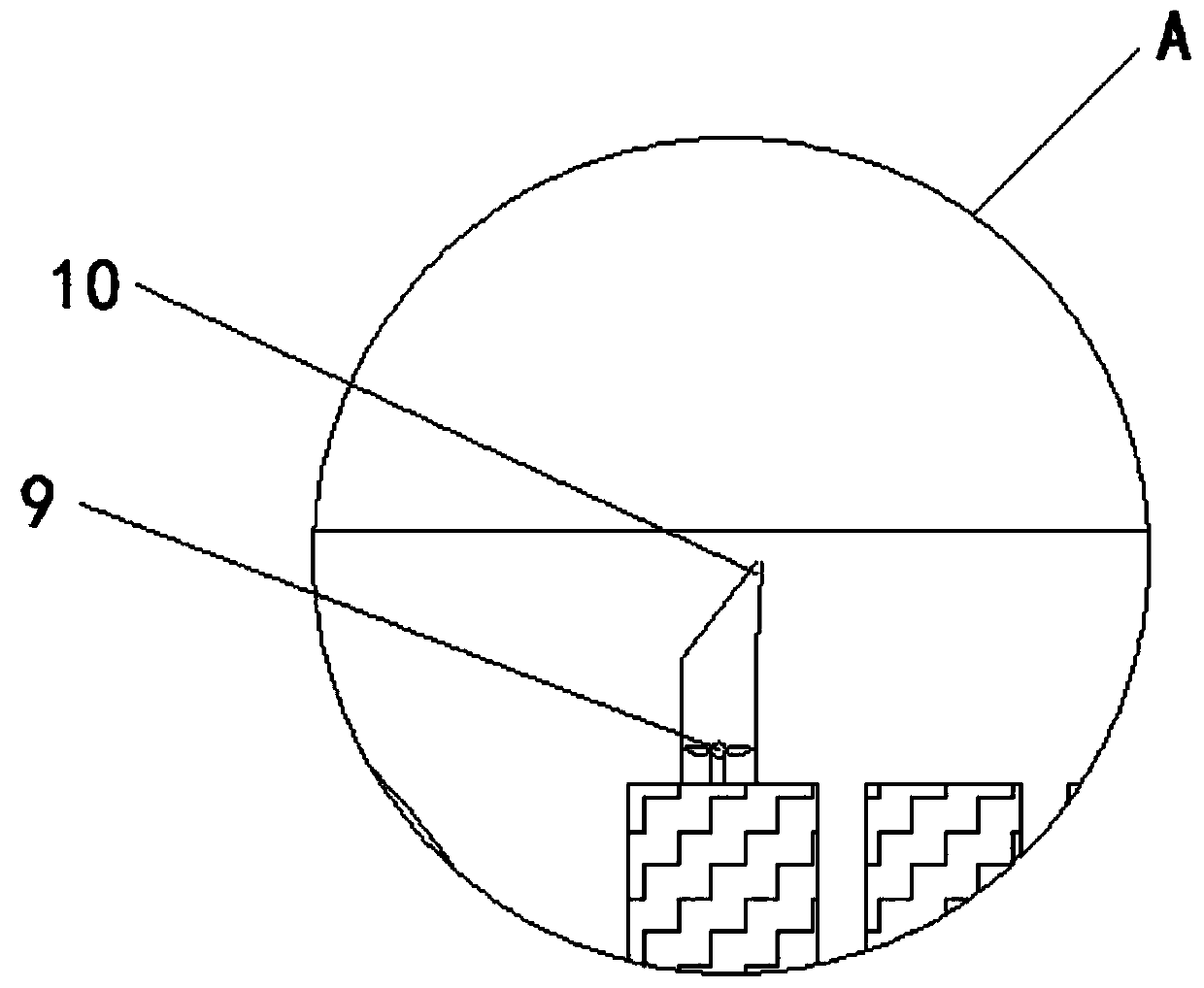

Loose stock dyeing device

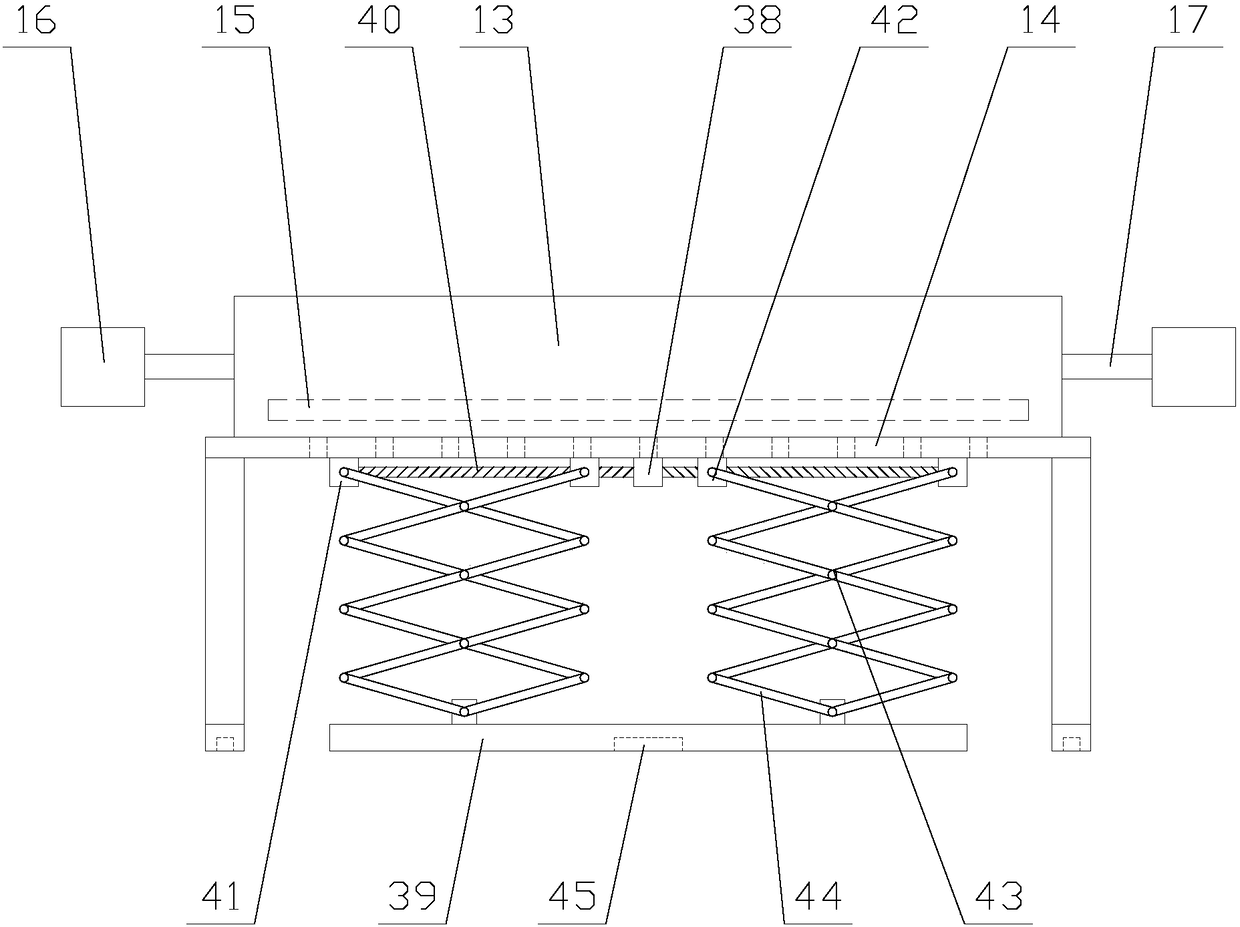

ActiveCN103882637AEvenly dyedConvey evenlyTextile treatment machine partsLiquid/gas/vapor fibres/slivers/rovings treatmentFiberProcess efficiency

The invention relates to a loose stock dyeing device and belongs to the technical field of stock dyeing devices. The loose stock dyeing device comprises a cotton grabbing device, a net forming device, a steeping device, a mangle device, a coiling device, a cold-batch fixation device, a uncoiling device, a washing device, a squeezing device, a splitting device and a drying device, wherein the cotton grabbing device, the net forming device, the steeping device, the mangle device, the coiling device, the cold-batch fixation device, the uncoiling device, the washing device, the squeezing device, the splitting device and the drying device are sequentially arranged. A loose stock net after squeezing is sent to the splitting device to be split and sent to the drying device to be dried. According to the technical scheme, the defects that continuous production cannot be performed and processing efficiency is low in the prior art are overcome, and the defects that dyeing is uneven, drying efficiency is low and energy consumption is large in drying loose stock with a net-shaped structure are overcome. In the processing process, stock damage is little, and the quality of finished stock products is ensured.

Owner:SHAOXING GUOZHOU TEXTILE NEW MATERIAL

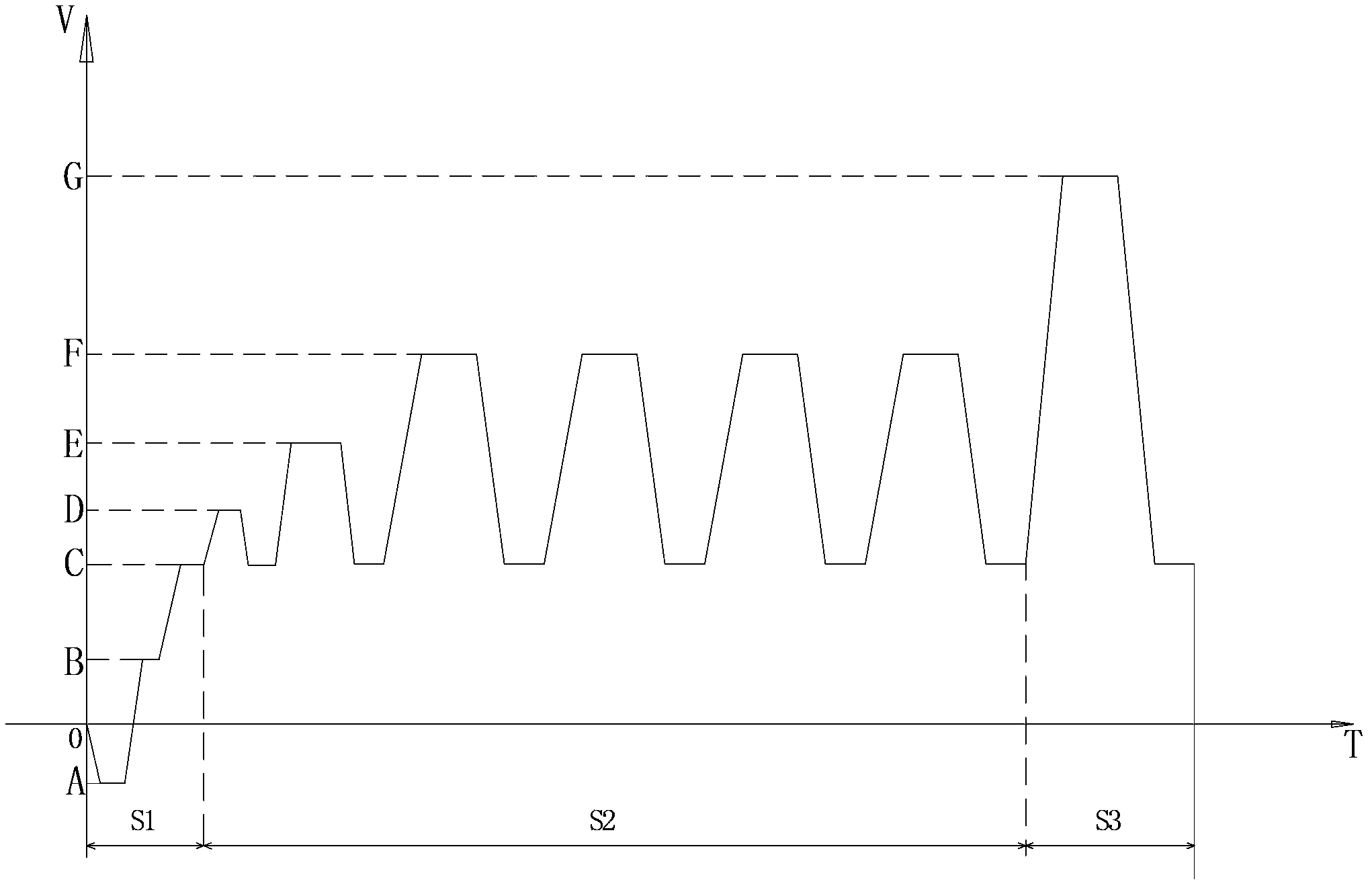

Dewatering distributed control method of washing machine

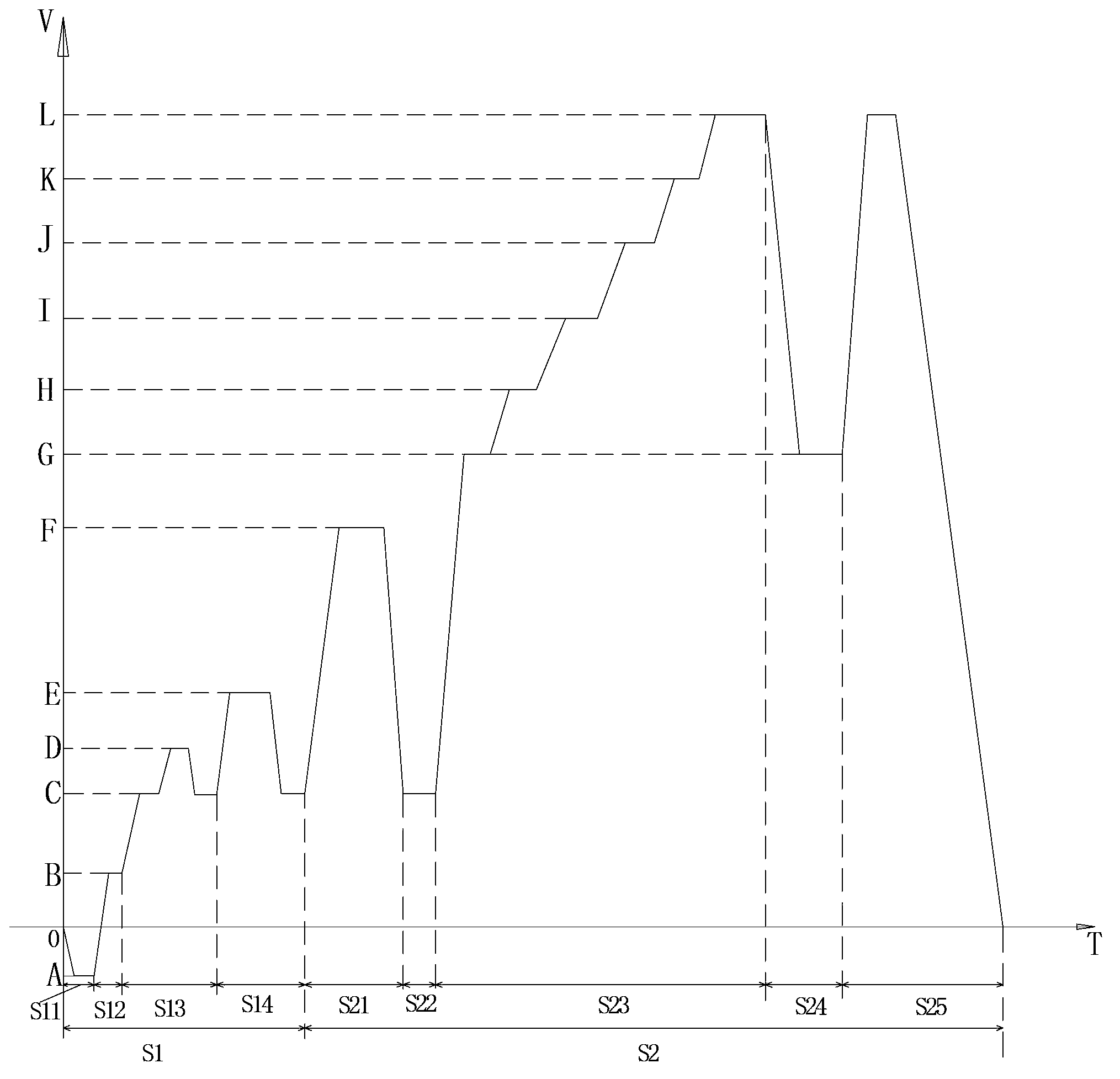

ActiveCN104233702AReduce noiseReduce energy consumptionControl devices for washing apparatusTextiles and paperReducerControl theory

The invention relates to a dewatering distributed control method of a washing machine. Before the washing machine starts dewatering, an inner tub is controlled to speed up to a set speed V1 till stableness, a step of repeatedly determining an eccentric value of a load is added, and the eccentric value of the load is corrected after the eccentric value of the load meets set conditions; during the step of repeatedly determining the eccentric value of the load, the eccentric value of the load is repeatedly detected after the inner tub is controlled to slow down each time, multiple preset eccentric limits which gradually decrease are preset in order, and each preset eccentric limit corresponds to a corresponding distribution phase; an actual detected eccentric value is compared to the preset eccentric limits to judge the distribution phase corresponding to the actual detected eccentric value, and the inner tub is controlled to rotate into the corresponding distribution phase. The eccentric value of the load is repeatedly determined in a gradual decrease manner and corrected, dewatering is stable, vibration is low, noise is low, energy consumption is low, dewatering rate is high, and the service lives of parts of the washing machine, such as a bearing and a reducer, are prolonged.

