Toothed pressure-maintaining filter-pressing method and equipment

A tooth-like and equipment technology, applied in the field of press filtration solid-liquid separation equipment, can solve the problems of unstable air pressure control, long water filtering time, insufficient efficiency, etc., to avoid instability, stabilize the dehydration process, and improve the dehydration effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

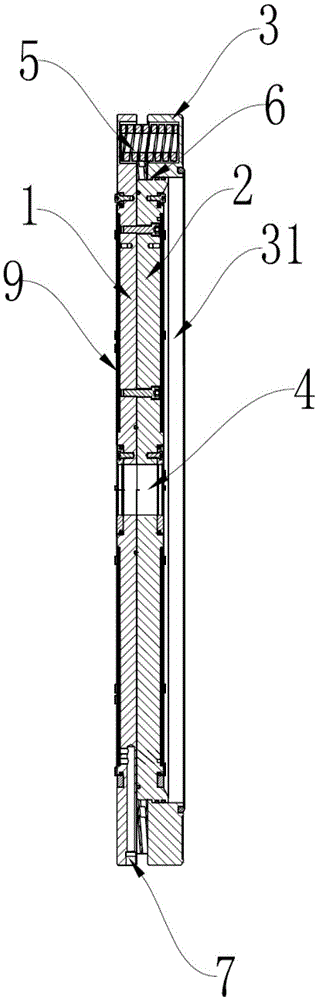

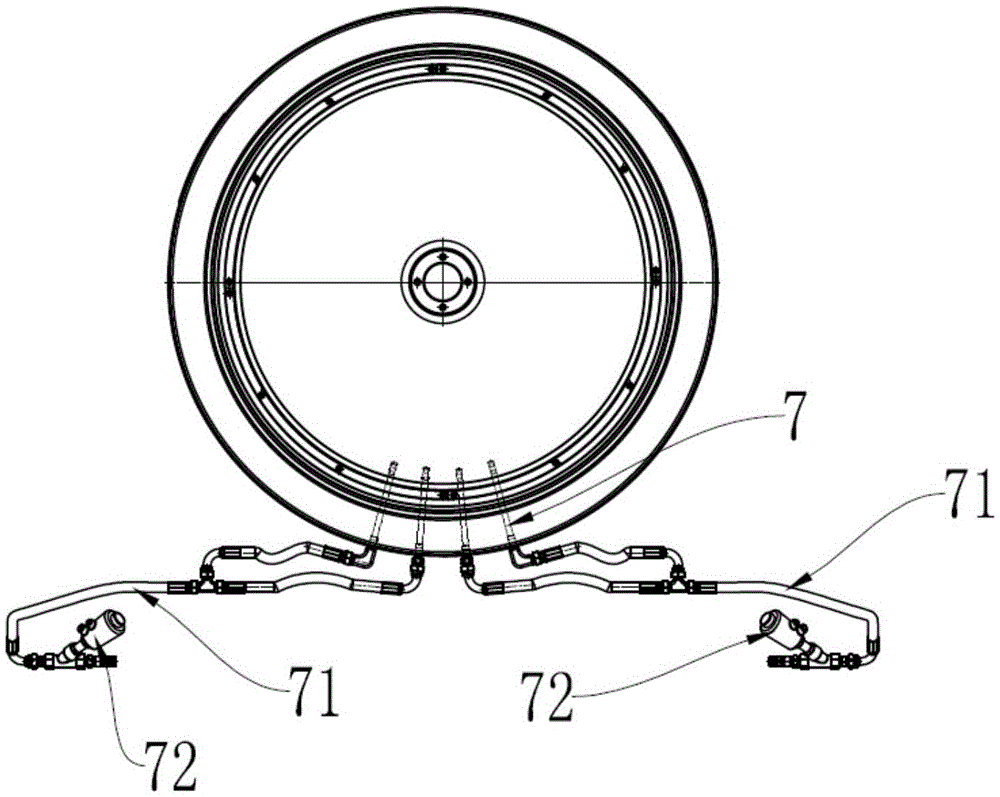

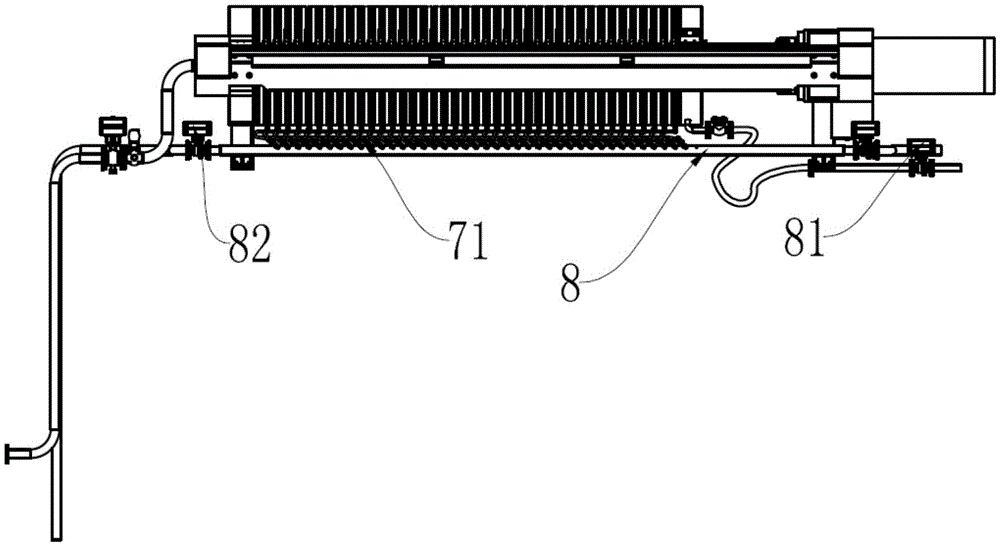

[0050] Embodiment 1—a kind of dentate pressure maintaining pressure filtration method, comprises the following steps:

[0051] (1) Start the hydraulic device, and push the plate to press and seal the filter plate;

[0052] (2) The hydraulic cylinder maintains pressure, the pressure is 13kg, and the push plate is fixed;

[0053] (3) The material pump pumps the material to be press-filtered into the press-filter space through the material channel, and the pressure of the hydraulic cylinder is raised to 60kg, and the pressure is maintained;

[0054] (4) Under the power of the material pump, the material in the filter press space is squeezed once, and the pressure of the hydraulic cylinder is raised to 100kg;

[0055] (5) The push plate continues to move forward, and after the filter press plate is stressed, the segmented tooth-shaped secondary pressing is performed again, and the pressure value variation range of the hydraulic cylinder is divided into 3 segments, and the pressur...

Embodiment 3

[0064] Embodiment 3—a kind of dentate pressure maintaining pressure filtration method, comprises the following steps:

[0065] (1) Start the hydraulic device, and push the plate to press and seal the filter plate;

[0066] (2) The hydraulic cylinder maintains pressure, the pressure is 15kg, and the push plate is fixed;

[0067] (3) The material pump pumps the material to be filtered into the filter press space through the material channel, and the pressure of the hydraulic cylinder is raised to 80kg, and the pressure is maintained;

[0068] (4) Under the power of the material pump, the material in the filter press space is squeezed, and the pressure of the hydraulic cylinder is raised to 120kg;

[0069] (5) The push plate continues to move forward. After the filter press plate is stressed, the segmented tooth-shaped secondary pressing is performed again, and the pressure value variation range of the hydraulic cylinder is divided into 4 segments. The pressure value in each seg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com