Owner:QINGDAO HAIER DRUM WASHING MACHINE

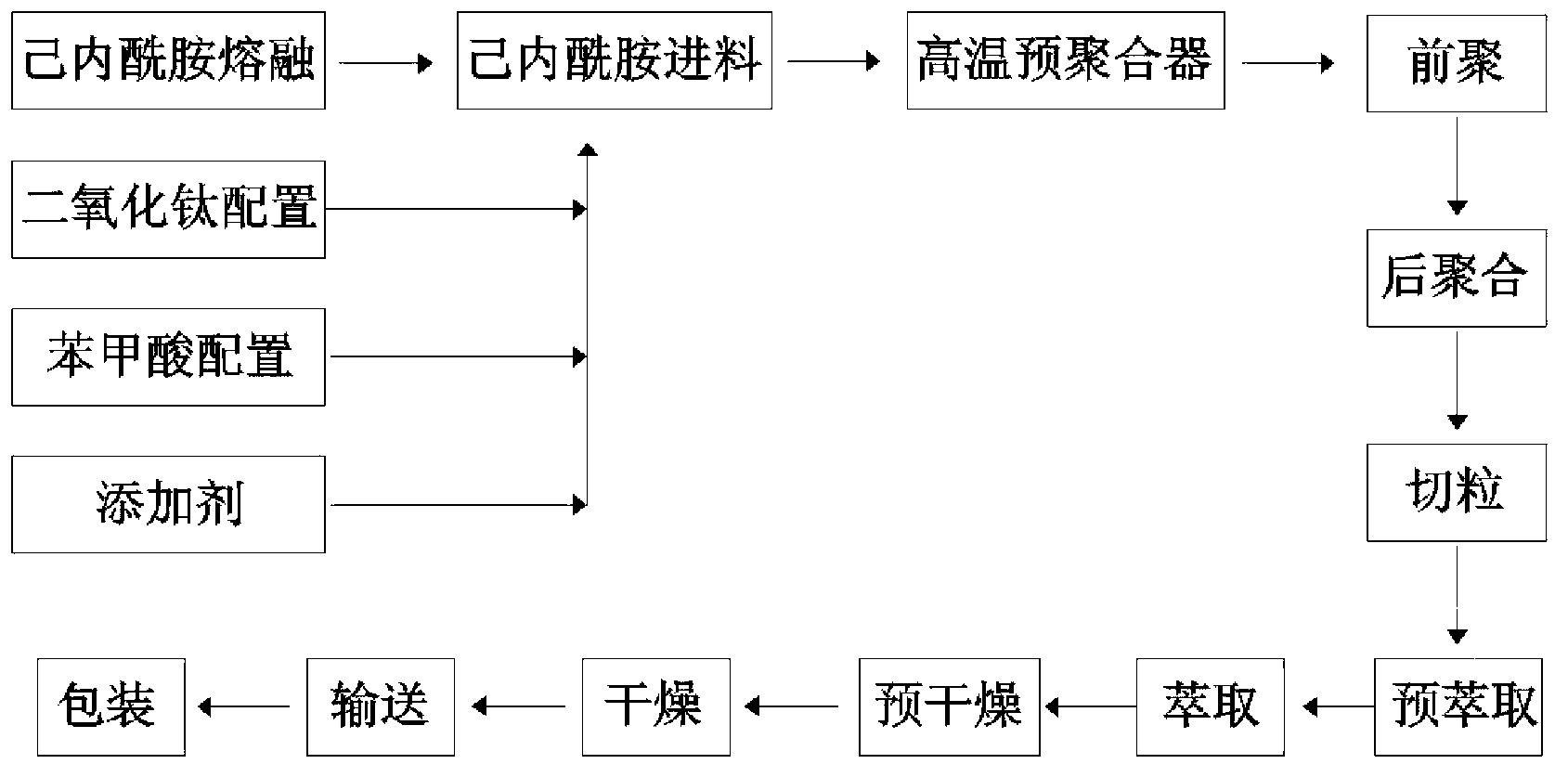

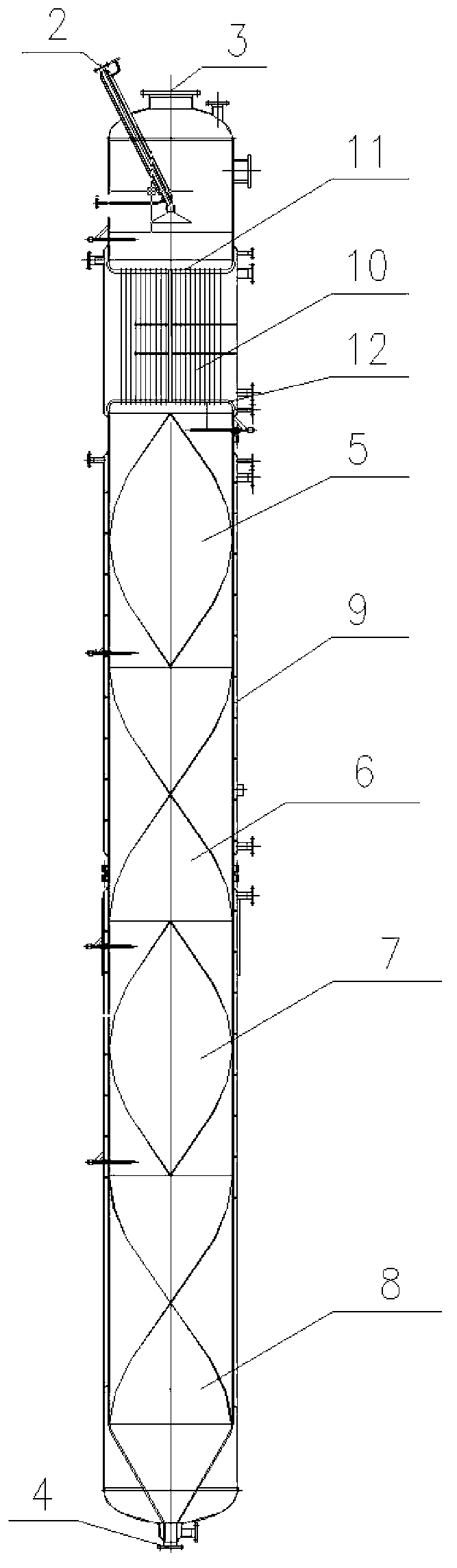

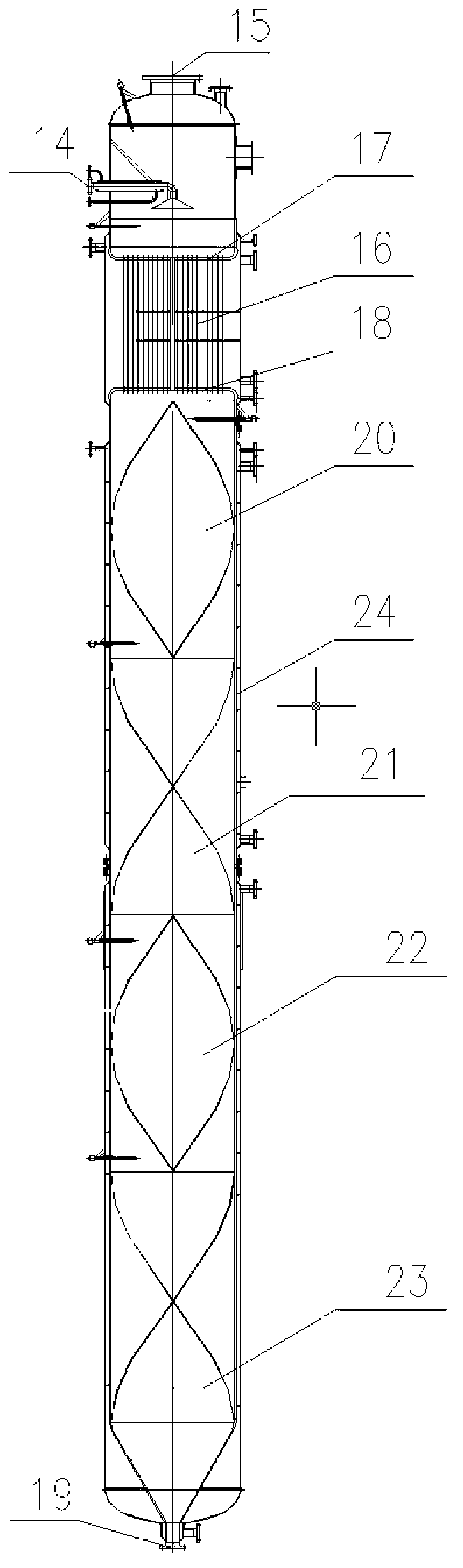

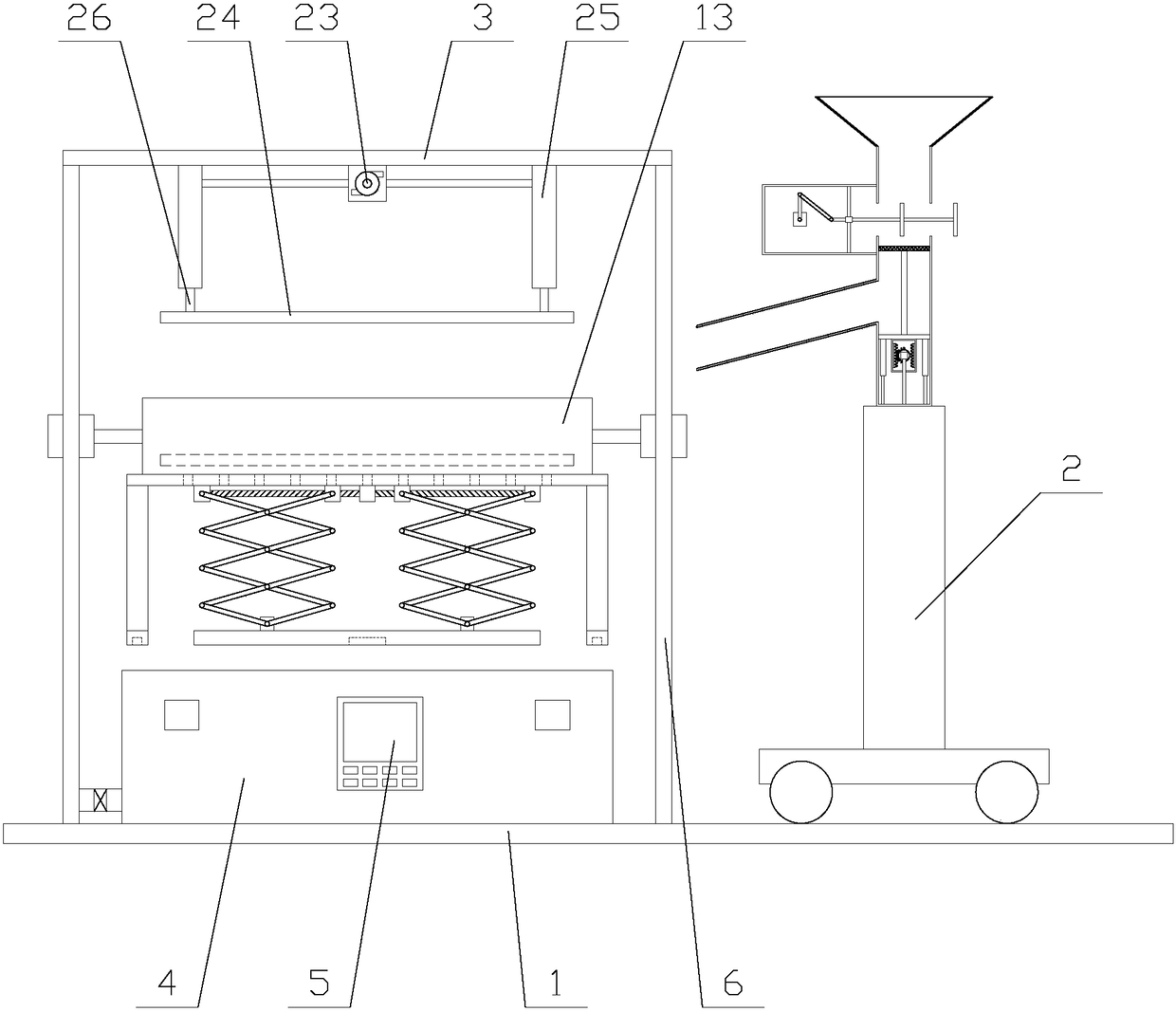

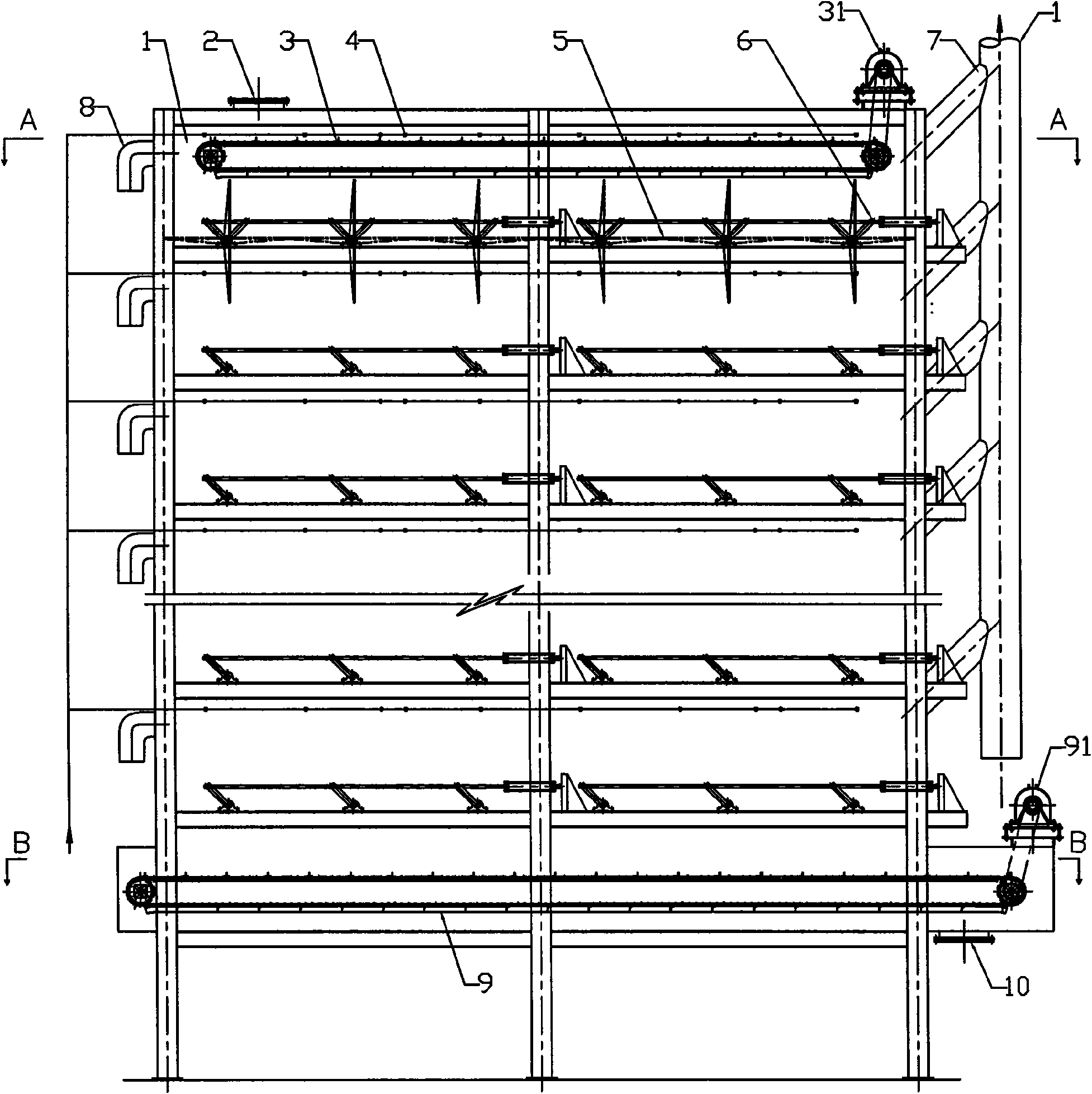

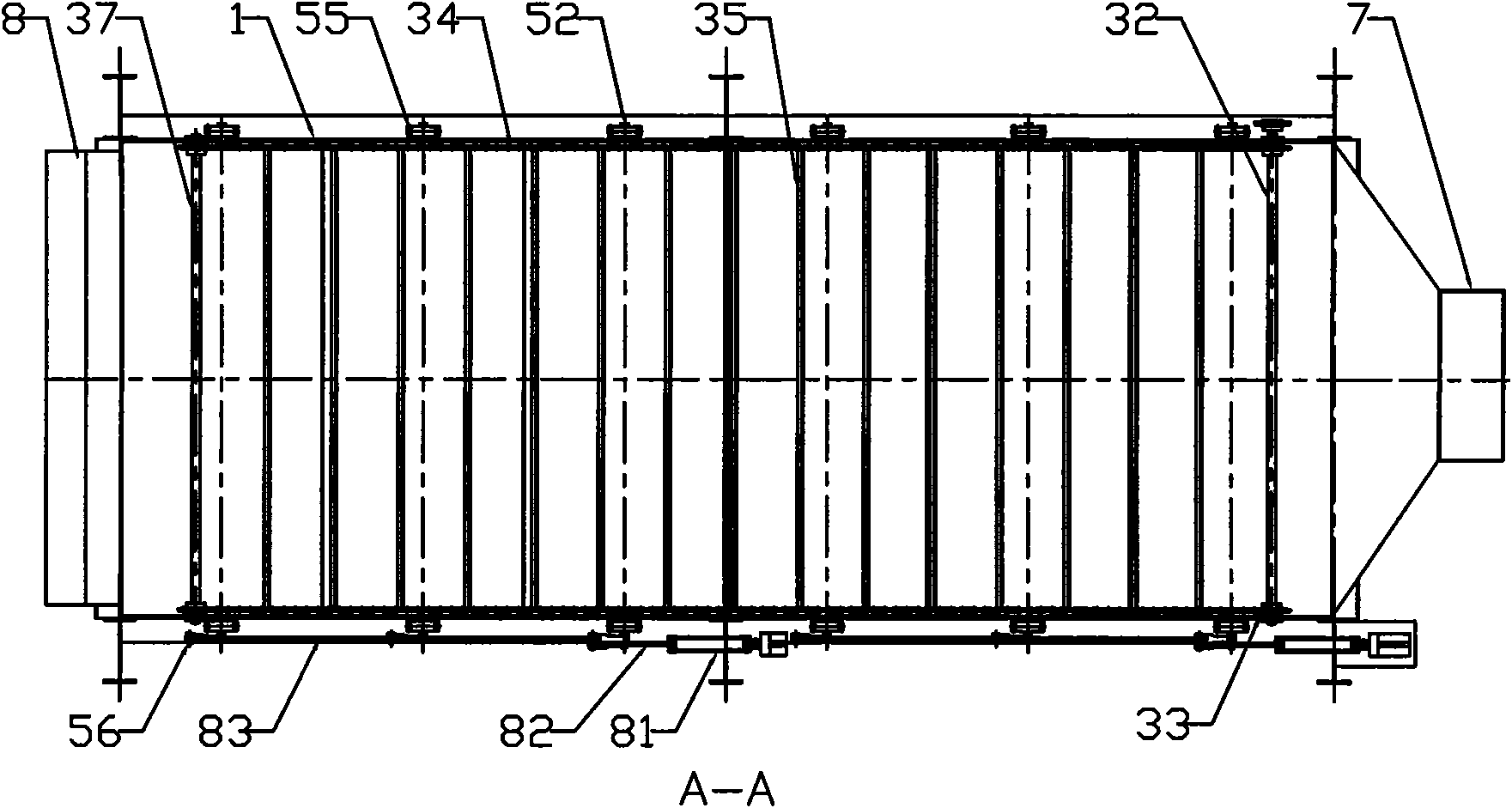

Polyamide polymerization production process and equipment for same

The invention relates to a polyamide polymerization production process and equipment for the same. The polyamide polymerization production process comprises the following steps of: carrying out prepolymerization on melted caprolactam, titanium dioxide, benzoic acid, and the like at a high temperature, and then carrying out front polymerization and post polymerization; pelleting; pre-extracting; extracting; pre-drying; and drying to obtain a product. The production equipment comprises a hexanolactam melting system, a preparation system, a feed system, a high-temperature prepolymerization device, a front polymerization tower, a rear polymerization tower, a pelleting system, a pre-extraction tower, an extraction tower, a pre-drying tower, a drying tower, and the like. According to the invention, static state flow guide spiral mixer assemblies are additionally arranged in the extraction tower and the lower sections of each row of tubes of the high-temperature prepolymerization device, the front polymerization tower and the post polymerization tower; the polyamide hydrolyzing ring opening and dewatering are more uniform and sufficient and faster; the front polyaddition reaction is sufficient and stable; the rear polycondensation stage is more uniform and stable in molecular distribution; the extraction tower more sufficiently and stably extracts a caprolactam monomer; the pre-drying tower can be used for removing the surface moisture of a slice; the drying tower dries combined water; a recovery system can be used for recovering an oligomer and extracts the caprolactam monomer contained in water.

Owner:武汉森大科技研究发展中心

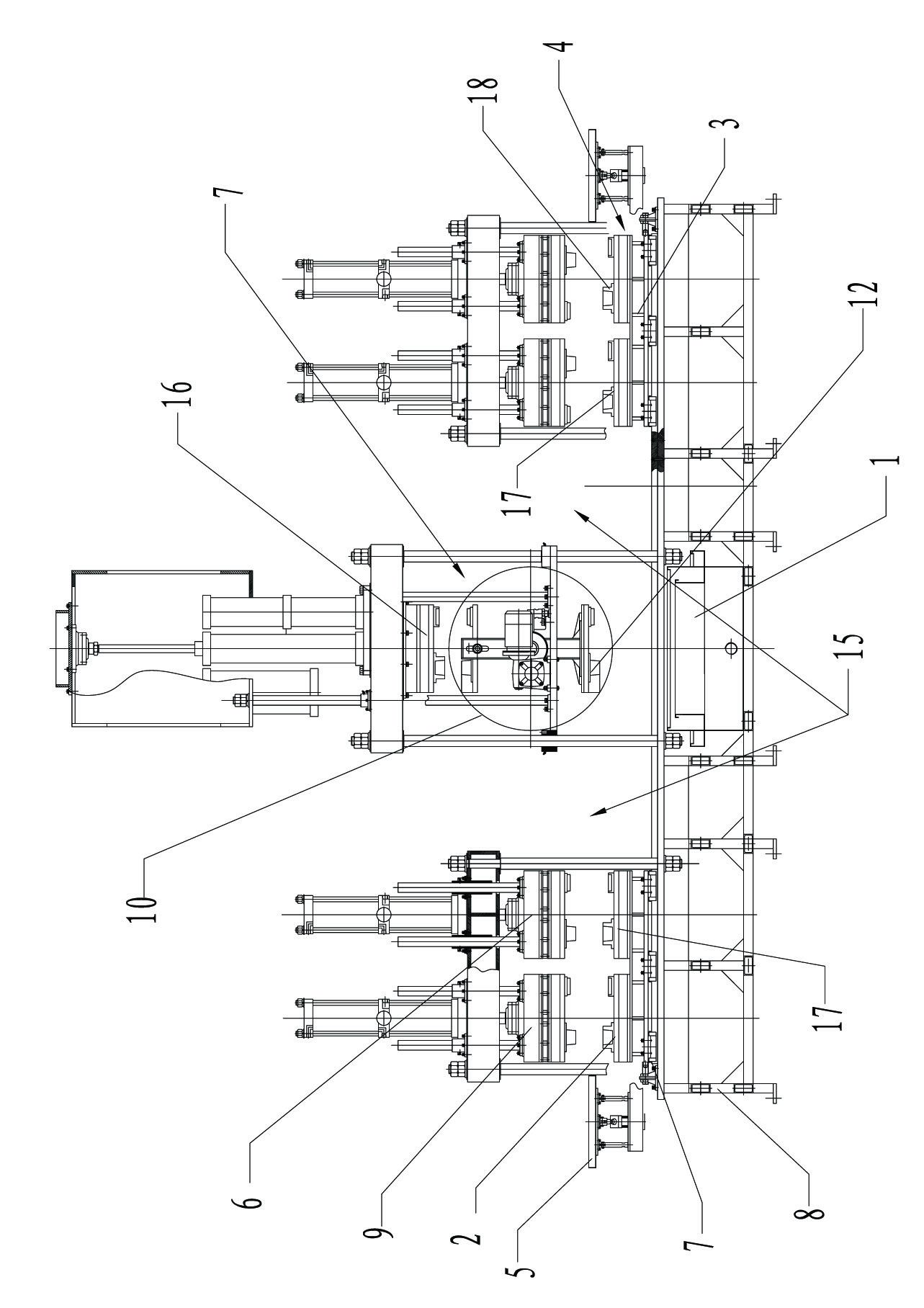

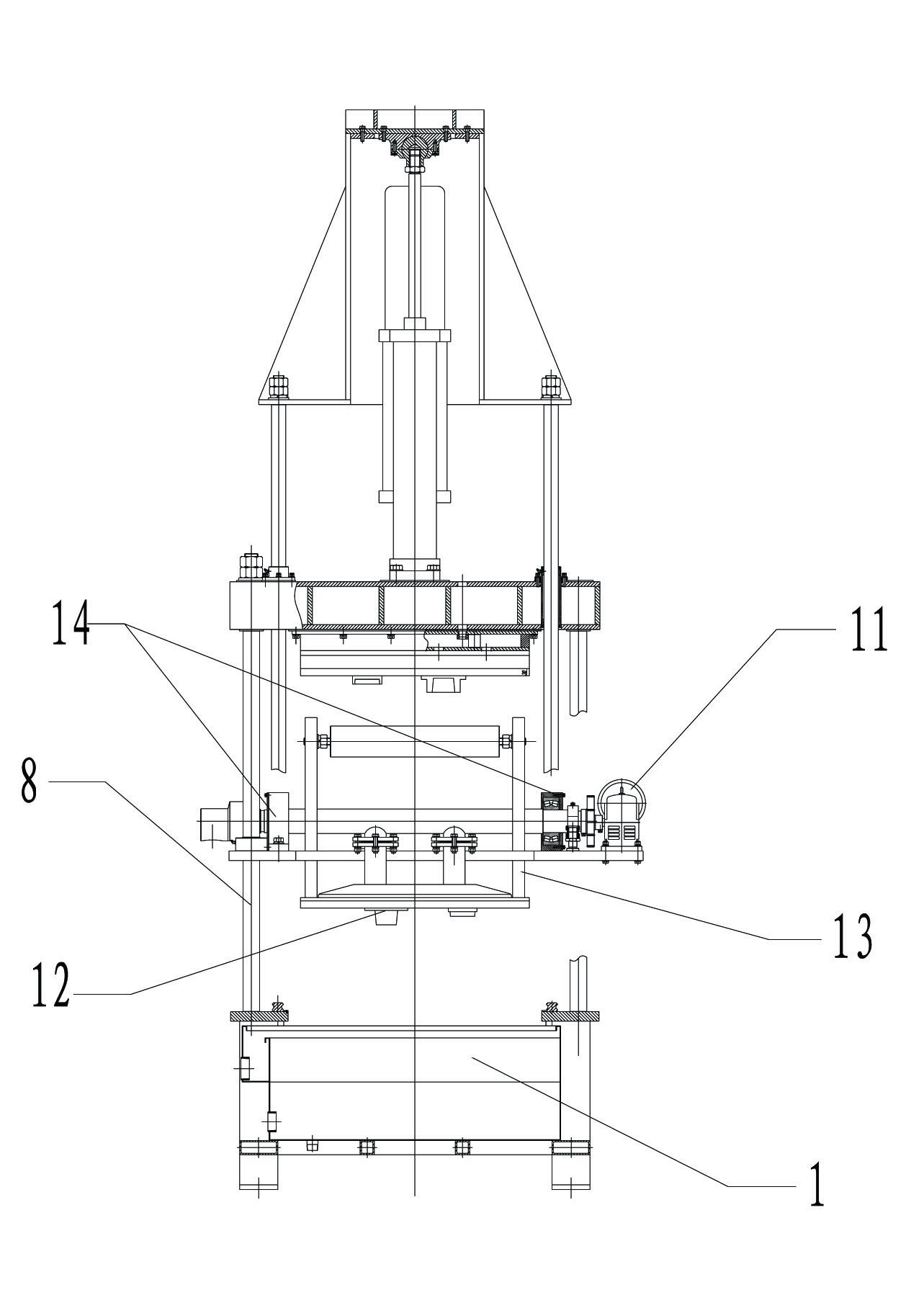

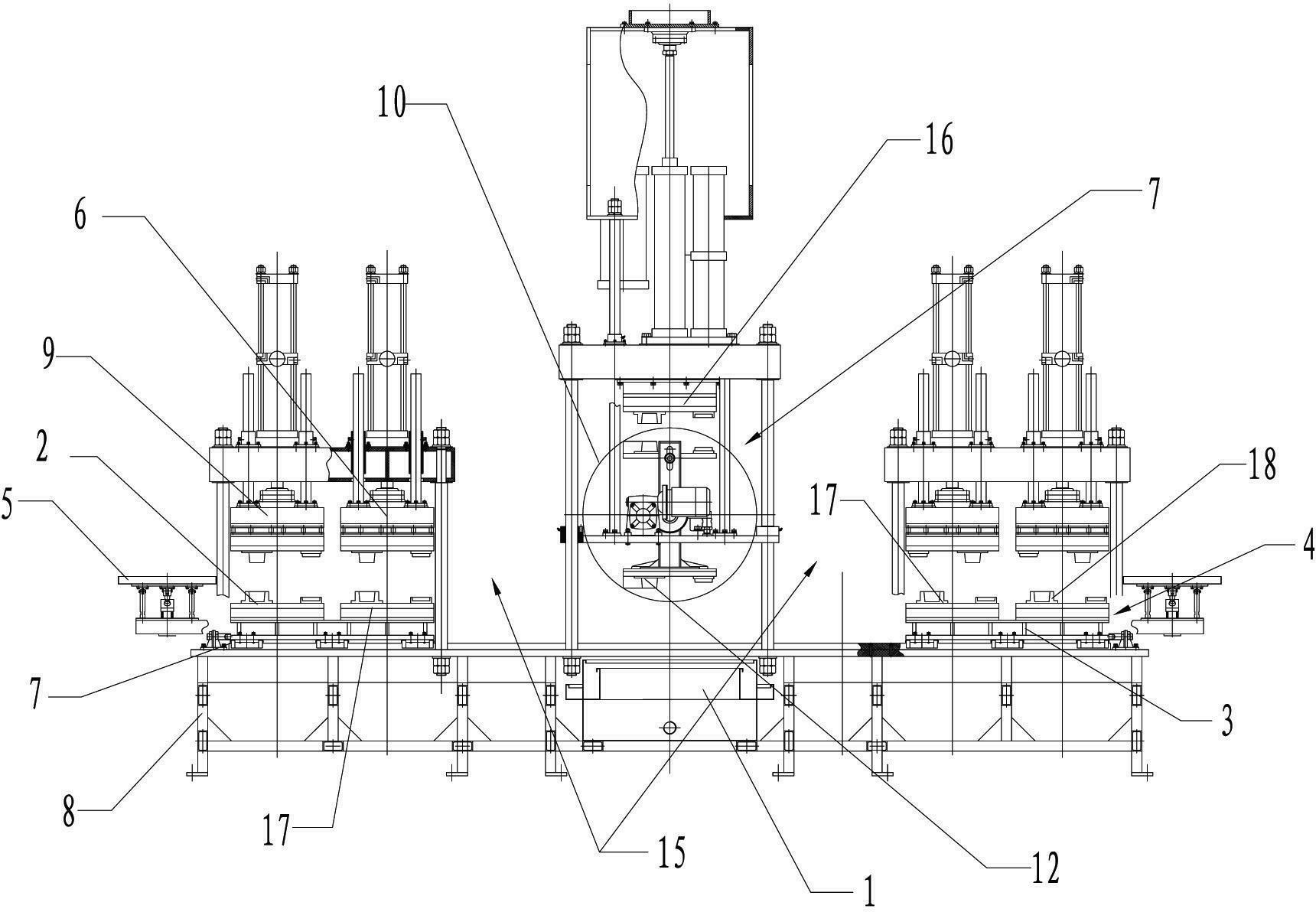

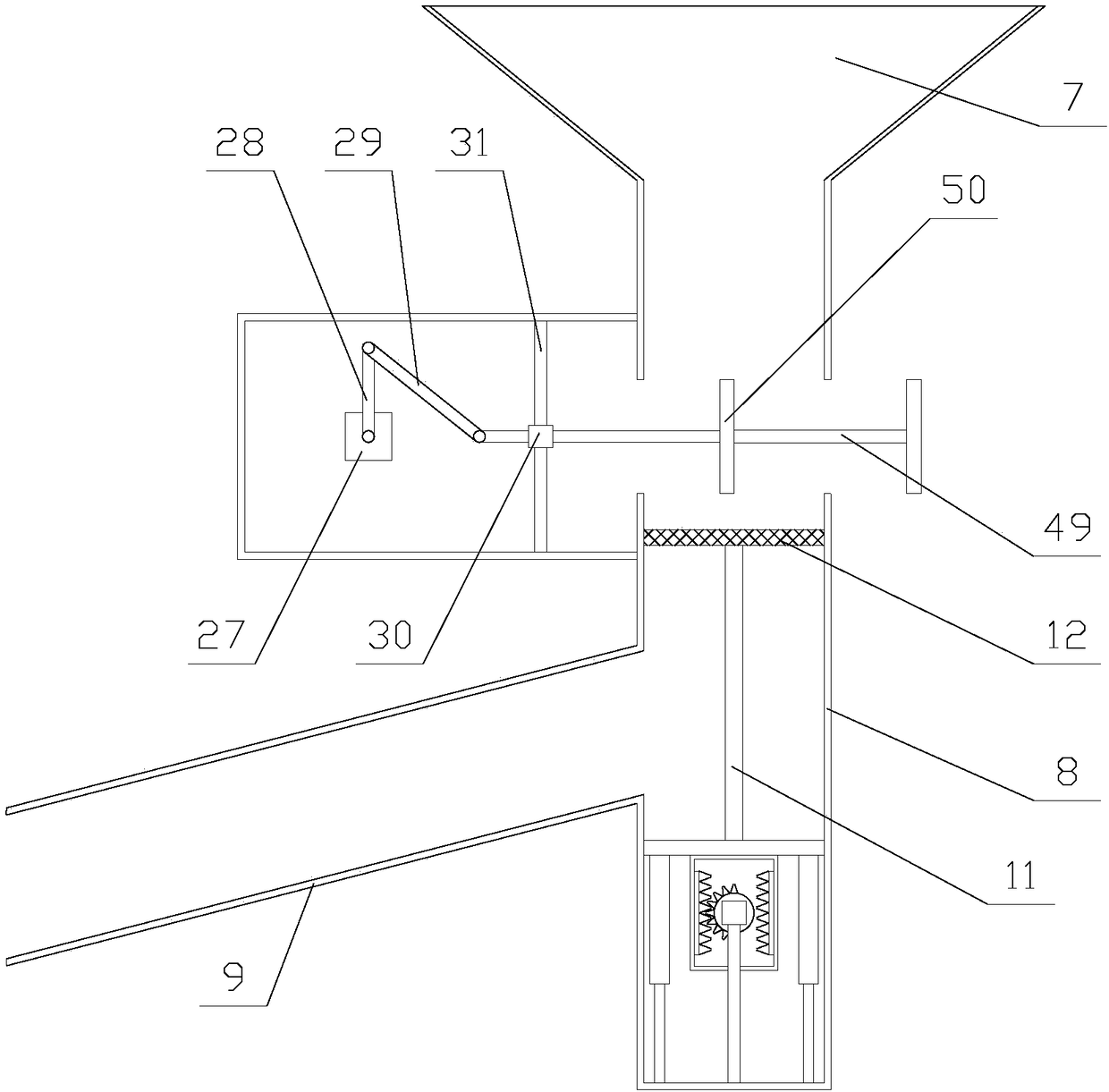

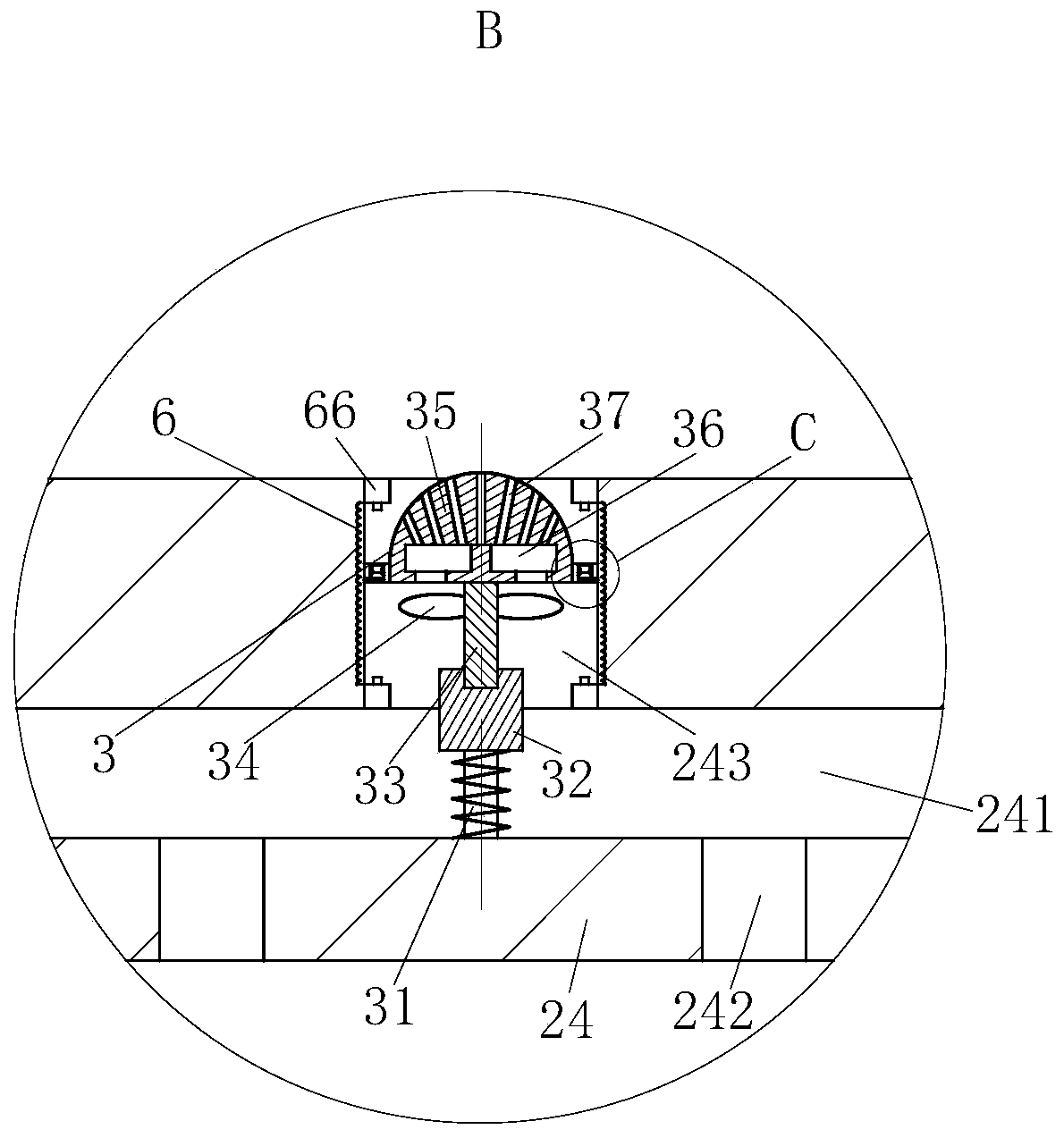

Plate-frame type anti-blocking sludge dewatering machine with long service life

InactiveCN108479182AAvoid cloggingAvoid damageSludge treatment by de-watering/drying/thickeningFiltration circuitsCause blockageEngineering

The invention relates to a plate-frame type anti-blocking sludge dewatering machine with long service life. The dewatering machine comprises a conveying mechanism, a pressing mechanism, a water tank,a controller, a cleaning mechanism and a dewatering mechanism; the conveying mechanism comprises a hopper, a material pipe, an oblique tube and a cleaning room, the dewatering mechanism comprises a frame, a stencil, filter cloth, two rotating assemblies and four supporting assemblies, and the cleaning mechanism comprises a water pump, a moving tube, a second filter screen, two translation assemblies and a plurality of nozzles. According to the dewatering machine, sludge is transported through the conveying mechanism, large debris is isolated by a first filter screen to prevent the filter clothfrom being scratched and damaged when the sludge is squeezed, the service life of the filter cloth is ensured, the sludge flows smoothly, the debris on the first filter screen is removed in time through a cleaning assembly, the filter cloth is turned over under the driving of a first motor, the filter cloth is washed and cleaned by the cleaning mechanism to prevent the sludge from adhering to thefilter cloth to cause blockage, and the smooth progress of subsequent sludge dewatering is ensured.

Owner:晋江市意翔环保科技有限公司

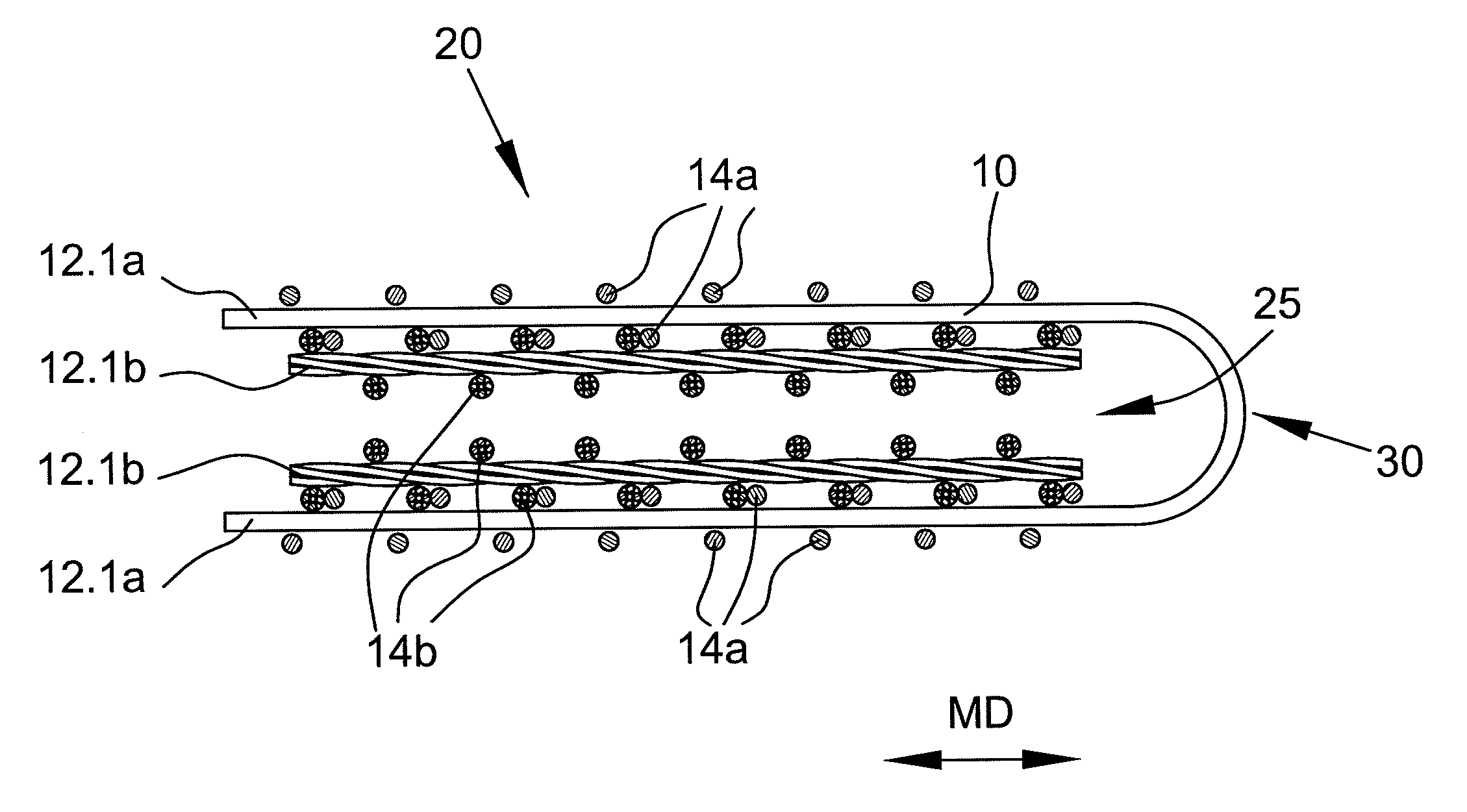

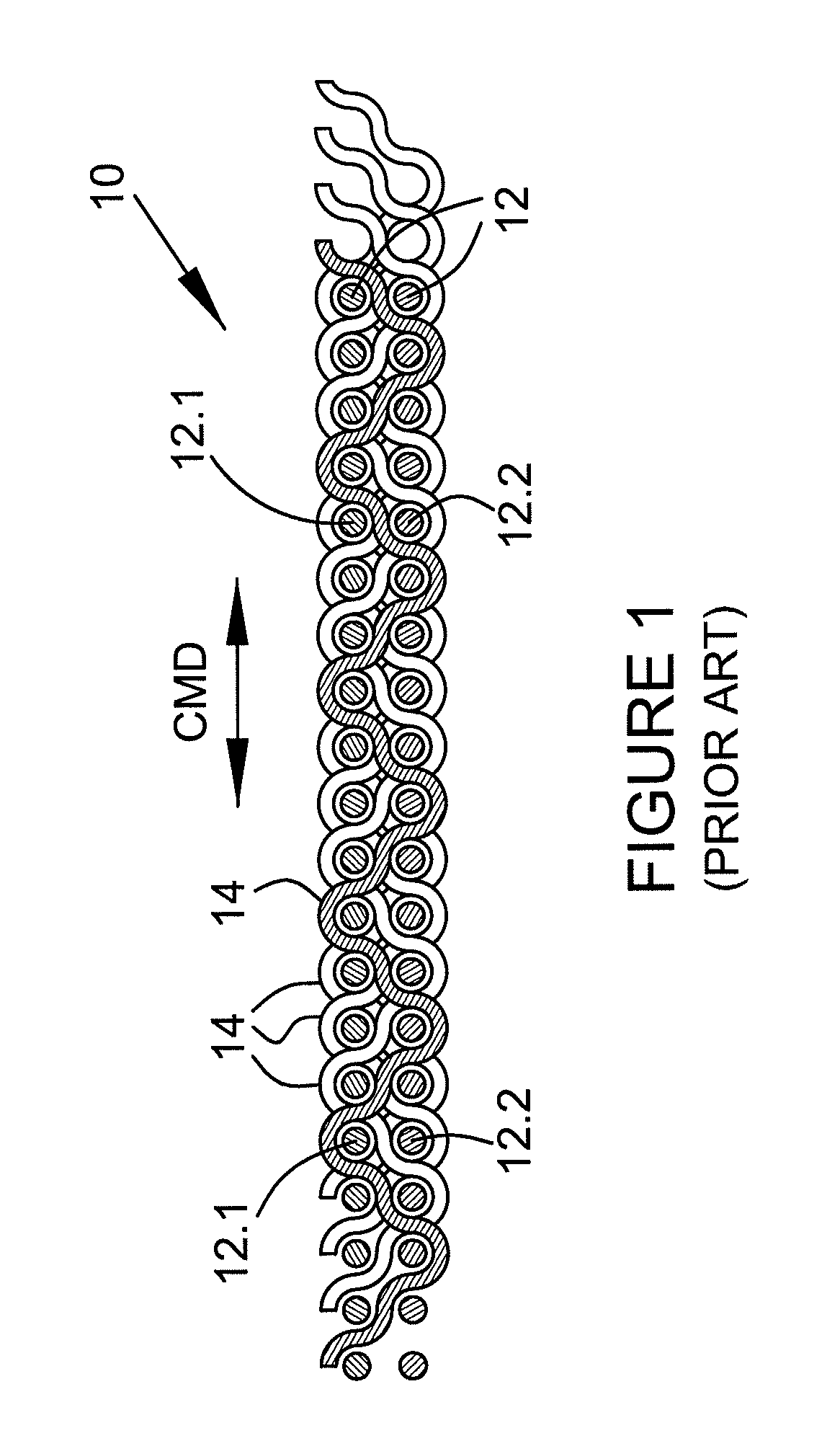

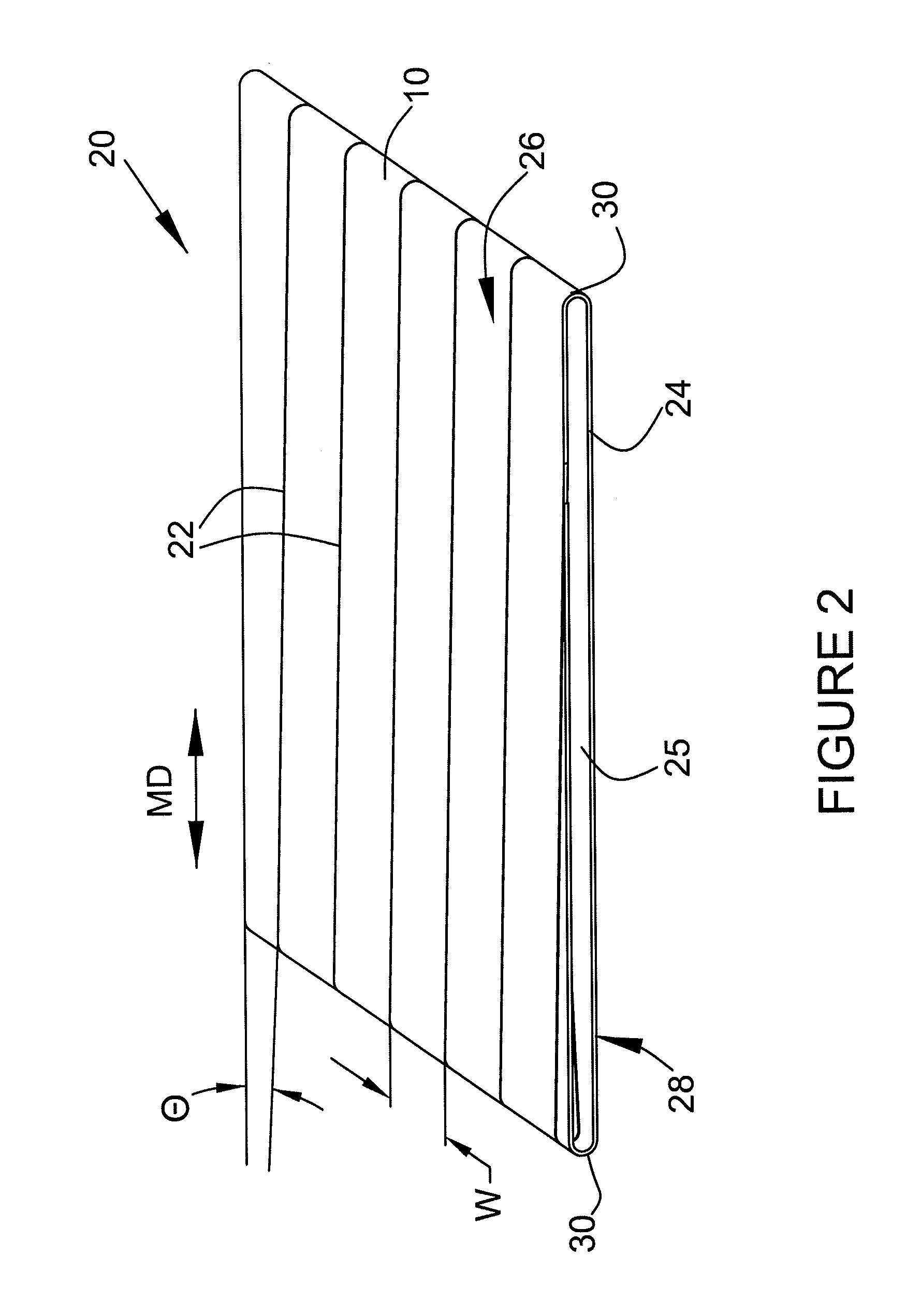

Multiaxial press felt base fabric including cabled monofilaments

ActiveUS20130020043A1Maintain volumeUniform qualityPaper/cardboardPress sectionPapermakingEngineering

A multiaxial press felt base fabric construction is provided in which the base fabric is formed from a spirally wound precursor textile strip having a width that is less than an overall width of the assembled papermaking fabric and which is joined together along neighboring adjacent edges to form a fabric tube. At least one of: 100% of the MD yarns located on one surface of the precursor textile strip are comprised of cabled yarns or from 50% to 100% of the CD yarns are a cabled yarn. The MD yarns are arranged as vertically stacked pairs for compression resistance to provide void volume, and the vertically stacked arrangement is maintained by interweaving with one system of CD weft yarns.

Owner:ASTENJOHNSON

Seawater fish ovum electron-microscope scanning sample preparing method

InactiveCN1865901AQuality assurancePrevent collapsePreparing sample for investigationScanning probe techniquesAlcoholPhosphate

The disclosed preparation method for ovum of sea fish as TEM sample comprises: fixing fresh fish ovum by glutaral solution diluted by phosphate buffer, cleaning, dewatering the ovum by 20-70% alcohol with concentration gradient increased by 10% and 75-100% alcohol with concentration gradient increased by 5% as two stages, then dewatering in pure acetone with CaCl2 as agent; then, drying at critic point, and spraying gold for the sample. This invention has ovum completion rate as 93.8-96.7% with low cost and convenient operation.

Owner:SOUTH CHINA SEA INST OF OCEANOLOGY - CHINESE ACAD OF SCI

Method for preparing vital wheat gluten flour

The invention relates to a method for preparing vital wheat gluten flour, and belongs to processing methods of edible protein. The method comprises the following steps: a. adding water to wheat flour to be made into flour dough; b. naturally curing and washing the flour dough with the water to obtain a gluten flour clot; and c. freezing and drying the gluten flour clot to obtain the vital wheat gluten flour, wherein, the freezing temperature is minus 5-minus 6 DEG C, and the freezing time is 8-10 hours.

Owner:TIANJIN ZHONGYING HEALTH FOOD

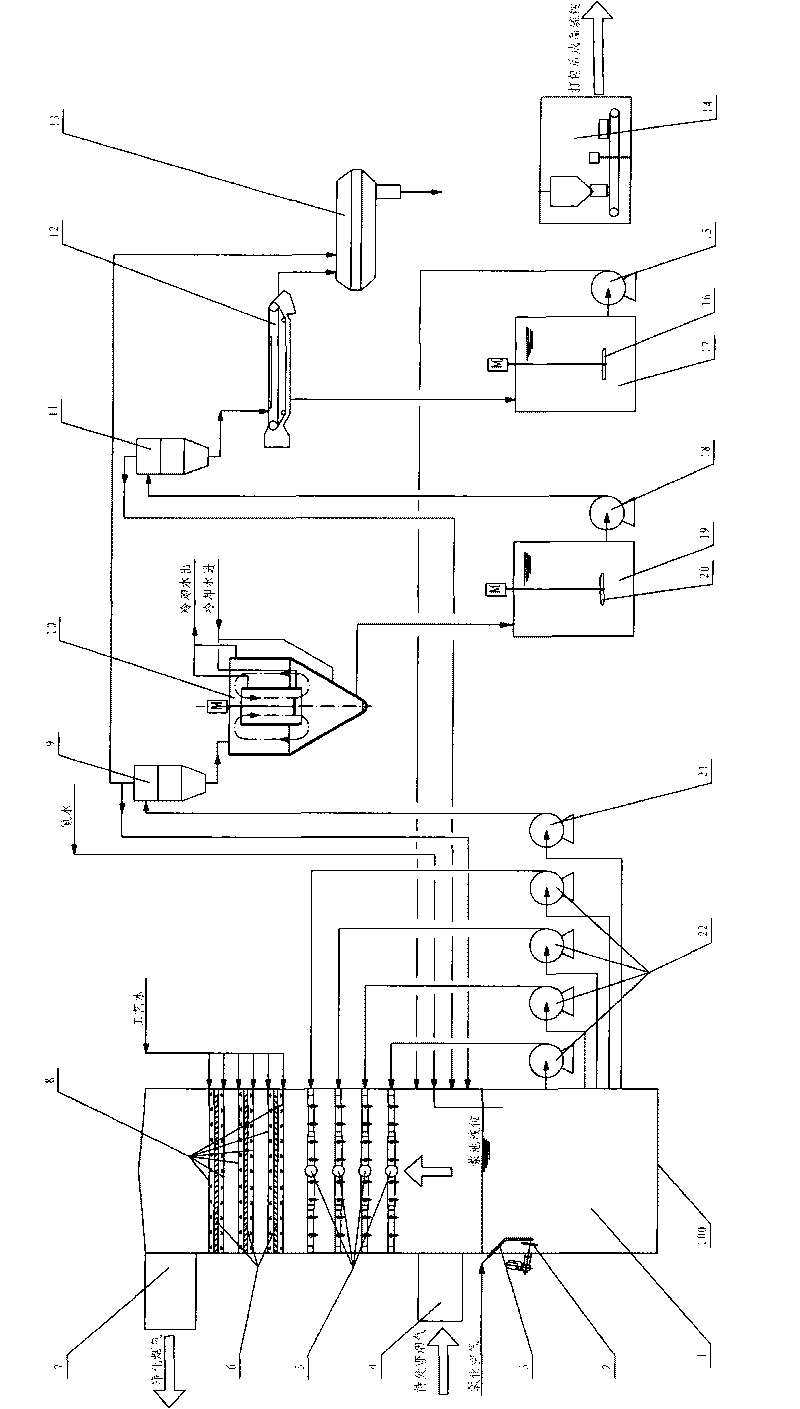

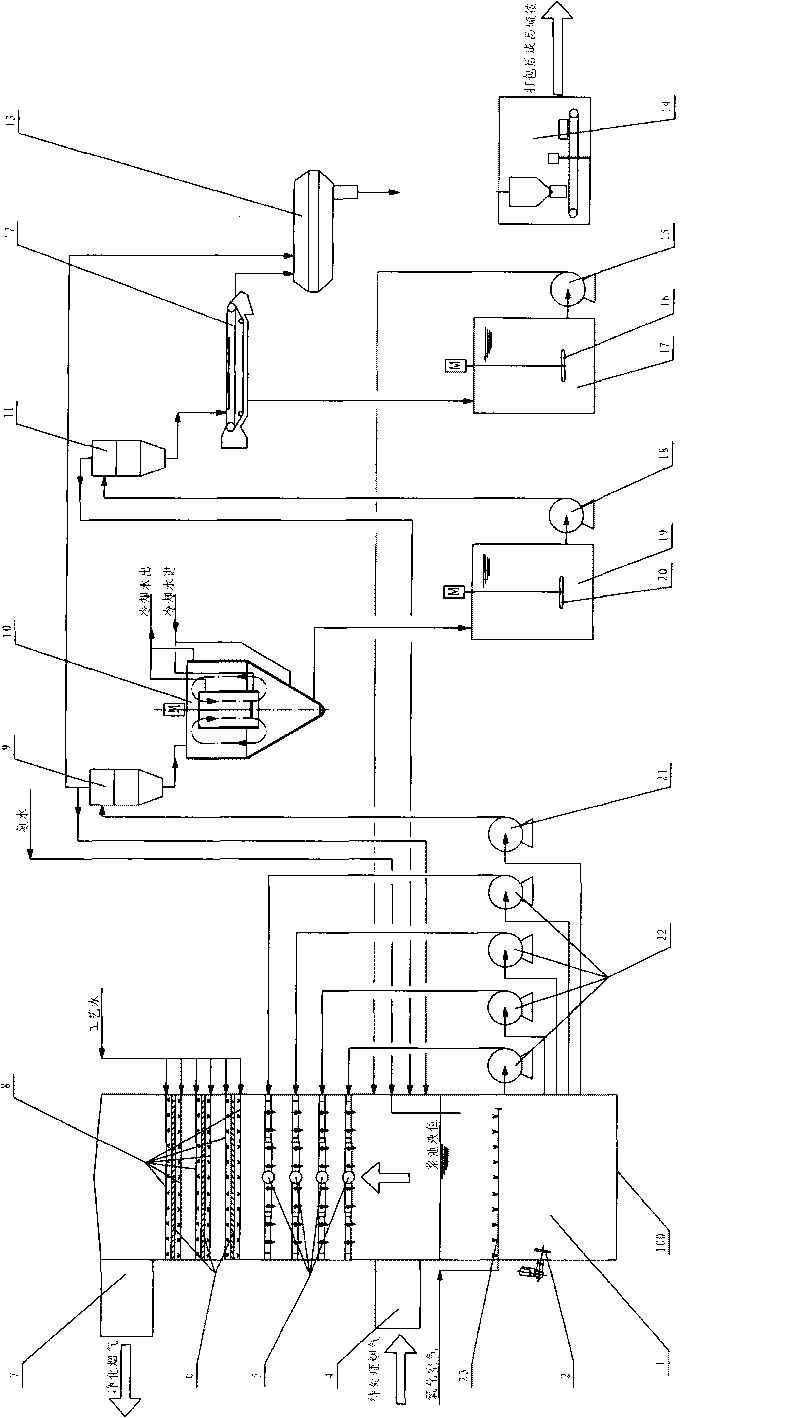

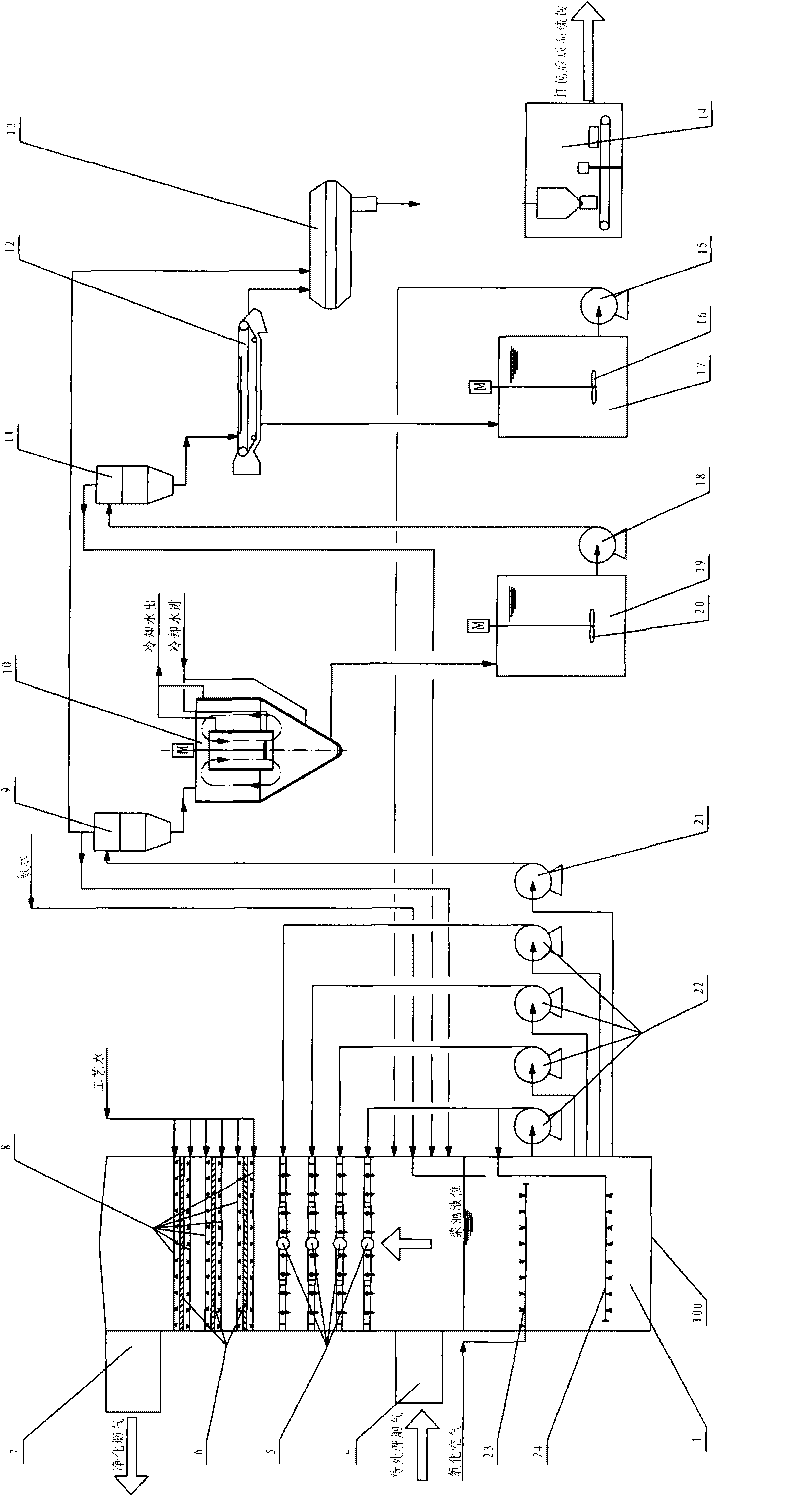

Process and device for processing smoke containing sulfur dioxide and preparing solid ammonium sulfate

InactiveCN101757848ADetermine the designSimple designDispersed particle separationAmmonium sulfatesSlurryRotational flow

The invention relates to a process and a device for processing smoke containing sulfur dioxide and preparing solid ammonium sulfate. The original smoke is purified after sprayed, washed and demisted by ammonium sulfate slurry; the sulfur dioxide in the smoke reacts with injected ammonia water and oxidation air to generate ammonium sulfate and form crystals; and after the ammonium sulfate slurry carries out cooling crystallization, primary rotational flow, secondary rotational flow, dehydration and drying, the solid ammonium sulfate is obtained. The device comprises an absorbing tower, a circulating pump, a cooling crystallizer, a primary whirlcone, a secondary whirlcone and dehydrating and drying equipment. The invention integrally finishes the absorption and the oxidation of the sulfur dioxide and the crystallizing process of the ammonium sulfate in the absorbing tower, sorts the ammonium sulfate crystals with larger particles by the cooling crystallizer and the two stages of whirlcones and can obtain an ammonium sulfate solid with lower energy consumption.

Owner:BEIJING BOOTES ELECTRIC POWER SCI & TECH

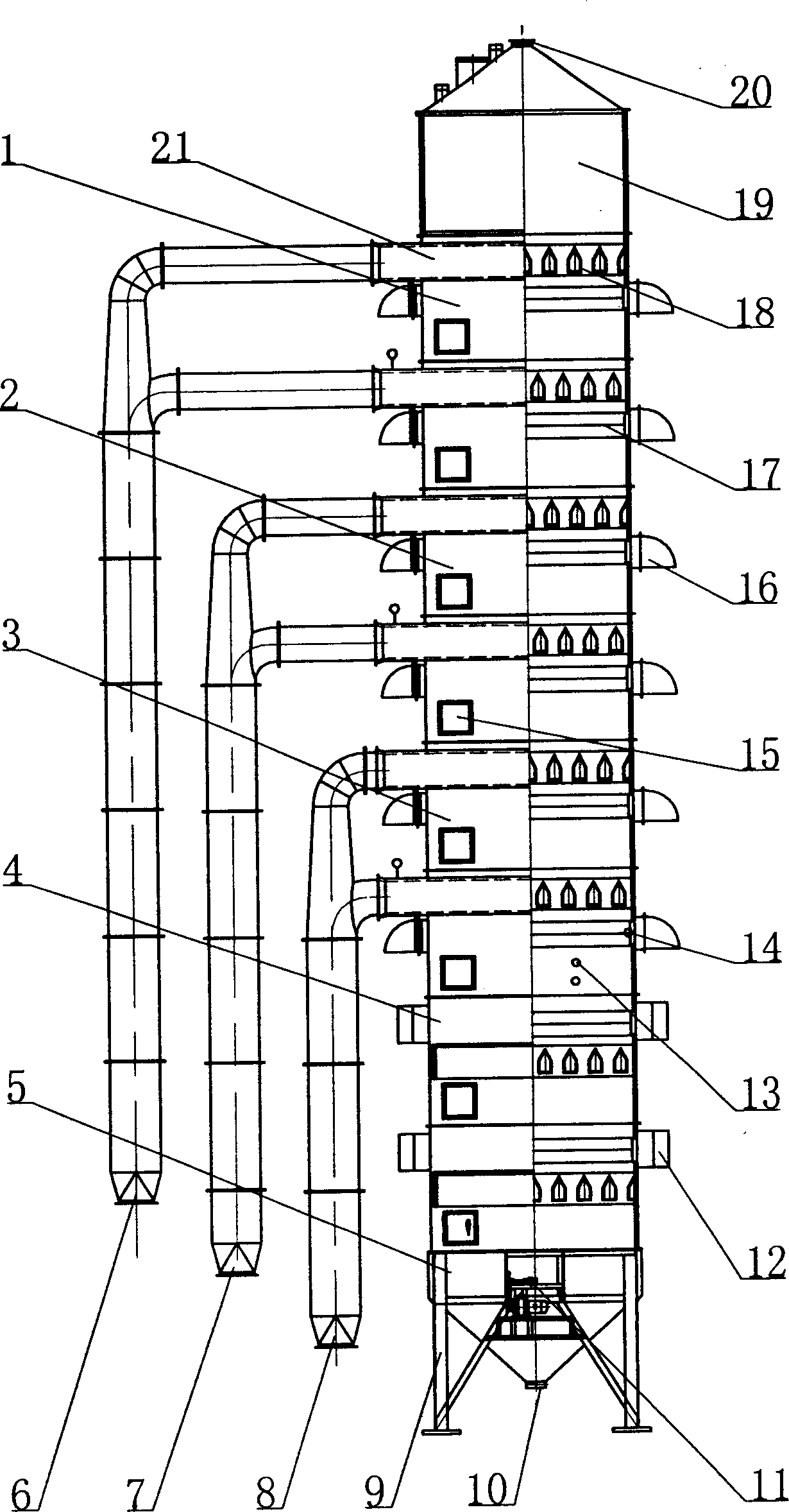

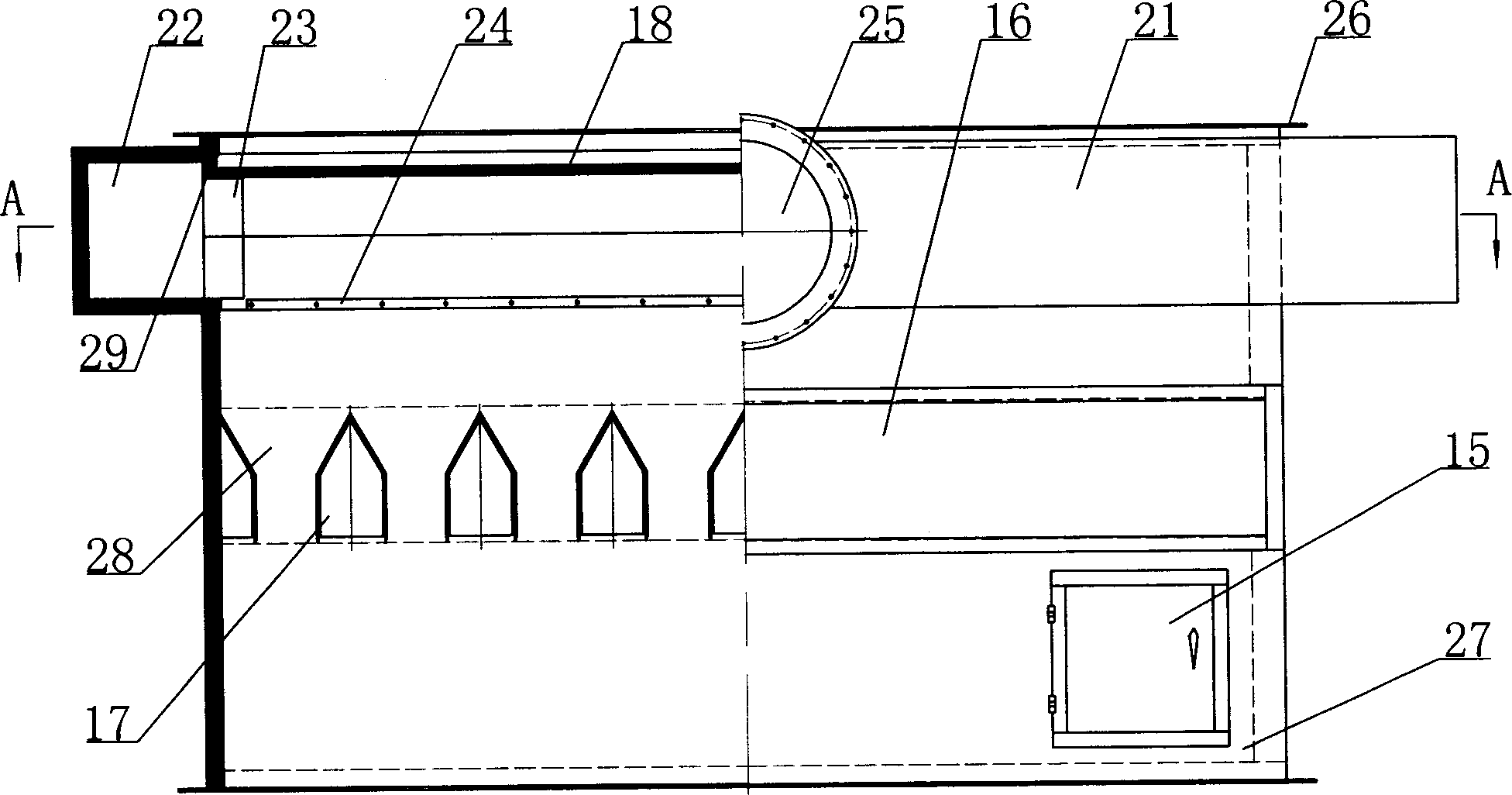

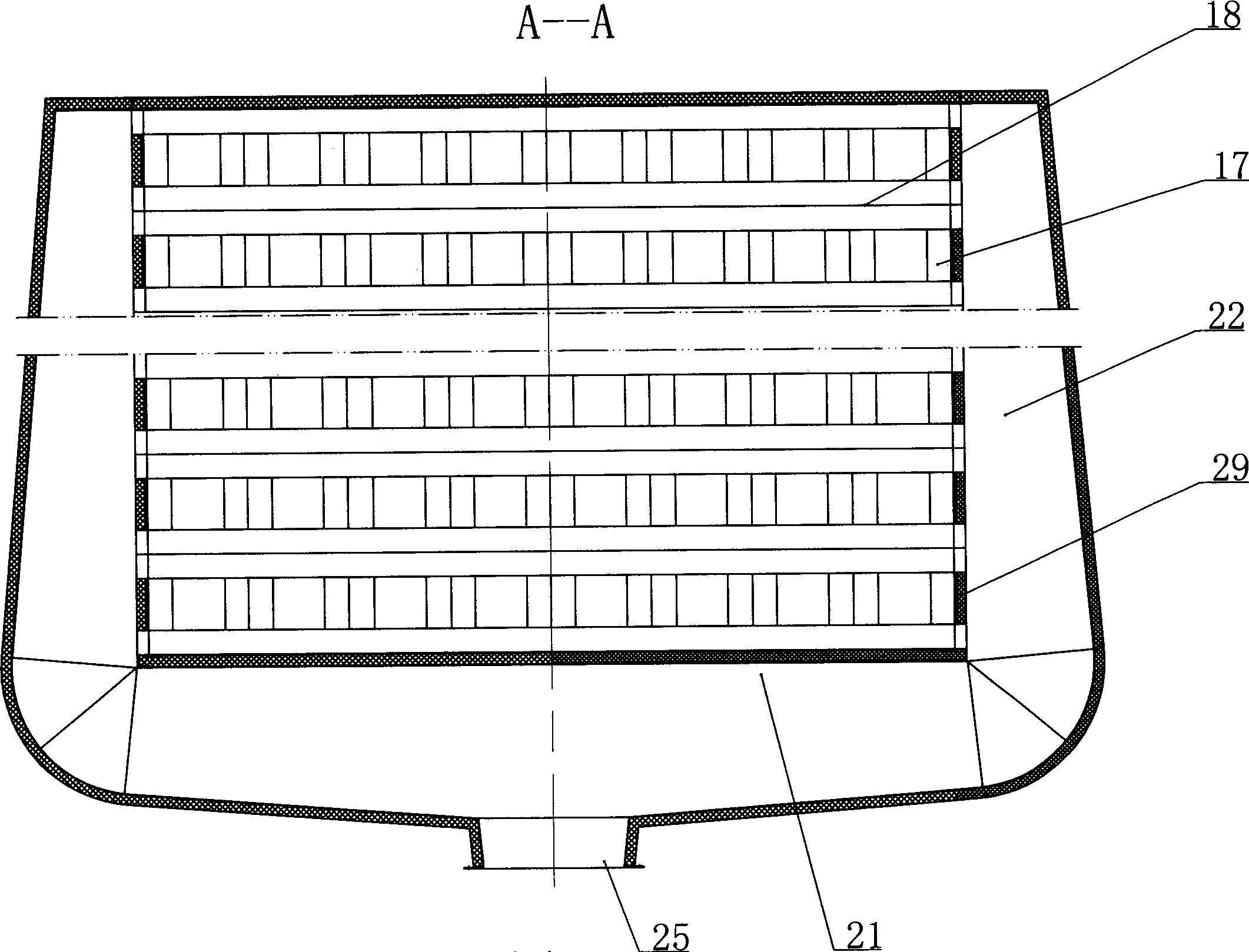

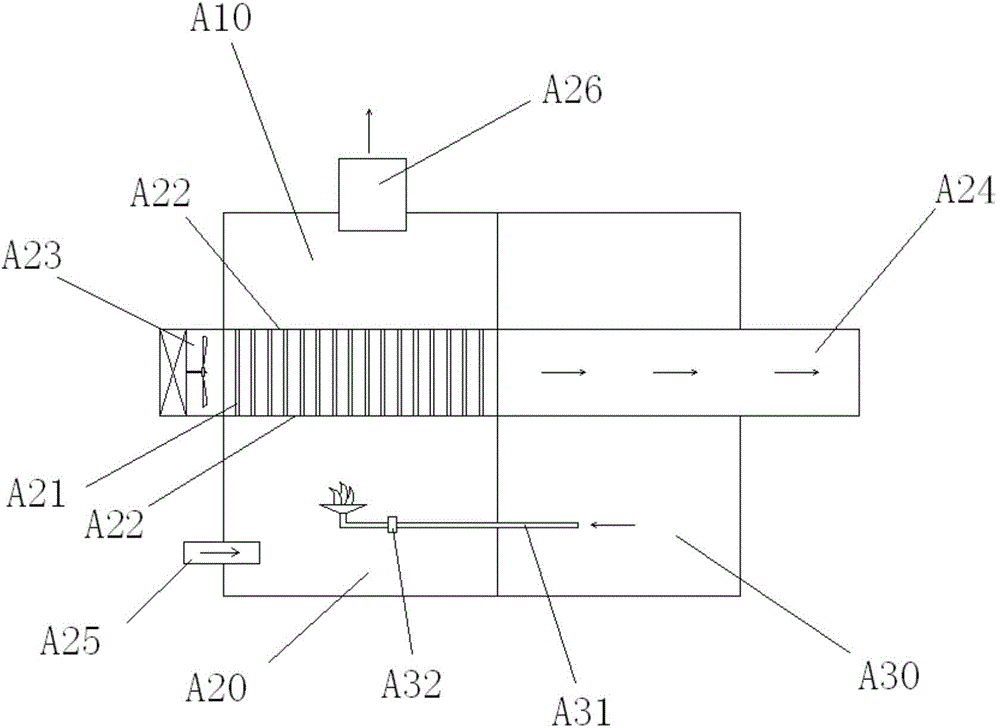

Raw state grain drying apparatus

InactiveCN1811310AReasonable structure matchingLess investmentDrying solid materials with heatHearth type furnacesEngineeringHeat control

The raw state grain drying apparatus includes storing barn, discharging barn and machine and controller in between. The machine includes wind guiding no-bottom boxes in sandwich or single wall structure and slowly dewatering cavities crossly arranged inside the machine body, at least one heat-controlling slow dewatering part and one cooling and slow dewatering part, a hot blast port, a moisture discharging port and a cold blast distributor. The present invention is superior to available technology, and has high grain stoving quality, reasonable dewatering process, easy operation, high control precision, low power consumption, low running cost, great once dewatering rate and other advantages.

Owner:辽宁中田干燥设备制造有限公司

Fermentation process of bean dregs

InactiveCN101584379ANot easy to dehydrateEvenly dehydratedAnimal feeding stuffPre treatmentFermentation

The invention provides a fermentation process of bean dregs, the bean dregs fermented after pretreatment, the material after the fermentation is subjected to dehydration working section to obtain finished products, the dehydration working section comprises the following steps that: the material after the fermentation is extruded so that moisture content of the material can reduce to 30-40%; the material is continually fed into a tube bundle hot-air drier for drying, the temperature of the tube bundle hot-air drier is controlled in a range from 50 to 70 DEG C so that moisture content of the material can reduce to 25-30%; the material is then fed into the hot-air drier for drying so that moisture content of the material can reduce to 13-15%, at last, the material is cooled by cold wind so that moisture content of the material can reduce below 12%. The invention uses the method of stepped dehydration to thereby shorten the time for dehydration and uses different dehydration methods at stages in which different moisture contents are present to thereby avoid the problem that when being directly dried by hot wind for dehydration at relatively high moisture content, the material becomes sticky and is liable to block, and to thereby enable dehydration of the material to be more even.

Owner:HENAN UNIVERSITY OF TECHNOLOGY +1

Chemical material finished product dehydration tank

ActiveCN109916155APrevent proliferationReduce moisture contentDrying gas arrangementsDrying machines with non-progressive movementsAir blowerDehydration

The invention belongs to the technical field of chemical machinery, in particular to a chemical material finished product dehydration tank comprising a frame body, a gas conveying mechanism, a diffusing mechanism, an air outlet mechanism, a dust removing mechanism, a circulation mechanism and a filtering mechanism; the gas conveying mechanism comprises a hot air blower, a gas conveying pipe and adispersing rod; the upper and lower ends of the dispersing rod are vertically and fixedly mounted on the upper and lower walls of the inner end of the frame body, the dispersing rod is internally provided with a dispersing groove, and the outer surface of the dispersing rod is evenly and fixedly connected with flow guide plates; the flow guide plates are arranged to be in a round cover shape, theflow guide plates are sealed through a circular pipe, a leaking hole is formed in the wall of the flow guide plate at the lowest end, and placing frames are arranged below the flow guide plates; the placing frames are arranged in round pipes, the inner sides of the placing frames are evenly and fixedly connected to the outer surface of the dispersing rod, and the lower walls of the placing framesare internally provided with gas separation grooves. The chemical material finished product dehydration tank is mainly used for solving the problems that an existing dehydration tank cannot completelydehydrate chemical materials, and energy is wasted in the dehydration process.

Owner:双键化工(泰兴)有限公司

Vegetable dehydration-drying machine

InactiveCN105249502AEvenly dehydratedDehydration and drying evenlyFood treatmentAgricultural engineeringHot blast

The invention discloses a vegetable dehydration-drying machine which comprises an exhaust fan, a high-temperature hot-blast stove, a feeding inlet, an outer wall, a screen, stirring rods, a rotating shaft, a water outlet pipe, a water tank, a water inlet pipe, a water-cooling machine, a water outlet, a discharging outlet, a machine seat and a motor, wherein the exhaust fan is connected with a machine body through an air inlet, and fixedly mounted on the machine seat; the high-temperature hot-blast stove is connected with an inter wall through an air pipe; a heating block is arranged in the high-temperature hot-blast stove; the feeding inlet penetrates through the outer wall, the inner wall and the screen, and is fixedly mounted at the upper left end of the machine body; the inner wall is arranged between the outer wall and the screen; the outer wall is connected with the water tank through the water inlet pipe and the water outlet pipe; the discharging outlet is arranged at the lower right corner of the machine body; the motor is fixedly connected with the machine seat through a supporting platform; the motor is rotationally connected with the stirring rods through the rotating shaft. The vegetable dehydration-drying machine needs not to be shut down in a charging process, and the original color and luster of vegetables can be kept after dehydration, so that the heat efficiency is high, and the quality is guaranteed.

Owner:LEIYANG XINGNONG ANIMAL HUSBANDRY CO LTD

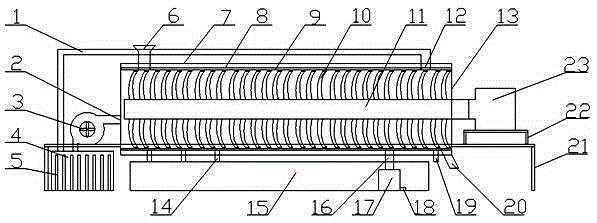

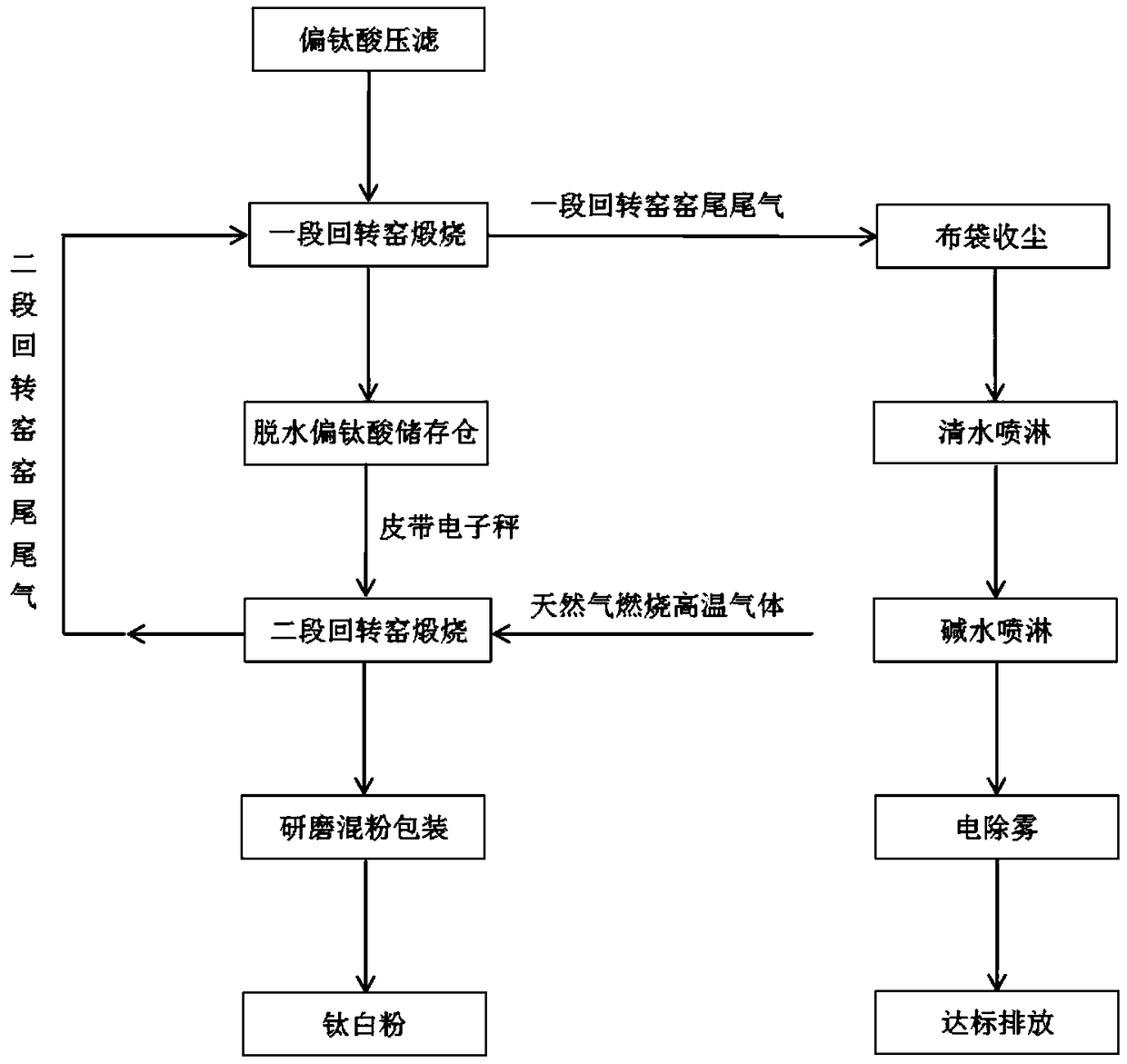

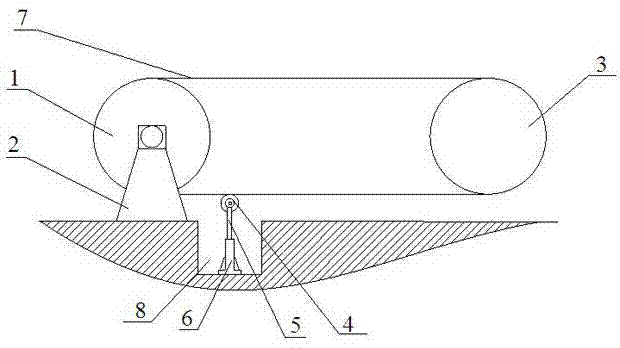

Method for preparing titanium dioxide by calcining metatitanic acid in double-section rotary kiln

ActiveCN108793244AImprove calcination recoveryEffective temperature controlTitanium dioxideGrain growthEnergy consumption

The invention discloses a method for preparing titanium dioxide by calcining metatitanic acid in a double-section rotary kiln. The method comprises the following steps: enabling metatitanic acid afterfilter pressing to successively perform dehydration in a first-section rotary kiln for calcining, and perform desulfuration, crystal type transform and grain growth in a second-section rotary kiln for calcining, to obtain a kiln falling product, and performing grinding and powder mixing on the kiln falling product, wherein a heat source of the second-section rotary kiln for calcining is from a high-temperature gas generated by calcining a natural gas, a heat source of the first-section rotary kiln for calcining is from a kiln tail gas generated by the calcining of the second-section rotary kiln, and the kiln tail gas generated by the calcining of the first-section rotary kiln successively passes through a dust collecting chamber and a bag dust collector for recovering kiln tail dust. Themethod is capable of improving the quality of the titanium dioxide, and improving a calcining recovery rate of the rotary kiln, wherein the recovery rate is up to 99.8%. The energy consumption of thenatural gas is reduced by 30-45%, and a usage amount of the natural gas is reduced.

Owner:CNMC GUANGXI PGMA

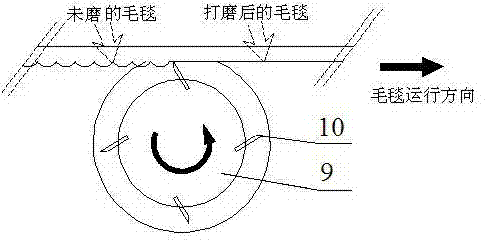

Paper making felt setting machine

ActiveCN103882650AEvenly dehydratedImprove page qualityHeating/cooling textile fabricsElectric machineryThermal treatment

The invention discloses a paper making felt setting machine which comprises a motor, a hot oil roller, a tensioning roller and a cutting and polishing device, wherein the motor drives the hot oil roller to rotate; a paper making felt is tensioned between the hot oil roller and the tensioning roller; the position of the cutting and polishing device is adjustable; when the cutting and polishing device is adjusted to be contacted with the surface of the paper making felt, the surface of the paper making felt is cut and polished. The paper making felt setting machine is provided with the cutting and polishing device, a mechanical polishing mode is adopted, the uneven surface of the paper making felt is cut and polished through the cutting and polishing device, felt mark is difficultly formed on the paper surface when the obtained paper making felt setting machine is used, the paper dehydration is uniform, and the quality of the paper is improved. The paper making felt setting machine is simple in structure and convenient to use, the hardened surface of the paper making felt subjected to heating treatment of the hot oil roller can be removed, and the paper dehydration efficiency is improved.

Owner:JIANGSU JINNI ENGINEERED FABRIC CO LTD

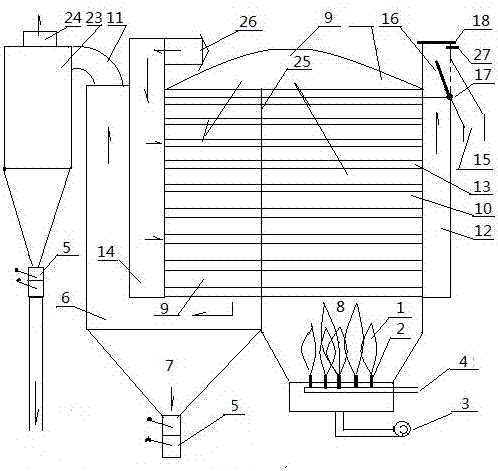

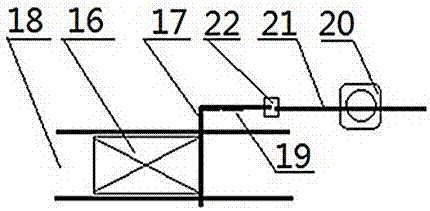

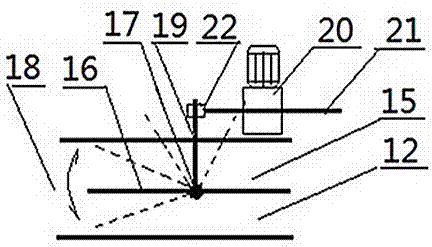

Fuel gas hot blast stove

InactiveCN107957137AImprove product qualityEvenly dehydratedDrying gas arrangementsAir heatersCombustion chamberAir filter

The invention discloses a fuel gas hot blast stove. The hot blast stove comprises the fuel gas flame, nozzles, an air return pipe, a lower ash bucket, a hot blast stove combustion chamber, an air return chamber, a main air chamber, an air outlet pipe, a hot air flue air outlet chamber, a hot air exchange pipe, a hot air flue air inlet chamber, a cold air pipe, an adjustable air door, an air door shaft, a hot air exhaust port, an air door shaft connecting lever, an electric screw motor, an electric screw, a dust remover, a dust remover exhaust pipe, a middle partition plate, an air filter and atemperature sensor; and the hot blast stove is characterized in that the hot blast stove is internally provided with an air blower, a heat exchanger is provided with the lower ash bucket, and an ashdischarging valve is used for automatically locking the air and discharging the ash; the hot air subjected to the heat exchange passes through the dust remover and is discharged to a chimney through an induced draft fan; a hot air exchange pipe is arranged between a secondary hot air flue main air chamber and the air return chamber and is made of stainless steel materials; the air exchanges heat through the hot air exchange pipe and then reaches a secondary hot air exhaust port; the electric screw is controlled by an thermo-sensitive adjusting device to enable the adjustable air door to undergo the thermo-sensitive adjustment, and constant-temperature air discharging is achieved. The exchange furnace is simple in design and high in exchange rate, is a very ideal constant-temperature dryingair source for grains and can be widely popularized.

Owner:杨朴

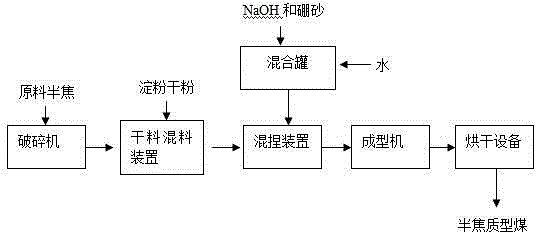

Method for producing semicoke briquette coal based on dry biomass binder

ActiveCN104673420ANot easy to decomposeImprove adhesionSolid fuelsWaste based fuelBriquetteAqueous solution

The invention discloses a method for producing a semicoke briquette coal based on a dry biomass binder. The method comprises the following steps: smashing the raw material semicoke into semicoke powders, uniformly mixing the semicoke powders with the starch dry powders by sending into a dry material mixing device, fully mixing the mixture with a NaOH and borax mixed water solution by sending into a mixed kneading device, performing extrusion forming in a forming machine to obtain a briquette coal wet pellet, baking the briquette coal wet pellet till the water content is less than 2%, cooling and packaging to obtain the semicoke briquette coal. By adopting the method for producing the semicoke briquette coal by using the biomass binder prepared by a dry method, the binder components are added in batches, high in accuracy, simultaneously separated and mixed, easy to mix and short in mixed kneading time; in the mixed kneading, forming and drying processes, the inside reaction rims of the binder components and the raw material semicoke are bound, the dewatering is uniform in the drying process, the briquette coal is hard to crack and the whole pellet rate is high.

Owner:新疆乾海环保科技有限公司

Rapid forming method for fly pupas

The invention relates to a rapid forming method for fly pupas and belongs to the technical field of ecological breeding methods. The rapid forming method includes the six steps of pupation basin designing, pupa expediting material designing, dewatering, pupating, separating and storing. In detail, the rapid forming method includes the steps that a plastic basin with the specification of 80cm*60cm*15cm is selected to serve as a pupation basin, and the color is white; pupa expediting material is prepared; then the pupa expediting material and the fly pupas are added into the pupation basin according to the proportion of 1:2 by weight and mixed slightly, and meanwhile a 6-7cm height is reserved in the basin to prevent adult maggots from climbing out; temperature is controlled to be 33-38 DEG C, meanwhile, sufficient oxygen are supplied, the fly maggots are stirred one time per 6 hours, in the stirring process, the fly maggots which have become puce are stirred upwards as far as possible, and the fly maggots are completely pupated within 48-60 hours; when all the adult maggots in the pupation basin become puce, a 30-mesh sieve is used for sieving and separating the pupa expediting material and the pupas at once; the separated pupas are transferred into a pupa storage device for storage. By the adoption of the method, pupation is rapid and easy, operation is easy, besides, the activity storage of the fly pupas is good, and the hatching rate of the pupas is high.

Owner:JIANGMEN XINTAI BIOLOGICAL PROTEINS

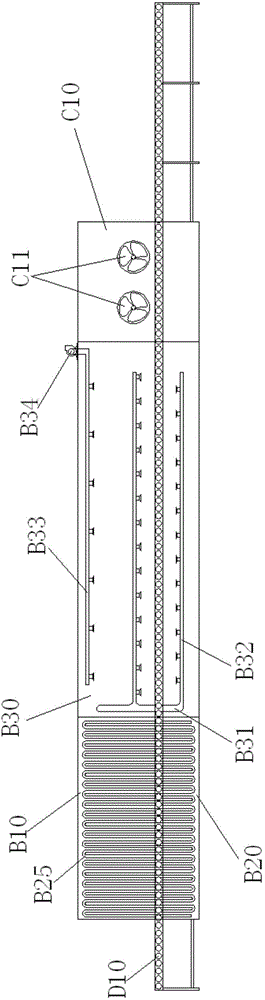

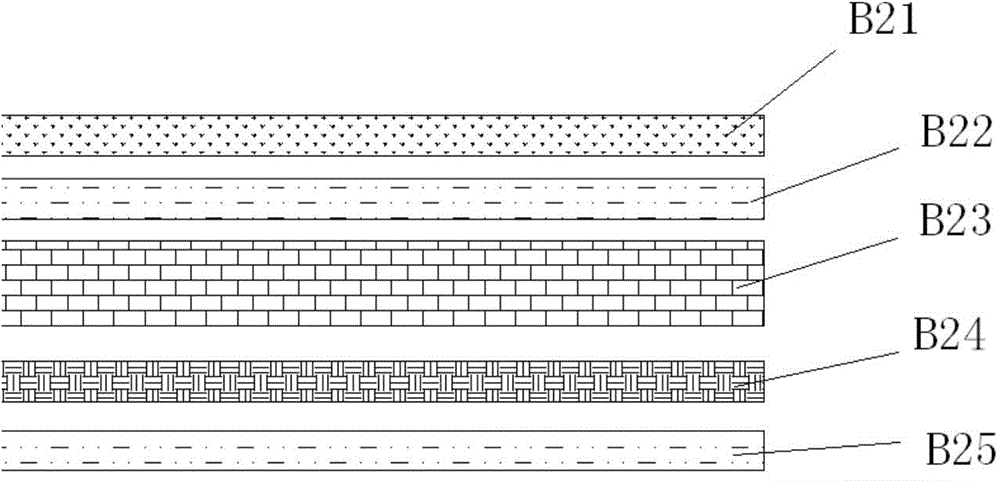

Veneer timber drying equipment

ActiveCN104567307AEvenly dehydratedImprove quality and efficiencyDrying gas arrangementsDrying machines with progressive movementsThermal energyHigh energy

The invention relates to veneer timber drying equipment, which comprises a heating unit, a drying unit, a cooling unit, an automatic stacking unit and a conveying line. Because a preheating area is arranged in front of a high-temperature area of the drying unit, veneers can be pre-dehydrated before being dried, middle temperature difference transition is smooth, and uniform and deep dehydration during drying is facilitated, so the product quality and the production efficiency are increased; meanwhile, the outer layer of the preheating area is provided with heat-absorbing coating for converting solar energy into heat energy, so no pollution is emitted. The veneer timber drying equipment perfectly solves the technical problems of nonuniform drying, high energy consumption and low efficiency existing in the prior art.

Owner:佛山市海科专利投资运营有限公司

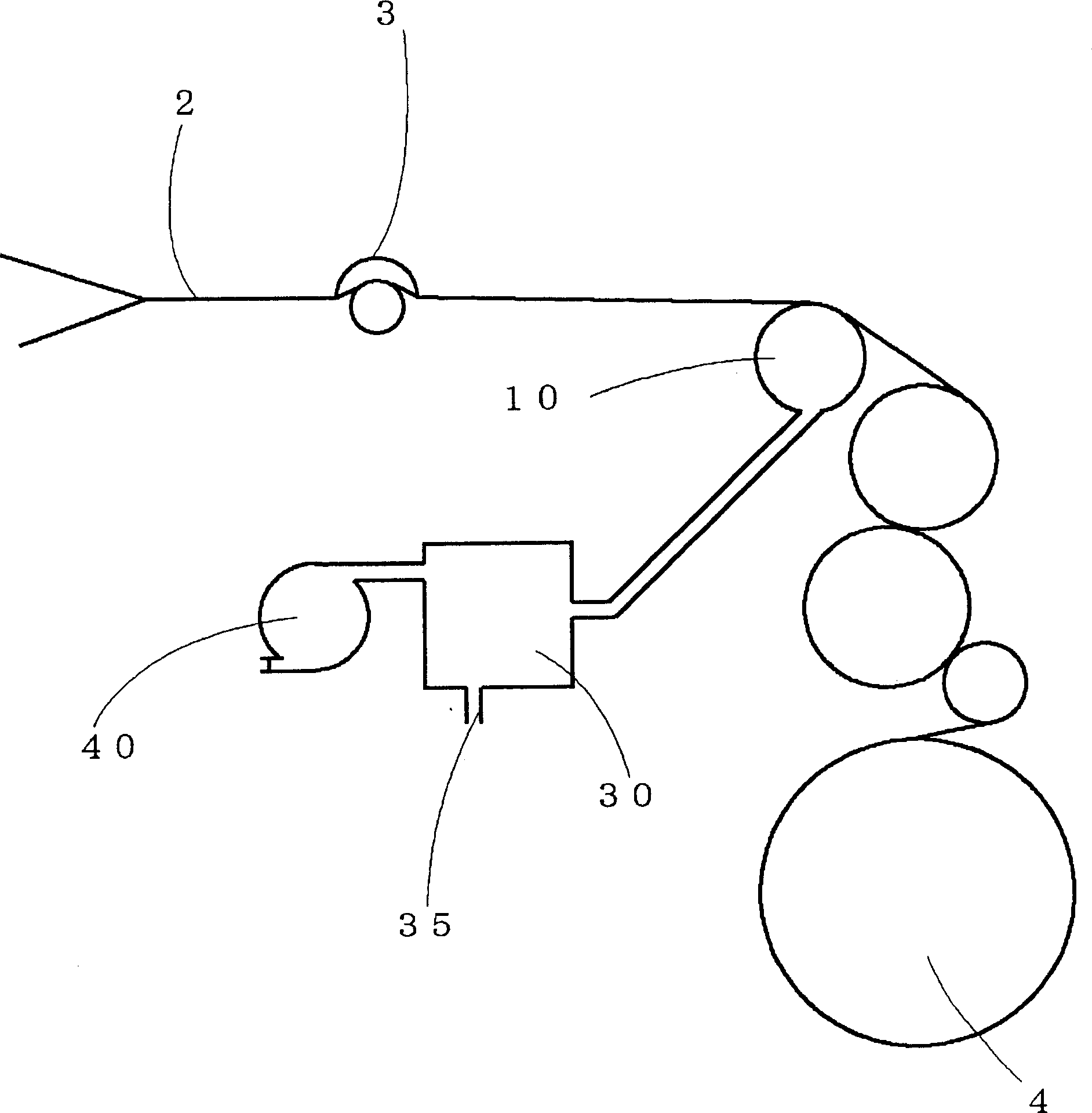

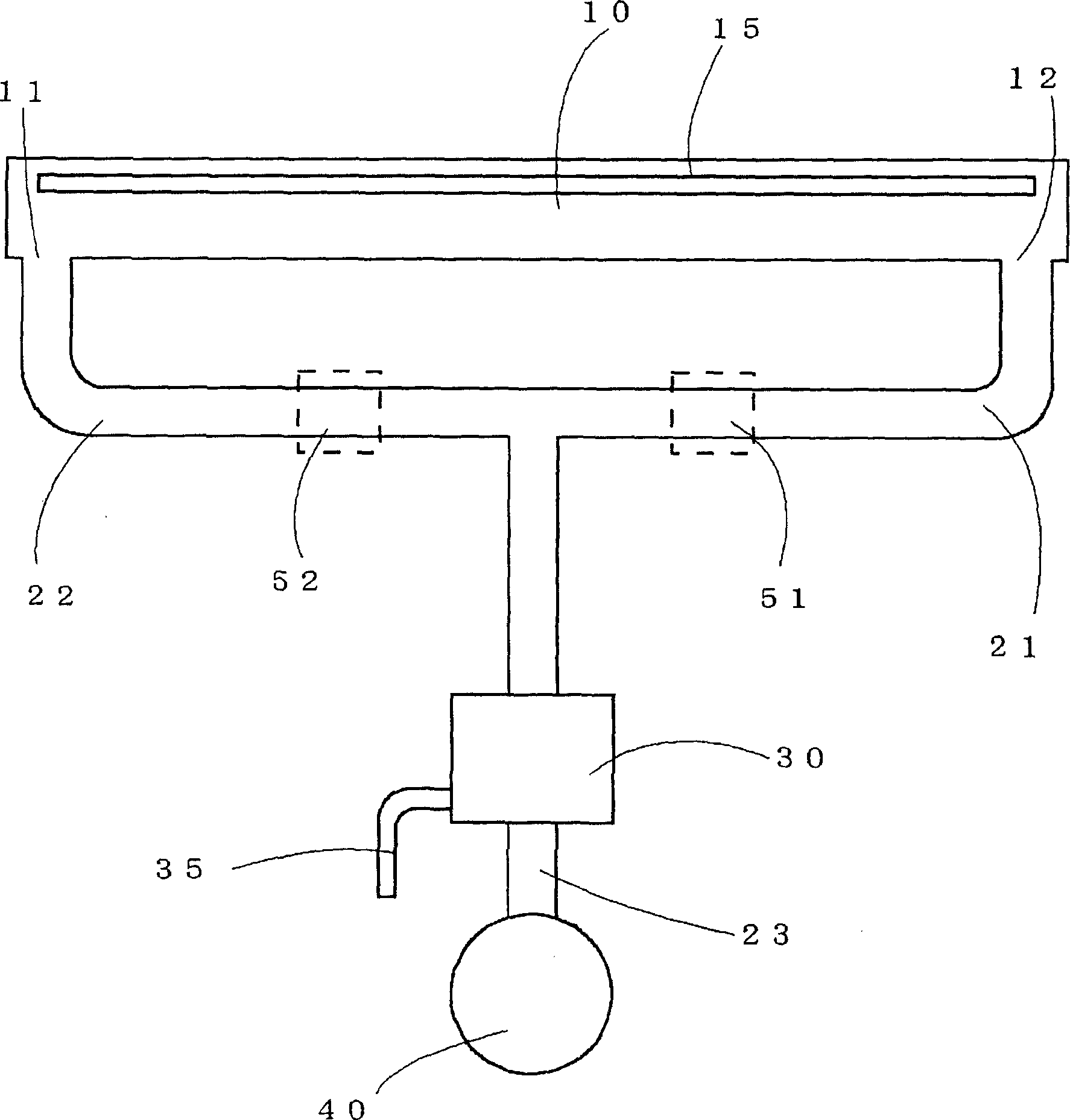

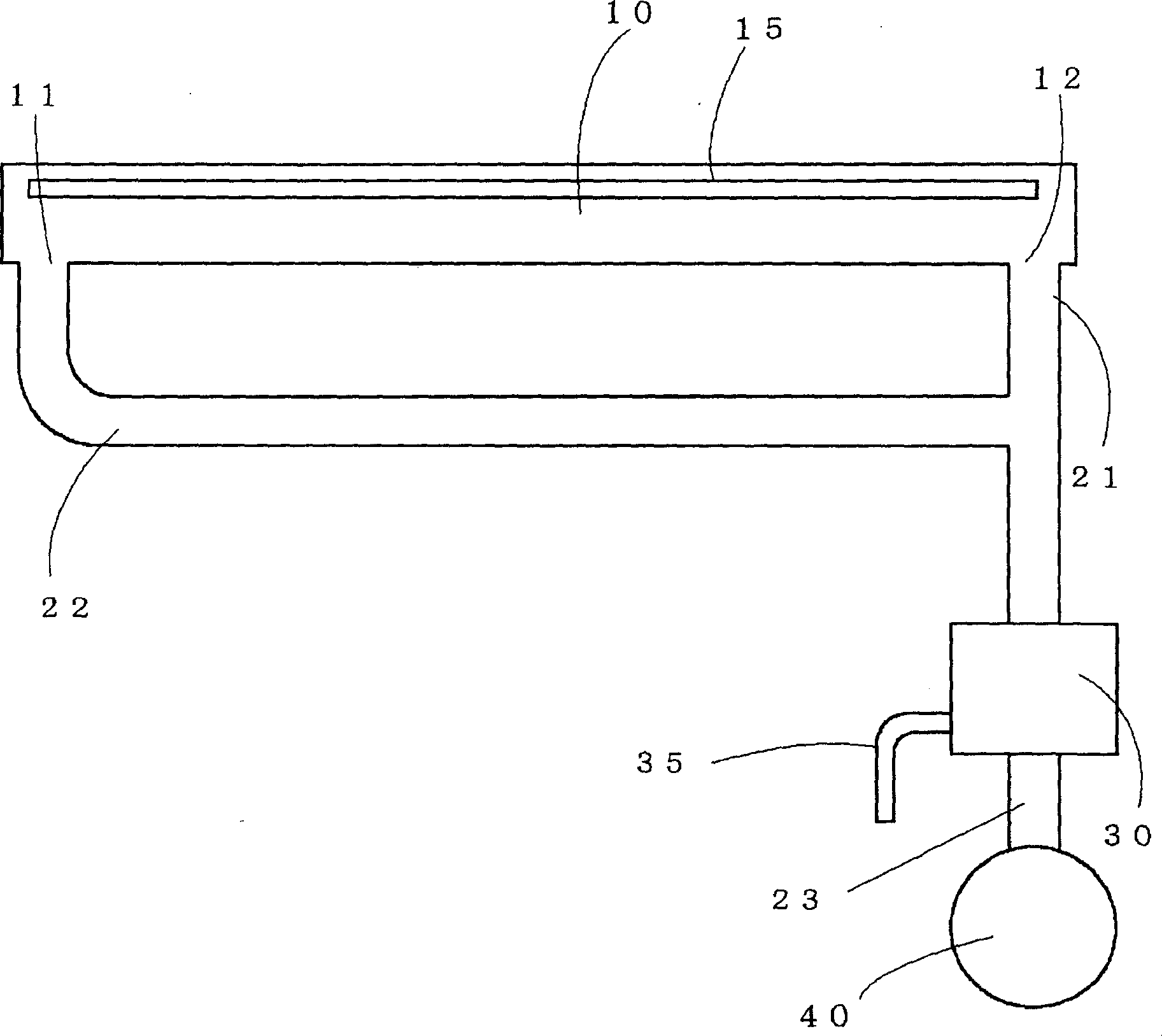

Dewater device of water-jet loom

InactiveCN1724736AEvenly dehydratedUniform moisture contentLoomsAuxillary apparatusYarnAgricultural engineering

The invention provides a machine dehydration plant of the water spray weaving machine, consisting of a pumping pipe, a moisture trap, an aspirator, a first connecting pipe, a second connecting pipe, a third connecting pipe, wherein the pumping pipe is arranged between the frame of the loom and is provided with an attracting opening which contacts the fabric; the first connecting pipe is connected with the common moisture trap from the anti-yarn feeding lateral terminal part of the pumping pipe; the second connecting pipe is connected with the moisture trap from the yarn feeding lateral terminal part of the pumping pipe; the third connecting pipe connects the moisture trap and the aspirator; the pressure loss of the first connecting pipe is equal to or less than the pressure loss of the second connecting pipe. The machine dehydration plant of the water spray weaving machine is capable of keeping the water ratio of dehydrated fabric more evenly.

Owner:TSUDAKOMA KOGYO KK

Toothed pressure-maintaining filter-pressing method and equipment

ActiveCN105561645AAvoid instabilityImprove dehydration effectMembrane filtersFiltration separationHydraulic cylinderInstability

The invention relates to a toothed pressure-maintaining filter-pressing method and equipment. The toothed pressure-maintaining filter-pressing method comprises a prepressing process, a feeding process, a primary squeezing process and a secondary squeezing process, the secondary squeezing process is a segmented toothed squeeze dewatering process, a hydraulic cylinder is driven to act so that pressure values in all segments are increased gradually, when the squeezing pressure value reaches a first set pressure value, the hydraulic cylinder is driven to act to reduce the squeezing value to a second set pressure value, and operation of the next segment is executed. According to the toothed pressure-maintaining filter-pressing method and equipment thereof, pressure of the hydraulic cylinder can be in a steadily increased state, instability of pressure of the hydraulic cylinder is avoided, a material and a filter-pressing plate are transiently buffered when being squeezed, the filter-pressing plate is protected to a certain degree, the material dewatering effect is greatly improved, the dewatering process is stable, dewatering efficiency is high, and resources are saved.

Owner:福建省创绿机械股份有限公司

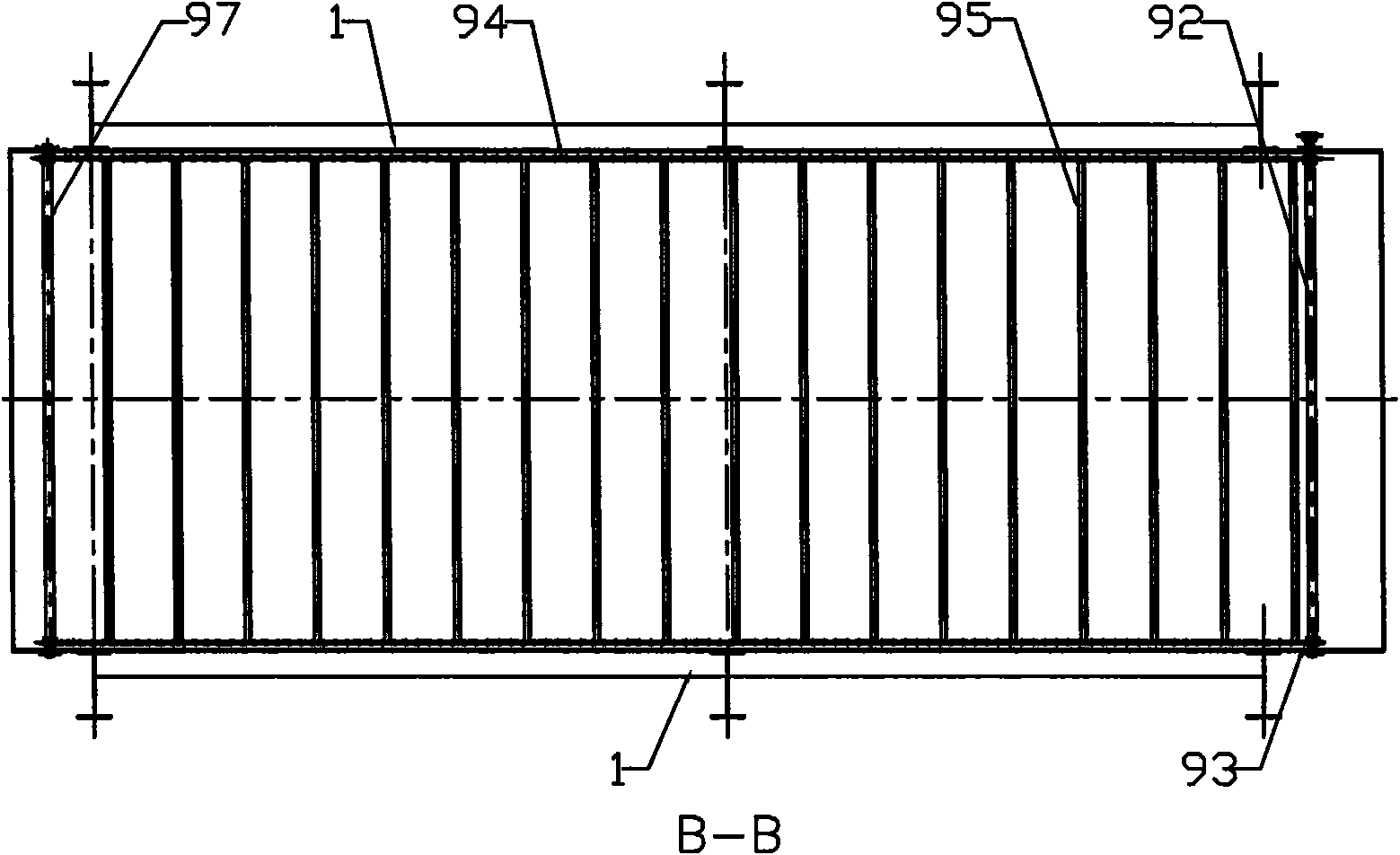

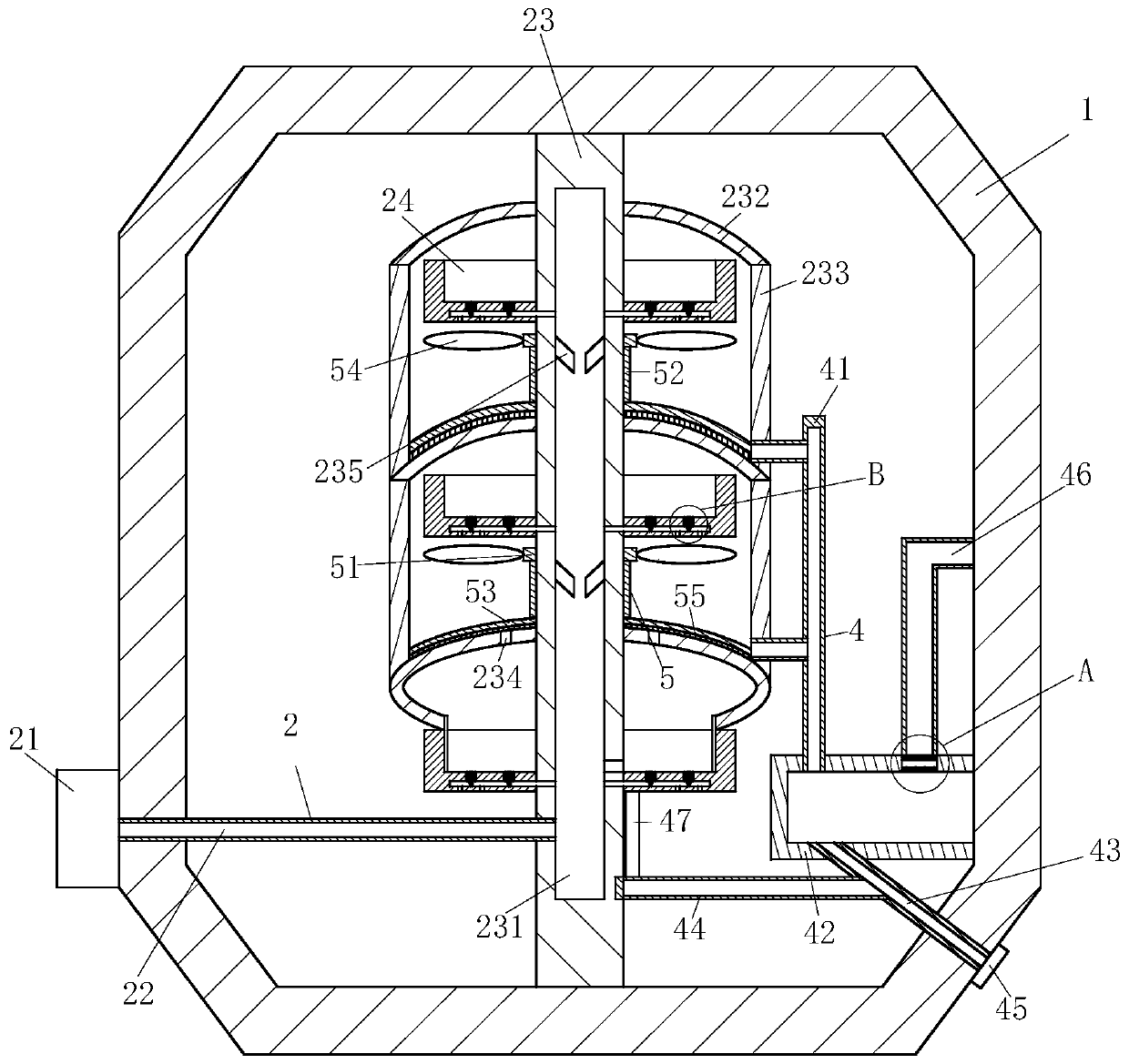

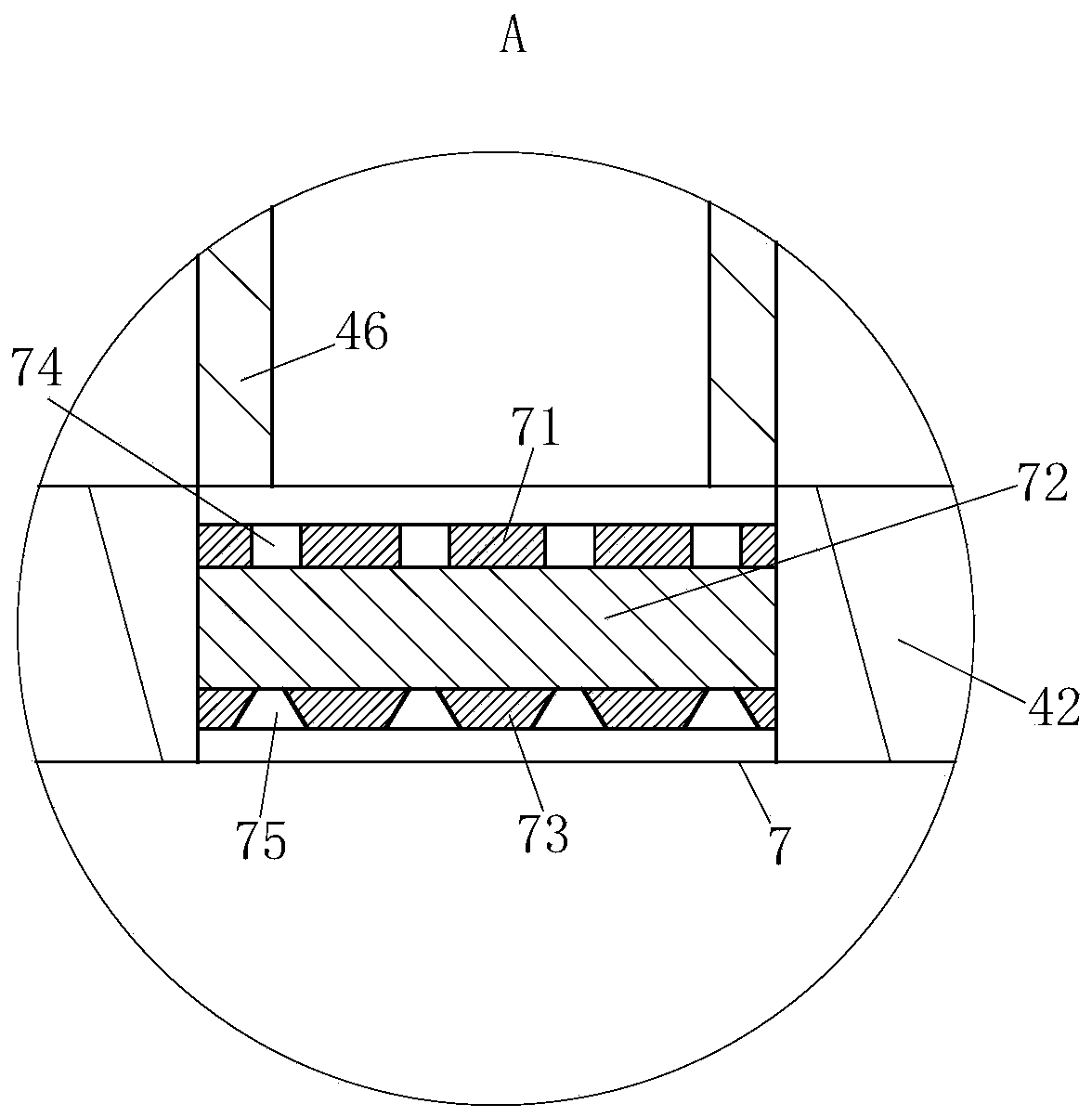

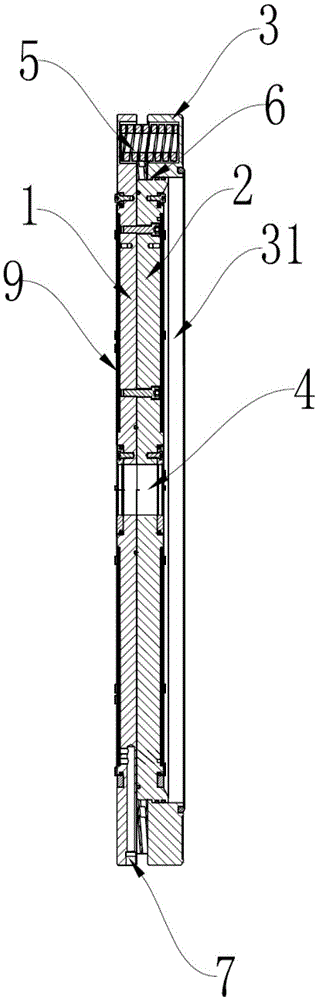

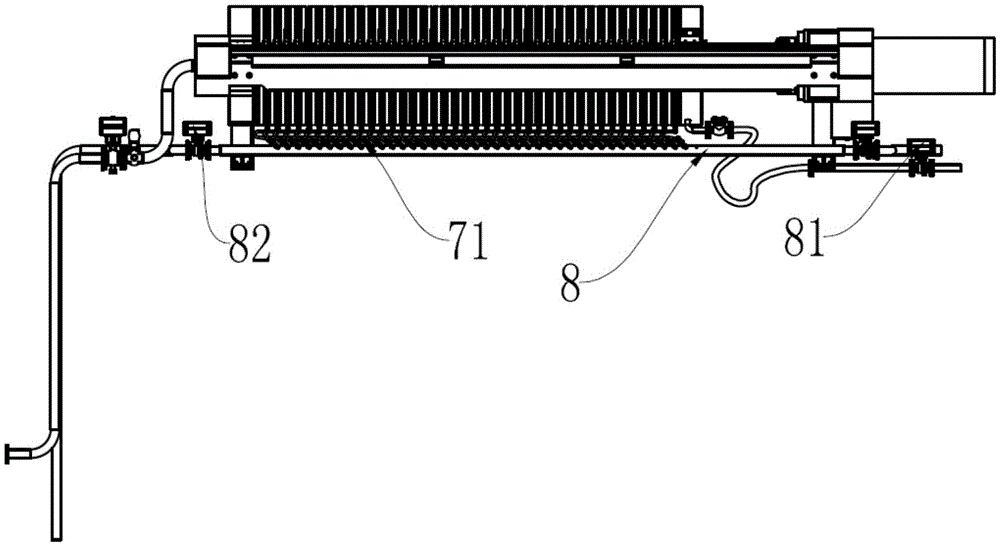

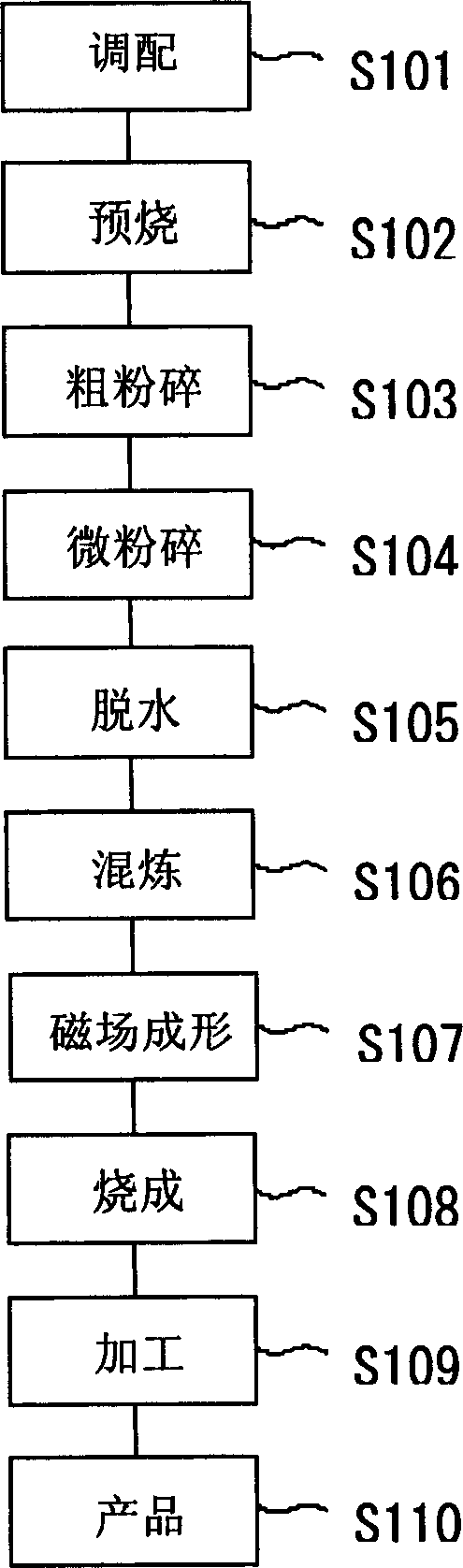

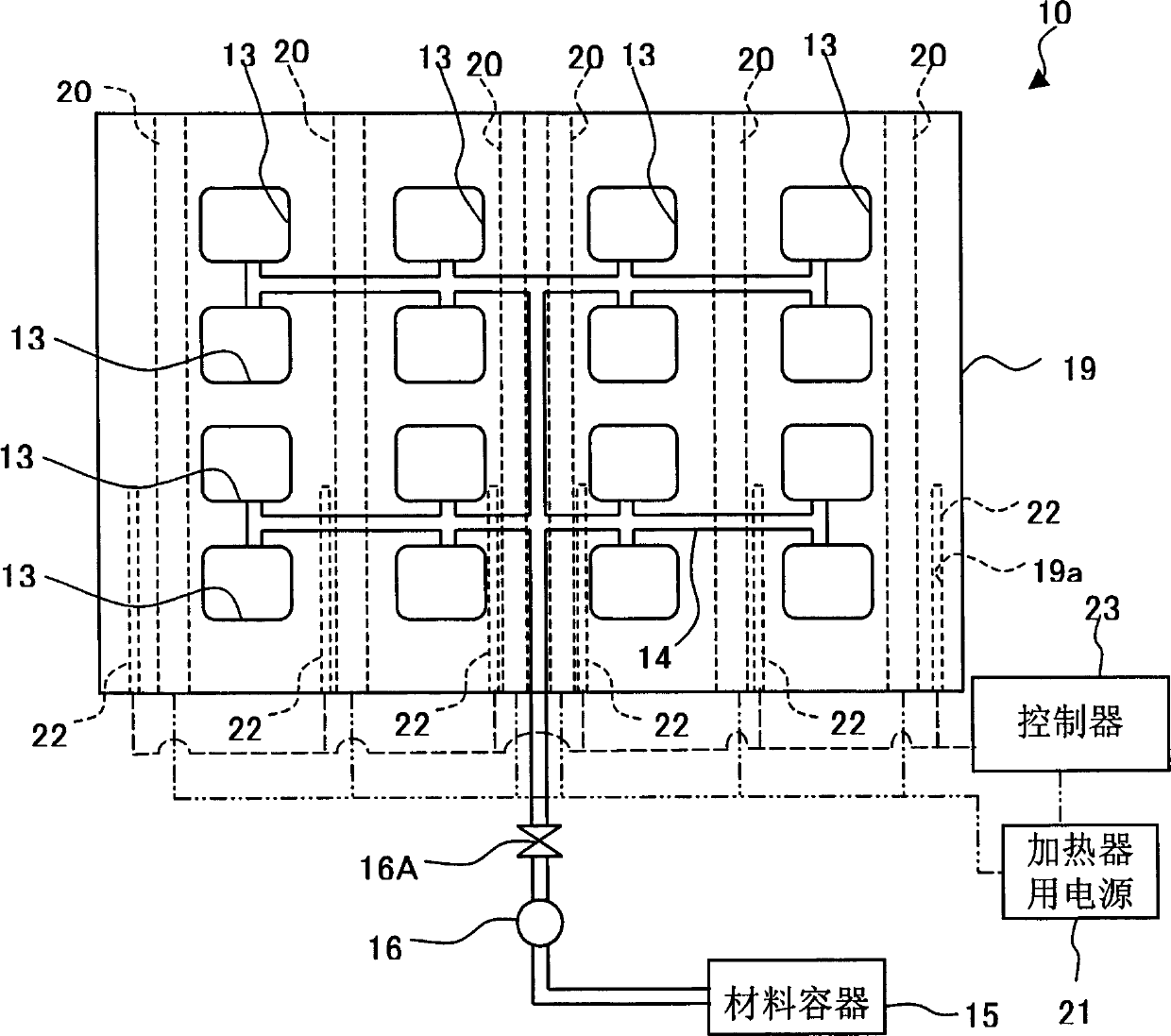

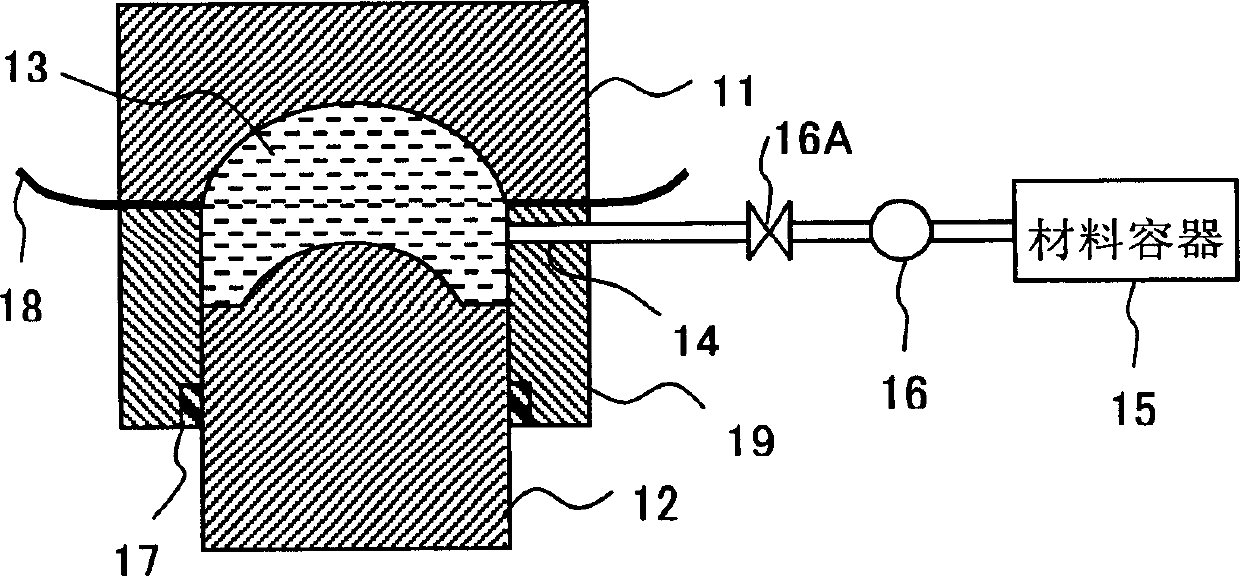

Magnetic field generating apparatus, method for manufacturing ferrite magnet, and mold

ActiveCN1764991ALow viscosity coefficientUniform densityCeramic shaping apparatusInductances/transformers/magnets manufactureEngineeringSlurry

An object of the present invention is to provide a magnetic field shaping device, a ferrite magnet manufacturing method, etc., which can improve the yield of the manufacturing process and stabilize the quality. When performing magnetic field shaping, a female mold (19) having a plurality of mold cavities (13) is heated to a predetermined temperature by a heater member (20) under the control of a controller (23). As the heating temperature, it is preferable to control with the controller (23) so that the temperature (T1) of the female mold (19) detected by the sensor (22) is 40°C or more. In this way, by heating the female mold (19), the temperature of the molding slurry in the cavity (13) can be increased, so that the dehydration property can be improved, and the yield of the product can be improved.

Owner:TDK CORPARATION

Non-woven fabric dyeing and dewatering box capable of making non-woven fabric subjected to uniform dewatering after dyeing

ActiveCN110453417AEvenly dehydratedUniform dyeingLiquid/gas/vapor removal by suctionPulp and paper industryNonwoven fabric

The invention relates to the technical field of dyeing of non-woven fabrics, and discloses a non-woven dyeing dewatering box capable of making a non-woven fabric subjected to uniform dewatering afterdyeing. The box comprises a box body, a feed inlet is formed in the left side of the box body, a dustproof plug is fixedly connected to the interior of the feed inlet, air outlets are formed in the portions, located above the feed inlet, of the two sides of the box body, an exhaust fan is fixedly connected to the interior of each air outlet, liquid sucking openings are uniformly formed in the surface of a bellows, liquid sucking fans are fixedly connected to the interiors of the liquid sucking openings. A heating rod is fixedly connected to the axis of each hollow shaft, eight breather pipes are uniformly arranged in the hollow shafts, and a blow fan is fixedly connected to the bottom of each breather pipe. The non-woven dyeing dewatering box capable of making the non-woven fabric subjected to uniform dewatering after dyeing can be matched with a wind plate through the bellows for use, and by combining cooperative use of the liquid sucking fan and the liquid sucking openings and cooperative use of wind holes and support shafts, the effect that fabric dyeing is uniform is achieved.

Owner:SUZHOU KANGFU INTELLIGENT TECH CO LTD

Ozone-hydroxyl free radical combined catalytic oxidation sludge conditioning method

ActiveCN106348560ASmooth sludge dewateringMoisture content is stableSludge treatment by de-watering/drying/thickeningSludge treatment by oxidationFerrous sulfate heptahydrateChemistry

The invention discloses an ozone-hydroxyl free radical combined catalytic oxidation sludge conditioning method. The method includes following steps: adding sludge with water content of 92-99.5% into a mixed solution of ferrous sulfate heptahydrate and sulfamic acid for mixing reaction; adding a liquid-state hydrogen peroxide for mixing reaction; enabling a product after reaction to enter a reinforced reaction tank for aeration treatment to realize sludge oxidation wall breaking, wherein gas is generated by a low-temperature plasma reactor and contains ozone and hydroxyl free radicals and free electrons; enabling a sludge product after treatment to enter a plate-and-frame filter press for press filtering to obtain a sludge cake with water content of 50-62%. The hydroxyl free radicals generated by a sludge conditioning agent used in the method has good oxidizing performance and can damage extracellular polymeric substance and cell walls, bound water bound in the sludge is released to be free water, and the existence form of water in the sludge is changed; a water filtering passage in the dewatering process of the sludge is built, so that dewatering of the sludge is smoother, and the water content of the sludge cake is ensured to stably reach standards. An aeration system in the reaction tank can further realize sludge oxidation wall-breaking effect, so that consumption of the two agents is lowered.

Owner:陕西鼎益源投资有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com